Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Lift and Carry interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Lift and Carry Interview

Q 1. Describe your experience with various lifting techniques (e.g., proper lifting posture, using equipment).

My experience encompasses a wide range of lifting techniques, prioritizing safety and efficiency. I’m proficient in various methods, adapting my approach based on the object’s weight, shape, and the environment. Proper lifting posture is paramount; this involves maintaining a neutral spine, bending at the knees and hips, keeping the load close to the body, and using leg muscles to lift, not the back. I’ve extensively used equipment like pallet jacks, hand trucks, and lifting straps to safely handle heavy or awkward loads. For instance, when moving heavy boxes, I use a hand truck to distribute the weight and reduce strain. When lifting large or unwieldy objects, I use lifting straps to secure a balanced grip and distribute the weight evenly.

- Proper Lifting Posture: Feet shoulder-width apart, bend at knees and hips, keep back straight, grip firmly, lift smoothly using leg muscles.

- Equipment Usage: Pallet jacks for large, heavy pallets; hand trucks for boxes or other stackable items; lifting straps for awkward or irregularly shaped loads; cranes or forklifts for extremely heavy or inaccessible items.

Q 2. What is your maximum weight capacity for lifting?

My maximum weight capacity for lifting is 50kg (110 lbs) without the use of mechanical assistance. This is based on my physical capabilities and training to prevent injury. It’s crucial to remember that this is a guideline, and I would always assess the situation and potentially use equipment or request assistance if the weight exceeds my comfortable lifting limit or if there are other risk factors involved, like awkward shapes or uneven surfaces.

Q 3. How do you assess the weight of an object before lifting?

Assessing the weight of an object before lifting is critical for safety. I employ a multi-faceted approach: I visually inspect the object’s size and materials, considering its density. If possible, I try to feel the weight by gently pushing or tilting the object. If there’s no indication of weight, I ask for the weight of the object or check for a weight label. If all else fails, I’ll err on the side of caution and estimate it as heavier than I think to prevent injury.

- Visual Inspection: Size, material, and general construction give an initial indication of weight.

- Physical Assessment: A gentle push or tilt can provide a sense of the object’s weight.

- Weight Labels and Documentation: Check for weight indicated on boxes or in shipping documents.

- Seeking Clarification: If uncertain, seek confirmation from others involved.

Q 4. Explain your understanding of ergonomic principles in lifting and carrying.

Ergonomic principles are central to safe lifting and carrying. They focus on minimizing physical strain and risk of injury by optimizing the work environment and techniques. This involves maintaining a neutral spine during lifting, keeping the load close to the body, avoiding twisting or reaching, and ensuring a stable base of support. Understanding the human body’s biomechanics is critical in this context. For example, lifting with a bent back puts significant strain on the spine, increasing the risk of back injury. In contrast, using legs to do the lifting, while keeping the back straight, distributes the load more evenly.

Q 5. What safety precautions do you take when lifting heavy objects?

Safety is my top priority. Before lifting any heavy object, I assess the load, my capabilities, and the environment. This includes checking the surrounding area for hazards, ensuring a clear path, using appropriate equipment when necessary, and requesting help if needed. I always maintain a firm grip and lift smoothly, avoiding sudden jerks. I also communicate my intentions to those around me to prevent accidents. Post-lift, I assess my own body for any signs of strain, and report any issues.

- Assessment: Assess the object, environment, and your own capabilities.

- Equipment: Use appropriate equipment (hand trucks, lifting straps, etc.).

- Communication: Inform others of your intentions.

- Self-Assessment: Check for any strain after lifting.

Q 6. Describe a time you had to lift an unusually heavy or awkwardly shaped object. What was your approach?

During a warehouse move, I had to lift an unusually large and heavy piece of equipment—an old printing press. It was awkward to maneuver due to its size and uneven weight distribution. My approach involved several steps: First, I assessed its weight (approximately 150kg, far exceeding my solo lifting capacity). Second, I recruited two strong colleagues, and we used lifting straps to evenly distribute the weight. We carefully coordinated our movements to lift simultaneously and slowly, maintaining proper body posture. Third, using a hand truck, we moved the equipment to its destination. Good communication was crucial in coordinating this effort and avoiding any mishaps.

Q 7. Have you ever experienced a lifting-related injury? If so, how did it occur, and what did you learn from it?

Yes, I once experienced a minor back strain while lifting a heavy box improperly. It occurred because I twisted while lifting and didn’t keep the load close to my body. This taught me the importance of following ergonomic principles meticulously. It reinforced the necessity of proper posture, appropriate equipment use, and asking for help when needed, rather than attempting tasks exceeding my capabilities.

Q 8. How do you prioritize safety when working under time constraints?

Prioritizing safety under time constraints requires a proactive, not reactive, approach. It’s about building safety into every step, not rushing through it. Think of it like a tightrope walk – speed is dangerous without the proper balance and safety measures.

My strategy involves:

- Risk Assessment: Even under pressure, I quickly assess the load, the environment (obstacles, slippery surfaces), and my physical capacity. This takes only seconds but prevents major problems.

- Proper Technique: I never compromise on proper lifting techniques (explained further in other answers). Speeding up means nothing if I injure myself.

- Communication: If working with others, clear and concise communication about the plan is crucial. This eliminates miscommunication that might lead to accidents.

- Seeking Assistance: If the time pressure is stemming from an overload of work, I would not hesitate to ask for help or re-prioritize tasks. Safety always trumps speed.

- Refusal: If the risk is too high, even with assistance, I would respectfully refuse the task until appropriate safety measures are in place. My health is more important than meeting an unrealistic deadline.

Example: Once, while moving heavy boxes in a warehouse during a busy period, I noticed a spill on the floor. Instead of rushing, I immediately stopped, cleaned the area, and communicated the hazard to my colleagues. This extra minute prevented a potential slip and fall.

Q 9. What types of lifting equipment are you familiar with (e.g., pallet jacks, hand trucks, hoists)?

I’m familiar with a wide range of lifting equipment, each suited for different tasks and loads. My experience includes:

- Pallet Jacks: Ideal for moving heavy pallets across relatively smooth, level surfaces. I understand the importance of ensuring the pallet is stable and the jack is properly maintained.

- Hand Trucks (Two-Wheel & Four-Wheel): Two-wheel trucks are great for smaller, heavier loads over short distances, while four-wheel trucks are more stable for larger, bulkier items and longer distances. Proper weight distribution is key.

- Hoists (Overhead & Chain): For very heavy loads, hoists are essential. I understand safe operating procedures, weight limits, and proper attachment techniques. I’m proficient in using both manual and motorized hoists, understanding the safety implications of each.

- Come-Along (Ratchet) Hoists: Used for pulling or hoisting loads in scenarios where the load cannot be lifted directly overhead.

- Lever Hoists: Ideal for pulling, lifting, or clamping heavy objects with a mechanical advantage.

Knowing when to use each piece of equipment is crucial for efficient and safe lifting operations. Choosing the wrong equipment can lead to injuries or damage to goods.

Q 10. How would you handle a situation where a load is too heavy for you to lift alone?

If a load is too heavy for me alone, I would never attempt to lift it. Doing so puts me and potentially others at risk of serious injury. My response would involve:

- Assessment: I’d reassess the load and the environment to determine the best course of action.

- Seeking Assistance: I’d immediately get help from a coworker, supervisor, or call for assistance using designated protocols.

- Proper Lifting Equipment: If feasible, I’d suggest using appropriate lifting equipment, such as a hand truck, pallet jack, or hoist.

- Replanning: In some cases, the task might require a different approach, perhaps breaking the load down into smaller, manageable parts or using a different method altogether.

- Documentation: Depending on company policy, I would document the situation, the assistance received, and the safe method used to lift the load.

Example: While working on a construction site, I encountered a heavy concrete slab that I couldn’t safely lift. Instead of trying, I immediately got two colleagues to help, ensuring we used proper lifting techniques and maintained communication throughout the process.

Q 11. What are the signs of potential lifting injuries, and how would you respond?

Recognizing potential lifting injuries is crucial for preventing them. Signs can be immediate or develop over time. I’m trained to watch for:

- Sudden, Sharp Pain: In the back, neck, shoulders, or legs, usually indicating a strain or tear.

- Muscle Spasms: Sudden involuntary muscle contractions.

- Numbness or Tingling: In the arms or legs, suggesting nerve compression.

- Reduced Range of Motion: Difficulty bending, twisting, or lifting.

- Swelling or Bruising: Around the affected area.

- Fatigue or Weakness: Persistent tiredness and inability to perform tasks efficiently.

My Response:

- Stop Lifting Immediately: Do not continue if I feel pain or discomfort.

- Report the Incident: Inform my supervisor or manager immediately.

- Seek Medical Attention: If necessary, consult a doctor or other medical professional.

- Follow Company Protocol: Follow company procedures for reporting injuries and completing necessary paperwork.

- Modify Tasks (if necessary): After recovery, I’d work with my manager to modify lifting tasks to prevent recurrence of injury.

Example: I once experienced a minor back strain after lifting a heavy object. I immediately stopped work, reported it to my supervisor, and took time to recover. This prevented the issue from becoming a chronic problem.

Q 12. Explain your understanding of load balancing and its importance.

Load balancing is the art of distributing weight evenly to maintain stability and prevent strain. It’s like building a balanced seesaw; if the weight is uneven, it will tip over. In lifting, it means keeping the center of gravity close to your body and avoiding twisting.

Importance:

- Reduces Strain: Even weight distribution minimizes stress on muscles and joints.

- Enhances Stability: Prevents the load from shifting and causing loss of balance, leading to injury.

- Increases Efficiency: Balanced lifting requires less effort and improves overall productivity.

- Minimizes Risk: Reduces the chance of strains, sprains, and back injuries.

Practical Application: When lifting a box, I ensure it is centered and close to my body to maintain a stable posture. If lifting an object from the ground, I bend my knees and use my legs, not my back. I avoid twisting motions by pivoting my feet instead of my spine.

Q 13. How do you ensure a stable base of support when lifting and carrying?

A stable base of support is essential for safe lifting. This means having a wide, firm stance to maintain balance. Imagine trying to lift a heavy object on one leg – it’s unstable and dangerous. A wide stance creates a strong foundation.

Techniques:

- Feet Shoulder-Width Apart: Provides a broad base of support.

- Feet Slightly Apart and pointed in direction of lift: Better balance when moving the load.

- Knees Bent: Lowers the center of gravity, improving stability.

- Back Straight: Prevents strain on the spine.

- Core Engaged: Strengthens your core muscles for better support.

Example: Before lifting anything heavy, I always position my feet shoulder-width apart, bend my knees, keep my back straight, and engage my core. This ensures that I am ready for the lift and reduces the risk of injury.

Q 14. What are the different types of hand trucks and what are their applications?

Hand trucks come in various types, each designed for specific applications:

- Two-Wheel Hand Trucks (also known as ‘dolly’): These are commonly used for lighter loads and navigating tighter spaces. They’re excellent for moving boxes or smaller items, particularly those with handles.

- Four-Wheel Hand Trucks (also known as ‘four-wheel dollies’ or ‘platform trucks’): More stable than two-wheel trucks, making them suitable for larger, heavier, and bulkier loads. Ideal for warehouses and transporting pallets over longer distances.

- Stair Climbing Hand Trucks: Designed for moving loads up and down stairs. They typically have a mechanism to allow them to rotate and traverse stairs safely.

- Heavy-Duty Hand Trucks: Built for extremely heavy loads; often feature reinforced frames and larger wheels for increased durability and stability.

- Specialized Hand Trucks: There are specialized hand trucks designed for specific industries and loads, such as those for moving drums, appliances, or other oddly shaped objects.

Applications:

The choice of hand truck depends entirely on the weight, size, and shape of the load, as well as the terrain. Using an inappropriate hand truck can significantly increase the risk of accidents and injuries. Proper load distribution on any hand truck is critical to prevent tip-overs.

Q 15. What are the limitations of manual lifting and when is mechanical assistance necessary?

Manual lifting has inherent limitations, primarily stemming from the physical capabilities of humans. Our bodies aren’t designed for repetitive heavy lifting or awkward postures. Exceeding our physical limits leads to musculoskeletal disorders (MSDs) like back pain, strains, and sprains. Factors contributing to these limitations include the weight of the object, its size and shape, the distance it needs to be moved, the posture required, and the frequency of lifting.

Mechanical assistance becomes necessary when the task surpasses human capabilities, posing a significant risk of injury. This is especially true for:

- Heavy loads: Anything exceeding the recommended weight limits for safe manual handling.

- Awkward lifts: Lifting objects above shoulder height, from below the knees, or in twisted positions.

- Repetitive lifting: Repeated lifting throughout the day increases the risk of cumulative trauma.

- Poor ergonomics: Work environments lacking proper space, lighting, or equipment contribute to increased risk.

- Hazardous materials: Lifting materials that are sharp, corrosive, or otherwise dangerous demands mechanical aid to minimize risk.

For example, imagine lifting a 50kg engine block repeatedly. Mechanical assistance, such as a hoist or forklift, would be crucial to prevent injuries. The cost of MSDs – both in terms of employee health and lost productivity – far outweighs the investment in appropriate lifting equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with using lifting straps or other assistive devices.

I have extensive experience utilizing lifting straps and other assistive devices. Lifting straps, for instance, redistribute the weight, reducing the strain on the back and improving grip. I’ve used them successfully when moving heavy furniture, engine components, or large packages. The technique involves securing the straps around the object, evenly distributing weight on the shoulders and reducing the need to bend at the waist or twist unnaturally.

Furthermore, I’m proficient with pallet jacks, hand trucks, and other mechanical aids. My experience includes operating these tools to efficiently move materials of varying sizes and weights. I’m trained in their safe operation, which includes regular inspections for damage and knowing when to use additional safety measures (like securing loose straps).

In one specific instance, I was tasked with moving a heavy piece of equipment (around 150kg) that wasn’t ideal for a forklift. By using a combination of lifting straps and a hand truck, I was able to maneuver the equipment safely and efficiently, avoiding the risk of injury or equipment damage. Understanding the correct application of these tools is paramount in safe material handling.

Q 17. What is your understanding of workplace safety regulations related to lifting and carrying?

My understanding of workplace safety regulations concerning lifting and carrying is comprehensive. These regulations emphasize the importance of risk assessments, proper training, the provision of appropriate personal protective equipment (PPE), and the implementation of safe work practices. Regulations typically define weight limits for manual handling, specifying maximum permissible weights for various tasks and worker demographics. They also detail the use of mechanical aids and the implementation of ergonomic principles to minimize the risk of MSDs.

Key aspects covered by these regulations include:

- Risk Assessment: Identifying and evaluating potential lifting hazards in the workplace.

- Training: Providing employees with comprehensive training on safe lifting techniques, including the use of assistive devices.

- Engineering Controls: Implementing engineering solutions, such as conveyors or hoists, to reduce manual handling.

- Administrative Controls: Implementing safe work procedures, establishing weight limits, and rotating tasks to minimize risk.

- Personal Protective Equipment (PPE): Providing appropriate PPE, such as gloves and safety shoes, to protect workers from injuries.

Failure to comply with these regulations can result in significant penalties, including fines and legal action. More importantly, non-compliance puts workers at serious risk of injury.

Q 18. How would you communicate potential lifting hazards to your supervisor or colleagues?

Communicating potential lifting hazards is a critical aspect of workplace safety. My approach is proactive and involves clear, concise, and respectful communication. I would first conduct a thorough risk assessment, documenting observations and potential hazards. This assessment would include the weight of the objects, the distances involved, the environment, and any potential ergonomic issues.

I would then communicate these findings to my supervisor or colleagues using a structured approach, such as:

- Formal Reporting: Using incident report forms or other established channels to document hazards.

- Direct Communication: Speaking directly to my supervisor or colleagues to discuss the identified hazards and propose solutions.

- Visual Aids: Using photographs or diagrams to illustrate the identified risks.

- Team Discussions: Participating in safety meetings to discuss potential hazards and solutions collectively.

For example, if I observed that a certain task consistently involved lifting heavy boxes from an awkward height, I would report this to my supervisor, suggesting the use of a forklift or other mechanical assistance to mitigate the risk.

Q 19. How do you adapt your lifting techniques to different environments (e.g., uneven surfaces, confined spaces)?

Adapting lifting techniques to different environments requires careful consideration of the specific challenges each presents. Uneven surfaces introduce instability, requiring a wider base of support and a slower, more controlled lifting motion. Confined spaces limit movement, necessitating a different approach to body positioning and the careful selection of lifting techniques.

Here’s how I adapt:

- Uneven Surfaces: I widen my stance for better balance, ensure a firm footing, and perform the lift with more deliberate movements. I might use assistive devices like a hand truck to minimize the strain on my back. I also avoid lifting in such conditions if possible.

- Confined Spaces: I carefully assess the space to determine the best body posture and lifting technique. I might need to break the lift into smaller stages or use specialized equipment designed for confined spaces. Safety is paramount in such conditions, and taking additional precautions is vital.

- Other Challenging Environments: For example, when lifting on stairs, I would be extremely cautious, potentially opting for a different approach or requesting mechanical assistance.

In all cases, I prioritize safety and would not attempt a lift if it significantly compromised my safety or the safety of others. A safe lift always trumps speed and efficiency.

Q 20. How do you maintain your physical fitness to safely perform lifting tasks?

Maintaining physical fitness is paramount for safe lifting. My approach combines regular exercise, proper nutrition, and a focus on flexibility and core strength. I focus on exercises that strengthen my back, legs, and core muscles, essential for supporting the spine during lifting.

My fitness routine includes:

- Strength Training: Regular strength training exercises targeting major muscle groups, including squats, deadlifts (with proper form!), and rows.

- Cardiovascular Exercise: Maintaining cardiovascular health improves overall fitness and stamina.

- Flexibility and Stretching: Regular stretching exercises enhance flexibility and range of motion, preventing muscle stiffness and injuries.

- Proper Nutrition: A balanced diet rich in protein, vitamins, and minerals is crucial for muscle repair and overall health.

I also prioritize adequate rest and recovery, recognizing that overtraining can increase the risk of injury. I regularly listen to my body and avoid pushing myself beyond my limits.

Q 21. What is your understanding of the proper procedures for lifting and carrying different types of materials (e.g., fragile items, hazardous materials)?

Lifting different materials requires adjusting techniques to prevent damage and ensure safety. Fragile items demand extra care, while hazardous materials necessitate additional precautions.

Fragile Items: I use two hands to provide a stable grip, avoiding sudden movements or jarring impacts. I may use padding or cushioning to protect the item during the lift and transport. I will lift these items closer to the body to maximize control and stability.

Hazardous Materials: These require appropriate PPE, such as gloves, safety glasses, and potentially respirators, depending on the nature of the hazard. I’ll follow specific handling instructions outlined on the packaging or in safety data sheets (SDS). I ensure proper ventilation and avoid contact with the material. The correct use of specialized equipment, like spill kits and containment vessels, is also a key aspect of handling these substances.

Other Materials: For heavy or bulky items, I might use appropriate equipment, like hand trucks or forklifts. For awkward-shaped items, I’d carefully plan the lift, ensuring a stable grip and avoiding twisting or reaching movements.

My approach is always guided by the principle of prioritizing safety and minimizing risks. It’s crucial to never hesitate to ask for assistance or use appropriate lifting equipment whenever there’s any doubt about the ability to handle a particular object safely.

Q 22. Describe your experience working with team members to lift and carry heavy loads collaboratively.

Teamwork is paramount when lifting heavy loads. My approach centers on clear communication, proper technique, and a shared understanding of the task. Before we begin, we always assess the weight, the distance it needs to be moved, and any potential obstacles. We then assign roles based on individual strengths and capabilities – someone might be designated as the ‘leader’ to guide the lift, others focused on maintaining balance and stability. For instance, during a recent warehouse move, we were tasked with relocating a large industrial freezer. We used a combination of a hand truck and teamwork, with two people at the rear stabilizing and guiding the hand truck, and two people at the front ensuring a controlled and even lift. We constantly communicated our actions, using verbal cues like ‘Ready? Lift!’, and ‘Left a bit’, ensuring a smooth, coordinated movement that prevented strain and injury. This collaborative approach not only made the task easier but also significantly reduced the risk of accidents.

Q 23. What is your approach to managing fatigue during lifting tasks?

Managing fatigue during lifting is crucial for preventing injuries. My strategy involves a multifaceted approach. First, I prioritize proper posture and lifting techniques – maintaining a straight back, bending at the knees, and keeping the load close to my body. I also advocate for frequent breaks – short, regular rest periods can significantly reduce muscle fatigue and the risk of injury. Staying hydrated is essential; dehydration can lead to muscle cramps and decreased performance. Finally, I encourage regular physical activity outside of work to build overall strength and stamina, making the job itself less physically demanding. In one instance, while unloading a truck filled with building materials, we implemented a system of short, five-minute breaks every 30 minutes. This proved incredibly effective in keeping the team energized and focused, preventing any serious fatigue-related incidents.

Q 24. Explain your knowledge of the different classes of levers and how they apply to lifting.

Understanding levers is fundamental to efficient lifting. There are three classes of levers:

- First-class lever: The fulcrum (pivot point) is located between the effort (force applied) and the load (object being lifted). Think of a seesaw. In lifting, using a pry bar to lift a heavy object is an example; the pry bar’s fulcrum is the point where it contacts the ground.

- Second-class lever: The load is located between the fulcrum and the effort. A wheelbarrow is a classic example; the wheel is the fulcrum, the load is in the wheelbarrow, and the effort is applied at the handles. Lifting heavy objects with a dolly employs this principle.

- Third-class lever: The effort is between the fulcrum and the load. Most human limbs operate as third-class levers. Think of lifting a weight with your arm; your elbow is the fulcrum, your bicep applies the effort, and the weight is the load. While less mechanically advantageous for heavy lifting, understanding this lever class highlights the importance of minimizing the distance between your hand and your body when lifting.

By understanding these lever classes, we can choose tools and techniques that maximize efficiency and minimize exertion. For example, if we are trying to lift a heavy box, positioning a dolly under it will change the lever class from a predominantly third-class lever (lifting with just our muscles) to a second-class lever (using the dolly to create mechanical advantage).

Q 25. How do you assess the risk of potential back injuries before lifting an object?

Assessing risk before lifting involves a thorough evaluation. I start by visually inspecting the object – its weight, shape, and condition. I consider whether it is properly packaged or secured, to prevent shifting or dropping. The environment also plays a key role – is the floor level and stable? Are there any obstacles or tripping hazards that could cause an accident? Then, I evaluate the load relative to my physical capabilities. Is the object too heavy, or awkwardly shaped, for me to lift safely alone? If so, assistance is required. If there’s any doubt, I would rather err on the side of caution and seek help. I’m trained to identify risk factors, and I always prioritize safety above all else. For instance, before attempting to lift a heavy piece of machinery, I’d carefully inspect the machinery for any loose parts, ensure a clear path, and if necessary, request the assistance of a team and appropriate lifting equipment.

Q 26. How familiar are you with the use of a lifting chart or similar weight-handling guidelines?

I am very familiar with lifting charts and weight-handling guidelines. These charts provide crucial information on maximum safe weights for various lifting tasks and individual capabilities, taking into account factors like the distance of the lift, the height of the lift, the frequency, and the physical capabilities of the lifter. They’re essential tools for risk management in any lifting situation. These charts help ensure we do not exceed safe limits, thus preventing injuries. My experience includes using charts published by OSHA (Occupational Safety and Health Administration) as well as those provided by our company. These charts are not merely guidelines; they represent a critical safety precaution that’s incorporated into every lift planning session.

Q 27. Describe a time you had to improvise a lifting solution due to a lack of available equipment.

During a renovation project, we needed to move a very heavy, oddly-shaped stone column. We lacked a forklift or crane, so we had to improvise. We assessed the stone’s weight and center of gravity, then used a combination of strong ropes, sturdy planks, and strategically placed rollers to create a makeshift system to move it. This required careful planning and coordination, with team members working together to guide the stone smoothly along the planks. It was a challenging situation, but it highlighted the importance of creative problem-solving when faced with limited resources. The careful planning and teamwork helped us complete the task safely and efficiently without causing any damage.

Q 28. How do you ensure the proper storage and handling of lifted items to prevent damage?

Proper storage and handling after a lift are critical for preventing damage. This includes storing items in designated areas, away from walkways and other hazards. Fragile items must be stored carefully, potentially using protective padding or specialized racks. We also need to consider the environment – items shouldn’t be stored in areas subject to extreme temperatures or moisture that could cause damage. Stacking materials correctly to ensure stability is essential, avoiding unstable piles that could collapse. We follow FIFO (First-In, First-Out) principles whenever appropriate, preventing items from being crushed or forgotten. For example, after a pallet of delicate glass products was delivered, we carefully stored it on designated racking system with sufficient support, away from potential impacts, ensuring its protection until needed.

Key Topics to Learn for Lift and Carry Interview

- Ergonomics and Body Mechanics: Understanding proper lifting techniques to minimize injury risk, including posture, foot placement, and using leg strength.

- Weight Distribution and Balance: Analyzing load distribution to maintain stability and control during the lift and carry process. Practical application includes understanding center of gravity and its impact on lifting.

- Safety Procedures and Regulations: Familiarizing yourself with industry-standard safety protocols and regulations related to lifting and carrying heavy objects. This includes understanding potential hazards and mitigation strategies.

- Equipment Selection and Use: Knowing which tools and equipment (e.g., dollies, hand trucks) are appropriate for different lifting tasks and how to use them safely and efficiently.

- Material Handling Techniques: Mastering various lifting techniques for different types of loads, considering factors like size, shape, and weight. This includes understanding the benefits and limitations of different lifting methods.

- Assessing Lifting Risks: Developing the ability to assess potential hazards before lifting, such as uneven surfaces, obstacles, and environmental conditions. This involves proactive risk management and problem-solving.

- Teamwork and Communication: Understanding the importance of communication and collaboration in team lifting scenarios, emphasizing safety and efficiency.

Next Steps

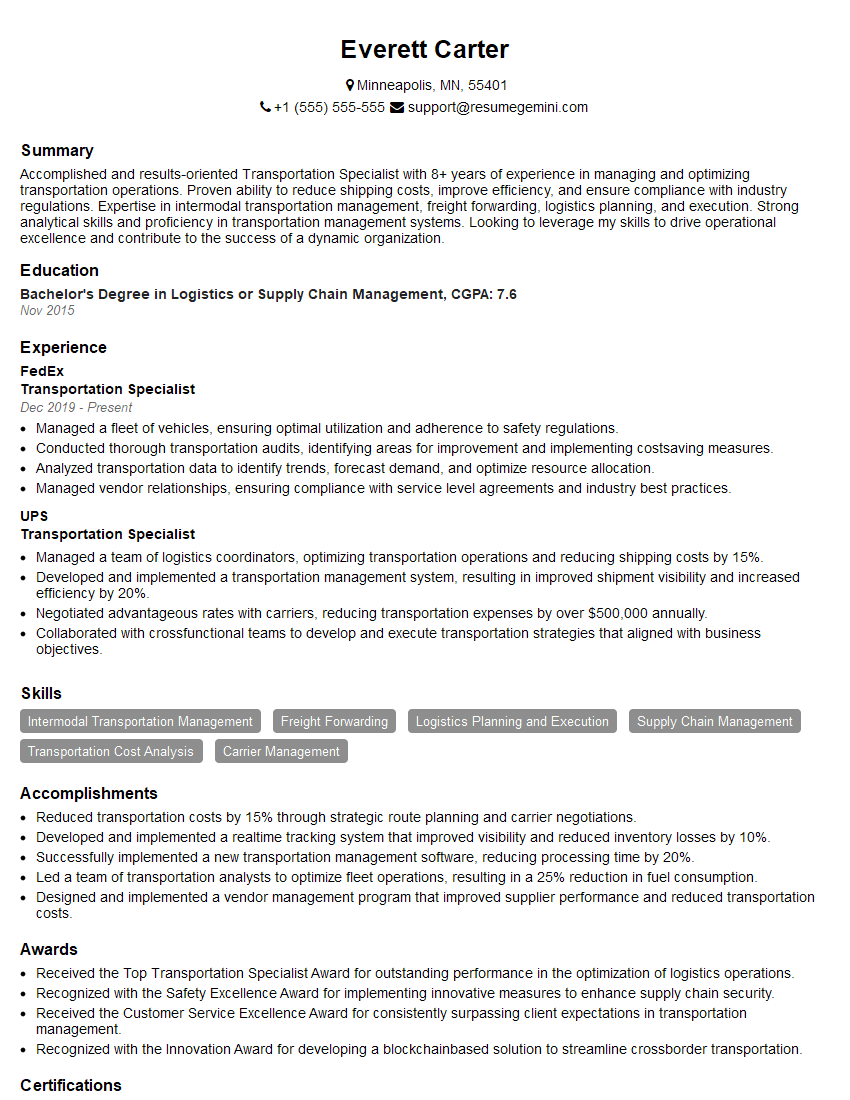

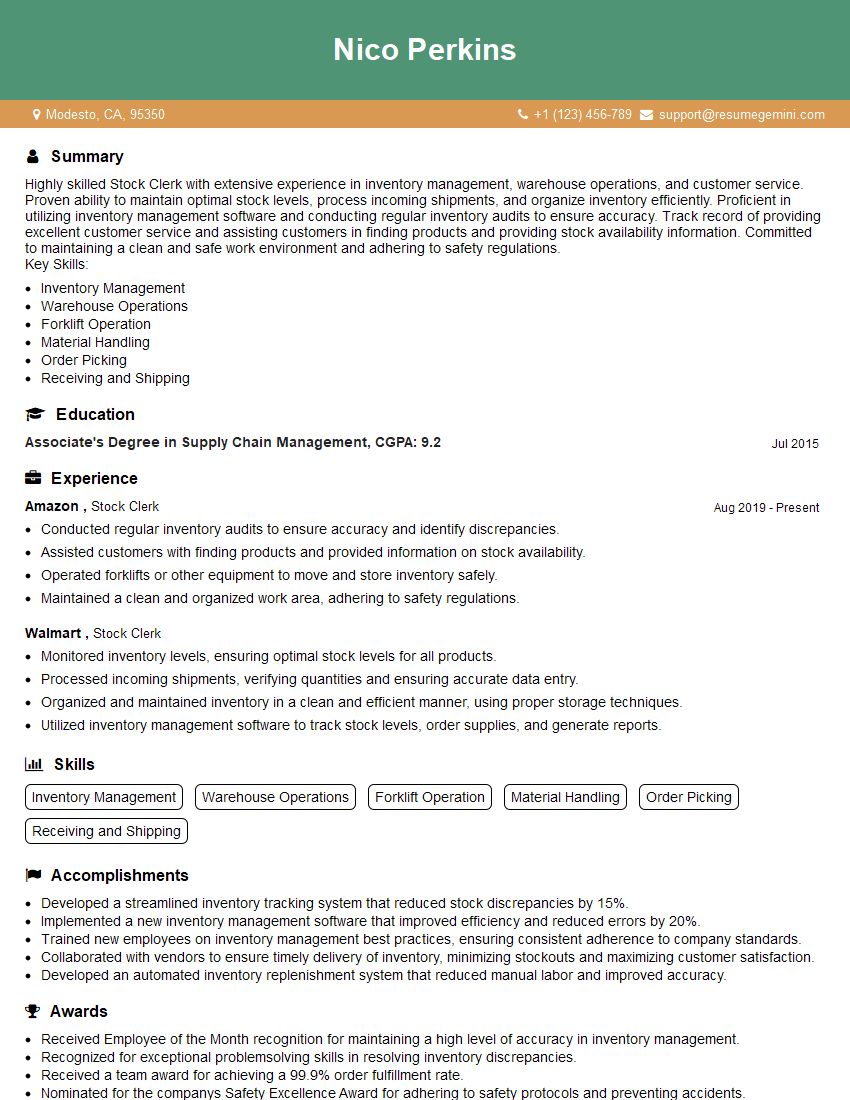

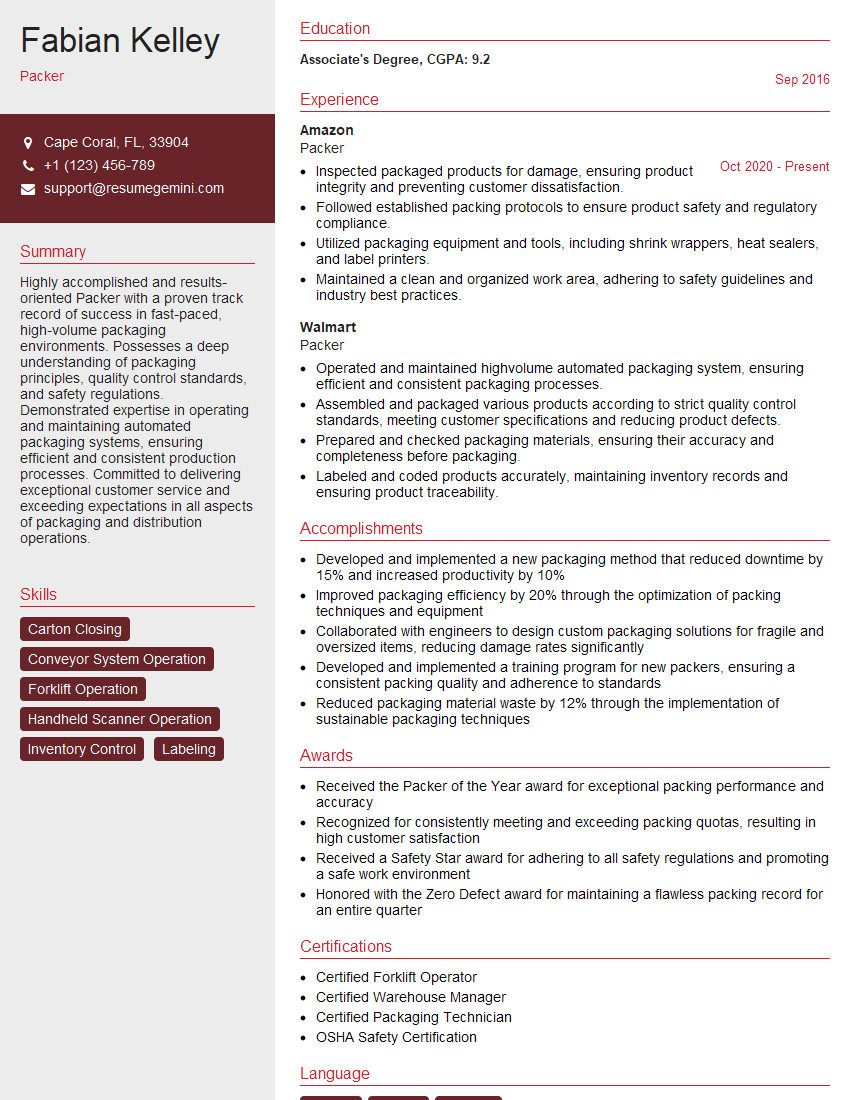

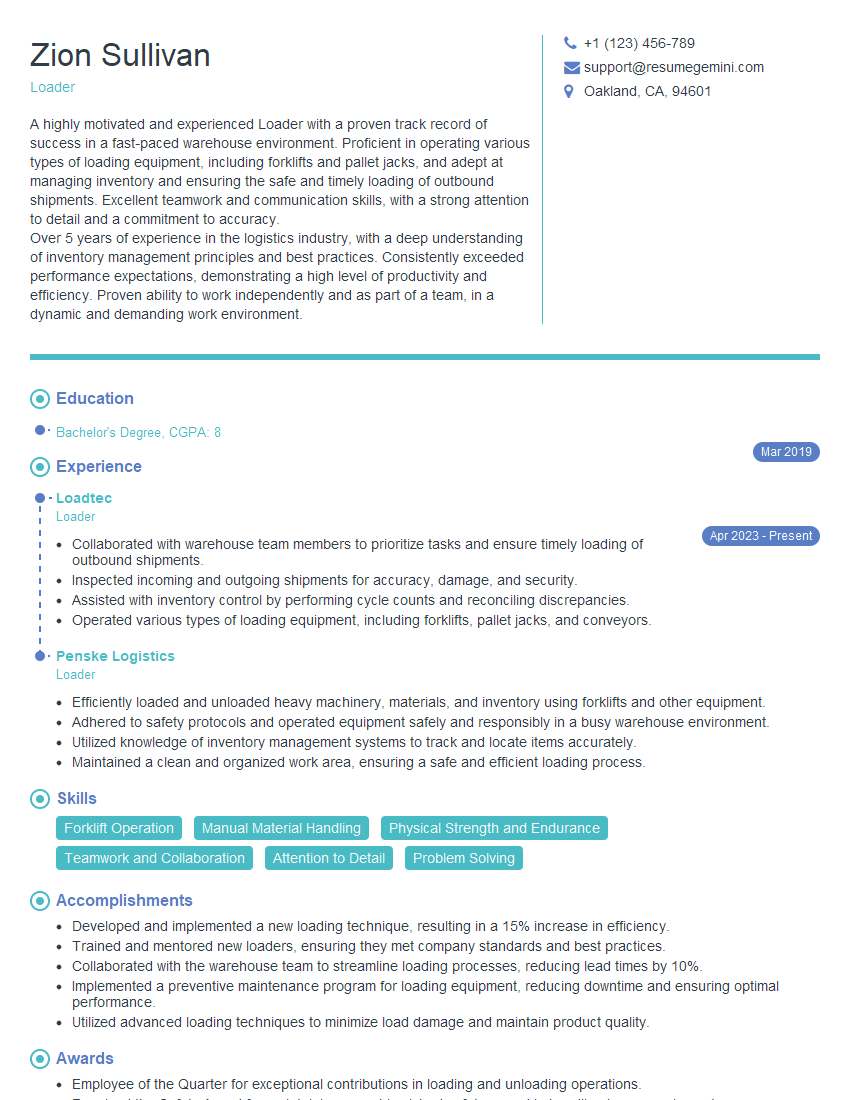

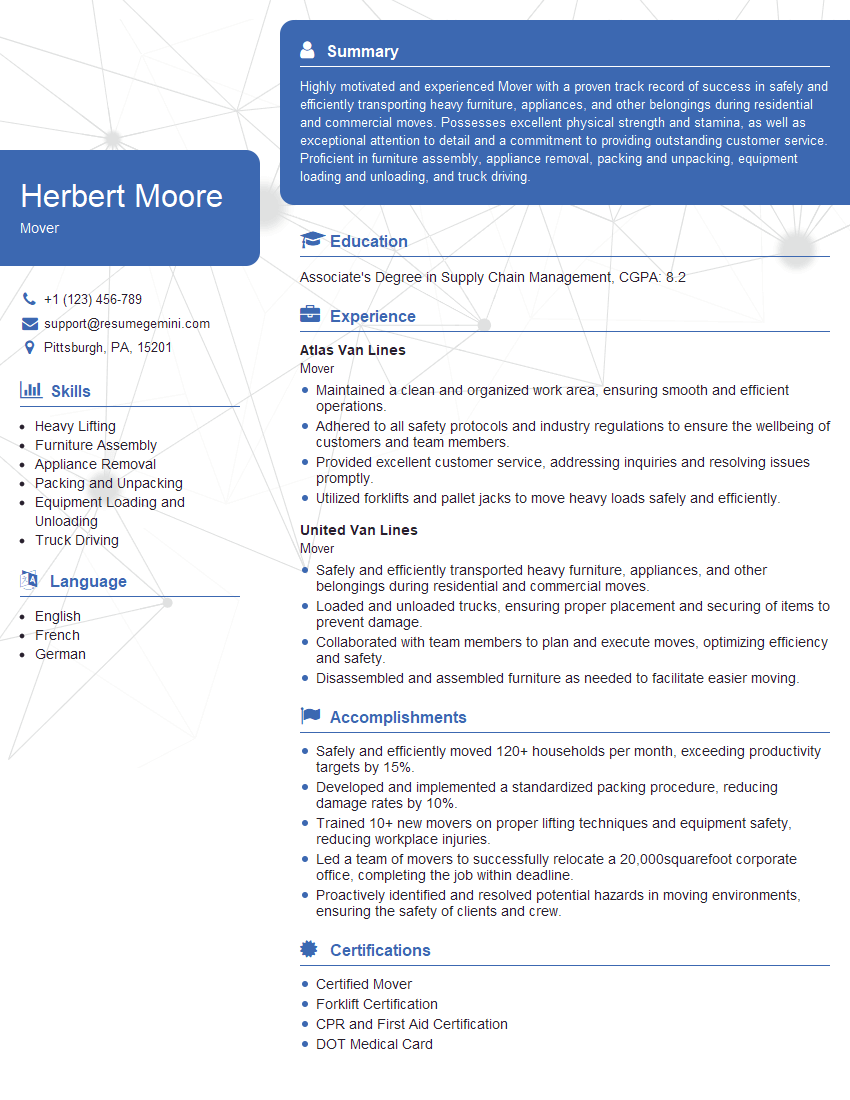

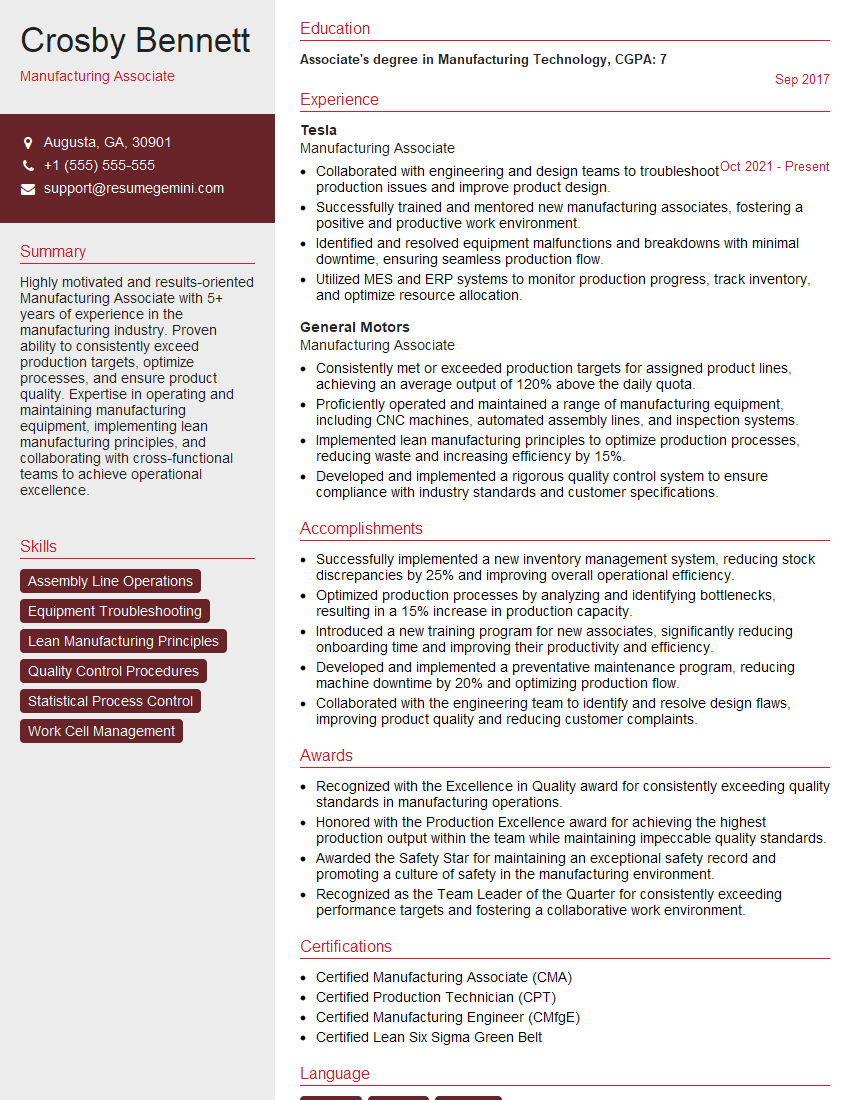

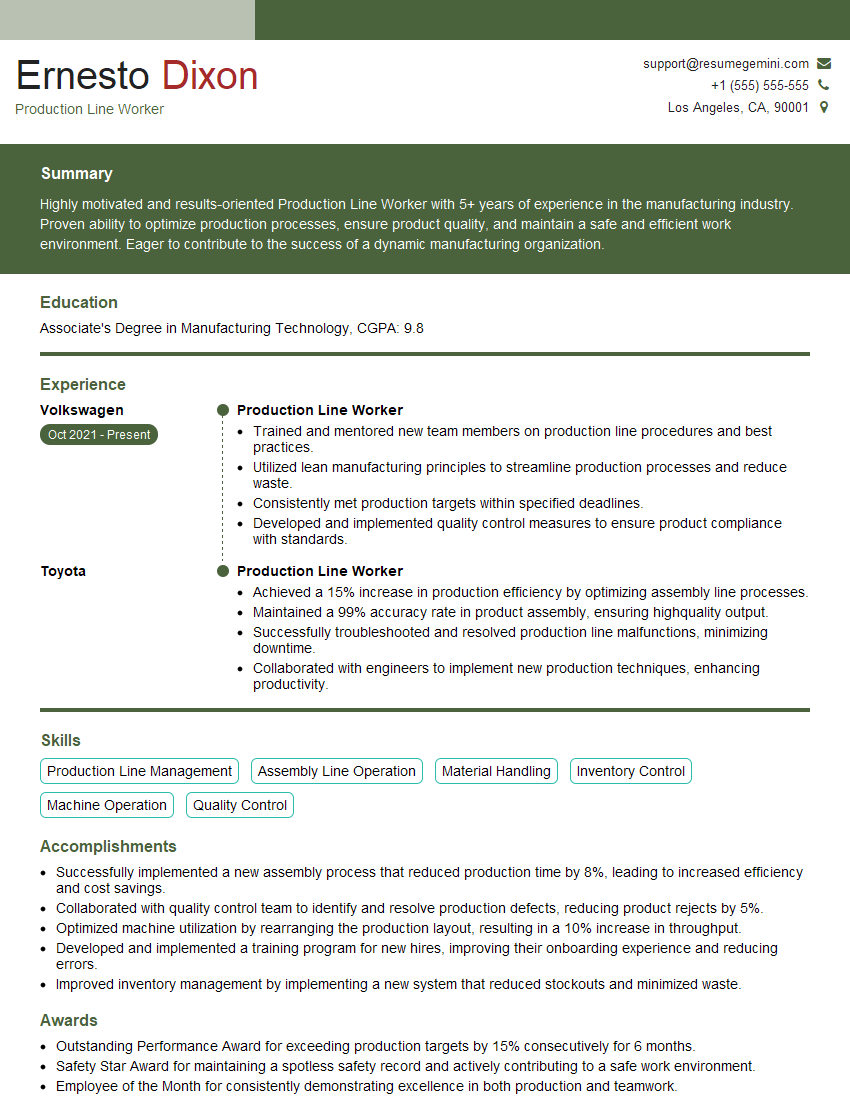

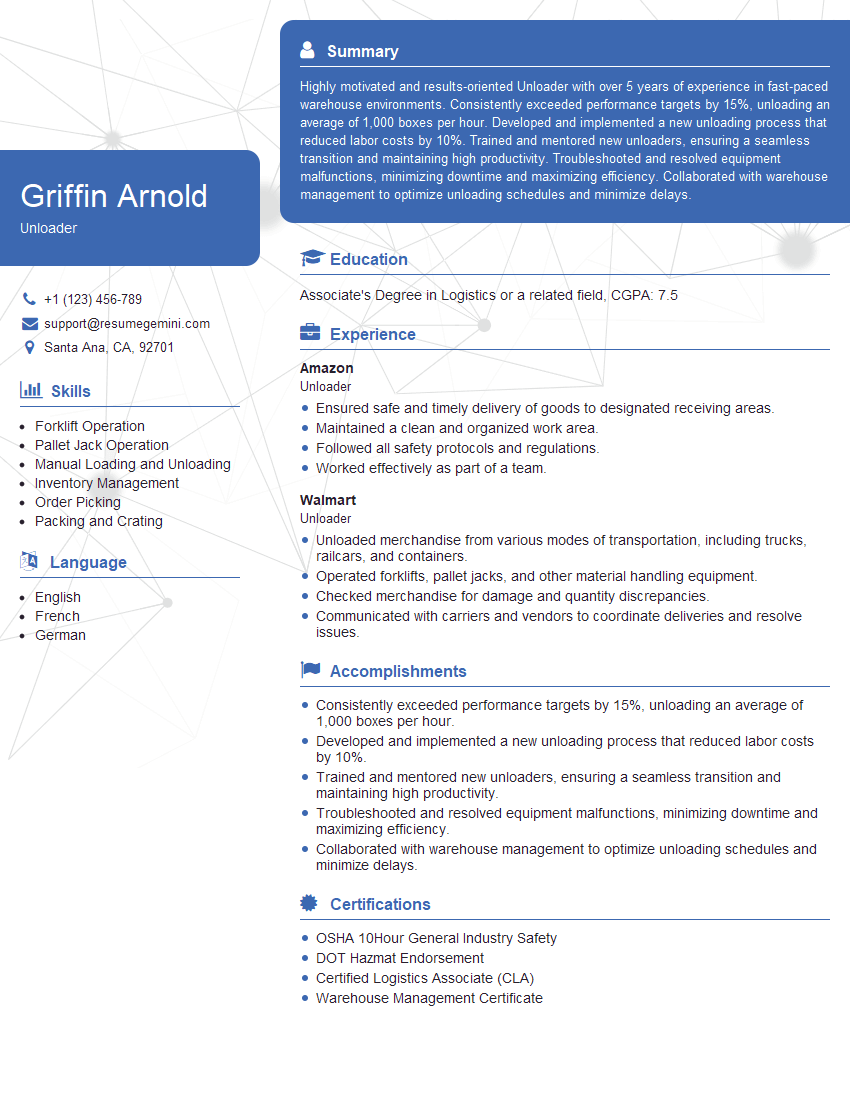

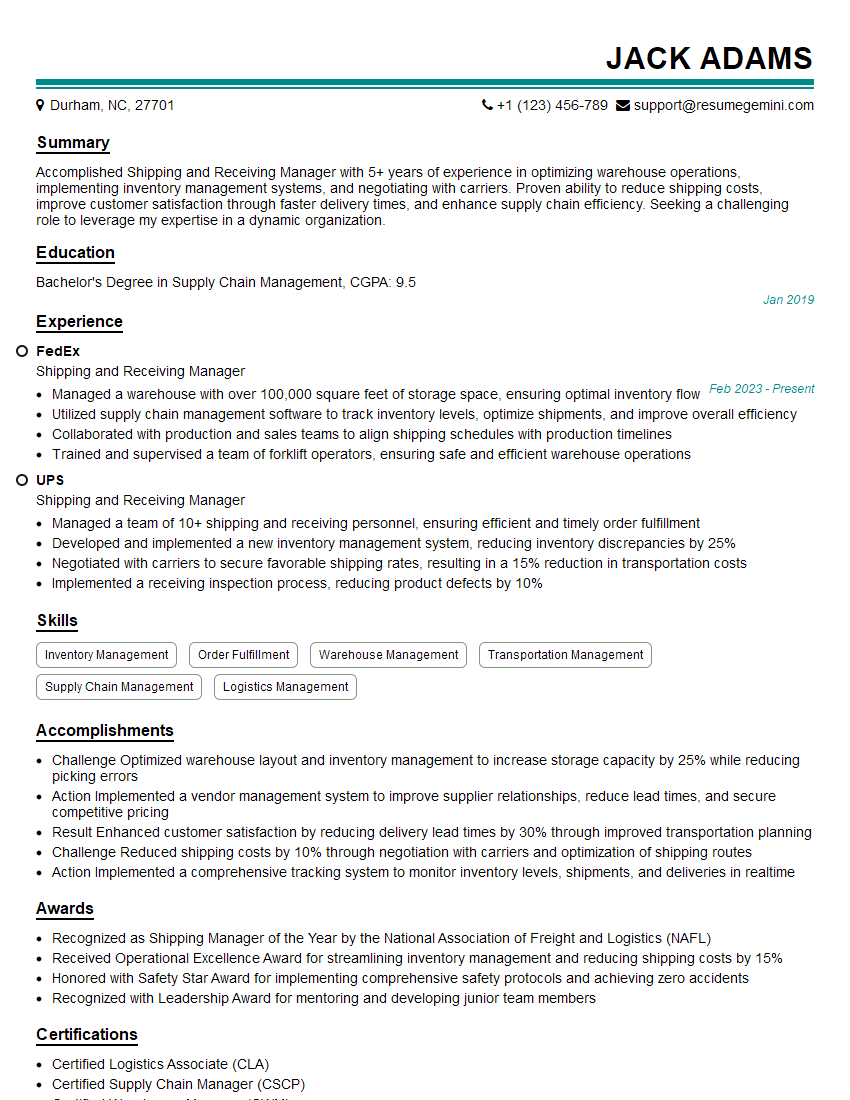

Mastering Lift and Carry techniques is crucial for career advancement in many industries, showcasing your commitment to safety and efficiency. A strong understanding of these principles demonstrates your value to potential employers. To significantly increase your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. We highly recommend using ResumeGemini, a trusted resource, to build a professional resume that stands out. Examples of resumes tailored to the Lift and Carry field are available below to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good