Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Coffee Production interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Coffee Production Interview

Q 1. Explain the different stages of coffee processing from cherry to bean.

Coffee processing is a journey from cherry to cup, and it’s fascinatingly complex. It begins with harvesting ripe coffee cherries. These cherries are then processed to separate the beans from the fruit. There are three main processing methods:

- Washed/Wet Process: Cherries are depulped, fermented, washed, and dried. This method produces a cleaner, brighter cup profile.

- Natural/Dry Process: Cherries are dried whole in the sun, then depulped. This results in a fruitier, sweeter cup with more body.

- Honey Process: A hybrid method where some of the mucilage (sticky layer) is left on the beans during drying, resulting in a balance between the washed and natural processes.

After drying, the beans are hulled (removing the parchment layer) and then sorted and graded. Finally, they are ready for export and further processing, such as roasting.

Q 2. Describe the various coffee bean varieties and their flavor profiles.

There’s a vast world of coffee varieties, each offering unique flavor profiles. Arabica and Robusta are the two major species, with numerous cultivars within each.

- Arabica: Generally known for its higher quality, nuanced flavors, and lower caffeine content. Examples include Typica (a classic with balanced acidity and body), Bourbon (similar to Typica but often fruitier), Geisha (renowned for its floral and tea-like notes), and Caturra (a high-yielding variety with a sweet, clean taste).

- Robusta: Offers a stronger, bolder flavor with higher caffeine and a more robust body. It’s often used in espresso blends or as a cheaper option.

Flavor profiles vary tremendously depending on factors like terroir (soil, climate, altitude), processing method, and roasting style. For example, an Ethiopian Yirgacheffe Arabica is famous for its bright citrus acidity and floral aromas, whereas a Sumatran Mandheling is known for its earthy, full-bodied profile and low acidity.

Q 3. What are the key factors influencing coffee bean quality?

Coffee bean quality is a complex interplay of various factors. Think of it as a recipe with many crucial ingredients:

- Varietal: The genetic makeup of the coffee plant determines baseline flavor characteristics.

- Terroir: Altitude, soil composition, rainfall, and sunlight all significantly impact bean development and flavor.

- Farming Practices: Proper cultivation, harvesting techniques (selective picking of ripe cherries is crucial), and post-harvest processing methods are critical.

- Storage: Proper storage after processing prevents degradation and preserves quality. Beans should be stored in cool, dark, airtight containers to maintain freshness.

A single flaw in any of these areas can impact the final cup quality, demonstrating the interconnectedness of factors from farm to cup.

Q 4. How do you ensure consistent coffee quality throughout the production process?

Ensuring consistent coffee quality demands meticulous attention throughout the supply chain. This requires:

- Strict Quality Control at Each Stage: From cherry selection to milling and roasting, regular quality checks are vital to identify and correct any deviation from standards.

- Traceability: Tracking coffee beans from origin to finished product allows for identifying sources of inconsistencies and implementing corrective measures.

- Standardized Processes: Clear, well-defined procedures for all processes—from farming practices to roasting profiles—minimize variations.

- Supplier Relationships: Building strong relationships with farmers ensures consistent quality from the source and provides opportunities for collaboration and improvement.

Imagine a symphony orchestra: every musician must play their part perfectly for a harmonious performance. In coffee production, every step needs to be consistent to achieve the desired final product.

Q 5. Explain the process of coffee roasting and its impact on flavor.

Coffee roasting is a crucial stage where green coffee beans are transformed into the aromatic, flavorful beans we know and love. The process involves heating beans to specific temperatures, triggering chemical changes that drastically impact flavor and aroma.

During roasting, beans undergo several stages: drying, browning, and development. The roasting profile (temperature and duration) dictates the final flavor. Too short a roast yields under-developed flavors, while over-roasting leads to bitterness and burnt notes. Key factors to manage include:

- Temperature: Precise temperature control is essential for achieving the desired roast level.

- Time: The roasting duration dictates how the beans develop their flavors.

- Bean Type: Different bean varieties react differently to the roasting process, requiring tailored roasting profiles.

Think of roasting as cooking: a slight change in the temperature or time can dramatically change the outcome.

Q 6. What are the different coffee roasting levels and their characteristics?

Roasting levels are categorized by color and flavor characteristics. While descriptions can vary, common levels include:

- Light Roast: Beans are light brown, with high acidity, delicate flavors, and a more vibrant aroma.

- Medium Roast: A balance of acidity and body, with more pronounced flavors than light roasts.

- Medium-Dark Roast: Stronger flavors, full body, less acidity, and a more intense aroma.

- Dark Roast: Dark brown beans with reduced acidity, bolder flavors, and often a smoky or bittersweet taste.

The choice of roast level depends on personal preference and the type of coffee being brewed; some beans benefit from lighter roasts to highlight their delicate flavors, while others excel with darker roasts that emphasize body and intensity.

Q 7. Describe the sensory evaluation process for coffee (cupping).

Cupping, or sensory evaluation, is a standardized method to assess the quality of coffee. It involves a systematic approach to evaluating various sensory attributes:

- Aroma: The dry and wet aroma of the ground coffee are assessed.

- Flavor: The taste, including acidity, sweetness, bitterness, body, and aftertaste, is evaluated.

- Acidity: The brightness and liveliness of the coffee.

- Body: The mouthfeel, how the coffee feels in your mouth.

- Aftertaste: The lingering flavor after swallowing.

Professionals use a specific cupping protocol: grinding beans, blooming, and slurping the coffee to assess these aspects, providing a comprehensive evaluation of coffee quality. Cupping is essential for quality control, sourcing, and product development.

Q 8. How do you identify defects in green coffee beans?

Identifying defects in green coffee beans is crucial for ensuring quality. It’s a multi-sensory process, combining visual inspection with the occasional use of touch and smell. We look for defects broadly categorized as primary and secondary defects.

Primary Defects: These affect the bean’s inherent quality and are usually caused during the growing or processing stages. Examples include: Black beans (overripe or severely damaged), Broken beans (cracked or split), Immature beans (greenish, under-developed), and Insect damage (holes or webbing). The presence of these defects significantly impacts the final cup quality.

Secondary Defects: These are less severe, often affecting the bean’s appearance but not necessarily its internal quality. Examples include Quakers (hard, dense beans that don’t roast properly), Stony beans (hard, heavy beans, usually indicating mineral content), and Damaged beans (with minor cracks or blemishes). Though less detrimental, high percentages of secondary defects can still indicate issues in processing or storage.

We typically use a combination of manual sorting, using specialized sieves to separate beans by size, and electronic color sorters, which use cameras and sensors to identify and remove defective beans based on their color and shape. The percentage of defects is meticulously recorded and plays a significant role in determining the bean’s overall grade and price.

Q 9. What are the common challenges in coffee production and how can they be addressed?

Coffee production faces numerous challenges, many intertwined and influenced by climate change.

Climate Change: Erratic rainfall, extreme temperatures, and increased pest infestations directly impact yield and quality. Mitigation: Implementing drought-resistant varieties, optimizing irrigation systems based on precise weather data, and employing integrated pest management strategies are essential.

Disease and Pests: Coffee plants are susceptible to various diseases (like coffee leaf rust) and pests, leading to significant crop losses. Mitigation: Regular crop monitoring, early detection through remote sensing, biocontrol measures (introducing natural predators), and disease-resistant varieties are crucial for managing this.

Price Volatility: Global coffee prices fluctuate significantly, making it difficult for farmers to plan investments and secure a stable income. Mitigation: Fair trade practices, direct trade relationships with roasters, diversification of income streams (e.g., agroforestry), and risk management tools can help mitigate price volatility’s impact.

Labor Shortages: Coffee farming is labor-intensive, and attracting and retaining skilled workers, particularly in remote areas, is a persistent issue. Mitigation: Investing in community development, offering competitive wages and benefits, and mechanizing labor-intensive tasks are all important steps.

Addressing these challenges requires a holistic approach involving farmers, researchers, governments, and the coffee industry as a whole. Collaboration and sustainable practices are paramount for the future of coffee production.

Q 10. Explain the importance of sustainable coffee farming practices.

Sustainable coffee farming is not just a trend; it’s a necessity for the long-term viability of the industry. It focuses on integrating environmental, economic, and social considerations into every stage of coffee production.

Environmental Benefits: Sustainable practices protect biodiversity, conserve water resources, reduce carbon emissions, and minimize soil erosion. This includes adopting shade-grown methods, reducing chemical inputs, and promoting agroforestry (integrating trees with coffee plants).

Economic Benefits: Sustainable farms often see increased efficiency and reduced input costs, leading to improved profitability. This is particularly true in the long run. Fair trade and direct trade models often support sustainable practices and provide better prices for farmers.

Social Benefits: Sustainable practices empower local communities, ensuring fair wages, safe working conditions, and access to education and healthcare for farmworkers. This strengthens the social fabric of coffee-growing regions.

Examples of sustainable practices include using organic fertilizers, implementing water-efficient irrigation, diversifying crops, and promoting fair labor practices. It’s a continuous improvement process, involving continuous learning and adaptation.

Q 11. Describe the role of traceability in coffee production.

Traceability in coffee production is the ability to track the journey of a coffee bean from the farm to the cup. It’s crucial for ensuring quality, transparency, and accountability across the supply chain.

A robust traceability system involves detailed record-keeping at each stage of production: farm identification, harvesting dates, processing methods, and transportation details. This information can be encoded on the coffee bag, using unique lot numbers or barcodes, linking the beans to their origin and journey. This allows consumers to understand where their coffee came from, how it was grown, and who produced it.

Traceability helps build trust between consumers and producers, supporting fair trade practices and fostering direct relationships. It also facilitates quality control and helps identify problems within the supply chain quickly and efficiently. For example, if a batch of coffee is found to have quality issues, traceability allows pinpointing the specific farm or processing facility responsible, facilitating corrective action and preventing future issues. In essence, it provides accountability and transparency throughout the coffee journey.

Q 12. What are the key factors to consider when selecting coffee beans for a specific roast profile?

Selecting coffee beans for a specific roast profile is crucial for achieving the desired cup characteristics. Key factors to consider include:

Bean Density: High-density beans tend to roast more evenly and produce a fuller-bodied cup. Low-density beans roast faster, potentially leading to unevenness.

Bean Size and Shape: Uniform bean size ensures consistent roasting and extraction. Irregular shapes can lead to uneven roasting.

Origin and Variety: Different origins and varieties (Arabica or Robusta) possess unique flavor profiles and roasting characteristics. Arabica beans, for example, are generally considered more aromatic and nuanced.

Moisture Content: The initial moisture content significantly affects roasting time and final bean characteristics. Too much moisture can lead to uneven roasting and potential defects.

Processing Method: Washed, natural, or honey processed beans all have different flavor profiles and density characteristics, requiring different roasting approaches.

Defect Rate: The presence of defects affects both the roast quality and the cup profile. A higher defect rate could require adjusted roasting parameters.

The selection process often involves sensory evaluation (cupping) of green beans to assess their quality and potential roast characteristics, coupled with analyzing physical attributes like density and size. This allows roasters to choose beans that best align with their desired roast profile and target cup characteristics.

Q 13. How do you manage inventory and ensure the freshness of green coffee beans?

Managing green coffee bean inventory and ensuring freshness is paramount. The key is to minimize exposure to air, moisture, and fluctuating temperatures, all of which negatively affect bean quality over time.

Storage Environment: Green coffee beans should be stored in a cool, dark, dry, and well-ventilated environment, ideally with controlled temperature and humidity (around 65°F and 60% relative humidity).

Packaging: Using airtight containers or bags (e.g., vacuum-sealed bags) helps prevent oxidation and moisture absorption, preserving bean freshness.

First-In, First-Out (FIFO) System: Implementing a FIFO system ensures that the oldest beans are used first, preventing spoilage and maintaining inventory rotation.

Regular Monitoring: Regular checks for signs of spoilage (molds, pests, off-odors), and monitoring storage conditions (temperature, humidity) help prevent quality issues.

Inventory management software or spreadsheets can help track bean origin, arrival dates, and usage, aiding in effective FIFO implementation and minimizing waste. By diligently following these storage and handling practices, the freshness and quality of green coffee beans can be preserved for extended periods, ensuring consistent cup quality.

Q 14. Describe your experience with coffee quality control measures.

My experience with coffee quality control measures encompasses all stages of the supply chain, from farm to cup. It’s a multifaceted process.

Green Bean Quality Control: This starts with assessing the green beans upon arrival, using visual inspection, sieving, and electronic sorting to identify and remove defects. Cupping is used to evaluate the cup characteristics of various lots to ensure consistency and quality.

Roasting Quality Control: During roasting, precise monitoring of temperature, time, and airflow is crucial for achieving the desired roast profile. Regular calibration of roasting equipment is essential, alongside sensory evaluation (cupping) of roasted beans to ensure quality and consistency.

Brewing and Cupping: Systematic brewing techniques and cupping sessions are employed to evaluate the final cup characteristics. Trained cuppers assess the aroma, flavor, acidity, body, and overall balance of the coffee, identifying any defects or inconsistencies.

Record Keeping and Traceability: Detailed record-keeping at each stage, combined with a robust traceability system, allows us to track and analyze quality parameters throughout the entire process, aiding in identifying and resolving issues quickly.

Statistical Process Control (SPC) techniques are used to monitor quality parameters continuously and identify trends or deviations, allowing for proactive adjustments to processes and ensuring consistency in the final product. This holistic approach to quality control ensures that the coffee we deliver consistently meets the highest standards of quality and flavor.

Q 15. What are the different methods of coffee brewing and their impact on flavor?

Coffee brewing methods significantly impact the final cup’s flavor profile. Different techniques extract varying amounts of compounds from the coffee grounds, resulting in diverse taste experiences. Think of it like baking a cake – using different ingredients and methods produces vastly different results.

- Pour Over (e.g., Hario V60, Chemex): This method emphasizes precision and control. Slowly pouring hot water over coffee grounds allows for nuanced extraction, highlighting the bean’s origin characteristics and acidity. It often results in a clean, bright, and nuanced cup.

- French Press: A full immersion method where grounds steep directly in hot water. This produces a bolder, more full-bodied cup with more sediment and oils, resulting in a richer mouthfeel and potentially a slightly muddier flavor profile.

- Drip Coffee Maker (Automatic): A convenient method using filters and consistent water flow. While simpler, it can offer a balanced cup, though less nuanced than pour over. The quality relies heavily on the quality of the grinder and the bean.

- Espresso: Uses high pressure to force hot water through finely ground coffee. This method extracts a concentrated, intensely flavored shot, characterized by crema (a layer of foam) and often a bittersweet flavor.

- AeroPress: A versatile method combining immersion and pressure, offering a clean and balanced cup with good control over extraction.

The choice of brewing method depends on personal preference and the desired flavor profile. For example, a light roast might be best enjoyed with a pour-over method to highlight its delicate flavors, while a dark roast might be better suited for a French press to emphasize its boldness.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle customer complaints related to coffee quality?

Handling customer complaints regarding coffee quality requires a systematic and empathetic approach. My first priority is to actively listen to the customer’s concerns and validate their feelings. I would never dismiss a complaint, even if it seems unreasonable at first. A dissatisfied customer represents a lost opportunity and potentially negative reviews.

I would follow these steps:

- Acknowledge and Apologize: Express sincere regret for their negative experience.

- Gather Information: Ask detailed questions about the coffee (type, brewing method used, purchase date, any noticeable issues like stale smell or off-taste). Requesting photos or samples of the coffee can be helpful.

- Investigate the Issue: Check batch information, roast date, storage conditions, and possibly conduct a blind taste test to identify any potential problems in the production or supply chain.

- Offer a Solution: Based on the investigation, I’d offer a suitable resolution, which could include a replacement bag of coffee, a refund, a discount on future purchases, or a personalized explanation of the situation.

- Follow Up: After resolving the issue, I would follow up with the customer to ensure their satisfaction and to prevent future problems. Their feedback is crucial for improving our processes and product quality.

Ultimately, turning a negative experience into a positive one can strengthen customer loyalty and brand reputation. It’s about demonstrating care and commitment to quality.

Q 17. What are your experience with different coffee extraction methods?

My experience with coffee extraction methods spans various techniques, from traditional methods to modern innovations. I’ve worked extensively with pour-over techniques (Hario V60, Chemex), French press, espresso machines (both manual and automatic), drip coffee makers, and the AeroPress. This diverse experience allows me to understand the nuances of each method and its impact on the final brew.

For example, my expertise with espresso extraction includes understanding grind size’s critical role, water temperature, and pressure to achieve optimal extraction and crema formation. I’ve also explored different filter papers and their influence on clarity and body in pour-over methods. I understand the variables that affect extraction yield, including brew ratio, bloom time, and water temperature – all of which can be fine-tuned for various coffee types and desired flavor profiles.

My experience also includes troubleshooting issues like channeling (uneven water distribution during brewing), which leads to under-extraction in certain areas and over-extraction in others. This requires precise technique and proper equipment maintenance to mitigate.

Q 18. What is your understanding of fair trade and direct trade coffee?

Fair trade and direct trade are ethical sourcing models that aim to ensure better prices, working conditions, and environmental practices for coffee farmers. While both strive for better equity, they differ in their approach.

Fair Trade: This is a certification system with specific standards that farmers must meet to receive the Fair Trade label. These standards encompass fair minimum prices, social premiums for community projects, and environmental sustainability practices. Fair Trade aims to create a safety net and guaranteed minimum price for farmers, protecting them from market volatility.

Direct Trade: This is a less formalized approach where roasters build direct relationships with individual farmers or cooperatives, often bypassing intermediaries like exporters and importers. This fosters transparency, allows for personalized agreements, and enables more flexible pricing structures based on quality and market demand. Direct trade prioritizes building lasting relationships and empowering farmers with greater control over their business.

In essence, both models prioritize ethical sourcing, but direct trade allows for greater flexibility and customization, potentially leading to even stronger partnerships between roasters and farmers. Many roasters combine elements of both to maximize benefits for farmers and ensure quality.

Q 19. How do you stay updated with the latest trends and innovations in coffee production?

Staying updated on the latest coffee production trends and innovations is crucial for remaining competitive and providing high-quality products. I utilize several strategies:

- Industry Publications and Journals: I regularly read trade publications such as Roast Magazine and Coffee Review to learn about new processing techniques, roasting technologies, and consumer preferences.

- Conferences and Workshops: Attending industry conferences like the Specialty Coffee Association’s events (SCA) allows for networking with experts, learning about cutting-edge research, and observing the latest brewing and roasting equipment.

- Online Resources: I actively follow leading coffee blogs, podcasts (e.g., Barista Hustle), and online communities dedicated to coffee production. This provides access to a wealth of information from different perspectives.

- Farmer Relationships: Maintaining direct contact with coffee farmers provides invaluable insights into their challenges, innovations, and evolving farming practices. It allows for understanding issues from the ground up.

- Experimentation: I actively experiment with different processing methods, roasting techniques, and brewing styles to test and adapt innovations to my work.

Continuous learning is essential in this dynamic industry to ensure I remain ahead of the curve and deliver exceptional coffee products.

Q 20. Describe your experience with coffee production equipment and machinery.

My experience encompasses a wide range of coffee production equipment, from small-scale artisanal tools to larger-scale commercial machinery. I am proficient in operating and maintaining:

- Roasters: I have hands-on experience with both small-batch drum roasters and larger-capacity fluid-bed roasters, understanding the intricacies of heat control, airflow, and bean-specific roasting profiles.

- Grinders: I’m familiar with various grinder types, from burr grinders (essential for consistent particle size) to various espresso grinder models, understanding how grind size impacts extraction.

- Brewing Equipment: As mentioned earlier, my experience includes pour-over devices, French presses, espresso machines, and automated drip brewers. This includes understanding maintenance and cleaning procedures for optimal performance.

- Storage Equipment: Proper storage is vital for maintaining coffee quality. My experience includes using air-tight containers, specialized storage facilities that control temperature and humidity.

Beyond operation, I understand the importance of regular maintenance and calibration to ensure equipment operates efficiently and delivers consistent results. Troubleshooting malfunctions and implementing preventative maintenance are crucial skills I possess.

Q 21. What are the key metrics you use to measure the success of coffee production operations?

Measuring the success of coffee production operations involves a multi-faceted approach focusing on both quality and efficiency. Key metrics I utilize include:

- Yield: Measuring the amount of roasted coffee produced from a given amount of green coffee beans helps assess efficiency in the roasting process.

- Roast Consistency: Utilizing color analysis tools and cupping scores to ensure consistent roasting profiles across batches. Inconsistent roasts impact flavor and quality.

- Cup Quality Scores: Using standardized cupping protocols (like the SCA cupping protocol) helps objectively evaluate the sensory characteristics of the brewed coffee, including aroma, flavor, acidity, and body.

- Customer Satisfaction: Monitoring customer feedback through surveys, reviews, and direct communication provides valuable insights into product quality and overall experience.

- Waste Reduction: Tracking waste generated during the roasting and brewing processes to identify areas for improvement and optimize resource utilization.

- Cost of Production: Analyzing production costs (including green coffee, labor, energy, and packaging) to determine profitability and identify opportunities for cost optimization.

- Employee Satisfaction: A happy and motivated team is crucial for success. Monitoring employee morale and productivity contributes to overall efficiency and product quality.

By tracking and analyzing these metrics, I can identify areas of strength, areas needing improvement, and make data-driven decisions to optimize the entire coffee production process.

Q 22. How do you manage and motivate a team in a coffee production environment?

Managing and motivating a team in coffee production requires a blend of strong leadership, clear communication, and a focus on shared goals. It’s similar to conducting an orchestra – each member plays a crucial role, and their harmonious efforts produce the final masterpiece (our high-quality coffee).

- Clear Expectations and Roles: I begin by clearly defining individual roles and responsibilities, ensuring everyone understands their contribution to the overall production process. This minimizes confusion and overlaps.

- Open Communication: Regular team meetings, both formal and informal, are essential for open dialogue. I encourage feedback and actively listen to concerns, fostering a collaborative environment.

- Recognition and Rewards: Recognizing individual and team achievements, both big and small, is crucial. This can range from verbal praise to performance-based bonuses, depending on the company structure. Celebrating successes boosts morale and reinforces positive behavior.

- Training and Development: Investing in employee training programs ensures everyone stays updated on best practices and emerging technologies. This demonstrates commitment to their growth and increases job satisfaction.

- Fair and Consistent Treatment: Maintaining fairness and consistency in my interactions with team members builds trust and respect. This is fundamental to a positive and productive work environment.

For example, during harvest season, I implemented a friendly competition between picking teams, rewarding the team with the highest yield of quality beans with a celebratory lunch. This boosted productivity and fostered a positive, competitive spirit.

Q 23. Describe a time you had to solve a problem related to coffee quality.

We once experienced a significant drop in the sweetness and aroma of our Arabica beans. Initial sensory analysis suggested a problem during the drying process. We systematically investigated potential causes:

- Drying Conditions: We examined the temperature, humidity, and airflow in our drying facility. We found inconsistent airflow, leading to uneven drying and potentially causing fermentation issues in some beans.

- Bean Maturity: We reviewed our harvesting procedures to ensure only ripe cherries were picked. We discovered inconsistencies in ripeness assessment, leading to under-ripe cherries in the mix.

- Post-Harvest Handling: We analyzed our sorting and processing steps. We identified a bottleneck where beans were being held too long before processing, contributing to quality degradation.

To resolve this, we invested in improved drying equipment to ensure uniform airflow, implemented stricter harvesting guidelines with more thorough ripeness checks, and streamlined the post-harvest process to minimize storage time. Through these focused improvements, we significantly restored the quality of our beans, learning valuable lessons about process control and the critical nature of even the smallest steps.

Q 24. What are the different types of coffee defects and how do you address them?

Coffee defects can significantly impact the final product’s quality, aroma, and taste. They can be broadly categorized into:

- Primary Defects: These are defects present in the green coffee bean, such as

quakers(un-developed beans),blacks(overripe or damaged beans), andbroken beans. These are usually detected visually during sorting. - Secondary Defects: These emerge during processing or storage. Examples include

insect damage,mold,mustiness, andoff-flavors. These require careful sensory evaluation and possibly laboratory analysis to pinpoint the cause.

Addressing defects requires a multi-pronged approach:

- Prevention: Implementing strict quality control measures at each stage of the production process, from harvesting to storage, is crucial. This includes careful selection of beans, proper drying techniques, and pest management.

- Detection: Utilizing visual inspection, density separation, and sensory evaluation to identify and remove defective beans. Modern technologies like color sorters can also assist in automated defect removal.

- Mitigation: For defects that can’t be completely removed, careful roasting techniques can sometimes mitigate their impact on the final product’s flavor profile. However, severe defects may require discarding the affected beans.

For instance, if we detect high levels of insect damage, we trace it back to the storage facilities, improving sanitation and implementing pest control strategies to prevent future occurrences.

Q 25. How do you ensure food safety compliance in coffee production?

Ensuring food safety compliance is paramount in coffee production. It involves adhering to rigorous standards throughout the entire process, from farm to cup. We achieve this through:

- Good Agricultural Practices (GAP): Implementing GAP ensures that coffee is cultivated using environmentally sustainable methods that minimize the use of harmful chemicals and protect the health of workers.

- Good Manufacturing Practices (GMP): Maintaining clean and hygienic processing facilities, using appropriate equipment, and implementing rigorous sanitation protocols throughout the production process are crucial. Regular inspections and employee training are key to compliance.

- Hazard Analysis and Critical Control Points (HACCP): This systematic approach identifies potential hazards and establishes critical control points to prevent or eliminate them. This is a cornerstone of food safety management systems.

- Regular Audits and Testing: We conduct regular internal and external audits to ensure our practices meet all regulatory requirements. Microbiological testing of both green coffee and finished products is essential to detect any contamination.

- Traceability: Establishing a robust traceability system allows us to track the coffee’s journey from the farm to the consumer, enabling quick identification and response in case of any safety issues.

For example, we conduct regular microbial testing of our water supply and maintain meticulous records of all cleaning and sanitation procedures in our roasting facility.

Q 26. What is your experience with coffee packaging and storage?

My experience encompasses all aspects of coffee packaging and storage, focusing on preserving the quality and extending the shelf life of our coffee.

- Packaging Materials: We carefully select packaging materials based on their barrier properties to prevent oxidation, moisture absorption, and aroma loss. This might involve using specialized valves to release gases or employing materials with excellent UV protection.

- Packaging Design: The packaging design is crucial for preserving freshness. We use airtight seals and consider factors such as the size and shape of the package to minimize air exposure.

- Storage Conditions: Proper storage is vital. Coffee should be stored in a cool, dark, and dry environment away from strong odors. We monitor temperature and humidity levels in our warehouses to ensure optimal storage conditions.

- Best Before Dates: Accurate labeling with clear ‘best before’ dates is critical for informing consumers about the optimal consumption window. We use validated methods to determine these dates.

For instance, we transitioned from flexible pouches to a more advanced multilayer packaging that reduces oxygen ingress, significantly extending the shelf life of our ground coffee without affecting its flavor.

Q 27. Explain your understanding of the coffee supply chain from farm to cup.

The coffee supply chain is a complex network extending from the coffee farm to the consumer’s cup. It involves several key stages:

- Farming: This begins with the cultivation of coffee cherries, involving activities like planting, pruning, fertilization, and pest control. The quality of the green bean is largely determined during this phase.

- Harvesting and Processing: Ripe cherries are harvested and processed to extract the green coffee beans. Methods vary, including washed, natural, and honey processes, each imparting unique characteristics to the beans.

- Exporting and Trading: Processed green coffee beans are exported to buyers worldwide. Trading involves negotiations between producers, exporters, importers, and roasters.

- Roasting: Roasting transforms green beans into the flavorful and aromatic coffee we know. The roasting process significantly influences the coffee’s final taste profile.

- Grinding and Packaging: Roasted beans are ground (if necessary) and packaged for sale to consumers. The packaging plays a vital role in preserving the coffee’s quality and extending its shelf life.

- Distribution and Retail: The coffee is distributed to wholesalers, retailers, and cafes, ultimately reaching the consumer.

Understanding the entire supply chain allows for identifying and addressing bottlenecks or quality issues at each stage, ensuring a consistent and high-quality product reaches the consumer.

Q 28. How do you manage costs and optimize efficiency in coffee production?

Managing costs and optimizing efficiency in coffee production is crucial for profitability and sustainability. I employ several strategies:

- Yield Optimization: Maximizing the yield of high-quality beans through improved farming practices, efficient harvesting techniques, and precise processing methods. This directly impacts input costs per unit of output.

- Process Improvement: Regularly assessing and improving our production processes to eliminate waste, minimize energy consumption, and improve efficiency. Lean manufacturing principles can be particularly effective in this area.

- Inventory Management: Effective inventory control prevents spoilage, reduces storage costs, and ensures a steady supply of materials without excessive stockpiling.

- Supplier Relationships: Developing strong relationships with reliable suppliers can lead to better pricing and timely delivery of inputs, reducing procurement costs.

- Technology Adoption: Investing in appropriate technology, such as automated sorting systems and efficient roasting equipment, can significantly improve productivity and reduce labor costs while maintaining quality.

- Waste Reduction: Implementing measures to minimize waste at all stages of the production process, from by-products repurposing to energy-efficient drying methods.

For example, we implemented a new drying system that reduced energy consumption by 20%, leading to significant cost savings without compromising bean quality. Continual monitoring and analysis of our cost structure allow for proactive adjustments and continuous improvement.

Key Topics to Learn for Coffee Production Interview

- Cultivation and Agronomy: Understanding optimal growing conditions (climate, soil, altitude), sustainable farming practices, disease and pest management, and the impact of varietals on bean characteristics.

- Harvesting and Processing: Different harvesting methods (selective picking vs. strip picking), processing techniques (washed, natural, honey), and their influence on the final cup profile. Practical application: analyzing the cost-effectiveness and quality implications of different processing methods.

- Quality Control and Assurance: Implementing quality checks at each stage of production, from farm to cup. Understanding cupping protocols and sensory evaluation techniques. Problem-solving: identifying and addressing quality issues at different points in the supply chain.

- Post-Harvest Handling and Storage: Proper drying, milling, and storage techniques to maintain bean quality and prevent defects. Understanding the impact of storage conditions on aroma and flavor development.

- Supply Chain Management: Tracing coffee from farm to consumer, understanding logistics, fair trade practices, and the role of certifications (e.g., organic, Rainforest Alliance). Practical application: optimizing the supply chain for efficiency and sustainability.

- Coffee Industry Trends and Regulations: Staying updated on current market trends, consumer preferences, and relevant industry regulations (e.g., food safety standards). Problem-solving: adapting to evolving market demands and regulatory changes.

- Equipment and Machinery: Familiarity with common processing equipment and machinery used in coffee production. Troubleshooting basic equipment malfunctions.

Next Steps

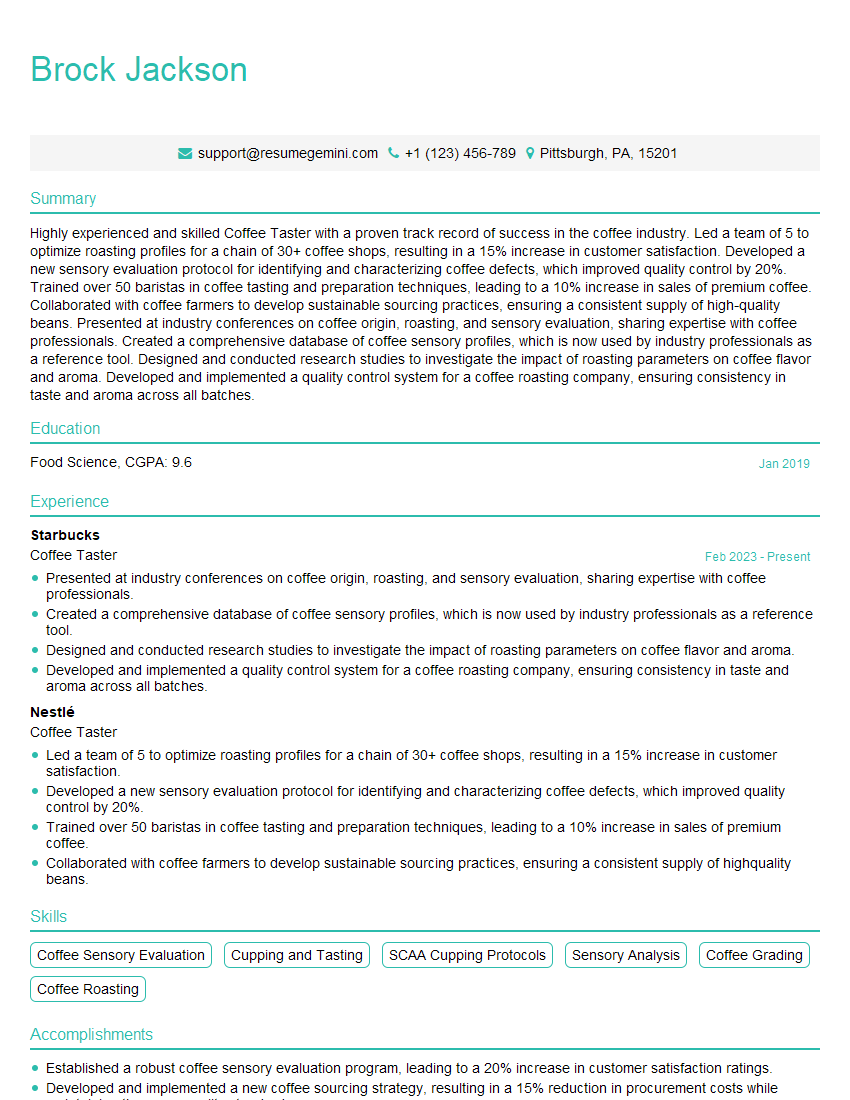

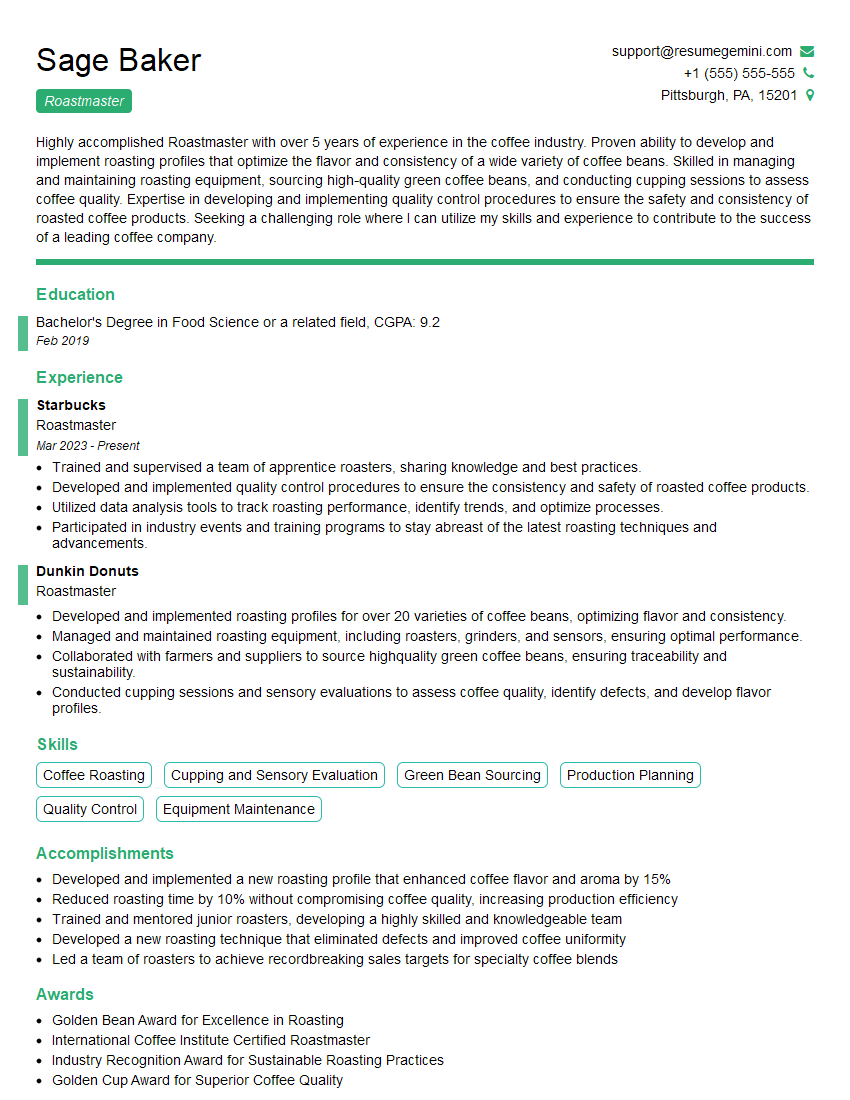

Mastering coffee production opens doors to exciting career opportunities in a dynamic and growing industry. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to the Coffee Production industry, allowing you to craft a compelling application that showcases your expertise and lands you your dream job. Invest time in refining your resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good