Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Pole Climbing and Maintenance interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Pole Climbing and Maintenance Interview

Q 1. Describe your experience with different climbing techniques (e.g., body belt, saddle, ascenders).

My experience encompasses a wide range of pole climbing techniques, each suited to different situations and pole types. The most common are body belt climbing, saddle climbing, and ascender-assisted climbing.

- Body Belt Climbing: This is a traditional method, primarily used for shorter poles or quick tasks. It involves using a safety harness secured around the waist and legs, and relying on friction and leg strength to ascend and descend. It’s simpler to learn but less efficient for taller poles.

- Saddle Climbing: This involves using a climbing saddle, which provides more comfort and support over longer climbs. The saddle distributes weight more evenly, reducing strain on the legs and back. A friction hitch, like a Prusik knot, is often used to create a secure and adjustable ascent and descent mechanism. It’s generally preferred for longer climbs and heavier loads.

- Ascender-Assisted Climbing: This technique uses ascenders—mechanical devices that grip the climbing rope, making ascent easier and less strenuous. It’s crucial for safety and efficiency on taller structures, especially when carrying equipment. I’m proficient with various ascender models and understand their limitations and proper use.

The choice of technique depends heavily on factors like pole height, the type of work being performed (e.g., inspection, maintenance, repair), and personal preference. Safety is paramount, and I always select the most appropriate method for the task at hand.

Q 2. What safety procedures do you follow before, during, and after pole climbing?

Safety is my top priority. My pre-climb procedures are rigorous and involve a comprehensive checklist:

- Pre-climb Inspection: A thorough visual inspection of the pole, including its base, shaft, and attachments, looking for any signs of damage or deterioration.

- Equipment Check: Verifying the condition and functionality of all my climbing gear, including harnesses, ropes, ascenders, and other safety equipment.

- Weather Assessment: Evaluating the weather conditions – high winds, rain, or ice significantly impact safety and necessitate adjustments or postponement.

- Communication Plan: Establishing clear communication with a ground crew to ensure someone is always monitoring my ascent and descent.

During the climb, I maintain constant awareness of my surroundings and my body’s limits. I employ proper rope management and use redundant safety systems where possible. I pause frequently to reassess conditions and take breaks as needed.

After the climb, I conduct a post-climb equipment inspection, ensuring everything is in proper condition. I document all work performed, noting any issues found and actions taken. A detailed report is also filed regarding the pole’s condition and any necessary follow-up repairs.

Q 3. Explain your understanding of fall protection systems and their limitations.

Fall protection systems for pole climbing primarily focus on arresting a fall if one occurs. Common systems utilize a climbing harness, a rope, and a fall arrest device. The effectiveness depends on many factors.

- System Type: Different systems have varying limitations regarding fall distance and shock absorption capabilities. Some systems are designed for specific pole types or climbing techniques.

- Rope Condition: A damaged or worn rope significantly compromises the system’s ability to arrest a fall effectively. Regular inspection and replacement are crucial.

- Anchor Points: The security of the anchor point plays a vital role. A weak or poorly installed anchor could fail under stress.

- Environmental Factors: Weather conditions (e.g., ice, rain) can affect the rope’s grip and the system’s performance.

It’s essential to understand that even the best fall protection system has limitations. No system is foolproof, and the most effective fall protection strategy involves a combination of proper technique, equipment maintenance, and risk assessment to minimize the likelihood of a fall.

Q 4. How do you inspect a pole for damage or deterioration before climbing?

Before climbing, I conduct a meticulous pole inspection. This involves a visual assessment as well as a physical check.

- Visual Inspection: I carefully examine the entire pole’s surface for cracks, splits, rot (in wooden poles), corrosion (in metal poles), significant wear and tear, and any signs of previous damage or repairs. I specifically check the base and any attachment points for instability.

- Physical Check: I look for any signs of instability by carefully tapping or probing the pole’s surface. This is particularly important to identify internal decay or hollowing out, which might not be evident visually. I also assess the surrounding ground for any signs of erosion or undermining at the base of the pole.

If I find any significant damage or signs of deterioration, I will not climb the pole unless appropriate repairs are made or a qualified engineer assesses the structural integrity. Safety is my top priority. I thoroughly document my findings before, during, and after the inspection.

Q 5. What are the common causes of pole failures, and how can they be prevented?

Pole failures can stem from a variety of causes, many of which are preventable with proper maintenance and inspection practices.

- Deterioration: Wood poles can rot and decay due to moisture and insect infestation. Metal poles are prone to corrosion, especially in damp environments. Concrete poles can crack or degrade over time due to weathering and stress.

- Overloading: Exceeding the pole’s design load capacity can lead to failure. This might involve attaching heavy equipment or using inappropriate climbing techniques that put undue stress on the pole.

- Improper Installation: If a pole is not installed correctly, it’s more vulnerable to failure. This includes inadequate grounding and improper setting in the ground.

- Ground Settlement: Changes in the ground surrounding the base of the pole can create stress and instability. Erosion or shifting soil can lead to weakening and subsequent failure.

- Environmental Factors: Extreme weather conditions, such as strong winds, ice, or lightning strikes, can contribute to pole failure.

Prevention involves regular inspections, proactive maintenance (including repairs and treatment), proper installation techniques, adherence to load limits, and an awareness of environmental conditions. Adopting these preventative measures significantly reduces the risk of pole failure.

Q 6. Describe your experience working with different types of pole materials (e.g., wood, concrete, steel).

I have extensive experience working with various pole materials. Each material presents unique challenges and necessitates different safety precautions:

- Wooden Poles: These are susceptible to rot and insect damage, requiring regular inspections for decay and the use of appropriate climbing techniques to avoid damaging the already weakened structure.

- Concrete Poles: These are generally strong but can crack or develop internal defects over time, requiring attention to proper inspection techniques to detect potential issues.

- Steel Poles: While robust, steel poles can corrode, especially in certain environments. Regular inspections for rust and other forms of corrosion are critical. Additionally, sharp edges and potentially exposed metal require extra care during climbing.

My approach adapts to the material. I use specialized techniques and safety equipment for each pole type to mitigate the unique risks they present. For example, I use different climbing gear and techniques for climbing a fiberglass pole compared to a wood or steel pole. Understanding the properties of each material is crucial for safe and efficient pole maintenance.

Q 7. How do you handle different weather conditions while climbing a pole?

Weather conditions drastically affect pole climbing safety and efficiency. I always assess the weather before, during, and after the climb.

- High Winds: Climbing in high winds is extremely dangerous. I will postpone the climb if wind speeds exceed safe limits. If winds pick up unexpectedly during a climb, I will descend immediately.

- Rain: Rain reduces friction, making climbing more challenging and potentially dangerous. I always use appropriate rain gear and may adjust my climbing techniques for safety.

- Ice: Ice is incredibly dangerous and makes climbing almost impossible. I will absolutely not climb in icy conditions. This may necessitate postponing the climb until the ice melts.

- Extreme Temperatures: Both extreme heat and cold can cause fatigue and impact performance. I adjust accordingly, taking breaks, hydrating properly, and wearing appropriate clothing.

I monitor weather conditions continuously using reliable forecasts and visual observation. My decisions regarding whether or not to climb always prioritize safety. Postponing a climb is often the safest and most responsible course of action in adverse weather conditions.

Q 8. What tools and equipment are essential for pole climbing and maintenance?

Safety is paramount in pole climbing and maintenance, and the right tools are essential for both efficiency and safety. The list varies slightly depending on the specific task, but here’s a core set of essential equipment:

- Climbing Gear: This includes a safety harness with a full-body design, climbing gaffs (spikes), a lineman’s belt, and a safety rope with a shock-absorbing lanyard. The harness is your lifeline, ensuring you’re securely attached to the pole at all times.

- Hand Tools: These are crucial for various tasks. Expect to find a variety of screwdrivers (both flathead and Phillips), pliers (including lineman’s pliers), wire cutters, a voltage tester, and a set of wrenches.

- Pole Tools: Specialized tools designed for working on poles include a fiberglass or wooden pole for pushing and pulling wires, as well as tools for connecting and disconnecting equipment.

- Measuring and Testing Equipment: Accurate measurements and voltage readings are essential. This might include a measuring tape, voltage indicators, and possibly a multimeter for more complex troubleshooting.

- Personal Protective Equipment (PPE): This is non-negotiable. Always use safety glasses or goggles, insulating gloves, hard hats, and appropriate work boots. Depending on the task, a face shield may also be necessary.

For example, during a recent job replacing a faulty transformer, having the right combination of insulated tools and a properly functioning voltage tester allowed me to safely isolate the faulty component and carry out the replacement efficiently and safely.

Q 9. Explain your experience with aerial lift trucks and bucket trucks.

I have extensive experience operating both aerial lift trucks and bucket trucks. These are invaluable tools for efficient and safe access to higher sections of poles, especially when dealing with larger or more complex tasks. Aerial lift trucks are generally more versatile for a broader range of tasks, allowing for precise positioning and horizontal movement, while bucket trucks offer a more contained work platform that’s excellent for focused work on a single pole or section.

My experience includes regular inspections and maintenance of these vehicles, ensuring their operational safety, including pre-operational checks of hydraulic systems, safety restraints, and electrical systems. I’m also proficient in understanding the limitations of each truck’s reach and load capacity, ensuring the work is always completed safely within those limitations.

For instance, while replacing a damaged crossarm on a tall pole, the bucket truck’s stability and contained platform proved safer and more efficient than using a conventional aerial lift for this type of focused, overhead work. Proper use of these trucks helps minimize risk and maximizes efficiency.

Q 10. How do you perform routine maintenance on utility poles?

Routine maintenance on utility poles is crucial for preventing outages and ensuring the long-term integrity of the power grid. A typical routine includes:

- Visual Inspection: Thoroughly checking the pole for signs of damage such as cracks, rot, insect infestation, or loose hardware. This often involves using binoculars to spot potential problems from a distance.

- Hardware Tightening: Ensuring all bolts, nuts, and connections are tight and secure. Loose connections can be a significant safety hazard and contribute to equipment failure.

- Crossarm Inspection: Checking the crossarms for any cracks or signs of deterioration. Crossarms are critical for supporting the electrical lines, so their condition is paramount.

- Insulator Inspection: Inspecting insulators for cracks, chips, or any signs of contamination. Dirty or damaged insulators can significantly impact the system’s efficiency and safety.

- Vegetation Clearance: Trimming back any vegetation that’s too close to the lines. Overgrown branches can cause shorts or outages, especially during stormy weather.

- Grounding Check: Verifying the integrity of the grounding system to ensure proper electrical safety.

Regularly following these steps helps prevent more extensive repairs, and minimizes the likelihood of service interruptions. Think of it like maintaining a car – regular oil changes and inspections prevent major breakdowns later.

Q 11. Describe your experience with underground cable locating and repair.

My experience with underground cable locating and repair is extensive. Locating underground cables is critical for preventing accidental damage during excavation or other ground-disturbing activities. This involves using sophisticated tools and techniques:

- Cable Locators: These devices use electromagnetic signals to pinpoint the location of underground cables. Different types of locators exist, each designed to detect different types of cables.

- Ground Penetrating Radar (GPR): GPR uses radar pulses to create images of the subsurface, allowing for a more detailed view of cable locations and depth.

- Digging and Repair: Once a cable is located, careful excavation is necessary to expose it for repair. This often involves hand digging to minimize the risk of damaging the cable.

- Testing: Before restoring the cable to service, testing is required to ensure its integrity and safe operation.

I’ve been involved in numerous projects where accurate cable location prevented damage to crucial infrastructure and avoided costly delays. For example, on a recent road construction project, precise cable location prevented accidental damage to communication lines buried beneath the road, saving significant time and money.

Q 12. How do you troubleshoot common electrical problems on poles?

Troubleshooting electrical problems on poles requires a systematic approach. It often starts with safety precautions: always de-energize the affected lines before starting any work. Then, the process usually follows these steps:

- Visual Inspection: A thorough examination of the line, insulators, and connections for any visible damage or anomalies. Look for things like burnt components or loose connections.

- Voltage Testing: Using a voltage tester or multimeter to check for voltage presence and identify the location of faults. This should always be done with appropriate safety precautions.

- Continuity Testing: Verifying the electrical continuity of circuits and components to identify breaks or shorts.

- Component Testing: Individually testing components such as transformers, insulators, or fuses to pinpoint the source of the problem.

- Documentation: Keeping accurate records of all findings and steps taken.

For example, a recent outage traced to a faulty transformer was easily resolved after a systematic testing process ruled out other possibilities. Without a careful approach, the fault might have been misdiagnosed and led to more extensive and costly repairs.

Q 13. What are the regulations and safety standards you follow during pole climbing?

Safety is paramount in pole climbing and maintenance. My work strictly adheres to OSHA regulations and industry best practices. These include:

- Proper Training and Certification: I’m fully trained and certified in pole climbing and related safety procedures.

- Fall Protection: Always using a properly fitted and inspected safety harness, climbing gear, and safety rope.

- Lockout/Tagout Procedures: Following strict procedures to de-energize lines before any work is undertaken.

- Pre-Job Planning: Careful planning and risk assessment before commencing any task, including weather conditions and potential hazards.

- Regular Inspections: Regularly inspecting all equipment to ensure it’s in safe working order.

- Communication Protocols: Clear communication with ground crew to coordinate tasks and ensure a safe work environment.

Ignoring these regulations is not only dangerous but illegal. These standards safeguard my safety and the safety of those around me. It’s a way of working that’s ingrained in every aspect of what I do.

Q 14. How do you communicate effectively with your team while working at heights?

Effective communication while working at heights is critical for safety and efficiency. We utilize a combination of methods:

- Hand Signals: A pre-established set of hand signals for clear and unambiguous communication, especially when verbal communication is difficult or risky.

- Two-Way Radios: Constant communication through two-way radios is essential for coordinating tasks, relaying observations, and addressing any issues.

- Pre-Job Briefings: Clear pre-job briefings cover the task, potential hazards, and communication protocols.

- Clear and Concise Language: Using clear and concise language to avoid misunderstandings and ensure that everyone knows what’s happening.

For example, during a challenging repair job, a well-timed hand signal alerted my team to a potential hazard on the ground, preventing an accident. Clear communication isn’t just about words, it’s a combination of systems, training, and mutual understanding.

Q 15. Explain your experience with working in confined spaces.

Working in confined spaces, such as climbing utility poles, requires a heightened awareness of safety protocols. My experience encompasses years of working at heights, meticulously following safety regulations, and utilizing appropriate personal protective equipment (PPE). This includes always using a properly inspected safety harness, climbing belt, and fall protection system. Before each climb, a thorough pole inspection is conducted to identify any potential hazards, like damaged wood or broken crossarms. I’m proficient in understanding and applying confined-space entry procedures, including atmospheric testing when necessary. For instance, I once had to respond to a suspected gas leak near a pole. Before ascending, I used a gas detector to ensure the air was safe to breathe. This prevented a potentially hazardous situation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with various types of cable splicing and termination.

My experience in cable splicing and termination covers a wide range of techniques for various cable types, including copper, fiber optic, and coaxial cables. I’m skilled in various splicing methods such as the Western Union splice, Britannia splice, and various connector types like compression connectors and heat-shrink connectors. For fiber optics, I’m proficient in fusion splicing and mechanical splicing. The selection of the correct splicing method depends entirely on the cable type, application, and required performance. For example, the Western Union splice is ideal for simple applications with low-voltage DC power while fusion splicing is crucial for maintaining signal integrity in fiber optics. Proper insulation and sealing are critical aspects of every termination to ensure waterproofing and prevent electrical faults. I’ve consistently met industry standards for quality and reliability, verified through testing procedures.

Q 17. How do you handle emergency situations while climbing a pole?

Emergency situations while pole climbing require quick thinking and decisive action. My training emphasizes risk assessment and preparedness. If I experience a fall, my fall protection system will automatically engage, but I would also activate my emergency communication device immediately to alert my crew. If equipment malfunctions, I have backup equipment, and I’m trained to troubleshoot common issues on the pole. In case of electrical shock, knowing how to safely detach myself from the pole and administer first aid is crucial. I’ve also participated in extensive rescue training scenarios, honing my skills in self-rescue and assisting other climbers. For example, during a storm, a limb fell unexpectedly and caused a minor equipment failure. My prompt response and use of backup gear prevented a serious accident.

Q 18. What are your skills in using different types of hand tools?

I’m highly proficient in using a variety of hand tools essential for pole climbing and maintenance. This includes, but isn’t limited to: lineman’s pliers, wire cutters, cable grips, screwdrivers (both standard and specialized), crescent wrenches, and various types of specialized tools for working with specific cable types and connectors. I understand the importance of tool maintenance, ensuring that each tool is in proper working order before use and cleaning and storing tools properly after each use. This prevents accidental damage and ensures the longevity of the tools. My ability to select and use the appropriate tool for a given task is a crucial part of efficient and safe work practices.

Q 19. How do you ensure the safe handling and storage of hazardous materials?

Safe handling and storage of hazardous materials are paramount. I adhere strictly to all relevant safety regulations and company policies regarding the handling of chemicals, solvents, and other potentially hazardous materials. This includes proper use of PPE like gloves, eye protection, and respirators. All hazardous materials are stored in designated areas, labeled correctly, and in containers designed to prevent spills and leaks. I’m trained in spill response procedures, knowing how to effectively contain and clean up any spills according to the manufacturer’s instructions and regulatory requirements. I also ensure that all safety data sheets (SDS) are readily available and reviewed before working with any new material. My consistent adherence to these protocols ensures that I and my fellow workers remain safe and that the environment is protected.

Q 20. Describe your experience with fiberglass and its use in utility work.

Fiberglass is extensively used in utility work due to its strength, lightweight nature, and excellent electrical insulating properties. I’m experienced in handling and working with fiberglass poles, crossarms, and other components. I understand the importance of proper handling techniques to avoid damage or injury, especially given the potential for fiberglass splinters. I’m aware of the proper disposal methods for broken or damaged fiberglass materials, as well as safe procedures for working with it during inclement weather, ensuring I don’t risk damage to the material or my own safety. I’ve frequently worked with both solid and composite fiberglass materials and understand the differences in their properties and applications.

Q 21. How do you calculate the weight capacity of a pole?

Calculating the weight capacity of a utility pole is a crucial safety aspect. It involves considering several factors: the pole’s material (wood, concrete, or fiberglass), its dimensions (height, diameter at the base and top), and the type of soil or foundation it’s set in. There are established engineering formulas and industry standards used for this calculation, often incorporating factors for wind load and ice accumulation. I use these industry standard calculation methods and relevant engineering documents to determine the maximum safe weight the pole can support, always erring on the side of caution and using safety factors to account for unforeseen circumstances. Failing to accurately calculate weight capacity can lead to pole failure and significant safety hazards.

Q 22. How do you identify and report potential hazards on a worksite?

Identifying and reporting potential hazards on a pole climbing worksite is paramount for safety. My approach involves a systematic pre-job inspection and continuous hazard awareness during the work itself. This begins with a thorough visual assessment of the pole, surrounding environment, and equipment.

- Pole Inspection: I look for signs of deterioration such as cracks, rot, insect infestation, or loose hardware. I also check for proper grounding and the condition of the climbing equipment attached to the pole.

- Environmental Assessment: This includes identifying obstacles like overhead power lines, nearby trees, uneven terrain, and weather conditions (e.g., high winds, rain, or ice). I also consider the presence of wildlife or any potential human interference.

- Equipment Check: This is crucial and involves verifying the functionality and safety of all my climbing gear, including harnesses, ropes, safety straps, and tools. I always ensure everything is in good condition and properly secured.

Once a potential hazard is identified, I immediately report it using the company’s established reporting system, which might involve a written report, verbal communication with my supervisor, or using a dedicated mobile app. This report includes a detailed description of the hazard, its location, the potential risks, and recommended corrective actions.

For example, if I find a significant crack on a pole, I’ll immediately stop work and clearly document the crack’s location, size, and orientation in my report, along with pictures or videos, requesting an engineering assessment and the pole’s potential replacement.

Q 23. Explain your understanding of lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are critical for preventing accidental energization of equipment during maintenance. They ensure that energy sources are isolated and secured, preventing injuries or fatalities. My understanding encompasses a strict adherence to these steps:

- Preparation: I begin by identifying all potential energy sources connected to the equipment—electrical, mechanical, hydraulic, pneumatic—and confirming that they are shut down.

- Lockout: I then apply a lockout device, such as a padlock, to the energy isolation point to physically prevent the energy source from being re-energized. Only authorized personnel can have a key or combination to that device.

- Tagout: I attach a tag clearly identifying the worker responsible for the lockout, the date and time of lockout, and the reason for lockout. This visual warning alerts others of the hazards and prevents unauthorized access or re-energization.

- Verification: Before starting any work, I double-check that the equipment is de-energized by testing the circuits or operating the equipment (with supervision if necessary).

- Tagout Removal: Once the work is completed, and everything is verified safe, I remove the lockout and tagout devices. This process involves a verification check with my supervisor.

Imagine working on a distribution transformer. Before even approaching it, I would follow LOTO precisely. I would open and lock the circuit breaker, then attach a tag. Only after verification will I begin the maintenance.

Q 24. Describe your knowledge of different types of insulators and their functions.

Insulators are crucial components in power transmission systems; they prevent the flow of current from the energized conductor to the supporting structure or ground. Different types exist, each with specific characteristics:

- Porcelain Insulators: These are traditional, widely used insulators known for their high dielectric strength and resistance to harsh weather. They are typically made from high-quality ceramic material, and their excellent mechanical strength is well-suited for heavier loads.

- Glass Insulators: Offering similar high dielectric strength to porcelain, glass insulators are known for their high resistance to surface contamination. This advantage is particularly helpful in heavily polluted environments.

- Polymer Insulators: These are increasingly popular due to their lightweight design, hydrophobicity (resistance to water absorption), and relatively low cost. They are a durable option in many circumstances and resist the effects of UV radiation.

- Composite Insulators: These combine different materials (e.g., fiberglass reinforced epoxy resin) for optimal mechanical and electrical properties. This allows them to resist higher voltages and withstand extreme environmental conditions, such as high winds and heavy snow or ice build-up.

The selection of the proper insulator depends on several factors, including voltage level, environmental conditions, and the mechanical strength required. For instance, in areas with heavy pollution, glass insulators might be preferred. High-voltage transmission lines often employ composite insulators for their superior strength and durability.

Q 25. How do you maintain accurate records of your work?

Maintaining accurate records is fundamental in pole climbing and maintenance for accountability, safety, and efficient work management. My approach combines digital and paper-based methods to ensure comprehensive record-keeping:

- Digital Records: I use dedicated software or apps provided by the company, generally mobile applications, to document daily work progress. This includes recording pole locations (often using GPS coordinates), work performed (including inspections, repairs, and replacements), materials used, and any significant observations. Photos and videos are always included for added visual verification.

- Paper-Based Records: I also maintain physical work orders, inspection reports, and material checklists. This acts as a backup to the digital records and is useful in environments with poor cellular or internet connectivity.

- Data Synchronization: Upon completing a task, I promptly synchronize my digital records with the central database, ensuring information is readily available for my colleagues and superiors. This includes providing a clear summary of findings, including potential hazards or necessary future work.

This approach ensures that every job is thoroughly documented, facilitating efficient tracking of maintenance schedules, cost analysis, and future planning. This process is also essential for compliance audits and for responding efficiently to potential future problems.

Q 26. What is your experience with using aerial photography or drone technology in pole inspection?

Aerial photography and drone technology have revolutionized pole inspection. I have experience using drones equipped with high-resolution cameras to inspect poles in hard-to-reach or dangerous areas. Drones provide:

- Improved Safety: Reduced risk to personnel by minimizing the need for direct physical access to high-voltage equipment.

- Enhanced Efficiency: Quicker inspections, covering a larger area in a shorter time compared to traditional methods.

- Detailed Images: High-resolution images and video allow for thorough inspection of pole structures, insulators, and hardware. This is especially useful to check for damage or wear that could be missed from the ground.

- Data Analysis: Advanced software can automatically analyze drone images to identify potential hazards and create detailed reports.

In one recent project, using a drone equipped with thermal imaging, I discovered overheating in a transformer on a difficult-to-access pole. Early detection allowed us to prevent potential failures and avoid prolonged outages.

Q 27. How do you stay up to date with the latest industry standards and safety regulations?

Staying current with industry standards and safety regulations is a continuous process, essential for safe and efficient work. My approach involves several strategies:

- Professional Organizations: Active membership in organizations like the IEEE (Institute of Electrical and Electronics Engineers) provides access to the latest industry publications, standards, and safety guidelines.

- Training Courses and Seminars: Regularly attending specialized training courses and seminars on pole climbing, maintenance, and safety protocols ensures my skills and knowledge remain up to date. This is especially important when new technologies or regulations are implemented.

- Online Resources: I utilize online resources, such as industry-specific websites and professional journals, to access the most recent information on safety regulations, best practices, and emerging trends.

- Manufacturer Updates: I keep abreast of updates and training from manufacturers of climbing equipment and other safety gear to ensure I am utilizing the best equipment and techniques.

- Company Training Programs: Participating in company-mandated safety training and continuing education programs keeps my knowledge aligned with company policies and industry regulations.

This multifaceted approach ensures that I maintain a high level of competency and remain compliant with all applicable rules and regulations.

Q 28. Describe your problem-solving approach when encountering unexpected challenges during pole climbing and maintenance.

Unexpected challenges are inevitable in pole climbing and maintenance. My problem-solving approach involves a systematic process:

- Assessment: First, I carefully assess the situation, identifying the nature and extent of the challenge. This is crucial for avoiding risky solutions or unintended consequences.

- Safety First: Safety is always paramount. If I encounter a situation that poses a safety risk, I immediately halt the work and implement appropriate safety measures. If needed, I will contact supervisors and specialized equipment.

- Resource Mobilization: I utilize the available resources, including tools, equipment, and my team’s expertise, to find the best solution. This may involve communication with engineers, managers, or other specialists.

- Creative Solutions: Sometimes standard approaches may not work. In such instances, I employ creative thinking and apply my knowledge to adapt existing techniques or develop innovative solutions.

- Documentation and Reporting: Regardless of whether the challenge was minor or major, I meticulously document the issue, the steps taken to resolve it, and the outcome. This aids in identifying recurring problems and improving future work procedures.

For example, I once encountered a broken insulator on a live line. Instead of attempting a risky repair myself, I immediately called for qualified support, secured the area, and implemented proper LOTO procedures. This prevented injury and ensured a safe resolution by qualified personnel.

Key Topics to Learn for Pole Climbing and Maintenance Interview

- Safety Regulations and Procedures: Understanding and applying OSHA regulations, safe work practices, and emergency procedures related to pole climbing and maintenance.

- Climbing Techniques and Equipment: Proficiency in various climbing techniques (e.g., ascending, descending, working at height), knowledge of different climbing equipment (e.g., safety harnesses, ropes, ascenders), and their proper use and maintenance.

- Pole Inspection and Assessment: Identifying potential hazards, assessing pole condition (e.g., rot, damage, wear), and documenting findings accurately.

- Maintenance and Repair Procedures: Knowledge of various maintenance tasks (e.g., replacing insulators, tightening connections, repairing damaged components), understanding repair techniques, and using appropriate tools.

- Troubleshooting and Problem-Solving: Diagnosing and resolving common issues encountered during pole climbing and maintenance, demonstrating effective problem-solving skills in challenging situations.

- Electrical Safety and Awareness: Understanding the risks associated with working near energized lines, adhering to electrical safety protocols, and employing appropriate safety measures.

- Documentation and Reporting: Accurately recording work performed, maintenance activities, and any identified issues using clear and concise documentation.

- Teamwork and Communication: Highlighting experience working collaboratively with a team, effectively communicating technical information, and following instructions.

Next Steps

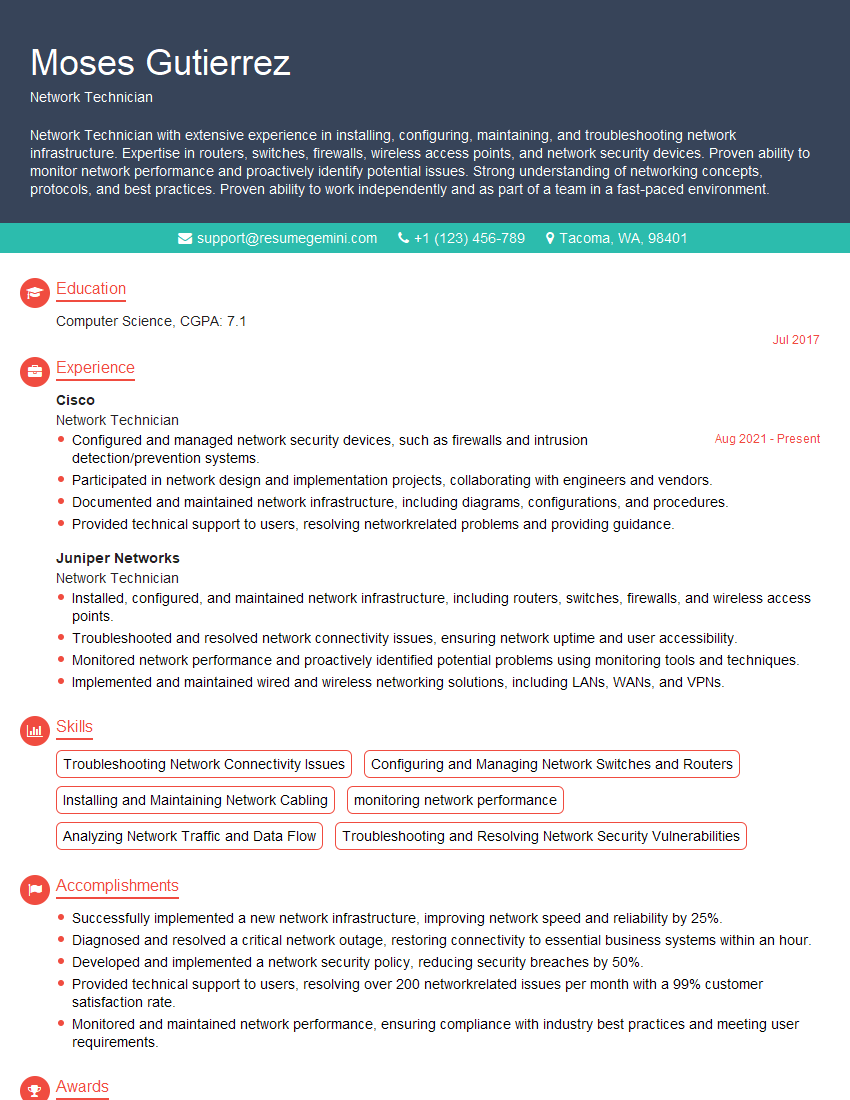

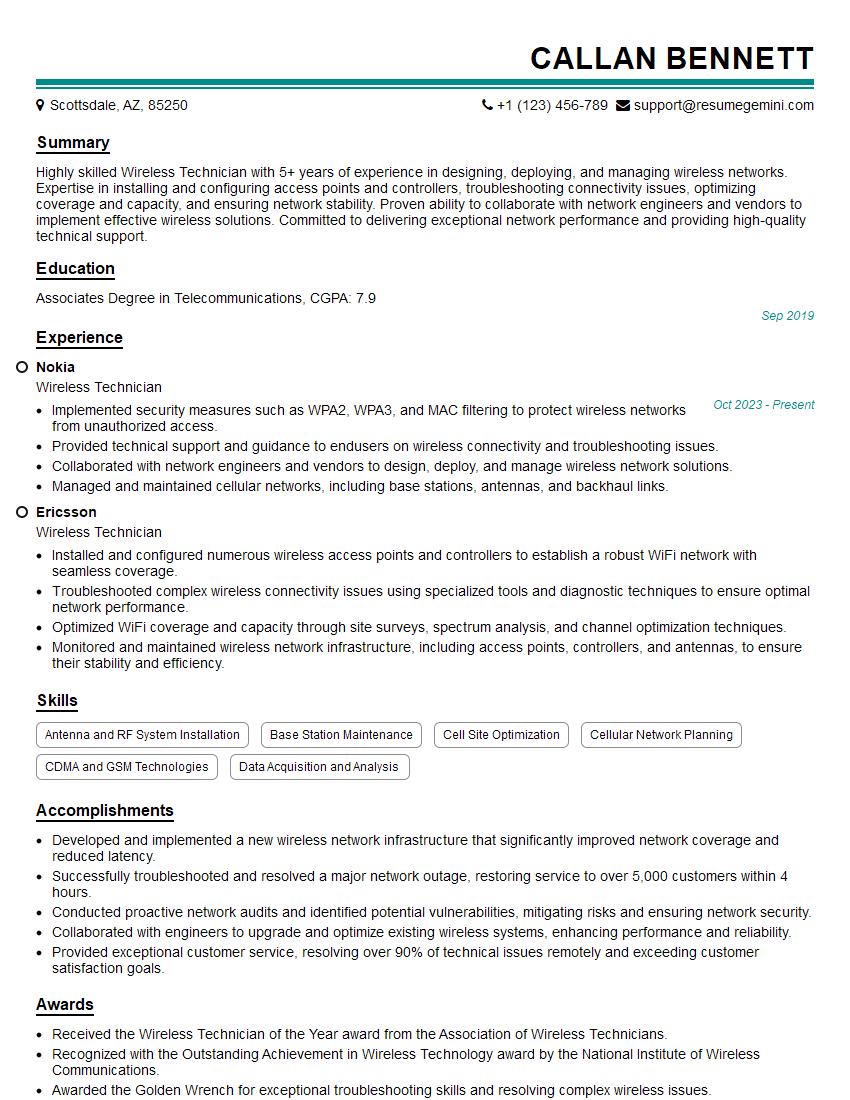

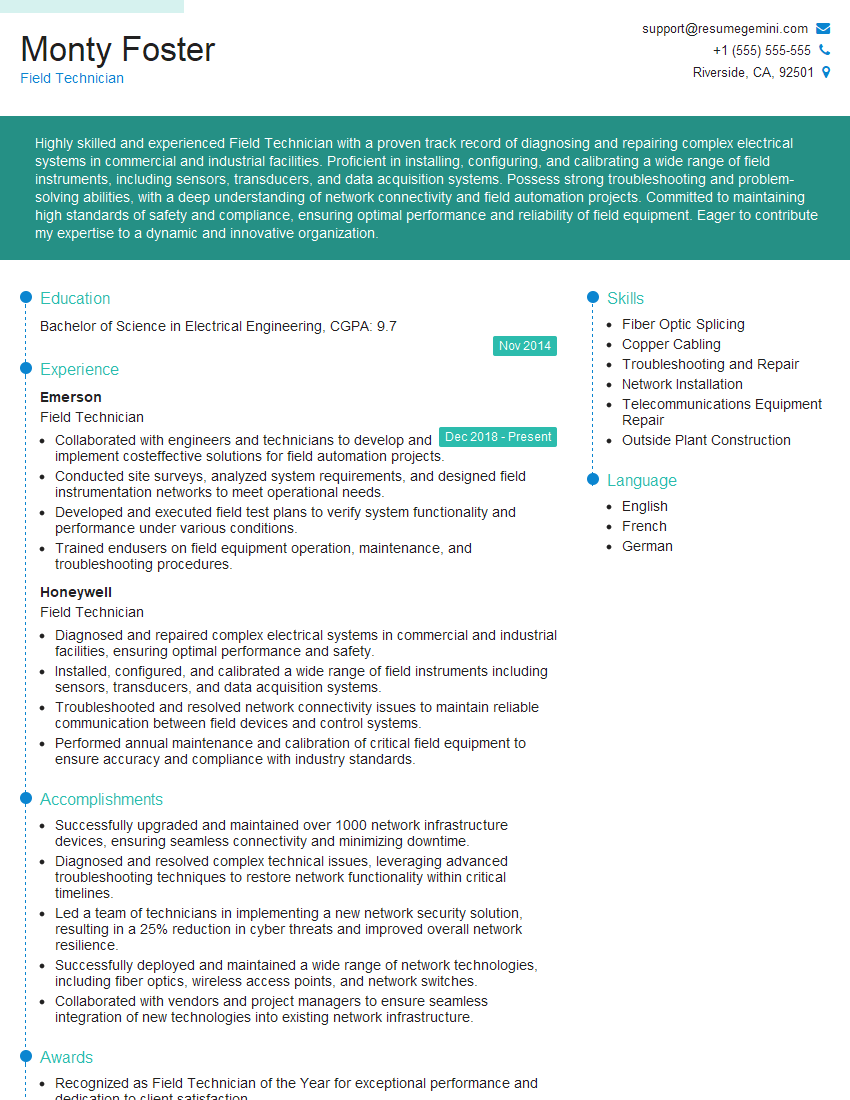

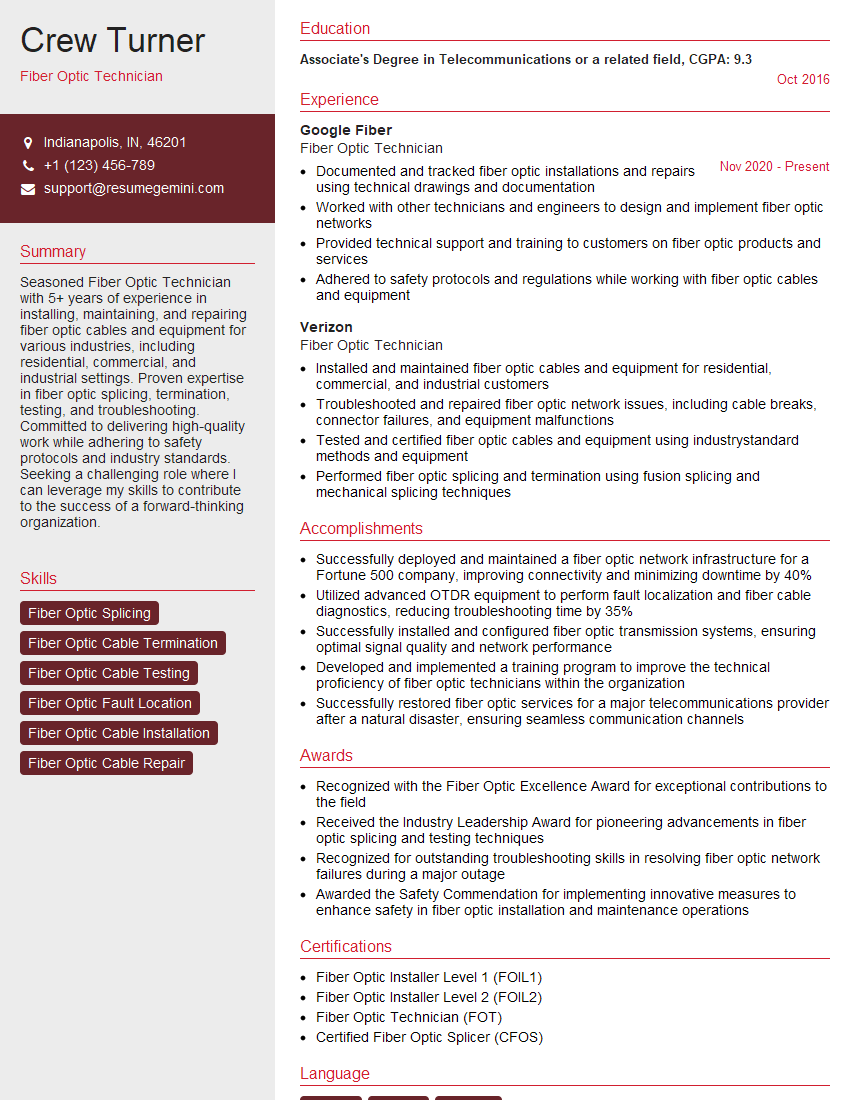

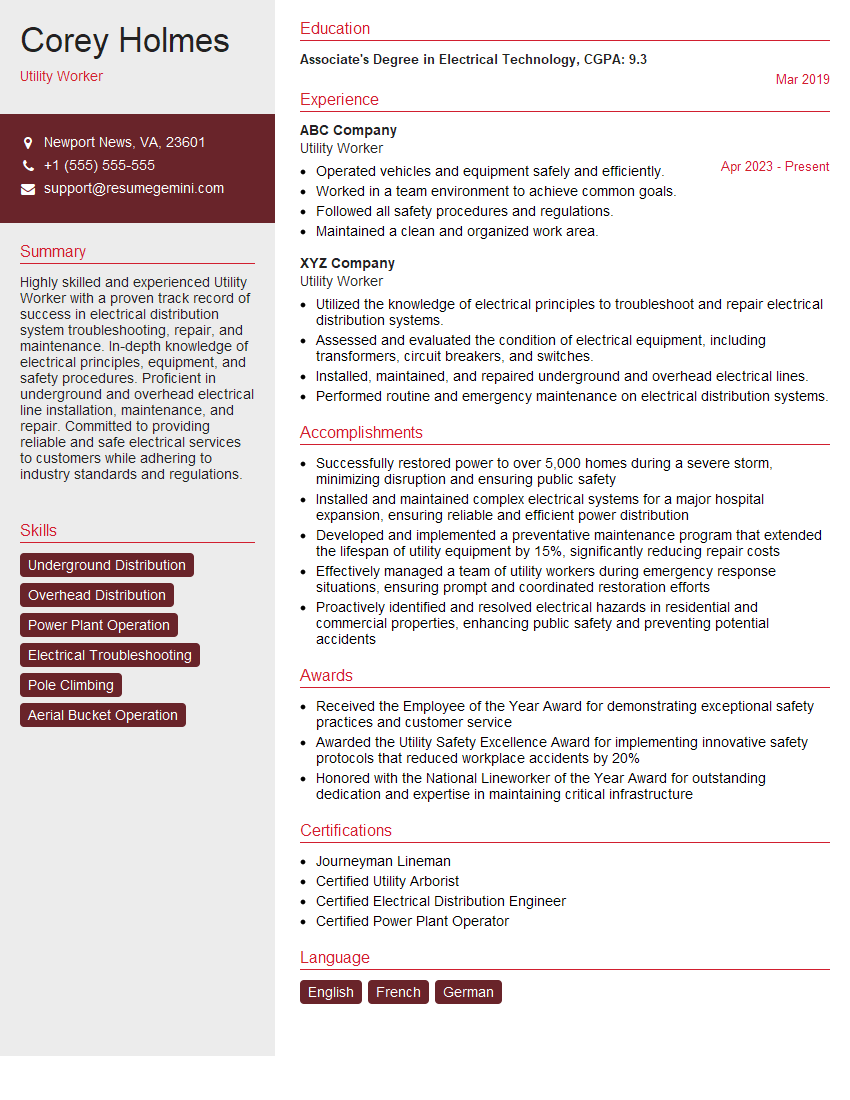

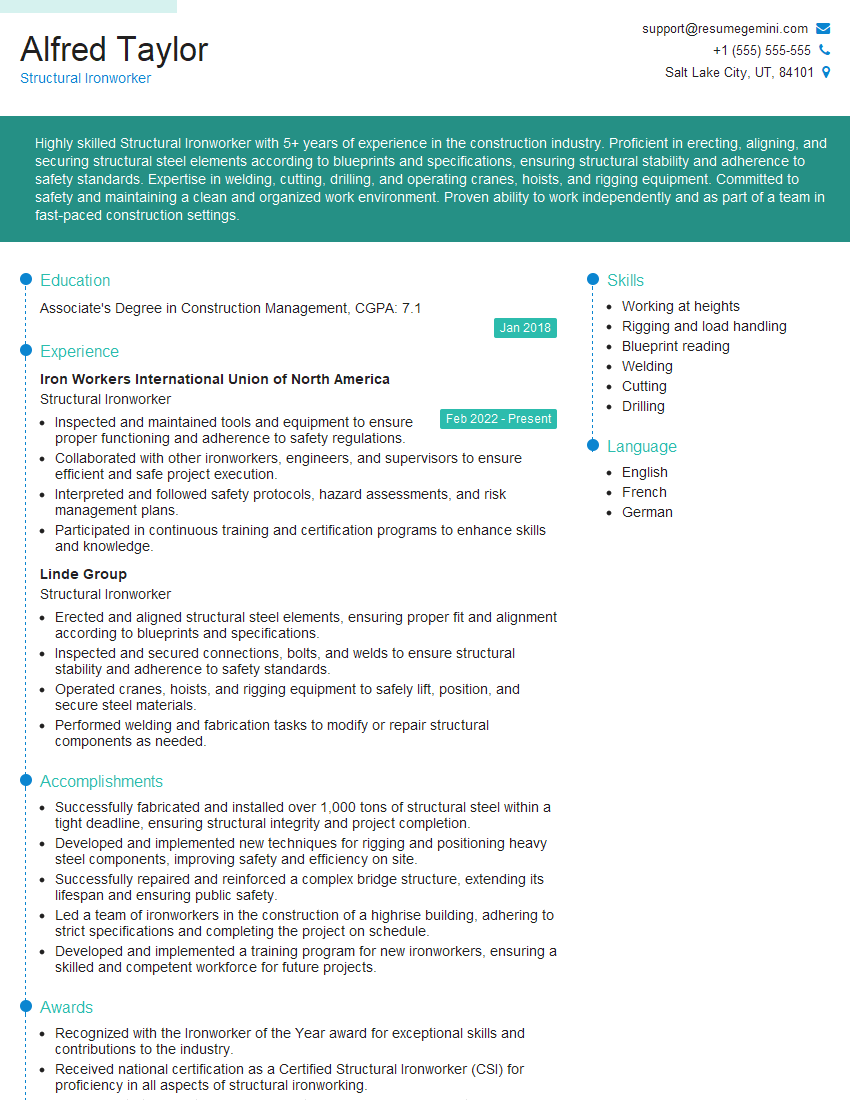

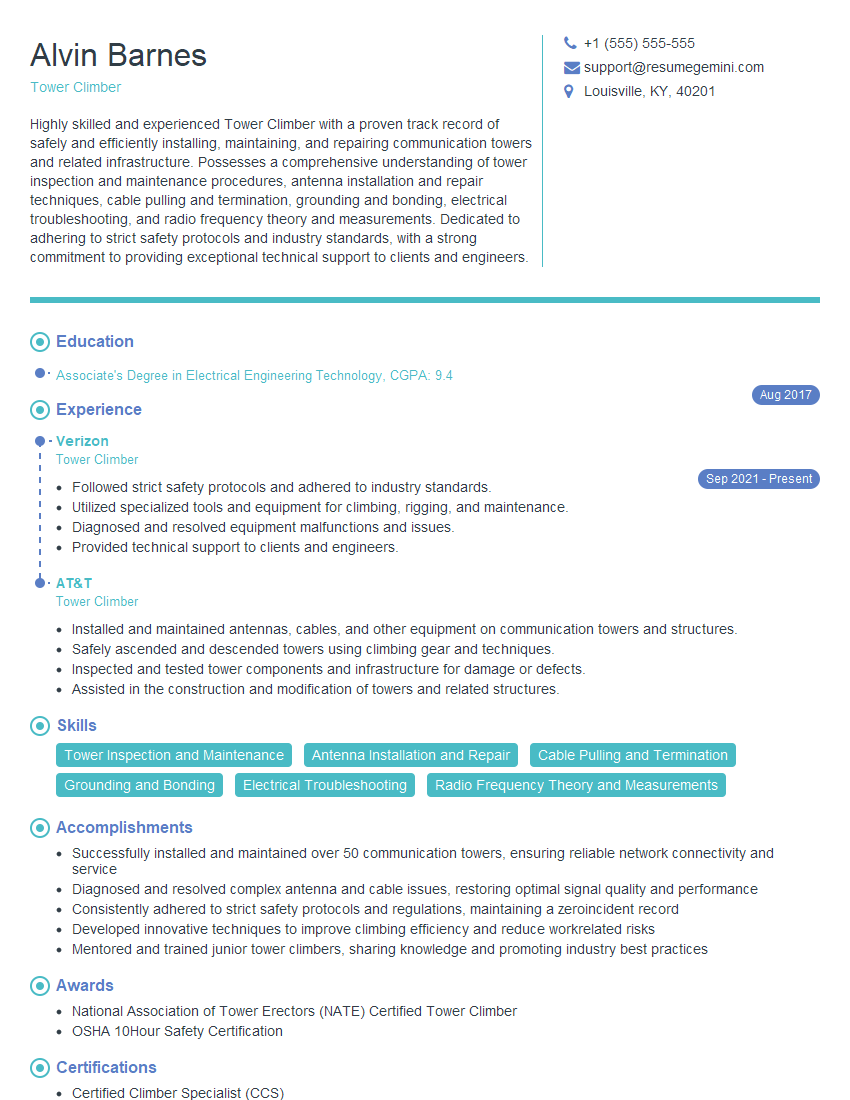

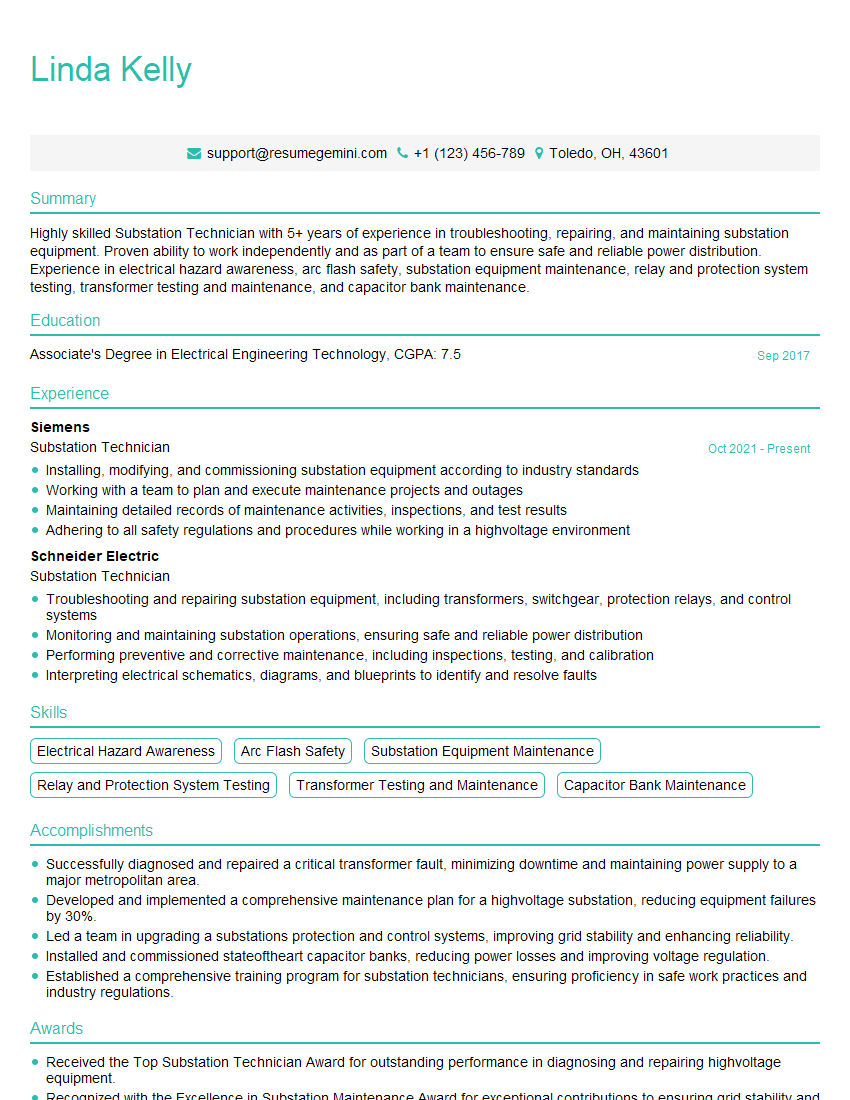

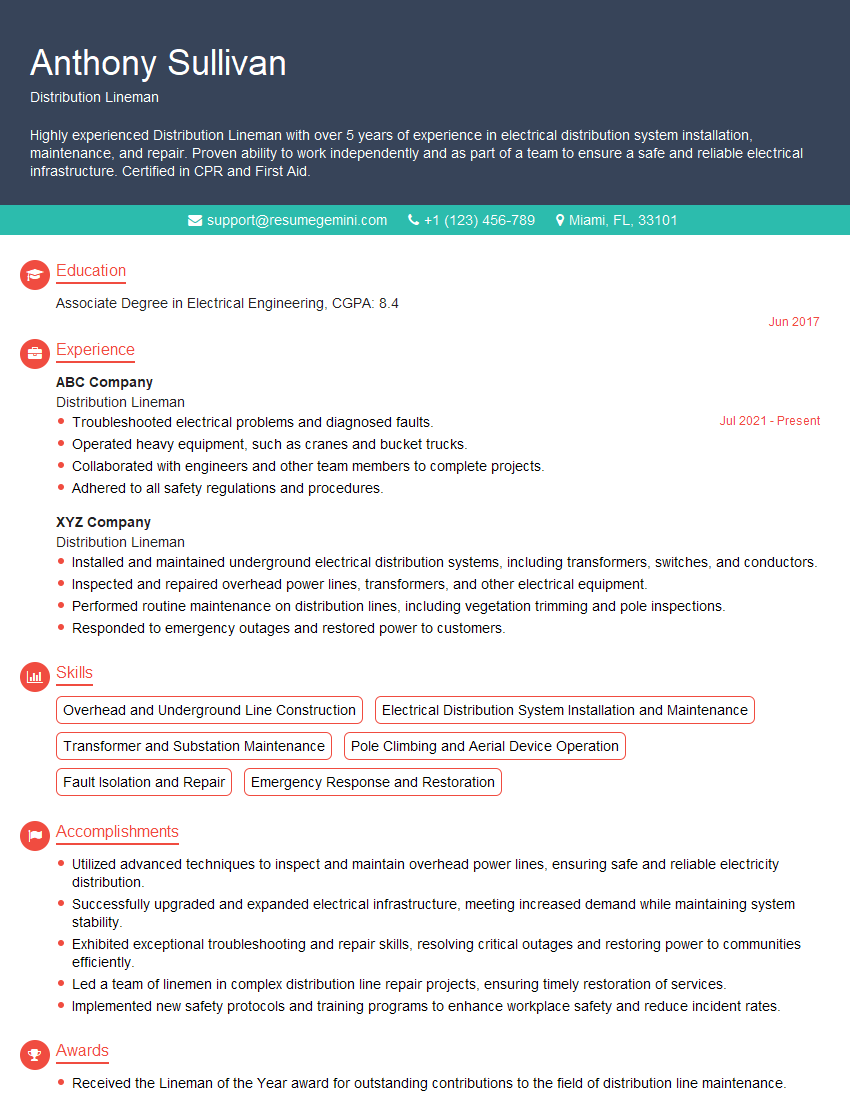

Mastering Pole Climbing and Maintenance opens doors to a rewarding career with excellent growth potential within the utilities and telecommunications sectors. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your skills and experience. We provide examples of resumes specifically designed for Pole Climbing and Maintenance professionals to help guide you through the process. Take the next step towards your dream career – build your best resume with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good