Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Optical Measurement Techniques interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Optical Measurement Techniques Interview

Q 1. Explain the principles of interferometry and its applications in optical measurement.

Interferometry is a powerful optical measurement technique based on the principle of wave interference. When two or more light waves overlap, they interfere, creating a pattern of alternating bright and dark fringes. The spacing and intensity of these fringes are directly related to the difference in the optical path lengths of the interfering waves. This difference can be caused by variations in the refractive index of a medium or by changes in the physical distance the light travels.

In optical measurement, we exploit this relationship to determine extremely small displacements, surface irregularities, or refractive index variations with incredibly high precision. For example, a Michelson interferometer uses a beam splitter to divide a laser beam into two paths. One path reflects off a fixed mirror, the other off a movable mirror. When the reflected beams recombine, the resulting interference pattern reveals the displacement of the movable mirror, providing sub-nanometer resolution.

- Applications: Interferometry finds applications in diverse fields. In metrology, it’s used to measure extremely precise distances, angles, and surface roughness. In materials science, it characterizes the optical properties of materials and detects subtle changes in refractive index. In astronomy, it’s employed in large telescopes to enhance resolution and image quality (e.g., adaptive optics).

Q 2. Describe different types of optical sensors and their respective advantages and limitations.

Optical sensors utilize light to measure physical parameters. Many types exist, each with strengths and weaknesses:

- Photodiodes: These convert light intensity into an electrical current. They are simple, inexpensive, and widely used in light detection and ranging (LIDAR) systems. However, their response is limited by their sensitivity and dynamic range.

- Photomultiplier tubes (PMTs): Highly sensitive detectors amplifying weak light signals. Used in applications requiring extremely low light level detection, such as fluorescence microscopy. However, they are fragile and require high voltage.

- Charge-coupled devices (CCDs) and complementary metal-oxide-semiconductors (CMOS): These are image sensors forming a two-dimensional array of light-sensitive pixels. They’re found in cameras, spectrometers, and many imaging applications. CCDs generally offer higher sensitivity but CMOS sensors offer faster readout speeds.

- Fiber optic sensors: These embed optical fibers within a sensing element, with changes in light transmitted through the fiber indicating changes in the measurand (temperature, pressure, strain, etc.). They offer high sensitivity, immunity to electromagnetic interference, and remote sensing capabilities, but can be more complex and expensive to implement.

The choice of sensor depends critically on the specific application’s requirements, such as sensitivity, dynamic range, response time, cost, and environmental conditions.

Q 3. How does laser triangulation work, and what are its applications in 3D surface profiling?

Laser triangulation uses a laser beam to project a point of light onto a surface. A camera observes this point from a different angle. The position of the point on the camera’s image plane is related to the distance and angle of the surface point relative to the laser and camera. By changing the laser beam position or scanning it across the surface, a 3D profile of the object is constructed.

Imagine shining a flashlight onto a wall at an angle. As you move the flashlight, the spot of light moves on the wall. Laser triangulation is a sophisticated version of this idea, using precise laser positioning and camera imaging to determine the 3D coordinates of each surface point.

- Applications: This technique is widely used in 3D surface profiling for applications such as reverse engineering (creating CAD models from physical objects), quality control in manufacturing (measuring surface defects), medical imaging (creating 3D models of human organs), and robotics (object recognition and navigation).

Q 4. What are the common sources of error in optical measurement systems, and how can they be minimized?

Several error sources can affect optical measurement accuracy:

- Environmental factors: Temperature fluctuations, vibrations, and air currents can alter the optical path length or affect the sensor’s stability.

- Calibration errors: Inaccuracies in the calibration process can lead to systematic errors.

- Noise: Electronic noise from the sensor or other components can corrupt the measurement signal.

- Lens imperfections: Aberrations in optical components can distort the image and introduce errors in measurements.

- Non-linearity: The sensor’s response might not be perfectly linear across its measurement range, introducing errors.

Minimizing errors requires careful system design and implementation. Temperature stabilization, vibration isolation, proper shielding, high-quality optical components, and regular calibration are crucial. Statistical analysis techniques can also help to identify and account for random errors.

Q 5. Explain the concept of optical resolution and its relationship to wavelength and aperture.

Optical resolution refers to the ability of an optical system to distinguish between two closely spaced objects or features. It’s fundamentally limited by the wavelength of light used and the aperture (diameter) of the optical system.

The Rayleigh criterion is a common measure of resolution. It states that two point sources are just resolvable when the center of the diffraction pattern of one source coincides with the first minimum of the diffraction pattern of the other. This leads to the approximate relationship: Resolution ≈ 0.61λ/NA, where λ is the wavelength and NA is the numerical aperture (NA = n sin θ, where n is the refractive index of the medium and θ is the half-angle of the cone of light entering the optical system).

Using shorter wavelengths and larger apertures enhances resolution. This is why high-resolution microscopes often use UV light or even electrons, which have much shorter wavelengths than visible light.

Q 6. Describe different methods for calibrating optical measurement instruments.

Optical instrument calibration involves comparing the instrument’s readings to known standards. Several methods exist:

- Traceable standards: Using calibrated standards traceable to national or international standards organizations ensures accuracy and comparability. This might involve using precisely known lengths or refractive index standards.

- Comparison methods: Comparing the instrument’s readings to a reference instrument with known accuracy. This is particularly useful for instruments measuring relative quantities like displacements.

- Calibration artifacts: Using precisely manufactured objects with known dimensions or properties (e.g., gauge blocks, diffraction gratings) to verify the instrument’s accuracy.

- In-situ calibration: Calibrating the instrument while it’s in its operating environment. This accounts for environmental influences that might not be present during laboratory calibration.

The choice of calibration method depends on the instrument’s type, its intended application, and the required accuracy level. Calibration should be performed regularly to maintain the instrument’s accuracy over time.

Q 7. How do you choose the appropriate optical measurement technique for a specific application?

Selecting the appropriate optical measurement technique involves a careful consideration of several factors:

- Measurement requirements: What needs to be measured (distance, shape, refractive index, etc.)? What is the required accuracy and precision?

- Object characteristics: What are the size, shape, surface properties, and optical properties of the object being measured?

- Environmental conditions: What are the temperature, humidity, vibration, and lighting conditions?

- Cost and complexity: What is the available budget and technical expertise?

- Throughput requirements: How many measurements need to be made, and how quickly?

For example, for high-precision measurement of surface roughness, interferometry might be ideal. However, for rapid 3D scanning of large objects, laser triangulation or structured light scanning would be more suitable. Careful analysis of these factors is essential for selecting the optimal technique to meet the specific application needs.

Q 8. What are the advantages and disadvantages of using coherent versus incoherent light sources in optical metrology?

The choice between coherent and incoherent light sources in optical metrology significantly impacts the measurement technique’s capabilities. Coherent sources, like lasers, exhibit a fixed phase relationship between emitted waves, leading to phenomena like interference. Incoherent sources, such as LEDs or incandescent lamps, lack this phase relationship.

- Coherent Light Advantages: High spatial and temporal coherence allows for extremely precise measurements, enabling techniques like interferometry for nanometer-scale resolution. The high intensity also improves signal-to-noise ratio.

- Coherent Light Disadvantages: Speckle noise (discussed later) can be a significant drawback, affecting image quality and measurement accuracy. Coherent sources can be sensitive to environmental disturbances and require careful alignment.

- Incoherent Light Advantages: Less sensitive to environmental disturbances and generally simpler to implement. They avoid the speckle problem associated with coherent light.

- Incoherent Light Disadvantages: Lower spatial and temporal coherence limits the achievable precision. They typically require longer integration times to achieve sufficient signal strength, leading to slower measurements.

Example: Interferometry relies on coherent light to measure surface roughness or displacement with high accuracy. On the other hand, techniques like optical profilometry using white light sources can provide broader surface information without the speckle issue, although with lower resolution.

Q 9. Explain the concept of speckle and its impact on optical measurements.

Speckle is a granular interference pattern that arises when coherent light scatters from a rough surface. Imagine shining a laser pointer on a wall with a slightly uneven texture; the resulting grainy pattern is speckle. This pattern is not an inherent property of the surface itself but a result of the interference of numerous scattered wavefronts.

Impact on Optical Measurements: Speckle noise significantly reduces the accuracy and precision of optical measurements, especially in techniques like coherent imaging and interferometry. It can obscure fine details and introduce random variations in intensity that are mistaken for actual surface features. It is particularly problematic in applications requiring high resolution and sensitivity.

Mitigation Techniques: Several methods exist to reduce the impact of speckle. These include using spatial filtering techniques, employing speckle reduction algorithms in image processing, or using incoherent light sources. Rotating diffusers or employing techniques like speckle correlation can also help.

Q 10. How do you compensate for environmental factors (temperature, vibration) in precision optical measurements?

Environmental factors like temperature fluctuations and vibrations severely affect the accuracy of precision optical measurements. They introduce systematic errors that must be carefully compensated for.

- Temperature Compensation: Maintaining a stable temperature environment is crucial. This is often achieved using temperature-controlled enclosures or chambers. Active temperature control systems, along with materials with low thermal expansion coefficients for optical components, minimize temperature-induced drifts. Software correction algorithms based on temperature sensors can also compensate for residual drift.

- Vibration Isolation: Vibrations can introduce noise into measurements and blur images. Vibration isolation systems, such as active or passive vibration damping tables, are used to minimize these effects. These tables absorb vibrations, preventing them from transferring to the optical setup. Careful design of the optical system, minimizing sensitive parts’ movement, is equally critical.

Example: In a high-precision interferometry setup measuring a nanometer-scale displacement, a temperature fluctuation of even 0.1°C can lead to significant errors. Implementing a temperature-controlled environment and using appropriate software correction ensures accurate results.

Q 11. Describe your experience with different types of optical interferometers (e.g., Michelson, Mach-Zehnder).

I have extensive experience with various interferometers, particularly Michelson and Mach-Zehnder interferometers. These are fundamental tools in optical metrology for measuring surface profiles, refractive indices, and optical path differences with high precision.

- Michelson Interferometer: This classic design uses a beam splitter to divide a light beam into two paths, reflecting each off a separate mirror and recombining them to produce interference fringes. It’s simple and widely used for applications like optical flat testing and measuring small displacements.

- Mach-Zehnder Interferometer: This interferometer utilizes two beam splitters, creating two separate arms for the light beams. It’s more robust to misalignment compared to the Michelson interferometer and allows for easier introduction of test samples into one of the arms. It’s advantageous for applications such as refractive index measurements and flow visualization.

My experience includes designing, aligning, and operating these interferometers for diverse applications, encompassing both manual and automated measurement systems. I am familiar with various techniques for analyzing the resulting interference patterns to extract precise quantitative data.

Q 12. Explain the working principle of a confocal microscope and its applications in optical metrology.

A confocal microscope utilizes a pinhole aperture in conjunction with a point light source (usually a laser) to achieve high-resolution three-dimensional imaging. It only detects light that is reflected or emitted from the focal plane, effectively rejecting out-of-focus light.

Working Principle: A focused laser beam scans across the sample. The reflected or emitted light from the focal plane passes through the pinhole and is detected. Light from above or below the focal plane is blocked by the pinhole. By scanning the laser beam and synchronously moving the pinhole, a three-dimensional image is constructed.

Applications in Optical Metrology: Confocal microscopy is widely used for high-resolution surface profiling, measurement of surface roughness, and inspection of microstructures. It’s invaluable in various fields, from semiconductor manufacturing to biological imaging. The ability to obtain z-stacks (a series of images at different depths) provides crucial information for 3D surface reconstruction.

Example: In semiconductor manufacturing, confocal microscopy is employed for precise measurements of linewidths and critical dimensions on integrated circuits, ensuring quality control and process optimization.

Q 13. How do you analyze and interpret data obtained from optical measurement systems?

Data analysis and interpretation in optical measurement systems involve several key steps, depending on the specific technique used. The general approach includes data acquisition, noise reduction, calibration, and finally quantitative analysis.

- Data Acquisition: Raw data from optical systems (e.g., intensity profiles, interferograms, images) are collected using appropriate hardware and software.

- Noise Reduction: Techniques like averaging, filtering (e.g., spatial filtering, Fourier filtering), and background subtraction are employed to remove noise from the acquired data, improving the signal-to-noise ratio.

- Calibration: The measurement system is calibrated using known standards to establish a relationship between the measured signals and the corresponding physical quantities. This involves correcting for systematic errors and ensuring accuracy.

- Quantitative Analysis: Appropriate algorithms and software are utilized to extract quantitative information from the processed data. This might involve fitting curves, performing Fourier transforms, or applying other signal processing techniques. The results are then interpreted in the context of the measurement objectives.

Example: In interferometry, fringe analysis is performed to extract surface height information from interference patterns. This often involves fitting the fringes with mathematical models or using Fourier transform techniques to determine the phase shift, enabling precise measurements of surface profiles.

Q 14. What software packages are you proficient in for data acquisition and analysis in optical metrology?

I am proficient in several software packages commonly used for data acquisition and analysis in optical metrology. My experience includes using:

- MATLAB: A powerful tool for signal processing, image analysis, and data visualization. I use it extensively for developing custom algorithms for data analysis and automating measurement processes.

- LabVIEW: I’m proficient in using LabVIEW for instrument control, data acquisition, and creating custom user interfaces for optical measurement systems.

- ImageJ/Fiji: This open-source image processing software is invaluable for analyzing microscopic images, performing image segmentation, and quantitative measurements.

- Specialized Software Packages: Depending on the specific instrument, I have experience using dedicated software packages provided by manufacturers for data acquisition and analysis. This includes software for optical profilers, interferometers, and confocal microscopes.

My expertise extends beyond just using these packages; I am comfortable developing custom scripts and macros to tailor data analysis workflows to specific needs.

Q 15. Describe your experience with optical fiber sensors and their applications.

Optical fiber sensors leverage the principles of light propagation through optical fibers to measure various physical parameters. My experience encompasses designing, implementing, and troubleshooting a wide range of these sensors. I’ve worked extensively with sensors based on different principles, including intensity modulation, phase modulation, and polarization modulation. For instance, I developed a fiber Bragg grating (FBG) sensor system for structural health monitoring in a bridge project. The system used multiple FBGs embedded within the bridge’s structure to monitor strain and temperature variations in real-time, providing valuable data for preventative maintenance. Another project involved using interferometric fiber optic sensors to measure micro-displacements in a precision manufacturing environment. The high sensitivity of these sensors allowed us to achieve sub-nanometer resolution, crucial for ensuring the quality of the manufactured parts. My expertise also extends to the development of fiber optic sensors for chemical sensing, using techniques like evanescent wave absorption spectroscopy.

- Applications: Structural health monitoring, pressure sensing, temperature sensing, chemical sensing, biomedical sensing, and more.

- Sensor types: Fiber Bragg grating (FBG) sensors, Fabry-Perot interferometers, Mach-Zehnder interferometers.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the principle of ellipsometry and its applications in thin film metrology.

Ellipsometry is an optical technique used to characterize thin films by analyzing the polarization changes of light reflected from a surface. When polarized light reflects off a thin film, its polarization state alters depending on the film’s thickness, refractive index, and other optical properties. Ellipsometry measures these changes with great precision. The principle is based on analyzing the change in polarization state (expressed as ψ and Δ) of the reflected light. These parameters are related to the optical properties of the film and substrate through complex equations which require sophisticated mathematical models for accurate analysis. Software solutions are commonly used for determining the optical constants of the film.

Applications in Thin Film Metrology: Ellipsometry is incredibly versatile and finds applications in various fields, including:

- Semiconductor industry: Characterizing the thickness and refractive index of thin films in microelectronic devices.

- Optics industry: Measuring the optical properties of anti-reflection coatings and other optical thin films.

- Material science: Investigating the surface and interface properties of various materials.

- Biomedical engineering: Analyzing the thickness and composition of biofilms and other biological layers.

Q 17. How would you troubleshoot a problem with an optical measurement system that is producing inaccurate results?

Troubleshooting an optical measurement system yielding inaccurate results requires a systematic approach. I would begin with a thorough examination of each component and step of the measurement process. My troubleshooting steps would include:

- Verification of Alignment: Checking the alignment of optical components (lasers, lenses, detectors) is paramount. Misalignment can lead to significant errors. I would use precision alignment tools and procedures.

- Calibration and Standardization: Ensuring all instruments (power meters, spectrometers, etc.) are properly calibrated and traceable to national standards is critical. Regular calibration prevents drift and ensures accuracy.

- Environmental Factors: Temperature fluctuations, vibrations, and air currents can affect optical measurements. I would assess the environmental conditions and implement necessary control measures.

- Signal-to-Noise Ratio (SNR): A low SNR indicates significant noise interfering with the measurement. I would investigate potential noise sources (e.g., electronic noise, ambient light) and implement noise reduction techniques, such as averaging or filtering.

- Software and Data Acquisition: I would verify the accuracy of the data acquisition software and the algorithms used for data processing. Errors in these areas can introduce significant inaccuracies.

- Component Degradation: Optical components can degrade over time, impacting the system’s performance. I would inspect all components for signs of damage or degradation and replace them if necessary.

By systematically investigating these areas, I can usually pinpoint the source of the problem and implement corrective actions.

Q 18. What are the safety precautions you would take when working with lasers?

Laser safety is of utmost importance. My approach to working with lasers is always guided by the principle of minimizing risk. I adhere to these safety precautions:

- Eye Protection: Always wear appropriate laser safety eyewear with the correct optical density (OD) rating for the laser’s wavelength and power level. This is the most crucial safety measure.

- Laser Enclosure and Beam Path: Enclosing lasers and using beam stops or other safety measures to prevent stray reflections or accidental exposure is vital.

- Proper Signage and Warnings: Clearly marked areas and warning signs are essential to alert others to the presence of lasers.

- Laser Safety Training: Ensuring that all personnel working with lasers have received comprehensive laser safety training is crucial.

- Emergency Procedures: Having well-defined emergency procedures in place, including a plan for dealing with accidents and laser-related injuries is crucial.

- Regular Maintenance and Inspections: Regular checks on laser systems and safety interlocks will prevent unexpected accidents.

In summary, a multifaceted approach to laser safety, incorporating both personal protective measures and environmental controls, is paramount.

Q 19. Describe your experience with different types of optical detectors (e.g., photodiodes, CCD cameras).

I have extensive experience with various optical detectors, each suited for specific applications. My experience includes:

- Photodiodes: These are highly sensitive semiconductor devices that convert light into electrical current. I’ve used photodiodes in applications requiring high speed and linearity, such as optical power measurements and optical communication systems. Different types of photodiodes (e.g., PIN photodiodes, avalanche photodiodes) provide varying levels of sensitivity and speed.

- CCD (Charge-Coupled Device) Cameras: These are widely used in imaging applications, capturing light intensities across a two-dimensional array of pixels. I’ve used CCD cameras in various projects, such as optical microscopy, interferometry, and machine vision. Their advantages include high spatial resolution and the ability to capture images over a wide range of wavelengths.

- Other detectors: My experience also encompasses other detector types, including photomultiplier tubes (PMTs) for low-light applications and CMOS (Complementary Metal-Oxide-Semiconductor) image sensors for cost-effective imaging.

The choice of detector depends heavily on the application requirements in terms of sensitivity, speed, spectral range, and spatial resolution.

Q 20. Explain the difference between absolute and relative optical measurements.

The difference between absolute and relative optical measurements lies in their reference points.

- Absolute measurements determine the actual value of an optical quantity (e.g., power, intensity, wavelength) without relying on a reference measurement. This typically involves a direct calibration to a known standard, like a NIST-traceable power meter. For example, measuring the absolute power of a laser using a calibrated power meter provides an absolute measurement.

- Relative measurements determine the change or difference in an optical quantity relative to a reference point or a previous measurement. For example, measuring the change in reflectivity of a surface before and after a treatment is a relative measurement. The accuracy depends heavily on the stability of the reference point and the repeatability of the measurement setup.

The choice between absolute and relative measurements depends on the specific application. Absolute measurements are necessary when the actual value of the optical quantity is critical, while relative measurements are suitable when only the change or difference in the optical quantity is of interest.

Q 21. How do you ensure the accuracy and traceability of optical measurement results?

Ensuring the accuracy and traceability of optical measurement results is crucial for the validity of any scientific or engineering work. I employ several strategies to achieve this:

- Calibration and Traceability: All measurement instruments (e.g., power meters, spectrometers, wavemeters) are regularly calibrated against national or international standards (e.g., NIST, PTB). This establishes a chain of traceability, linking the measurements to well-defined standards.

- Uncertainty Analysis: A thorough uncertainty analysis is performed to quantify the sources of error in the measurements. This includes identifying systematic and random errors and estimating their contribution to the overall measurement uncertainty. Reporting the uncertainty along with the measurement result enhances transparency and reliability.

- Standard Operating Procedures (SOPs): Detailed SOPs are followed to maintain consistency and reduce variability in the measurement process. These SOPs outline procedures for instrument setup, data acquisition, data processing, and quality control checks.

- Regular System Checks: The optical measurement system undergoes regular checks and maintenance to ensure its proper functioning and prevent degradation that might compromise accuracy.

- Data Management and Record Keeping: All measurement data, calibration certificates, and other relevant information are meticulously documented and archived. This allows for data review, analysis, and reproducibility of the results.

By implementing these strategies, I can ensure the high accuracy, reliability, and traceability of my optical measurement results.

Q 22. Describe your experience with optical alignment techniques.

Optical alignment is crucial for many optical systems, ensuring that light travels along the intended path. My experience encompasses various techniques, from simple methods using lasers and apertures to sophisticated automated systems. I’ve worked extensively with:

- Autocollimation: This technique uses a collimated beam reflected back onto itself to precisely align optical components, like mirrors or lenses, with sub-micron accuracy. For instance, I used autocollimation to align a complex interferometer for high-precision distance measurements.

- Kinematic mounts: These mounts provide precise and repeatable adjustments, minimizing the degrees of freedom, which is vital for stable alignment. I’ve utilized these mounts in several applications, including fiber optic coupling and laser beam steering.

- Shack-Hartmann wavefront sensors: These sensors measure the wavefront distortion of a light beam, allowing for real-time feedback and iterative alignment adjustments. This is particularly useful in adaptive optics systems that compensate for atmospheric turbulence.

- Software-based alignment procedures: Many modern alignment tasks are aided by software which analyzes images or sensor data to guide the user toward optimal alignment. I’ve developed and implemented algorithms for automated alignment using these techniques.

My expertise in these methods has enabled me to successfully align diverse optical systems, improving their performance and ensuring reliable operation.

Q 23. Explain the concept of diffraction and its effect on optical measurements.

Diffraction is the bending of light waves as they pass through an aperture or around an obstacle. Think of it like water waves bending around a rock in a stream. In optical measurements, diffraction affects the sharpness and resolution of images. The smaller the aperture or feature, the more significant the diffraction effects.

For example, in microscopy, the diffraction limit restricts the minimum resolvable distance between two points. This means we can’t see features smaller than a certain size, which is approximately half the wavelength of light used. This limit is overcome, to some extent, with techniques like super-resolution microscopy.

In interferometry, diffraction affects the fringe pattern, potentially introducing errors in measurements of surface roughness or displacement. Careful consideration of diffraction effects is essential in designing and interpreting optical measurements, particularly those involving small features or high resolution.

Q 24. What are the limitations of using optical methods for measuring certain parameters?

Optical measurement methods, while powerful, have limitations. Some key restrictions include:

- Diffraction Limit: As discussed, the wavelength of light limits the resolution, preventing the accurate measurement of extremely small features.

- Scattering and Absorption: Light can be scattered or absorbed by the sample, leading to inaccurate measurements, particularly in opaque or highly scattering materials.

- Surface Quality: Highly reflective or rough surfaces can affect the accuracy of optical measurements, particularly in interferometry or profilometry.

- Environmental Effects: Temperature fluctuations, vibrations, and air currents can introduce errors in precise optical measurements. These factors need careful control or compensation.

- Limited Sensitivity: Depending on the technique, optical measurements may lack sufficient sensitivity for some applications, such as measuring extremely small displacements or subtle variations in refractive index.

It’s crucial to carefully consider these limitations when choosing an optical measurement technique and to implement appropriate measures to mitigate their impact. Often, a combination of techniques or the incorporation of other measurement methods can help overcome these limitations.

Q 25. Explain your understanding of different types of optical filters and their applications.

Optical filters selectively transmit or block light of specific wavelengths or polarization states. They are essential components in many optical systems. Common types include:

- Bandpass filters: Transmit light within a narrow wavelength range and block light outside this range. These are used to isolate specific spectral lines in spectroscopy or to reduce background noise.

- Longpass filters: Transmit light above a certain cutoff wavelength. These are useful for removing unwanted short-wavelength light, such as in fluorescence microscopy.

- Shortpass filters: Transmit light below a certain cutoff wavelength. These are complementary to longpass filters.

- Neutral density filters: Reduce the intensity of light without significantly altering its spectral distribution. These are used to control light levels in various optical systems.

- Polarization filters: Transmit light of a specific polarization state (e.g., linear or circular). These are crucial in reducing glare or enhancing contrast.

For example, in fluorescence microscopy, bandpass filters are used to isolate the emitted fluorescence signal from the excitation light. In astronomy, narrowband filters are used to isolate specific emission lines from celestial objects. The selection of the appropriate filter is crucial to optimize performance in a specific optical measurement application.

Q 26. Describe your experience with automated optical inspection (AOI) systems.

My experience with Automated Optical Inspection (AOI) systems includes both operation and programming. I have worked with systems employing various techniques, including:

- Machine vision: AOI systems often employ machine vision techniques to analyze images of components or products, identifying defects like scratches, cracks, or misalignments. I have experience developing algorithms for defect detection and classification using image processing techniques.

- Laser scanning: Laser scanning is used to create high-resolution 3D models of surfaces, enabling precise measurements of dimensions and surface profiles. I’ve used this technology for quality control in manufacturing.

- Optical coherence tomography (OCT): OCT is a non-invasive imaging technique that uses low-coherence interferometry to create cross-sectional images of objects. I’ve applied this for inspection of layered structures and internal defects.

My experience has been focused on developing and optimizing algorithms for automated defect detection, improving the efficiency and accuracy of the inspection process while reducing the need for manual intervention. For example, I worked on improving an AOI system used in the manufacture of printed circuit boards, reducing the false-positive rate by 15%.

Q 27. What are the latest advancements in optical measurement techniques that you are aware of?

The field of optical measurement techniques is constantly evolving. Recent advancements include:

- Super-resolution microscopy: Techniques such as STED and PALM microscopy push beyond the diffraction limit, allowing for the imaging and measurement of nanoscale structures.

- Digital holography: This technique allows for the recording and reconstruction of 3D wavefronts, providing detailed information about the shape and properties of objects.

- Optical coherence tomography (OCT): Developments in OCT have led to higher speed, higher resolution imaging, extending its applications in biomedicine and industrial inspection.

- Advanced image processing techniques: Machine learning and deep learning algorithms are increasingly being used for automated image analysis and feature extraction in optical metrology.

- Integrated photonics: The integration of optical components onto chips offers the potential for miniaturized and highly efficient optical measurement systems.

These advancements are driving significant improvements in the accuracy, speed, and versatility of optical measurement techniques across numerous fields.

Q 28. Explain your experience with image processing techniques used in optical metrology.

Image processing is fundamental to many optical metrology techniques. My experience encompasses a wide range of techniques including:

- Image enhancement: Techniques like filtering, noise reduction, and contrast enhancement improve the quality of images before further analysis.

- Feature extraction: Algorithms are used to identify and extract relevant features from images, such as edges, corners, or textures. For example, I used edge detection to measure the diameter of micro-wires in a precision manufacturing setting.

- Image segmentation: This involves partitioning an image into meaningful regions, separating the object of interest from the background. I have experience using various segmentation techniques, such as thresholding and region growing.

- Image registration: This involves aligning multiple images to compensate for movement or variations in acquisition. This is crucial for techniques like digital image correlation (DIC), used for strain measurement.

- Pattern recognition: Advanced algorithms are used to identify and classify patterns or defects in images, automating quality control processes. I’ve used machine learning algorithms to improve the accuracy of defect detection in automated optical inspection systems.

My proficiency in these techniques is critical in translating raw optical data into meaningful quantitative measurements, facilitating accurate and efficient analysis.

Key Topics to Learn for Optical Measurement Techniques Interview

- Interferometry: Understand the principles of various interferometric techniques (e.g., Michelson, Mach-Zehnder) and their applications in precision measurements. Explore limitations and error sources.

- Diffraction and its Applications: Grasp the concepts of diffraction gratings, diffraction limits, and their use in spectroscopy and metrology. Be prepared to discuss practical applications like optical profilometry.

- Optical Microscopy: Familiarize yourself with different types of optical microscopes (e.g., bright-field, dark-field, confocal) and their respective strengths and weaknesses. Understand resolution limits and image processing techniques.

- Light Sources and Detectors: Gain a solid understanding of various light sources (lasers, LEDs) and detectors (photodiodes, CCDs) and their characteristics relevant to optical measurement systems. Be prepared to discuss their selection criteria for specific applications.

- Image Processing and Analysis: Develop proficiency in image processing techniques used to extract quantitative data from optical measurements. This includes noise reduction, image enhancement, and feature extraction.

- Fiber Optics and Sensors: Understand the principles of fiber optic sensing and its applications in various measurement scenarios. This could include topics like fiber Bragg gratings and interferometric fiber sensors.

- Calibration and Uncertainty Analysis: Master the importance of calibration procedures and techniques for ensuring accurate and reliable measurements. Understand how to assess and report measurement uncertainty.

- Specific Optical Measurement Techniques: Depending on the job description, delve deeper into specific techniques such as ellipsometry, polarimetry, or optical coherence tomography (OCT).

- Problem-Solving and Troubleshooting: Practice diagnosing and resolving common issues encountered in optical measurement systems. Develop a methodical approach to troubleshooting.

Next Steps

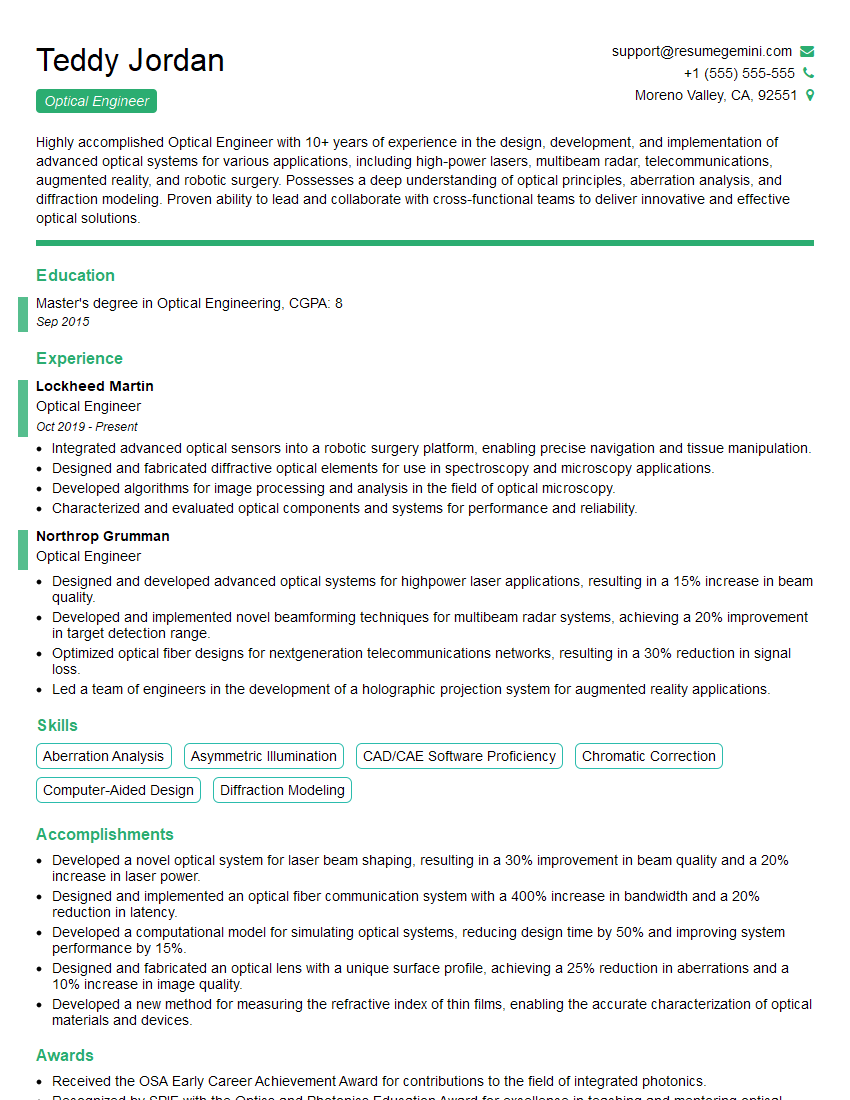

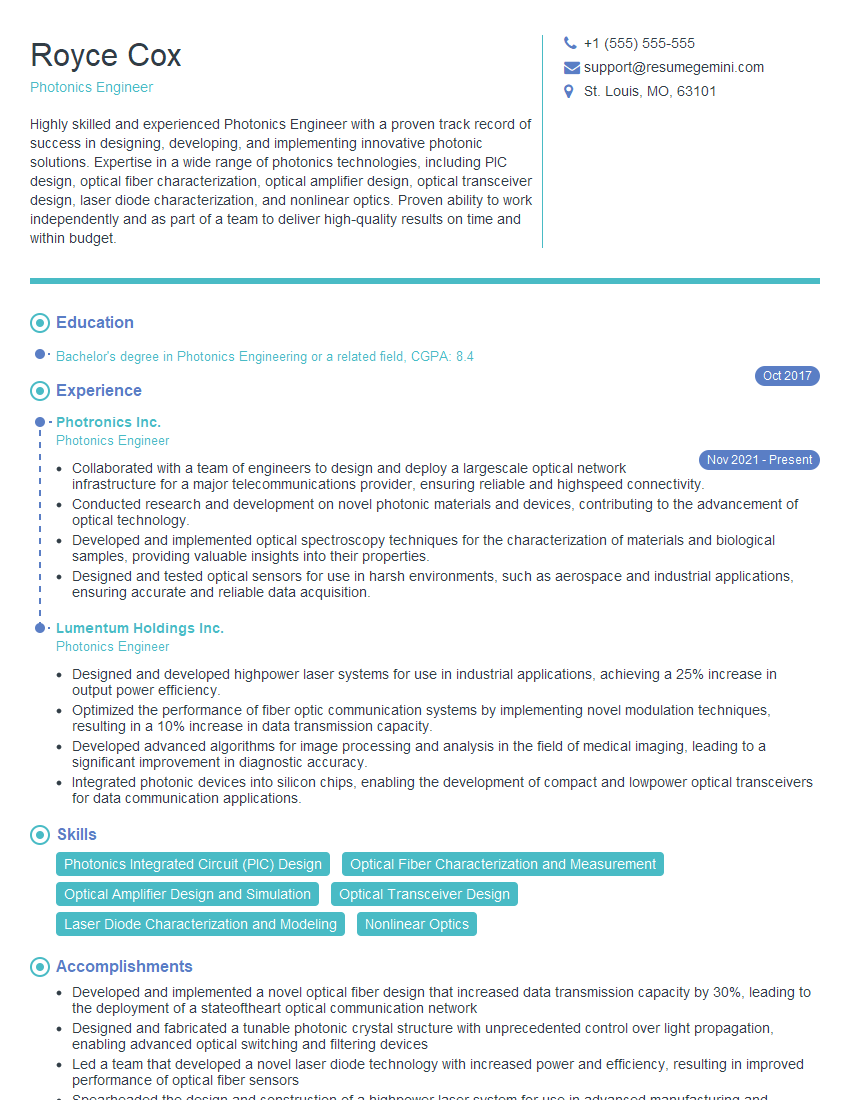

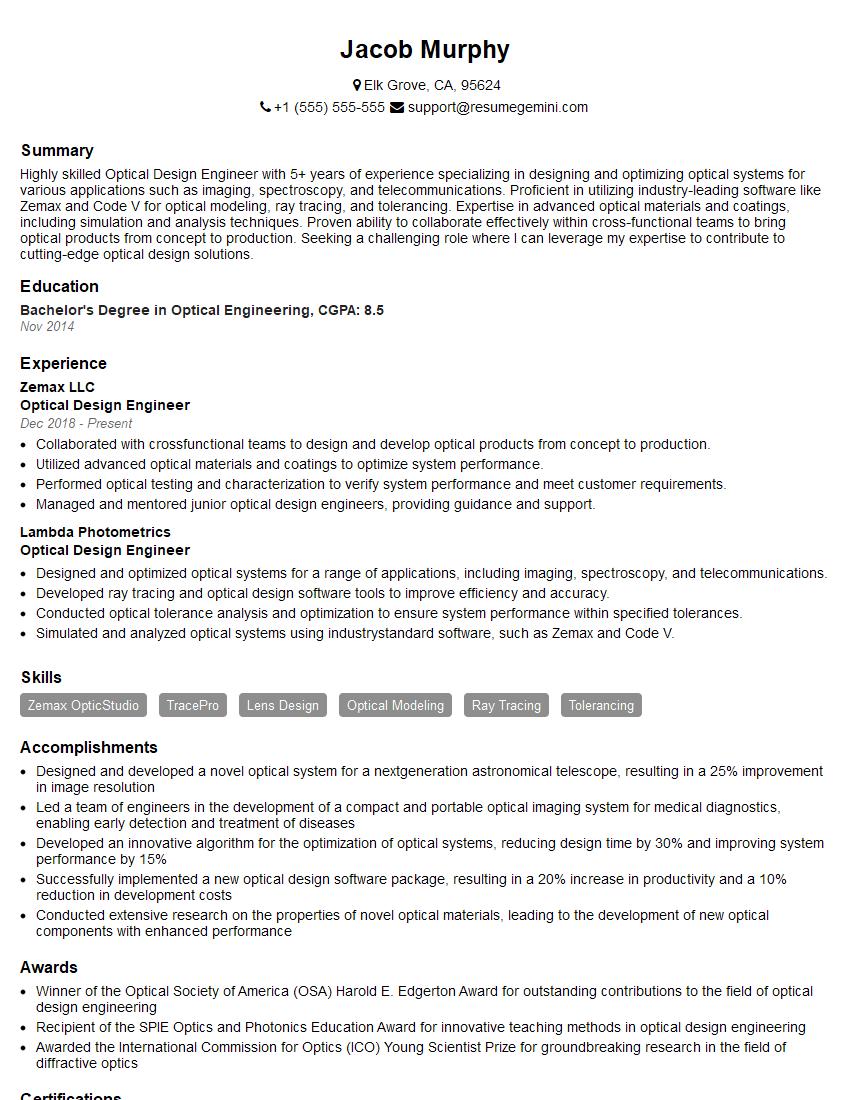

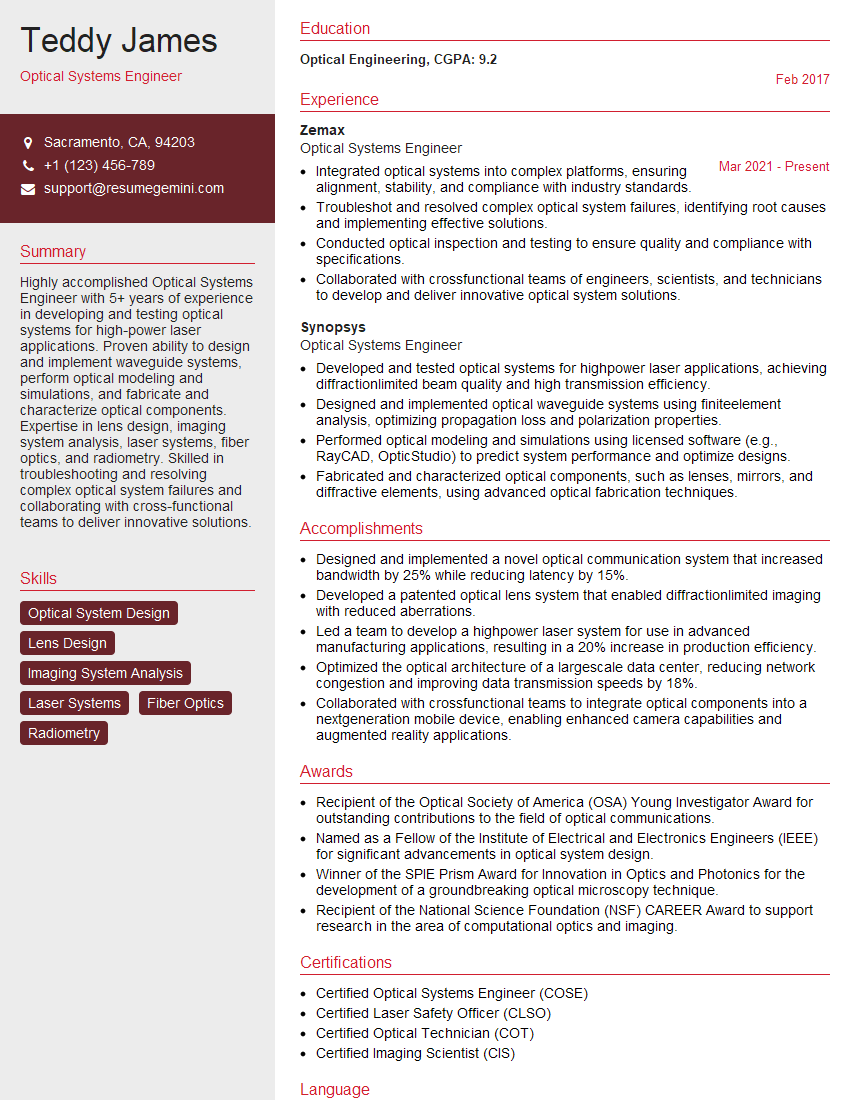

Mastering Optical Measurement Techniques opens doors to exciting career opportunities in diverse fields, from advanced manufacturing and materials science to biomedical engineering and environmental monitoring. A strong foundation in these techniques significantly enhances your employability and positions you for career advancement. To increase your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and effective resume that showcases your skills and experience. ResumeGemini provides examples of resumes tailored to Optical Measurement Techniques to guide you in creating a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good