The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Metrology and Gage Management interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Metrology and Gage Management Interview

Q 1. Explain the concept of Measurement Uncertainty.

Measurement uncertainty quantifies the doubt associated with a measured value. It’s not about mistakes, but rather the inherent limitations of any measurement process. Think of it like aiming at a bullseye: even with a perfect technique, your arrows won’t all land exactly in the center. Measurement uncertainty acknowledges this inherent variability. It’s expressed as a range of values, typically with a confidence level (e.g., ±0.1 mm with 95% confidence). This range represents the plausible interval where the true value likely lies.

Several factors contribute to measurement uncertainty. These include:

- Instrument limitations: The precision of the measuring device itself.

- Environmental factors: Temperature, humidity, and vibrations can subtly influence readings.

- Observer variation: Different people might read a scale slightly differently.

- Methodological uncertainties: Limitations in the measurement procedure itself.

Understanding measurement uncertainty is crucial for making informed decisions. For example, a small uncertainty might be acceptable when measuring the length of a tabletop, but a much smaller uncertainty is required when manufacturing precision components for a spacecraft.

Q 2. Describe different types of Gage R&R studies and their applications.

Gage Repeatability and Reproducibility (Gage R&R) studies assess the variability within a measurement system. They help determine if the measurement system is capable of measuring the parts with the required precision. There are several types:

- Method 1: ANOVA (Analysis of Variance): This is the most common approach, using statistical methods to partition the total variation into components attributable to repeatability (variation due to the same operator using the same gage multiple times on the same part), reproducibility (variation due to different operators using the same gage on the same part), and part-to-part variation. It requires a larger sample size.

- Method 2: Average and Range Method: This simplified approach is suitable for smaller sample sizes. It uses the average range of measurements to estimate variability.

- Method 3: Cross Method: This method is used to analyze measurements taken by multiple operators on multiple parts, providing insights into both repeatability and reproducibility.

Applications: Gage R&R studies are vital during the design and validation of measurement systems. They are critical in ensuring that measurements are reliable and consistent, preventing defects caused by inaccurate or imprecise measurements. For instance, a Gage R&R study might be conducted before mass-production of a new product to ensure that the quality control measuring equipment is fit for the task.

Q 3. What are the key elements of a successful Gage Management system?

A successful Gage Management System requires a holistic approach, encompassing several key elements:

- Calibration program: A comprehensive and documented schedule for regular calibration of all measuring equipment using traceable standards.

- Gage identification and tracking: A unique identifier for each gage, maintained in a database, enabling traceability throughout its lifecycle.

- Gage maintenance and repair: Procedures and training for proper handling, cleaning, and repair of measuring equipment.

- Control charts and statistical process control: Monitoring gage performance over time through control charts helps identify potential problems early on.

- Standard operating procedures (SOPs): Clear, documented instructions on how to use each gage accurately and consistently.

- Training and competency assessment: Ensuring all personnel involved in measurement are adequately trained and competent in the use of the equipment.

- Regular Gage R&R studies: Periodic evaluation of the measurement system’s capability.

- Corrective actions: Processes for identifying and rectifying issues related to gage performance or measurement errors.

A strong gage management system is essential to minimize measurement errors, improve product quality, and meet regulatory requirements.

Q 4. How do you identify and address systematic errors in measurement?

Systematic errors are consistent and predictable biases in measurement. They are not random fluctuations but rather consistent deviations from the true value. Identifying and addressing them requires a methodical approach:

- Control Chart Analysis: Plotting measurement data over time can reveal trends or shifts indicating a systematic error. For example, a consistently high reading might suggest a bias in the instrument’s calibration.

- Calibration Checks: Regularly calibrating measurement equipment against traceable standards helps identify instrument drift or bias.

- Environmental Monitoring: Observing and controlling environmental factors such as temperature and humidity that might systematically affect measurements.

- Operator Bias Analysis: Studying measurements made by different operators can uncover inconsistencies due to differences in technique or interpretation.

- Round Robin Testing: Sending the same item to multiple laboratories for measurement can help identify systematic biases in specific labs or methods.

Once identified, systematic errors are addressed by recalibrating the equipment, adjusting the measurement procedure, improving operator training, or implementing environmental controls. Ignoring systematic errors can lead to significant inaccuracies and unreliable results.

Q 5. Explain the difference between accuracy and precision in metrology.

In metrology, accuracy and precision are distinct but related concepts. Accuracy refers to how close a measured value is to the true value. Precision, on the other hand, refers to how close repeated measurements are to each other, regardless of their proximity to the true value.

Imagine shooting at a target:

- High accuracy, high precision: All shots are clustered tightly together near the bullseye.

- Low accuracy, high precision: All shots are clustered tightly together, but far from the bullseye (consistent error).

- High accuracy, low precision: Shots are scattered around the bullseye (random error).

- Low accuracy, low precision: Shots are scattered widely, far from the bullseye.

A measurement system can be precise without being accurate (systematic error), but it cannot be accurate without being reasonably precise.

Q 6. What are the common methods for calibrating measurement equipment?

Calibration methods vary depending on the type of measurement equipment. Common methods include:

- Direct comparison: Comparing the output of the instrument to a known standard using a calibrated reference standard.

- Indirect comparison: Using a calibrated intermediary device to compare the instrument’s output to a standard.

- Calibration using certified reference materials (CRMs): Using materials with precisely known properties to verify the accuracy of instruments.

- In-situ calibration: Calibrating the instrument while it is in its operational environment.

- Traceability: Linking the calibration process to national or international standards, establishing a chain of comparability.

The frequency of calibration depends on the instrument’s criticality, stability, and usage. Calibration certificates provide documentation of the calibration results and should always be maintained.

Q 7. How do you interpret a Gage R&R study report?

A Gage R&R study report typically includes:

- Study details: Information about the parts measured, operators involved, and the gage used.

- ANOVA table: A statistical table showing the variance components (repeatability, reproducibility, and part-to-part variation).

- Percent contribution: The percentage of total variation attributable to each component (repeatability, reproducibility, and part-to-part).

- %Study Variation: The percentage of total variation attributed to the measurement system.

- Number of Distinct Categories: How many categories the gage can distinguish between, a measure of its capability.

- Graphs: Visual representations of the data, such as box plots, showing the distribution of measurements.

Interpretation focuses on the percentage of variation attributable to the measurement system. A low percentage (generally less than 10%) indicates an acceptable measurement system, while a high percentage suggests significant measurement variability that needs to be addressed. The report helps to determine if the measurement system is suitable for its intended use.

Q 8. What are the different types of Coordinate Measuring Machines (CMMs)?

Coordinate Measuring Machines (CMMs) come in various types, primarily categorized by their measurement techniques and the way they contact the part being measured. The three main types are:

- Contact CMMs: These use a probe, typically a stylus, to physically touch the surface of the part. The probe’s movements are precisely measured to determine the part’s geometry. They are highly accurate but can be slower and potentially damage delicate parts. Think of it like meticulously feeling the contours of a sculpture with your fingers.

- Non-Contact CMMs (Optical CMMs): These utilize optical sensors, like laser scanners or vision systems, to measure the part without physical contact. This eliminates the risk of damage and allows for faster measurement of complex shapes. Imagine using a 3D scanner to create a digital model of an object.

- Hybrid CMMs: These combine both contact and non-contact techniques, offering the advantages of both. For instance, a system might use a laser scanner for initial surface mapping and then a contact probe for precise measurements of critical features.

The choice of CMM type depends on the application, the part’s material and geometry, the required accuracy, and the budget. For example, a contact CMM is suitable for high-precision measurements of hard metal parts, while an optical CMM is better for measuring complex shapes or fragile objects.

Q 9. Describe your experience with Statistical Process Control (SPC) in metrology.

My experience with Statistical Process Control (SPC) in metrology is extensive. I’ve used SPC techniques throughout my career to monitor measurement processes, identify potential sources of variation, and ensure the accuracy and reliability of our measurements. This involves:

- Control Charts: I regularly create and analyze control charts, such as X-bar and R charts, to monitor the stability and capability of our measurement systems. For example, I might monitor the diameter measurements of a batch of shafts using an X-bar chart to detect any trends or shifts indicating a problem with the machine or the process.

- Capability Analysis: This involves determining if a process is capable of meeting specified tolerances. I’ve used techniques like Cp and Cpk to assess process capability and identify areas for improvement. A low Cpk value, for instance, would indicate that the process is not producing parts within the required tolerances consistently.

- Gauge R&R Studies: These are critical for evaluating the repeatability and reproducibility of measurement devices and procedures. I’ve conducted numerous Gauge R&R studies to identify potential sources of measurement error and ensure the accuracy of our measuring instruments.

Through the application of SPC, I’ve been able to significantly reduce measurement variability, improve process control, and ensure compliance with industry standards. For instance, implementing control charts for a particular CMM revealed a pattern of drift that wasn’t apparent otherwise, leading to prompt recalibration and improved measurement accuracy.

Q 10. How do you manage and maintain a metrology laboratory?

Managing and maintaining a metrology laboratory requires a multifaceted approach focusing on environmental control, equipment maintenance, and quality assurance. Key aspects include:

- Environmental Control: Maintaining a stable temperature and humidity is crucial for minimizing measurement errors. This involves regular monitoring of environmental parameters and using appropriate climate control systems. Variations can affect the dimensions of parts and the accuracy of measuring instruments.

- Equipment Calibration and Maintenance: A rigorous calibration schedule is essential. Each instrument requires regular calibration traceable to national or international standards. Preventative maintenance, following manufacturer’s recommendations, is critical for instrument longevity and accuracy. I would implement a CMMS (Computerized Maintenance Management System) to track calibrations and preventative maintenance schedules.

- Cleanliness and Organization: A clean and organized laboratory is vital. This reduces the risk of contamination, damage to parts, and errors. Specific cleaning procedures for different instruments and surfaces are crucial. Proper storage of calibration standards and equipment is also essential.

- Personnel Training: Ensuring staff is properly trained on the use and maintenance of equipment is crucial for consistent results and adherence to standard operating procedures. Regular training sessions and competency assessments are essential.

- Quality System Compliance: Adherence to ISO 9001 or other relevant standards is important for the credibility and reliability of the lab’s services. This necessitates meticulous record-keeping, documentation, and auditing.

In practice, I employ a preventative maintenance schedule and a clear traceability system for all equipment. This proactive approach significantly minimizes downtime, ensures accuracy, and supports continuous improvement.

Q 11. Explain the concept of traceability in calibration.

Traceability in calibration ensures that measurements can be linked back to internationally recognized standards. It’s a chain of comparisons that demonstrates the accuracy of a measuring instrument by comparing it to a known standard of higher accuracy. Think of it as a family tree for your measurements, with each generation linked to the one before it.

This chain usually starts with a national metrology institute (NMI), like NIST in the United States, which maintains primary standards. These standards are then used to calibrate secondary standards, which in turn calibrate working standards used in everyday measurements. Each step in the chain documents the uncertainty associated with each comparison.

For example, a company’s micrometer might be calibrated against a certified gauge block (secondary standard) that has been previously calibrated by a certified calibration laboratory, who in turn, traces its calibration back to the NMI. This unbroken chain of comparisons provides confidence in the accuracy of the micrometer’s measurements.

Lack of traceability can lead to significant issues like product non-conformity, costly recalls, and even safety hazards. Proper traceability is therefore essential for quality control, regulatory compliance, and customer confidence.

Q 12. What are some common sources of measurement error?

Measurement errors can arise from a variety of sources, broadly categorized as:

- Environmental Factors: Temperature, humidity, vibration, and even air pressure can affect measurements. For instance, changes in temperature can cause dimensional changes in the part being measured and also the measuring instrument.

- Instrument Errors: These include errors due to instrument calibration, wear and tear, limitations in resolution, or even improper use. A worn-out caliper, for example, might give consistently inaccurate readings.

- Operator Errors: Human factors play a large role. Parallax error (reading a scale from an angle), improper handling of the instrument, or misinterpretation of the results are common operator-related sources of error.

- Part Errors: The part being measured itself might have variations due to manufacturing imperfections, deformation, or damage.

- Method Errors: The measurement method chosen can introduce errors. Incorrect fixturing, improper probing technique in CMM measurements, or the use of an inappropriate measurement technique can all lead to errors.

Understanding and minimizing these sources of error through proper calibration, training, process control, and environmental monitoring is essential for ensuring the accuracy and reliability of measurements.

Q 13. How do you validate a new measurement process?

Validating a new measurement process involves a structured approach to demonstrate its capability and accuracy. This usually involves:

- Defining Requirements: Clearly define the measurement objectives, specifications, and tolerances.

- Developing the Method: Establish a detailed measurement procedure, including equipment selection, setup, and data acquisition techniques.

- Gauge R&R Study: Perform a gauge repeatability and reproducibility study to assess the variability of the measurement system itself.

- Measurement System Analysis (MSA): Evaluate the overall performance of the measurement system, including bias, linearity, and stability.

- Validation Study: Conduct a validation study using reference standards or certified parts to compare the new method’s results against known values. This often involves statistical analysis to determine the accuracy and precision of the method.

- Documentation: Thoroughly document all aspects of the validation process, including the methodology, results, and conclusions.

For example, when validating a new vision system for measuring the dimensions of circuit boards, we would conduct a Gauge R&R to assess the system’s variability, then measure calibrated reference boards to compare results against known values and finally, document all findings, including statistical analyses, showing that the process meets the established requirements.

Q 14. What are the different types of gauges used in manufacturing?

Gauges are specialized measuring instruments used in manufacturing for quick and easy verification of part dimensions, often during production. They’re categorized by function and design. Some common types include:

- Go/No-Go Gauges: These simple gauges quickly determine if a part meets minimum and maximum tolerance limits. A go gauge fits over a part that meets the minimum dimension, and a no-go gauge only fits over a part smaller than the maximum limit. Think of it like a simple pass/fail test.

- Plug Gauges: Cylindrical gauges used to check internal diameters of holes.

- Ring Gauges: Used to check external diameters of shafts or pins.

- Snap Gauges: These have adjustable jaws to measure the dimensions of a part directly.

- Thread Gauges: Used to check the accuracy of screw threads.

- Profile Gauges: These are used to check the shape and dimensions of complex parts.

The choice of gauge depends on the specific part being measured and the required accuracy. Go/No-Go gauges are suitable for high-volume production where speed and simplicity are prioritized, while more complex gauges are used when higher accuracy or more detailed measurements are needed.

Q 15. Describe your experience with using statistical software for metrology data analysis.

My experience with statistical software in metrology is extensive. I’m proficient in using packages like Minitab, JMP, and R for various analyses. For instance, I’ve used Minitab extensively for Gage R&R studies to assess the variability introduced by measurement systems. This involves analyzing data to determine the contribution of the operator, the gage itself, and the part variation. JMP’s powerful visualization tools are invaluable for quickly identifying trends and outliers in large datasets, crucial for identifying potential measurement errors. With R, I’ve developed custom scripts for more complex statistical process control (SPC) charting and capability analysis, enabling proactive identification of process shifts and preventing defects. A recent project involved using R to analyze thousands of measurements from a complex manufacturing process, leading to the identification of a previously unknown source of variation in our automated measuring system.

Specifically, I’m comfortable performing analyses such as ANOVA (Analysis of Variance), regression analysis, and capability studies (Cp, Cpk). I also leverage statistical process control (SPC) charts – such as X-bar and R charts, and individuals and moving range charts – to monitor measurement process stability. This allows for proactive identification of issues and helps us prevent out-of-control situations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle non-conforming measurements?

Handling non-conforming measurements requires a systematic approach. First, I thoroughly investigate the cause. This involves reviewing the measurement process, equipment calibration status, and operator training. Is there a clear trend indicating a systematic error? Are there random outliers? Then, depending on the root cause, several actions may be taken.

- For systematic errors: Recalibration or repair of equipment is necessary. Operator retraining might be required. Process adjustments might be necessary to eliminate the root cause of the measurement error.

- For random errors: If the errors are within acceptable limits of tolerance, these data points might still be used; however, their number and influence should be assessed carefully. If not acceptable, the data points might be discarded and the measurements repeated.

- Investigation and documentation: Regardless of the type of error, a thorough investigation is critical and it must be meticulously documented, including the corrective actions taken and the verification of their effectiveness. The corrective actions may include updated standard operating procedures and implementing new quality control checks.

For example, if a series of measurements from a particular gauge consistently read high, a recalibration or even replacement of that gauge would be necessary. On the other hand, if a single outlier is detected, further investigation into potential procedural errors would be required before deciding whether to re-measure or discard the data point.

Q 17. Explain the importance of proper documentation in metrology.

Proper documentation is the cornerstone of a reliable metrology system. It provides a traceable record of all measurement activities, ensuring accuracy and accountability. This includes detailed records of calibration certificates, equipment maintenance logs, measurement procedures, and data analysis results. Without comprehensive documentation, the integrity of the measurement data is questionable, potentially leading to incorrect decisions and costly consequences.

Imagine a scenario where a critical component fails due to a flawed measurement. Without proper documentation, it would be nearly impossible to trace the root cause, determine liability, or prevent similar failures in the future. Effective documentation ensures traceability—the ability to follow the history of a measurement from its origin to its final use—making it a critical element for quality control and compliance. In regulated industries like aerospace or pharmaceuticals, traceability is essential for meeting stringent regulatory requirements.

Q 18. What are your preferred methods for root cause analysis in metrological problems?

My preferred methods for root cause analysis in metrological problems are a combination of techniques, depending on the nature of the problem. I frequently utilize tools like:

- 5 Whys: A simple yet powerful technique to repeatedly ask ‘why’ to uncover the underlying cause of a problem. This iterative process helps drill down to the root of the issue, rather than just treating the symptoms.

- Fishbone Diagrams (Ishikawa Diagrams): These diagrams help visually organize potential causes categorized by factors such as people, methods, machines, materials, environment, and measurement. They facilitate brainstorming and collaborative problem-solving.

- Data Analysis: Statistical analysis of measurement data—using techniques like control charts and regression analysis—is crucial for identifying trends and patterns that point toward root causes. For example, a control chart showing a systematic drift might indicate a problem with equipment calibration or environmental factors.

I find a combination of these techniques most effective. For instance, I might start with the 5 Whys to get a preliminary understanding of the problem, then use a fishbone diagram to organize potential causes identified, and finally, perform data analysis to confirm or refute those hypotheses.

Q 19. Describe your experience with different types of measurement standards.

My experience encompasses various measurement standards, including national and international standards. I’m familiar with standards issued by organizations like NIST (National Institute of Standards and Technology) and ISO (International Organization for Standardization). I have practical experience with standards related to dimensional metrology (e.g., length, diameter, angle), mass, temperature, and force measurements. For example, I’ve worked extensively with ISO 9001:2015 quality management standards, which are fundamental for establishing and maintaining a robust metrology system within an organization. I understand the importance of traceability to national standards through calibration certificates for measurement equipment. Furthermore, I’m familiar with industry-specific standards and guidelines, adapting my approach based on the client’s needs and the regulatory requirements applicable to their industry.

Q 20. How do you ensure the integrity of measurement data?

Ensuring the integrity of measurement data is paramount. This involves a multi-faceted approach that encompasses several key aspects. Firstly, proper equipment selection and calibration are crucial. This means using equipment appropriate for the measurement task and ensuring that it’s regularly calibrated against traceable standards. Secondly, well-defined and documented measurement procedures are vital to minimize operator error. These procedures should clearly outline the steps involved, the required equipment, and the acceptance criteria. Third, rigorous data handling and analysis practices should be followed, checking for outliers, trends, and systematic errors. Data should be securely stored and managed to prevent accidental alteration or loss. Finally, regular audits and internal reviews help to identify and address any weaknesses in the measurement system.

For example, we implement a system where all measurement data is electronically recorded and stored, eliminating the risk of transcription errors. Data validation checks are built into our systems to flag potential outliers or inconsistencies. A regular audit trail ensures that any changes to data or procedures are documented and reviewed.

Q 21. How do you select appropriate measurement equipment for a given task?

Selecting appropriate measurement equipment involves a careful consideration of several factors. Firstly, the required accuracy and precision of the measurement are crucial. If high precision is required, then a high-precision instrument must be chosen. The range of the measurement also plays a vital role, as the instrument must be able to accommodate the expected values. Next, factors such as the size and shape of the part, material characteristics, and environmental conditions should all be taken into account. Finally, the cost of the instrument and its ease of use must be considered.

For example, when measuring the diameter of a small, precisely machined part, a high-precision micrometer might be necessary. However, for measuring the length of a large steel beam, a less precise but longer-range measuring tape might be more appropriate. This process involves balancing the required accuracy with the practicality and cost of the instrument.

Q 22. Describe your experience with different types of metrology software.

My experience with metrology software spans a range of applications, from basic data acquisition to sophisticated statistical process control (SPC) and dimensional analysis. I’ve worked extensively with software packages like PolyWorks, which is excellent for 3D scanning data processing and reverse engineering. I’m also proficient in CMM software such as PC-DMIS, capable of programming complex measurement routines and analyzing results. For statistical analysis and reporting, I’ve used Minitab and JMP extensively, creating control charts and performing capability studies. Finally, I have experience integrating metrology data into enterprise resource planning (ERP) systems to improve overall quality management. Each software’s strengths vary; for example, PolyWorks excels in handling complex geometries, while PC-DMIS provides robust tools for precise dimensional measurement. Selecting the right software depends heavily on the specific needs of the project and the complexity of the parts being measured.

Q 23. Explain your understanding of tolerance analysis.

Tolerance analysis is crucial for ensuring that manufactured parts meet design specifications. It’s the process of evaluating the cumulative effect of tolerances on a final assembly or product. Imagine building a car; each part has its own manufacturing tolerances (e.g., the piston diameter might be allowed to vary within a certain range). Tolerance analysis determines if the combined variations of all parts will still result in a functioning assembly that meets the overall design requirements. This is often done using statistical methods, considering both the magnitude and distribution of individual tolerances. We frequently use techniques like root sum square (RSS) analysis for independent tolerances and Monte Carlo simulations for more complex scenarios with interdependent tolerances. For instance, a poorly executed tolerance analysis can lead to assembly issues, requiring expensive rework or even product recalls. A well-executed analysis proactively identifies potential problems early in the design phase, allowing for design adjustments to minimize risk.

Q 24. How do you manage and maintain calibration records?

Maintaining accurate calibration records is paramount for compliance and reliable measurement. Our system uses a computerized maintenance management system (CMMS) to track calibration due dates, instrument history, and associated documentation. Each instrument has a unique ID, and all calibration activities, including certificates, are electronically linked. We follow a strict schedule, with automated reminders ensuring timely calibrations. The system generates reports showing calibration status, overdue instruments, and historical data. This digital approach ensures traceability, simplifies audits, and minimizes the risk of human error. For example, if a measurement is questioned, we can easily trace the instrument’s calibration history to verify its accuracy at the time of the measurement. Beyond the CMMS, we maintain a physical archive of key documents, adhering to data retention policies.

Q 25. Describe a challenging metrology project you’ve worked on and how you overcame obstacles.

One challenging project involved verifying the dimensional accuracy of a complex aerospace component. The part had intricate features and tight tolerances, making traditional measurement methods unreliable. The initial approach using a coordinate measuring machine (CMM) proved inadequate due to accessibility limitations in certain areas. We overcame this by employing a combination of methods: We used a high-resolution 3D scanner to capture the entire part’s geometry, then used specialized software to perform the dimensional analysis on the digital model. This approach allowed us to access all areas of the component, providing a complete dimensional assessment. This project highlighted the importance of adaptability and the need to integrate multiple metrology techniques to solve complex problems. It also demonstrated the power of advanced software tools for data analysis and visualization. The project’s success led to significant improvements in our production process and ensured the quality of the aerospace component.

Q 26. What are the key performance indicators (KPIs) you would use to track the effectiveness of a gage management program?

Key performance indicators (KPIs) for a gage management program should focus on effectiveness, efficiency, and compliance. These include:

- Calibration accuracy: The percentage of gages calibrated within acceptable tolerances.

- Calibration overdue rate: The percentage of gages overdue for calibration.

- Calibration cycle time: The average time taken to calibrate a gage.

- Cost per calibration: The average cost of calibrating a gage.

- Number of gage-related nonconformances: Tracking the number of quality issues attributed to faulty gages.

- Compliance with standards: Ensuring adherence to relevant standards like ISO 9001 or ISO/IEC 17025.

Q 27. How do you stay current with advancements in metrology and measurement technologies?

Staying current in metrology requires a multifaceted approach. I regularly attend conferences and workshops, such as those offered by the American Society for Quality (ASQ) and the National Institute of Standards and Technology (NIST). I also actively read industry publications and journals, focusing on emerging technologies and best practices. Online resources, such as manufacturers’ websites and technical articles, are also valuable sources of information. Furthermore, I actively participate in professional organizations and networks, exchanging knowledge and experiences with other metrologists. This continuous learning ensures that I remain at the forefront of advancements in measurement technology and techniques, applying the most up-to-date methods to our processes.

Q 28. Explain your understanding of ISO standards related to metrology.

My understanding of ISO standards related to metrology encompasses several key documents. ISO 9001 focuses on quality management systems, providing a framework for ensuring consistent product quality, which includes reliable measurement processes. ISO/IEC 17025 is crucial for calibration and testing laboratories, establishing criteria for competence and impartiality. It sets requirements for managing uncertainty, traceability, and calibration records. Understanding these standards is critical for ensuring compliance, generating trust in measurement results, and demonstrating competence. These standards are foundational to establishing a robust and credible metrology program within any organization, emphasizing accuracy, traceability, and continual improvement.

Key Topics to Learn for Metrology and Gage Management Interview

- Measurement Uncertainty and Error Analysis: Understanding sources of error, propagation of uncertainty, and methods for minimizing measurement uncertainty. Practical application: Analyzing measurement data to determine the reliability of a process.

- Calibration and Traceability: Understanding calibration procedures, standards, and traceability to national or international standards. Practical application: Developing and implementing a calibration schedule for measurement equipment.

- Gage R&R Studies: Performing Gage Repeatability and Reproducibility studies to assess the variability of measurement systems. Practical application: Identifying and mitigating sources of variation in a measurement process.

- Statistical Process Control (SPC) in Metrology: Applying SPC techniques to monitor and control measurement processes. Practical application: Using control charts to detect shifts in process capability.

- Selection and Application of Measurement Instruments: Understanding the capabilities and limitations of various measurement instruments and selecting appropriate instruments for specific applications. Practical application: Justifying the purchase of new measurement equipment based on technical needs.

- Metrology Standards and Regulations: Familiarity with relevant industry standards and regulations related to measurement. Practical application: Ensuring compliance with relevant standards in a manufacturing environment.

- Data Acquisition and Analysis: Understanding methods for collecting, analyzing, and interpreting measurement data. Practical application: Using statistical software to analyze measurement data and draw conclusions.

- Problem-Solving and Root Cause Analysis: Applying problem-solving methodologies to identify and resolve issues related to measurement systems. Practical application: Troubleshooting a malfunctioning measurement instrument.

Next Steps

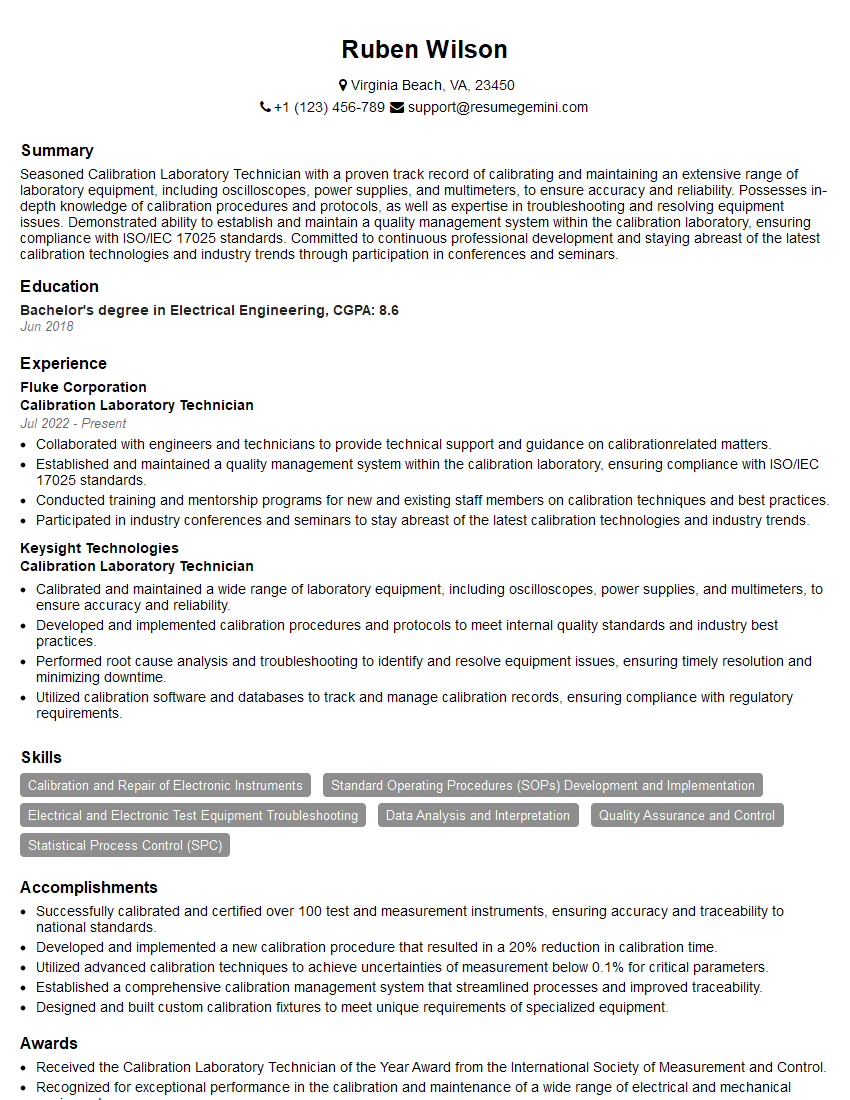

Mastering Metrology and Gage Management opens doors to exciting career opportunities in quality control, manufacturing, and engineering. A strong understanding of these principles is highly valued by employers and demonstrates your commitment to precision and accuracy. To significantly increase your chances of landing your dream role, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini offers examples of resumes tailored to Metrology and Gage Management to guide you through the process. Invest time in creating a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good