Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Roof Support interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Roof Support Interview

Q 1. Explain the different types of roof support systems.

Roof support systems are crucial for the structural integrity of a building. They transfer the weight of the roof, snow, and other loads down to the walls and foundation. Different systems are employed depending on factors like building size, roof type, and local climate. Here are some common types:

- Trusses: These prefabricated assemblies of lumber or engineered wood are highly efficient in spanning large distances and distributing loads. They come in various designs like scissor trusses, gable trusses, and hip trusses, each optimized for specific roof geometries.

- Rafters: Traditional roof support members, rafters are individual pieces of lumber that slope from the ridge to the wall plates. They’re typically used for smaller spans and steeper roofs.

- Beams and Girders: These horizontal structural members support rafters or trusses. Beams span shorter distances, while girders support larger areas and often carry heavier loads.

- Purlin Systems: Often used with metal roofing, purlins are horizontal members that run along the roof slope and support the roofing material. They rest on top of trusses or rafters.

- Arch Systems: Employing curved structural elements, arch systems are particularly suitable for large spans and can provide an aesthetically pleasing design.

The choice of system depends on a comprehensive structural analysis considering the load requirements and specific design considerations.

Q 2. Describe your experience with calculating roof loads and stresses.

Calculating roof loads and stresses is a critical part of my work. I use established engineering principles and software to ensure the roof system can withstand all anticipated loads. This involves:

- Determining Dead Loads: This includes the weight of the roofing material, structural members (trusses, rafters), insulation, and any permanently attached equipment.

- Determining Live Loads: This encompasses the weight of snow, rain, and occupancy (people, furniture). I use local building codes and snow load maps to determine appropriate live load values. For example, a mountainous region will require considerably higher snow load calculations than a coastal region.

- Wind Loads: Wind pressure can exert significant forces on a roof, especially in high-wind areas. I utilize wind load maps and specialized software to model wind effects.

- Using Software: I use structural analysis software like RISA or SAP2000 to model the roof structure, input the loads, and calculate stresses in each member. This helps me to identify potential weak points and ensure adequate safety factors are maintained.

For example, in a recent project, I utilized RISA-3D to model a complex hipped roof. The software helped me optimize the truss design and spacing to minimize material usage while maintaining structural integrity under various load conditions, saving both money and resources.

Q 3. How do you identify potential roof support failures during an inspection?

Identifying potential roof support failures during an inspection requires a thorough and systematic approach. I look for:

- Sagging or deflection of rafters or trusses: Visible drooping indicates excessive load or structural weakness.

- Cracks in structural members: These can indicate overloading, deterioration, or improper construction.

- Evidence of water damage: Rotting wood, mold, or staining suggests water intrusion, which can weaken the structure significantly.

- Loose connections: Fasteners that are pulling out or connections that are failing indicate a compromised structural system.

- Signs of insect infestation: Termites and other wood-boring insects can severely weaken structural members.

- Damaged roofing material: While not always indicative of structural failure, significant damage to the roofing can be an indicator that other components are also stressed.

I use a combination of visual inspection, close-up examination, and occasionally non-destructive testing (NDT) techniques to thoroughly assess the condition of the roof support system. For example, a moisture meter can help detect hidden water damage within structural members.

Q 4. What are the common causes of roof collapses?

Roof collapses are serious events often stemming from a combination of factors. The most common causes include:

- Excessive snow or ice accumulation: This is particularly dangerous in regions with heavy snowfall. Improper snow removal can also contribute to collapse.

- Water damage and rot: Continuous exposure to moisture weakens wood members, reducing their load-bearing capacity. This is exacerbated by poor ventilation.

- Improper design or construction: Errors in the design calculations or during construction can lead to structural deficiencies.

- Age and deterioration of materials: Over time, materials degrade and become less resistant to loads.

- Wind damage: High winds can exert significant uplift forces on a roof, particularly on poorly designed or maintained structures.

- Lack of maintenance: Regular inspections and maintenance are critical for identifying and addressing potential problems before they lead to a collapse.

A recent case I investigated involved a partial roof collapse due to heavy snow. The initial design had underestimated snow load for the region. This highlighted the importance of accurately assessing environmental factors during the design stage.

Q 5. Explain the importance of proper ventilation in roof support.

Proper ventilation is crucial for roof support because it prevents moisture buildup within the roof assembly. Moisture can lead to:

- Wood rot: Moisture weakens structural members, compromising their strength and stability. This can drastically reduce the lifespan and load-carrying capacity of the roof structure.

- Mold and mildew growth: This degrades the roofing material and insulation, further reducing the roof’s effectiveness.

- Ice dam formation: In cold climates, ice dams can form along the eaves, causing significant damage to the roof and gutters. This extra weight puts added stress on the roof structure.

By ensuring adequate ventilation, you create airflow that helps to dry out the roof assembly, preventing moisture-related damage and maintaining the structural integrity of the support system. Good ventilation also helps maintain a consistent temperature within the attic space, further extending the life of the roof structure.

Q 6. What are the different types of roofing materials and their impact on support systems?

Different roofing materials have varying weights and properties, influencing the design of the supporting structure. Heavier materials require stronger supports. Here are some examples:

- Asphalt shingles: Relatively lightweight and commonly used, asphalt shingles present minimal challenges to support systems. However, extensive ice damming can create additional weight.

- Tile roofing: Clay or concrete tiles are considerably heavier than asphalt shingles, requiring stronger rafters or trusses and potentially closer spacing.

- Metal roofing: Though lightweight compared to tile, metal roofing’s susceptibility to wind uplift requires careful consideration of wind load calculations and appropriate fastening.

- Slate roofing: One of the heaviest roofing materials, slate requires robust support systems designed to withstand considerable weight.

For example, a design using slate roofing would necessitate a significantly stronger truss system than one using asphalt shingles. The weight of the material directly impacts the size and spacing of support members, as well as the overall design of the structure.

Q 7. How do you determine the appropriate size and spacing of roof trusses?

Determining the appropriate size and spacing of roof trusses involves a detailed structural analysis. Factors considered include:

- Roof span: The distance between the supporting walls significantly influences truss size. Larger spans require larger and/or more closely spaced trusses.

- Roof load: The total weight (dead and live loads) the roof will carry dictates the required strength of the trusses.

- Truss design: Different truss designs (e.g., gable, hip) have varying load-bearing capacities.

- Building codes and standards: Local building codes specify minimum requirements for truss size and spacing to ensure safety.

- Material properties: The strength of the lumber or engineered wood used in the trusses is a critical factor.

I use engineering software and established design standards to perform these calculations. The software analyzes the forces acting on the trusses and determines the optimal size and spacing to prevent excessive deflection and ensure structural integrity. A properly spaced truss system, supported by well-engineered designs, guarantees the building’s long-term durability and safety.

Q 8. Describe your experience with different types of roof framing.

My experience encompasses a wide range of roof framing systems, from traditional timber framing to modern steel structures and engineered wood products. I’m proficient in designing and analyzing various configurations, including:

- Truss systems: I’ve worked extensively with both wood and steel trusses, understanding their load-bearing capabilities and design limitations. For instance, I recently optimized a truss design for a large warehouse, reducing material costs by 15% without compromising structural integrity.

- Rafter systems: I have experience with both simple and complex rafter systems, including hip, valley, and gable roofs. I know how to properly calculate rafter lengths, spacing, and connections to ensure stability.

- Space frames: I’ve been involved in projects utilizing space frames, which are particularly suitable for large spans and complex geometries. These often require sophisticated analysis to ensure adequate load distribution.

- Hybrid systems: Combining different materials and framing techniques is sometimes necessary for optimal design. For example, I’ve used a combination of steel beams and timber rafters for a renovation project, where the existing building presented unique challenges.

My understanding goes beyond the simple structural design; it includes consideration for factors like wind loads, snow loads, and seismic activity, tailored to specific geographic locations and building codes.

Q 9. Explain the role of purlins and girts in roof support.

Purlins and girts are crucial secondary structural members that significantly contribute to roof support. They transfer the load from the roof covering to the primary structural elements (trusses, rafters, or beams).

- Purlins: These horizontal members run along the length of the roof, supporting the roof covering (tiles, sheets, etc.). They act like small beams distributing the weight across the main structural frame. Think of them as the ‘ribs’ of the roof.

- Girts: These are horizontal members that run along the exterior walls of a building, supporting the cladding and transferring loads to the primary structure. They provide lateral stability and also support the roof purlins in some cases.

The spacing and size of purlins and girts are carefully calculated based on the type of roofing material, the anticipated snow and wind loads, and the overall roof design. For example, heavier roofing materials require closer purlin spacing to avoid excessive deflection. Incorrectly sized or spaced purlins and girts can lead to structural failure or premature deterioration of the roof.

Q 10. How do you assess the condition of existing roof support structures?

Assessing the condition of existing roof support structures involves a thorough visual inspection combined with more detailed investigations as needed. My assessment process generally includes:

- Visual inspection: I examine the entire structure looking for signs of damage like cracks, rot, rust, sagging, or deflection in purlins, rafters, trusses, and supporting walls. I also check for signs of pest infestation or water damage.

- Load testing (where necessary): If visual inspection reveals potential concerns, load testing might be conducted to determine the actual load-bearing capacity of the structure. This could involve using specialized equipment to apply controlled loads and measure deflections.

- Non-destructive testing (NDT): For hidden damage, techniques like ultrasonic testing or ground penetrating radar can be employed to assess the internal condition of structural members without causing further damage.

- Material sampling: Samples of timber or steel can be taken for laboratory testing to determine their strength and durability. This is especially crucial for older structures where material degradation may be a concern.

Based on the findings, I provide a comprehensive report detailing the condition of the structure, identifying any areas of concern, and recommending necessary repairs or strengthening measures. This process is critical to ensuring the safety and longevity of the building.

Q 11. What are the safety regulations related to roof support work?

Safety is paramount in roof support work. Compliance with relevant Occupational Safety and Health Administration (OSHA) regulations or equivalent local standards is mandatory. Key safety regulations include:

- Fall protection: Working at heights requires the use of appropriate fall protection systems, such as harnesses, lifelines, and anchor points. This is the single most important safety measure.

- Scaffolding and access equipment: Proper scaffolding must be used for all elevated work, ensuring it’s adequately secured and inspected regularly. Access equipment, like ladders, must be in good condition and used correctly.

- Personal protective equipment (PPE): Workers must wear appropriate PPE, including hard hats, safety glasses, gloves, and high-visibility clothing.

- Training and competency: All personnel involved in roof support work must be adequately trained and competent in their respective tasks. This includes understanding the hazards associated with the work and knowing how to mitigate them.

- Safe work procedures: Detailed safety procedures must be developed and followed for all aspects of the work, including inspections, material handling, and tool usage.

I meticulously ensure adherence to all applicable safety regulations and continually strive to maintain a safe work environment. Any deviation from safety standards is immediately addressed and corrected.

Q 12. Describe your experience with using specialized software for roof design and analysis.

I have extensive experience using specialized software for roof design and analysis. My proficiency includes programs like RISA-3D, SAP2000, and AutoCAD. These tools allow for accurate modeling, analysis, and design of complex roof structures.

For example, using RISA-3D, I recently modeled a large-scale industrial building’s roof, incorporating wind and snow load data specific to the site location. The software allowed me to analyze the stresses on various components and optimize the design to minimize material usage while maintaining structural integrity. This resulted in significant cost savings for the client.

Beyond structural analysis, these programs are crucial for generating detailed drawings and specifications, ensuring effective communication and collaboration throughout the design and construction phases of a project. I am also proficient in using software for quantity takeoff and cost estimation, allowing for accurate budgeting and project management.

Q 13. How do you handle unexpected issues during a roof support project?

Unexpected issues are inevitable in construction projects. My approach to handling them involves a structured problem-solving process:

- Immediate assessment: I promptly assess the situation to understand the nature and extent of the issue. This might involve re-examining the design drawings, conducting further inspections, or consulting with other specialists.

- Risk assessment: I analyze the potential risks associated with the issue, considering safety implications and potential delays to the project schedule.

- Solution development: I develop potential solutions, weighing the costs, benefits, and risks of each option. This involves considering alternative design approaches or construction methods.

- Implementation and monitoring: Once a solution is chosen, I oversee its implementation, ensuring it’s carried out safely and efficiently. Regular monitoring is crucial to ensure that the issue is resolved and doesn’t resurface.

- Documentation: I maintain detailed records of the issue, the solutions implemented, and any lessons learned. This helps prevent similar issues in the future.

For example, I once encountered unforeseen soil conditions during the construction of a new roof support system that affected the foundation. I immediately halted work, conducted geotechnical investigations, and adapted the design to accommodate the unstable soil, avoiding a potential catastrophic failure.

Q 14. What is your experience with roof waterproofing and its relation to support?

Roof waterproofing is integral to the long-term performance and structural integrity of a building. Water damage can weaken structural members, leading to premature failure. My experience highlights the close relationship between roof support and waterproofing:

- Preventing water ingress: Proper roof support prevents sagging and ponding, which can cause water to accumulate and penetrate the roof covering. A well-supported roof ensures the efficient shedding of water.

- Maintaining proper slopes: The design of the roof support system is crucial in ensuring the proper slope for effective water drainage. Inadequate slope can lead to water pooling and subsequent damage.

- Protecting structural members: A well-designed waterproofing system protects the underlying structural members (purlins, rafters, trusses) from moisture, preventing rot, corrosion, and degradation. This ensures the longevity of the roof support structure.

- Repair and maintenance: During inspections, I carefully evaluate the waterproofing system alongside the structural components. Any signs of leakage or damage are immediately addressed to prevent further problems and structural compromise.

A collaborative approach with waterproofing specialists is essential. I work closely with them to ensure that the waterproofing system is compatible with the chosen roof support structure and that both are optimized for longevity and performance. For instance, I might specify flashings and details that provide extra protection at critical areas around penetrations or valleys.

Q 15. How do you manage a team during a roof support project?

Managing a roof support team requires a blend of technical expertise and strong leadership. I begin by clearly defining roles and responsibilities, ensuring each team member understands their contribution to the overall project goal. This includes engineers, skilled laborers, and potentially subcontractors. Open communication is paramount; daily briefings and regular progress meetings keep everyone informed and address any emerging challenges promptly. I foster a collaborative environment where team members feel comfortable sharing ideas and raising concerns. Safety is always the top priority; I enforce strict adherence to safety protocols and conduct regular safety inspections. Finally, effective project management tools, like Gantt charts and task management software, ensure we stay on schedule and within budget.

For example, on a recent large-scale warehouse project, I implemented a system of daily stand-up meetings where team members could highlight their progress, identify roadblocks, and coordinate their actions. This simple step significantly improved communication and reduced the likelihood of errors or delays.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of building codes related to roof support.

My understanding of building codes related to roof support is comprehensive. These codes, which vary by location (e.g., IBC, local ordinances), dictate minimum requirements for structural strength, load capacity, and material specifications. They address aspects like snow load, wind load, dead load (weight of the roof itself), and live load (occupancy, equipment). Understanding these codes is crucial for designing and implementing a safe and compliant roof support system. I am adept at interpreting the relevant sections of the code and applying them to specific project needs. This includes understanding allowable stresses for different materials, proper connection details, and necessary inspections. Failure to comply with building codes can lead to significant structural issues, legal liabilities, and even catastrophic failures.

For instance, the code might specify minimum size requirements for rafters or trusses based on the anticipated snow load in a particular region. Ignoring this requirement could lead to a roof collapse during a heavy snowfall.

Q 17. Describe your experience with different types of roof insulation and their effect on support.

Different types of roof insulation significantly influence the design of the roof support system. Insulation adds weight, a critical factor in load calculations. Heavier insulation, like spray foam, requires a stronger support structure compared to lighter materials like fiberglass batts. Furthermore, some insulation types may have specific moisture-resistance properties that affect the longevity and structural integrity of the supporting members. For example, if moisture penetrates poorly insulated areas, it can lead to wood rot and weaken the structural integrity of the roof.

I’ve worked with various insulation types, including fiberglass, cellulose, spray polyurethane foam (SPF), and rigid foam boards. When selecting insulation, I consider its R-value (thermal resistance), weight, moisture resistance, and potential impact on the structural design. The weight of the insulation is factored into the overall load calculations to ensure the support system can handle the increased weight without compromising structural integrity.

Q 18. How do you create a detailed roof support plan?

Creating a detailed roof support plan involves a systematic approach. It starts with a thorough site assessment, including architectural drawings, existing conditions, and any special considerations (e.g., unusual roof geometry, seismic zones). I then conduct load calculations, determining the dead load, live load (snow, wind, rain), and any other potential loads. This informs the selection of appropriate structural members (beams, columns, trusses, rafters) and connection details. The plan includes detailed drawings showing the placement and sizing of all support elements, including specifications for materials and fasteners. It also incorporates safety considerations, such as fall protection measures and access points for maintenance.

For example, if the roof is in a high-wind area, the plan will incorporate stronger, more resilient support systems to withstand the increased wind loads. The plan will also clearly outline the sequence of installation for different components.

Q 19. Explain your process for selecting appropriate roof support materials.

Selecting appropriate roof support materials is crucial for the long-term performance and safety of the structure. I consider several factors: strength-to-weight ratio, durability, resistance to environmental factors (moisture, pests), cost-effectiveness, and availability. Common materials include wood (engineered lumber, dimensional lumber), steel (beams, columns), and concrete. The choice depends on factors such as the span length, load requirements, budget, and aesthetic preferences. For example, in a long-span application, steel might be more suitable than wood due to its higher strength-to-weight ratio. However, wood might be preferred in applications where aesthetics are important.

I always ensure that materials meet or exceed the specified building codes and industry standards. I will also consider the environmental impact of the materials selected to ensure sustainability.

Q 20. What are the limitations of different roof support systems?

Different roof support systems have limitations. For instance, wood framing, while widely used and cost-effective, has limitations in terms of span capacity compared to steel or engineered wood products. Steel structures, while strong, can be susceptible to corrosion and require proper protection against the elements. Trusses, while efficient for long spans, are vulnerable to damage if individual members are compromised. Masonry walls, often used as support, might have lower load-bearing capacity compared to steel or concrete columns. Each system requires careful consideration of its strengths and weaknesses to ensure it’s appropriate for the specific application and environmental conditions.

For example, in areas with high seismic activity, a wood-framed system may require additional bracing or reinforcement to ensure stability during an earthquake. Improper design or construction can exacerbate these limitations.

Q 21. How do you ensure the structural integrity of a roof during renovations?

Ensuring structural integrity during renovations requires a cautious approach. I start by performing a thorough assessment of the existing roof structure to identify any signs of weakness, damage, or deterioration. This often involves non-destructive testing techniques to assess the condition of the existing members. Then, I carefully plan the renovation work, minimizing any disturbance to the existing support system. Temporary shoring or bracing might be necessary to maintain stability while work is underway. New support elements are integrated seamlessly with the existing structure, using appropriate connection techniques to ensure a stable and load-bearing system. Regular inspections throughout the renovation process are vital to identify and address any unforeseen issues.

For example, if we’re adding a new dormer, we might need to reinforce existing rafters or install additional support beams to distribute the added load effectively and prevent stress on the existing roof structure. The plan will outline how this reinforcement is to be accomplished while the roof is still supporting the rest of the building.

Q 22. What are your methods for documenting roof support inspections?

My method for documenting roof support inspections is thorough and meticulous, ensuring comprehensive records for future reference and potential legal needs. I utilize a combination of digital and physical documentation. This includes:

- Digital Photography and Videography: High-resolution images and videos capture the overall condition of the roof structure, highlighting areas of concern like cracks, rust, or sagging. I use geotagging to precisely locate problem areas.

- Detailed Inspection Reports: These reports are meticulously compiled using standardized templates, including the date, location, client information, and a comprehensive description of the roof system. They identify the type of roofing materials, the condition of the supporting structure (trusses, rafters, purlins, etc.), and any observed deficiencies. Any recommendations for repair or replacement are detailed here.

- Schematic Drawings and Measurements: For complex structures, I create or update schematic drawings illustrating the roof’s geometry, structural members, and the location of penetrations. Key dimensions are meticulously recorded to aid in future planning and repairs.

- Software Integration: I often integrate data from drone inspections (where appropriate) and utilize software to create 3D models of the roof structure for a more detailed visualization.

- Physical Documentation: I also keep a hard copy of all documentation, stored in a secure location in case of digital loss or corruption.

This multi-faceted approach guarantees a complete and legally defensible record of the roof’s condition.

Q 23. Explain your experience with repairing damaged roof support systems.

My experience with repairing damaged roof support systems is extensive and involves a phased approach prioritizing safety and structural integrity. It begins with a careful assessment of the damage, identifying the root cause and extent of the problem. This might include rotted timbers, rusted steel, or damage from extreme weather.

The repair process typically involves:

- Safe Access and Isolation: Securing the work area and establishing fall protection are paramount. This often involves scaffolding or other elevated work platforms.

- Damage Removal and Assessment: Removing damaged sections carefully while minimizing further compromise to the structure. This stage might involve cutting away rotten wood or removing corroded steel components.

- Structural Reinforcement: Replacing damaged components with appropriately sized and graded materials. This often involves sistering weakened beams or replacing them entirely. I might also use specialized techniques like adding steel plates or reinforcing straps to improve structural capacity.

- Material Selection: This is crucial, and I select materials based on factors like load capacity, durability, and compatibility with existing elements. Pressure-treated lumber, galvanized steel, and composite materials are often used in these repairs.

- Final Inspection: Before work is signed off, a thorough inspection is done to ensure that all repairs have met structural requirements and building codes are adhered to.

For example, I recently worked on a project where significant rot had compromised several rafters in a historic building. After thorough assessment, we carefully removed the damaged sections and replaced them with pressure treated timbers of similar size and strength. The supporting structure was reinforced using heavy-duty metal brackets. The entire process was meticulously documented, meeting all historic preservation standards.

Q 24. How do you communicate technical information to non-technical stakeholders?

Communicating technical information to non-technical stakeholders requires a clear and concise approach, avoiding jargon. I prioritize using simple language and visual aids to facilitate understanding. My strategy involves:

- Analogies and Real-World Examples: Explaining complex concepts using relatable analogies helps clients grasp the information better. For instance, explaining the function of a truss might involve comparing it to a bridge structure.

- Visual Aids: Diagrams, photographs, and even 3D models are exceptionally helpful. A picture is truly worth a thousand words when discussing roof structural issues.

- Step-by-Step Explanations: Breaking down complex processes into easily digestible steps prevents overwhelming the client with too much technical detail at once.

- Active Listening and Feedback: Ensuring I understand the client’s concerns and clarifying any questions promptly promotes trust and confidence.

- Written Summaries: Following up with concise written reports summarizes key findings and recommendations, ensuring clear documentation for future reference.

For example, when explaining the need for roof support repairs to a homeowner, I avoid terms like ‘purlins’ and instead focus on practical consequences like potential leaks or structural failure. Using simple diagrams, I illustrate the problem and its solution, emphasizing safety and cost-effectiveness.

Q 25. What is your experience with different types of roof penetrations and their support requirements?

Roof penetrations, such as chimneys, vents, skylights, and HVAC units, require careful consideration for their support requirements to prevent leaks and structural compromise. The support needed depends greatly on the type of penetration and its size and weight.

Here are some examples:

- Chimneys: Often require substantial support, usually involving dedicated masonry or steel supports extending into the roof structure and properly flashing to prevent water ingress.

- Skylights: Need strong framing that distributes the weight evenly and provides adequate sealing against leaks. Curb mounted skylights have a built-in framework that simplifies installation and ensures proper support.

- HVAC Units: Require supports that can handle their weight and vibrations. These might include specialized mounts or dedicated framing integrated into the roof structure.

- Vents: While smaller and lighter, proper flashing and support are still crucial to prevent leaks. They usually integrate with the underlying roof structure without extensive additional support.

I thoroughly assess each penetration during inspections, evaluating the existing support and ensuring it meets the required structural and waterproofing standards. If deficiencies are found, appropriate remediation is recommended and implemented using best practices to ensure longevity and prevent future damage.

Q 26. How do you address the challenges posed by different weather conditions during roof support work?

Weather conditions pose significant challenges during roof support work. Safety and efficiency are significantly impacted. My approach involves:

- Weather Monitoring: Closely monitoring weather forecasts to schedule work during favorable conditions, postponing work if necessary for safety reasons.

- Safety Precautions: Implementing enhanced safety measures during adverse conditions, including additional fall protection, secure anchoring points, and appropriate clothing and equipment.

- Material Protection: Protecting materials from rain and wind damage using tarps, covers, or storage inside if conditions deteriorate rapidly.

- Adaptive Techniques: Adjusting work methods to accommodate weather challenges. For example, working during shorter time windows, modifying scaffolding setups, or implementing alternative repair strategies based on current conditions.

- Emergency Procedures: Establishing clear emergency procedures to handle unexpected weather events, such as sudden storms or high winds.

For example, I once had to halt work on a roof repair due to an unexpected thunderstorm. We secured all tools and equipment, and evacuated the site to ensure everyone’s safety. Work resumed only after the storm passed, and conditions were deemed safe.

Q 27. Describe your experience with working on various roof types (gable, hip, flat, etc.).

My experience encompasses a wide range of roof types, including gable, hip, flat, and more complex designs. Each type presents unique challenges and considerations regarding roof support.

- Gable Roofs: These roofs utilize trusses or rafters to support the roof load, with the load concentrating at the ridge and eaves. Inspection focuses on the structural integrity of these members, looking for signs of weakness or decay.

- Hip Roofs: These have sloping sides that meet at a central ridge, resulting in a more complex load distribution. Support strategies often require specialized calculations and the use of purlins and rafters that can manage the sloping load transfer.

- Flat Roofs: Require a different approach, often using beams, girders, and decking systems to handle the weight of the roofing membrane and other imposed loads. These systems are vulnerable to ponding water, which necessitates robust drainage and support.

- Complex Roofs: Structures with multiple slopes, dormers, and other features demand a thorough understanding of structural mechanics to ensure proper load distribution. Detailed structural analysis and specialized engineering might be required.

My expertise lies in understanding the distinct load paths and support mechanisms for each roof type, allowing me to identify potential problems and develop effective repair strategies.

Q 28. What software or tools are you proficient in for roof design and analysis?

I am proficient in several software and tools for roof design and analysis. This includes:

- AutoCAD: For creating detailed drawings and schematics of roof structures, including dimensions, materials, and support systems.

- Revit: For building information modeling (BIM), providing a 3D model for analysis and coordination with other building systems.

- RISA-2D/3D: Powerful structural analysis software used for calculating loads and stresses on roof structures, validating the adequacy of existing or proposed support systems.

- SketchUp: For quick conceptual design and visualization of roof structures.

- Microsoft Office Suite: For report writing, documentation, and data management.

Proficiency in these tools enables me to conduct thorough analyses, optimize designs, and create accurate documentation for both technical and non-technical audiences. The combination of software expertise and practical field experience allows me to deliver comprehensive and reliable solutions for roof support challenges.

Key Topics to Learn for Roof Support Interview

- Structural Analysis of Roof Systems: Understanding load calculations (dead load, live load, snow load, wind load), stress distribution, and material properties crucial for roof stability.

- Roof Support Components and their Functions: Detailed knowledge of rafters, trusses, purlins, girders, columns, and bracing systems, including their individual roles and interactions within the overall structure.

- Common Roof Types and their Supporting Structures: Familiarity with gable, hip, gambrel, shed, and flat roofs; understanding the unique support requirements for each type.

- Material Selection and Properties: Knowledge of different roofing materials (wood, steel, concrete) and their strengths, weaknesses, and suitability for various roof designs and load conditions.

- Construction Methods and Techniques: Understanding the practical aspects of roof construction, including installation procedures, safety regulations, and quality control measures.

- Troubleshooting and Problem-Solving: Ability to identify potential structural weaknesses, diagnose common roof problems (e.g., leaks, sagging), and propose effective solutions.

- Building Codes and Regulations: Familiarity with relevant building codes and regulations pertaining to roof design, construction, and safety.

- Sustainability and Energy Efficiency in Roof Design: Understanding principles of sustainable design and the role of roof systems in energy efficiency (e.g., insulation, ventilation).

- Software and Design Tools: Familiarity with relevant software used in roof design and analysis (mentioning specific software is optional, focus on the skill instead).

Next Steps

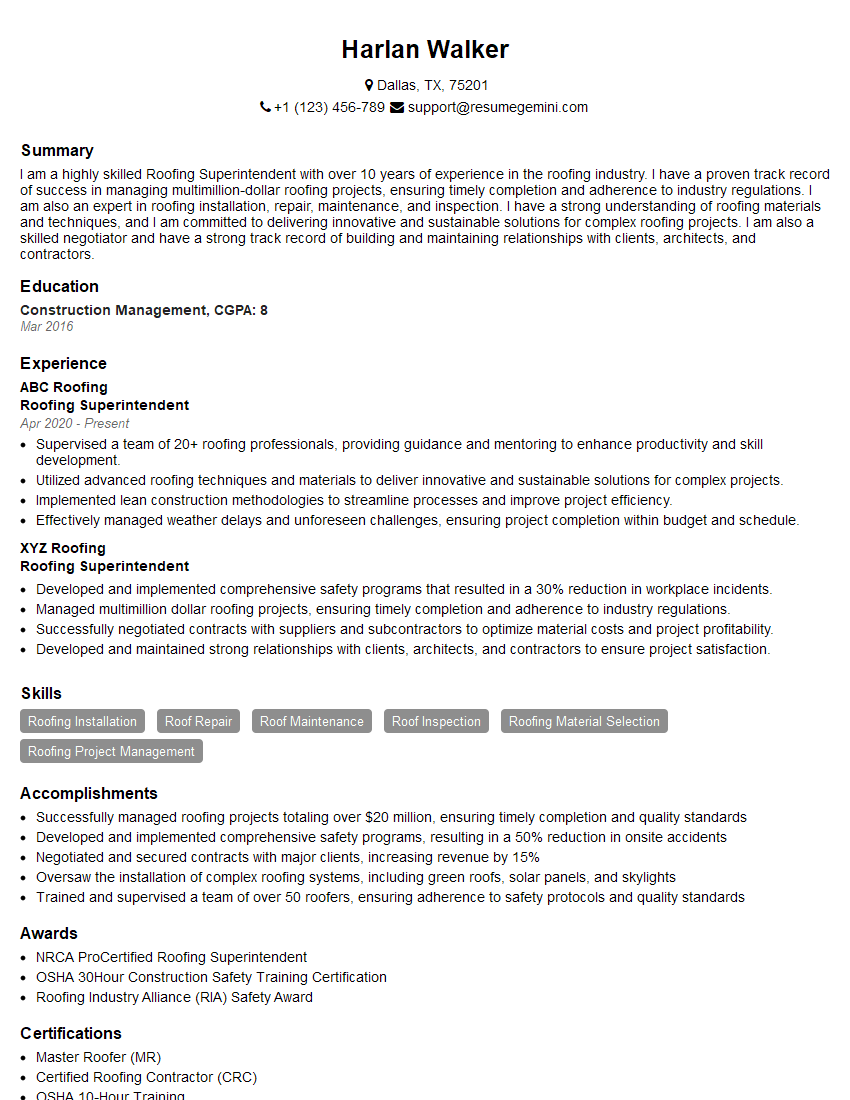

Mastering Roof Support principles is vital for career advancement in the construction and engineering fields, opening doors to specialized roles and increased earning potential. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Roof Support are available to guide you through this process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good