Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top ISO Certification Compliance interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in ISO Certification Compliance Interview

Q 1. Explain the PDCA cycle and its application in ISO certification.

The PDCA cycle, or Plan-Do-Check-Act cycle, is a foundational methodology for continuous improvement. It’s a four-step iterative process used to achieve quality management objectives. In the context of ISO certification, it’s integral to maintaining compliance and striving for excellence.

- Plan: This stage involves defining objectives, processes, and resources needed to achieve those objectives. For example, if your objective is to reduce customer complaints, you might plan specific training for staff on handling customer inquiries and implement a new complaint tracking system.

- Do: This is the implementation phase. You put your plan into action, carrying out the defined processes and monitoring progress. This might involve conducting the staff training and launching the new complaint system.

- Check: This is the monitoring and evaluation phase. You measure the results against your planned objectives and identify any deviations or non-conformances. This could entail analyzing complaint data after implementing the new system to see if complaint rates have dropped.

- Act: This is the corrective and preventive action phase. Based on the ‘Check’ stage, you take actions to address any issues and improve the processes further. Perhaps the training wasn’t effective, and you need to revise it; or the new complaint system needs adjustments for improved data capture.

The PDCA cycle isn’t a one-time process; it’s a continuous loop. By repeatedly applying PDCA, organizations can systematically identify areas for improvement and ensure consistent compliance with ISO standards.

Q 2. Describe the differences between ISO 9001, ISO 14001, and ISO 27001.

While all three – ISO 9001, ISO 14001, and ISO 27001 – are internationally recognized standards focusing on management systems, they address different aspects of an organization.

- ISO 9001 (Quality Management Systems): This standard focuses on establishing, implementing, maintaining, and continually improving a quality management system to enhance customer satisfaction. It emphasizes customer focus, process approach, leadership, engagement of people, and improvement.

- ISO 14001 (Environmental Management Systems): This standard focuses on establishing, implementing, maintaining, and continually improving an environmental management system to minimize environmental impact. It emphasizes legal compliance, pollution prevention, and continual improvement of environmental performance. Think reducing waste, conserving energy, and managing emissions.

- ISO 27001 (Information Security Management Systems): This standard focuses on establishing, implementing, maintaining, and continually improving an information security management system to protect sensitive information. It emphasizes confidentiality, integrity, and availability of information assets.

Think of it this way: ISO 9001 ensures you’re consistently producing high-quality products or services; ISO 14001 ensures you’re doing so responsibly towards the environment; and ISO 27001 ensures you’re protecting sensitive data throughout the process. An organization might hold multiple ISO certifications simultaneously.

Q 3. What are the key elements of a robust internal audit program?

A robust internal audit program is crucial for maintaining ISO compliance. Key elements include:

- Scope and Planning: Clearly define the scope of the audit, including departments, processes, and standards covered. Create a detailed audit plan outlining timelines, resources, and team assignments.

- Auditor Competence: Auditors should possess sufficient knowledge of the relevant ISO standards and auditing techniques. Training and certification are essential.

- Audit Methodology: Establish a systematic approach for conducting audits, such as using checklists, observation, interviews, and document review.

- Objective Evidence: Auditors must gather objective evidence to support their findings. This could include examining records, observing processes, and interviewing personnel.

- Reporting and Follow-up: The audit report should clearly document findings, non-conformances, and recommendations. Effective follow-up is essential to ensure that corrective and preventive actions are implemented.

- Management Review: Audit reports should be reviewed by management to assess the overall effectiveness of the management system and identify areas needing improvement.

For example, an internal audit of a manufacturing facility might involve reviewing production records, observing safety protocols, and interviewing employees to assess compliance with ISO 9001 and ISO 14001 requirements. Regular audits, coupled with management review, create a cycle of continuous improvement.

Q 4. How do you ensure compliance with ISO standards across multiple departments?

Ensuring ISO compliance across multiple departments requires a well-defined and integrated management system. Key strategies include:

- Centralized Management System: Establish a single, overarching management system that integrates relevant ISO standards across all departments. This avoids departmental silos and ensures consistent implementation.

- Cross-functional Teams: Create cross-functional teams to address ISO requirements. This promotes collaboration and communication among departments.

- Training and Communication: Provide comprehensive training to all employees on relevant ISO standards and their responsibilities. Regular communication reinforces understanding and fosters a culture of compliance.

- Clear Roles and Responsibilities: Define clear roles and responsibilities for each department and individual regarding ISO compliance. This prevents confusion and accountability gaps.

- Standardized Procedures: Develop and implement standardized procedures for key processes across all departments. This ensures consistency and minimizes variation.

- Regular Monitoring and Auditing: Conduct regular internal audits to monitor compliance and identify areas for improvement across all departments.

For example, a company with ISO 9001 and ISO 27001 certifications might establish a central quality and security management team responsible for overseeing compliance across sales, marketing, IT, and production departments. This ensures consistency in processes and documentation across the organization.

Q 5. Explain your understanding of corrective and preventive actions (CAPA).

Corrective and Preventive Actions (CAPA) are crucial for addressing non-conformances and preventing their recurrence. Corrective actions address existing non-conformances, while preventive actions address potential future non-conformances.

- Corrective Action: This focuses on eliminating the root cause of a problem that has already occurred. For instance, if a customer complaint reveals a defect in a product, corrective action would involve identifying the cause of the defect (e.g., faulty equipment, inadequate training), correcting it, and potentially recalling affected products.

- Preventive Action: This aims to prevent potential future problems. If the root cause analysis of the faulty equipment reveals a need for better preventative maintenance procedures, implementing a new maintenance schedule would be a preventive action.

The key to effective CAPA is thorough root cause analysis. Simply addressing the symptom won’t prevent future problems. A robust CAPA process includes documenting the non-conformance, investigating the root cause, implementing corrective and preventive actions, verifying their effectiveness, and monitoring for recurrence.

Q 6. How do you handle non-conformances identified during an audit?

Handling non-conformances identified during an audit is a systematic process. It begins with documenting each non-conformance, clearly describing the deviation from the ISO standard. Then:

- Root Cause Analysis: Investigate the underlying cause of the non-conformance, going beyond just the immediate symptoms. Use techniques like 5 Whys or fishbone diagrams.

- Corrective Action Planning: Develop a plan to address the identified root cause and eliminate the non-conformance. This plan should include specific actions, responsibilities, timelines, and resources.

- Implementation of Corrective Actions: Implement the planned corrective actions promptly.

- Verification of Effectiveness: Verify that the corrective actions have effectively eliminated the non-conformance and prevent recurrence.

- Documentation: Thoroughly document all aspects of the process, including the initial non-conformances, root cause analysis, corrective actions, verification of effectiveness, and follow-up.

For instance, if an audit reveals inadequate employee training resulting in non-compliant procedures, the corrective action might involve designing and delivering a new training program, followed by testing and verification of employee competency. Preventive actions might involve integrating regular refresher training into the work schedule.

Q 7. Describe your experience with documenting and maintaining ISO management systems.

Documenting and maintaining ISO management systems is paramount for demonstrating compliance. My experience encompasses all phases, from initial system development to ongoing maintenance and improvement.

- System Development: I’ve been involved in creating comprehensive documentation for various ISO standards, including policy manuals, procedure documents, work instructions, forms, and records. This includes aligning the documentation with the specific requirements of the chosen ISO standard.

- Version Control: I’m proficient in using version control systems to manage document revisions, ensuring that only the most up-to-date versions are used. This prevents confusion and maintains the integrity of the system.

- Document Control Procedures: I’ve implemented and maintained robust document control procedures to manage document creation, review, approval, distribution, and retention, adhering to guidelines for document change management.

- Record Management: I have experience in establishing and managing record-keeping systems to ensure the organization maintains evidence of compliance with ISO standards. This includes defining retention periods and secure storage mechanisms for vital records.

- Continuous Improvement: I regularly review and update the management system documentation to reflect changes in business processes, technology, and regulatory requirements. This ensures the system remains relevant and effective.

My approach to documentation prioritizes clarity, accuracy, accessibility, and traceability. Well-maintained documentation is not just a compliance requirement; it’s a valuable asset for operational efficiency and continuous improvement.

Q 8. What are the key performance indicators (KPIs) for measuring ISO compliance?

Key Performance Indicators (KPIs) for ISO compliance aren’t standardized across all ISO standards (like ISO 9001, ISO 14001, ISO 27001, etc.), as they depend heavily on the specific standard and the organization’s context. However, several common KPIs help measure the effectiveness of an organization’s ISO management system. These KPIs can be broadly categorized into areas such as effectiveness, efficiency, and conformance.

Effectiveness: This measures how well the management system achieves its intended goals. Examples include the number of nonconformities identified and corrected, customer satisfaction rates related to quality or environmental performance, and the reduction in environmental impact (for ISO 14001).

Efficiency: This focuses on resource optimization. Examples include the cost of nonconformities, time taken for corrective actions, and resource usage for environmental initiatives.

Conformance: This reflects the adherence to ISO requirements. Examples include the percentage of audits passed, the number of documented procedures followed, and the effectiveness of internal audits in identifying nonconformities.

For example, an organization implementing ISO 9001 might track the number of customer complaints resolved within a specific timeframe as a KPI for effectiveness. For ISO 14001, they might monitor their waste reduction rate as a KPI for efficiency. The key is to select KPIs that are measurable, relevant, and aligned with the organization’s specific objectives and the requirements of the chosen ISO standard.

Q 9. How do you stay updated with changes and revisions to ISO standards?

Staying updated on ISO standard changes and revisions is crucial for maintaining compliance. I employ a multi-pronged approach:

Subscription to Official Sources: I subscribe to updates from the International Organization for Standardization (ISO) directly. This ensures I receive official notifications about revisions, amendments, and new publications.

Professional Networks and Associations: I actively participate in professional networks and associations focused on ISO standards. These provide opportunities to learn from other experts, attend webinars, and receive updates on upcoming changes.

Industry Publications and Journals: Regularly reviewing specialized publications and journals focused on quality management, environmental management, or information security (depending on the relevant ISO standard) keeps me informed of industry best practices and interpretation of changes in ISO standards.

Consultancy and Training: Engaging with reputable ISO consultancies and attending training courses offers in-depth analysis and practical guidance on the latest revisions and implementation strategies.

Think of it like a doctor staying updated with medical advancements – continuous learning is essential to provide accurate and up-to-date advice.

Q 10. Describe your experience conducting gap analysis for ISO certification.

Conducting a gap analysis is a systematic process of identifying the differences between an organization’s current state and the requirements of an ISO standard. My approach involves these steps:

Understanding the Standard: Thoroughly review the specific ISO standard requirements relevant to the organization.

Document Review: Examine existing documentation, including policies, procedures, work instructions, and records, to assess current practices.

On-Site Assessment: Conduct on-site observations and interviews with personnel at all levels to understand actual practices and identify any discrepancies between documented procedures and reality.

Comparison and Identification of Gaps: Compare the organization’s current state against the ISO standard requirements, meticulously documenting any gaps or areas needing improvement.

Prioritization of Gaps: Categorize identified gaps based on their criticality and potential impact, focusing on high-risk areas first.

Report and Recommendations: Generate a comprehensive report detailing the identified gaps, their severity, and recommendations for corrective actions.

For example, in a recent gap analysis for ISO 9001, I discovered that a client lacked a robust system for managing customer complaints. This was documented as a major gap, and recommendations included implementing a standardized complaint handling procedure and training staff on its use.

Q 11. Explain your approach to managing stakeholder expectations during an ISO implementation.

Managing stakeholder expectations during ISO implementation requires proactive communication and engagement. My approach focuses on:

Initial Stakeholder Mapping: Identifying all stakeholders, including employees at all levels, management, customers, and suppliers, and understanding their concerns and expectations.

Transparent Communication: Regularly communicating project updates, progress, challenges, and timelines to all stakeholders through various channels (e.g., meetings, newsletters, emails).

Training and Education: Providing appropriate training to employees on the ISO standard and their roles in achieving compliance.

Feedback Mechanisms: Establishing mechanisms for gathering feedback from stakeholders and addressing their concerns promptly.

Regular Reviews and Reporting: Conducting regular progress reviews and providing reports to stakeholders on the status of the implementation.

For example, I’ve successfully managed stakeholder expectations by organizing regular town hall meetings to discuss the ISO implementation, answer questions, and address concerns directly, thus fostering collaboration and building buy-in from all levels of the organization.

Q 12. How do you prioritize corrective actions based on risk assessment?

Prioritizing corrective actions based on risk assessment is crucial for effective ISO implementation. I use a risk-based approach:

Risk Identification: Identify potential risks associated with each nonconformity identified during audits or other processes.

Risk Analysis: Evaluate the likelihood and impact of each risk. A risk matrix can be used to visually represent the severity of each risk (likelihood x impact).

Risk Prioritization: Prioritize corrective actions based on the risk assessment. High-risk nonconformities requiring immediate action are addressed first, followed by medium and low-risk items.

Resource Allocation: Allocate resources (time, personnel, budget) effectively based on the prioritized risks.

Monitoring and Review: Monitor the effectiveness of implemented corrective actions and review the risk assessment periodically to adapt to changing circumstances.

For instance, a nonconformity posing a high risk to product safety would be prioritized over a minor documentation issue. This ensures that resources are focused on addressing the most critical issues first.

Q 13. Describe your experience with ISO certification audits – both internal and external.

I have extensive experience with both internal and external ISO certification audits. Internal audits are crucial for identifying areas of non-compliance before an external audit. My approach involves:

Planning: Developing an audit plan based on the scope, standard requirements, and risk assessment.

Execution: Conducting the audit using appropriate audit techniques (e.g., document review, interviews, observations).

Reporting: Documenting findings, including nonconformities, and reporting to management.

Follow-up: Ensuring corrective actions are implemented and verified.

External audits are conducted by independent certification bodies to verify compliance. My experience includes preparing for these audits, managing communication with the auditors, and ensuring all necessary documentation is available. Successfully navigating both internal and external audits demonstrates a strong commitment to ISO compliance.

Q 14. What are the common challenges encountered during ISO implementation?

Several common challenges arise during ISO implementation:

Lack of Management Commitment: Without strong leadership support and commitment, implementation efforts can falter.

Inadequate Training and Communication: Employees need sufficient training and clear communication to understand their roles and responsibilities.

Resistance to Change: Implementing a new management system can disrupt established processes, leading to resistance from employees.

Insufficient Resources: Implementation requires adequate resources (time, budget, personnel) to be successful.

Maintaining Compliance Over Time: Ongoing monitoring, internal audits, and continuous improvement are essential to sustain compliance after certification.

Overcoming these challenges requires proactive planning, effective communication, strong leadership, and a commitment to continuous improvement. For example, addressing resistance to change often involves involving employees in the process, highlighting the benefits of ISO certification, and providing ongoing support and training.

Q 15. How do you ensure the effectiveness of ISO management systems?

Ensuring the effectiveness of an ISO management system is a continuous process, not a one-time event. It hinges on a robust cycle of planning, implementation, monitoring, review, and improvement. Think of it like maintaining a finely tuned machine – regular checks and adjustments are crucial for optimal performance.

- Regular Internal Audits: These are crucial for identifying gaps and non-conformances in the system before they become major issues. We schedule regular audits, using a risk-based approach to prioritize areas of higher vulnerability. For example, if a particular process has a history of errors, we’d allocate more audit time to it.

- Management Review: This high-level review ensures top management is actively involved and committed to the system’s effectiveness. It’s where we assess performance against objectives, identify areas for improvement, and allocate resources accordingly. We use key performance indicators (KPIs) to track progress and identify trends.

- Corrective and Preventive Actions (CAPA): This is the reactive and proactive process for addressing identified issues. A robust CAPA system ensures that when a problem occurs, we don’t just fix the immediate problem but also investigate the root cause and implement measures to prevent it from happening again. For example, if a product defect is found, we’d investigate the manufacturing process to identify and eliminate the root cause, documenting all steps taken.

- Continuous Improvement: The Plan-Do-Check-Act (PDCA) cycle is the backbone of continuous improvement. We constantly seek ways to enhance our processes, improve efficiency, and ensure compliance. This could involve implementing new technologies, refining existing procedures, or training staff on best practices.

By consistently applying these elements, we ensure that the ISO management system remains effective, meeting the organization’s objectives and demonstrating ongoing compliance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle conflicts between different ISO standards?

Conflicts between different ISO standards are surprisingly common, especially in organizations adopting multiple standards (e.g., ISO 9001, ISO 14001, ISO 27001). The key is to integrate them effectively rather than treat them as separate entities. This involves a careful analysis and alignment of requirements.

- Identify Overlapping Requirements: First, we identify areas where requirements overlap or conflict. This often involves detailed comparison of clauses and requirements across the relevant standards.

- Prioritization and Hierarchy: If direct conflict exists, we prioritize requirements based on organizational context and risk assessment. For instance, in a conflict between a safety requirement (e.g., ISO 45001) and a cost-optimization requirement (e.g., ISO 9001), safety always takes precedence.

- Integrated Management System (IMS): The optimal solution is often the implementation of an IMS. This unifies multiple ISO standards under a single, integrated framework, minimizing redundancies and maximizing efficiency. It leverages common elements like the PDCA cycle and risk-based thinking to achieve synergy.

- Documentation: We meticulously document the process of conflict resolution, including the rationale for prioritization and any chosen compromises. This ensures transparency and traceability.

For example, if a process needs to be both efficient (ISO 9001) and environmentally friendly (ISO 14001), we might incorporate environmentally friendly practices into the design of the efficient process itself. This eliminates conflict by finding a synergistic solution.

Q 17. What is your understanding of risk-based thinking in ISO standards?

Risk-based thinking is not just a requirement in many ISO standards; it’s the foundation for proactive management and continuous improvement. It emphasizes identifying, assessing, and mitigating potential risks and opportunities before they impact the organization’s objectives. Think of it as a proactive approach to problem-solving, rather than reacting to issues after they arise.

- Risk Identification: This involves brainstorming potential hazards that could affect the organization’s ability to achieve its objectives. We use various techniques, including SWOT analysis, brainstorming sessions, and hazard checklists. For example, in a manufacturing setting, we would identify risks related to equipment failure, supply chain disruptions, and employee safety.

- Risk Assessment: This involves analyzing the likelihood and potential impact of each identified risk. We often use risk matrices to visually represent this information, helping prioritize mitigation efforts.

- Risk Treatment: Once risks are assessed, appropriate controls are implemented to mitigate them. These might include preventative measures (e.g., regular equipment maintenance), contingency plans (e.g., backup suppliers), or risk acceptance (acknowledging a risk but deciding not to implement controls due to low likelihood or impact).

- Risk Monitoring and Review: Risk is a dynamic factor. It’s essential to monitor the effectiveness of controls over time and regularly review the risk assessment process to account for changes in the business environment.

Risk-based thinking helps organizations proactively address potential problems, improving efficiency, reducing costs, and ensuring compliance. It moves away from a purely reactive approach, where issues are dealt with only after they occur.

Q 18. Explain your experience with root cause analysis.

Root cause analysis (RCA) is a crucial problem-solving technique used to identify the underlying causes of non-conformances or incidents. It’s about digging deeper than just treating the symptoms to prevent recurrence. It’s like a detective investigating a crime; you need to find the root cause, not just the immediate evidence.

- 5 Whys: This is a simple yet effective technique. By repeatedly asking ‘why’ after each answer, we delve deeper into the layers of causality until we reach the root cause. For example, if a machine malfunctions, we might ask: Why did it malfunction? (worn parts). Why were the parts worn? (lack of maintenance). Why was there a lack of maintenance? (inadequate training). Why was there inadequate training? (budget constraints).

- Fishbone Diagram (Ishikawa Diagram): This visual tool helps structure the brainstorming process, identifying potential root causes categorized by different factors (e.g., people, methods, machines, materials, environment, management). This allows for a structured and comprehensive approach.

- Fault Tree Analysis (FTA): This is a more complex technique used for intricate systems or critical failures. It starts with the unwanted event (top event) and works backward to identify the contributing causes.

My experience includes using these techniques in various contexts, from investigating customer complaints to analyzing production line failures. The key to successful RCA is a collaborative approach, involving relevant stakeholders and documenting the findings thoroughly to ensure effective corrective and preventive actions.

Q 19. Describe your proficiency in using audit management software.

I have extensive experience using various audit management software, including [mention specific software examples, e.g., AuditBoard, Archer, Planview Enterprise One]. Proficiency with these tools allows me to streamline the audit process, improving efficiency and accuracy.

- Scheduling and Planning: The software allows for efficient scheduling of audits, assigning auditors, and managing resources effectively. This ensures all areas are audited in a timely manner and according to risk priorities.

- Evidence Collection and Management: These tools provide secure storage for audit evidence, ensuring compliance with documentation requirements. They help track and organize the collected evidence, ensuring its integrity and accessibility.

- Reporting and Analysis: The software provides tools to generate comprehensive audit reports, including key findings, non-conformances, and corrective actions. The reports can be customized for different audiences and used to track progress towards continuous improvement.

- Workflow Automation: Many audit management software solutions automate workflows, such as notifications, reminders, and approvals, reducing manual effort and minimizing potential errors.

My experience extends to configuring, customizing, and training others on the use of these systems, demonstrating a comprehensive understanding of their capabilities and applications within the context of ISO certification compliance.

Q 20. How do you maintain the confidentiality of audit findings?

Maintaining the confidentiality of audit findings is paramount. It’s a matter of professional ethics and often a legal requirement. We implement strict measures to protect sensitive information.

- Access Control: Access to audit findings is strictly limited to authorized personnel on a need-to-know basis. We use password-protected documents, secure file sharing systems, and access control lists to regulate access.

- Data Encryption: Sensitive data is encrypted both in transit and at rest to protect it from unauthorized access, even if a system is compromised.

- Confidentiality Agreements: All audit team members sign confidentiality agreements, committing to protecting sensitive information. This reinforces the seriousness of maintaining confidentiality.

- Secure Data Disposal: Once audit findings are no longer needed, we securely dispose of the data according to established procedures to prevent unauthorized access.

- Regular Security Audits: Internal audits and penetration testing of systems helps identify and address vulnerabilities before they can be exploited.

We treat confidentiality as an ongoing process, not just a policy. Regular training for staff on data security protocols ensures everyone understands their responsibility in protecting sensitive information. This is crucial for maintaining trust and complying with regulations.

Q 21. What is your experience with the implementation of a document control system?

Implementing a robust document control system is fundamental to ISO compliance. It ensures that documents are current, accurate, readily available, and controlled throughout their lifecycle. Think of it as a librarian meticulously organizing and maintaining a library; ensuring the right books are available to the right people at the right time.

- Document Identification and Version Control: Each document is uniquely identified and version controlled to prevent confusion and ensure everyone is using the latest version. We often use a numbering system that indicates revision levels.

- Document Review and Approval: A formal process is established for reviewing and approving documents before they are released or updated. This ensures accuracy and consistency.

- Document Distribution and Access: A controlled system is in place for distributing documents. This could involve a secure document management system that restricts access based on user roles and permissions.

- Document Storage and Retrieval: Documents are stored in a secure, organized manner, ensuring easy retrieval. Physical and electronic documents must both be managed effectively.

- Document Obsoletion and Disposal: A process for managing obsolete documents is crucial. This includes archiving old versions and securely disposing of documents that are no longer needed.

My experience includes implementing and managing document control systems in various organizational settings, encompassing both manual and electronic systems. I have a deep understanding of the importance of this system for maintaining ISO compliance and ensuring the overall effectiveness of the management system.

Q 22. How do you ensure that the ISO management system is integrated with business objectives?

Integrating an ISO management system with business objectives is crucial for ensuring that the system isn’t just a box-ticking exercise but a genuine driver of business success. It’s about aligning the system’s goals with the overarching strategic aims of the organization.

- Strategic Alignment: Start by clearly defining the organization’s strategic goals. Then, map the ISO requirements to these goals. For example, if a key objective is to reduce customer complaints, the ISO 9001 quality management system can be instrumental in achieving this through process improvements and customer feedback mechanisms.

- Performance Indicators (KPIs): Establish measurable KPIs that track progress towards both business objectives and ISO compliance. These KPIs should be regularly monitored and reviewed. This might include metrics like customer satisfaction scores, defect rates, or the number of nonconformances identified during internal audits.

- Management Review: The management review process (a requirement of most ISO standards) provides a formal platform for assessing the effectiveness of the integrated management system. This review should analyze how well the system is contributing to achieving strategic goals and identify areas for improvement.

- Resource Allocation: Ensure sufficient resources (financial, human, technological) are allocated to the ISO management system to support its effective implementation and ongoing maintenance. This shows a commitment to the system’s importance to the business.

For example, a manufacturing company aiming to increase market share might integrate its ISO 9001:2015 system with its marketing and sales strategies, using quality data to build customer trust and brand reputation.

Q 23. Explain your understanding of continuous improvement principles within the context of ISO.

Continuous improvement, often referred to as Kaizen, is the heart of any effective ISO management system. It’s a cyclical process of identifying areas for improvement, implementing changes, and then monitoring the effects of those changes. Within the context of ISO, this means constantly striving to enhance the effectiveness of the management system itself and the organization’s performance.

- Plan-Do-Check-Act (PDCA) Cycle: The PDCA cycle is a fundamental framework for continuous improvement. It involves planning a change, implementing it (doing), checking the results, and acting on the findings to make further improvements. This cycle is iterative and ongoing.

- Internal Audits: Regular internal audits help identify gaps and areas where the management system can be improved. The findings are then used to implement corrective actions.

- Management Review: As previously mentioned, the management review process plays a critical role in analyzing performance data and identifying areas needing improvement across the entire system.

- Corrective and Preventive Actions (CAPA): A robust CAPA system is essential for addressing nonconformances and preventing their recurrence. This means not just fixing immediate problems but also analyzing the root cause and implementing preventative measures to avoid future issues.

- Data Analysis: Analyzing performance data from various sources, like customer feedback and operational metrics, allows for data-driven decision-making and identification of improvement opportunities.

Think of it like maintaining a car. Regularly checking the oil, tires, and brakes prevents larger, more costly problems later. Similarly, continuous improvement in an ISO system prevents larger compliance failures and keeps the organization running smoothly and efficiently.

Q 24. Describe a time when you had to overcome a significant compliance challenge.

During my time at a previous company, we faced a significant challenge when a new regulatory requirement was introduced with a very short implementation timeframe. The regulation impacted a key aspect of our manufacturing process, and non-compliance risked substantial penalties.

To overcome this, I implemented the following steps:

- Emergency Team Formation: I assembled a cross-functional team comprising experts in legal, operations, and quality management to address the issue.

- Gap Analysis: We conducted a thorough gap analysis to pinpoint the specific areas where we needed to make changes to meet the new regulatory requirements.

- Prioritization and Resource Allocation: We prioritized tasks based on their urgency and impact. This required careful allocation of resources, including personnel and budget.

- Rapid Implementation Plan: We developed a detailed implementation plan with clearly defined timelines and responsibilities. This involved extensive training for staff and re-engineering portions of our manufacturing process.

- Continuous Monitoring: We continuously monitored our progress and made necessary adjustments to the plan as needed. We also proactively communicated our progress to relevant stakeholders, including regulatory bodies.

Through proactive problem-solving and team collaboration, we successfully met the regulatory deadline without incurring any penalties. This experience underscored the importance of a flexible, responsive, and well-communicated ISO management system.

Q 25. How do you ensure employee engagement and buy-in for ISO compliance?

Securing employee buy-in for ISO compliance is critical for the success of any ISO management system. It’s not enough to just implement the system; employees must understand its value and actively participate in its maintenance.

- Communication and Education: Clear and consistent communication is essential. Employees need to understand why ISO compliance is important for the organization and how it benefits them. This involves explaining the benefits in simple terms, avoiding jargon.

- Training and Development: Comprehensive training programs should be provided to ensure all employees understand their roles and responsibilities within the ISO management system. Training should be tailored to different roles and levels of understanding.

- Employee Involvement: Actively involve employees in the design and implementation of the ISO management system. Seeking their input on processes and procedures demonstrates respect for their expertise and increases their ownership of the system.

- Recognition and Rewards: Recognize and reward employees who actively contribute to ISO compliance. This could involve public acknowledgment, bonus programs, or opportunities for professional development.

- Feedback Mechanisms: Establish mechanisms for gathering employee feedback on the ISO management system. This could include surveys, focus groups, or suggestion boxes. Using this feedback shows that management values their opinions and helps improve the system.

For instance, I’ve used gamification techniques in the past, turning compliance tasks into team challenges with rewards, fostering a positive and collaborative atmosphere around ISO compliance.

Q 26. What are your strengths and weaknesses in relation to ISO certification compliance?

My strengths lie in my deep understanding of ISO standards, my proven ability to develop and implement effective ISO management systems, and my experience in leading and motivating teams to achieve compliance. I’m highly analytical, detail-oriented, and possess strong problem-solving skills. I also have a proven track record of successfully navigating complex compliance challenges.

One area for development is expanding my knowledge of specific industry-specific regulations. While I have a solid foundation in general ISO standards, gaining deeper expertise in specific sectors would further enhance my capabilities. I’m actively pursuing relevant certifications and training to address this.

Q 27. What are your salary expectations for this role?

My salary expectations are in the range of [Insert Salary Range] per year. This is based on my experience, skills, and the requirements of this role. I’m open to discussing this further based on the specifics of the compensation package.

Q 28. Do you have any questions for me?

I have several questions. Firstly, could you elaborate on the company’s current ISO certification status and any upcoming challenges related to ISO compliance? Secondly, what opportunities exist for professional development and growth within this role? Finally, what is the company culture like concerning collaboration and teamwork?

Key Topics to Learn for ISO Certification Compliance Interview

- Understanding ISO Standards: Familiarize yourself with the core principles and requirements of relevant ISO standards (e.g., ISO 9001, ISO 14001, ISO 27001), focusing on their underlying philosophy and intent.

- Implementation and Auditing: Gain a practical understanding of how ISO standards are implemented within organizations. Explore the various stages of an audit process, including internal audits, management reviews, and certification audits. Consider the role of documentation and evidence gathering.

- Risk Management and Compliance: Master the concepts of risk assessment, risk treatment, and risk monitoring within the framework of ISO compliance. Learn how to identify and mitigate potential risks to ensure consistent adherence to standards.

- Continuous Improvement: Understand the PDCA (Plan-Do-Check-Act) cycle and its application in maintaining and improving ISO certification. Learn how to identify areas for improvement and implement corrective actions.

- Legal and Regulatory Compliance: Explore the intersection of ISO standards and relevant legal and regulatory requirements. Understand how to ensure compliance with both.

- Internal Communication and Training: Learn the importance of effective communication and employee training programs to foster a culture of compliance within an organization.

- Specific Industry Applications: Research how ISO standards are applied in your target industry. This demonstrates practical knowledge and a commitment to specialization.

Next Steps

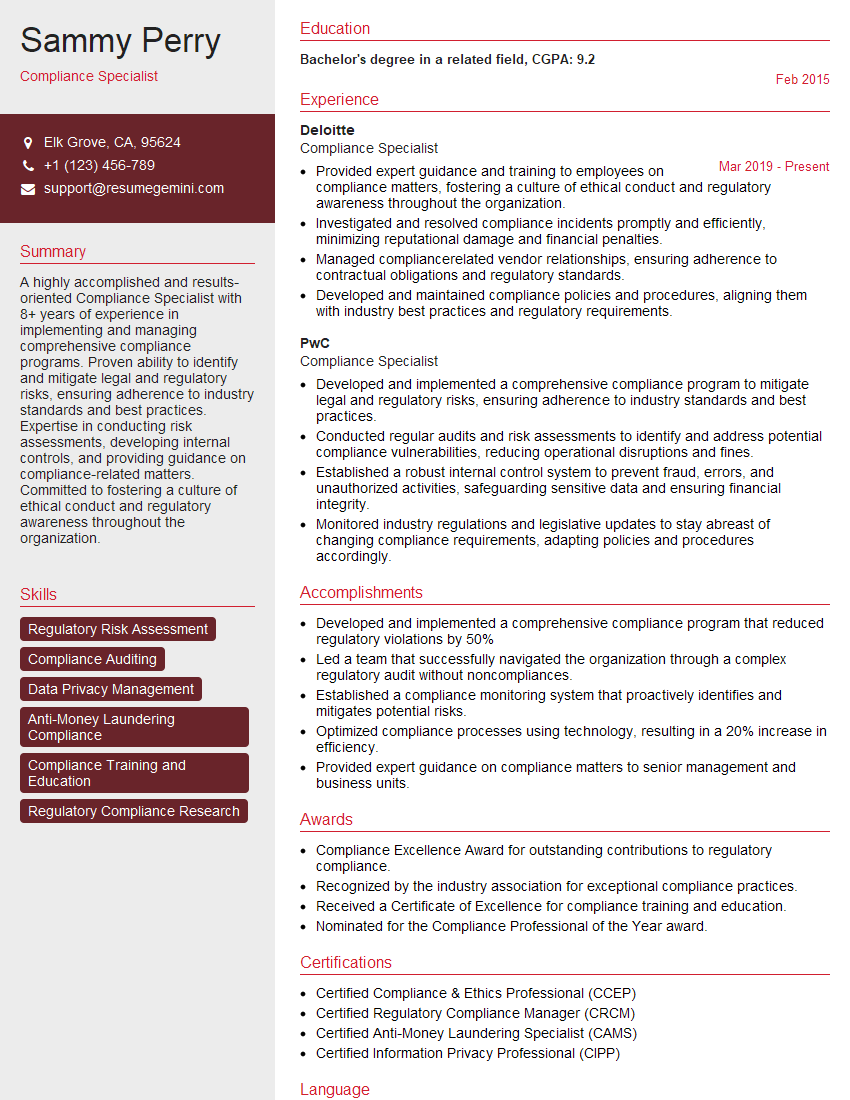

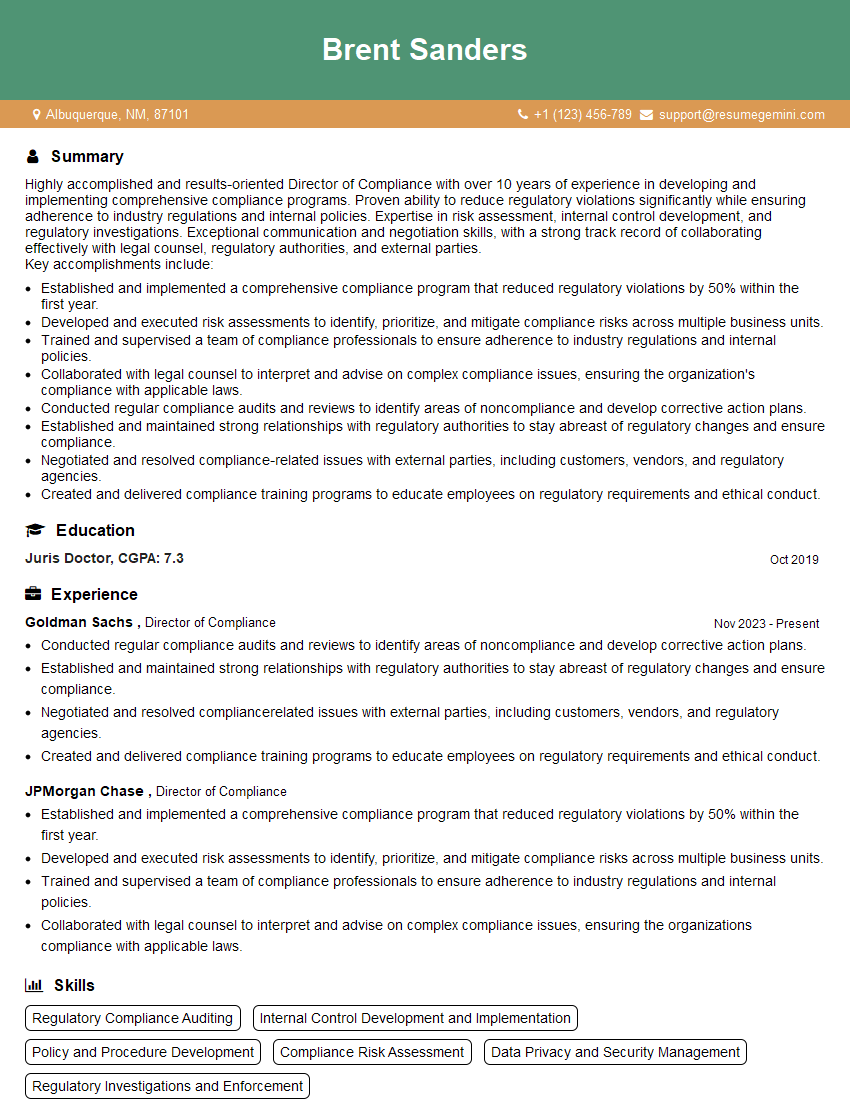

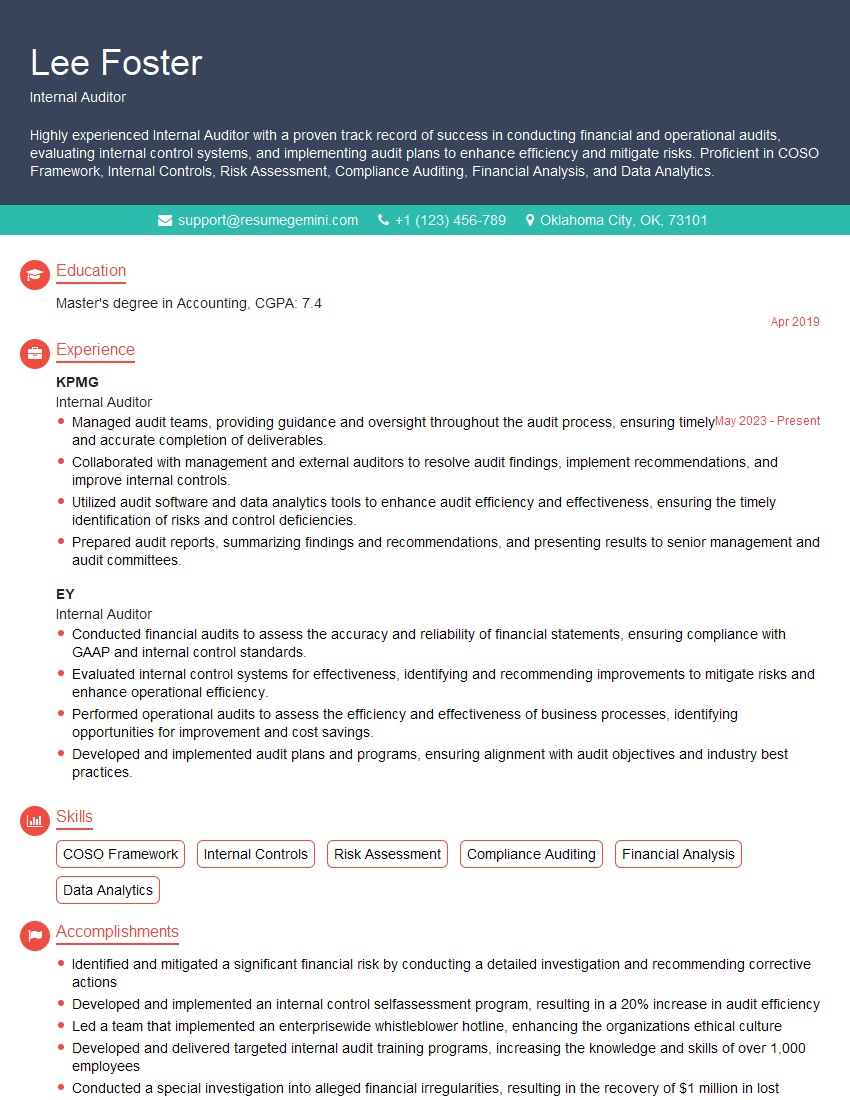

Mastering ISO Certification Compliance significantly enhances your career prospects, opening doors to rewarding roles in quality management, compliance, and auditing. A strong, ATS-friendly resume is crucial for showcasing your skills and experience to potential employers. To maximize your chances, leverage ResumeGemini to craft a compelling and effective resume tailored to the specific demands of your target roles. ResumeGemini provides examples of resumes optimized for ISO Certification Compliance, helping you present your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good