Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Custom Fur Creation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Custom Fur Creation Interview

Q 1. Describe your experience with various fur types (e.g., mink, fox, rabbit).

My experience encompasses a wide range of fur types, each with its unique properties. Mink, for example, is known for its luxurious, dense underfur and lustrous guard hairs, making it ideal for creating sleek, elegant garments. Fox fur, on the other hand, boasts a longer, more textured guard hair, offering a bolder, more dramatic aesthetic. Finally, rabbit fur provides a softer, more delicate feel, often used for creating plush linings or lighter-weight outerwear. Understanding these inherent differences is crucial; the drape, the sheen, even the way the fur responds to dyeing, all depend on the animal of origin.

I’ve worked extensively with all three—and many more—developing a keen eye for identifying quality and choosing the best fur for a given design. For instance, a client wanting a classic, understated coat might prefer the refined look of mink, while someone looking for a more statement piece might choose the vibrant character of fox. This choice fundamentally shapes the entire design and construction process.

Q 2. Explain your process for creating a custom fur garment pattern.

Creating a custom fur garment pattern is a meticulous process that combines traditional draping techniques with modern digital tools. It begins with a thorough consultation with the client, understanding their vision, desired fit, and any specific design elements. Next, I create a base pattern using either muslin or a similar draping fabric, paying close attention to the body’s natural curves and proportions. This process often involves multiple fittings to refine the silhouette and ensure a perfect fit.

Once the base pattern is finalized, I adapt it for fur by adding seam allowances, considering the fur’s thickness and potential expansion during construction. This step often involves making adjustments for the fur’s nap (the direction of hair growth), ensuring a consistent flow and preventing any undesirable visual distortions. The final pattern pieces are then carefully numbered and labeled for accurate cutting and assembly.

The entire process demands both precision and artistic sensibility, seamlessly merging technical expertise with an understanding of design principles.

Q 3. How do you handle challenging fur patterns or complex designs?

Challenging fur patterns or complex designs require a strategic approach and often involve breaking down the project into smaller, manageable sections. Intricate details, such as sculpted three-dimensional elements or complex intarsia (inlay) work, might demand the creation of specialized small pattern pieces and careful consideration of fur placement to maintain visual continuity. For instance, creating a fur coat featuring an elaborate floral motif would require meticulously piecing together smaller fur sections to form the desired pattern.

I utilize a variety of techniques, such as creating templates and using specialized stitching methods, to ensure accurate alignment and a clean finish. This often involves utilizing advanced marking techniques to clearly delineate sections, and working with skilled assistants to manage the complexity of the construction.

Problem-solving is key; I often sketch out different construction strategies, evaluate potential challenges, and develop contingency plans before actually starting the assembly process.

Q 4. What techniques do you use to ensure the durability of a fur garment?

Durability in a fur garment hinges on meticulous craftsmanship and the selection of appropriate materials and techniques. I use only high-quality, durable threads, employing specialized stitching methods that minimize stress points and prevent tearing. Reinforcing seams, particularly in high-stress areas such as shoulders, cuffs, and hems, is crucial. This often involves using techniques like ‘bar tacking’ or applying interfacing to add extra strength.

Proper pelt preparation is equally important. Before cutting, I carefully examine each pelt for any weaknesses or damage, ensuring that only the highest quality sections are used in critical areas. Furthermore, proper care instructions are provided to the client to maintain the garment’s integrity. This includes advice on storage, cleaning, and professional maintenance.

Q 5. Describe your experience with fur dyeing and finishing techniques.

My experience with fur dyeing and finishing extends to a variety of techniques, from traditional methods using natural dyes to more modern processes involving chemical dyes. Each method yields unique results and necessitates careful attention to detail. Natural dyes offer subtle, often nuanced color variations, whereas chemical dyes provide more consistent and vibrant results. The selection depends on the client’s preferences and the desired aesthetic for the garment.

Finishing techniques are equally important and include processes like brushing, shearing, and plucking, all of which impact the final texture and appearance of the fur. For instance, shearing can be used to create a smoother, more uniform texture, while plucking can add a more naturally distressed look. Understanding the interplay between dyeing and finishing techniques allows me to achieve a wide range of effects, from classic sophistication to highly creative and contemporary styles.

Q 6. How do you assess the quality of fur pelts before starting a project?

Assessing the quality of fur pelts is a critical first step in any project. I evaluate several key factors, including the density and luster of the fur, the thickness and suppleness of the skin, and the overall condition of the pelt. I check for any signs of damage, such as scars, thinning, or insect damage. The pelt’s origin and history, if known, are also important factors to consider. Sometimes, even the scent can offer clues about the pelt’s quality.

I use a combination of visual inspection and tactile evaluation to assess the pelt’s quality. A high-quality pelt will feel soft, dense, and supple, with a consistent fur length and color. A close examination under good lighting helps identify any subtle imperfections that might affect the final garment. I might even hold the pelt up to light to see the translucence of the skin, this helps me judge the pelt’s overall quality.

Q 7. What software or tools do you use for fur design and pattern making?

While traditional pattern-making techniques remain fundamental, I also utilize digital tools to enhance efficiency and precision. I use CAD software for creating and modifying patterns, ensuring accurate scaling and seamless integration of intricate design elements. This allows for precise adjustments and helps minimize material waste. These digital tools compliment my traditional skills and speed up the process, particularly for complex designs.

Beyond CAD, I rely on specialized software for generating realistic 3D renderings of the final product, allowing me to present my designs to clients in a visually compelling way. This helps clients visualize the final product before the actual construction even begins, allowing for changes in the initial design phase.

Q 8. Explain your understanding of different fur sewing techniques.

Fur sewing techniques require specialized skills due to the unique nature of fur. Different techniques are employed depending on the type of fur, the desired outcome, and the garment’s design.

- Seaming: This involves joining two pieces of fur. Methods include machine sewing (using specialized fur needles and a walking foot to prevent slippage) or hand-sewing (using a slip stitch or ladder stitch for an invisible seam). The choice depends on the fur’s thickness and the visibility of the seam. For example, a delicate sable would require hand-sewing for a pristine finish, while a thicker sheepskin might tolerate machine sewing.

- Cutting: Precision is key when cutting fur, as it’s prone to fraying. Sharp shears are crucial. The direction of the nap (the fur’s natural direction of growth) must be carefully considered to ensure a consistent and aesthetically pleasing result. Cutting against the nap can create a less desirable, bristly appearance.

- Patching & Repair: This calls for matching fur texture, colour and nap direction as closely as possible. Often involves careful cutting and stitching of a patch to replace damaged sections.

- Appliqué: This technique involves adding smaller pieces of fur onto a base fabric or another piece of fur to create intricate designs. Accuracy in cutting and placement is critical to avoid visible seams.

Q 9. How do you manage time effectively when working on multiple fur projects?

Managing multiple fur projects effectively requires meticulous planning and organization. I utilize a project management system that combines digital tools and physical organization. This helps me track deadlines, materials, and progress on each project simultaneously.

- Prioritization: I prioritize projects based on deadlines and client urgency, using a Kanban-style board to visually track the workflow.

- Time Blocking: I allocate specific time blocks to each project to maintain focus and prevent task switching. For instance, I may dedicate two hours to cutting and sewing a specific garment and then transition to another project.

- Material Organization: A well-organized workspace and material storage system are crucial. This means labelling all materials clearly and storing them in a way that allows for easy access. For example, I use colour-coded bins for different fur types to find the right one instantly.

- Regular Check-ins: Regularly reviewing my progress against deadlines helps me identify potential delays and adjust my schedule accordingly. This allows me to communicate proactively with clients about potential changes in timelines.

Q 10. Describe your experience with fur repair and restoration.

Fur repair and restoration is a delicate art requiring patience, precision and a deep understanding of fur properties. My experience encompasses a wide range of repairs, from minor damage to extensive restoration.

- Damage Assessment: The first step is a thorough assessment of the damage, determining the extent of the problem and the best approach for repair. Is it a simple tear, a worn area, or significant fur loss?

- Material Selection: Finding a suitable patch or replacement fur is crucial. This often involves sourcing material similar in type, colour, and texture to the original garment.

- Repair Techniques: Different repair techniques are used based on the type and extent of damage. These include patching, reshaping, and even fur reconstruction in some cases. This sometimes involves using specialized glues and weaving techniques.

- Finishing: The final step involves meticulous cleaning and conditioning of the repaired area to blend it seamlessly with the original garment, maintaining the integrity of the fur.

For example, I once restored a vintage fox stole with significant damage to the tail. This involved painstakingly patching and reconstructing sections of the tail, carefully matching the fur to ensure an invisible repair.

Q 11. How do you handle customer requests and ensure client satisfaction?

Client satisfaction is paramount. I approach each client interaction with professionalism, empathy, and a strong focus on communication.

- Consultation: I begin with a thorough consultation to understand their needs, preferences, and the specific requirements of their project. This includes discussions on design, fur type, budget, and timeline.

- Detailed Quotation: A detailed quotation outlining all costs and the project timeline is provided.

- Regular Updates: I keep clients regularly informed of the project’s progress, addressing any questions or concerns promptly and transparently.

- Feedback Integration: I actively solicit feedback throughout the process, integrating client input to ensure the final product aligns with their vision.

- Post-Project Support: After project completion, I provide guidance on cleaning and care to extend the garment’s lifespan.

Q 12. What are your preferred methods for cleaning and maintaining fur garments?

Cleaning and maintaining fur garments requires specialized techniques to avoid damage. Professional cleaning is usually recommended, but gentle home care can help extend the life of the garment between professional cleanings.

- Professional Cleaning: For a thorough cleaning, professional furriers are best equipped to handle the delicate nature of fur. They have specialized cleaning solutions and techniques to remove dirt and odors without damaging the fur.

- Gentle Home Care: Between professional cleanings, light brushing with a soft-bristled brush can help remove loose dirt and debris. Avoid getting fur wet, as this can damage the pelt and affect the shape and luster.

- Storage: Proper storage is essential to prevent damage from insects, dust and light. Garments should be stored in breathable bags or garment bags in a cool, dark, and dry place. Cedar chips can help deter moths and other insects.

- Avoidance of Harsh Chemicals: Never use harsh chemicals or strong detergents, as these can damage the fur and affect its natural oils.

Q 13. Explain your understanding of ethical sourcing and sustainable fur practices.

Ethical sourcing and sustainable practices are central to my work. I prioritize using furs that are ethically sourced, ensuring no cruelty was involved in their production. I also look for recycled or upcycled fur whenever possible.

- Traceability: I actively seek out suppliers that provide transparent information about the origin and processing of their fur, ensuring compliance with ethical standards and regulations.

- Sustainable Practices: I support and promote sustainable fur practices, which include reducing waste, using environmentally friendly cleaning products, and implementing proper disposal methods for fur scraps and remnants.

- Supporting Responsible Ranching: I favor fur sourced from ranches adhering to high welfare standards for animals throughout their lives, from birth to harvesting.

- Transparency with Clients: I am transparent with my clients about the sourcing of the fur I use, providing them with information about the origin and ethical standards adhered to during production.

For example, I often source vintage fur garments, giving them a second life while reducing demand for newly harvested pelts.

Q 14. How do you address challenges related to fur storage and preservation?

Proper storage and preservation are vital for maintaining the quality and longevity of fur garments. Improper storage can lead to damage from pests, moisture, and light.

- Cool, Dry Environment: Furs should be stored in a cool, dry, and dark environment. Fluctuations in temperature and humidity can cause damage to the fur.

- Breathable Storage: Use breathable garment bags or cedar chests to allow for air circulation and prevent the buildup of moisture. Avoid airtight containers.

- Pest Control: To prevent insect damage, cedar chips, mothballs (used cautiously), or professional pest control methods can be employed.

- Professional Cleaning Before Storage: Clean the fur garment professionally before storing it to remove dirt and debris that could attract pests or damage the fur.

- Avoid Direct Sunlight and Heat: Direct sunlight and heat can fade and damage fur, causing discoloration and brittleness. Therefore, proper storage location selection is crucial.

Q 15. Describe your problem-solving approach when encountering unexpected issues during fur fabrication.

My problem-solving approach when facing unexpected issues during fur fabrication is systematic and methodical. I begin by carefully assessing the problem, identifying the root cause. This often involves a visual inspection of the fur, examining the stitching, and checking my pattern and measurements.

For example, if I encounter uneven fur density in a finished piece, I’ll trace it back to check my initial fur selection, the cutting process, and the sewing technique used. Was the fur consistently dense? Did I account for natural variations in fur thickness during the cutting? Was the tension on my sewing machine appropriate for the type of fur?

Once the root cause is identified, I develop a solution. This might involve adjusting sewing machine settings, re-cutting the problematic section, or exploring alternative techniques. Throughout this process, meticulous record-keeping is vital, allowing for efficient problem-solving and preventing similar issues in the future. I often document solutions and challenges in a dedicated journal, complete with photos and notes, creating a valuable resource for reference.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your strengths and weaknesses as a custom fur creator?

My strengths lie in my meticulous attention to detail, my proficiency in a variety of fur finishing techniques, and my ability to work with diverse fur types. I’m adept at interpreting complex patterns and translating them into high-quality, finished pieces. I also possess excellent problem-solving skills, as demonstrated in my previous response. I’m confident in my ability to meet deadlines and deliver projects to a consistently high standard.

However, like any craftsman, I’m continually seeking to improve. One area I’m focusing on is expanding my knowledge of advanced digital pattern-making techniques. While I’m proficient with traditional methods, integrating digital tools would enhance efficiency and precision. Another area for development is expanding my network within the fur creation community to access new ideas and collaborations.

Q 17. How do you stay up-to-date with the latest trends and techniques in fur creation?

Staying current in the dynamic field of fur creation requires a multi-faceted approach. I regularly attend industry workshops and conferences, both in-person and online. These events provide invaluable opportunities to learn about new techniques, materials, and trends directly from experts. I also subscribe to relevant trade publications and follow leading furriers and designers on social media platforms.

Furthermore, I actively engage in online communities and forums dedicated to fur craftsmanship. This allows me to participate in discussions, share knowledge, and learn from the experiences of others. Continuously seeking out and actively engaging with this information keeps my skills sharp and ensures I’m at the forefront of innovation.

Q 18. Describe your experience with working with different types of fur sewing machines.

My experience encompasses a range of fur sewing machines, from industrial-grade models to specialized machines designed for delicate furs. I’m proficient with both straight-stitch and walking-foot machines, understanding how to adjust stitch length, tension, and pressure to suit the specific characteristics of each fur type. For instance, heavier furs require a more robust machine with adjustable pressure feet to prevent damage to the fur.

I’m also familiar with machines equipped with specialized features, such as those designed for creating intricate fur appliqués or for handling particularly delicate fabrics used in conjunction with fur. The ability to adapt my techniques to different machines is crucial for achieving optimal results with diverse materials and designs.

Q 19. How do you ensure the accuracy of your measurements and cutting techniques?

Accuracy in measurements and cutting is paramount in fur creation. I employ a combination of precise measuring tools, including flexible measuring tapes and rulers, and meticulous cutting techniques. Before cutting, I always double-check my measurements against the pattern several times. For intricate patterns, I use specialized marking tools to ensure accuracy.

I utilize sharp shears and rotary cutters for clean and precise cuts, minimizing any damage to the fur fibers. To maintain precision, I regularly sharpen my tools and use appropriate cutting surfaces. The use of pattern weights is essential to ensure the pattern stays in place during the cutting process. Careful attention to these details consistently yields accurate and well-defined pieces.

Q 20. Explain your understanding of different fur finishing techniques (e.g., shearing, plucking).

Fur finishing techniques are crucial for achieving the desired look and feel of a garment. Shearing involves using specialized shears to create a uniform, even length of fur, often used to create a sleek, modern look. Plucking, on the other hand, is a more meticulous process of removing individual hairs to create textural variations and highlight specific areas. It’s often used to create a more vintage or distressed effect.

Other finishing techniques include brushing, which helps to restore the natural luster of the fur and remove any loose hairs; dyeing, to achieve specific colors; and various other treatments which address aspects of the fur’s density, texture and luster. The choice of finishing techniques depends entirely on the design, the type of fur, and the desired final aesthetic. My expertise lies in choosing the optimal combination of these techniques to produce a high-quality, visually appealing result.

Q 21. How do you collaborate effectively with other team members in a fur creation setting?

Effective collaboration is essential in a fur creation setting. I believe in open communication and clear role definition. Before starting a project, I ensure all team members understand their responsibilities and deadlines. I actively listen to colleagues’ input, respecting their expertise and experience.

For example, when working with a pattern maker, I collaborate closely to ensure the pattern is suitable for the chosen fur and allows for accurate construction. Similarly, I work closely with seamstresses to ensure seamless integration of the fur components into the garment. Regular check-ins and progress meetings are crucial to identify potential challenges early on and to maintain a positive and productive working relationship.

Q 22. How do you handle client feedback and incorporate it into your designs?

Client feedback is paramount in custom fur creation. I begin by actively listening to their vision, understanding not just their desired aesthetic but also their practical needs and budget. I then translate that feedback into design sketches, often creating multiple options to present for discussion. This iterative process involves presenting mock-ups (possibly using less expensive fabrics initially to visualize the design) and incorporating feedback at each stage. For example, a client might initially want a full-length fox fur coat, but after seeing a mock-up, they might prefer a shorter, more modern style. I’ll incorporate that change, adjusting the pattern and fur placement accordingly. The final design is only finalized after complete client approval.

This collaborative approach ensures the final garment exceeds expectations and reflects the client’s personal style and functional requirements. I believe in transparency and clear communication throughout the process, offering alternative solutions or modifications when necessary.

Q 23. Describe your experience with different fur-related accessories and embellishments.

My experience encompasses a wide array of fur-related accessories and embellishments. I’ve worked with everything from intricate beading and embroidery on fur trim, to the addition of leather accents, delicate lace appliqués, and even custom-designed metal hardware (buckles, clasps). I’ve used feathers to add texture and visual interest, incorporating them seamlessly into designs. For example, I once created a collar using dyed rabbit fur, embellished with hand-sewn silk embroidery and small, strategically placed peacock feathers, achieving a luxurious and uniquely textured piece.

I’m also proficient in utilizing various techniques for attaching embellishments to fur, selecting the optimal method depending on the fur type and the embellishment’s material. This ensures that the additions are secure and maintain the integrity of the fur itself.

Q 24. How would you approach designing a fur garment for a specific client need?

Designing a fur garment for a specific client need begins with a thorough consultation. I ask detailed questions about their lifestyle, the intended use of the garment (formal wear, casual wear, outerwear), their preferred style, and any allergies or sensitivities they might have. I also discuss the budget to ensure realistic expectations. For example, a client needing a warm, waterproof parka for arctic conditions would require a different design and fur type compared to a client wanting a glamorous evening wrap.

After understanding the client’s needs, I’ll create custom patterns specifically designed for their measurements and preferences. I’ll carefully select the fur type, considering its warmth, durability, and suitability for the climate and intended use. The entire design process—from pattern creation to final construction—is tailored to the client’s individual specifications and expectations.

Q 25. What are your safety precautions when handling fur and related tools?

Safety is my top priority. When handling fur, I always wear a dust mask to prevent inhaling fur fibers, which can be irritating to the lungs. Sharp tools like shears and needles require extra caution. I use protective gloves to avoid cuts and handle sharp tools with care. Additionally, my workspace is well-lit and organized to minimize tripping hazards. Proper ventilation helps dissipate any potential fumes from cleaning solutions or other materials used in the fur-crafting process. I regularly inspect and maintain my equipment to prevent malfunctions.

I also store furs and materials properly to prevent damage and maintain their quality. Fur storage requires a cool, dry environment to prevent moth infestation and damage. Any chemicals are handled according to their safety data sheets. Regular cleaning of the workspace is essential to avoid allergens and potential contamination.

Q 26. What is your experience with creating custom fur trim or appliqué?

I have extensive experience crafting custom fur trim and appliqué. This involves carefully selecting the fur type, and dyeing or bleaching it if necessary to achieve the desired color. The fur is then shaped and cut precisely to the design specifications, often using specialized tools and techniques for intricate shapes. I’ve created everything from simple borders and accents to elaborate, three-dimensional appliqué designs that add depth and visual complexity to garments.

For instance, I once created a custom fur appliqué for a client’s jacket. The design involved intricate floral motifs crafted from different colored fox and mink fur, which were then carefully sewn onto a silk base. This required patience, precision, and a thorough understanding of different fur textures and their behavior when stitched together. Secure attachment is crucial, and I always select the appropriate stitching method to ensure durability and a professional finish.

Q 27. How do you handle variations in fur pelt quality and density?

Variations in fur pelt quality and density are inherent in the material. I account for these variations during the design and construction process. For example, I might use denser fur in areas requiring more warmth or durability, such as the collar or cuffs of a coat, and less dense fur for areas with less stress or where a lighter look is desired. This requires careful planning and pattern adjustments.

Before starting a project, I thoroughly inspect the pelts, assessing their quality, density, and any imperfections. This allows me to plan the layout of the fur on the garment strategically, minimizing the visibility of any flaws and maximizing the use of the highest quality areas. My experience allows me to anticipate and compensate for variations, resulting in a cohesive and high-quality finished product.

Q 28. Describe your familiarity with different types of fur backing materials.

My familiarity with different types of fur backing materials is extensive. The choice of backing material significantly impacts the drape, durability, and overall feel of the finished garment. Common backing materials include leather, silk, cotton, and various types of bonded fabrics. Each has its own properties:

- Leather: Provides excellent durability and a luxurious feel but can be stiff and less flexible.

- Silk: Offers a smooth, luxurious drape but is less durable than leather.

- Cotton: A more affordable option providing a breathable backing, suitable for lighter furs.

- Bonded fabrics: Offer varying degrees of support and flexibility, often used for creating a more structured look.

I select the backing material based on the type of fur, the design of the garment, and the client’s preferences. The decision also takes into account factors like breathability, drape, and the overall desired aesthetic of the finished piece.

Key Topics to Learn for Custom Fur Creation Interview

- Client Consultation & Design: Understanding client needs, translating creative briefs into design concepts, and presenting design options effectively.

- Fur Selection & Sourcing: Knowledge of different fur types, qualities, and sourcing practices; understanding ethical and sustainable sourcing.

- Pattern Making & Cutting: Proficiency in drafting and adjusting patterns to accommodate diverse fur types and design complexities; precision cutting techniques for minimizing waste.

- Sewing & Construction Techniques: Mastery of specialized sewing techniques for fur, including hand stitching, machine stitching, and finishing methods for a professional look.

- Fur Trimming & Finishing: Techniques for shaping, blending, and finishing fur garments to achieve a desired aesthetic; understanding the importance of detail and precision.

- Quality Control & Inspection: Identifying and addressing potential defects, ensuring consistency in quality, and adhering to industry standards.

- Production Planning & Management: Estimating time and materials needed, managing timelines effectively, and troubleshooting potential production challenges.

- Problem-Solving & Adaptability: Handling unexpected issues during the design and production process; demonstrating resourcefulness and creativity in finding solutions.

- Industry Trends & Innovation: Staying updated on the latest trends in fur fashion, materials, and techniques; exploring innovative approaches to custom fur creation.

Next Steps

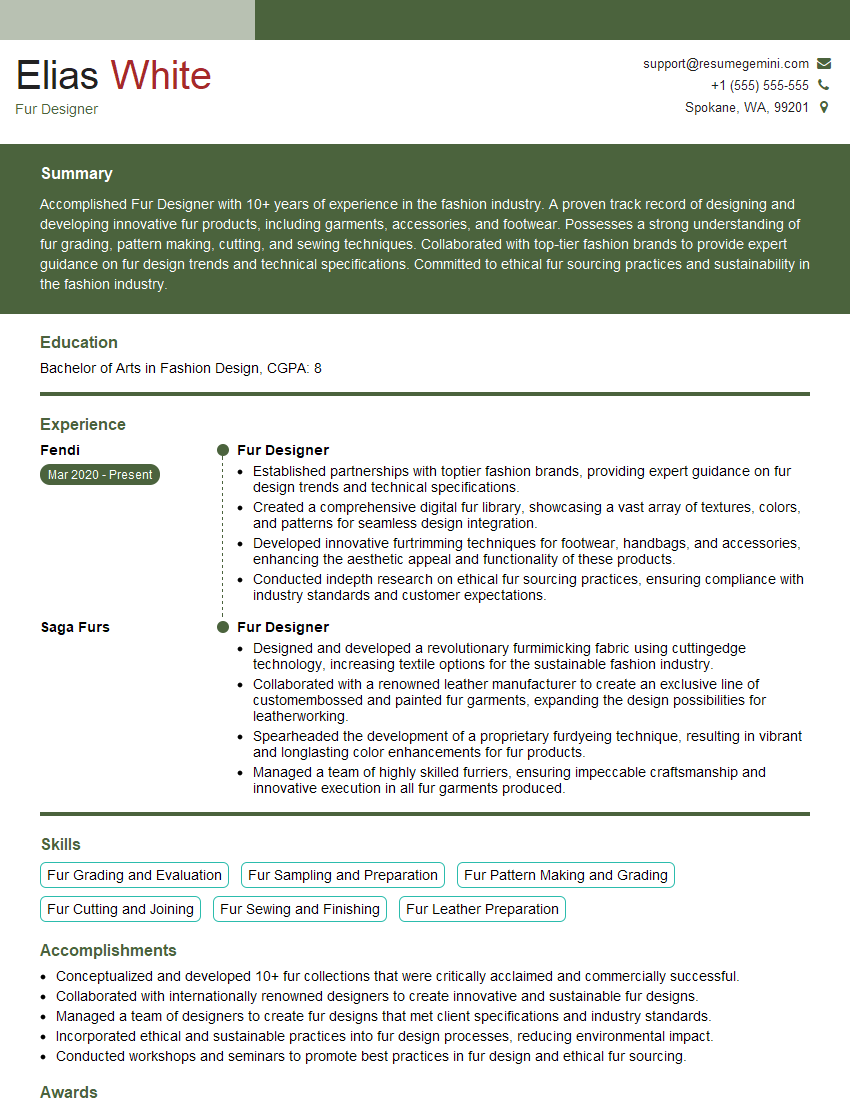

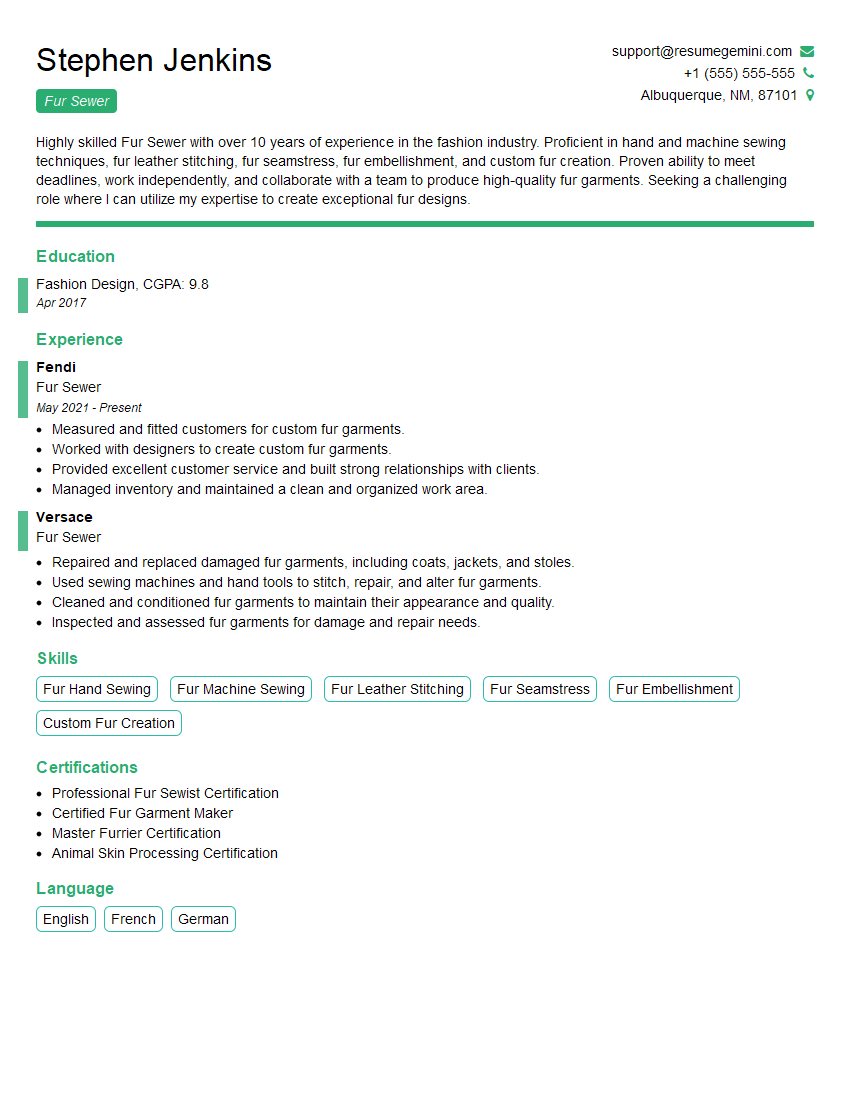

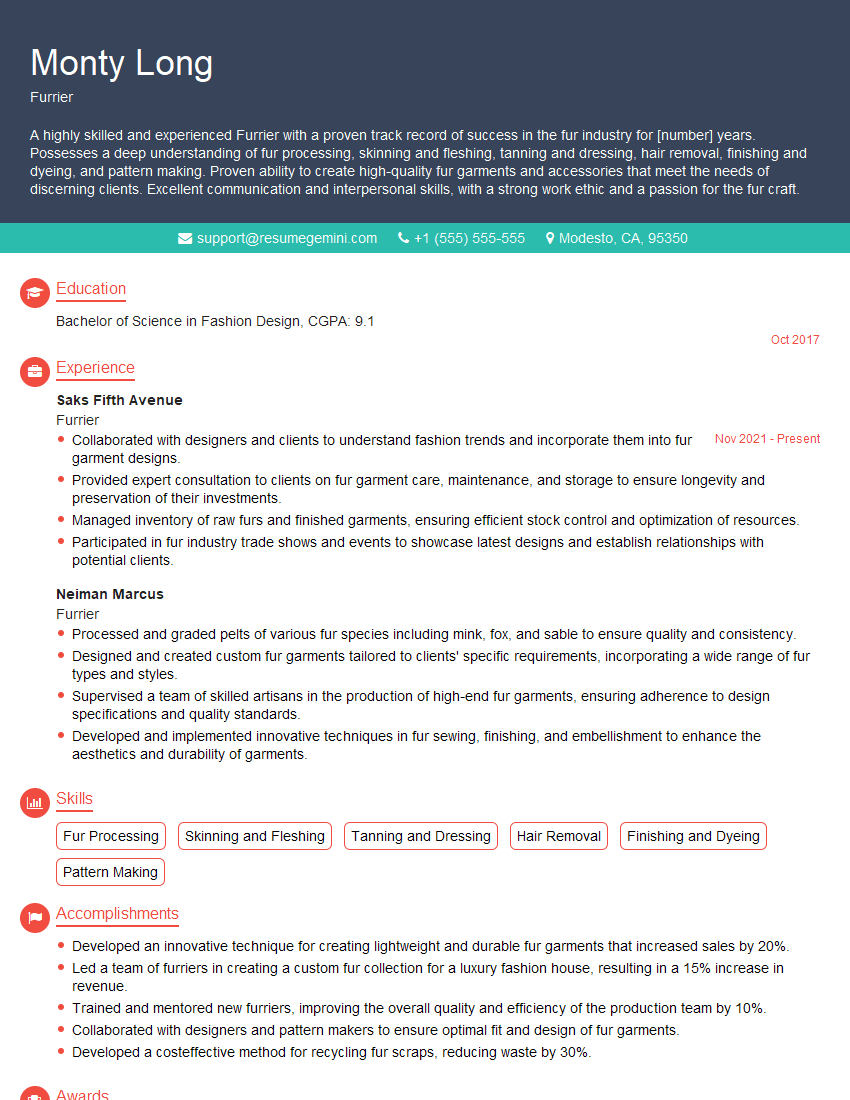

Mastering custom fur creation opens doors to exciting career opportunities in a niche and highly creative field. Demonstrating expertise in this area significantly enhances your employability and positions you for advancement. To maximize your job prospects, create a resume that showcases your skills and experience effectively. An ATS-friendly resume is crucial for getting your application noticed by recruiters and hiring managers. We highly recommend using ResumeGemini to craft a professional and compelling resume that highlights your unique qualifications. Examples of resumes tailored to Custom Fur Creation are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good