The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Sewing Machines interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Sewing Machines Interview

Q 1. What types of sewing machine needles are you familiar with and how do you select the appropriate needle for a specific fabric?

Sewing machine needles come in a wide variety of types, each designed for a specific fabric weight and type. Choosing the right needle is crucial for preventing skipped stitches, broken needles, and fabric damage. The needle system is identified by a number, followed by a letter. The number indicates the needle size (e.g., 11, 14, 16, 18), with higher numbers indicating thicker needles for heavier fabrics. The letter indicates the needle’s point type.

- Universal Needles: These are the most common and versatile, suitable for a range of fabrics from lightweight cotton to medium-weight wools. They have a slightly rounded point.

- Ballpoint Needles: Designed for knits and other stretch fabrics. Their rounded point slides between the loops of the knit fabric rather than piercing them, preventing skipped stitches and fabric damage.

- Sharp Needles: Ideal for woven fabrics like linen, silk, and cotton. The sharp point easily penetrates the fabric fibers.

- Jeans Needles: Stronger needles with a reinforced shaft to withstand the thick, tough denim fabric.

- Leather Needles: Feature a strong, sharp point and cutting edges to pierce thick leather.

- Microtex Needles: These needles have a very fine point and are perfect for fine fabrics like chiffon and silk. They make extremely small, neat stitches that aren’t visible on the fabric.

Selecting the right needle: Always consult your fabric’s weight and type. For delicate fabrics, choose a smaller needle size (e.g., 9-12) and a sharp or microtex needle. For heavy fabrics, use a larger needle size (e.g., 16-18) and a stronger needle like a jeans or leather needle. If you’re unsure, it’s always best to start with a smaller needle and gradually increase the size if needed.

For instance, sewing chiffon requires a size 8 or 9 microtex needle, while sewing heavy denim might call for a size 16 or 18 jeans needle.

Q 2. Describe the different types of sewing machine stitches and their applications.

Sewing machines offer a variety of stitches, each with a specific purpose. The most basic are:

- Straight Stitch: The foundation of sewing, used for seams, topstitching, and many other applications.

- Zigzag Stitch: Used for securing seams, finishing edges (preventing fraying), and decorative stitching. Its width and length are adjustable.

- Overlock Stitch (Serger Stitch): A stitch that cuts and finishes the raw edge simultaneously; usually requires a serger machine.

- Blind Hem Stitch: Creates an almost invisible hem, particularly useful for trousers or skirts.

- Buttonhole Stitch: Creates buttonholes with automated settings; different machines have different styles available.

- Decorative Stitches: Numerous decorative stitches are available on many machines, from simple patterns to complex designs, primarily for embellishment.

Applications: Straight stitch is fundamental for constructing garments. Zigzag stitch is vital for reinforcing seams on stretch fabrics and preventing fraying. Overlock stitches are excellent for preventing fraying on seams used in clothing items that might experience friction. Buttonhole stitches add functionality. Decorative stitches enhance the aesthetic appeal of finished garments.

Q 3. How do you troubleshoot a sewing machine that is skipping stitches?

Skipped stitches are a common sewing machine problem. Troubleshooting involves a systematic approach:

- Check the Needle: Ensure the needle is inserted correctly, is sharp, and appropriate for the fabric. A bent, dull, or incorrectly inserted needle is a common culprit.

- Inspect the Thread: Make sure the thread is the correct type and weight for your fabric and machine, is not tangled or frayed, and is correctly threaded. Knots in the thread can cause skipped stitches.

- Examine the Tension: Improper tension can cause skipped stitches. Check both the upper and lower tension settings. Too much upper tension will pull the thread to the top, while too much lower tension will pull the thread to the bottom, both resulting in skipped stitches.

- Verify the Stitch Length: An extremely long stitch length can also cause skipped stitches, as the feed dogs might not have enough time to properly move the fabric.

- Check the Feed Dogs: Make sure the feed dogs are clean and working properly, moving the fabric smoothly. Lint, dust, or other debris can hinder their movement.

- Inspect the Bobbin: A poorly wound bobbin can lead to skipped stitches. Ensure the bobbin is wound correctly and the thread is properly placed in the bobbin case.

- Clean the Machine: Dust and lint buildup in the machine’s mechanisms can obstruct smooth operation. Regularly clean the machine according to manufacturer instructions.

I often find that a simple fix, like replacing the needle, solves the problem in a majority of cases.

Q 4. Explain the process of threading a sewing machine, including the correct tension settings.

Threading a sewing machine varies slightly depending on the model, but the general principles remain the same. First, consult your machine’s manual for specific instructions. Incorrect threading can damage your machine or cause sewing issues.

- Raise the Presser Foot: Ensure the presser foot is raised to allow easy thread passage.

- Wind the Bobbin: Wind the bobbin with the correct thread type. Improperly wound bobbins are common causes of sewing problems.

- Insert the Bobbin: Place the wound bobbin into the bobbin case and insert the bobbin case into the machine.

- Thread the Upper Thread: Follow the machine’s threading path, often indicated by arrows or numbers. Guide the thread through each component, such as the tension discs, take-up lever, and needle.

- Set the Tension: This setting is crucial for balancing the upper and lower threads. The tension dial is typically numbered; start with the middle setting and adjust as needed. Too much tension will result in puckering; too little will cause loose stitches.

- Test the Threading: Sew a test seam on a scrap fabric to confirm the machine is threading correctly and the tension is set appropriately.

Proper tension is essential for even stitch formation. It should be balanced, so the upper and lower threads interlock smoothly without pulling or bunching. Too much upper tension will cause the top thread to lie flat on the top of the fabric, while too little tension will make the stitches loose and uneven.

Q 5. How do you maintain and clean a sewing machine to ensure optimal performance?

Regular maintenance is crucial for the longevity and performance of a sewing machine. This involves both cleaning and lubrication.

- Regular Cleaning: Brush away loose lint and dust from the machine’s exterior and under the presser foot. Use a brush, compressed air, or a vacuum cleaner to remove any debris from the feed dogs and bobbin area.

- Lubrication: Apply sewing machine oil to the moving parts as recommended by the manufacturer. Over-lubrication can cause issues, so follow the instructions carefully. This is vital for preventing wear and tear and maintaining smooth operation.

- Bobbin Case Cleaning: Clean the bobbin case regularly to remove lint and other debris. A small brush is useful for this task.

- Needle Replacement: Regularly replace your needles to ensure they are sharp and clean. A blunt needle can cause skipped stitches and damage to the fabric.

- Storage: When not in use, cover the machine to protect it from dust and damage. Store it in a dry place.

I recommend cleaning the machine after every few hours of use, and lubricating it at least once a month, or as per the manufacturer’s guidelines. This prevents excessive wear, maintains functionality, and reduces the risk of damage. For instance, neglecting to clean the bobbin area will make your machine much more prone to skipping stitches.

Q 6. What safety precautions do you take when operating industrial sewing machines?

Industrial sewing machines are powerful and can pose safety risks. Here are some key precautions:

- Proper Training: Always receive thorough training on the specific machine before operating it.

- Guard Use: Use all safety guards and shields provided on the machine. These guards protect against needles, belts, and moving parts.

- Clothing: Wear appropriate clothing – loose clothing can get caught in moving parts. Avoid wearing jewelry.

- Hair Restraint: Tie back long hair to prevent it from getting caught in the machine.

- Machine Maintenance: Regular maintenance is crucial to prevent malfunctions that could cause injury. Report any issues to the maintenance team immediately.

- Emergency Stops: Learn how to use the emergency stop button and know its location.

- Safe Work Area: Keep the work area clean, organized, and well-lit.

- Eye Protection: Consider wearing safety glasses to protect against flying debris.

Ignoring these precautions can result in serious injury. A seemingly minor oversight, like failing to tie back long hair, could lead to a severe accident.

Q 7. How do you identify and repair common sewing machine malfunctions?

Identifying and repairing sewing machine malfunctions requires a systematic approach and a basic understanding of the machine’s mechanics. Always consult your machine’s manual.

- Observe the Problem: Note exactly what’s happening: skipped stitches, noisy operation, broken needles, inconsistent stitch formation etc.

- Check the Obvious: Start with the simplest solutions: is the needle inserted correctly? Is the thread correctly threaded? Is the bobbin correctly wound and inserted? Is the tension correct?

- Isolate the Problem: If the problem persists, try to isolate the source: is it a problem with the needle, the thread, the tension, the bobbin, or the mechanical parts of the machine?

- Troubleshooting: Follow the troubleshooting steps outlined in your manual. Many manuals have charts guiding the user through common problems.

- Consult Resources: If the problem persists, consult online resources, repair manuals, or contact a professional sewing machine technician. Avoid attempting complex repairs without the necessary skills and knowledge, as doing so could cause further damage.

- Repair or Replace: Some problems, like a broken motor or severely damaged parts, require professional repair or parts replacement.

For example, if the machine is making a loud grinding noise, it might indicate a mechanical problem requiring professional attention. However, a simple issue like a bent needle can be quickly and easily resolved by replacing the needle. Always proceed with caution and be mindful of safety.

Q 8. Describe your experience with different types of sewing machine feet and their uses.

Sewing machine feet are essential tools that dictate the type of stitch and fabric manipulation possible. Think of them as specialized attachments that transform your machine’s capabilities. My experience encompasses a wide range, from basic feet to highly specialized ones.

- General-purpose foot: This is your workhorse, ideal for most straight stitching and zigzag applications. It’s the default foot on most machines.

- Zipper foot: Its narrow design allows for precise stitching close to the zipper teeth, ensuring a clean, professional finish. I’ve used this extensively when crafting garments and bags.

- Buttonhole foot: This specialized foot guides the fabric for creating consistent, professional-looking buttonholes. Different types exist for various buttonhole styles. Mastering this foot is crucial for tailoring.

- Walking foot: This is crucial for even feed on multiple layers of fabric or difficult-to-manage materials like leather or denim. It prevents slippage and ensures consistent stitching, something I frequently rely on for quilting projects.

- Overcast foot: Used for finishing raw edges to prevent fraying. This foot creates a neat, decorative edge and is invaluable for creating durable garments. I find this indispensable for projects requiring durability.

- Blind hem foot: This creates nearly invisible hems, perfect for professional-looking finishes on skirts, trousers, and curtains. I use this frequently for tailored garments.

Selecting the correct foot is key to achieving optimal results. The wrong foot can lead to skipped stitches, puckering, or uneven seams. It’s like using the right tool for the job in any craft – precision is paramount.

Q 9. What is your experience with computerized sewing machines?

My experience with computerized sewing machines is extensive. I’m proficient in operating various models, from basic to advanced features. These machines offer unparalleled control and precision. They’re excellent for both beginners and experts.

- Precise stitch control: Computerized machines allow for meticulous adjustments to stitch length, width, and density, leading to consistently high-quality results. I’ve found this especially useful when working with delicate fabrics or intricate designs.

- Pre-programmed stitches: A wide variety of pre-programmed stitches eliminates the need for manual adjustments for common tasks, significantly speeding up the sewing process. This makes them ideal for projects with repetitive stitching.

- Needle position adjustments: The ability to precisely control the needle position is critical for tasks like edge stitching or sewing close to seams. This level of control is invaluable for achieving professional-quality seams.

- Advanced features: Many computerized machines offer features like automatic buttonhole makers, needle threaders, and even embroidery capabilities, enhancing both speed and precision. I use these frequently to increase efficiency and create more intricate designs.

However, computerized machines require a certain level of technical understanding. Troubleshooting can be more complex compared to mechanical machines, but the precision and ease of use outweigh the complexities in most cases. I’ve found them to be invaluable in achieving consistent results and exploring advanced sewing techniques.

Q 10. How familiar are you with different sewing machine brands and models?

My familiarity with sewing machine brands and models is comprehensive. I have experience with major brands such as Singer, Brother, Janome, Bernina, and Pfaff, both domestic and industrial models. I understand the strengths and weaknesses of each brand and model, from entry-level machines to high-end professional units.

For example, I know Singer machines are known for their reliability and affordability, while Bernina machines are recognized for their precision and advanced features. Similarly, I’m aware of specific models within each brand, their capabilities, and potential maintenance issues. This knowledge allows me to recommend the best machine for a particular need, based on the user’s skill level, budget, and project requirements. This is particularly crucial when advising clients or assisting with repairs.

Q 11. How do you adjust the stitch length and width on a sewing machine?

Adjusting stitch length and width varies slightly depending on the sewing machine model, but the general principles are consistent. Most machines use dials or digital displays for these adjustments.

- Stitch length: This controls the distance between each stitch. A shorter stitch length (e.g., 1.5 mm) is ideal for seams requiring strength and durability, such as in garments or upholstery. Longer stitch lengths (e.g., 4 mm) are useful for basting or decorative stitching. The dial is usually labeled with numbers or markings representing stitch length in millimeters (mm).

- Stitch width: This controls the width of the zigzag stitch or other decorative stitches. A narrower width creates a tighter zigzag, while a wider width creates a looser one. The dial or display is typically labeled with numbers representing the width in millimeters (mm) or with markings illustrating different widths.

Experimentation is crucial. Understanding how different stitch lengths and widths affect the final product is essential for selecting the appropriate settings for various projects. It’s akin to choosing the right brush size for a painting – the right tool makes all the difference.

Q 12. What is your experience with industrial sewing machine lubrication and maintenance?

My experience with industrial sewing machine lubrication and maintenance is extensive. Industrial machines require regular and meticulous care to ensure optimal performance and longevity. Neglect can lead to costly repairs or even machine failure.

- Regular oiling: Industrial machines require regular lubrication of moving parts with specialized sewing machine oil. This prevents wear and tear and ensures smooth operation. The frequency of oiling depends on usage, but a daily routine is often recommended.

- Cleaning: Lint, dust, and thread buildup can hinder performance. Regular cleaning is vital using compressed air or a brush. I’ve seen many machines suffer due to neglected cleaning.

- Timing and hook adjustments: Industrial machines have intricate timing mechanisms that require periodic adjustment to ensure consistent stitch formation. These adjustments require specialized knowledge and tools.

- Preventive maintenance: This includes regular checks for loose screws, worn parts, and any indication of problems. Early detection allows for timely repairs, preventing major issues.

Proper lubrication and maintenance are critical for ensuring optimal performance and extending the lifespan of industrial sewing machines. I’ve seen firsthand the difference between well-maintained machines and those that have been neglected – the difference in efficiency and longevity is significant.

Q 13. Explain your experience with troubleshooting bobbin issues.

Troubleshooting bobbin issues is a common task. The bobbin is the heart of the lower stitching mechanism, and issues can cause skipped stitches, tangled thread, or even machine jams. My experience covers a wide range of problems.

- Incorrect bobbin winding: Improperly wound bobbins are a frequent cause of problems. I ensure proper tension and winding techniques are followed to avoid this.

- Bobbin case issues: Problems with the bobbin case, such as incorrect placement or damage, can lead to issues. I can identify and resolve these issues through careful inspection and adjustment.

- Thread tension problems: Incorrect bobbin tension often causes skipped stitches or tangled thread. I’ve learned to adjust both upper and lower tensions to resolve these issues.

- Bobbin not seating properly: A common problem, this can be solved by ensuring the bobbin is correctly inserted into the bobbin case and that the case is correctly positioned in the machine.

Troubleshooting bobbin problems involves a systematic approach – checking the bobbin winding, case, tension, and placement in sequence. It’s like solving a puzzle; each step gets you closer to the solution, and experience helps in quickly identifying the root cause.

Q 14. Describe your process for setting up a sewing machine for a specific project.

Setting up a sewing machine for a specific project involves a methodical approach. It’s not just about threading the machine; it’s about optimizing it for the task at hand.

- Choose the right needle: The needle type depends on the fabric type (e.g., denim, silk, jersey). Incorrect needles can damage fabric or lead to skipped stitches. It’s like choosing the right paintbrush for the canvas.

- Select the correct foot: The foot dictates the stitch type and fabric handling. The wrong foot can lead to uneven stitching or damage. As mentioned before, choosing the right foot is essential for professional quality.

- Adjust stitch settings: Stitch length and width should be optimized for the fabric and desired result. Experimentation is key here.

- Thread the machine: Using the correct thread type and threading the machine correctly is crucial. Incorrect threading will lead to immediate failure.

- Test stitch: Always test the settings on a scrap piece of fabric before starting on the actual project. This prevents costly mistakes on the final product.

This process ensures the machine is prepared for optimal performance, minimizing errors and maximizing the quality of the finished project. It’s a vital step, ensuring that every project is executed flawlessly.

Q 15. How do you ensure consistent stitch quality throughout a production run?

Maintaining consistent stitch quality throughout a production run is paramount for delivering high-quality garments. It’s a multifaceted process requiring attention to several key areas. Think of it like baking a cake – you need the right ingredients and the right process to get the same perfect result every time.

- Regular Machine Maintenance: This includes daily lubrication, cleaning of the bobbin case and hook area, and checking the tension settings. A well-maintained machine runs smoothly and produces even stitches. Neglecting this is like trying to bake a cake with a dirty oven – the results will be inconsistent.

- Consistent Thread and Needle Selection: Using the correct thread type and needle size for the fabric is crucial. The wrong combination can lead to skipped stitches, broken needles, or inconsistent stitch length. Imagine trying to sew heavy denim with a fine needle and thin thread – disaster!

- Proper Tension Adjustment: The upper and lower thread tension must be balanced to achieve the perfect stitch. Too much tension can cause puckering, while too little can lead to loose stitches. This is like finding the perfect balance between the sugar and flour in your cake recipe.

- Consistent Sewing Speed: Maintaining a consistent sewing speed prevents variations in stitch length and overall quality. Rushing the process is like trying to whisk your cake batter too quickly – it won’t turn out right.

- Regular Quality Checks: Periodically inspect the stitches throughout the production run to catch any inconsistencies early. A stitch quality check is like tasting your cake batter as you go to make sure it’s perfect.

By diligently following these steps, we can ensure consistent stitch quality, leading to a higher-quality product and minimizing waste.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of broken needles and how do you prevent them?

Broken needles are a common frustration in sewing, often stemming from preventable issues. Think of the needle as the heart of the machine – protecting it is key.

- Incorrect Needle Selection: Using the wrong needle size or type for the fabric is the most common cause. A needle too fine for a heavy fabric will bend or break; conversely, a needle too thick for a delicate fabric can cause damage and breakage. This is like trying to hammer a nail with a screwdriver – it won’t work and will damage the tools.

- Bent Needles: Hitting a pin or other hard object embedded in the fabric will bend the needle, leading to breakage. Regular fabric inspection is crucial here. It’s like hitting a rock when driving – the impact can seriously damage your vehicle.

- Incorrect Needle Placement: Not inserting the needle all the way into the needle clamp or misaligning it can cause breakage. This is similar to not properly installing a lightbulb; it won’t function correctly and might break.

- Improper Thread Tension: Excessive tension puts extra strain on the needle, increasing the risk of breakage. It’s like overtightening a bolt – eventually, it will snap.

- Low-Quality Needles: Using inferior-quality needles increases the chance of breakage. Always opt for reputable brands that provide consistent quality. This is similar to choosing quality ingredients for baking – using cheaper substitutes impacts the final product.

Prevention focuses on careful needle selection, thorough fabric inspection, proper needle insertion and tension adjustment, and using high-quality needles.

Q 17. How do you handle fabric jams in a sewing machine?

Fabric jams are a common sewing machine problem, but a methodical approach can quickly resolve them. Think of it like a traffic jam – you need to carefully navigate the blockage.

- Turn off and unplug the machine: Safety first! Always disconnect power before attempting any repairs.

- Raise the presser foot and needle: This provides easier access to the jammed fabric.

- Locate the jam: Carefully examine the machine to pinpoint where the fabric is caught. It might be under the presser foot, in the bobbin area, or near the feed dogs.

- Gently remove the fabric: Use tweezers or your fingers to carefully remove the jammed fabric. Avoid pulling too hard, as this could damage the machine. Think of it like delicately untangling a pair of headphones.

- Check for obstructions: Once the jam is cleared, check for any other obstructions, such as broken threads or lint build-up.

- Inspect the feed dogs: Ensure the feed dogs are moving freely and aren’t obstructed.

- Re-thread the machine: After clearing the jam, re-thread the machine and check the tension.

Understanding the common jam points, patience, and a careful approach will usually resolve fabric jams without causing damage to the machine.

Q 18. Describe your experience working with different types of fabrics and their sewing requirements.

Experience with diverse fabrics is essential for a skilled sewing machine operator. Each fabric presents unique challenges and demands tailored sewing techniques. Think of it like cooking – you wouldn’t use the same recipe for a cake as you would for a stew.

- Lightweight Fabrics (Silk, Chiffon): These delicate fabrics require fine needles, low sewing speeds, and careful handling to prevent snags and tears. We often use a walking foot to prevent slippage.

- Medium-Weight Fabrics (Cotton, Linen): These fabrics generally sew well with a universal needle and standard settings. The stitch length and tension might need minor adjustments depending on the specific weave.

- Heavyweight Fabrics (Denim, Canvas): These require heavier needles, stronger thread, and possibly a reduced stitch length to prevent skipped stitches. A denim needle is preferable for its strength.

- Stretchy Fabrics (Lycra, Jersey): These fabrics require special needles (ballpoint or stretch needles) designed to avoid piercing the fibers and causing runs. A walking foot can aid in even feeding. A zigzag stitch is often preferred.

- Specialty Fabrics (Leather, Suede): These require specialized needles and may necessitate using different machine settings and foot attachments.

My experience encompasses handling the full spectrum of fabric types, allowing me to adapt to any sewing project and achieve consistently high-quality results.

Q 19. What are the different types of sewing machine motors and their characteristics?

Sewing machine motors come in different types, each with its own characteristics and suitability for various applications. Think of them as different engines for different cars – each optimized for a particular purpose.

- Direct Drive Motors: These motors are directly connected to the sewing machine mechanism, offering smooth, quiet operation, and precise speed control. They’re generally more efficient and less prone to vibration. Think of this as a high-performance sports car engine.

- Belt-Driven Motors: These use a belt to transfer power from the motor to the machine. They’re often less expensive but may be noisier and less efficient than direct-drive motors. These are like the reliable workhorse engine of a pickup truck.

- Servo Motors: These are a type of direct-drive motor offering superior speed control and responsiveness, often found in higher-end industrial sewing machines. They offer precise control and can handle heavy-duty sewing tasks. This is equivalent to a sophisticated hybrid engine.

The choice of motor depends on factors such as budget, required sewing speed, noise tolerance, and the type of sewing tasks to be performed. High-end industrial machines tend to favor direct-drive or servo motors for their precision and power.

Q 20. How familiar are you with sewing machine timing and its importance?

Sewing machine timing refers to the precise coordination between the needle’s movement and the hook’s action in the bobbin case. It’s crucial for proper stitch formation and the overall performance of the sewing machine. Think of it as the timing of a finely tuned orchestra – every instrument must play in perfect harmony.

Proper timing ensures that the needle perfectly interacts with the hook to create the interlocking stitch. Incorrect timing leads to problems such as skipped stitches, broken needles, and inconsistent stitch quality. It’s like trying to play a piece of music where the notes are out of sync.

My experience includes troubleshooting and adjusting timing issues, which involves careful examination of the timing marks on the machine and making adjustments using specialized tools. This requires a deep understanding of the internal mechanics of the sewing machine. A slightly off timing can significantly impact the final stitch quality.

Q 21. Describe your experience with preventative maintenance of sewing machines.

Preventative maintenance is crucial for extending the lifespan and ensuring the optimal performance of sewing machines. It’s like regular servicing of a car – preventing small problems from becoming major ones. A consistent maintenance schedule ensures smooth operation and minimizes downtime.

- Daily Cleaning: Removing lint, thread trimmings, and dust from the bobbin case, hook area, and feed dogs prevents build-up that can impede function.

- Regular Lubrication: Applying sewing machine oil to moving parts reduces friction and wear. This is especially important in high-use environments.

- Needle and Thread Inspection: Regularly checking the needle for damage and using the correct needle and thread for the fabric prevents breakage and inconsistent stitching.

- Tension Adjustment Checks: Regularly checking and adjusting the upper and lower thread tension ensures consistent stitch formation.

- Periodic Professional Servicing: Scheduling professional servicing at recommended intervals (typically once or twice a year depending on usage) ensures thorough inspection and adjustments by a qualified technician. This is like a comprehensive car service that covers various systems.

My approach to preventative maintenance is proactive, systematic, and ensures machines are kept in peak condition, minimizing costly repairs and maximizing productivity.

Q 22. What software or systems do you have experience with related to sewing machine operation or programming?

While there aren’t specific ‘sewing machine programming languages’ in the same way you’d find in software development, my experience involves interacting with several systems relevant to sewing machine operation and optimization. This includes:

Computerized Sewing Machine Interfaces: I’m proficient with the user interfaces and control panels of various computerized industrial sewing machines, enabling me to program stitch patterns, adjust stitch settings (length, width, density), and manage other machine parameters such as speed and needle position.

Production Management Software: I’ve worked with software for tracking production output, managing orders, scheduling tasks, and generating reports. This often involves integrating data from sewing machine sensors or production counters. Examples include software that helps track stitch counts, downtime, and material usage.

Data Acquisition and Analysis: In advanced settings, I have experience collecting data from sewing machines (e.g., using sensors to monitor needle vibration or motor load) and analyzing this data to optimize machine performance or identify potential problems before they escalate. This might involve simple spreadsheet software or more specialized data analysis tools.

Q 23. How do you handle production deadlines and prioritize tasks when working with sewing machines?

Meeting production deadlines with sewing machines requires a methodical approach. My strategy typically involves:

Prioritization: I assess all tasks based on urgency and importance (using methods like Eisenhower Matrix). Urgent, critical tasks, such as fulfilling time-sensitive orders, always take precedence.

Efficient Workflow: I optimize the sewing process by ensuring smooth transitions between tasks, minimizing downtime (e.g., by pre-threading needles, preparing materials). I anticipate potential bottlenecks and proactively address them.

Communication: Open communication with colleagues and supervisors about potential delays or challenges is crucial for proactive problem-solving. This allows for adjustments to the schedule when necessary.

Batching Similar Tasks: Grouping similar tasks (e.g., sewing identical seams) improves efficiency by reducing setup time between different operations.

Continuous Improvement: I regularly analyze our production process to identify areas for improvement in speed and efficiency. This might include tweaking settings on the sewing machine or suggesting improved workflow processes.

Q 24. Describe a time you had to troubleshoot a complex sewing machine problem. What was the issue, and how did you solve it?

I once encountered a situation where a high-speed industrial sewing machine was producing inconsistent stitches – sometimes perfect, sometimes skipped stitches or broken threads. Initial troubleshooting steps (checking needle, thread, tension) yielded no results.

Troubleshooting Process:

Systematic Elimination: I systematically checked each component: I replaced the needle, bobbin, and thread, checked the tension settings on both the upper and lower thread, and examined the hook assembly.

Internal Inspection: After confirming the external components were sound, I carefully disassembled the machine’s feed dog mechanism, looking for any signs of damage, wear, or misalignment. I cleaned and lubricated all moving parts.

Timing and Synchronization: I found the issue stemmed from a slight misalignment in the timing of the hook and needle. The hook was not catching the thread loop consistently. This required precise adjustment using the timing screws, which involved carefully turning and testing.

Resolution: After meticulously adjusting the timing mechanism and reassembling the feed dog, the machine resumed producing consistent stitches. The problem was not a single faulty part but rather a subtle misalignment that required careful observation and adjustment.

Q 25. What is your understanding of different sewing machine drive systems (e.g., direct drive, belt drive)?

Sewing machine drive systems significantly influence machine performance and maintenance. Here’s a comparison:

Direct Drive: These systems connect the motor directly to the sewing machine’s needle shaft. This eliminates the need for belts and pulleys, reducing power loss and resulting in smoother, quieter operation with greater precision. They are often found in high-end industrial machines due to improved speed control and reduced maintenance.

Belt Drive: In these systems, a motor drives a belt that rotates a series of pulleys, ultimately driving the needle. They are more common in simpler, less expensive machines. Belts can wear out over time, requiring replacement, and the system is slightly less efficient than direct drive due to energy loss from friction.

The choice depends on the application. Direct drive is preferable for high-precision, high-speed work, while belt drives are suitable for less demanding tasks where cost-effectiveness is prioritized.

Q 26. How do you ensure the safety of yourself and others while operating and maintaining industrial sewing equipment?

Safety is paramount when working with industrial sewing equipment. My practices include:

Regular Maintenance: Regularly inspecting and maintaining the machines is crucial for preventing malfunctions that could cause injury. This involves checking belts, lubrication, and ensuring all safety guards are in place and functioning.

Proper Training: I ensure that all operators have received thorough training on safe operating procedures, including how to handle the machine, use safety guards, and respond to emergencies.

Personal Protective Equipment (PPE): Always using appropriate PPE, such as safety glasses, to protect eyes from flying debris, is essential. Depending on the task, this might also include gloves to protect hands and hearing protection in noisy environments.

Emergency Procedures: Knowing and practicing emergency procedures for power outages, machine malfunctions, or accidents is critical. Having a clear understanding of where to locate the emergency shut-off and first-aid kits is vital.

Clean and Organized Workspace: Maintaining a clean and organized workspace minimizes the risk of accidents caused by clutter or tripping hazards.

Q 27. Explain the importance of proper needle and thread selection for different fabric types.

Proper needle and thread selection is crucial for achieving high-quality stitching and preventing damage to both the fabric and the machine. Different fabrics have different thicknesses, textures, and strengths, requiring appropriate needles and threads:

Fabric Type: Lightweight fabrics (silk, chiffon) require fine needles and fine threads to avoid creating holes or damage. Heavy fabrics (denim, canvas) need heavier needles and stronger threads to penetrate the material effectively.

Needle Type: Needle types vary (e.g., sharp, ballpoint, stretch). Sharp needles are suitable for woven fabrics, while ballpoint needles are designed for knit fabrics to prevent snagging or running.

Needle Size: Needle size is indicated by a number; higher numbers indicate finer needles. The needle size should be matched to both the fabric and the thread type.

Thread Type: Thread should be chosen for its strength and consistency. Polyester thread is often a good all-purpose choice, but specialty threads may be necessary for specific fabrics or stitch types.

Incorrect needle or thread selection can lead to broken needles, skipped stitches, damaged fabric, and even machine damage. It’s essential to consult a needle and thread chart for guidance when selecting appropriate materials.

Q 28. How familiar are you with the different types of presser feet used in industrial sewing machines?

My familiarity with industrial sewing machine presser feet is extensive. These feet are specialized tools that perform various functions, enabling versatile stitching applications. Examples include:

Standard Presser Foot: Used for general sewing tasks on most fabrics.

Zipper Foot: Allows for precise stitching close to zippers without sewing over the zipper teeth.

Buttonhole Foot: Creates buttonholes of consistent size and shape.

Blind Stitch Foot: Creates nearly invisible hems.

Rolled Hem Foot: Creates narrow, professional-looking rolled hems on delicate fabrics.

Walking Foot: Helps to feed multiple layers of fabric evenly, particularly useful for quilting or sewing thick materials.

Cording Foot: Creates cords or decorative stitching while sewing.

The correct presser foot is crucial for a particular sewing task, ensuring quality and efficiency. I understand their applications and how to properly attach and adjust them on different types of industrial sewing machines.

Key Topics to Learn for Sewing Machines Interview

- Mechanical Operation: Understanding the inner workings of sewing machines, including feed dogs, stitch formation, tension mechanisms, and bobbin systems. Practical application: Troubleshooting common mechanical issues like skipped stitches or uneven feeding.

- Types of Sewing Machines: Familiarity with various machine types (e.g., industrial, domestic, serger, embroidery) and their respective applications. Practical application: Matching machine type to specific sewing tasks and fabrics.

- Sewing Machine Maintenance: Knowledge of regular maintenance procedures, lubrication, cleaning, and needle/thread selection. Practical application: Preventing breakdowns and ensuring optimal machine performance.

- Fabric & Thread Selection: Understanding the properties of different fabrics and how to select appropriate needles and threads for various materials. Practical application: Achieving high-quality stitches and preventing needle breakage.

- Troubleshooting & Repair: Ability to diagnose and solve common sewing machine problems. Practical application: Quickly identifying and fixing issues to minimize downtime.

- Safety Procedures: Awareness of safety protocols when operating and maintaining sewing machines. Practical application: Protecting oneself and others from potential hazards.

- Industrial Sewing Machine Operation (if applicable): Specialized knowledge of high-speed industrial machines, including their unique features and maintenance requirements. Practical application: Efficient and effective operation in a production environment.

Next Steps

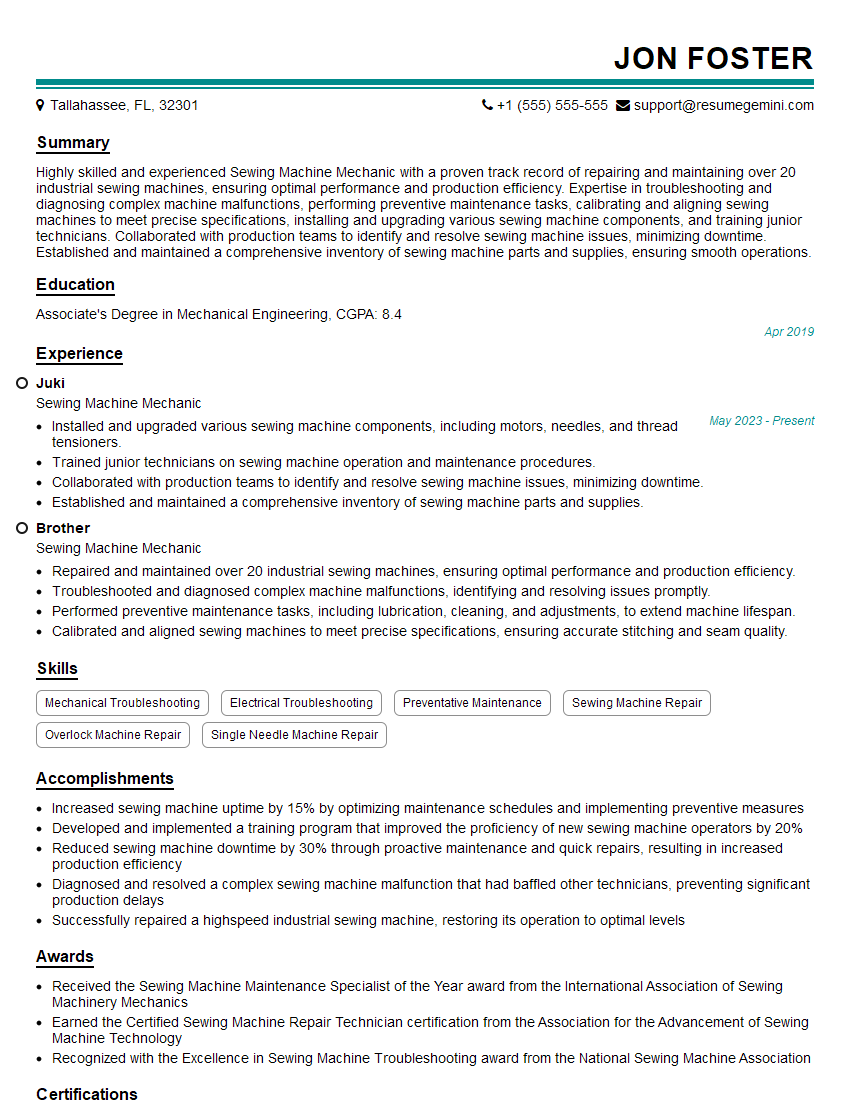

Mastering the intricacies of sewing machines opens doors to exciting career opportunities in fashion, manufacturing, and repair. A strong understanding of these machines demonstrates valuable technical skills and problem-solving abilities, highly sought after by employers. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that catches the eye of recruiters. Examples of resumes tailored to the sewing machine industry are available, providing you with a powerful template to showcase your qualifications. Take the next step in your career journey – build a winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good