Preparation is the key to success in any interview. In this post, we’ll explore crucial Roasting Techniques interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Roasting Techniques Interview

Q 1. Describe the Maillard reaction and its importance in coffee roasting.

The Maillard reaction is a chemical reaction between amino acids and reducing sugars that gives browned food its distinctive flavor. Think of the delicious aroma of freshly baked bread or seared steak – that’s the Maillard reaction in action! In coffee roasting, it’s crucial because it’s responsible for the development of hundreds of volatile aromatic compounds and contributes significantly to the coffee’s flavor profile. It begins around 200°C (392°F) and accelerates as the temperature increases. The reaction’s complexity is why different roast levels yield such diverse flavor characteristics.

Without the Maillard reaction, roasted coffee would be bland and lack the rich, nuanced flavors we appreciate. The specific amino acids and sugars present in the green coffee beans, along with the roasting temperature and time, influence the intensity and type of Maillard reaction products formed, leading to the vast spectrum of coffee flavors we experience.

Q 2. Explain the difference between light, medium, and dark roasts.

The terms ‘light,’ ‘medium,’ and ‘dark’ roasts describe the degree to which the coffee beans have been roasted. It’s not a precise scientific measure but rather a general classification based on visual cues and flavor profiles. Think of it like cooking a steak: rare, medium-rare, and well-done.

- Light Roast: Beans retain their original structure and a lighter color, typically light brown. They often exhibit brighter acidity, more nuanced origin characteristics (like floral or fruity notes), and a lighter body. The Maillard reaction is just beginning in this stage.

- Medium Roast: The beans have developed more color, typically a medium brown, with a slightly oily surface. They showcase a balance of acidity, body, and flavor complexity, offering a blend of the bean’s origin characteristics and the Maillard reaction’s contributions. The balance of acidity and sweetness is usually more prominent.

- Dark Roast: Beans are dark brown, almost black, with a significantly oily surface. These roasts are typically bolder, less acidic, and have a strong, sometimes bitter, flavor profile. The Maillard reaction is advanced, and other chemical processes like pyrolysis (the breakdown of organic matter at high temperatures) contribute to their characteristics. Origin nuances are often masked.

Q 3. What are the key factors affecting bean development during roasting?

Several key factors influence bean development during roasting. Think of it as a delicate dance of heat, time, and bean characteristics:

- Temperature: The most critical factor. A higher temperature accelerates the roasting process, leading to quicker development but potentially to uneven roasting or burnt beans.

- Time: The duration of the roast directly impacts the final roast level. Longer roasts lead to a darker roast, while shorter ones result in lighter roasts.

- Bean characteristics: The type of bean (Arabica, Robusta, etc.), its origin, and its initial density significantly affect how it roasts. Denser beans take longer to roast than less dense ones.

- Airflow: Proper airflow ensures even heat distribution, preventing uneven roasting and maximizing the development of each bean. Insufficient airflow can lead to uneven roasting and potential scorching.

- Roast environment (e.g. humidity and pressure): While less immediately impactful than temperature and time, these variables can subtly impact development. Humidity, for example, affects how quickly beans lose moisture.

Q 4. How do you identify and prevent common roasting defects?

Identifying and preventing roasting defects requires a keen eye, experience, and understanding of the roasting process. Common defects include:

- Uneven roasting: Some beans might be under-roasted while others are over-roasted. This is typically due to poor airflow or inconsistent heat distribution. Prevention: Ensure proper airflow and even heat distribution within the roaster.

- Quakers (under-roasted beans): These are pale beans that haven’t undergone proper chemical changes. Prevention: Adjust the roasting profile to ensure proper development time and temperature.

- Bean splitting: Cracking of beans during roasting, often from rapid expansion of gases. Prevention: Manage the roast temperature to prevent sudden pressure changes inside the beans.

- Burnt beans (scorched beans): Over-roasted beans have a bitter taste and smoky aroma. Prevention: Carefully monitor the roasting temperature and the visual cues for the correct roast level.

Regularly cleaning and maintaining the roaster is also critical in preventing defects.

Q 5. Describe your experience with different roasting machines (e.g., fluid bed, drum roasters).

My experience encompasses both drum roasters and fluid bed roasters. Drum roasters, the traditional type, use a rotating cylinder to roast beans, offering a gentler process excellent for developing nuanced flavors. I’ve extensively worked with a 5-kilogram Probat drum roaster, mastering its precise temperature control and airflow adjustments to produce consistent roast profiles. Fluid bed roasters, on the other hand, utilize a bed of hot air to roast beans, providing exceptional speed and consistency. I’ve used a smaller 1-kilogram fluid bed roaster for experimentation and smaller batch roasting, finding its rapid heating and precise temperature control useful for quick development cycles.

Each machine has its strengths and weaknesses. Drum roasters allow for more nuanced control over flavor development due to their gentler heat application, while fluid bed roasters are faster and better suited for large-scale production and consistency, and can improve efficiency in terms of energy and time consumption.

Q 6. How do you monitor and control roast profiles?

Monitoring and controlling roast profiles is paramount for consistent quality. I use a combination of visual cues, temperature monitoring, and roast-specific software. I typically monitor:

- Bean temperature: Measured with a thermocouple inside the roasting chamber. This helps to track the roasting process’s progression and avoid overheating.

- Exhaust temperature: Measures the temperature of the gases leaving the roaster. It’s useful for assessing the heat transfer and the overall roast progression.

- Rate of rise (ROR): Measures the speed at which the bean temperature is increasing. It helps to identify key phases of the roasting process, such as the first and second crack.

Roast-specific software, like Artisan or RoastMaster, allows me to record and analyze roast profiles to ensure quality and repeatability. I can create and fine-tune roast profiles based on specific bean characteristics and desired flavor outcomes. Data logging allows me to make informed adjustments to the roaster parameters such as airflow and drum speed and to detect even subtle variations.

Q 7. Explain the concept of First Crack and Second Crack.

First crack and second crack are audible and visual indicators of significant changes within the coffee bean during the roasting process. They signal key stages of development. Imagine the beans as tiny popcorn kernels – the cracking sounds are like popcorn popping!

- First crack: This is the first audible cracking sound, indicating the bean is releasing trapped moisture and gases. It marks the transition from drying to browning, and when many roasters aim for a lighter roast profile.

- Second crack: This is a more rapid and intense series of cracking sounds, indicating significant chemical changes within the bean (including more development of Maillard reaction products and other important flavor components). Roasting past this point typically leads to darker roasts with a more robust flavor profile, though potentially increased bitterness if overdone.

These are important indicators but should be considered alongside temperature readings, bean color, and other sensory cues to determine the optimum roast level for the desired flavor profile. The specific timing of these cracks can vary depending on the bean’s origin, density, and the roasting parameters used.

Q 8. How do you adjust roast profiles based on bean origin and characteristics?

Adjusting roast profiles based on bean origin and characteristics is crucial for bringing out the best in each coffee. Think of it like cooking – you wouldn’t roast a delicate fish the same way you’d sear a steak. Different beans have varying densities, moisture content, and inherent flavor profiles influenced by altitude, processing method, and variety. For example, a high-grown Ethiopian Yirgacheffe, known for its bright acidity and floral aromatics, will require a lighter roast to preserve these delicate nuances. A denser Indonesian Mandheling, with its rich body and earthy notes, can handle a darker roast without becoming bitter.

My approach involves a combination of experience and data. I start with a base profile, adjusting based on the bean’s characteristics. For high-density beans, I’ll often extend the roast time to ensure even heat penetration. For beans with high moisture content, I might adjust the charge temperature to prevent channeling. I constantly monitor the bean’s development using a roast machine with a color-based roast curve system (like Agtron) and a temperature sensor. I might also conduct smaller test roasts to fine-tune the profile before scaling up to larger batches. I document every roast, creating a database for future reference. This data-driven approach allows for consistent and optimized roasting for each unique bean.

Q 9. What are your methods for ensuring consistent roast quality?

Consistent roast quality is paramount. It’s the foundation of a successful coffee business. My methods focus on control and precision at every stage. This begins with using a well-maintained roaster, regularly calibrated for temperature accuracy and airflow consistency. I meticulously weigh out green beans for each roast ensuring uniformity, and I use consistent pre-heating protocols before the green beans are introduced.

During the roast, I actively monitor the roast curve, noting key markers like first crack and second crack (these are audible and visual signs indicating specific stages in the roast). This allows me to identify any deviations from the target profile and make adjustments in real-time. Post-roast, I employ a cooling tray that ensures even cooling of the beans to prevent uneven roasting and further development. Regular maintenance of my equipment including cleaning and calibrating reduces variability. Finally, I use cupping sessions to analyze the roasted beans and identify any inconsistencies, enabling continual improvement of my methods.

Q 10. How do you assess the quality of roasted coffee beans?

Assessing roasted coffee quality involves a multi-sensory approach. It’s not just about looking at the beans; it’s about understanding their overall profile. I begin by visually inspecting the beans for uniformity of color, size, and absence of defects. Over-roasted beans will be dark, oily, and may exhibit cracking. Under-roasted beans will appear lighter and may be unevenly colored.

The aroma is another important indicator – a good roast will display complex and pleasant aromas relevant to the origin and variety of the bean, while off-flavors like burnt, rubbery, or acidic notes indicate problems. I then move to a taste test (cupping). Cupping allows me to evaluate the roasted coffee’s flavor profile, including acidity, body, sweetness, and aftertaste. It helps identify any defects that might not be apparent during visual inspection or aroma evaluation. I also document all observations to maintain a record of each batch’s quality.

Q 11. What cupping techniques do you use to evaluate roasted coffee?

Cupping, or coffee tasting, is a standardized method for evaluating roasted coffee. It involves brewing multiple samples under consistent conditions to isolate the flavor characteristics of the coffee. I start by grinding the beans to a uniform size and using a specific amount of coffee and water at a measured temperature. The brewed coffee is then poured into small cups (cupping bowls) and allowed to bloom (a critical step where the coffee releases gases) before stirring.

The slurping technique is used to aerate the coffee across the palate, allowing for a full sensory experience. I assess the aroma, flavor notes (sweetness, acidity, bitterness, body, etc.), balance, and aftertaste. I employ a scoring system to consistently assess the samples across multiple sessions and record my findings for comparison and analysis. This helps identify the best roast profiles and detect flaws or inconsistencies in the roasting process, allowing for continuous refinement.

Q 12. How do you manage inventory and minimize waste in a roasting facility?

Efficient inventory management and waste minimization are critical for profitability and sustainability in a roasting facility. I use a first-in, first-out (FIFO) system to ensure that older green coffee beans are roasted first, minimizing storage time and preventing spoilage. I maintain detailed inventory records, using software to track green coffee stocks, roasted coffee inventory, and sales data. This system provides real-time insight into stock levels and helps predict future needs.

Waste reduction strategies include careful planning of roast sizes to minimize excess roasted coffee. I also ensure that all chaff (the thin skin removed during roasting) is collected and disposed of properly. Regular maintenance of the roasting equipment helps prevent equipment failure and reduce energy waste. Implementing procedures to prevent bean damage and spillage helps maintain efficiency and prevent losses. By monitoring key performance indicators (KPIs) such as waste percentage and inventory turnover, I can identify areas for further improvement and optimize the efficiency of my facility.

Q 13. Describe your experience with green coffee sourcing and selection.

My experience with green coffee sourcing and selection is extensive. I work directly with importers and farmers to ensure the quality and traceability of my green beans. This starts with understanding the terroir (environmental factors influencing the bean) and processing methods used for each coffee. I consider factors such as altitude, rainfall, soil type, processing method (washed, natural, honey), and the coffee variety.

I often visit origin farms when possible to personally assess the quality of the beans and build relationships with producers. When sourcing, I prioritize transparency and sustainability. I look for certifications (like Fairtrade or organic) that ensure ethical and environmentally friendly farming practices. Before committing to a large purchase, I order small sample batches to evaluate their roast characteristics and cup quality. This thorough selection process allows me to consistently source high-quality green beans suited for my specific roasting needs and aligns with my commitment to ethical sourcing.

Q 14. Explain the relationship between roast level and bean characteristics (e.g., acidity, body).

The roast level significantly impacts bean characteristics, particularly acidity, body, and flavor complexity. Imagine baking a cake: a lightly baked cake will have a softer texture and more delicate flavors, whereas an over-baked one might be dry and intensely caramelized. Similarly, roast level transforms the coffee bean.

Lighter roasts (such as a light or cinnamon roast) retain more of the bean’s origin characteristics: higher acidity, brighter flavors, and a lighter body. As the roast progresses (medium, medium-dark, dark, etc.), the acidity decreases, the body becomes fuller, and the flavors develop towards more roasted notes like chocolate, nuts, and caramel. A darker roast will often mask some of the bean’s original subtleties. This relationship is not linear; different beans react differently to varying roast levels. Some might develop undesirable bitterness more quickly at darker roasts, while others might handle darker levels very well. Understanding this relationship allows me to tailor the roast level to highlight the desired flavor profile for a specific bean and roast it to the desired level of expression.

Q 15. What are the common challenges in coffee roasting and how do you address them?

Coffee roasting presents numerous challenges, often intertwined and demanding a holistic approach. One major hurdle is achieving consistent roast profiles. Slight variations in bean density, moisture content, or ambient temperature can significantly impact the final product. This is addressed through meticulous pre-roasting analysis, including bean density measurement and moisture content testing. We also employ precise control over the roasting machine, including calibrated temperature sensors and airflow adjustments.

Another challenge is preventing bean defects, such as scorching or under-roasting. This requires a deep understanding of the roast curve (the relationship between time, temperature, and bean development) and continuous monitoring of the roast, often utilizing a combination of visual cues (bean color) and machine data (temperature, airflow). Addressing this involves careful control over the heating profile and mastering the art of “dropping” the beans at the optimal point. For example, if beans are developing unevenly, I might adjust the drum speed to improve heat distribution. Similarly, if I notice scorching, I’ll immediately lower the temperature or increase airflow.

Finally, maintaining quality and consistency across large batches is crucial. Inconsistencies can be caused by variations in green coffee quality, machine performance, or even operator skill. To overcome this, we implement rigorous quality control checks at each stage, from green coffee sourcing to final cupping. Comprehensive data logging and analysis help us identify and address any recurring problems. Regular machine calibration and staff training are also essential components of our strategy.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What safety protocols do you follow during the roasting process?

Safety is paramount in the coffee roasting process. Our protocols start with proper personal protective equipment (PPE), including heat-resistant gloves, closed-toe shoes, and safety glasses. We also maintain a clean and organized workspace, free from tripping hazards. This reduces the risk of accidents caused by spills or equipment malfunctions.

The roaster itself is a significant source of potential hazards, including high temperatures and moving parts. Regular inspections of the roaster and its components are crucial. Before each roast, we carefully check all safety mechanisms, including emergency stops and temperature controls. We strictly adhere to manufacturers’ safety guidelines and conduct regular safety training for all staff. Proper ventilation is crucial to remove potentially harmful gases and fumes produced during roasting. Our system includes a powerful exhaust system and regular filter maintenance.

Furthermore, we have established strict procedures for handling hot beans and chaff (the dried skin that separates from the beans during roasting). Cool-down procedures are strictly followed to avoid burns. We also have a comprehensive emergency response plan in place in case of accidents or equipment malfunctions. This plan details procedures for fire safety, medical emergencies, and equipment shut-down.

Q 17. How do you maintain and troubleshoot roasting equipment?

Maintaining and troubleshooting roasting equipment is a continuous process that involves both preventive maintenance and reactive problem-solving. Preventive maintenance includes regular cleaning, lubrication, and inspection of all moving parts. We adhere to a strict schedule for these activities, documented and tracked meticulously. This ensures that the roaster operates optimally and extends its lifespan.

Troubleshooting often involves systematic diagnosis. If the roaster malfunctions, we start by checking the most obvious things, like power supply and gas connections. We then systematically examine the different components, using diagnostic tools and our knowledge of the roaster’s inner workings. For example, if the temperature isn’t reading correctly, I might check the thermocouples for damage or calibration issues. If the airflow is inconsistent, I might investigate the blower fan and its associated ductwork. Detailed logging of machine performance and maintenance procedures is crucial for efficient troubleshooting.

Our approach is documented and easily accessible to all staff. We also have a relationship with the equipment manufacturer for guidance on more complex issues, and we regularly attend training to stay up to date with the latest maintenance practices.

Q 18. Describe your experience with data logging and analysis in coffee roasting.

Data logging and analysis are integral to my roasting process. I utilize sophisticated roasting software that records key parameters during each roast, including temperature, airflow, bean charge weight, and roast time. This data is then analyzed to optimize roast profiles and to ensure consistency across batches. The data helps us understand how various factors affect the roast, such as bean origin and moisture content.

For example, if I notice a consistent flaw in a specific roast profile, I can review the data to pinpoint the exact point in the roast where the problem occurs. This might reveal a need for an adjustment in temperature ramp-up, airflow, or roast time. By analyzing this data, we can gradually refine our roasting techniques to achieve a consistently high-quality product. We use statistical analysis techniques, such as comparing average roast times and temperatures across various batches, to identify trends and make informed decisions.

Furthermore, data logging allows us to track long-term trends and make adjustments based on seasonal changes, bean sourcing variations, and environmental factors. This data-driven approach enables us to constantly improve our roasting process and produce the most consistent and flavorful coffee possible.

Q 19. What software or tools do you use for roast profile management?

For roast profile management, I primarily utilize Artisan and RoastMaster software. These platforms provide comprehensive tools for creating, storing, and analyzing roast profiles. They allow me to precisely control parameters like temperature, airflow, and drum speed, and they record detailed data throughout the roasting process. This enables me to easily replicate successful roasts and fine-tune them for optimal results.

The software also facilitates comparison across different profiles, allowing for easy identification of successful strategies and adjustments for consistent quality. The data export capabilities allow me to share profiles with other roasters or to analyze trends over time. The ability to visualize the data graphically makes it simple to identify areas for improvement.

Additionally, I use spreadsheets and databases to supplement the software data, providing a more comprehensive view of my roasting operations. This approach allows me to track not only the roasting data but also other relevant factors such as green coffee quality, cupping notes, and sales data to achieve a fully integrated overview of the business.

Q 20. How do you stay updated on the latest advancements in coffee roasting techniques?

Staying current with advancements in coffee roasting requires a multi-faceted approach. I regularly attend industry conferences and workshops, both locally and internationally. These events provide invaluable opportunities to learn from leading roasters, equipment manufacturers, and coffee researchers. Networking with peers is also crucial for exchanging ideas and best practices.

I also subscribe to relevant industry publications and online resources, keeping myself informed about the latest technologies, techniques, and research findings. This includes following industry blogs, participating in online forums, and accessing scientific literature on coffee roasting. The development of new roasting technologies, for example, requires constant attention. Understanding the implications of new equipment or roasting methods and determining its applicability to my existing process requires diligent research and up-to-date knowledge.

Furthermore, continuous experimentation and a commitment to learning from each roast are essential. Each roast is an opportunity to refine my techniques and gain a deeper understanding of the roasting process. I maintain detailed records of each roast, documenting any changes and their effects on the final product. This continual feedback loop ensures that I am constantly improving my skills and adapting to the ever-evolving world of coffee roasting.

Q 21. Explain your experience with different types of coffee beans (Arabica, Robusta, etc.).

My experience encompasses a wide range of coffee beans, including Arabica and Robusta varieties. Arabica beans are renowned for their complex flavor profiles and aromatic characteristics. They require careful attention to roasting, as they are generally more delicate and susceptible to over-roasting than Robusta beans. Different Arabica varieties exhibit unique roasting characteristics; for example, Yirgacheffe beans from Ethiopia might require a lighter roast to preserve their bright acidity, whereas Sumatran beans might benefit from a fuller roast to enhance their body and earthy notes.

Robusta beans, on the other hand, are typically more robust and less sensitive to roasting errors. They tend to have a higher caffeine content and a more bitter, earthy flavor profile. Their greater resilience allows for darker roasts, which can enhance their boldness. However, over-roasting can lead to unpleasant burnt notes. The specific roasting approach for Robusta beans also depends on the specific origin and desired outcome. For instance, Vietnamese Robusta might be roasted to a darker level to intensify its characteristic chocolatey flavors.

Beyond Arabica and Robusta, I have experience with other specialty coffee beans, each with its own unique characteristics and roasting requirements. Understanding these nuances is crucial for achieving the best possible flavor profiles. This knowledge allows me to tailor my roasting techniques to each specific bean type to achieve the desired cup quality.

Q 22. What are your sensory skills in evaluating roasted coffee?

My sensory evaluation of roasted coffee is a crucial part of my work. It goes beyond simply tasting; it’s a holistic process engaging all senses. I start with visual assessment: color, bean size uniformity, and the presence of any defects. Then, I carefully sniff the aroma, identifying notes like chocolate, caramel, fruit, or floral hints, paying close attention to intensity and complexity. The actual tasting involves assessing acidity, body, sweetness, and aftertaste. I look for balance and harmony between these elements. Finally, the tactile sense is important—how the beans feel in my hand, their texture, density—provides extra clues about their roast profile.

For example, a properly roasted bean will have a consistent color, a satisfying snap when cracked, and a vibrant aroma. Conversely, an under-roasted bean might taste sour and grassy, while an over-roasted bean may taste bitter and ashy. I’ve developed my skills over years of practice, constantly calibrating my senses through cuppings and comparative tastings.

Q 23. Describe your experience working in a team environment in a roasting facility.

In a roasting facility, teamwork is paramount. I’ve worked in environments where seamless collaboration between roasters, quality control personnel, and logistics teams is key to success. For example, in one facility, we used a collaborative platform to track roast profiles, share feedback on bean quality, and manage inventory effectively. This minimized errors and improved efficiency. My role involved not only executing the roasting process but also actively contributing to team discussions, problem-solving, and training newer colleagues. We regularly held cuppings together to refine our palates and share knowledge about the nuanced flavors of different beans and roast levels. This shared learning environment greatly enhanced our collective expertise.

Q 24. How do you ensure compliance with food safety regulations in coffee roasting?

Food safety is my top priority. We strictly adhere to HACCP (Hazard Analysis and Critical Control Points) principles and follow all relevant local and international food safety regulations. This starts with sourcing high-quality green beans from reputable suppliers who provide certifications and traceability information. We maintain rigorous cleaning and sanitation protocols in the roasting facility, including regular equipment cleaning and pest control. We monitor temperature and humidity levels throughout the roasting process to prevent microbial growth. All our processes are documented and regularly audited to ensure compliance. Finally, we have a comprehensive recall procedure in place, should an issue arise. It’s a holistic approach – proactive measures are combined with stringent monitoring and documentation.

Q 25. What is your understanding of the impact of roasting on coffee flavor development?

Roasting dramatically impacts coffee’s flavor development. The process involves applying heat to green coffee beans, causing chemical reactions that release volatile aromatic compounds and transform their chemical structure. The Maillard reaction, for instance, contributes significantly to the development of flavors like caramel and chocolate. Roasting time, temperature, and the bean’s origin all play significant roles. A lighter roast will retain more acidity and showcase the bean’s origin characteristics, while a darker roast emphasizes bolder, more bitter notes. It’s a delicate balance; a slight deviation in roast parameters can lead to drastic changes in the cup profile. Understanding the science behind the roasting process enables me to achieve desired flavor profiles and ensure consistency in the final product.

Q 26. How do you address customer feedback related to roasted coffee quality?

Customer feedback is invaluable. We actively solicit it through various channels like online surveys, tasting notes, and direct communication. Negative feedback is addressed systematically. First, we analyze the feedback, identifying recurring issues and patterns. Is the problem consistent across batches or specific to a particular bean? We might then conduct sensory evaluations of the implicated batch and compare it to other batches. Based on the analysis, we make adjustments in our roasting process, sourcing, or quality control procedures. We always respond promptly and professionally to customers, acknowledging their feedback and outlining the steps taken to address their concerns. This approach has strengthened our brand reputation and improved product quality over time.

Q 27. How do you handle unexpected issues during a roasting session?

Unexpected issues during roasting can range from equipment malfunctions to inconsistent bean quality. My approach is methodical. First, I assess the situation, identifying the root cause of the problem. Is it a sensor malfunction? A problem with the gas supply? Or an unexpected variation in bean moisture content? Then, I take immediate corrective action – either fixing the immediate issue or mitigating the impact. This might involve adjusting the roast parameters mid-session, isolating the affected batch, or contacting maintenance personnel. After the session, a thorough investigation helps prevent future recurrences, which usually involves documenting the event, identifying contributing factors, and implementing preventive measures.

Q 28. Describe your experience with different types of roasting machines and their capabilities.

I have extensive experience with various roasting machines, from small-batch drum roasters to large-scale fluid bed roasters. Each machine has unique capabilities and limitations. Drum roasters, for instance, offer excellent control over the roast profile but have lower throughput. Fluid bed roasters, on the other hand, are ideal for high-volume roasting but require a slightly different approach to managing roast parameters. I’m proficient in operating and maintaining these machines, understanding their nuances and optimizing their performance for specific beans and desired roast levels. My experience includes using both gas-fired and electric roasters, giving me a versatile skill set adaptable to various roasting environments.

Key Topics to Learn for Roasting Techniques Interview

- Heat Transfer and its impact on bean development: Understanding conduction, convection, and radiation within the roasting environment and how they affect bean characteristics.

- Roast Profiles and their application: Analyzing different roast profiles (e.g., light, medium, dark) and their effect on flavor development, aroma, and acidity. Practical application involves adjusting roast profiles based on bean origin and desired outcome.

- Bean Characteristics and their influence on roasting: Understanding how factors like bean density, moisture content, and origin affect roasting time and temperature requirements. This includes troubleshooting issues arising from variations in bean quality.

- Sensory Evaluation and Quality Control: Developing skills in cupping and evaluating roasted beans for defects, flavor profile, and overall quality. This involves understanding the relationship between roast level and sensory attributes.

- Equipment Operation and Maintenance: Demonstrating knowledge of various roasting equipment (e.g., drum roasters, fluid bed roasters) and their proper operation, maintenance, and troubleshooting procedures.

- Green Coffee Sourcing and Quality Assessment: Understanding the importance of selecting high-quality green coffee beans and the processes involved in assessing their suitability for roasting.

- Safety and Hygiene in the Roasting Process: Adherence to safety protocols and maintaining a hygienic roasting environment to ensure food safety and prevent equipment damage.

- Roast Curve Analysis and Interpretation: Understanding and interpreting roast curves to optimize roasting parameters and achieve consistent results.

Next Steps

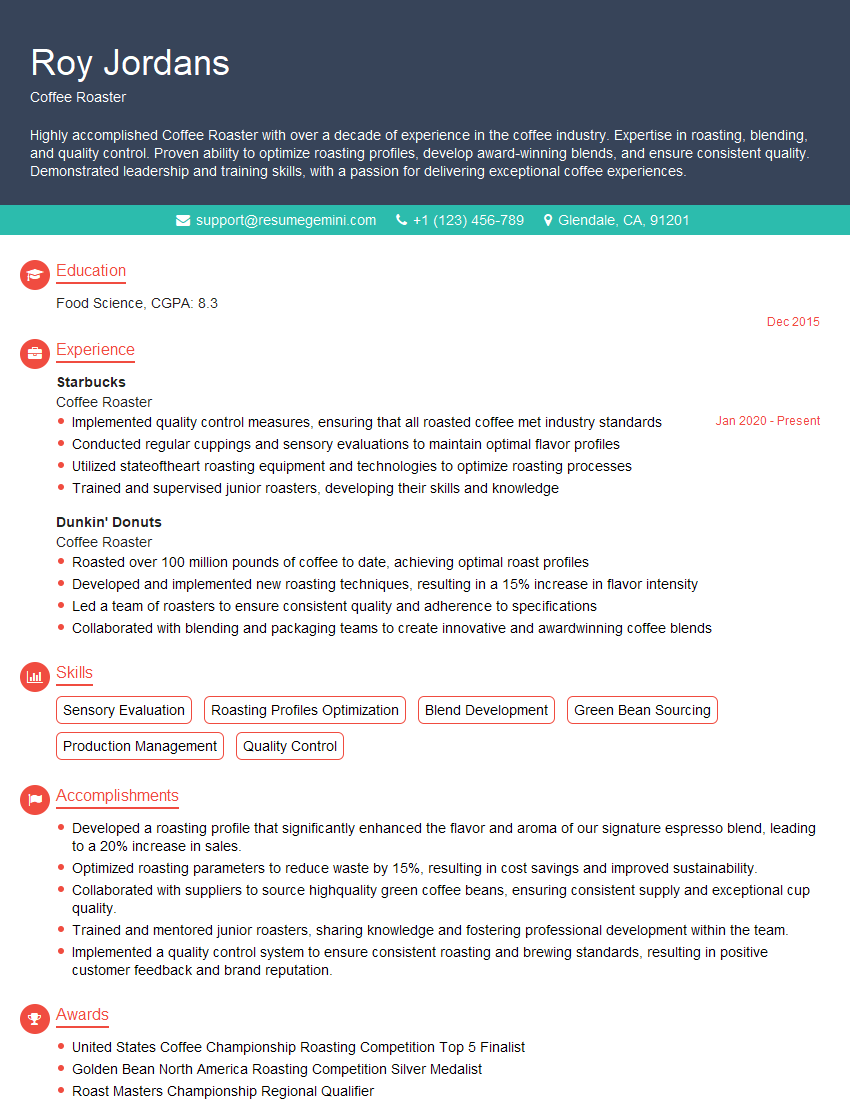

Mastering roasting techniques is crucial for career advancement in the specialty coffee industry, opening doors to exciting opportunities in production, quality control, and even coffee research. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Roasting Techniques are available to guide you, showcasing best practices for this specific field.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good