Cracking a skill-specific interview, like one for Laser Diode Characterization, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Laser Diode Characterization Interview

Q 1. Explain the different methods for measuring the output power of a laser diode.

Measuring the output power of a laser diode is crucial for various applications. We primarily use power meters, which are devices that measure the optical power incident on a sensor. These meters typically employ a calibrated photodiode that converts the optical power into an electrical signal, which is then processed and displayed as power in units like milliwatts (mW) or watts (W).

- Thermal power meters: These are robust and relatively inexpensive, using a thermal sensor to measure the power absorbed by a material. They’re useful for high-power lasers, but they have slower response times and are less accurate for lower power levels.

- Photodiode power meters: These offer faster response times and higher accuracy, especially for lower power lasers, making them suitable for most laser diode characterization. Different photodiodes are chosen based on the wavelength of the laser diode.

- Integrating spheres: For high accuracy or if you need to measure the total power emitted in all directions, an integrating sphere is used. This device captures and distributes the light evenly before reaching the sensor, greatly reducing measurement error.

For example, in a fiber optic communication system, accurate power measurement is vital to ensure optimal signal transmission. A miscalibrated power meter could lead to signal loss or system failure.

Q 2. Describe the process of characterizing the spectral characteristics of a laser diode.

Characterizing the spectral characteristics of a laser diode involves analyzing its emitted light’s wavelength and linewidth. The most common tool for this is an optical spectrum analyzer (OSA).

An OSA works by dispersing the light based on its wavelength using a diffraction grating or prism. This spread spectrum is then measured by a photodetector array. The resulting output is a graph showing the intensity of the light as a function of wavelength, revealing the central wavelength, linewidth, and any side modes.

The central wavelength represents the dominant wavelength emitted. The linewidth defines the spectral width of the laser emission, indicating its purity or monochromaticity. Narrower linewidths are generally better for applications requiring high spectral precision, like spectroscopy. The OSA also reveals side modes, representing other wavelengths present at lower intensities. These can affect applications requiring spectral purity.

For example, in optical sensing, the precise wavelength and linewidth are critical. The presence of side modes might interfere with the intended measurement, leading to inaccurate results. Therefore, careful spectral characterization using an OSA is essential to choose a suitable laser diode.

Q 3. How do you measure the beam quality (M²) of a laser diode?

Beam quality, often quantified by the M² factor (beam propagation ratio), describes how close a laser beam is to an ideal Gaussian beam. A Gaussian beam has the lowest possible divergence for a given beam diameter. An M² value of 1 indicates an ideal Gaussian beam. Higher M² values indicate poorer beam quality with greater divergence.

We measure M² using a beam profiler. This instrument measures the beam’s spatial intensity profile at multiple planes along its propagation axis. By analyzing the changes in beam size and divergence, the beam quality factor (M²) is calculated. The process typically involves fitting the measured beam profile data to a theoretical Gaussian model to determine the M² factor.

Different beam profilers are available, some using cameras with high spatial resolution, others using scanning slit methods. The choice depends on the laser power and wavelength. For example, in laser material processing, a low M² value is desirable for focused energy delivery and precise machining.

Q 4. What are the key parameters used to characterize the temperature dependence of a laser diode?

The temperature dependence of a laser diode is critical as temperature fluctuations significantly impact its performance. The key parameters include:

- Threshold current (Ith): The current required to initiate lasing increases with temperature.

- Output power (Pout): The output power typically increases with temperature to a certain point, then starts to decrease.

- Central wavelength (λ): The lasing wavelength shifts with temperature, typically showing a linear relationship.

- Slope efficiency (ηs): This represents the efficiency of converting input current into optical power and often decreases with increasing temperature.

These parameters are usually characterized by measuring them at various operating temperatures, often using a temperature-controlled mount. The data is then plotted to show the temperature dependence of each parameter, which is essential for designing temperature control systems in laser applications. For example, in telecommunications, maintaining a stable operating temperature is crucial to avoid wavelength drift and ensure signal quality.

Q 5. Explain the concept of threshold current in a laser diode and how it’s determined.

The threshold current (Ith) is the minimum current required to initiate lasing in a laser diode. Below this current, the diode emits spontaneous emission, a broad spectrum of light. Above Ith, stimulated emission dominates, producing coherent and monochromatic light.

Determining Ith involves measuring the light output power (Pout) as a function of the injection current (I). The resulting light-current (L-I) curve shows a distinct change in slope at Ith. This point marks the transition from spontaneous to stimulated emission. We can find Ith by extrapolating the linear portion of the L-I curve above Ith back to the x-axis (Pout=0).

Precise determination of Ith might require careful data analysis to account for background noise and nonlinearity near the threshold. Understanding Ith is essential in optimizing laser diode design and operation for better energy efficiency and performance. A higher Ith indicates less efficient lasing action.

Q 6. What are the common failure mechanisms in laser diodes?

Laser diodes, despite their robustness, are susceptible to several failure mechanisms:

- Catastrophic optical damage (COD): High optical power densities can damage the facet of the laser diode, leading to sudden failure.

- Dark line defects (DLDs): These are defects within the active region of the diode that absorb light and reduce the laser’s output power. They can propagate and lead to complete failure.

- Electro-migration: The flow of current can cause material migration within the device, leading to degradation and ultimately failure.

- Facet degradation: The laser’s output facet is vulnerable to oxidation and degradation, reducing its reflectivity and efficiency over time.

Understanding these mechanisms is critical for designing more reliable laser diodes and implementing appropriate operating conditions and environmental protection strategies. For instance, avoiding excessive operating currents, limiting exposure to high temperatures, and using protective coatings can all help to increase the lifespan of laser diodes.

Q 7. How do you determine the reliability of a laser diode?

Determining the reliability of a laser diode involves evaluating its lifespan under specified operating conditions. Accelerated life testing is commonly used, where the devices are subjected to conditions that accelerate degradation processes. This involves operating the laser diodes at higher-than-normal temperatures, currents, or optical powers.

Data obtained from accelerated life testing is used to estimate the lifetime under normal operating conditions using statistical models like the Arrhenius equation. This equation relates the failure rate to temperature, allowing us to extrapolate the results from accelerated testing to normal operating temperatures.

Other reliability metrics include the mean time to failure (MTTF), failure rate, and the activation energy, which reflects the sensitivity of failure rate to temperature. Reliability tests are essential to ensure that laser diodes meet the demands of their respective applications, particularly in critical systems like medical lasers or space applications where failure can have significant consequences.

Q 8. Describe the differences between Fabry-Perot and distributed feedback laser diodes.

Fabry-Perot and Distributed Feedback (DFB) laser diodes are both semiconductor lasers, but they differ fundamentally in how they achieve lasing and the resulting spectral output. Think of it like this: a Fabry-Perot laser is like a simple musical instrument, producing a range of notes (wavelengths), while a DFB laser is like a precisely tuned instrument, producing a single, pure note.

A Fabry-Perot laser diode uses two cleaved facets of the semiconductor material as mirrors to form an optical resonator. Light bounces back and forth between these facets, building up intensity and eventually lasing. This simple structure leads to a broad range of wavelengths lasing simultaneously, resulting in a multi-modal output. This is because the resonator supports multiple longitudinal modes.

A Distributed Feedback (DFB) laser diode, on the other hand, incorporates a periodic grating structure within the active region. This grating acts as a distributed Bragg reflector, selecting only one specific wavelength for lasing. The grating selectively reflects the desired wavelength back into the active region, enhancing its amplification while suppressing other wavelengths. This results in a single-mode output with very narrow linewidth.

- Fabry-Perot: Multi-mode operation, broader linewidth, simpler structure, lower cost.

- DFB: Single-mode operation, narrow linewidth, more complex structure, higher cost, ideal for applications requiring high spectral purity such as telecommunications.

In essence, the choice between Fabry-Perot and DFB lasers depends heavily on the application. If spectral purity is crucial, a DFB laser is preferred. If cost and simplicity are prioritized and a broad wavelength range is acceptable, a Fabry-Perot laser might be suitable.

Q 9. What are the advantages and disadvantages of different laser diode packaging methods?

Laser diode packaging is crucial for protecting the delicate device and providing a reliable interface for the optical fiber or other optical components. Different packaging methods offer various advantages and disadvantages.

- TO-can (Transistor Outline): This is a common package, relatively inexpensive and easy to handle. However, it’s bulky and not ideal for high-density applications. It also offers limited thermal management capabilities, affecting performance especially at higher powers.

- Butterfly package: These are compact and designed for fiber coupling; they offer good thermal management. However, they are generally more expensive than TO-cans.

- Surface mount packages (SMD): Small size and suited for automated assembly processes. The thermal management can be a challenge depending on the specific design and size.

- Fiber pigtailed packages: These directly integrate a fiber optic cable with the laser diode, making coupling very efficient and stable. This simplifies system assembly and improves stability but can be expensive and less flexible.

The optimal choice depends on the application’s requirements. For example, a high-power laser might require a package with excellent thermal management, while a cost-sensitive application might opt for a simpler, less expensive TO-can package. A telecommunications application would likely prefer a fiber pigtailed package to maximize ease of use and system stability. Choosing the appropriate package is vital for maintaining the laser’s performance and lifetime.

Q 10. How do you measure the modulation bandwidth of a laser diode?

The modulation bandwidth of a laser diode signifies the maximum frequency at which the laser can be effectively modulated while maintaining sufficient output power and linearity. Measuring it involves applying a sinusoidal modulation signal to the laser diode and observing the response of the optical output power.

A common technique is to use a network analyzer. The process generally involves:

- Setup: A sinusoidal signal of varying frequency is applied to the laser diode’s bias current using a function generator. The optical output is detected by a photodetector.

- Measurement: The amplitude and phase of the detected optical signal are measured as a function of the modulation frequency.

- Analysis: The modulation response (magnitude and phase) is plotted against the frequency. The 3-dB bandwidth, which is the frequency at which the optical power drops by 3 dB (half power) from its low frequency value, represents the modulation bandwidth.

Careful attention must be paid to the various parameters: maintaining constant bias current, using appropriate attenuators, minimizing reflections in the optical system, and ensuring the photodetector has a sufficient bandwidth. Accurate measurement of the modulation bandwidth is vital for applications like high-speed data transmission where fast modulation response is critical. An insufficient bandwidth will limit the data rate.

Q 11. Explain the effect of operating temperature on laser diode performance.

Temperature significantly affects laser diode performance. As the temperature increases, several parameters change, impacting the laser’s operational characteristics.

- Threshold current (Ith): The threshold current, the minimum current needed for lasing, increases with temperature. This implies needing more current to maintain the same optical power at higher temperatures.

- Output power: The output power typically increases initially with temperature, reaching a maximum before declining. This is because increased temperature affects the gain and loss mechanisms within the laser diode.

- Wavelength: The emission wavelength shifts with temperature, typically exhibiting a linear change. This temperature sensitivity requires precise temperature control for applications that demand specific wavelength stability.

- Linewidth: The linewidth of the laser output might broaden with increasing temperature, reducing spectral purity.

For stable operation, temperature control is often necessary. Thermoelectric coolers (TECs) are commonly used to maintain a constant operating temperature for lasers requiring stability. Accurate thermal management prevents overheating and maintains the laser’s performance, reliability, and extends its lifespan.

Q 12. What is the role of a bias tee in laser diode characterization?

A bias tee is a crucial component in laser diode characterization, especially when applying high-frequency modulation signals. It allows for the simultaneous application of both a DC bias current and an AC modulation signal to the laser diode. The key function is the isolation of DC and AC components. Imagine it as a simple traffic controller, allowing DC current to flow smoothly while allowing the AC signal to pass through separately without interfering with each other.

A bias tee typically consists of a DC blocking capacitor and an RF choke (inductor). The capacitor allows the AC modulation signal to pass through while blocking the DC bias current. The inductor allows the DC bias current to pass while blocking the AC signal from reaching the power supply. This arrangement provides a clean DC bias while permitting the application of the AC modulation signal without affecting the bias current, ensuring accurate and stable laser operation during characterization.

Without a bias tee, it would be very difficult to apply a high-frequency modulation signal without affecting the DC bias current, leading to inaccurate measurements and potentially damaging the laser diode.

Q 13. How do you characterize the polarization of a laser diode’s output?

Characterizing the polarization of a laser diode’s output is essential as many applications are sensitive to the polarization state. Laser diodes typically emit linearly polarized light, but the polarization direction and its stability can vary depending on the device and its operating conditions.

The most common method is using a polarization analyzer. This instrument measures the power in various polarization states. A typical setup involves:

- Polarizer: Rotate a linear polarizer in the path of the laser beam. Measure the transmitted optical power as a function of the polarizer’s angle. The maximum transmitted power indicates the dominant polarization direction.

- Polarization beam splitter (PBS): A PBS separates the light into two orthogonal polarization states (typically horizontal and vertical). Measuring the power in each output port determines the degree of polarization and the polarization ratio.

- Polarization controller: If needed, a polarization controller can be used to manipulate the polarization state before measurement, for more detailed analysis.

Measuring the polarization state is critical in optical communication systems, optical sensing, and other applications where polarization-dependent losses can significantly affect system performance. Understanding and controlling the polarization is important for maximizing efficiency and reliability.

Q 14. Explain the concept of optical feedback and its impact on laser diode operation.

Optical feedback occurs when a portion of the laser diode’s emitted light reflects back into the laser cavity, either from external reflectors or imperfections in the optical system. Think of it as a feedback loop similar to an audio amplifier that can cause both positive and negative effects.

Impact on Laser Operation:

- Linewidth narrowing: In some cases, weak feedback can slightly reduce the laser linewidth, improving spectral purity.

- Wavelength shift: Feedback can cause the lasing wavelength to shift, potentially affecting the functionality of optical systems requiring precise wavelength control.

- Intensity noise: More significant feedback can lead to increased intensity noise, resulting in unstable output power and affecting the signal quality.

- Mode hopping: Strong optical feedback can cause the laser to jump between different longitudinal modes, resulting in abrupt changes in the laser’s wavelength, intensity, and polarization.

- Relaxation oscillations: Feedback can excite relaxation oscillations, leading to damped oscillations in the laser output power at certain frequencies, which impact the modulation characteristics and stability.

Careful design of the optical system is crucial to minimize optical feedback. This involves using anti-reflection coatings on optical components, appropriate fiber connectors, and well-designed optical isolators to prevent reflected light from reaching the laser diode. Proper management of optical feedback is critical for maintaining the stability, reliability, and performance of the laser system.

Q 15. Describe the use of optical spectrum analyzers in laser diode testing.

Optical Spectrum Analyzers (OSAs) are crucial in laser diode testing because they provide a detailed spectral analysis of the emitted light. Think of it like a sophisticated prism that not only separates the light into its constituent wavelengths but also precisely measures the intensity of each wavelength. This is vital for several reasons:

- Wavelength Measurement: OSAs accurately determine the central wavelength of the laser diode’s emission and its spectral width (how spread out the wavelengths are). This is critical for applications requiring precise wavelength control, such as optical communication systems.

- Mode Hopping Analysis: Laser diodes can sometimes jump between different operating wavelengths (mode hopping), leading to instability. OSAs help identify and quantify this mode hopping behavior.

- Side Mode Suppression Ratio (SMSR) Measurement: Ideally, a laser diode should emit most of its power at a single wavelength. OSAs measure the SMSR, which indicates how much power is emitted at wavelengths other than the main emission peak. A high SMSR is desirable for many applications.

- Spectral Purity Assessment: OSAs reveal the overall spectral purity of the laser emission, helping to assess the presence of unwanted noise or spurious emissions.

For example, in a fiber optic communication system, precise wavelength control is crucial for proper signal transmission. An OSA would be used to ensure the laser diode operates at the specified wavelength and has a narrow spectral width to minimize signal distortion.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret a laser diode’s Light-Current (L-I) curve?

The Light-Current (L-I) curve plots the optical power output of a laser diode as a function of the injected current. It’s a fundamental characteristic that reveals key operational parameters. The curve typically shows three distinct regions:

- Linear Region: At low currents, the optical power increases linearly with the injected current. This region is ideal for applications requiring a linear relationship between input and output.

- Threshold Region: As the current increases, the laser diode reaches its threshold current (Ith). Below this current, spontaneous emission dominates, producing weak light. Above Ith, stimulated emission becomes significant, leading to a sharp increase in optical power.

- Saturation Region: At high currents, the optical power increases more slowly and eventually saturates. This is due to factors like heating effects and carrier saturation within the laser cavity.

Interpreting the L-I curve involves identifying Ith, the slope of the linear region (related to differential quantum efficiency), and the saturation power. Deviations from the ideal curve can indicate problems like degradation or non-uniformities in the laser diode.

Imagine it like filling a water balloon: at first, the balloon expands proportionally (linear region) as you add water (current). Then, you reach a point where the balloon expands rapidly as you add more water (threshold). Finally, the balloon becomes full and doesn’t expand much even if you continue adding water (saturation).

Q 17. What is the significance of the external quantum efficiency?

External Quantum Efficiency (EQE) represents the ratio of the number of photons emitted from the laser diode to the number of electrons injected into it. It essentially tells us how efficiently the electrical energy is converted into optical energy. A higher EQE is always desired.

The formula for EQE is:

EQE = (Number of photons emitted) / (Number of electrons injected)EQE is typically expressed as a percentage. A higher EQE indicates that a greater portion of the injected electrons are contributing to the generation of photons. Factors like material quality, device design, and operating temperature significantly influence the EQE. A low EQE implies energy losses through non-radiative recombination processes, reducing the laser’s power output for a given current. In practical terms, a high EQE translates into a more power-efficient laser diode, reducing energy consumption and heat generation.

Q 18. Explain the concept of differential quantum efficiency.

Differential Quantum Efficiency (DQE) is the slope of the linear portion of the L-I curve. It describes how much the optical output power changes for a small change in the injected current around the lasing threshold. Unlike EQE, which considers the total efficiency, DQE focuses on the efficiency of light generation *in the linear region* of operation.

Mathematically, DQE is the derivative of the optical power with respect to current in the linear region.

The significance of DQE lies in its ability to characterize the laser diode’s behavior in its normal operating range. A high DQE indicates a more efficient light generation process in this region. DQE is often used to compare different laser diode designs or to assess the impact of aging or other factors on laser performance. In contrast to EQE, which is a broad measure across all operational conditions, DQE offers a more fine-grained analysis of efficiency within the linear region, where the device is often used.

Q 19. What are the methods to measure the wavelength of a laser diode?

Several methods exist for measuring the wavelength of a laser diode:

- Optical Spectrum Analyzer (OSA): As discussed previously, OSAs provide the most accurate and detailed wavelength measurement, along with other spectral information.

- Wavelength Meter: These instruments are specifically designed for precise wavelength measurement. They are typically faster than OSAs but may offer less detailed spectral information.

- Grating Spectrometer: This technique utilizes a diffraction grating to disperse the light, allowing for wavelength determination based on the angular separation of the diffracted beams. While less precise than OSAs or wavelength meters, it’s a more readily available technique in some research settings.

- Fabry-Perot Interferometer: This interferometric technique provides a relatively simple way to measure wavelength, offering moderate accuracy. It’s often used for coarse measurements or for monitoring wavelength changes over time.

The choice of method depends on the required accuracy, availability of equipment, and the specific application. For high-precision applications such as telecommunications, OSAs or wavelength meters are preferred, whereas grating spectrometers or Fabry-Perot interferometers may suffice for less demanding applications.

Q 20. How do you assess the linearity of a laser diode’s modulation response?

Assessing the linearity of a laser diode’s modulation response is crucial for applications that require high-fidelity signal transmission, such as optical communication. This involves evaluating how accurately the optical output power follows the input modulation signal.

The assessment is usually done by modulating the laser diode with a sinusoidal signal at various frequencies and measuring the amplitude and phase of the resulting optical output. The linearity is evaluated by comparing the output waveform to the input waveform. Several metrics are used:

- Harmonic Distortion: Measures the presence of unwanted harmonic frequencies in the output signal. Lower harmonic distortion indicates better linearity.

- Intermodulation Distortion (IMD): Measures the distortion produced when two or more signals are simultaneously modulating the laser. This is especially important for multi-channel communication systems.

- Spurious-Free Dynamic Range (SFDR): This specifies the range of optical power over which the modulation response remains linear. A higher SFDR is desirable.

By measuring these parameters at different modulation frequencies and power levels, a comprehensive assessment of the laser diode’s linearity can be achieved. Nonlinearity can lead to signal distortion and reduced data transmission quality in applications like high-speed optical communication, impacting overall system performance.

Q 21. Explain the use of an optical power meter in laser diode characterization.

Optical power meters are essential tools for measuring the absolute optical power output of a laser diode. They are simple to use and provide a direct measurement of the emitted power in units like milliwatts (mW) or microwatts (µW).

In laser diode characterization, optical power meters are used for several purposes:

- Determining Absolute Power: Measuring the absolute optical power output at different injection currents is crucial for constructing the L-I curve and determining key parameters like threshold current and saturation power.

- Efficiency Measurement: The measured optical power, combined with the injected current, allows calculation of the EQE and DQE.

- Output Power Stability Analysis: By monitoring the output power over time, the stability and reliability of the laser diode can be assessed.

- Power Monitoring During Testing: Optical power meters are essential for monitoring power levels during different tests, ensuring the laser diode is operating within its safe limits.

For example, during the manufacturing process, optical power meters are extensively used to ensure that each laser diode meets its specified power output specifications. In research, power meters are indispensable for precisely measuring power levels during experiments involving laser diodes.

Q 22. Describe the principles behind laser diode testing using a spectrum analyzer.

A spectrum analyzer is crucial for characterizing the spectral properties of a laser diode. It measures the optical power distribution across different wavelengths, revealing key parameters like central wavelength, linewidth, and side-mode suppression ratio (SMSR). The principle is simple: light from the laser diode is coupled into the spectrum analyzer, which disperses the light based on wavelength using a diffraction grating. A detector then measures the intensity at each wavelength, generating a spectral profile displayed on a screen.

For example, we might use a spectrum analyzer to verify that a laser diode intended for telecommunications operates within the specified wavelength range (e.g., 1550 nm) and exhibits a narrow linewidth (e.g., <100 kHz) to minimize chromatic dispersion in fiber optic cables. A low SMSR, on the other hand, indicates unwanted modes that could degrade system performance.

Q 23. How do you determine the coherence length of a laser diode’s emission?

Coherence length describes the distance over which a laser’s light maintains a constant phase relationship. A long coherence length implies highly monochromatic light. We can determine it using interferometry, specifically a Michelson interferometer. In this setup, the laser light is split into two arms, one with a fixed path length and the other with a variable path length. The beams are then recombined, and the resulting interference pattern is measured as the path length difference is varied.

The visibility of the interference fringes gradually decreases as the path length difference increases. The coherence length is roughly defined as the path length difference at which the fringe visibility drops to approximately 1/e (about 37%) of its maximum value. Alternatively, we can analyze the spectral linewidth of the laser – a narrower linewidth generally correlates with a longer coherence length. The relationship is approximately given by: Coherence Length ≈ λ2 / Δλ, where λ is the central wavelength and Δλ is the linewidth.

Q 24. Explain the impact of aging on laser diode performance.

Aging significantly impacts laser diode performance. Several degradation mechanisms contribute, including:

- Catastrophic optical damage (COD): This refers to sudden failure due to overheating or high optical power.

- Gradual degradation: This involves a slow decrease in output power, an increase in threshold current, and a shift in wavelength. It’s often due to internal material degradation, such as defects in the active region, or facet degradation.

- Dark line defects (DLDs): These are non-radiative recombination centers that appear in the active region, causing a reduction in efficiency.

These effects reduce the laser’s lifespan and reliability. Careful thermal management and operational parameters are crucial in mitigating degradation. Regular monitoring of key parameters like output power, threshold current, and wavelength during operation helps in predicting and preventing premature failure.

Q 25. What are common noise sources affecting laser diode output?

Several noise sources can affect laser diode output:

- Shot noise: This is inherent to the quantum nature of light and arises from the random arrival of photons at the detector.

- Thermal noise: Fluctuations in temperature affect the refractive index of the laser cavity and hence the output power and wavelength.

- Relative Intensity Noise (RIN): Intensity fluctuations of the laser output, often expressed in dB/Hz.

- 1/f noise: This low-frequency noise is thought to originate from various mechanisms within the laser diode.

- Mode partition noise: In multimode lasers, fluctuations in the power distribution among different longitudinal modes contribute to noise.

Proper thermal control, stable bias current supplies, and careful selection of laser diodes with low RIN are strategies to minimize noise in applications like optical communication systems where noise is critical.

Q 26. How do you select the appropriate laser diode for a given application?

Selecting the appropriate laser diode involves considering several key factors:

- Wavelength: This depends on the application, e.g., 650 nm for red laser pointers, 1550 nm for optical communication.

- Output power: The required power level depends on the application’s needs, ranging from microwatts to watts.

- Beam quality (M2): This describes the divergence of the beam and is crucial for focusing and beam shaping. Lower M2 is desirable for applications requiring tight focusing.

- Spectral linewidth: A narrow linewidth is desirable for applications sensitive to coherence, like interferometry.

- Modulation bandwidth: For applications requiring fast modulation, such as optical communication, a high modulation bandwidth is needed.

- Cost and reliability: These are practical factors influencing the final choice.

For instance, a high-power, high-brightness laser diode might be suitable for material processing, while a low-power, narrow-linewidth laser might be better for spectroscopy.

Q 27. Describe your experience with different laser diode characterization equipment.

My experience encompasses a wide range of laser diode characterization equipment, including:

- Optical spectrum analyzers: Used extensively for measuring wavelength, linewidth, and side-mode suppression ratio.

- Power meters: Essential for measuring the absolute output power of the laser diode.

- Optical power meters with integrating spheres: For accurate measurements of total emitted optical power, even for highly divergent beams.

- Current-voltage (I-V) characterization systems: Used to determine the laser diode’s I-V curve and threshold current.

- Light-current (L-I) curves characterization systems: To determine the laser diode output power as a function of input current.

- Michelson interferometers: For measuring coherence length.

- Beam profilers: To characterize the laser beam’s spatial profile (e.g., beam diameter, shape, M2).

I am proficient in operating and interpreting data from these instruments, ensuring accurate and reliable characterization of laser diodes.

Q 28. Explain a time you encountered a challenging laser diode characterization problem and how you solved it.

I once encountered a situation where a newly designed laser diode exhibited significantly lower output power than expected. Initial tests showed a surprisingly high threshold current. We suspected a problem with the fabrication process affecting the active region.

To troubleshoot, we systematically investigated various aspects:

- Microscopic inspection: Revealed the presence of dark-line defects in the active region of some diodes.

- Detailed electrical measurements: Confirmed higher than normal series resistance in affected devices.

- Spectral analysis: Showed broadened linewidth and a reduced side-mode suppression ratio in the faulty lasers.

We concluded that defects introduced during the epitaxial growth process were responsible for the poor performance. By optimizing the growth parameters and implementing stricter quality control, we were able to significantly improve the yield and performance of subsequent laser diode batches.

Key Topics to Learn for Laser Diode Characterization Interview

- Device Physics: Understanding the underlying principles of laser diode operation, including spontaneous and stimulated emission, population inversion, and gain mechanisms. Consider exploring different types of laser diodes (e.g., Fabry-Perot, DFB).

- Optical Characterization: Mastering techniques for measuring key parameters such as output power, wavelength, spectral linewidth, beam profile, and beam divergence. Think about the equipment used and data analysis methods.

- Electrical Characterization: Familiarize yourself with measuring current-voltage (I-V) characteristics, threshold current, and the effects of temperature on device performance. Understand the importance of these measurements in device optimization.

- Temperature Dependence: Analyzing how temperature impacts laser diode performance, including shifts in wavelength and changes in output power. This is crucial for real-world applications.

- Reliability and Degradation: Understanding the factors contributing to laser diode degradation and lifetime limitations. Consider aging mechanisms and techniques for reliability testing.

- Practical Applications: Explore the diverse applications of laser diodes, such as optical communication, sensing, laser scanning, and material processing. Being able to relate your theoretical knowledge to real-world applications demonstrates a deeper understanding.

- Problem-Solving: Practice interpreting experimental data, identifying potential issues based on characterization results, and proposing solutions to optimize laser diode performance. This is often the focus of technical interviews.

Next Steps

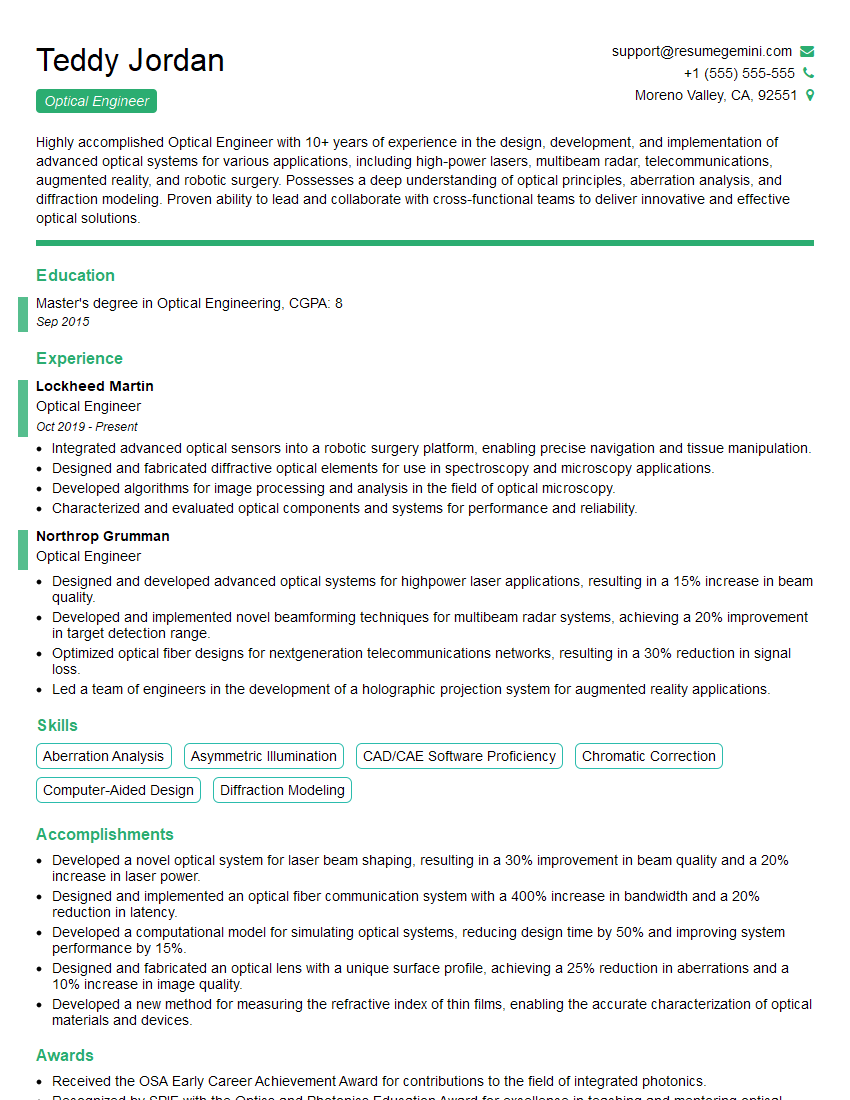

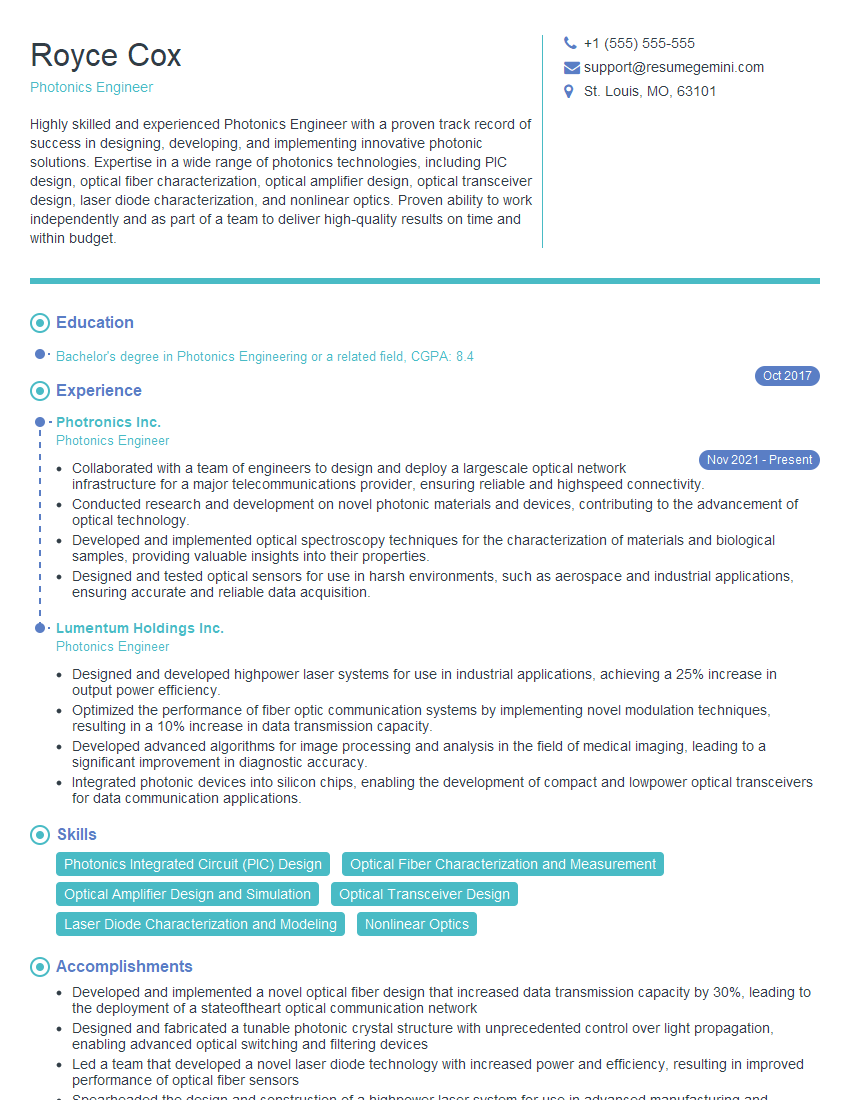

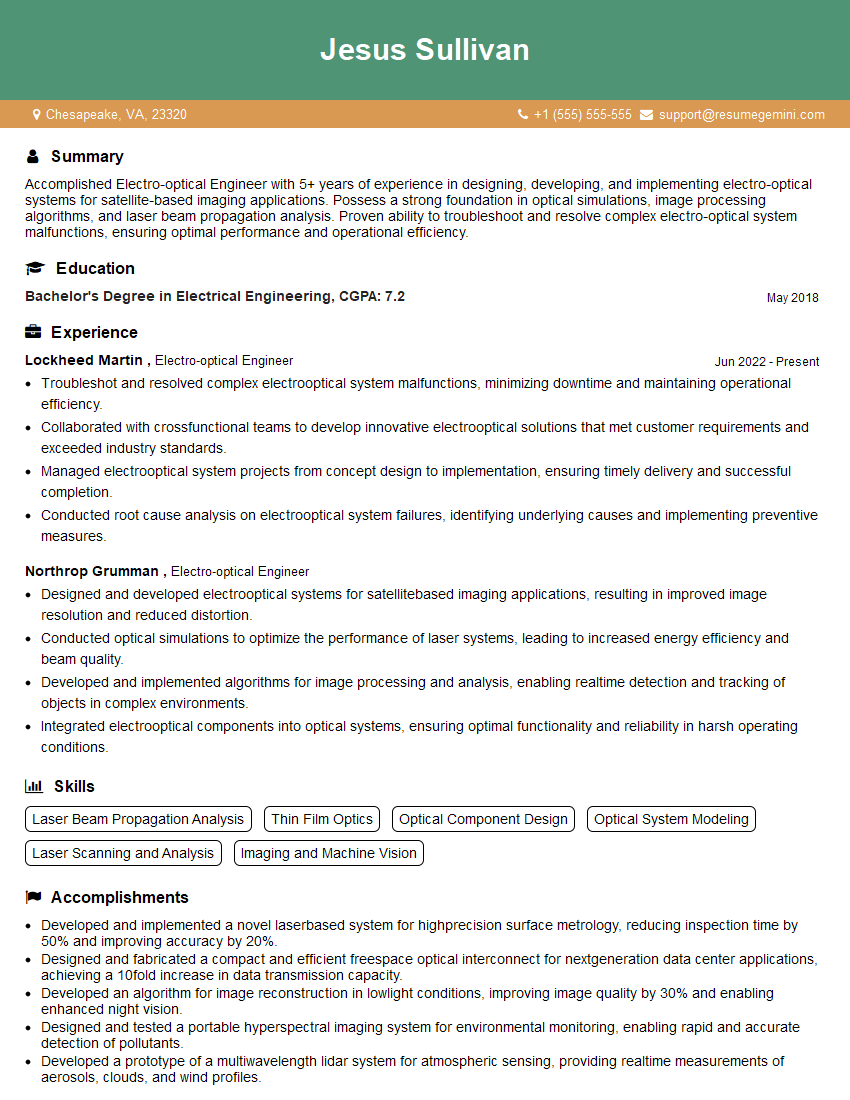

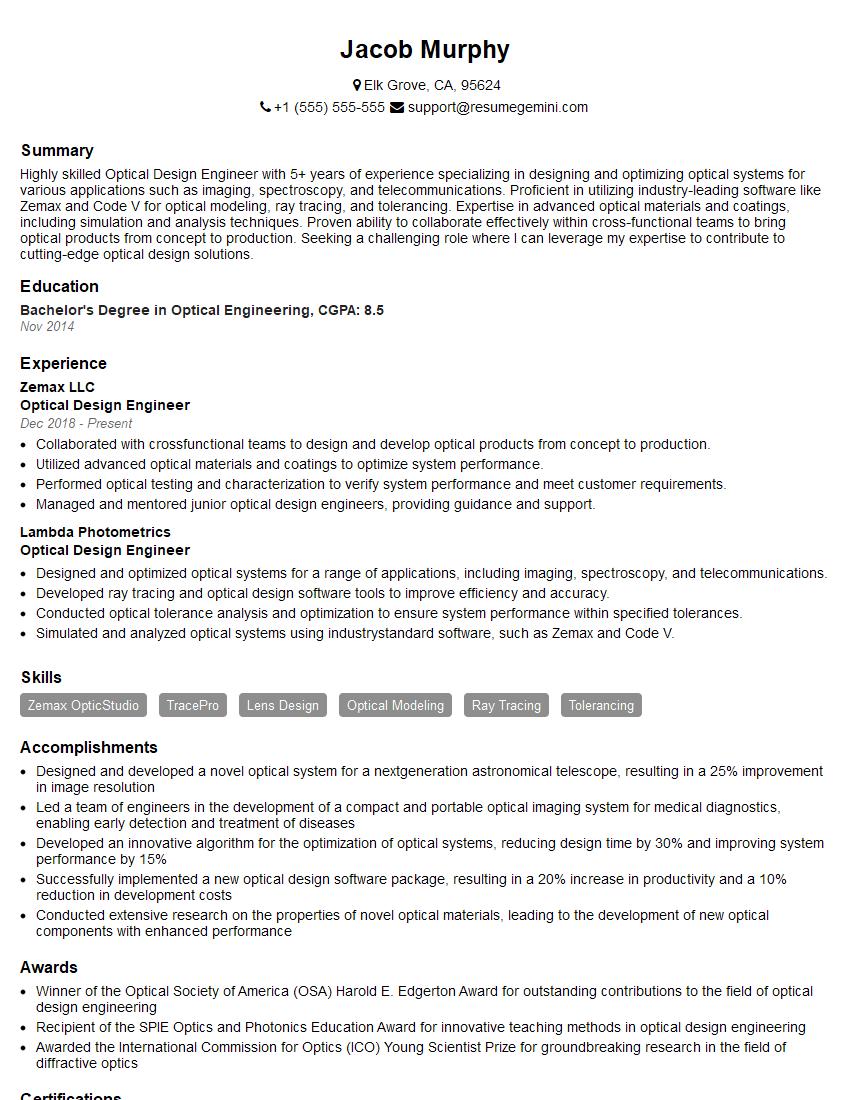

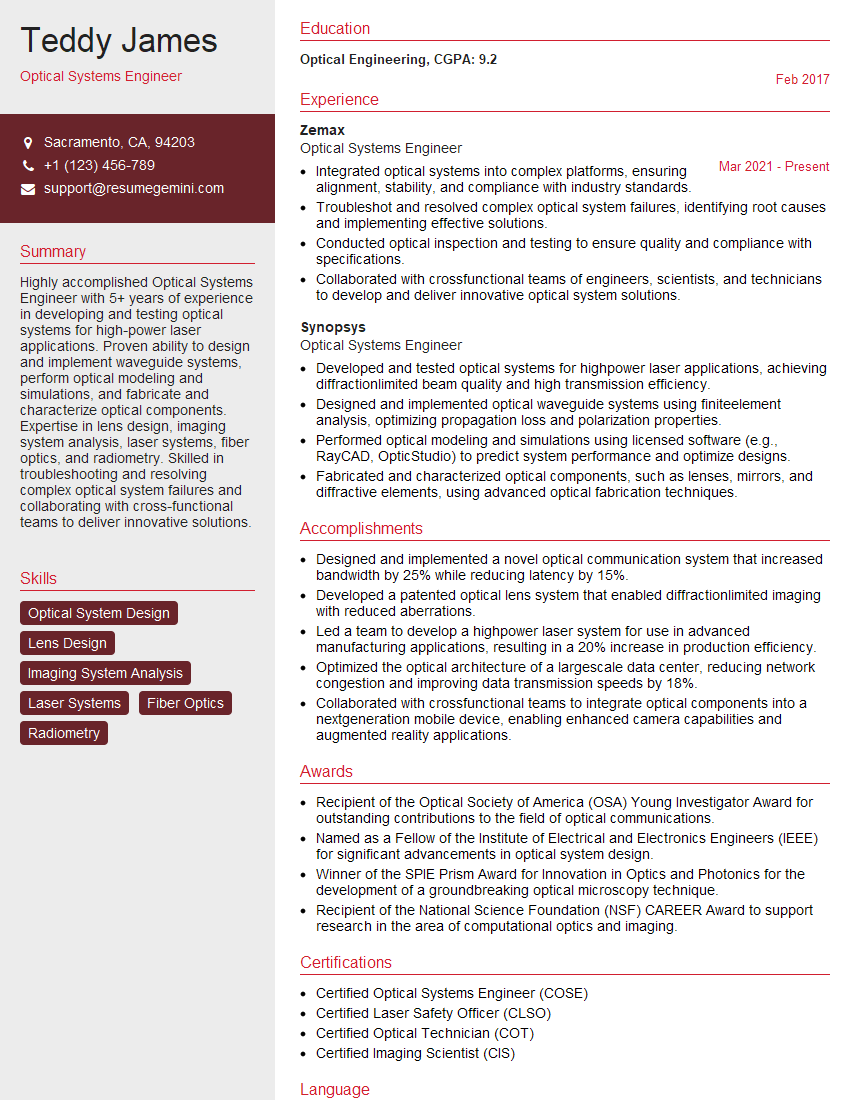

Mastering laser diode characterization is essential for career advancement in photonics, optoelectronics, and related fields. A strong understanding of these concepts opens doors to exciting roles in research, development, and manufacturing. To significantly boost your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you craft a professional and effective resume tailored to highlight your skills and experience in laser diode characterization. Examples of resumes tailored to this specific field are available to further guide your resume-building process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good