Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Tolerance Analysis and Dimensional Control interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Tolerance Analysis and Dimensional Control Interview

Q 1. Explain the concept of tolerance stack-up analysis.

Tolerance stack-up analysis is a crucial process in engineering design that determines the overall tolerance of an assembly based on the individual tolerances of its components. Imagine building a LEGO castle: each brick has slight variations in size, and these small variations accumulate to affect the final structure’s dimensions. Tolerance stack-up analysis helps us predict the potential range of variation in the final assembly’s dimensions, ensuring it meets design specifications.

Essentially, it’s about understanding how individual component tolerances combine—additively or otherwise—to influence the overall assembly’s performance and functionality. If the accumulated tolerance is too large, the assembly might not function correctly, leading to costly rework or product failure.

Q 2. Describe different methods for tolerance stack-up analysis (e.g., worst-case, RSS, Monte Carlo).

Several methods exist for performing tolerance stack-up analysis, each with its own strengths and weaknesses:

- Worst-Case Analysis: This method assumes that all component tolerances accumulate in the most unfavorable direction, resulting in the largest possible variation. It’s simple to calculate but often overly conservative, potentially leading to unnecessarily tight tolerances on individual components.

- Root Sum Square (RSS) Analysis: This statistical method assumes that component variations are random and normally distributed. It calculates the overall tolerance as the square root of the sum of the squares of the individual tolerances. This approach is less conservative than worst-case analysis but requires a good understanding of the statistical distribution of component variations.

- Monte Carlo Simulation: This sophisticated method uses a computer program to simulate thousands of assembly instances, each with randomly selected component dimensions within their specified tolerances. The resulting distribution of overall dimensions provides a much more realistic assessment of the overall tolerance. It captures the complexities of interactions between different components better than other methods.

Q 3. What are the advantages and disadvantages of each tolerance stack-up method?

Let’s compare the advantages and disadvantages of each method:

- Worst-Case:

- Advantages: Simple to calculate, guarantees the assembly will always fit within specified limits (though perhaps unnecessarily tightly).

- Disadvantages: Overly conservative, leading to increased manufacturing costs due to tighter tolerances.

- RSS:

- Advantages: Less conservative than worst-case, providing a more realistic estimate of the overall tolerance.

- Disadvantages: Assumes normally distributed tolerances, which may not always be the case. Does not account for potential correlations between component variations.

- Monte Carlo:

- Advantages: Provides a realistic distribution of overall dimensions, considering interactions between components. Can handle non-normal distributions.

- Disadvantages: More complex and computationally intensive than other methods. Requires sophisticated software.

Q 4. How do you determine the appropriate tolerance for a given dimension?

Determining the appropriate tolerance for a given dimension involves a careful balance between functionality and cost. Several factors influence this decision:

- Functional Requirements: The primary driver is how much variation can be tolerated without affecting the assembly’s performance. A tight tolerance is needed for critical dimensions, while less-critical dimensions can tolerate greater variation.

- Manufacturing Capabilities: The chosen tolerance must be achievable with the available manufacturing processes. Setting tolerances too tight can result in increased production costs or even make manufacturing impossible.

- Cost Considerations: Tighter tolerances generally increase manufacturing costs. A cost-benefit analysis is crucial, weighing the added expense against the benefits of improved accuracy.

- Material Properties: Material properties, like shrinkage during manufacturing, can impact tolerance. This is crucial for considerations in processes like casting or molding.

The process usually involves iterating between tolerance analysis and design adjustments until an optimal balance is achieved.

Q 5. Explain the principles of Geometric Dimensioning and Tolerancing (GD&T).

Geometric Dimensioning and Tolerancing (GD&T) is a system for defining and communicating engineering tolerances. Unlike traditional dimensioning, which only specifies nominal values, GD&T uses symbols and tolerancing zones to define permissible variations in form, orientation, location, and runout of features. This provides a more complete and unambiguous description of part geometry.

GD&T uses a set of symbols to clearly communicate acceptable variations. For example, a position tolerance specifies an allowable deviation from a true position, while a flatness tolerance limits the allowable deviation from a perfect plane. GD&T enhances communication, reduces ambiguity, and improves the overall quality of manufactured parts.

Q 6. Interpret a drawing with GD&T symbols and tolerances.

To interpret a drawing with GD&T symbols, one must understand the meaning of each symbol and its associated tolerance value. For instance, a circle with a cross inside it indicates a position tolerance. The number next to it represents the allowable deviation from the nominal position. A symbol depicting a perpendicularity tolerance ensures features remain perpendicular to a datum reference frame within the given tolerance zone.

For a practical example, let’s say a drawing shows a hole with a position tolerance of ±0.1mm. This means the center of the hole must lie within a 0.2mm diameter zone centered at the nominal position. The interpretation of GD&T requires a thorough understanding of its symbols and principles and how they relate to the functionality of the part.

Without a specific drawing to interpret, I can only provide general guidance. A visual example and explanation would aid in effective interpretation.

Q 7. How do you use statistical methods in tolerance analysis?

Statistical methods are crucial in tolerance analysis, especially for complex assemblies. They allow for a more realistic assessment of the overall tolerance by incorporating the variability inherent in manufacturing processes.

Here’s how statistical methods are used:

- Distribution Analysis: Determining the probability distribution of component dimensions. This is often assumed to be normal (Gaussian), but other distributions might be more appropriate depending on the manufacturing process.

- Tolerance Calculations: Using statistical methods like RSS or Monte Carlo simulations to calculate the overall tolerance of the assembly, considering the distribution of individual component dimensions.

- Capability Analysis: Assessing the capability of the manufacturing process to meet the specified tolerances. This involves comparing the variation of the process with the allowed tolerance.

- Process Control: Statistical process control (SPC) charts are used to monitor the manufacturing process and detect any shifts in the mean or variation of the component dimensions.

By using these statistical techniques, engineers can make more informed decisions about design and manufacturing, ultimately reducing costs and improving product quality.

Q 8. What is the difference between unilateral and bilateral tolerances?

Unilateral and bilateral tolerances define the allowable variation of a dimension. The key difference lies in the permissible direction of that variation.

- Unilateral Tolerance: Specifies the allowable variation from a basic dimension in only one direction. Think of it as a one-sided limit. For example, a shaft with a diameter of 10mm ±0.1mm (bilateral) could be expressed unilaterally as 10mm +0.1mm/-0.0mm (maximum variation of +0.1mm above the basic size only). This is useful when a minimum dimension is crucial for functionality.

- Bilateral Tolerance: Allows variation from a basic dimension in both directions (above and below). This is the most common type of tolerance. For example, a hole with a diameter of 20mm ±0.2mm means the acceptable range is 19.8mm to 20.2mm.

Imagine fitting a shaft into a hole. A unilateral tolerance on the shaft might ensure it’s never too small to fit, while a bilateral tolerance on the hole provides leeway on both the maximum and minimum size.

Q 9. How do you handle tolerances in assembly drawings?

Handling tolerances on assembly drawings requires careful consideration and clear communication. It involves defining tolerances for individual components and then analyzing how those tolerances accumulate during assembly. This is crucial for ensuring the final assembly meets its functional requirements.

- Geometric Dimensioning and Tolerancing (GD&T): GD&T symbols are used to specify tolerances precisely. They define form, orientation, location, and runout of features, ensuring components mate properly. Examples include circularity, flatness, perpendicularity, position, and more.

- Tolerance Stack-Up Analysis: This process determines the overall tolerance of the final assembly by considering the individual tolerances of its components. Statistical methods are often used for a more realistic assessment. Worst-case scenarios are also analyzed.

- Clear Communication: The drawing must clearly indicate the tolerance for each feature using GD&T symbols, and also include the relevant datum references which define the geometric relationship of individual features.

For instance, if an assembly requires a specific gap between two parts, the tolerances of each part’s relevant dimensions must be carefully chosen so that the gap remains within acceptable limits, even with manufacturing variations.

Q 10. Explain the concept of ‘fit’ in engineering design and how tolerances influence it.

In engineering design, ‘fit’ describes the relationship between two mating parts. Tolerances directly influence the type of fit achieved. A proper fit is critical for functionality and reliability.

- Clearance Fit: One part fits loosely within another, allowing for some free movement. This requires larger tolerances on both mating parts.

- Interference Fit: One part fits tightly within another, requiring some force to assemble. This implies tighter tolerances, potentially with unilateral tolerances for specific features to guarantee interference fit.

- Transition Fit: Falls between clearance and interference fits, allowing for a slight degree of freedom depending on tolerances and application.

Consider a piston and cylinder assembly. A clearance fit is needed to allow for lubrication and thermal expansion, and here tolerances allow for a small gap. On the other hand, a press-fit component like a shaft in a hub might require an interference fit, where tolerances ensure a certain level of interference for securing the parts, and prevent loosening over time.

Q 11. Describe the process of creating a tolerance analysis report.

A tolerance analysis report documents the results of a tolerance stack-up analysis. It provides a comprehensive overview of the potential variations in an assembly and assesses whether the design meets its functional requirements.

- Scope: Clearly defines the assembly and the specific dimensions analyzed.

- Methodology: Describes the method used for the analysis, such as worst-case or statistical analysis (e.g., Monte Carlo simulation).

- Tolerance Data: Presents the tolerance values for individual components and their sources.

- Calculations: Shows the step-by-step calculations used to determine the overall tolerance of the assembly, including any assumptions made.

- Results: Summarizes the analysis results, showing the range of possible variations and their implications for the assembly’s function.

- Conclusions and Recommendations: States whether the design is acceptable based on tolerance analysis and proposes potential design improvements if necessary.

The report should be clear, concise, and easy to understand, even for those without extensive engineering knowledge. Tables and charts can effectively present complex data.

Q 12. How do you identify and address potential tolerance issues in a design?

Identifying and addressing tolerance issues requires a systematic approach.

- Tolerance Stack-up Analysis: The first step is performing a detailed tolerance stack-up analysis to assess the overall tolerance of the assembly. This helps pinpoint dimensions with excessive variations.

- Design Review: Review the design to identify potential sources of tolerance problems. For example, complex geometries or features with tight tolerances can increase manufacturing challenges and cost.

- Manufacturing Process Review: Evaluate the manufacturing processes used to produce the components. Inefficient processes might lead to larger variations.

- Design Optimization: Adjust the design, tolerances, or manufacturing processes to reduce the overall tolerance and improve functionality. This could involve simplifying the design, changing material selection, or investing in improved manufacturing techniques.

- Statistical Process Control (SPC): Implementing SPC during manufacturing can help monitor and control variations, reducing the risk of exceeding tolerances.

For example, if a tolerance analysis reveals a critical dimension with a high probability of exceeding its limits, the design might be modified to use a simpler geometry or looser tolerance, or the manufacturing process may be improved to reduce the variation of that dimension.

Q 13. What software tools are you familiar with for performing tolerance analysis?

Several software tools are used for tolerance analysis, each with its own strengths and weaknesses.

- 3D CAD software (e.g., SolidWorks, Creo, Inventor): Many modern CAD packages include tolerance analysis capabilities, often integrated with GD&T tools. They allow for simulating the assembly process and predicting the impact of tolerances.

- Specialized tolerance analysis software (e.g., CETOL, Tolerance Analyst): These programs offer more advanced analysis techniques, such as Monte Carlo simulations, and can handle complex assemblies more effectively.

- Spreadsheet software (e.g., Microsoft Excel): Simple tolerance analyses can be performed using spreadsheets. However, this approach can become cumbersome for complex assemblies.

The choice of software depends on factors such as the complexity of the assembly, the level of detail needed in the analysis, and the available resources.

Q 14. How do you communicate tolerance requirements to manufacturing personnel?

Effective communication of tolerance requirements is essential for successful manufacturing.

- Clear Drawings: Use detailed assembly and part drawings with clear GD&T annotations.

- Tolerance Tables: Create separate tables that summarize tolerances for each part, making it easier for manufacturers to understand. Be mindful of units and use consistent notation.

- Manufacturing Process Capability Studies: Collaborate with manufacturers to assess their process capability and ensure they can consistently meet the specified tolerances. This often involves capability studies to validate manufacturing process control and verify manufacturing precision and tolerance consistency.

- Training and Collaboration: Provide training to manufacturing personnel on interpreting GD&T symbols and understanding tolerance requirements. Establish open communication channels for addressing any questions or concerns.

Remember that clear communication reduces errors and rework, and leads to better collaboration between design and manufacturing teams. A shared understanding of tolerances prevents misunderstandings and ensures that the final product meets its specifications.

Q 15. What are common sources of dimensional variation in manufacturing processes?

Dimensional variation in manufacturing arises from numerous sources, broadly categorized into process-related and material-related factors. Process variations stem from inconsistencies in machine settings, tool wear, operator skill, and environmental conditions like temperature and humidity. For example, a CNC machine might have slight variations in its positioning system over time leading to inconsistent cuts. Material variations include inconsistencies in raw material properties like density, hardness, and thermal expansion. Think of casting processes; the cooling rate can affect the final dimensions significantly.

- Machine Variability: Wear and tear on cutting tools, vibrations, and inaccuracies in machine positioning.

- Tooling Issues: Improperly maintained or worn tooling can introduce dimensional inconsistencies. Imagine a drill bit that’s slightly off-center; each hole will be affected.

- Process Parameters: Fluctuations in temperature, pressure, or feed rate can alter the final dimensions of a part.

- Material Properties: Variations in the raw material’s composition, density, and inherent properties such as shrinkage during curing.

- Human Factors: Operator error, inconsistent handling, or improper setup procedures.

- Environmental Factors: Temperature and humidity fluctuations in the manufacturing environment can cause dimensional changes.

Career Expert Tips:

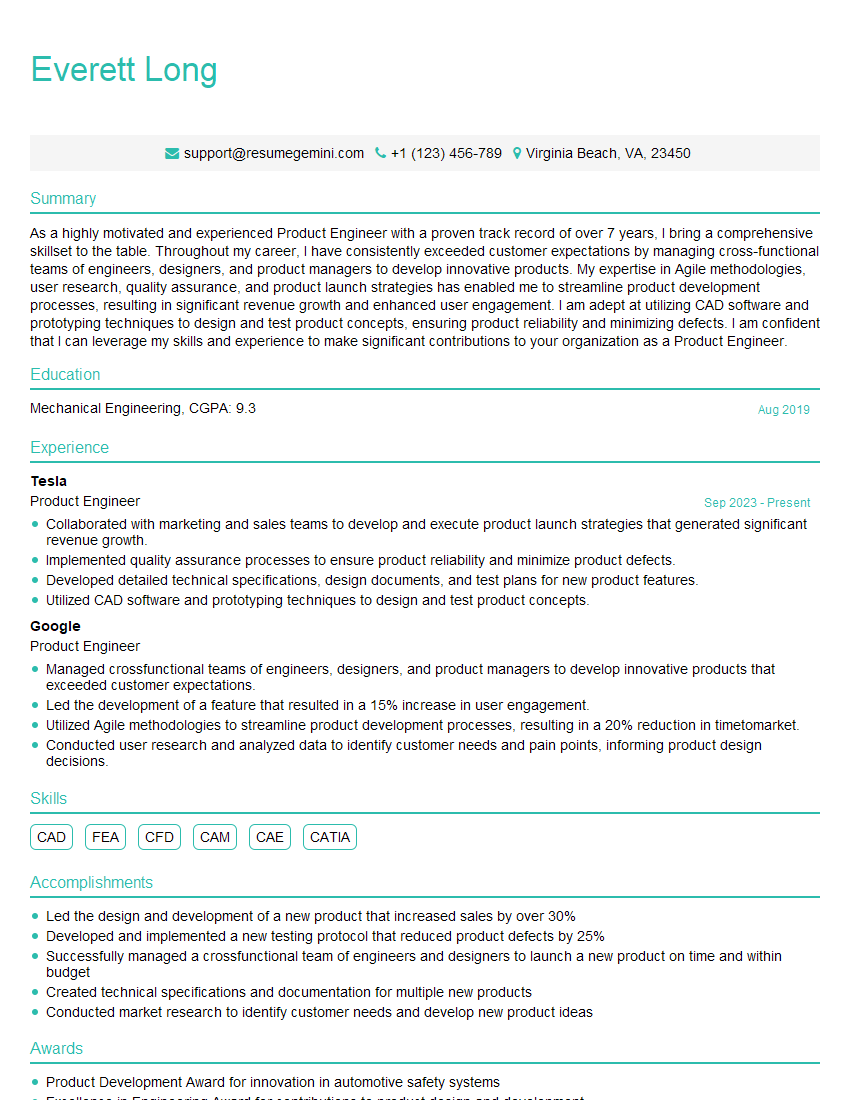

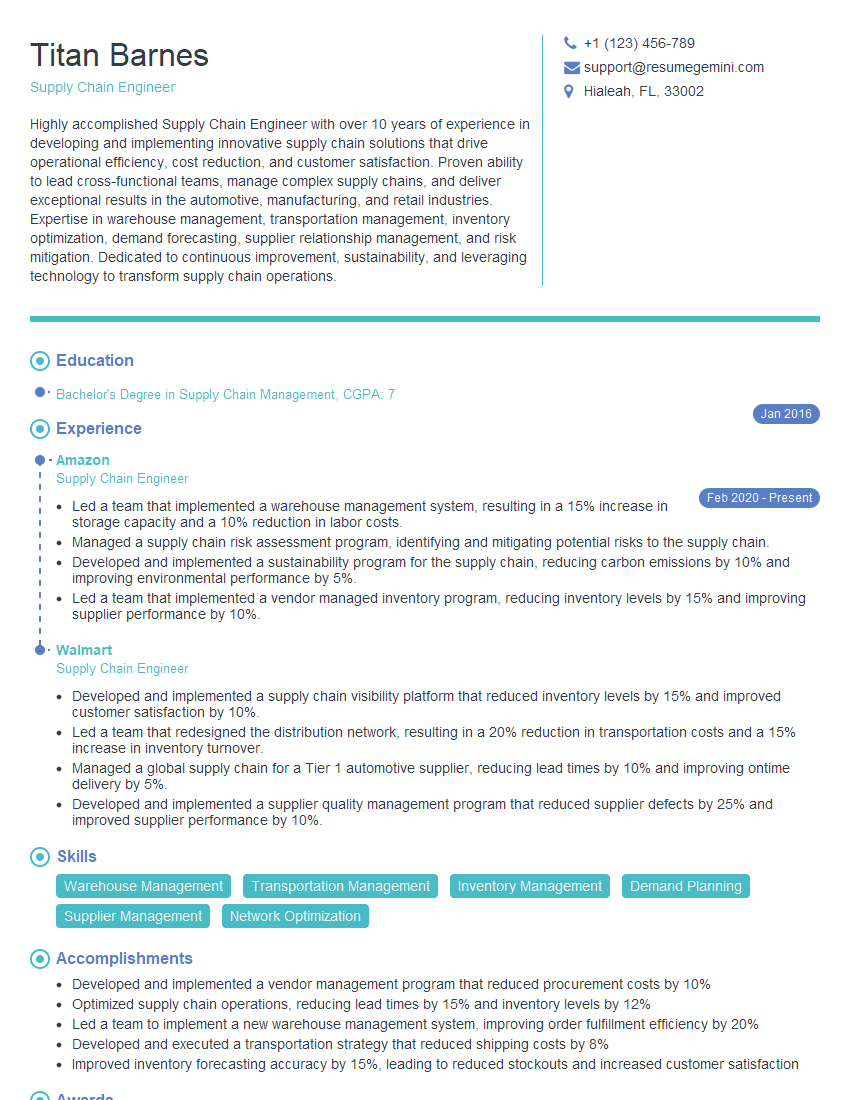

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure that manufactured parts meet specified tolerances?

Ensuring manufactured parts meet specified tolerances involves a multifaceted approach that starts with design and extends through manufacturing and inspection. This requires meticulous control over every stage of the process. It begins with robust design for manufacturing (DFM) principles, choosing tolerances that are achievable and economically viable. Precise machine calibration, regular maintenance, and use of appropriate tooling are critical. Process capability studies, like Cp and Cpk analysis, quantitatively assess how well the process is performing relative to the specified tolerances. Real-time monitoring using Statistical Process Control (SPC) charts helps identify deviations early. Finally, rigorous inspection and quality control, potentially including automated inspection systems, are essential to ensure that non-conforming parts are identified and rejected.

For instance, if we’re manufacturing a precision shaft with a tight diameter tolerance, we would employ a CNC lathe with high precision, regularly calibrate the tooling, and use SPC charts to monitor the diameter measurements of the shafts produced throughout the run. Any deviations beyond the control limits would trigger investigation and corrective action.

Q 17. Describe your experience with measurement systems analysis (MSA).

My experience with Measurement Systems Analysis (MSA) is extensive. I’ve conducted numerous MSAs using various techniques, including Gage R&R studies (both ANOVA and graphical methods), bias studies, and linearity studies. I’m proficient in analyzing the data to determine the accuracy, precision, and repeatability and reproducibility of measurement systems. I understand the importance of selecting appropriate sampling methods and ensuring the operators are properly trained to minimize measurement error. For example, in a recent project involving the measurement of surface roughness, we conducted a Gage R&R study to identify the variability introduced by the measurement device and the operators using it. This allowed us to determine if the measurement system was capable of providing data sufficiently precise to distinguish between conforming and non-conforming parts.

This analysis led to improved operator training, resulting in reduced measurement variability and improved confidence in our inspection data.

Q 18. Explain the concept of gauge repeatability and reproducibility (GR&R).

Gauge Repeatability and Reproducibility (GR&R) is a statistical method used to assess the variation inherent in a measurement system. Repeatability refers to the variation observed when the same operator measures the same part multiple times using the same gauge. Reproducibility refers to the variation observed when different operators measure the same part using the same gauge. The goal of a GR&R study is to quantify these variations and determine if the measurement system is capable of providing accurate and consistent measurements. A high GR&R indicates significant variability in the measurement system, potentially masking actual process variation and leading to incorrect conclusions about part conformance.

A GR&R study typically involves a designed experiment, measuring a sample of parts multiple times by multiple operators. The data are then analyzed using ANOVA (Analysis of Variance) to partition the total variation into components due to repeatability, reproducibility, and part-to-part variation. The results are often expressed as a percentage of the total variation attributable to the measurement system. An acceptable GR&R is generally considered to be less than 10% of the total variation, although the acceptable limit depends on the specific application and tolerance requirements.

Q 19. How do you use statistical process control (SPC) in tolerance control?

Statistical Process Control (SPC) plays a vital role in tolerance control by providing a framework for monitoring process variation and identifying potential sources of defects. Control charts, such as X-bar and R charts for variables data and p-charts or c-charts for attributes data, are used to track key process parameters related to dimensions. By plotting the measured dimensions over time, we can identify trends, shifts, and patterns that suggest process instability or drift. This allows for timely intervention to prevent the production of non-conforming parts.

For instance, we might use an X-bar and R chart to monitor the diameter of a machined part. If the data points consistently fall outside the control limits, it indicates that the process is out of control, and an investigation is required to identify the root cause of the variation (e.g., tool wear, machine misalignment). This proactive approach prevents the accumulation of non-conforming parts and ensures that the process remains within the specified tolerances.

Q 20. What is the relationship between tolerance analysis and quality control?

Tolerance analysis and quality control are intrinsically linked. Tolerance analysis is a predictive process that determines the potential variation in a final product based on the tolerances of its individual components. This informs the design and manufacturing processes, guiding the selection of appropriate tolerances for each component to ensure the final product meets its specifications. Quality control, on the other hand, is a reactive process that measures the actual variation observed in the manufacturing process and verifies whether the product meets the specified tolerances. It involves inspection, testing, and corrective actions.

In essence, tolerance analysis helps to prevent defects by anticipating potential sources of variation during design, while quality control helps to detect defects during manufacturing and provides feedback to improve the process. They are complementary approaches that work together to achieve high-quality manufacturing.

Q 21. How does material selection affect tolerances?

Material selection significantly influences achievable tolerances. Materials with inherent variability in properties (e.g., inconsistent density or shrinkage during curing) will naturally lead to wider tolerances in the final product. For example, using a material prone to warping or shrinkage will make it challenging to maintain tight tolerances. Materials with high thermal expansion coefficients may be more sensitive to environmental changes, increasing dimensional variation.

Conversely, selecting a material with consistent properties and low sensitivity to environmental factors facilitates tighter tolerances. The material’s machinability and its ability to hold a precise shape during processing also affect tolerance control. For instance, a material that is easily machined will allow for finer tolerances compared to a brittle material prone to cracking or chipping.

Q 22. How does manufacturing process capability influence tolerance achievement?

Manufacturing process capability directly dictates how well a process can consistently produce parts within specified tolerances. Think of it like archery: your process capability is how tightly your arrows group around the bullseye (the target dimension). A high capability process means the arrows are clustered closely together, indicating consistent production of parts near the nominal dimension. A low capability process results in a wider spread, meaning more parts fall outside the acceptable tolerance range.

For example, if you’re machining a shaft to a diameter of 10mm ±0.1mm, a highly capable lathe will consistently produce shafts within this range. However, a poorly maintained or improperly set-up lathe might produce shafts with diameters varying significantly, resulting in many parts outside the tolerance and increased scrap.

Factors influencing process capability include machine precision, tooling condition, operator skill, material consistency, and environmental controls. Statistical Process Control (SPC) tools like control charts are used to monitor and assess capability, ensuring that the process remains within acceptable limits.

Q 23. Describe your experience with tolerance optimization techniques.

Tolerance optimization is crucial for reducing manufacturing costs and improving product quality. My experience involves applying various techniques, including:

- Statistical Tolerance Analysis: This involves using statistical methods to predict the overall tolerance stack-up based on individual component tolerances. Software like Tolerance Analysis tools are extensively used to model and analyze complex assemblies.

- Worst-Case Tolerance Analysis: This more conservative approach assumes all components are at their extreme tolerance limits simultaneously. It provides a more pessimistic but safer estimate of the assembly’s overall tolerance.

- Root Mean Square (RMS) Tolerance Analysis: This statistical method considers the distribution of component tolerances, offering a more realistic estimate than Worst-Case but still accounting for variations.

- Tolerance Allocation: This involves strategically assigning tolerances to individual components to achieve the desired overall assembly tolerance (explained further in answer 4).

In a recent project involving a complex gear assembly, we used a combination of statistical and worst-case analysis to optimize the tolerances of individual gears and shafts. By carefully adjusting tolerances based on the analysis, we reduced manufacturing costs by 15% while maintaining the required assembly functionality.

Q 24. How do you handle tolerance issues that arise during the manufacturing process?

When tolerance issues arise during manufacturing, a systematic approach is essential. My approach involves:

- Identify and Quantify the Problem: Precisely measure the affected parts to determine the extent and nature of the deviation from the specified tolerances.

- Gather Data: Collect data on process parameters, machine settings, materials used, and operator inputs. This may involve reviewing process control charts, machine logs, and conducting operator interviews.

- Root Cause Analysis (RCA): Implement a structured RCA methodology like the 5 Whys or Fishbone diagram to pinpoint the underlying causes. (Detailed in answer 7)

- Implement Corrective Actions: Once the root cause is identified, implement appropriate corrective actions. This might involve recalibrating machines, replacing worn tooling, improving operator training, or modifying the manufacturing process itself.

- Verification: After implementing corrective actions, verify their effectiveness through additional measurements and process monitoring.

For instance, during the production of a precision bracket, we encountered an unacceptable level of warpage. Through RCA, we discovered that inadequate cooling after the forming process was the root cause. Implementing a new cooling system resolved the issue and brought the parts back within tolerance.

Q 25. Explain the concept of tolerance allocation.

Tolerance allocation is the process of strategically distributing the overall allowable tolerance of an assembly among its individual components. It’s like dividing a budget – you have a total budget (overall assembly tolerance) and need to decide how much to allocate to each item (component). The goal is to achieve the desired final assembly tolerance while minimizing manufacturing costs and complexity. Some components might be easier or cheaper to manufacture to tighter tolerances, while others might be more challenging.

There are various strategies for tolerance allocation, often involving a combination of factors like cost, manufacturing capability, and design sensitivity. Software tools are frequently used to automate this process and optimize the tolerance allocation based on different criteria.

Imagine assembling a simple device with three parts. The final assembly requires a total tolerance of ±0.5mm. Through tolerance allocation, we might assign ±0.2mm to one part, ±0.2mm to another, and ±0.1mm to the third. The sum of the individual tolerances (0.2 + 0.2 + 0.1 = 0.5) equals the total assembly tolerance. This distribution is chosen considering the manufacturing processes for each part and the cost associated with achieving each tolerance level.

Q 26. What is the significance of tolerance zones in GD&T?

In Geometric Dimensioning and Tolerancing (GD&T), tolerance zones define the allowable variation for a geometric characteristic of a part. They’re not just about size; they also encompass form, orientation, location, and runout. Instead of simply specifying a single dimension with tolerances (e.g., diameter 10 ± 0.1 mm), GD&T uses symbols and zones to control the geometric variations more precisely.

For example, a positional tolerance zone specifies a circular area within which the center point of a hole must lie. A cylindricity tolerance zone defines the allowable variation in the shape of a cylindrical feature from a perfect cylinder. These zones provide clear, unambiguous specifications, reducing misunderstandings between designers and manufacturers and improving the quality of the final product.

Tolerance zones in GD&T are crucial for ensuring proper function and interchangeability. By explicitly defining acceptable variations in geometry, GD&T reduces the risk of assembly issues and improves the overall quality of manufactured components.

Q 27. How do you verify the accuracy of measurement equipment?

Verifying the accuracy of measurement equipment is paramount for maintaining reliable tolerance control. This is achieved through a multi-pronged approach:

- Calibration: Measurement equipment should be regularly calibrated against traceable standards. This involves comparing the equipment’s readings to those of a known accurate standard and adjusting as needed. Calibration certificates document the accuracy and traceability of the equipment.

- Traceability: The calibration standards themselves must be traceable to national or international standards organizations to ensure consistency and accuracy.

- Regular Checks: Periodic checks using calibrated gauge blocks or other reference standards should be performed to monitor the equipment’s performance between formal calibrations.

- Control Charts: Using control charts can help track the stability of the measurement equipment over time and detect potential drifts or inaccuracies.

- Measurement System Analysis (MSA): A more comprehensive MSA evaluates the entire measurement system, including the equipment, operator, and method, to identify and quantify sources of variation. This helps determine the overall accuracy and repeatability of the measurements.

For instance, in our lab, we calibrate our CMM (Coordinate Measuring Machine) annually and perform regular checks using gauge blocks. We also maintain detailed calibration records and control charts to monitor its performance.

Q 28. Explain your experience with Root Cause Analysis in relation to tolerance issues.

Root Cause Analysis (RCA) is integral to resolving recurring tolerance issues. My experience involves utilizing various RCA techniques:

- 5 Whys: This iterative questioning technique helps drill down to the root cause by repeatedly asking “why” until the underlying problem is uncovered. This method is simple yet effective for identifying straightforward causes.

- Fishbone Diagram (Ishikawa Diagram): This visual tool categorizes potential causes of a problem (e.g., materials, methods, manpower, machines, measurements, environment) and helps systematically explore relationships between them. It’s beneficial for identifying multiple contributing factors.

- Fault Tree Analysis (FTA): This deductive approach constructs a tree-like diagram that shows how various events contribute to a top-level failure. It is especially useful for complex systems.

In one instance, we experienced consistent out-of-tolerance dimensions on a specific feature. Using a Fishbone diagram, we explored potential causes under different categories. We eventually identified the root cause as a combination of slightly worn tooling and inconsistent material properties. Addressing both issues through tooling replacement and stricter material control resolved the problem permanently.

Key Topics to Learn for Tolerance Analysis and Dimensional Control Interview

- Fundamentals of Geometric Dimensioning and Tolerancing (GD&T): Understanding basic GD&T symbols, datums, and tolerance zones is crucial for interpreting engineering drawings and specifications.

- Statistical Tolerance Analysis: Learn how to use statistical methods (e.g., root sum square, Monte Carlo simulation) to predict the overall variation in an assembly based on individual component tolerances.

- Tolerance Stack-up Analysis: Master techniques for analyzing how individual component tolerances accumulate to affect the overall assembly dimensions and functionality. This includes both worst-case and statistical approaches.

- Design for Manufacturing (DFM) considerations in Tolerance Analysis: Understand how manufacturing processes and capabilities influence the selection and assignment of tolerances.

- Practical Application: Case Studies: Review real-world examples of tolerance analysis applied to different engineering projects. Consider examples involving different manufacturing processes and assembly techniques.

- Tolerance Analysis Software: Familiarize yourself with common software tools used for tolerance analysis and simulation (mentioning specific software is optional, but can be helpful).

- Root Cause Analysis of Dimensional Issues: Develop your ability to identify the underlying reasons for dimensional discrepancies and propose corrective actions.

- Dimensional Measurement Techniques: Understand various measurement methods and their associated uncertainties (e.g., CMM, optical measurement systems).

- Process Capability Analysis: Learn how to assess the capability of manufacturing processes to meet specified tolerances.

Next Steps

Mastering Tolerance Analysis and Dimensional Control is vital for career advancement in engineering, manufacturing, and quality control. It demonstrates a critical understanding of design, manufacturing, and quality principles, making you a highly valuable asset to any team. To maximize your job prospects, it’s essential to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your expertise in Tolerance Analysis and Dimensional Control. Examples of resumes tailored to this field are available to guide you. Take the next step and create a resume that showcases your abilities and secures your dream role.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good