Cracking a skill-specific interview, like one for Electrical and Mechanical Engineering Principles, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Electrical and Mechanical Engineering Principles Interview

Q 1. Explain Ohm’s Law and its applications.

Ohm’s Law is a fundamental principle in electrical engineering that describes the relationship between voltage, current, and resistance in a circuit. It states that the current flowing through a conductor is directly proportional to the voltage across it and inversely proportional to its resistance. This relationship is expressed mathematically as:

V = IR

where:

Vrepresents voltage (measured in volts)Irepresents current (measured in amperes)Rrepresents resistance (measured in ohms)

Applications: Ohm’s Law is crucial for numerous applications, including:

- Circuit design: Engineers use it to calculate the appropriate resistor values needed to limit current flow in a circuit. For example, designing a simple LED circuit requires calculating the resistor value to prevent the LED from burning out due to excessive current.

- Troubleshooting: If a circuit isn’t working correctly, Ohm’s Law helps identify potential problems, like a faulty resistor or a short circuit.

- Power calculations: Combined with power formulas (P = IV, P = I²R, P = V²/R), Ohm’s Law allows for the calculation of power consumption in a circuit. This is essential for selecting appropriately sized power supplies.

- Sensor design: Many sensors, like thermistors (temperature sensors), rely on changes in resistance to measure a physical quantity. Ohm’s Law is used to convert the resistance change into a measurable voltage change.

Imagine you’re designing a circuit with a 5V power supply and an LED that requires 20mA of current. Using Ohm’s Law, you can calculate the necessary resistor value: R = V/I = 5V / 0.02A = 250 ohms. This ensures the LED operates correctly without damage.

Q 2. Describe different types of motors and their operating principles.

Motors convert electrical energy into mechanical energy, producing rotational motion. Several types exist, each with unique operating principles:

- DC Motors: These motors run on direct current (DC) electricity. There are several subtypes:

- Brushed DC Motors: Use brushes and a commutator to switch the current direction in the rotor, creating continuous rotation. Simple and inexpensive, but prone to wear and tear.

- Brushless DC Motors (BLDC): Employ electronic commutation instead of mechanical brushes, resulting in higher efficiency, longer lifespan, and quieter operation. Common in drones and electric vehicles.

- AC Motors: Operate on alternating current (AC) electricity. Key types include:

- Induction Motors (Asynchronous): The most common type of AC motor. They use a rotating magnetic field in the stator to induce current in the rotor, causing it to rotate. Simple, robust, and require little maintenance; found in household appliances and industrial machinery.

- Synchronous Motors: The rotor rotates at the same speed as the rotating magnetic field in the stator. They offer precise speed control and are often used in applications requiring constant speed, such as clocks and some industrial processes.

- Stepper Motors: Rotate in discrete steps rather than continuously. They are controlled digitally and are used in precise positioning applications like 3D printers and robotics.

Operating Principles Summary: All motors operate based on the fundamental principle of electromagnetic force. Current flowing through a conductor in a magnetic field experiences a force, causing rotation. The specific mechanisms for generating and controlling this force differ between motor types.

Q 3. What are the different types of gears and their applications?

Gears are toothed wheels that transmit rotational motion and torque between shafts. Different types exist, each suited for specific applications:

- Spur Gears: The simplest type, with straight teeth parallel to the axis of rotation. Suitable for parallel shafts but can be noisy at high speeds.

- Helical Gears: Have teeth inclined at an angle to the axis, resulting in smoother and quieter operation than spur gears. They can transmit higher loads but introduce axial thrust.

- Bevel Gears: Used to transmit power between intersecting shafts. They are commonly found in differential gears in vehicles.

- Worm Gears: A worm (screw) meshes with a worm gear (wheel). They provide high gear ratios and self-locking capabilities (the worm can drive the gear, but the gear cannot drive the worm). Used in applications requiring high torque reduction and self-locking, such as jacks and winches.

- Rack and Pinion Gears: A linear rack meshes with a circular pinion gear, converting rotary motion into linear motion or vice-versa. Used in steering mechanisms and linear actuators.

Applications: Gears are ubiquitous in machinery, from clocks and automobiles to industrial robots and wind turbines. The choice of gear type depends on factors such as speed ratio, torque requirements, noise levels, and space constraints.

Q 4. Explain the concept of torque and horsepower.

Torque is a measure of rotational force. It’s the twisting force that causes rotation and is measured in Newton-meters (Nm) or pound-feet (lb-ft). Think of it as the ‘strength’ of the rotation. A high-torque engine can easily move heavy loads.

Horsepower (hp) is a measure of power, representing the rate at which work is done. It indicates how quickly a motor can do work. One horsepower is approximately 746 watts.

The relationship between torque and horsepower is:

Horsepower = (Torque × RPM) / 5252

(where RPM is revolutions per minute). This equation highlights that a higher torque at a given RPM results in higher horsepower. A high-horsepower engine can perform work more quickly, but may not necessarily have high torque at low RPMs.

For example, a truck engine needs high torque at low speeds for pulling heavy loads, even if its horsepower isn’t exceptionally high. A race car engine, on the other hand, might have high horsepower but relatively less torque at lower RPMs, prioritizing acceleration and speed.

Q 5. How do you calculate power in an electrical circuit?

Power in an electrical circuit is the rate at which energy is consumed or delivered. It’s calculated using several formulas, all derived from Ohm’s Law:

P = IV(Power = Current × Voltage)P = I²R(Power = Current² × Resistance)P = V²/R(Power = Voltage² / Resistance)

where:

Pis power (measured in watts)Iis current (measured in amperes)Vis voltage (measured in volts)Ris resistance (measured in ohms)

The choice of formula depends on the available information. If you know the voltage and current, use P = IV. If you know the current and resistance, use P = I²R. And if you know the voltage and resistance, use P = V²/R.

For instance, a light bulb with a voltage of 120V and a current of 0.5A consumes P = IV = 120V × 0.5A = 60W of power.

Q 6. Describe the working principle of a transformer.

A transformer is a passive electrical device that transfers electrical energy between two circuits through electromagnetic induction. It primarily changes the voltage level of an AC signal while maintaining the power (ideally). It consists of two coils of wire, the primary and secondary windings, wound around a common ferromagnetic core.

Working Principle: An alternating current in the primary winding creates a time-varying magnetic field in the core. This changing magnetic field induces a voltage in the secondary winding. The ratio of the voltages in the primary and secondary windings is proportional to the ratio of the number of turns in each winding:

Vsecondary / Vprimary = Nsecondary / Nprimary

where:

Vsecondaryis the voltage in the secondary windingVprimaryis the voltage in the primary windingNsecondaryis the number of turns in the secondary windingNprimaryis the number of turns in the primary winding

If Nsecondary > Nprimary, the transformer steps up the voltage. If Nsecondary < Nprimary, it steps down the voltage. Transformers are essential for power transmission and distribution, allowing for efficient long-distance transmission at high voltages and subsequent stepping down to safe levels for use in homes and industries.

Q 7. What is the difference between AC and DC current?

The key difference between AC and DC current lies in the direction of electron flow:

- Direct Current (DC): Electrons flow in one direction only. Batteries and solar cells are common DC sources. The voltage remains relatively constant over time.

- Alternating Current (AC): Electrons periodically reverse their direction of flow. The voltage and current fluctuate sinusoidally (like a wave) with time. Household power outlets provide AC electricity.

Practical implications: DC is simpler to generate and use in low-voltage applications, while AC is more efficient for high-voltage long-distance transmission due to ease of voltage transformation using transformers. AC motors are often more robust and cheaper than DC motors, though advancements in electronics are blurring this line.

In short: DC flows in one direction, AC flows back and forth. This seemingly simple difference has massive implications for how electricity is generated, transmitted, and used in various applications.

Q 8. Explain the concept of thermal expansion and its significance in design.

Thermal expansion refers to the tendency of matter to change its volume in response to changes in temperature. When a material is heated, its particles gain kinetic energy and move further apart, causing the material to expand. Conversely, cooling causes contraction. This is a crucial consideration in design because neglecting thermal expansion can lead to significant problems.

Significance in Design: Imagine designing a bridge. If you don’t account for the expansion and contraction of the steel components due to temperature fluctuations, the bridge might buckle or crack in extreme temperatures. Therefore, expansion joints are incorporated to allow for this movement. These joints are gaps built into the bridge structure to absorb the changes in length. Similarly, in precision instruments like clocks or telescopes, thermal expansion can affect accuracy, hence materials with low thermal expansion coefficients are preferred.

Example: Power lines sag more on hot days due to thermal expansion. The designers need to account for this sag to prevent the lines from touching the ground.

Q 9. What are the different types of bearings and their applications?

Bearings are mechanical components that reduce friction between moving parts. Different types cater to varying needs and applications.

- Ball bearings: Consist of balls rolling between inner and outer rings. They offer low friction and are suitable for high speeds and radial loads (loads perpendicular to the shaft). Think of the wheels of your bicycle.

- Roller bearings: Utilize cylindrical or tapered rollers, offering higher load capacity than ball bearings, especially for axial loads (loads parallel to the shaft). These are commonly found in heavy machinery like conveyor systems.

- Plain bearings (Sleeve bearings): Simple, consisting of a sleeve surrounding a shaft. They are used where lubrication is readily available and loads are relatively low. An example is the crankshaft bearing in some engines.

- Thrust bearings: Designed to handle primarily axial loads, often found in applications like propeller shafts or vertical turbines.

- Magnetic bearings: These utilize magnetic forces to support a rotating shaft, eliminating friction altogether. They are used in high-precision applications like gyroscopes and magnetic resonance imaging (MRI) machines, but are more expensive and complex.

Q 10. How do you select appropriate materials for a mechanical design?

Material selection is a critical step in mechanical design. It involves considering multiple factors to ensure the component meets performance and durability requirements.

The selection process typically involves:

- Defining requirements: Identifying the forces, temperatures, corrosive environments, and other conditions the material will encounter.

- Material properties: Examining properties like tensile strength, yield strength, hardness, ductility, fatigue resistance, corrosion resistance, thermal conductivity, and cost. Data sheets and material databases are crucial resources.

- Trade-offs: Balancing different material properties. For instance, a high-strength material might be brittle, while a ductile material might not be as strong.

- Manufacturing considerations: Selecting a material that is easily machinable, castable, or weldable based on the manufacturing process.

- Cost-effectiveness: Considering the material cost in relation to its performance.

Example: Designing a car engine piston requires a material with high strength, low weight, and good wear resistance at high temperatures. Aluminum alloys are often chosen for this purpose.

Q 11. Describe different types of stress and strain.

Stress and strain are fundamental concepts in materials science. Stress is the internal force per unit area within a material, while strain is the deformation resulting from that stress.

- Tensile stress/strain: Caused by pulling forces, leading to elongation.

- Compressive stress/strain: Caused by pushing forces, leading to shortening.

- Shear stress/strain: Caused by forces parallel to the material surface, leading to deformation.

- Torsional stress/strain: Caused by twisting forces, leading to angular deformation.

- Bending stress/strain: A combination of tensile and compressive stresses caused by bending forces.

Example: When you bend a paperclip, the outer side experiences tensile stress and strain, while the inner side experiences compressive stress and strain.

Q 12. Explain the concept of fatigue failure in materials.

Fatigue failure occurs when a material fails under repeated cyclic loading, even if the maximum stress in each cycle is below the material’s ultimate tensile strength. This is because microscopic cracks initiate and propagate over time, eventually leading to fracture. The number of cycles to failure depends on the stress amplitude and material properties.

Factors influencing fatigue failure:

- Stress amplitude: Higher stress amplitudes lead to faster fatigue failure.

- Mean stress: The average stress over the cycle also impacts fatigue life.

- Material properties: Materials with higher fatigue strength resist fatigue failure better.

- Surface finish: Surface imperfections can act as crack initiation sites.

- Temperature: High temperatures can accelerate fatigue crack growth.

Example: A bridge experiences repeated cyclic loading from traffic. Fatigue failure can occur in the bridge components if not properly designed to handle these loads over a long period.

Q 13. What are the different types of welding techniques?

Welding is a joining process that fuses materials using heat or pressure (or both). Numerous techniques exist, each with its strengths and weaknesses.

- Shielded Metal Arc Welding (SMAW): Uses an electric arc to melt the base metal and a consumable electrode coated with flux. It is relatively inexpensive and portable but requires skilled operators.

- Gas Metal Arc Welding (GMAW): Uses an electric arc between a consumable wire electrode and the base metal, with a shielding gas to protect the weld from atmospheric contamination. It is faster and more efficient than SMAW.

- Gas Tungsten Arc Welding (GTAW): Uses a non-consumable tungsten electrode and an inert shielding gas. It produces high-quality welds with excellent control, but is slower and requires more skill.

- Resistance Welding: Uses heat generated by electrical resistance to fuse materials. It is fast and efficient for joining similar metals, such as spot welding in car body production.

- Laser Beam Welding (LBW): Uses a high-power laser beam to melt and fuse the materials. It is highly precise and can weld very thin materials.

Q 14. Explain the principles of fluid mechanics.

Fluid mechanics is the study of fluids (liquids and gases) at rest and in motion. It’s governed by fundamental principles:

- Conservation of mass: Mass is neither created nor destroyed in a fluid system. This leads to continuity equations describing flow rates.

- Conservation of momentum (Newton’s second law): Forces acting on a fluid element cause changes in its momentum. This leads to equations like the Navier-Stokes equations, describing fluid motion.

- Conservation of energy (first law of thermodynamics): Energy is conserved in a fluid system. This is essential in analyzing energy losses due to friction and heat transfer.

Key Concepts:

- Pressure: Force per unit area within a fluid.

- Viscosity: A measure of a fluid’s resistance to flow.

- Density: Mass per unit volume.

- Buoyancy: The upward force exerted on an object submerged in a fluid.

- Flow types: Laminar (smooth, ordered flow) and turbulent (chaotic, disordered flow).

Applications: Fluid mechanics principles are crucial in designing aircraft, pipelines, pumps, turbines, and many other engineering systems.

Q 15. What are the different types of pumps and their applications?

Pumps are devices that move fluids, typically liquids, by converting mechanical energy into hydraulic energy. Different pump types are suited for various applications based on factors like flow rate, pressure, fluid viscosity, and the presence of solids.

- Centrifugal Pumps: These are the most common type, using a rotating impeller to increase fluid velocity and pressure. They’re widely used in water supply systems, industrial processes, and HVAC systems. Think of your home water pump – it’s likely a centrifugal pump.

- Positive Displacement Pumps: These pumps trap a fixed volume of fluid and then force it into the discharge line. Sub-types include:

- Reciprocating Pumps: Use a piston or diaphragm to move fluid. These are suitable for high-pressure applications like hydraulic systems and chemical processing.

- Rotary Pumps: Utilize rotating elements (gears, lobes, screws) to move fluid. They are used in various industries, from food processing (handling viscous substances) to oil and gas (high viscosity fluids).

- Axial Flow Pumps: These pumps move fluid parallel to the shaft’s axis, generating high flow rates at relatively low pressures. They are often found in large-scale water management systems, such as irrigation and hydroelectric power plants.

The choice of pump depends heavily on the specific application. For example, a high-pressure, low-flow application might require a reciprocating pump, while a high-flow, low-pressure application might utilize a centrifugal pump.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you analyze a simple truss structure?

Analyzing a simple truss structure involves determining the forces in each member (whether they are in tension or compression). This is usually done using the methods of joints or sections, both based on static equilibrium principles (ΣFx = 0, ΣFy = 0, ΣM = 0).

Method of Joints: This method involves analyzing the forces at each joint individually. We start at a joint with only two unknown forces, solve for those forces using equilibrium equations, and then move to the next joint, using previously calculated forces. This continues until all member forces are determined.

Method of Sections: This method involves cutting through the truss structure with an imaginary section, creating a free-body diagram of a portion of the truss. By applying equilibrium equations to this free-body diagram, we can directly solve for the forces in the cut members.

Example: Consider a simple triangle truss with a load applied at the apex. Using the method of joints, starting at a support joint, we can determine the reaction forces at the supports. Then, analyzing each joint sequentially allows us to solve for the forces in each truss member.

Both methods are equally valid, but the choice depends on the structure’s complexity and which method leads to a more straightforward solution. Software packages are widely used for analyzing complex trusses, but understanding these fundamental methods is crucial.

Q 17. Explain the concept of control systems and feedback loops.

Control systems maintain a desired output from a system by manipulating its inputs. A key component is the feedback loop. Think of a thermostat controlling room temperature: it measures the actual temperature (feedback) and compares it to the setpoint (desired temperature). If there’s a difference (error), it adjusts the heating or cooling system (control action) to reduce the error.

A basic control system includes:

- Plant/Process: The system being controlled (e.g., a motor, a chemical reactor).

- Controller: The device that compares the desired output with the actual output and generates a control signal (e.g., a thermostat, a PLC).

- Actuator: A device that converts the control signal into a physical action on the plant (e.g., a valve, a motor).

- Sensor: Measures the actual output of the plant (e.g., a temperature sensor, a pressure sensor).

Open-loop systems lack feedback, making them less accurate and prone to disturbances. Closed-loop systems (feedback systems) use feedback to continuously adjust the control signal, leading to more precise and stable control. The thermostat example is a closed-loop system.

Q 18. What are PID controllers and how do they work?

PID controllers are widely used feedback controllers. PID stands for Proportional, Integral, and Derivative. They adjust the control signal based on three terms:

- Proportional (P): The control signal is proportional to the error. A larger error results in a larger control signal. This is the primary component, providing immediate response.

- Integral (I): This term accounts for accumulated error over time. It helps to eliminate steady-state error, meaning it helps the system reach the setpoint completely.

- Derivative (D): This term anticipates future error based on the rate of change of the error. It helps dampen oscillations and improve response time.

The overall control signal is the sum of these three components: Output = Kp * e(t) + Ki * ∫e(t)dt + Kd * de(t)/dt, where:

Kp,Ki, andKdare the tuning parameters (gain constants).e(t)is the error at timet.

Tuning these parameters is crucial to achieve optimal control performance. Improper tuning can lead to oscillations, sluggish response, or instability. Many methods exist for tuning PID controllers, ranging from simple trial and error to more sophisticated techniques.

Q 19. Describe the different types of sensors and their applications.

Sensors are devices that convert physical phenomena (temperature, pressure, light, etc.) into measurable electrical signals. A wide variety exists, each with unique characteristics and applications.

- Temperature Sensors: Thermocouples, RTDs (Resistance Temperature Detectors), thermistors. Used in ovens, refrigerators, industrial processes.

- Pressure Sensors: Piezoresistive, capacitive, strain gauge based. Applications include automotive systems, weather monitoring, industrial automation.

- Optical Sensors: Photodiodes, phototransistors, CCDs (Charge-Coupled Devices). Used in cameras, barcode scanners, medical imaging.

- Proximity Sensors: Ultrasonic, inductive, capacitive. Detect the presence of an object without physical contact. Used in robotics, manufacturing, automotive safety systems.

- Accelerometers: Measure acceleration. Used in smartphones, gaming consoles, navigation systems.

- Flow Sensors: Measure fluid flow rate. Used in industrial pipelines, water management systems.

The selection of a sensor depends on the application’s requirements: accuracy, range, response time, cost, and environmental conditions. For example, a high-precision temperature measurement in a scientific experiment would require a different sensor than a simple on/off temperature control in a home appliance.

Q 20. Explain the concept of signal processing.

Signal processing deals with analyzing, manipulating, and interpreting signals. Signals can be continuous (analog) or discrete (digital). The goal is often to extract useful information from signals that may be noisy or corrupted.

Common signal processing techniques include:

- Filtering: Removing unwanted noise or frequencies from a signal (e.g., removing high-frequency noise from an audio signal).

- Transformation: Converting a signal from one domain to another (e.g., Fourier transform to analyze frequency content).

- Compression: Reducing the size of a signal without significant loss of information (e.g., MP3 audio compression).

- Enhancement: Improving the quality or clarity of a signal (e.g., noise reduction, image sharpening).

Signal processing is crucial in many fields, including telecommunications, audio and video processing, medical imaging, and control systems. For instance, in telecommunications, signal processing is essential for encoding and decoding information for efficient transmission over channels.

Q 21. How do you troubleshoot a faulty electrical circuit?

Troubleshooting a faulty electrical circuit requires a systematic approach. Safety is paramount; always disconnect power before working on any circuit.

Steps:

- Visual Inspection: Carefully examine the circuit for any obvious problems like loose connections, burned components, or damaged wires.

- Check Power Supply: Verify that the power supply is providing the correct voltage and current.

- Use a Multimeter: A multimeter is essential. Use it to:

- Check for continuity: Test wires and components for breaks or shorts.

- Measure voltage: Check voltage at different points in the circuit to identify where the problem lies.

- Measure current: Measure current draw to detect excessive current consumption, which may indicate a short circuit.

- Isolate Faulty Components: Using the multimeter readings, systematically isolate the faulty component(s). This may involve replacing components one at a time until the fault is resolved.

- Check Wiring Diagrams: Refer to circuit diagrams to trace the circuit path and identify potential problem areas.

- Consult Datasheets: If specific components are suspected, check their datasheets for specifications and common failure modes.

Remember to always adhere to safety regulations. If you’re unsure about any aspect of the troubleshooting process, consult a qualified electrician.

Q 22. How do you design for manufacturability?

Designing for manufacturability (DFM) is a crucial aspect of engineering that focuses on optimizing a product’s design to make its production as efficient, cost-effective, and reliable as possible. It involves considering the entire manufacturing process from the initial design stages, anticipating potential challenges, and incorporating solutions to mitigate them. This proactive approach avoids costly redesigns and delays later in the production cycle.

- Material Selection: Choosing materials readily available, easy to process, and compatible with the chosen manufacturing methods is vital. For instance, using readily available aluminum alloys instead of a specialized, expensive material reduces costs and lead times.

- Tolerances: Defining realistic manufacturing tolerances is critical. Tight tolerances might increase production cost and complexity, whereas overly loose tolerances can compromise the product’s functionality. A balance must be struck, often through careful analysis of the part’s function and the capabilities of the manufacturing process.

- Assembly Considerations: DFM involves simplifying the assembly process. This includes designing parts that are easy to handle, orient, and join, reducing assembly time and labor costs. Features like snap-fits, alignment pins, and modular designs contribute to simplified assembly.

- Process Capability Analysis: This involves understanding the limitations and capabilities of the selected manufacturing processes. For instance, if injection molding is used, the design should consider the limitations of mold design and material flow.

- Testing and Iteration: Prototyping and testing are integral to DFM. This allows for early identification and resolution of manufacturability issues, reducing risks and rework during mass production. For example, a 3D printed prototype can be used to evaluate assembly challenges and potential design flaws before committing to expensive tooling.

For example, in designing a plastic housing for an electronic device, DFM would involve choosing a readily moldable plastic, designing for easy snap-fitting of components, and setting realistic tolerances to ensure consistent part dimensions without overly stressing the manufacturing process.

Q 23. What are common CAD software packages used in engineering?

Several CAD (Computer-Aided Design) software packages are widely used in engineering, each with its strengths and weaknesses. The choice depends on the specific application and the user’s preferences. Some of the most common include:

- SolidWorks: A popular choice for mechanical design, offering a wide range of tools for 3D modeling, simulation, and documentation.

- Autodesk Inventor: Another strong contender in mechanical design, particularly known for its integrated simulation capabilities and its ease of use in creating complex assemblies.

- AutoCAD: Primarily a 2D drafting software, but also includes 3D modeling capabilities. It remains a standard for detailed drawings and documentation in many industries.

- Creo Parametric (formerly Pro/ENGINEER): A powerful and versatile CAD/CAM/CAE software suite used extensively in aerospace, automotive, and other demanding industries.

- CATIA: A high-end CAD/CAM/CAE software often used in the aerospace and automotive sectors, known for its advanced capabilities in surface modeling and complex assemblies.

Many engineers also use specialized software for electrical design, such as Altium Designer for printed circuit board (PCB) design or EAGLE for less complex applications. The selection of software often depends on industry standards, company preferences, and project requirements. For example, in a project involving complex freeform surfaces for automotive body design, CATIA would be a suitable choice, whereas SolidWorks might suffice for a simpler mechanical assembly.

Q 24. Explain the concept of finite element analysis (FEA).

Finite Element Analysis (FEA) is a powerful computational technique used to predict the behavior of structures or systems under various conditions. It works by dividing a complex object into numerous smaller, simpler elements (hence, ‘finite elements’). Each element is analyzed individually, and the results are then combined to obtain an overall solution. This allows engineers to simulate complex scenarios like stress, strain, heat transfer, and fluid flow without resorting to expensive and time-consuming physical experiments.

The process typically involves:

- Geometric Modeling: Creating a 3D model of the structure or system using CAD software.

- Meshing: Dividing the model into a network of interconnected elements. The mesh density is crucial – finer meshes provide greater accuracy but increase computation time.

- Material Properties: Defining the material properties of each element, including elastic modulus, Poisson’s ratio, density, and thermal conductivity.

- Boundary Conditions: Specifying the constraints and loads applied to the model, such as fixed supports, applied forces, or temperature gradients.

- Solving: Utilizing FEA software to solve the system of equations that govern the element behavior. This typically involves advanced numerical methods.

- Post-Processing: Analyzing the results, which might include stress distributions, displacements, temperature fields, or fluid flow patterns.

For instance, in designing a bridge, FEA can help engineers determine the stress levels under various load conditions, ensuring the bridge’s structural integrity. Similarly, FEA can be used to analyze the thermal performance of electronic components, predicting temperature distributions and identifying potential hotspots.

Q 25. What are some common safety considerations in electrical and mechanical design?

Safety is paramount in both electrical and mechanical design. Numerous considerations must be addressed to ensure the safety of users, operators, and the surrounding environment. These can be broadly categorized as:

- Electrical Safety:

- Insulation: Proper insulation of electrical components is essential to prevent electric shock. This includes using appropriate insulation materials and ensuring sufficient insulation thickness.

- Grounding: Connecting conductive parts to earth ground provides a safe path for fault currents, reducing the risk of electric shock.

- Overcurrent Protection: Incorporating fuses, circuit breakers, and other protective devices to prevent damage from overloads and short circuits.

- Arc Flash Protection: Implementing safety measures to mitigate the hazards associated with electric arc flashes.

- Mechanical Safety:

- Guards and Enclosures: Protecting moving parts with guards or enclosures to prevent accidental contact and injuries.

- Emergency Stops: Providing readily accessible emergency stop switches to quickly halt dangerous operations.

- Strength and Stability: Ensuring components are sufficiently strong and stable to withstand anticipated loads and prevent failures.

- Ergonomics: Designing tools and equipment to minimize strain and fatigue on operators.

- Risk Assessment: Conducting a thorough risk assessment to identify and mitigate potential hazards.

For example, a machine with moving parts would require safety guards to prevent operator injury, and an electrical circuit would require fuses to protect against overloads. A well-designed system incorporates safety considerations at every stage of the design process.

Q 26. Explain your understanding of thermodynamics.

Thermodynamics is the branch of physics that deals with the relationships between heat, work, and other forms of energy. It’s governed by fundamental laws that dictate how energy transformations occur. Understanding thermodynamics is critical in various engineering applications, from power generation to refrigeration.

- Zeroth Law: If two systems are each in thermal equilibrium with a third, then they are in thermal equilibrium with each other.

- First Law (Conservation of Energy): Energy cannot be created or destroyed, only transformed from one form to another. This is expressed as ΔU = Q – W, where ΔU is the change in internal energy, Q is the heat added to the system, and W is the work done by the system.

- Second Law (Entropy): The total entropy of an isolated system can only increase over time, or remain constant in ideal cases where the system is in a steady state or undergoing a reversible process.

- Third Law: The entropy of a perfect crystal at absolute zero temperature is zero.

Thermodynamics concepts are applied extensively in designing efficient engines, analyzing power cycles (like Rankine and Brayton cycles), and developing refrigeration systems. For example, understanding the Carnot cycle, a theoretical thermodynamic cycle, helps engineers optimize the efficiency of heat engines. In designing a power plant, thermodynamic principles are crucial in selecting appropriate working fluids, optimizing component design, and ensuring efficient energy conversion.

Q 27. Describe your experience with project management tools.

I have extensive experience with various project management tools, adapting my choice based on project specifics and team preferences. My experience includes:

- Microsoft Project: For larger projects with complex schedules and resource allocation needs, Microsoft Project provides detailed Gantt charts, critical path analysis, and resource management capabilities. I’ve used it to manage multi-disciplinary projects, tracking progress against milestones and identifying potential delays.

- Jira: An agile project management tool suitable for iterative development projects. I’ve used Jira to manage software development projects, track bugs and feature requests, and ensure efficient collaboration within the team using scrum methodologies.

- Asana/Trello: For smaller projects or teams needing a simpler, more visual approach, Asana and Trello offer Kanban boards for task management and progress visualization. I’ve used these for less complex projects to streamline workflows and maintain transparency among team members.

- MS Excel/Spreadsheets: For straightforward projects, spreadsheets can effectively manage tasks, deadlines, and resources. I leverage this for managing simpler tasks, budgeting, and tracking project expenses.

My proficiency extends beyond simply using these tools. I understand the underlying principles of project management, including scheduling, risk management, and resource allocation, and I tailor my use of project management tools to best suit the specific needs of each project.

Q 28. How do you handle conflicting priorities in a project?

Conflicting priorities are common in project management. Handling them effectively requires a structured approach.

- Identify and Clarify: The first step is to clearly identify all conflicting priorities. This often involves discussions with stakeholders to understand the importance of each objective.

- Prioritization Framework: Employ a prioritization framework like MoSCoW (Must have, Should have, Could have, Won’t have) to rank priorities based on their importance and feasibility. This allows a systematic evaluation of trade-offs.

- Stakeholder Communication: Open and transparent communication with stakeholders is essential to reach a consensus on priorities. This might involve explaining trade-offs and potential consequences of choosing one option over another.

- Negotiation and Compromise: Negotiation is often necessary to find acceptable compromises. This requires effective communication skills and a willingness to find solutions that address the concerns of all parties involved.

- Documentation and Tracking: Document the agreed-upon priorities and the rationale behind the decisions. Regularly track progress and make adjustments as needed to ensure the project remains on track despite the initial conflicts.

For example, in a project with conflicting deadlines and budget constraints, using a MoSCoW method can help prioritize features. ‘Must-have’ features might be completed within the budget, whereas ‘should-have’ or ‘could-have’ features might be delayed or removed to stay within budget. This proactive approach prevents costly rework and maintains project success.

Key Topics to Learn for Electrical and Mechanical Engineering Principles Interview

- Circuit Analysis: Understand fundamental circuit laws (Ohm’s Law, Kirchhoff’s Laws), circuit theorems (Thevenin’s, Norton’s), and AC/DC circuit analysis techniques. Consider practical applications in power distribution systems or embedded systems.

- Thermodynamics and Heat Transfer: Grasp concepts like the first and second laws of thermodynamics, different modes of heat transfer (conduction, convection, radiation), and their applications in engine design or HVAC systems. Explore problem-solving approaches using relevant equations.

- Mechanics of Materials: Master stress-strain relationships, different types of stresses and strains, failure theories, and their applications in structural analysis and design. Practice solving problems related to beam bending, torsion, and buckling.

- Fluid Mechanics: Understand fluid properties, fluid statics, Bernoulli’s equation, and applications in areas like pipeline design or pump selection. Focus on problem-solving using equations and diagrams.

- Control Systems: Learn basic control system concepts like feedback control, transfer functions, stability analysis, and their applications in robotics, automation, or process control. Practice designing and analyzing simple control systems.

- Electrical Machines: Understand the principles of operation of various electrical machines (DC motors, AC motors, transformers) and their applications in industrial automation and power systems. Be prepared to discuss their characteristics and efficiency.

- Manufacturing Processes: Familiarize yourself with common manufacturing processes like machining, casting, forging, and their applications in different industries. Understand material selection considerations for different processes.

- Material Science: Understand the properties of different materials (metals, polymers, composites) and their selection criteria for specific engineering applications. Explore the relationship between material microstructure and macroscopic properties.

Next Steps

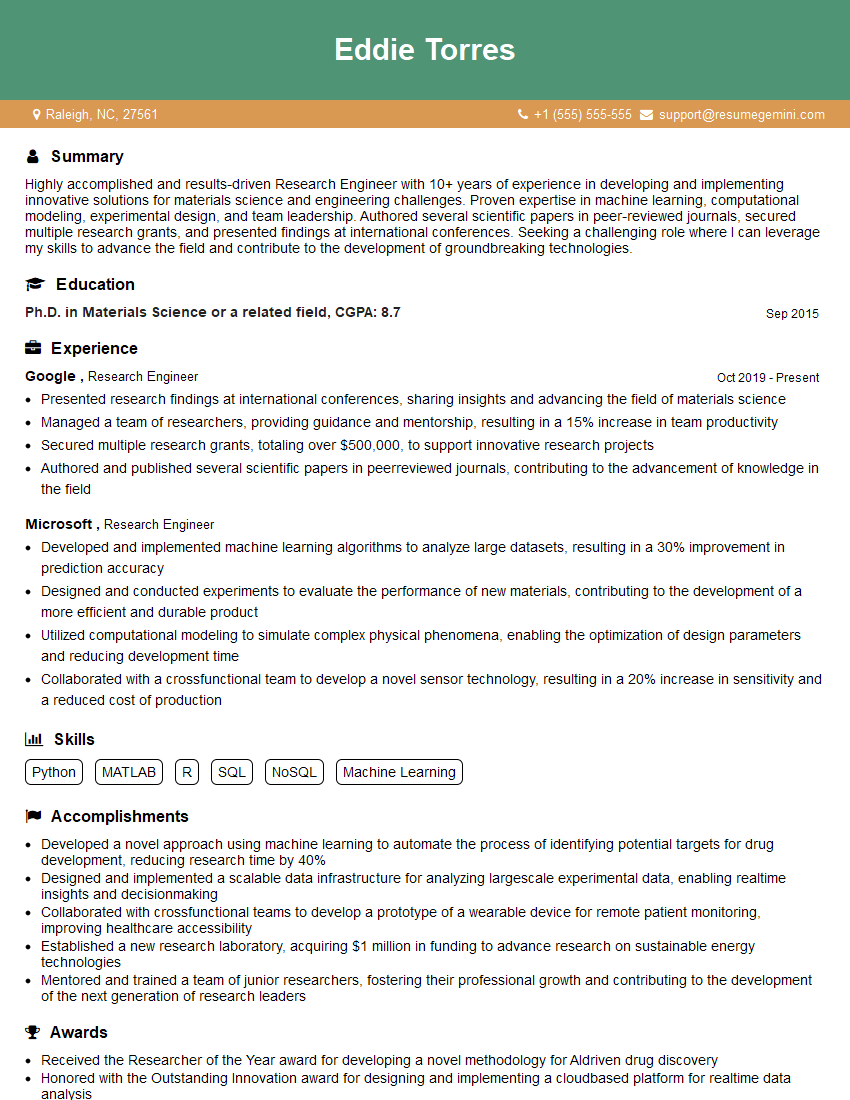

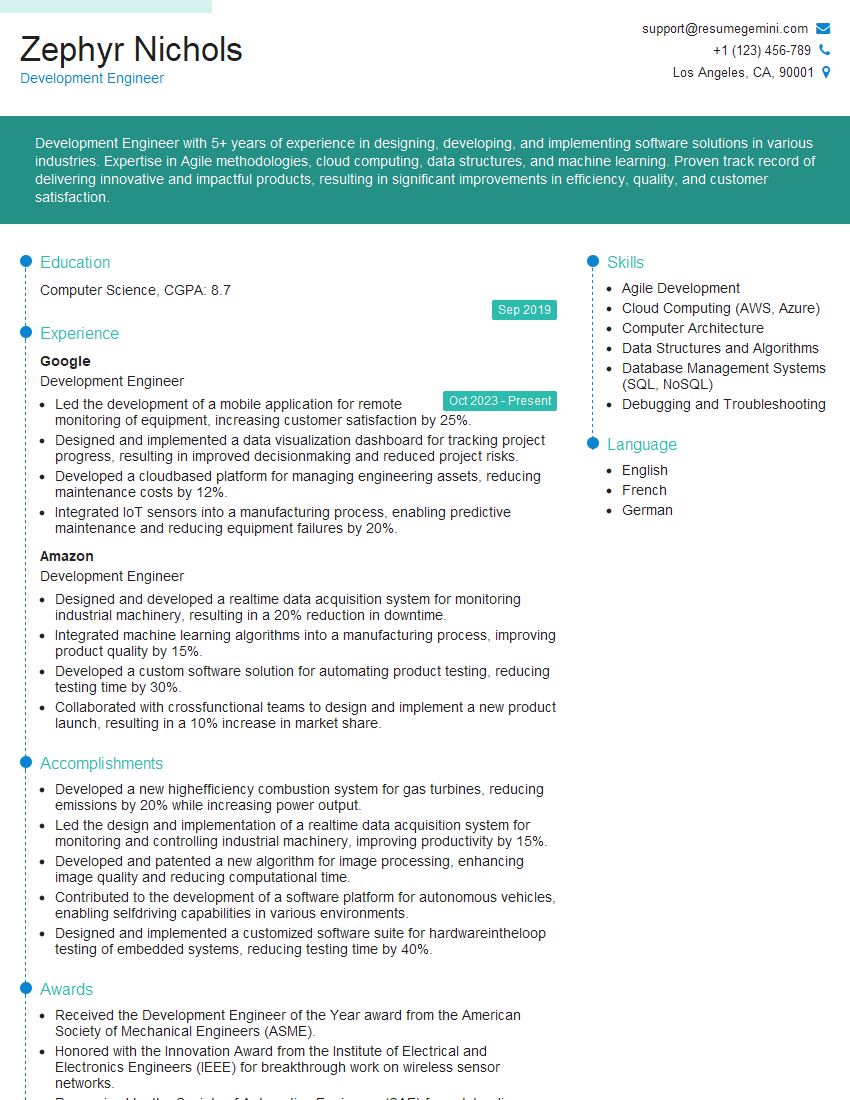

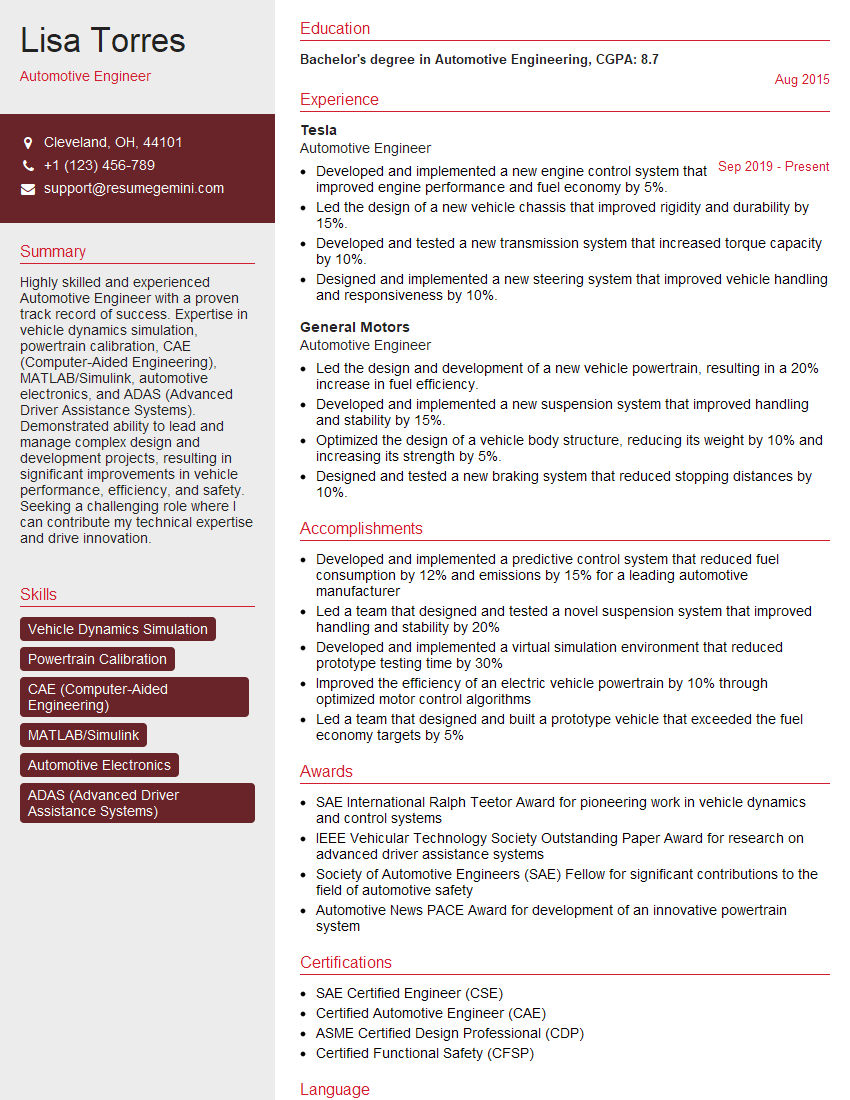

Mastering Electrical and Mechanical Engineering Principles is crucial for a successful and rewarding career. A strong understanding of these fundamentals opens doors to diverse and challenging roles within various industries. To maximize your job prospects, it’s essential to create a compelling and ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your expertise in Electrical and Mechanical Engineering Principles. Examples of resumes tailored to this field are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good