Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Sensor Calibration and Operation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Sensor Calibration and Operation Interview

Q 1. Explain the difference between accuracy and precision in sensor calibration.

Accuracy and precision are crucial concepts in sensor calibration, often confused but distinct. Accuracy refers to how close a measurement is to the true value. Think of it like hitting the bullseye on a dartboard – a highly accurate measurement consistently lands near the center. Precision, on the other hand, describes the reproducibility of measurements. It’s how close repeated measurements are to each other, regardless of their proximity to the true value. Imagine several darts clustered tightly together, but off-center – that’s high precision, but low accuracy. A sensor might be highly precise (giving consistent readings), but inaccurate if it’s not properly calibrated to the true value. For example, a pressure sensor consistently reading 10 PSI higher than the actual pressure is precise but inaccurate. Conversely, a sensor giving wildly different readings around the true value is inaccurate and imprecise.

Q 2. Describe the various types of sensor calibration methods.

Several methods exist for calibrating sensors, each with its own advantages and disadvantages. The choice depends on the sensor type, required accuracy, and available resources. Common methods include:

- Two-Point Calibration: This simple method uses two known reference points to create a linear relationship between the sensor’s output and the actual value. It’s quick and easy but less accurate for non-linear sensors.

- Multi-Point Calibration: More accurate than two-point calibration, this method uses multiple reference points across the sensor’s operating range to establish a more comprehensive calibration curve, accounting for non-linearities.

- Comparison Calibration: This involves comparing the sensor’s output to a known standard, high-accuracy sensor. The difference between the readings provides the calibration correction.

- In-situ Calibration: Calibration is performed in the sensor’s actual operating environment. This is particularly useful for sensors where environmental factors significantly impact performance, but it requires careful control of the environment.

- Factory Calibration: This is a calibration done by the manufacturer before the sensor leaves the factory and is often sufficient for many applications. However, it might need recalibration after prolonged use or exposure to harsh conditions.

Q 3. What are the common sources of error in sensor measurements?

Sensor measurements are susceptible to various error sources. These can be broadly classified as:

- Systematic Errors: These are consistent and repeatable errors that affect all measurements in a predictable way. Examples include sensor drift (gradual change in output over time), offset (constant difference between measured and actual values), and non-linearity (deviation from a straight-line relationship).

- Random Errors: These are unpredictable and vary randomly from measurement to measurement. Sources include electronic noise, thermal fluctuations, and variations in the measured quantity itself.

- Environmental Errors: External factors such as temperature, humidity, pressure, and electromagnetic interference can significantly impact sensor readings. For example, a temperature sensor’s readings can be affected by the ambient temperature if not properly compensated.

- Human Errors: Mistakes during measurement, calibration, or data handling contribute to errors. Proper training and standardized procedures help to mitigate these errors. Example: Incorrectly connecting the sensor.

Q 4. How do you select appropriate calibration standards?

Selecting appropriate calibration standards is crucial for accurate calibration. The standards must be traceable to national or international standards, have known uncertainties smaller than the sensor’s required accuracy, and be suitable for the sensor’s operating range and type. For example, calibrating a pressure sensor would require a pressure standard with a known accuracy and range appropriate for the pressure sensor’s application. Consider the following factors:

- Accuracy and Uncertainty: The standard’s accuracy should be significantly higher than the sensor being calibrated.

- Traceability: The standard should be traceable to a nationally or internationally recognized standards body.

- Stability: The standard should maintain its accuracy over time.

- Suitability: The standard should be compatible with the sensor’s type and operating range.

Selecting the wrong standards can lead to inaccurate calibration and unreliable sensor data.

Q 5. Explain the process of traceability in sensor calibration.

Traceability in sensor calibration refers to the unbroken chain of comparisons that link a sensor’s calibration to a recognized national or international standard. This ensures that the calibration is reliable and comparable across different laboratories and organizations. The chain typically begins with a national metrology institute (NMI) that maintains primary standards. These are then used to calibrate secondary standards, which are then used to calibrate working standards, and finally, the sensor itself. Each step in the chain includes uncertainty analysis, ensuring that the uncertainty associated with the sensor’s calibration can be determined. Documentation of each step in this chain is vital for demonstrating traceability.

Imagine a family tree. The NMI is the great-grandparent, the secondary standard is the grandparent, the working standard is the parent, and the sensor is the child. Each generation inherits accuracy from the previous one, documented through calibration certificates.

Q 6. What are the key performance indicators (KPIs) for a sensor calibration lab?

Key Performance Indicators (KPIs) for a sensor calibration lab help evaluate its efficiency and effectiveness. Some important KPIs include:

- Calibration turnaround time: The time taken to calibrate a sensor.

- Accuracy of calibration: How close the calibration results are to the true values.

- Uncertainty of measurement: The range within which the true value is expected to lie.

- Customer satisfaction: Measured through surveys or feedback.

- Equipment downtime: Time when calibration equipment is not operational.

- Calibration backlog: Number of sensors awaiting calibration.

- Compliance with standards: Adherence to relevant accreditation standards (e.g., ISO/IEC 17025).

Regular monitoring and analysis of these KPIs are essential for continuous improvement.

Q 7. How do you handle outliers in calibration data?

Outliers in calibration data represent measurements significantly deviating from the overall pattern. Handling them requires careful consideration. Simply discarding them without investigation is risky. Several approaches can be taken:

- Identify the cause: Investigate potential sources of error, such as sensor malfunction, environmental factors, or data entry mistakes. For example, a sudden power surge might cause an outlier in electrical measurements.

- Statistical analysis: Apply statistical tests like the Grubbs’ test to determine if an outlier is statistically significant. This helps make an objective decision about its inclusion or exclusion.

- Visual inspection: A scatter plot of the calibration data can reveal outliers visually. This helps identify potential problems.

- Data transformation: In some cases, data transformation (e.g., logarithmic transformation) can reduce the influence of outliers.

- Robust regression: Methods like robust regression are less sensitive to outliers than ordinary least squares regression.

Documenting the handling of outliers and the justification for any decisions is crucial for maintaining data integrity and traceability.

Q 8. Describe your experience with different types of sensors (e.g., temperature, pressure, flow).

My experience encompasses a wide range of sensors, from basic temperature and pressure sensors to more complex flow meters and specialized analytical sensors. For instance, I’ve extensively worked with thermocouples and RTDs for temperature measurement, understanding their different characteristics and sensitivities. With pressure sensors, I’ve handled both absolute and gauge pressure transducers, using various technologies like piezoresistive and capacitive sensing. In flow measurement, I’ve worked with both volumetric and mass flow meters, including ultrasonic and Coriolis flow meters, each requiring specific calibration techniques. This experience gives me a solid understanding of the nuances of each sensor type, enabling me to select appropriate calibration methods and ensure accurate measurement.

- Temperature Sensors: Thermocouples (Type K, J, T), RTDs (Platinum, Nickel), Thermistors

- Pressure Sensors: Piezoresistive, Capacitive, Strain Gauge based, Absolute, Gauge

- Flow Sensors: Ultrasonic, Coriolis, Turbine, Vortex shedding, Differential Pressure

Q 9. Explain the concept of sensor drift and how to mitigate it.

Sensor drift refers to the gradual change in a sensor’s output over time, even under constant input conditions. Imagine a bathroom scale that consistently reads a few pounds heavier each week, even if your weight remains the same – that’s drift. This can stem from various factors, such as temperature fluctuations, component aging, or mechanical wear. Mitigation strategies include:

- Regular Calibration: Frequent calibration against traceable standards is crucial to correct for drift and maintain accuracy. The frequency depends on the sensor type and application.

- Temperature Compensation: Employing temperature sensors alongside the main sensor and using algorithms to correct for temperature-induced drift.

- Stable Operating Conditions: Maintaining a constant operating temperature and minimizing vibration or shock reduces drift.

- High-Quality Components: Using sensors from reputable manufacturers with good stability characteristics.

- Proper Installation: Correct mounting and wiring techniques help avoid induced errors.

For example, in a process control application where a temperature sensor monitors a critical reaction, uncorrected drift could lead to faulty readings, potentially causing safety hazards or product defects. Regular calibration with temperature compensation significantly reduces this risk.

Q 10. How do you determine the calibration interval for a sensor?

Determining the calibration interval requires a careful consideration of several factors:

- Sensor Type and Stability: Some sensors are inherently more stable than others. A high-precision sensor might require less frequent calibration.

- Application Criticality: For critical applications (e.g., safety systems, medical devices), shorter calibration intervals are needed to ensure high reliability.

- Environmental Conditions: Harsh environments (high temperature, vibration) can accelerate drift, necessitating more frequent calibration.

- Historical Data: Analyzing past calibration data can reveal drift patterns and help determine a suitable interval.

- Regulatory Requirements: Industry regulations or standards might mandate specific calibration frequencies.

Often, a combination of these factors is used. For instance, a temperature sensor in a laboratory setting with moderate temperature variation might be calibrated annually, while a pressure sensor in an oil refinery might need monthly calibration due to the harsh environment.

Q 11. What are the safety precautions you take during sensor calibration?

Safety during sensor calibration is paramount. My approach includes:

- Lockout/Tagout Procedures: Ensuring that the equipment is isolated and de-energized before any calibration activities begin, preventing accidental activation.

- Personal Protective Equipment (PPE): Wearing appropriate PPE, such as safety glasses, gloves, and protective clothing, depending on the hazards associated with the sensor and its environment.

- Calibration in a Controlled Environment: Performing calibrations in a clean, well-ventilated area to minimize exposure to hazardous substances or conditions.

- Proper Handling of Calibration Equipment: Handling calibration equipment carefully to prevent damage or injury.

- Following Manufacturer’s Instructions: Adhering strictly to the manufacturer’s instructions for both the sensor and the calibration equipment.

For example, when calibrating a pressure sensor in a high-pressure system, I would ensure the system is completely depressurized before accessing the sensor and follow strict lockout/tagout procedures.

Q 12. Describe your experience with calibration software and data management systems.

I have extensive experience with various calibration software packages and data management systems. This includes software for automated calibration, data acquisition, and report generation. I’m proficient in using software to control calibration equipment, collect data, and analyze results. My experience with data management systems allows me to track calibration history, generate certificates of calibration, and manage sensor records effectively. This ensures traceability and compliance with regulatory requirements. I am familiar with both dedicated calibration software and integrating calibration data into larger enterprise resource planning (ERP) systems. For example, I’ve used Fluke Calibration software for various calibration tasks and have also integrated calibration data into a company’s CMMS (Computerized Maintenance Management System) for better asset tracking.

Q 13. How do you troubleshoot sensor calibration problems?

Troubleshooting sensor calibration problems involves a systematic approach:

- Verify Calibration Equipment: Ensure that the calibration equipment is functioning correctly and is properly calibrated itself.

- Check Wiring and Connections: Inspect all wiring and connections for faults, loose connections, or shorts.

- Inspect Sensor for Physical Damage: Look for any signs of physical damage to the sensor, such as cracks or corrosion.

- Review Calibration Procedure: Verify that the calibration procedure is being followed correctly.

- Analyze Calibration Data: Examine the calibration data for patterns or anomalies that may indicate a problem.

- Consider Environmental Factors: Check for environmental conditions that may be affecting the sensor’s performance.

For example, if a temperature sensor consistently reads low, I would first check the calibration equipment, then inspect the sensor’s wiring and for physical damage, and finally consider if the sensor is exposed to external heat sources affecting its readings.

Q 14. Explain the importance of calibration certificates and documentation.

Calibration certificates and documentation are crucial for several reasons:

- Traceability: They provide a traceable record of the calibration, demonstrating that the sensor meets specified accuracy requirements. This is especially important in regulated industries.

- Compliance: Calibration certificates demonstrate compliance with industry standards and regulations, avoiding potential penalties.

- Quality Assurance: They are essential for ensuring the quality and reliability of measurements and the products or processes they support.

- Legal Protection: Proper documentation protects organizations against legal liabilities arising from inaccurate measurements.

- Maintenance Records: Calibration records form part of the overall sensor maintenance history, aiding predictive maintenance strategies.

Without proper documentation, you have no proof that a sensor is operating within its specified tolerances, potentially compromising the validity of your measurements and potentially causing serious problems. For instance, in a pharmaceutical setting, this could affect the potency of medications, causing severe health consequences.

Q 15. What are the regulatory requirements for sensor calibration in your industry?

Regulatory requirements for sensor calibration vary significantly depending on the industry and the application. In industries like pharmaceuticals, aerospace, and medical device manufacturing, adherence to stringent standards like ISO 9001, ISO 17025, and GMP (Good Manufacturing Practices) is mandatory. These standards dictate the frequency of calibration, the traceability of calibration standards, record-keeping procedures, and the qualifications of personnel performing calibrations. For example, a pharmaceutical company producing drug delivery devices would need to follow strict guidelines for calibrating pressure sensors to ensure dosage accuracy, often involving periodic audits by regulatory bodies. Failure to comply can result in significant penalties, product recalls, and damage to reputation.

In other industries, regulations might be less formal, but best practices are still crucial. Think of environmental monitoring—calibration of air quality sensors needs to meet EPA (Environmental Protection Agency) guidelines, ensuring the accuracy of pollution readings. The common thread is the need for documented procedures and a traceable chain of custody for all calibration equipment and standards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy and reliability of calibration equipment?

Maintaining the accuracy and reliability of calibration equipment is paramount. We achieve this through a multi-pronged approach. Firstly, all our equipment undergoes regular calibration itself, using traceable standards from a nationally recognized metrology institute (NMI). This establishes a chain of traceability, linking our measurements back to fundamental SI units. We also employ a robust preventative maintenance program, including regular cleaning, inspection, and adjustment of the equipment, according to the manufacturer’s recommendations. This extends to rigorous environmental controls—our calibration lab maintains stable temperature and humidity conditions, minimizing drift and ensuring consistent performance.

Furthermore, we utilize statistical process control (SPC) to monitor the performance of our equipment over time. Any deviations from expected behavior are investigated, and corrective actions are taken promptly. For instance, if the standard deviation of measurements taken with a specific piece of equipment increases significantly, we would conduct a thorough investigation to determine the root cause, potentially involving recalibration or even replacement of the faulty equipment. Finally, we regularly conduct inter-laboratory comparisons with other accredited labs to validate the accuracy of our calibration procedures and the reliability of our equipment.

Q 17. Describe your experience with statistical process control (SPC) in calibration.

Statistical Process Control (SPC) is integral to our calibration process. We use control charts, such as X-bar and R charts, to monitor the performance of our calibration equipment and the consistency of our calibration procedures. For example, we might track the measurements obtained from a standard weight during repeated calibrations. The control chart helps us visually detect any trends or shifts indicating potential problems. Any point falling outside the control limits triggers an investigation—is the equipment malfunctioning? Is there a procedural error? Are the standards degrading?

SPC allows for proactive identification of problems before they significantly impact the accuracy of calibrations. It facilitates data-driven decision-making, improving the overall efficiency and effectiveness of our calibration process. Beyond control charts, we also utilize capability analysis to determine the precision and accuracy of our calibration procedures, ensuring they meet the required specifications.

Q 18. Explain your understanding of uncertainty analysis in sensor calibration.

Uncertainty analysis is crucial in sensor calibration; it quantifies the doubt associated with a measurement result. It’s not just about stating a value but also specifying how confident we are in that value. Uncertainty arises from various sources, including the resolution of the measuring instrument, the accuracy of the calibration standards, environmental factors (temperature, humidity), and the operator’s skill. We use a combination of Type A (statistical) and Type B (non-statistical) evaluations to estimate uncertainty.

Type A involves statistical analysis of repeated measurements, while Type B involves using engineering knowledge, manufacturer specifications, and other sources to estimate uncertainty components. All these components are combined using appropriate methods, often employing the root-sum-of-squares approach, to arrive at an overall combined standard uncertainty. This is then expressed as a confidence interval around the measured value. For example, a pressure sensor might be calibrated to 100 kPa ± 0.5 kPa (k=2), indicating a 95% confidence level that the true value lies within this range. Proper uncertainty analysis is essential for demonstrating the reliability and credibility of our calibration results.

Q 19. How do you validate the accuracy of a sensor calibration?

Validating the accuracy of a sensor calibration involves several steps. First, we compare the calibrated sensor’s readings against those of a traceable standard. This can involve comparing the sensor’s output to a known value at multiple points across the sensor’s operating range. A significant deviation from the expected value raises concerns about the calibration’s validity.

Second, we may use independent verification methods. For instance, if calibrating a temperature sensor, we could use a second, independently calibrated sensor to check its readings at various points. Third, we review the entire calibration process, checking for any procedural errors or inconsistencies that might have affected the results. Finally, all data, including uncertainty analysis and validation results, are documented and archived, ensuring traceability and compliance with relevant regulations.

Q 20. What are the different types of calibration standards available?

Calibration standards are crucial for ensuring traceability. They range from primary standards, which are directly linked to fundamental SI units and maintained by national metrology institutes, to secondary and working standards. Primary standards are exceptionally accurate and are used to calibrate secondary standards, which are then used to calibrate working standards used in daily operations.

The type of standard used depends on the application and the required accuracy. Examples include: precision weight sets for force calibration, precision thermometers for temperature calibration, high-accuracy voltage and current sources for electrical measurements, and certified reference materials for chemical analysis. Proper selection and handling of these standards are critical to minimizing uncertainty and maintaining calibration accuracy.

Q 21. Describe your experience with different calibration techniques (e.g., linearization, curve fitting).

Linearization and curve fitting are common calibration techniques used to compensate for non-linear sensor behavior. Many sensors don’t produce a perfectly linear output; their response might be curved or exhibit hysteresis. Linearization aims to create a linear relationship between the sensor’s input and output, simplifying data processing and interpretation. This often involves using a linear approximation of the sensor’s response curve within a specific range. For instance, a simple linear equation (y = mx + c) might be sufficient if the non-linearity is minor.

Curve fitting employs more sophisticated mathematical models, such as polynomial or exponential functions, to better represent the sensor’s non-linear response across its entire operating range. Software packages are commonly used for curve fitting, allowing us to determine the best-fit model and associated coefficients. The chosen model depends on the characteristics of the sensor and the required level of accuracy. Careful consideration of statistical parameters such as R-squared is vital to ensuring a good fit and minimizing errors. Proper documentation of the chosen calibration curve is crucial for traceability and accurate data interpretation.

Q 22. How do you handle sensor calibration in a hazardous environment?

Sensor calibration in hazardous environments demands meticulous planning and adherence to stringent safety protocols. It’s not just about the calibration procedure itself; it’s about ensuring the safety of the personnel involved.

My approach involves a multi-step process. First, a thorough risk assessment identifies potential hazards—explosive atmospheres, high temperatures, radiation, etc. This dictates the choice of equipment and methodologies. For example, intrinsically safe instruments are crucial in explosive environments. We might use remote calibration systems, minimizing direct human interaction with hazardous materials.

Next, we develop detailed Standard Operating Procedures (SOPs) that cover every aspect, from equipment preparation and calibration execution to emergency response plans. This includes specifying the use of appropriate Personal Protective Equipment (PPE) and following lockout/tagout procedures for isolating equipment. Regular training and drills reinforce safety protocols.

Finally, meticulous record-keeping is essential. Calibration data, along with a complete log of safety measures taken, becomes part of the permanent record, ensuring traceability and demonstrating compliance. For instance, in a nuclear power plant setting, this documentation is crucial for regulatory compliance.

Q 23. How do you manage calibration schedules and ensure timely calibration of sensors?

Managing calibration schedules is akin to orchestrating a complex symphony, where each sensor is an instrument requiring timely attention. We leverage a combination of methods to ensure on-time calibration. A computerized maintenance management system (CMMS) plays a critical role. It allows us to input sensor specifications, including recommended calibration intervals (often dictated by manufacturer recommendations or industry standards), and automatically generates schedules and alerts.

These schedules are not static; they’re dynamically adjusted based on sensor usage, environmental conditions, and observed performance. For instance, a sensor operating in a harsh, fluctuating environment might require more frequent calibration than one in a stable setting. We also build in buffer time to account for unforeseen delays.

Beyond the CMMS, regular reviews of calibration data help identify trends and potential issues. A sudden drift in sensor readings, for example, might signal the need for earlier than scheduled calibration. This proactive approach prevents costly downtime and ensures continuous, accurate data acquisition.

Q 24. What is your experience with automated calibration systems?

My experience with automated calibration systems spans several years, primarily focusing on systems designed for high-throughput environments. These systems offer significant advantages in terms of efficiency, repeatability, and reduced human error. I’ve worked with systems that incorporate robotic arms for precise sensor handling, automated data acquisition, and sophisticated software for analysis and report generation.

The advantages are compelling: automated systems substantially reduce calibration time, especially when dealing with a large number of sensors. The consistency of the automated process minimizes human variability, leading to more reliable and repeatable calibration results. Furthermore, automated systems often incorporate built-in diagnostics and error checking, further reducing errors.

However, there are also challenges. Initial setup and investment costs can be significant. Moreover, the adaptability of these systems varies; they may not be suitable for all sensor types or calibration methods. Proper training is vital for effective operation and maintenance of these sophisticated systems.

Q 25. Explain your understanding of sensor linearity and hysteresis.

Sensor linearity refers to the sensor’s ability to produce an output signal that is directly proportional to the measured input. Ideally, a linear sensor exhibits a straight-line relationship between input and output. Think of it like a perfectly balanced seesaw; the higher the weight on one side, the higher the other side rises in direct proportion.

Hysteresis, on the other hand, represents the difference in output for the same input value depending on whether the input is increasing or decreasing. Imagine stretching a rubber band; it doesn’t retract to its original length immediately when you release it. This lag in returning to the original position is analogous to hysteresis.

In practice, perfect linearity is rare. Deviations from linearity can be characterized and compensated for through calibration procedures. Understanding hysteresis is crucial; neglecting it can lead to significant errors, especially in dynamic measurements. We often use calibration curves to account for both non-linearity and hysteresis to correct sensor readings.

Q 26. How do you ensure the integrity of calibration data throughout its lifecycle?

Maintaining calibration data integrity is paramount; inaccurate or compromised data renders the entire calibration process useless. This begins with using a robust data management system that ensures data traceability and prevents unauthorized modification. We utilize secure databases and version control systems to manage calibration records. Each calibration event generates a unique identifier, linking it to the sensor, the calibration equipment, and the technician involved.

Data security is also a significant concern. Access to the database is controlled through role-based permissions, restricting access to authorized personnel only. Regular backups of the database are performed to safeguard against data loss. Data integrity is further ensured through regular audits and validation processes. These audits check for discrepancies, confirming the accuracy and reliability of the calibration data.

Finally, a comprehensive audit trail documents all changes made to the database, providing accountability and facilitating error tracing if required. This robust system ensures that calibration data maintains its integrity throughout its lifecycle, from acquisition to archiving.

Q 27. Describe your experience with different types of calibration reports.

My experience encompasses various calibration report types, each tailored to specific needs and regulatory requirements. A simple report might include basic information like sensor ID, calibration date, and key parameters like offset and gain. More comprehensive reports, often required by regulatory bodies, may include detailed statistical analysis, including linearity and hysteresis data, as well as a full traceability chain documenting all equipment and personnel involved.

Some reports are generated automatically by automated calibration systems, while others require manual input and analysis. For instance, in a pharmaceutical manufacturing environment, calibration reports must conform to strict Good Manufacturing Practices (GMP) guidelines, detailing every aspect of the process and providing complete traceability for compliance purposes.

I’m also familiar with electronic report formats like PDF, allowing for easy storage and distribution. Electronic formats provide benefits such as searchable databases and improved accessibility, enhancing the overall efficiency and streamlining the management of calibration records.

Q 28. What are your strategies for continuous improvement in sensor calibration processes?

Continuous improvement in sensor calibration processes is a journey, not a destination. My strategies focus on several key areas. First, regular performance reviews are crucial. Analyzing calibration data helps identify trends, potential issues, and opportunities for optimization. For example, consistently high error rates with a specific sensor type might signal the need for improved calibration techniques or the selection of more suitable sensors.

Secondly, we actively seek feedback from technicians involved in the calibration process. Their firsthand experience often reveals areas for improvement that might otherwise be missed. This could be as simple as suggesting a more ergonomic workflow or as significant as identifying weaknesses in the existing procedures.

Finally, staying current with advancements in sensor technology and calibration methodologies is crucial. Attending conferences, participating in professional development programs, and reviewing industry best practices help ensure that our processes remain state-of-the-art and efficient. The ultimate goal is to optimize accuracy, reduce downtime, and ensure compliance while consistently improving the overall efficiency and reliability of our calibration operations.

Key Topics to Learn for Sensor Calibration and Operation Interview

- Understanding Sensor Principles: Explore the fundamental physics behind various sensor types (e.g., capacitive, resistive, optical) and their operating principles. This includes understanding accuracy, precision, and resolution.

- Calibration Techniques: Master different calibration methods, including two-point, multi-point, and linearization techniques. Understand the importance of traceability and standard operating procedures.

- Error Analysis and Compensation: Learn to identify and analyze various sources of error (e.g., systematic, random) in sensor readings. Understand methods for compensating for these errors to improve accuracy.

- Data Acquisition and Processing: Familiarize yourself with data acquisition systems and signal processing techniques used in conjunction with sensors. This includes filtering, averaging, and data logging.

- Sensor Selection and Application: Understand the criteria for selecting appropriate sensors for specific applications, considering factors like environmental conditions, required accuracy, and cost.

- Troubleshooting and Maintenance: Develop problem-solving skills to diagnose and resolve common issues related to sensor malfunction, calibration drift, and signal noise. Understand preventative maintenance procedures.

- Safety Procedures: Become familiar with safety protocols and best practices related to handling and operating sensors, especially in potentially hazardous environments.

- Instrumentation and Measurement Systems: Understand how sensors integrate within larger instrumentation and measurement systems, including data communication protocols and interfaces.

Next Steps

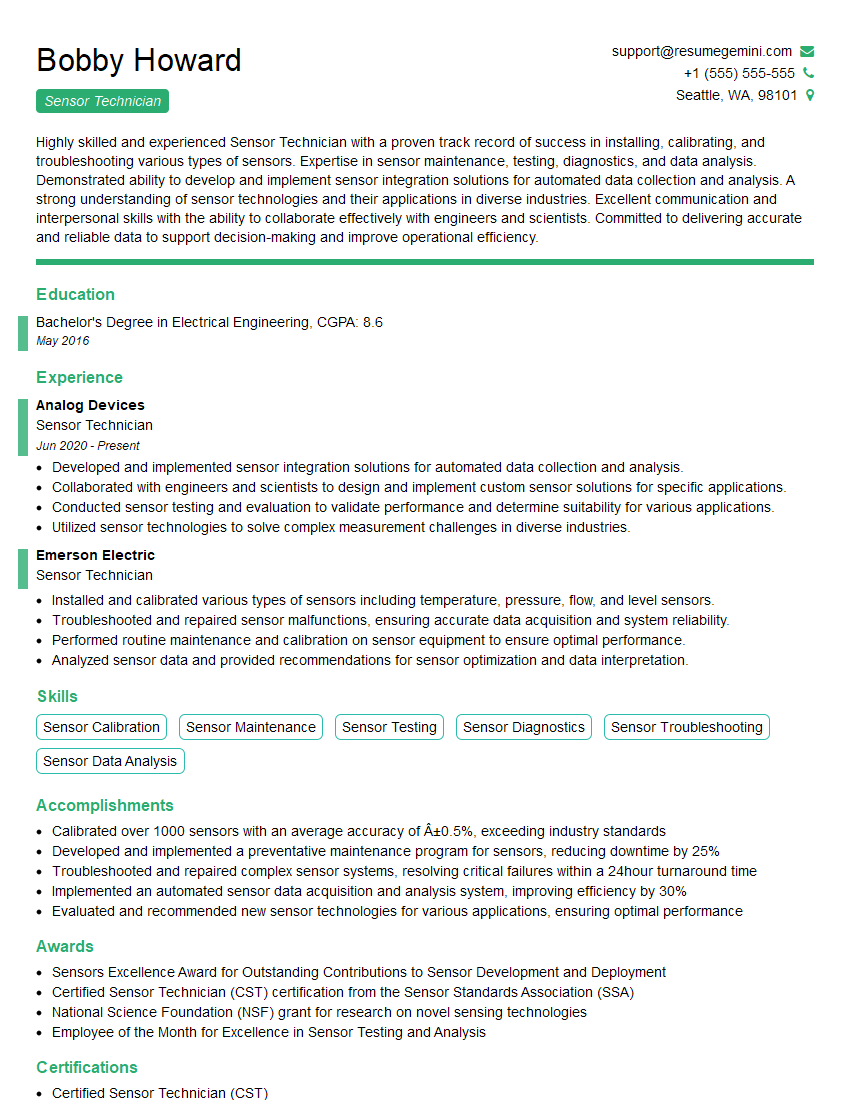

Mastering Sensor Calibration and Operation opens doors to exciting career opportunities in various industries, offering excellent growth potential and specialized expertise. To maximize your job prospects, it’s crucial to present your skills effectively. Crafting an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your qualifications shine. Examples of resumes tailored to Sensor Calibration and Operation are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good