Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Upstream and Downstream Process Development interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Upstream and Downstream Process Development Interview

Q 1. Describe the key differences between upstream and downstream processing.

Upstream and downstream processing are two distinct phases in biopharmaceutical production, representing the ‘before’ and ‘after’ of cell culture, respectively. Think of it like baking a cake: upstream is all about preparing the ingredients (growing the cells that produce the biopharmaceutical) and downstream is about transforming the raw batter (cell culture harvest) into the final product (purified biopharmaceutical).

- Upstream Processing: Focuses on the cultivation of cells, typically in bioreactors, to produce the desired biopharmaceutical. This involves cell line development, media optimization, bioreactor operation, and cell harvesting. It’s all about maximizing cell growth and product yield.

- Downstream Processing: Involves the purification and formulation of the biopharmaceutical product from the harvested cell culture. This includes a series of steps, such as clarification, purification (often using chromatography), formulation, and filling. It’s about removing impurities and ensuring the final product meets quality standards.

The key difference lies in their goals: Upstream aims for high productivity, while downstream aims for high purity.

Q 2. Explain the principles of cell culture optimization in upstream processing.

Cell culture optimization in upstream processing is crucial for maximizing biopharmaceutical production. It’s like fine-tuning a recipe to get the best possible cake. We aim to achieve high cell density, high product titers (amount of product per unit volume), and consistent product quality. This involves several strategies:

- Media Optimization: Developing the optimal nutrient composition for the cells, including sugars, amino acids, vitamins, and growth factors. Think of it as giving your cells the perfect ‘food’ to promote healthy growth and product formation. We often use Design of Experiments (DOE) approaches to efficiently screen numerous media components and concentrations.

- Temperature and pH Control: Maintaining optimal temperature and pH conditions within the bioreactor are crucial for cell health and productivity. Slight deviations can have significant negative impacts. Think about how a cake would be ruined if baked at the wrong temperature.

- Dissolved Oxygen Control: Adequate oxygen supply is vital for cell respiration and growth, particularly for mammalian cells. Monitoring and controlling dissolved oxygen levels is essential to prevent cell death.

- Bioreactor Design and Operation: The type of bioreactor (e.g., stirred-tank, perfusion) and its operating parameters (e.g., agitation, aeration) significantly influence cell growth and product formation. Choosing the correct bioreactor and carefully controlling its operation is crucial for efficient production.

Sophisticated techniques like fed-batch strategies, where nutrients are added incrementally throughout the culture, can further enhance productivity by avoiding nutrient limitation.

Q 3. What are the critical quality attributes (CQAs) you would monitor in an upstream process?

Critical Quality Attributes (CQAs) are the parameters that directly impact the safety and efficacy of the final biopharmaceutical product. In upstream processing, key CQAs include:

- Cell Viability: The percentage of live cells in the culture; it indicates the health and productivity of the cell population. Low viability leads to reduced product yield.

- Cell Density: The number of cells per unit volume; high cell density is generally desired for higher product titers.

- Product Titer: The concentration of the desired biopharmaceutical in the cell culture fluid; a key indicator of process efficiency.

- Host Cell Protein (HCP) levels: The amount of proteins originating from the host cells that remain in the cell culture fluid. High HCP levels indicate a need for more effective downstream purification to ensure product purity.

- DNA content: The amount of host cell DNA present in the harvested material, a crucial parameter related to product purity and safety.

- Endotoxin levels: The presence of lipopolysaccharides (LPS), which can cause adverse effects in patients. Controlling endotoxin levels is essential for product safety.

Continuous monitoring of these CQAs throughout the upstream process helps to maintain consistent product quality and facilitates early detection of any deviation from optimal operating conditions. For instance, a sudden drop in cell viability might indicate a problem with the media or bioreactor operation requiring immediate attention.

Q 4. Discuss various cell line selection strategies for biopharmaceutical production.

Cell line selection is a critical step in biopharmaceutical production. The ideal cell line should exhibit high productivity, stable expression of the target protein, and good growth characteristics. Several strategies are employed:

- CHO cells (Chinese Hamster Ovary): These are widely used due to their high productivity, ability to perform post-translational modifications (crucial for many biopharmaceuticals), and relatively well-characterized nature.

- HEK cells (Human Embryonic Kidney): These are also popular for their ease of transfection (introducing the gene for the desired protein) and high expression levels, particularly for certain proteins.

- NS0 myeloma cells: These are frequently used for producing monoclonal antibodies due to their high productivity and ability to secrete large amounts of protein.

- High-throughput screening: This involves screening a large library of cell clones to identify high-producing clones.

- Directed evolution: This technique uses genetic engineering to improve the properties of existing cell lines by introducing beneficial mutations. Think of it as breeding cells to optimize production and stability.

- Genome editing: Techniques like CRISPR-Cas9 allow precise modifications to the cell’s genome to improve productivity or stability. This offers precise control over cell line characteristics.

The selection process typically involves several rounds of screening and characterization to identify a cell line that meets all required criteria for robust, consistent biopharmaceutical production.

Q 5. How do you ensure the sterility of upstream processes?

Ensuring sterility in upstream processes is paramount to prevent contamination, which can compromise product quality and safety. This involves a multi-faceted approach:

- Aseptic Techniques: Strict adherence to aseptic techniques during all operations, including media preparation, cell seeding, and bioreactor operation. This involves using sterile equipment, working in laminar flow hoods, and employing proper gowning procedures. It’s like operating in a cleanroom environment to avoid contamination.

- Sterile Filtration: Filtering media, buffers, and other solutions through sterilizing-grade filters (typically 0.22 µm pore size) to remove microorganisms.

- Sterilization of Equipment: Bioreactors, tubing, and other equipment are routinely sterilized using autoclaving (high-pressure steam sterilization) or other suitable methods.

- Environmental Monitoring: Regular monitoring of the environment (air, surfaces) for microbial contamination using settle plates and swabs. This acts as an early warning system.

- Process Analytical Technology (PAT): Using real-time monitoring techniques to detect potential contamination early on.

The ultimate goal is to create a controlled environment that minimizes the risk of microbial contamination throughout the entire upstream process.

Q 6. Explain different methods for cell harvesting in upstream processing.

Cell harvesting is the process of separating cells from the cell culture fluid. Different methods are employed based on the cell type and downstream processing requirements:

- Centrifugation: A common and efficient method, particularly for suspension cells, where cells are separated from the supernatant by applying centrifugal force. Think of it like spinning down a salad to separate the water from the vegetables.

- Microfiltration: A membrane filtration technique suitable for both suspension and adherent cells. The cells are retained by the membrane, while the supernatant passes through. This is often used for large-scale cell harvesting.

- Tangential Flow Filtration (TFF): A type of membrane filtration where the fluid flows tangentially to the membrane surface, minimizing membrane clogging and allowing for higher throughput. It’s particularly useful for large-volume harvests.

- Diafiltration: A process combining ultrafiltration and diafiltration to remove soluble impurities from the cell harvest while concentrating the cells.

The choice of harvesting method depends on factors like cell type, scale of operation, and the subsequent downstream purification steps. For instance, TFF is preferred for high-volume processing due to its high efficiency and reduced processing time.

Q 7. Describe the different types of chromatography used in downstream processing.

Chromatography is the workhorse of downstream processing, used to separate and purify the desired biopharmaceutical from impurities. Several types are commonly employed:

- Ion Exchange Chromatography (IEX): Separates proteins based on their net charge. Proteins with opposite charges to the stationary phase bind, while others pass through. Think of it like magnets attracting opposite poles.

- Hydrophobic Interaction Chromatography (HIC): Separates proteins based on their hydrophobicity. Proteins with higher hydrophobicity bind more strongly to the hydrophobic stationary phase.

- Size Exclusion Chromatography (SEC), also known as Gel Filtration Chromatography: Separates proteins based on their size. Larger proteins elute first, while smaller proteins are retained longer in the column.

- Affinity Chromatography: Uses specific interactions (like antibody-antigen binding) between the target protein and a ligand immobilized on the stationary phase. This offers very high selectivity and purity.

- Protein A Chromatography: A specific type of affinity chromatography used for purification of monoclonal antibodies. Protein A binds specifically to the Fc region of antibodies.

Often, a combination of chromatographic techniques is used to achieve the desired level of purity. For example, Protein A chromatography might be used for initial capture, followed by IEX and SEC for polishing.

Q 8. Explain the principles of protein purification using affinity chromatography.

Affinity chromatography is a powerful protein purification technique that exploits the specific binding affinity between a target protein and a ligand immobilized on a chromatographic matrix. Imagine a fishing rod: the ligand is the bait, the target protein is the fish, and the matrix is the fishing line. Only the ‘fish’ (target protein) with the right ‘bait’ (ligand) will bind.

The process involves several steps:

- Ligand immobilization: A ligand with high specificity for the target protein is covalently attached to a solid support, typically a resin bead. Common ligands include antibodies, peptides, or small molecules.

- Sample application: A crude protein extract containing the target protein is passed through the column containing the immobilized ligand.

- Binding: The target protein specifically binds to the ligand, while other proteins pass through the column (unbound fraction).

- Washing: The column is washed with a buffer to remove any weakly bound impurities.

- Elution: The target protein is then eluted from the column by changing the buffer conditions (e.g., changing pH, ionic strength, or adding a competitive inhibitor) to disrupt the ligand-protein interaction. This releases the purified protein.

Example: Imagine purifying a histidine-tagged protein. The ligand would be nickel ions immobilized on a resin (nickel affinity chromatography). Only the histidine-tagged protein will bind, allowing for its separation from other proteins.

Q 9. What are the challenges associated with scaling up downstream processes?

Scaling up downstream processes from lab-scale to industrial production presents numerous challenges. It’s like trying to bake a single cake versus thousands; the recipe needs significant adjustments.

- Maintaining process consistency: Ensuring the same level of purity and yield at larger scales is crucial, and often requires optimization of parameters like flow rates, mixing times, and temperature control.

- Equipment limitations: Lab-scale equipment may not be easily scalable. Finding suitable large-scale bioreactors, chromatography columns, and filtration systems can be complex and expensive.

- Increased shear forces: Higher flow rates in larger systems can subject sensitive proteins to increased shear forces, leading to degradation. Careful design of equipment and process parameters is crucial.

- Mass transfer limitations: Efficient mixing and mass transfer become more challenging in larger volumes, potentially affecting binding kinetics in chromatography steps and overall process efficiency.

- Cost and feasibility: Scaling up requires significant investment in equipment, facilities, and personnel. Careful economic evaluation is essential to ensure the feasibility of the process.

For instance, a purification step that works flawlessly with a few milliliters of sample in the lab might be inefficient and expensive when dealing with hundreds or thousands of liters in a manufacturing plant. Careful process development and validation are vital to overcome these challenges.

Q 10. How do you evaluate the efficiency of a purification process?

Evaluating the efficiency of a purification process involves assessing several key parameters. It’s like grading a student; you need to look at several aspects to get a complete picture.

- Yield: The percentage of target protein recovered from the starting material. A high yield is obviously desirable.

- Purity: The concentration of the target protein relative to other impurities. Assessed by techniques like SDS-PAGE, HPLC, or mass spectrometry.

- Specific activity: The activity of the target protein (if it’s an enzyme) per milligram of protein. This indicates the removal of inactive forms of the protein.

- Recovery: The amount of the target protein recovered in each step, expressed as a percentage of the total amount in the starting material.

- Productivity: The amount of purified protein obtained per unit of time. A higher productivity means more efficient use of resources and time.

Calculating these parameters for each step and comparing them between different processes allows for a comprehensive assessment of purification efficiency. For example, a process with a high yield but low purity may require further optimization. A process with a high purity but very low yield might be too expensive for large-scale application.

Q 11. What are some common process analytical technology (PAT) tools used in process development?

Process Analytical Technology (PAT) tools provide real-time or near real-time information about a process, enabling better monitoring, control, and optimization. Think of them as ‘eyes’ and ‘sensors’ for the process.

- Spectroscopy (UV-Vis, NIR, Raman): Provides information about the concentration and properties of components in a sample without needing extensive sample preparation. Useful for monitoring protein concentration and purity throughout the process.

- Chromatography (HPLC, FPLC): Essential for detailed analysis of protein purity and identification of impurities. Provides quantitative information about individual protein species.

- Mass spectrometry (MS): Highly sensitive technique to identify and quantify proteins and impurities. Useful for identifying unknown contaminants and characterizing post-translational modifications.

- Flow cytometry: Allows for analysis of individual cells or particles, useful for monitoring cell viability and product quality in cell culture-based processes.

- Image analysis: Useful for automated monitoring of crystal growth in downstream processing of proteins.

These PAT tools enable continuous monitoring and faster identification of process deviations, ultimately leading to improved process control and product quality. Imagine using sensors to monitor temperature and pressure in a reactor—this is the essence of PAT.

Q 12. Explain the importance of design of experiments (DoE) in process optimization.

Design of Experiments (DoE) is a statistical approach to process optimization that involves systematically changing multiple process parameters simultaneously to determine their effect on the outcome. Instead of changing one parameter at a time, which can be inefficient, DoE allows us to explore the interactions between parameters more effectively.

Imagine a chef wanting to optimize a recipe. Instead of changing just one ingredient at a time (salt, then pepper, then sugar), they can use DoE to systematically alter the quantities of all three to determine the optimal combination for flavor.

DoE techniques like factorial designs or response surface methodologies help identify optimal conditions for maximizing yield, purity, and other critical quality attributes. They are far more efficient than traditional ‘one-factor-at-a-time’ methods, leading to faster process optimization and cost savings. The resulting data can be modeled, allowing for prediction of outcomes under various conditions.

Q 13. How do you address impurities and contaminants during downstream processing?

Addressing impurities and contaminants during downstream processing requires a multi-pronged approach, often employing several purification techniques in sequence. It’s like cleaning a house; you wouldn’t just use a vacuum cleaner—you’d use a variety of tools and methods.

- Clarification: Initial steps like centrifugation or filtration remove cells, cell debris, and other large particulate matter.

- Chromatography: Techniques like ion-exchange, hydrophobic interaction, and size-exclusion chromatography separate proteins based on their charge, hydrophobicity, and size, respectively. Affinity chromatography targets specific impurities or the desired protein.

- Precipitation: Techniques like ammonium sulfate precipitation selectively precipitate proteins based on their solubility, allowing separation of the target protein from impurities.

- Ultrafiltration/Diafiltration: These membrane-based techniques remove small molecules and buffer components, increasing the protein concentration and purity.

The specific strategy depends on the nature of the impurities and the properties of the target protein. Often, a combination of these techniques is required to achieve the desired level of purity.

Q 14. Discuss the regulatory requirements for process development and validation.

Regulatory requirements for process development and validation vary depending on the intended use of the protein product (e.g., therapeutic, diagnostic, industrial). However, there are common principles that apply across different regulatory agencies like the FDA (in the US) and EMA (in Europe).

- GMP Compliance: Good Manufacturing Practices (GMP) guidelines dictate the standards for manufacturing, ensuring consistent product quality and safety. This includes aspects such as equipment cleaning, operator training, and documentation.

- Process Validation: Demonstrates that the manufacturing process consistently produces a product that meets predefined quality attributes. This often involves three stages: process design qualification, process qualification, and continued process verification.

- Documentation: Meticulous record-keeping is critical, including detailed protocols, raw data, and reports, ensuring traceability and auditability of the process.

- Quality Control (QC) testing: Rigorous testing of the final product to ensure it meets specifications for purity, potency, safety, and stability is mandatory.

- Regulatory submissions: Detailed documentation of the process development and validation is submitted to regulatory authorities as part of approval applications. This is a crucial step for marketing any biotech product.

Failing to meet these regulatory requirements can lead to significant delays, financial losses, and even market withdrawal of the product. Therefore, adherence to regulatory guidelines is a critical aspect of successful process development.

Q 15. Describe your experience with process analytical technology (PAT) implementation.

Process Analytical Technology (PAT) implementation involves integrating real-time analytical technologies into the manufacturing process to enable continuous monitoring and control. This allows for a deeper understanding of the process and facilitates better decision-making, leading to improved product quality and reduced manufacturing costs. My experience spans several projects, including the implementation of in-line near-infrared (NIR) spectroscopy for monitoring protein concentration during cell culture, and the use of Raman spectroscopy for real-time identification of critical quality attributes (CQAs) during purification. In one particular project, we implemented PAT to reduce the variability in a downstream chromatography step. By continuously monitoring the conductivity and UV absorbance, we could adjust the gradient elution profile in real-time, optimizing the separation and improving the yield of our target protein. This resulted in a 15% increase in yield and a significant reduction in process variability.

PAT implementation requires a structured approach, starting with defining critical process parameters (CPPs) and CQAs, selecting appropriate analytical techniques, and integrating the sensors and software into the existing process control system. Validation of the analytical methods and the entire PAT system is crucial to ensure reliable data and regulatory compliance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot issues encountered during upstream or downstream processing?

Troubleshooting in upstream and downstream processing requires a systematic approach. It begins with careful observation and data analysis to identify the root cause of the problem. In upstream processing, issues could range from low cell density to contamination. For example, I once encountered unexpectedly low cell growth in a bioreactor. By analyzing the process data, including temperature, pH, dissolved oxygen, and nutrient levels, we identified a malfunctioning oxygen sensor that led to insufficient oxygen supply. Replacing the sensor resolved the issue. In downstream processing, challenges often arise during purification steps, such as low product recovery or poor purity. For example, a clogged chromatography column could result in low recovery. This requires careful investigation, potentially involving analysis of the column packing material, cleaning-in-place (CIP) procedures, and the feed stream itself.

A structured troubleshooting methodology – like a fault tree analysis – can be highly beneficial. It involves breaking down the problem into smaller components, identifying potential causes, and testing hypotheses through experimentation or further data analysis. Detailed record-keeping and documentation are crucial for effective troubleshooting and identifying recurring issues.

Q 17. What are the strategies for improving process yield and productivity?

Improving process yield and productivity involves a multi-faceted approach, focusing on optimization at each step of the process. In upstream processing, strategies include optimizing cell culture media, improving cell line performance through genetic engineering or adaptation, and optimizing bioreactor operation. For instance, we increased the cell density in our CHO cell cultures by implementing fed-batch strategies, carefully controlling nutrient addition throughout the culture period. This resulted in a 20% increase in product titre. Downstream processing improvements focus on optimizing purification steps to maximize product recovery and purity. This includes optimizing chromatography conditions, exploring alternative purification methods, and minimizing process losses due to adsorption or degradation.

Design of Experiments (DOE) methodologies are powerful tools for identifying and optimizing critical process parameters. By systematically varying several factors and analyzing the results, we can determine the optimal operating conditions for maximizing yield and productivity. Furthermore, continuous improvement initiatives, such as lean manufacturing principles, can help streamline the process, reduce waste, and improve overall efficiency.

Q 18. Explain the importance of process validation in the pharmaceutical industry.

Process validation in the pharmaceutical industry is crucial for ensuring the consistent manufacture of high-quality products that meet predefined specifications. It’s a documented program that provides a high degree of assurance that a specific process will consistently produce a product meeting its predetermined specifications and quality attributes. This involves demonstrating that the manufacturing process is robust and reliable, capable of consistently producing a safe and effective product batch after batch. Failure to validate processes can lead to product recalls, regulatory penalties, and potential harm to patients.

The validation process typically involves three stages: Process Design, Process Qualification, and Continued Process Verification. Process Design involves defining the critical process parameters (CPPs) and critical quality attributes (CQAs), while Process Qualification involves demonstrating that the process consistently meets its predetermined specifications under normal operating conditions. Continued Process Verification involves ongoing monitoring and testing to ensure that the process remains in a state of control.

Q 19. Describe your experience with different types of bioreactors.

My experience encompasses various bioreactor types, including stirred-tank, airlift, and perfusion bioreactors. Stirred-tank reactors are the most common type, using impellers for mixing and oxygen transfer. I’ve used these extensively for mammalian cell culture. Airlift bioreactors rely on gas sparging for mixing and are often preferred for shear-sensitive cells. Perfusion bioreactors continuously remove and replace culture media, allowing for higher cell densities and improved productivity. In one project, we transitioned from a batch stirred-tank bioreactor to a continuous perfusion system. This significantly increased our product yield due to the higher cell densities achieved. The selection of the optimal bioreactor depends on various factors, such as the type of cells being cultured, the desired cell density, and the product characteristics.

Each bioreactor type has its strengths and weaknesses. For example, stirred-tank reactors are versatile but can be prone to shear stress, whereas airlift reactors offer gentler mixing but may have limitations in scalability.

Q 20. What are the challenges associated with single-use technologies in bioprocessing?

Single-use technologies (SUTs) offer many advantages in bioprocessing, including reduced cleaning validation efforts, decreased risk of cross-contamination, and improved flexibility. However, several challenges exist. One major challenge is ensuring the integrity and sterility of single-use components. Thorough testing and quality control procedures are essential. Another challenge is the potential for extractables and leachables from the single-use materials to affect product quality or safety. Careful material selection and rigorous testing are crucial to mitigate this risk. Furthermore, the cost of SUTs can be higher than traditional stainless steel systems, especially for large-scale operations. Finally, the disposal of SUTs presents environmental and logistical challenges requiring careful waste management strategies.

Overcoming these challenges requires careful planning and selection of appropriate materials and suppliers, stringent quality control measures, and robust validation procedures. Careful consideration of the total cost of ownership, including material costs, waste disposal, and potential losses due to leaks or failures, is essential.

Q 21. How do you manage and interpret process data to optimize process parameters?

Managing and interpreting process data is critical for process optimization. This involves utilizing data from various sources, including bioreactors, chromatography systems, and analytical instruments. I typically employ statistical process control (SPC) charts and other data analysis techniques to identify trends and anomalies in the data. For example, I might use a control chart to monitor the cell density during a bioreactor run. Deviations from the established control limits would trigger an investigation to determine the root cause and implement corrective actions.

Data analytics software and tools like multivariate data analysis (MVDA) and machine learning algorithms can be powerful for identifying complex relationships between process parameters and product quality. This enables more informed decision-making and allows for the development of predictive models for process optimization. The use of these techniques not only helps in identifying areas for improvement but also supports the development of robust, consistent processes with reduced variability and increased efficiency.

Q 22. Explain your experience with different types of filtration techniques.

Filtration is a crucial unit operation in bioprocessing, employed to remove impurities from a biopharmaceutical product. Different techniques cater to specific needs depending on the particle size, concentration, and desired throughput.

- Depth Filtration: This involves passing the fluid through a porous medium where particles are trapped within the matrix. Think of it like a sieve with increasingly smaller pores. Examples include filter aids like diatomaceous earth and depth filters using cellulose or glass fibers. I’ve extensively used depth filtration for clarifying cell culture harvests, removing cellular debris before further downstream purification.

- Membrane Filtration: This uses semi-permeable membranes to separate components based on size. Different types exist including microfiltration (MF), ultrafiltration (UF), and nanofiltration (NF), each with varying pore sizes. UF, for example, is commonly used to concentrate proteins and remove smaller contaminants. I’ve applied UF in a project to concentrate a monoclonal antibody before loading it onto a chromatography column.

- Crossflow Filtration (Tangential Flow Filtration): Here, the feed solution flows tangentially across the membrane surface, minimizing cake formation and improving flux. This is highly efficient for large-scale processing and is often used for diafiltration steps. I’ve successfully implemented crossflow filtration in a continuous manufacturing setting to achieve high throughput and reduce processing time.

The choice of filtration technique depends on factors like the target molecule’s properties, desired purity, and the scale of the operation. Careful consideration of these factors is crucial to optimize the process and ensure product quality.

Q 23. Describe your knowledge of current Good Manufacturing Practices (cGMP).

Current Good Manufacturing Practices (cGMP) are a set of regulations ensuring the quality, safety, and efficacy of pharmaceutical products. My experience encompasses all aspects of cGMP compliance, from documentation and training to process validation and deviation management.

Specifically, I’m proficient in designing and executing experiments that meet cGMP requirements. This includes meticulous documentation of all experimental procedures, raw materials, and results. I’m experienced in developing and reviewing Standard Operating Procedures (SOPs) to ensure consistency and compliance. Furthermore, I’m skilled in handling deviations and investigating out-of-specification results following established procedures. I understand the importance of maintaining accurate and complete records, which are essential for regulatory audits and inspections. My experience includes working under strict regulatory guidelines, ensuring that all processes adhere to FDA, EMA, or other relevant regulatory agency expectations.

For example, during a recent project involving the purification of a therapeutic protein, I was responsible for ensuring full cGMP compliance at every step, from cell culture to final product formulation. This included maintaining detailed batch records, validating cleaning procedures, and ensuring proper calibration of all equipment. The project successfully passed a regulatory audit demonstrating my capability to manage a cGMP compliant project.

Q 24. What are the different methods used for viral clearance in bioprocessing?

Viral clearance is a critical step in biopharmaceutical manufacturing to eliminate or reduce viral contamination, safeguarding patients. Multiple methods are available, often used in combination for enhanced safety.

- Virus Filtration: This employs specialized filters with very small pore sizes (typically <20 nm) to physically remove viruses. This is a widely used method, particularly for larger viruses. I have utilized virus filtration using different filter types depending on the virus size and product characteristics.

- Inactivation: This approach uses physical or chemical agents to destroy viruses. Examples include low pH treatment, heat treatment, and solvent/detergent treatments. Solvents like tri(n-butyl) phosphate (TNBP) can effectively inactivate enveloped viruses. Each method needs careful optimization to ensure sufficient inactivation while maintaining product integrity. I’ve worked extensively with solvent/detergent inactivation, carefully balancing viral clearance with the impact on the target protein’s stability and activity.

- Chromatographic Methods: Certain chromatography techniques, like ion-exchange or affinity chromatography, can contribute to viral clearance by separating viruses based on their physicochemical properties. Although not the primary viral clearance step, it can provide an additional level of safety. This is often integrated with other strategies for enhanced effectiveness.

The selection of methods depends on factors such as virus type, product characteristics, and regulatory requirements. A robust viral clearance strategy often integrates multiple methods to minimize the viral load and maximize product safety.

Q 25. Explain how you would design an experiment to optimize a purification step.

Optimizing a purification step involves a systematic approach to improve yield, purity, and efficiency. I usually employ a Design of Experiments (DoE) strategy, such as a fractional factorial design or response surface methodology (RSM).

Let’s say we are optimizing a protein A chromatography step. The factors we might consider are:

- pH of the binding buffer

- Salt concentration

- Flow rate

- Load concentration

A fractional factorial design allows us to systematically investigate the effect of these factors and their interactions on the key responses, such as protein yield, purity, and the process time. We will then analyze the data using statistical methods (ANOVA) to determine the significant factors and their optimal levels. We can then use this information to design additional experiments, potentially employing RSM to fine-tune the conditions around the optimal point discovered from the initial DOE. We would monitor and analyze parameters like breakthrough curves, capacity, and binding affinity. The entire process would be meticulously documented following cGMP guidelines.

This stepwise approach ensures that we are not only optimizing a single factor but also understanding the interactions between factors, leading to a robust and efficient purification step. Documentation is essential to support the selection of the optimal operating parameters and validate the robustness of the process.

Q 26. What are your experiences with continuous manufacturing?

Continuous manufacturing offers significant advantages over traditional batch processing, including increased efficiency, reduced manufacturing time, and improved product consistency. My experience includes working on several projects that transitioned from batch to continuous processing. This typically involves a fundamental shift in how the entire process is designed, requiring an in-depth understanding of process kinetics and reaction engineering principles.

One project I worked on involved the continuous purification of a monoclonal antibody using a series of integrated chromatography columns. The continuous nature allowed us to significantly increase throughput while reducing the overall processing time. Challenges involved optimizing the flow rates, maintaining consistent column performance, and ensuring effective cleaning-in-place (CIP) procedures. We successfully demonstrated the scalability and robustness of the continuous process through extensive testing and validation. The reduced overall processing time and increased throughput also led to a decrease in the manufacturing footprint and cost.

Continuous manufacturing demands a different approach to process design, monitoring, and control than batch processing. Expertise in process analytical technology (PAT) is essential to ensure real-time monitoring and control of critical process parameters, allowing for prompt adjustments and maximizing process efficiency and consistency.

Q 27. How do you ensure the stability of a biopharmaceutical product?

Ensuring the stability of a biopharmaceutical product is critical for maintaining its efficacy and safety throughout its shelf life. This involves a multifaceted approach addressing various factors affecting protein stability:

- Formulation Development: This is a crucial aspect of stability studies. The selection of appropriate excipients (buffers, stabilizers, preservatives) can significantly impact protein stability, protecting it from degradation pathways such as aggregation, oxidation, or chemical hydrolysis. For example, using suitable buffer systems maintain pH within the optimal range for product stability. I’ve done extensive work in formulation development, utilizing various stabilizers and excipients to enhance protein shelf life.

- Stress Testing: This involves exposing the product to various stress conditions (e.g., temperature, humidity, light) to assess its stability and identify potential degradation pathways. Accelerated stability studies are performed using elevated temperatures to predict long-term stability more quickly. The data generated helps determine appropriate storage conditions and shelf life.

- Analytical Characterization: This involves rigorous analytical testing throughout the stability studies to assess changes in the product’s properties, such as protein aggregation, fragmentation, oxidation, and potency. Techniques like Size Exclusion Chromatography (SEC), mass spectrometry, and potency assays are used for detailed characterization.

A well-designed stability study allows us to define appropriate storage conditions, establish a reliable shelf life, and ensure consistent product quality throughout its use.

Q 28. Describe your experience with technology transfer from development to manufacturing.

Technology transfer from development to manufacturing is a critical phase, ensuring a smooth transition from a laboratory-scale process to large-scale production. My experience includes overseeing several technology transfer projects, emphasizing meticulous planning, execution, and documentation.

Key aspects include:

- Process Characterization: Thoroughly understanding the process parameters and critical quality attributes (CQAs) developed in the lab is essential before transferring to manufacturing. This involves detailed documentation of the process, including equipment specifications, operating parameters, and analytical methods.

- Scale-up Strategy: A well-defined scale-up strategy is crucial for successful transfer. This may involve a gradual increase in scale, ensuring that the process remains consistent at each level. I’ve used approaches like maintaining constant process parameters, such as shear rate, in different reactor scales.

- Equipment Qualification and Validation: This involves qualifying and validating the manufacturing equipment to ensure it meets the required specifications and produces the desired product quality. I’ve extensively utilized equipment like large-scale chromatography skids and bioreactors, carefully documenting the qualification and validation procedures.

- Training and Knowledge Transfer: Providing comprehensive training to the manufacturing team is crucial for ensuring consistency and reproducibility of the process. This often involves hands-on training and clear documentation of procedures.

Successful technology transfer requires effective communication and collaboration between development and manufacturing teams. Careful planning, well-defined procedures, and comprehensive documentation are essential for minimizing risks and ensuring a smooth transition, leading to consistent, high-quality product manufacturing.

Key Topics to Learn for Upstream and Downstream Process Development Interview

- Upstream Process Development:

- Cell line development and engineering: Understanding cell culture optimization, including media formulation, transfection techniques, and clone selection strategies.

- Process optimization and scale-up: Mastering techniques for transferring processes from small-scale to large-scale manufacturing, considering factors like mixing, mass transfer, and oxygen transfer.

- Bioreactor design and operation: Familiarizing yourself with different bioreactor types, their operating principles, and troubleshooting common issues.

- Analytical techniques for process monitoring and control: Understanding techniques such as HPLC, ELISA, and flow cytometry for monitoring critical process parameters (CPPs).

- Design of Experiments (DOE) and statistical analysis for process optimization: Applying statistical methods to efficiently improve process yield and quality.

- Downstream Process Development:

- Protein purification strategies: Understanding various chromatography techniques (e.g., affinity, ion exchange, size exclusion) and their applications.

- Process scale-up and validation: Transitioning purification processes from lab scale to manufacturing scale while ensuring consistent product quality.

- Formulation and stability studies: Developing stable formulations for long-term storage and transportation of the final product.

- Analytical methods for product characterization: Understanding techniques such as SDS-PAGE, mass spectrometry, and bioassays for evaluating product purity and potency.

- Regulatory compliance and Good Manufacturing Practices (GMP): Understanding the regulatory requirements for biopharmaceutical manufacturing.

- Problem-Solving and Critical Thinking:

- Troubleshooting common process challenges in both upstream and downstream processing.

- Applying your knowledge to solve realistic case studies relevant to the industry.

- Demonstrating a clear understanding of process economics and cost-effectiveness.

Next Steps

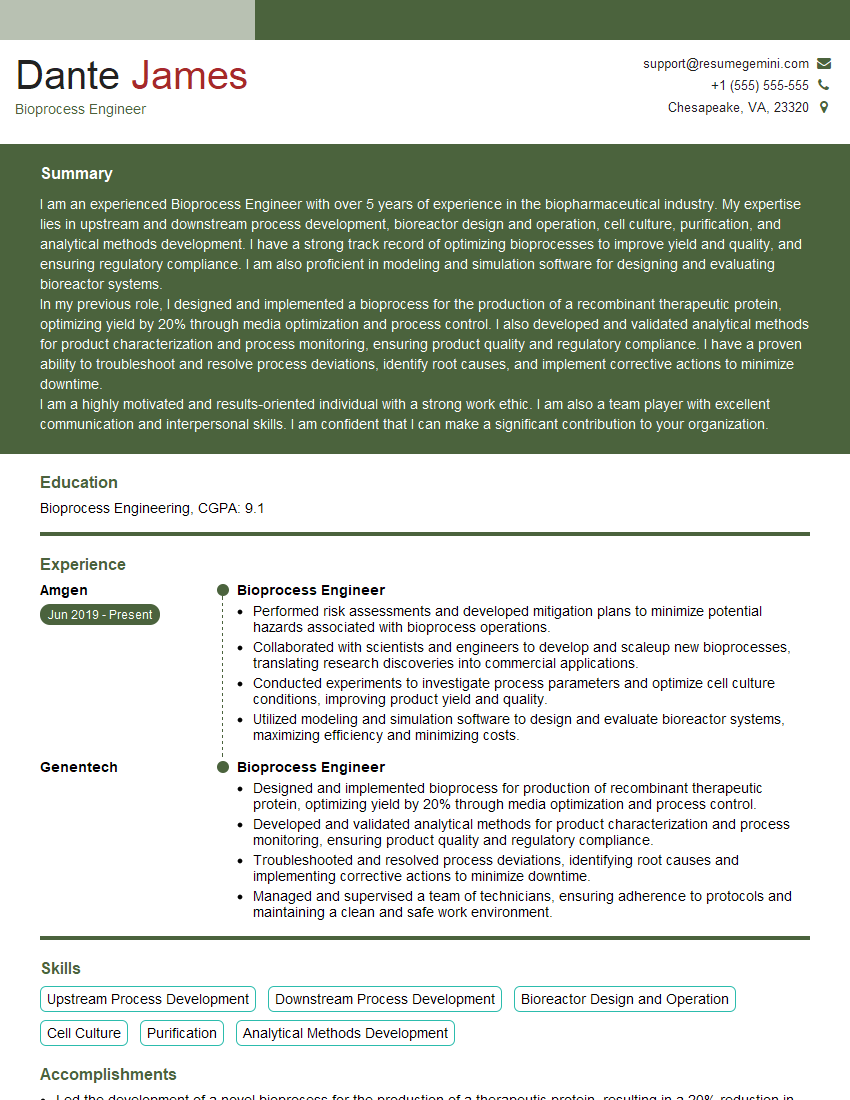

Mastering Upstream and Downstream Process Development is crucial for a successful and rewarding career in the biopharmaceutical industry. It opens doors to exciting roles with significant impact. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Upstream and Downstream Process Development are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good