Are you ready to stand out in your next interview? Understanding and preparing for Fur Garment Construction interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Fur Garment Construction Interview

Q 1. Explain the different types of fur pelts used in garment construction.

The world of fur pelts is incredibly diverse, with each type possessing unique characteristics affecting drape, durability, and overall aesthetic. We categorize them primarily by animal origin and processing.

- Minks: Known for their luxurious sheen, dense underfur, and relatively short guard hairs. They come in a huge variety of colors, from classic dark brown to vibrant pastels achieved through selective breeding.

- Foxes: Offer a wide range in texture and color, from the long, plush fur of the red fox to the striking, silvery tones of the silver fox. Their guard hairs are longer and more prominent than mink, giving a different visual effect.

- Sables: Highly prized for their incredibly soft, dense underfur and glossy guard hairs. They’re known for their rich brown and dark colorations and hold their shape well.

- Chinchillas: Famous for their incredibly dense, incredibly soft fur which is extremely lightweight. This creates a unique drape and luxurious feel.

- Raccoons: A more affordable option, raccoon fur has a distinctive ringed pattern and a slightly coarser texture.

- Sheared Fur: Many pelts undergo shearing, which removes the longer guard hairs, leaving only the soft underfur. This produces a velvety texture and is commonly seen in more affordable garments.

The choice of pelt significantly impacts the garment’s final look and feel, and understanding these differences is crucial for selecting the right fur for a particular design.

Q 2. Describe the process of pattern making for fur garments.

Pattern making for fur is a specialized skill, differing significantly from fabric pattern making. The key difference lies in the three-dimensionality and the unique drape of fur. We can’t simply flatten it out like fabric.

- Drafting the Base Pattern: We start with a standard sloper or base pattern, meticulously tailored to the specific garment type (coat, vest, stole, etc.).

- Fur Grain Placement: Crucially, we must account for the fur’s natural grain. The fur must flow in a consistent direction, minimizing disruptions to the overall visual appearance. Incorrect grain placement can lead to unsightly patches or uneven texture.

- Allowance for Drape: Fur drapes differently than fabric; it has volume and often doesn’t lay flat. Therefore, we must add extra seam allowances to account for the three-dimensional nature of the material and the movement of the fur.

- Muslin Mock-up: Before cutting the expensive fur, we create a muslin mock-up using inexpensive fabric. This allows us to test the pattern’s fit and make necessary adjustments.

- Final Fur Pattern: Once the muslin fit is perfect, we transfer the adjustments to the final fur pattern, ensuring accuracy and precision in the fur’s placement.

Imagine trying to sew a coat where the fur on one sleeve flows one way, and the other flows the opposite. It’s a disaster! This meticulous approach ensures a flawlessly finished garment.

Q 3. What are the key considerations when selecting fur for a specific garment?

Selecting the right fur is paramount. Several factors dictate the choice:

- Budget: Sable is far more expensive than rabbit. The budget dictates the type of fur.

- Desired Look and Feel: Do you want a plush, luxurious feel (like chinchilla) or a sleek, more structured look (like mink)?

- Garment Style: A flowing cape might call for a lightweight, drape-friendly fur like fox, whereas a sturdy winter coat might need the durability of a mink.

- Durability: Some furs, like mink, are more durable and resistant to wear than others.

- Ethical Considerations: Sourcing fur ethically and sustainably is increasingly important. Knowing the origin and the farming practices is crucial for responsible selection.

For example, a formal evening wrap might necessitate the elegance of sable, while a casual jacket might use a more robust and affordable option like raccoon.

Q 4. How do you ensure the proper matching of fur pelts during construction?

Matching fur pelts is akin to a puzzle, requiring skill and attention to detail. The goal is to seamlessly blend pelts for a uniform appearance.

- Careful Selection: We carefully select pelts with similar color, texture, and length of fur. Variations are inevitable, but we aim for minimal differences.

- Layering and Orientation: The pelts are laid out, ensuring the fur flows in the same direction across adjoining pieces. Paying attention to the natural markings and color variations allows for strategic placement to minimize noticeable seams.

- Pattern Matching: Similar to fabric pattern matching, we may need to align specific patterns or markings across seams to achieve a cohesive look. This is particularly important for pelts with striking patterns.

- Color Blending: Sometimes, subtle color differences are inevitable. We can strategically blend these using the techniques above, utilizing color gradients to minimize contrast and enhance the visual flow.

Imagine a patchwork quilt. We want the final product to look like a beautiful, uniform fabric, not an array of disjointed pieces. This careful matching is key to achieving that seamless integration of pelts.

Q 5. What techniques do you use to minimize fur slippage during sewing?

Fur slippage during sewing is a common challenge. Several techniques minimize this:

- Hand Sewing: Hand stitching, particularly with a specialized fur-sewing needle, provides the best control and minimizes slippage. This allows for secure stitches without damaging the fur.

- Special Stitches: Using small, precise stitches (like the backstitch) reduces the risk of slippage and ensures a strong seam.

- Underlining and Interlining: Applying a lightweight underlining or interlining beneath the fur provides stability and prevents shifting during construction.

- Temporary Tacking: Temporarily tacking seams before sewing the final stitches helps hold the fur in place and minimizes distortion.

- Using Fur-Specific Adhesives: In certain areas, specialized fur adhesives can be used to temporarily secure pieces together, offering support during stitching.

Think of it like building a stable structure. The more support you provide, the less likely the parts will shift or slide. These techniques ensure a secure and well-constructed garment.

Q 6. Explain the process of grading a fur pattern.

Grading a fur pattern involves adjusting the pattern’s dimensions to create different sizes. This is similar to grading fabric patterns, but with additional considerations for fur’s unique properties.

- Understanding Fur Properties: Unlike fabric, fur has volume and needs to be accounted for during grading. Simply increasing dimensions linearly will not always work.

- Gradual Increases: Grading should be done gradually, often in smaller increments than with fabric, to maintain the integrity and drape of the fur.

- Seam Allowances: Seam allowances may need to be adjusted to account for the added volume as sizes increase.

- Grain Lines: Maintaining consistent grain lines across all sizes is crucial for ensuring a uniform look and feel.

- Testing: It’s highly recommended to create test pieces in each graded size to ensure the fit and drape remain consistent across different sizes.

Think of it like baking a cake: if you increase the size without proportionally increasing other ingredients, you might end up with a flat or misshapen cake. The same principle applies here. Accurate grading ensures a well-fitting garment in every size.

Q 7. How do you handle difficult or problematic fur pelts during construction?

Handling problematic pelts requires creativity, experience, and a willingness to adapt. Challenges might include damaged areas, inconsistent fur density, or difficult-to-work-with pelts.

- Strategic Patching: For small tears or damaged areas, skillful patching with matching fur pieces can often go unnoticed. This often involves blending the patch into the surrounding fur.

- Creative Design Solutions: Sometimes, an issue can be incorporated into the design. A particularly dense area could become a design element, emphasizing a specific part of the garment.

- Blending Techniques: Careful placement of pelts can often mask inconsistencies in fur density or color, particularly if the garment allows for pattern or texture variations.

- Expert Consultation: For complex or extensive issues, consulting with other experienced furriers can sometimes provide insight and solutions.

Imagine working with a piece of wood that has a knot in it. A skilled craftsman might use this knot as a focal point in the final design, rather than hiding it. The same approach applies to problematic fur pelts – often, we can turn a challenge into a unique feature.

Q 8. Describe your experience with various fur sewing machines and their applications.

My experience with fur sewing machines spans over two decades, encompassing a wide range of models from various manufacturers. I’m proficient with both industrial and domestic machines, each suited to different tasks. Industrial machines, like the Juki DU-1181N or the Consew 226R, are crucial for heavy-duty stitching on thicker furs like mink or fox. Their powerful motors and robust construction allow for consistent stitching through multiple layers of pelts. Domestic machines, while not as powerful, are valuable for delicate work on lighter furs, such as rabbit or chinchilla, where a gentler touch is needed. The choice of machine is dictated by the fur type, the garment’s design complexity, and the desired stitch quality. For example, I’d use a specialized walking foot machine for even feed on particularly thick or slippery leathers.

For intricate details or smaller projects, I rely on specialized fur sewing machines equipped with features like micro-adjustable stitch length and needle positioning, allowing for precise control and minimizing damage to the delicate fur fibers. Choosing the right machine and needle is paramount in achieving professional results and preventing damage.

Q 9. What are the common challenges in fur garment construction and how do you overcome them?

Fur garment construction presents unique challenges. One of the most significant is working with the natural variations in pelt size and thickness. Each skin is unique, demanding careful pattern matching and skillful manipulation to avoid visible seams or distortion. Another hurdle is the delicate nature of fur fibers – they can easily be damaged by improper handling, stretching, or stitching. The slippage of the fur during stitching can also be problematic, requiring the use of specialized techniques, like basting, to hold the pelts in place.

I overcome these challenges through meticulous planning and precise execution. Careful pre-cutting, precise pattern placement, and the use of specialized sewing techniques like the ‘running stitch’ or ‘backstitch’ for seams, tailored to the fur type, are essential. Understanding the grain and drape of the fur is critical for achieving a seamless and aesthetically pleasing garment. I also use tools like specialized fur shears to handle the material properly and reduce stress on the fibers.

Q 10. Explain different fur stitching techniques and their suitability for various fur types.

Several fur stitching techniques exist, each best suited to specific fur types. The ‘running stitch’ is ideal for lightweight furs as it’s less likely to pierce the fibers. It’s incredibly versatile for both straight and curved seams. For heavier furs, like mink, a ‘backstitch’ is often used for strength and durability. This method reinforces seams and minimizes the chance of them ripping under stress. Then there’s the ‘blind stitch’, often employed for invisible seams, particularly useful in areas requiring an unobtrusive finish. This technique requires extra care and skill. Another critical method involves using specialized machine stitches for different types of fur, the selection of stitch determined by the thickness and type of fur to ensure the most secure join and prevent damage. This can include zig-zag stitches or special blind hems.

For example, I’d use a running stitch for a delicate rabbit fur lining, while a backstitch would be more appropriate for a heavier, more durable fox fur coat. Choosing the right stitch is crucial for longevity and preventing damage to the delicate fur fibers.

Q 11. How do you ensure the quality and durability of a finished fur garment?

Quality and durability in a finished fur garment are paramount. This begins with selecting high-quality pelts, ensuring they’re properly tanned and prepared. Careful attention to pattern making and cutting minimizes waste and maximizes pelt utilization. During construction, I use appropriate stitching techniques and reinforce stress points like cuffs and collars. The choice of lining material is crucial, prioritizing durability and breathability. Finally, proper finishing and cleaning maintain the garment’s appearance and longevity.

Quality control throughout the process is key. This includes regular inspections at each stage of production, from initial pelt selection to final garment completion. Attention to detail is crucial; I always ensure that seams are neat, the fur is smoothly aligned, and all components are securely fastened. By carefully following these steps, I ensure that the garments I create are not only beautiful but also exceptionally durable and long-lasting.

Q 12. Describe your experience with fur finishing techniques, such as glazing and shearing.

Fur finishing techniques like glazing and shearing are essential for achieving a uniform and polished look. Glazing involves carefully brushing the fur to align the fibers, enhancing sheen and creating a smooth surface. This is done to reduce any matting that may have occurred and create a refined finish. Shearing involves trimming the fur to achieve a consistent length and texture. This creates a more uniform and polished appearance, and is especially important for garments made from furs with uneven or excessively long fibers. Both glazing and shearing require precision and a keen eye for detail. The tools and techniques used must be tailored to the specific fur type and the desired effect.

For instance, I might use a more aggressive shearing technique on a shaggy sheepskin to create a smoother, more modern look, while a lighter touch would be necessary for a delicate chinchilla. The mastery of these techniques significantly impacts the finished garment’s quality and luxury feel. I use a variety of tools, from specialized shearing combs to high-quality brushes, always selecting the most appropriate tool for each job.

Q 13. How do you identify and address common fur garment defects?

Identifying and addressing fur garment defects requires a sharp eye and a deep understanding of fur properties. Common defects include uneven stitching, damaged or missing hairs, and inconsistencies in fur density. These defects can be identified visually during the production process and after finishing. Uneven stitching can often be repaired by careful hand stitching, while damage to the hairs can sometimes be subtly addressed with careful cleaning and combing. In some cases, more extensive repairs might be needed involving replacement sections of fur.

The approach to addressing the defect depends entirely on the specific issue and the fur’s type. In some instances, small defects can be easily rectified; however, major problems could require more complex solutions. My approach always involves minimizing further damage to the fur while making the repairs as discreet as possible. Prevention is crucial; by maintaining high standards throughout the construction process, the occurrence of major defects can be dramatically minimized.

Q 14. What are your methods for maintaining accurate cost estimations for fur garment production?

Accurate cost estimation in fur garment production is crucial for profitability. My method involves a detailed breakdown of costs across several key areas. This includes the cost of raw materials (pelts), labor costs (cutting, sewing, finishing), overhead (rent, utilities, equipment maintenance), and any additional costs such as design fees or specialized tools. I meticulously track material usage, labor hours per garment, and all other associated expenses.

I use industry-standard pricing guides for fur pelts and factor in potential waste during pattern cutting. Labor costs are calculated based on the garment’s complexity and the required skill level. Historical data from past projects provides valuable insights for refining future estimates. I employ software that tracks costs and materials usage to maintain accuracy and provide detailed reports, ensuring a transparent and accurate estimation of the entire production process. This detailed approach ensures that my pricing is competitive yet reflects the true cost and quality of the handcrafted garments.

Q 15. Explain your understanding of different fur lining materials and their applications.

Choosing the right lining for a fur garment is crucial for both its aesthetics and functionality. The lining protects the fur, adds comfort, and contributes to the overall drape and feel. Different lining materials offer varied benefits.

- Silk: A luxurious choice, silk linings are smooth against the skin, enhancing the garment’s luxurious feel. They are ideal for high-end fur coats and stoles where a delicate touch is desired. However, silk can be more delicate and require careful handling.

- Cupro: A sustainable and breathable alternative to silk, cupro linings offer a soft hand and excellent drape. They’re a popular choice for many furriers due to their durability and relatively low cost compared to silk.

- Satin: Satin linings provide a sleek, lustrous finish, reflecting light to enhance the fur’s sheen. Various satin weights are available, offering different levels of body and drape. The choice depends on the weight and style of the fur garment.

- Viscose: A versatile and affordable option, viscose linings offer a smooth surface, good drape, and are relatively easy to work with. However, they may not be as durable as other options.

- Wool: For warmer climates, a wool lining can add an extra layer of insulation. This is especially useful for heavier fur garments worn in colder climates. The choice of wool weight influences the garment’s warmth and overall bulk.

The selection of the lining material depends greatly on the client’s preference, the type of fur, the intended use of the garment, and the overall budget. For instance, a lightweight fox stole might benefit from a luxurious silk lining, while a heavy beaver coat might be better suited to a durable cupro lining.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working with different types of fur closures (buttons, hooks, zippers).

Fur garment closures require careful consideration due to the delicate nature of the fur. I’ve extensive experience with various closure types:

- Buttons: Ideally, large, high-quality buttons made from materials like horn, wood, or polished metal are used. These are less likely to snag the fur. Button placement is crucial to ensure proper alignment and avoid stress points on the fur.

- Hooks and Eyes: These offer a secure and discreet closure. The hooks must be carefully sewn to avoid pulling the fur, and strong, high-quality hooks and eyes are necessary for durability.

- Zippers: Invisible or concealed zippers are preferred for a seamless look. The zipper tape should be lightweight and flexible, and the teeth need to be fine enough to avoid snagging the fur. Careful stitching is essential to prevent puckering or damage to the fur.

In my experience, the selection of closure depends on the style of the garment and the client’s preference. For a classic, luxurious coat, large, ornate buttons might be appropriate. For a more modern, streamlined look, concealed zippers are often preferred. I always discuss closure options with the client, taking into account the practicality and aesthetic appeal.

Q 17. How do you handle client requests or alterations for fur garments?

Handling client requests and alterations for fur garments requires precision and a deep understanding of fur properties. I always begin with a thorough consultation to understand the client’s needs and the feasibility of the alteration. This involves examining the garment, assessing the condition of the fur, and understanding the desired changes.

- Minor alterations: Hem adjustments, sleeve length changes, or minor repairs are often manageable. These usually involve careful hand-stitching to avoid damaging the fur.

- Major alterations: Reshaping a garment, adding or removing fur sections, or significant structural changes require more extensive work and often involve pattern adjustments and careful fur placement.

- Repair work: This could include fixing tears, replacing damaged sections, or repairing worn seams. Careful matching of the fur is essential to ensure a seamless repair.

I clearly explain the process, potential challenges, and costs to the client before commencing any work. I prioritize preserving the integrity of the fur garment during any alteration, making sure any changes enhance its appearance and longevity. For example, if a client requests shortening a fur coat significantly, I advise on the best method to ensure the remaining fur retains its shape and doesn’t look awkward.

Q 18. What safety precautions do you take when working with fur and sewing equipment?

Safety is paramount when working with fur and sewing equipment. I adhere to strict safety protocols:

- Sharp objects: I always use sharp, well-maintained shears and needles to minimize the risk of accidental cuts or punctures. I store these tools safely when not in use.

- Sewing machine safety: I ensure my sewing machine is properly maintained and use appropriate safety guards. I never reach into the machine while it’s running.

- Personal protective equipment (PPE): I always wear safety glasses to protect my eyes from flying debris or needle fragments. Gloves are used when handling chemicals or working with delicate fur.

- Fur handling: I handle fur gently to avoid damage or breakage. I take care to avoid stretching or pulling the fur unnecessarily.

- Chemical safety: When working with dyes or cleaning solutions, I always work in a well-ventilated area and wear appropriate protective gear. I follow manufacturer’s instructions carefully.

Regular machine maintenance and a tidy workspace also contribute to a safe working environment. I never rush and maintain focus while operating machinery or handling sharp objects. Safety training is essential and I regularly update my knowledge to stay aware of best practices.

Q 19. Explain your experience with different fur dyeing methods.

Fur dyeing is a complex process requiring precise control over temperature, time, and chemical ratios. I have experience with several methods:

- Immersion dyeing: This involves submerging the fur in a dye bath. The process requires careful control of temperature and time to achieve even and consistent color. This method is best suited for dyeing whole skins or small pieces of fur.

- Brush dyeing: This technique is used for more localized coloring or for creating unique effects. The dye is applied directly to the fur using a brush, requiring precision and skill to create even coverage and avoid harsh lines.

- Airbrushing: This method offers even more control and precision for creating intricate patterns and designs. It’s suitable for creating highlights, shading, or subtle color variations.

The choice of dyeing method depends on the desired effect and the type of fur. For instance, immersion dyeing might be preferred for a solid, even color, while brush dyeing or airbrushing might be better for creating a more artistic or textured look. I always pre-test the dye on a sample piece of fur to ensure it reacts appropriately before dyeing the entire garment.

Q 20. What are your preferred tools and techniques for fur skinning and preparation?

Proper skinning and preparation are critical for ensuring the quality and durability of the final fur garment. My preferred tools and techniques:

- Sharp skinning knives: Specialized knives with varying blade shapes are essential for precise and efficient skinning. I use different knives for different areas of the animal to minimize damage to the hide.

- Fleshing tools: These tools are used to remove excess fat and tissue from the skin side of the hide, preparing it for tanning. Proper fleshing is crucial for preventing rot and ensuring a clean, supple hide.

- Stretching frames: These are used to stretch and dry the hides, ensuring even thickness and preventing shrinkage or distortion. Proper stretching is key for preserving the fur’s natural beauty.

- Tanning process: I use a combination of traditional and modern tanning techniques to achieve optimal results. This might involve various chemical treatments to preserve the hide, making it more durable and pliable.

My experience with various fur types dictates my approach to each animal. For example, thicker skinned animals like mink require different techniques compared to delicate fur like fox. The goal is always to minimize waste, maximize the useable hide, and preserve the fur’s natural quality and luster.

Q 21. Describe your experience with draping techniques for fur garments.

Draping is a crucial step in fur garment construction, as it determines the garment’s final shape and fit. It involves manipulating the fur skins on a dress form to create the desired silhouette.

- Understanding fur properties: This is vital. Different furs drape differently; some are more pliable and flexible than others. My experience with different fur types informs my draping techniques.

- Pattern manipulation: While a basic pattern might be used as a starting point, I often modify it during the draping process, based on how the fur falls and the desired silhouette. This involves careful pinning and adjusting the pattern pieces to optimize the use of the fur skins.

- Seaming strategies: I choose seam placement strategically to minimize waste and maximize the effect. This often involves combining pieces in ways that naturally complement the fur’s flow and pattern.

- Client consultation: I work closely with clients to understand their preferences and desired styles, tailoring the draping process accordingly. This collaborative process ensures that the final garment accurately reflects their vision.

Draping fur is an art form that combines technical skill with creative vision. It’s a crucial step that influences the garment’s overall look, feel, and unique character. I approach each project with a keen eye for detail and an understanding of how to work with the natural properties of the fur.

Q 22. How do you manage production timelines and deadlines in a fur garment workshop?

Managing production timelines in a fur garment workshop requires meticulous planning and a deep understanding of each stage’s duration. We begin by breaking down the project into smaller, manageable tasks – from pattern cutting and pelt selection to sewing, finishing, and quality control. Each task is assigned a realistic timeframe, considering factors like fur type, garment complexity, and available resources. We use project management software to track progress, identify potential bottlenecks, and adjust timelines as needed. For instance, if a particularly challenging pattern emerges, we might need to allocate extra time to the cutting phase. Regular team meetings ensure everyone is on track and any emerging issues are addressed proactively. Think of it like a relay race – each team member’s timely contribution is crucial for the final delivery.

We also prioritize clear communication with clients, setting realistic expectations from the outset and providing regular updates on progress. This ensures transparency and minimizes potential delays or misunderstandings. Missed deadlines are rare, but when they occur, we immediately analyze the cause – whether it’s material delays, unforeseen technical challenges, or unforeseen staff absences – and implement corrective measures to regain lost time and maintain client trust.

Q 23. Explain your understanding of fur garment care and maintenance.

Fur garment care is crucial for preserving their longevity and beauty. Proper storage is paramount. Fur garments should be stored in a cool, dry place, ideally in a breathable garment bag to protect them from dust and light. Avoid using airtight bags, as this can damage the fur. Direct sunlight and extreme temperatures should be avoided, as these can dry out the fur and cause it to become brittle. Regular brushing is key to maintaining the fur’s luster and preventing matting. A soft-bristled brush should be used gently, following the direction of the hair. Professional cleaning should be performed by specialists, using methods appropriate for the specific fur type. Avoid harsh chemicals and vigorous scrubbing, which can damage the fur and the garment’s underlying structure. Think of it like caring for fine silk – gentle handling and specialized cleaning are essential.

For minor stains, a damp cloth can be used carefully to blot (not rub) the affected area. Always test any cleaning solution on an inconspicuous area first. Never machine wash or dry clean fur garments without consulting a professional. Proper care ensures your fur garment will remain a cherished item for years to come.

Q 24. Describe your experience working with different fur patterns (e.g., let-out, full-skin).

My experience encompasses a wide range of fur patterns, including let-out and full-skin methods. Let-out patterns involve skillfully stretching and manipulating smaller pelts to create larger garment pieces, requiring precise cutting and sewing techniques to ensure a seamless, natural look. This often requires a deep understanding of fur grain and how to manipulate it without damaging the fibers. I’ve worked extensively with various let-out techniques, including those employed for coats, jackets, and collars. Full-skin patterns, on the other hand, utilize entire pelts with minimal cutting, resulting in a more luxurious look with fewer seams. This approach presents its own challenges, requiring expert knowledge of pelt grading and matching to achieve a consistent pattern and look across the garment.

Working with different patterns requires adaptability and a keen eye for detail. For example, let-out patterns for a luxurious mink coat require immense precision to ensure consistent flow and minimize visible seams. While a full-skin pattern, say, for a fox stole requires masterful grading and matching of pelts to achieve a visually stunning effect. Each pattern presents unique challenges and rewards, demanding mastery of different techniques.

Q 25. What is your experience with leather and fur combination garments?

I have extensive experience working with leather and fur combination garments. This requires a strong understanding of both materials’ properties and how they interact. Leather provides structure and durability, while fur adds luxury and warmth. The challenge lies in ensuring a harmonious blend, with the seams and transitions between leather and fur appearing seamless and natural. This often involves intricate stitching techniques and careful consideration of material thickness and drape. For instance, a leather jacket with a fur collar requires precise matching of leather and fur textures, and robust stitching techniques to ensure longevity and prevent tearing at the seams.

Different types of leather and fur require different stitching techniques and thread types. The compatibility of the two materials is critical; choosing appropriate bonding agents to ensure a firm yet flexible connection is crucial. I’ve worked on a variety of designs, from classic leather jackets with fur lining to more contemporary styles that incorporate both materials in creative and visually striking ways.

Q 26. How do you handle ethical and sustainable sourcing of fur pelts?

Ethical and sustainable sourcing of fur pelts is paramount. We prioritize working with suppliers committed to responsible practices and animal welfare. This includes ensuring that pelts originate from ranches adhering to strict humane treatment standards. We verify certifications and traceability throughout the supply chain, ensuring transparency and accountability. We favor furs from sustainable ranching practices that manage populations responsibly and minimize environmental impact. For example, we avoid using endangered or threatened species.

Documentation and transparency are key. We maintain detailed records of our suppliers and the origin of our pelts, allowing us to trace the entire supply chain and ensure compliance with ethical and legal regulations. We actively seek out and support suppliers who are committed to reducing their carbon footprint and minimizing their impact on the environment.

Q 27. Describe your experience with different quality control checks during fur garment production.

Quality control checks are integrated throughout the entire production process, starting from the initial pelt selection. We carefully inspect each pelt for quality, ensuring consistent color, texture, and density. During the cutting and sewing stages, meticulous checks are conducted to prevent errors and inconsistencies. We use specialized tools and lighting to detect minor flaws, ensuring each seam is perfectly aligned and securely stitched. After assembly, a final rigorous inspection is performed to assess the overall quality and finish of the garment, checking for any imperfections, misalignments, or inconsistencies in fur density or color. We maintain detailed records of all inspections, allowing for traceability and prompt identification of any issues.

Examples include checking for consistent fur density across the garment to ensure a uniform appearance, inspecting stitching quality to guarantee durability and prevent unraveling, and ensuring symmetrical placement of all design elements. Regular calibration of our tools and equipment is also crucial in maintaining consistency and accuracy throughout the production process. Our aim is to deliver impeccable quality that exceeds client expectations.

Q 28. Explain your problem-solving approach in case of production errors in fur garments.

My approach to problem-solving in fur garment production is systematic and proactive. When an error occurs, the first step is to thoroughly investigate its root cause. This involves analyzing the entire production process, from the initial design stage to the final quality control check. Is it a pattern cutting error? A sewing error? A material defect? We document the issue meticulously, using photography and detailed notes. Then, we devise a solution, considering factors such as the nature of the error, the time constraints, and the available resources. For minor flaws, we may implement localized repairs. For more significant issues, adjustments to the production process or even garment reconstruction might be necessary.

For instance, if a seam unravels, we trace the cause—was it due to incorrect stitch tension, low-quality thread, or poor alignment of the fabric? Based on this analysis, we adjust our stitching technique, switch to a stronger thread, or implement tighter quality control checks for seam alignment. It’s a process of continuous improvement. We regularly review these processes to identify recurring issues and prevent them in the future. This meticulous approach ensures our garments are of consistently high quality and that we can handle any challenges swiftly and effectively.

Key Topics to Learn for Fur Garment Construction Interview

- Fur Selection and Grading: Understanding different fur types, their properties (sheen, density, durability), and the process of grading furs for consistent quality and size.

- Pattern Making and Draping: Adapting patterns to the unique characteristics of fur, including draping techniques for achieving desired garment shapes and minimizing fur waste.

- Fur Sewing Techniques: Mastering specialized stitching methods for fur, such as blind stitching, saddle stitching, and techniques for handling different fur thicknesses and textures. Understanding the importance of minimizing visible stitches.

- Fur Trimming and Finishing: Proper techniques for shearing, plucking, and shaping fur to achieve a clean, polished finish. Knowledge of different finishing methods for edges and seams.

- Understanding Fur Garment Construction Methods: Familiarity with different construction methods like let-out, full-skin, and piecing techniques, and their suitability for various fur types and garment styles.

- Quality Control and Inspection: Identifying common defects in fur garments and understanding quality control procedures to ensure a high standard of craftsmanship.

- Working with Leather and Other Materials: Experience in combining fur with leather, suede, or other fabrics in garment construction, understanding the compatibility of materials and appropriate sewing techniques.

- Problem-Solving in Fur Garment Construction: Troubleshooting techniques for dealing with common challenges such as fur slippage, uneven pelts, and material imperfections. Understanding how to adapt techniques to overcome unexpected issues.

Next Steps

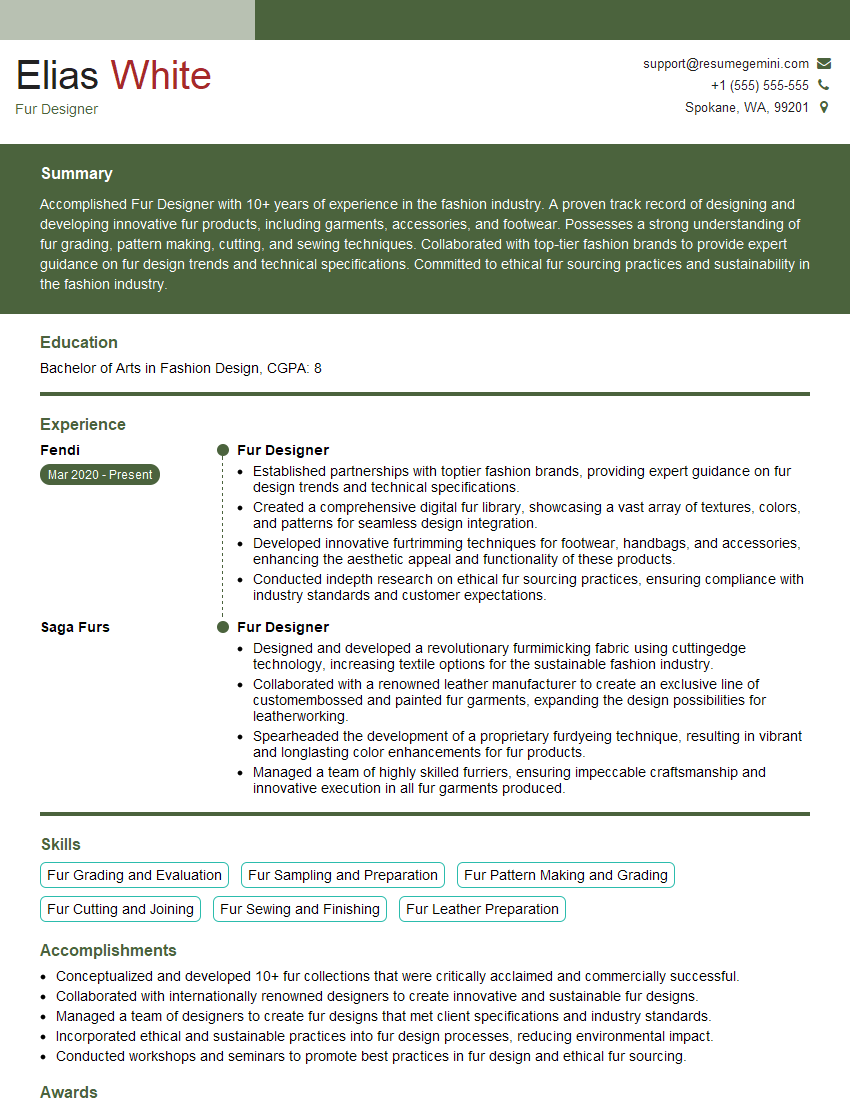

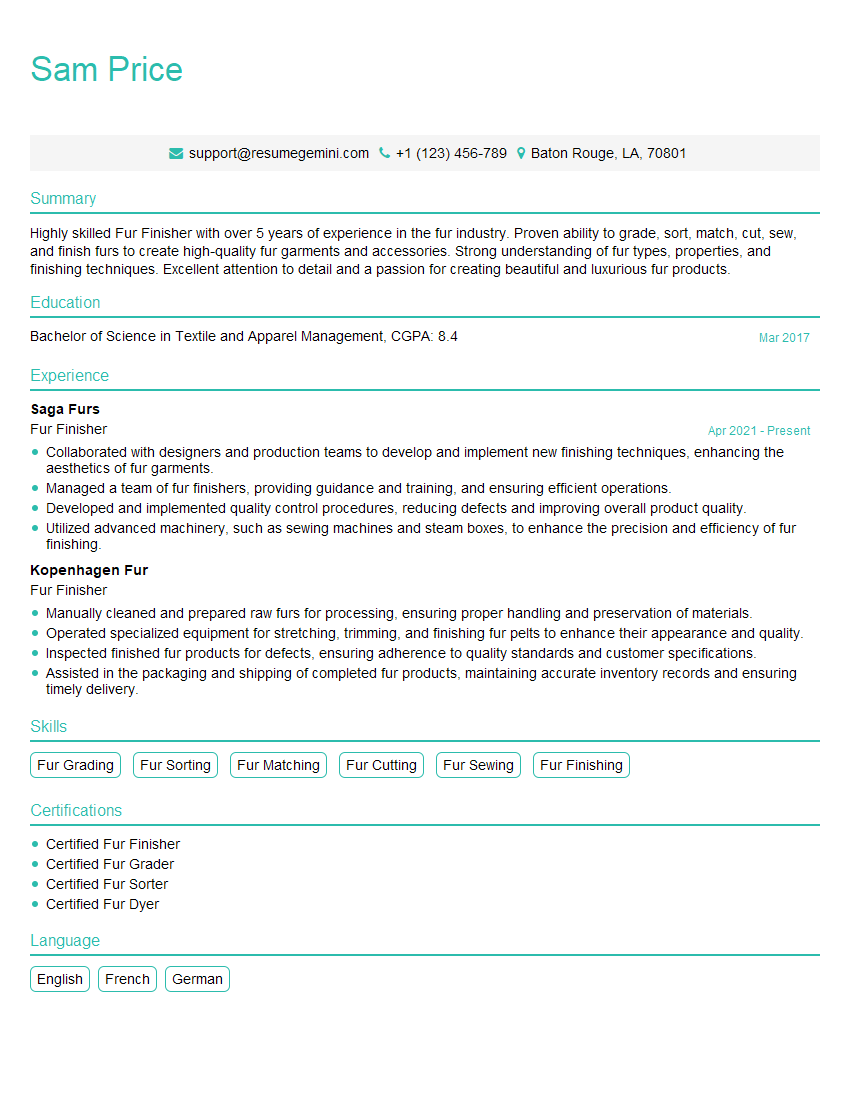

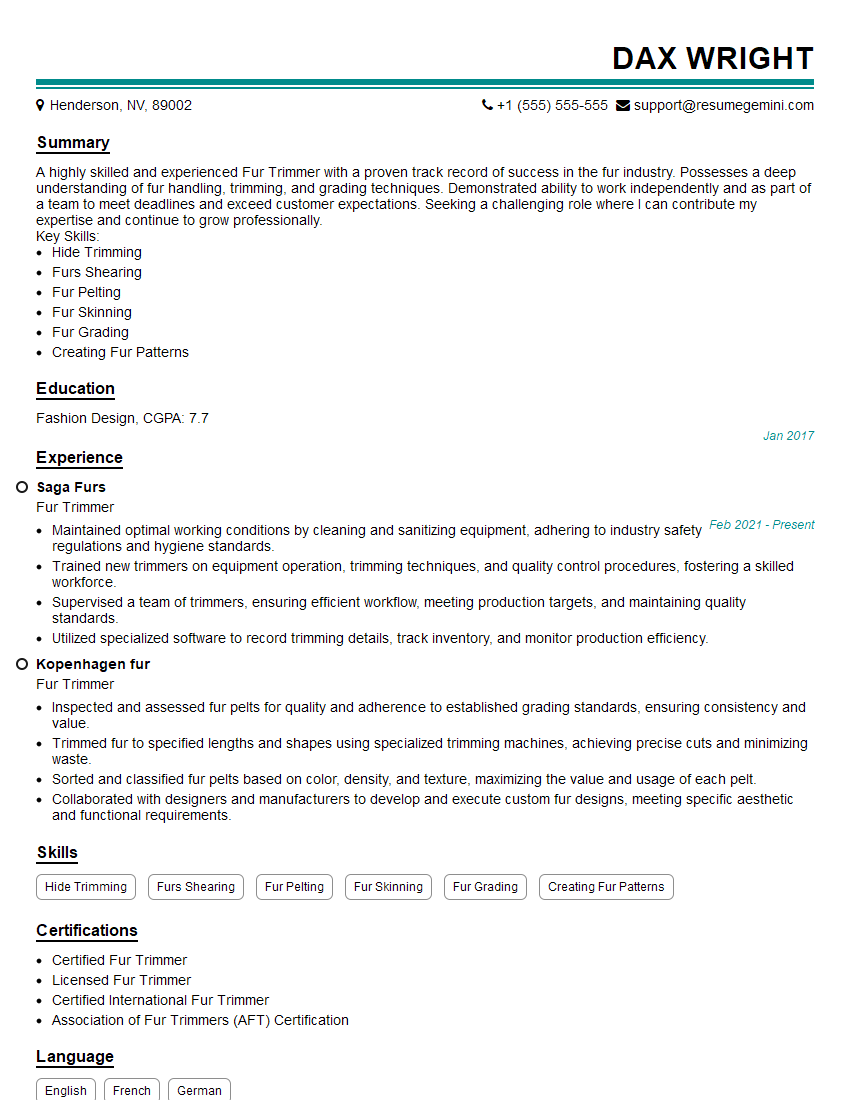

Mastering fur garment construction opens doors to exciting career opportunities in high-end fashion and luxury goods. Demonstrating expertise in this specialized field significantly enhances your employability and sets you apart from other candidates. To maximize your job prospects, create a strong, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the fur garment construction industry. ResumeGemini provides examples of resumes specifically designed for this field, ensuring your application stands out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good