The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Timber Harvesting Principles interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Timber Harvesting Principles Interview

Q 1. Explain the difference between clear-cut, shelterwood, and selection harvesting methods.

Timber harvesting methods differ significantly in their approach to tree removal and regeneration. Clear-cutting, shelterwood, and selection harvesting represent distinct strategies with varying impacts on the forest ecosystem.

Clear-cutting: This method involves removing all trees in a designated area. Imagine a clean slate – it’s a complete removal. While efficient and cost-effective, it can lead to significant soil erosion, loss of biodiversity, and altered microclimates. However, some species, like aspen or certain pines, actually thrive after clear-cutting, benefiting from the increased sunlight and open space. We typically use this method in areas where rapid regeneration of a specific species is desired.

Shelterwood harvesting: This is a more gradual approach. It involves removing trees in stages, leaving a number of mature trees behind to provide shelter for regenerating seedlings. Think of it as a gradual transition, preserving some of the forest’s existing structure. This helps to protect young trees from harsh weather and promotes a more natural regeneration process. We often employ this method with species that need shade during their early growth stages.

Selection harvesting: This method focuses on removing individual trees or small groups of trees, leaving the majority of the stand intact. This mimics natural forest dynamics and results in a more uneven-aged forest structure with greater biodiversity. It’s less disruptive but also less efficient and often more expensive than clear-cutting. This is ideal for species that regenerate well in the shade of the remaining trees and when maintaining a diverse age structure is crucial.

Q 2. Describe the process of pre-harvest planning and its importance.

Pre-harvest planning is paramount for a successful and sustainable logging operation. It’s like creating a blueprint before building a house – you wouldn’t start constructing without plans! This process involves a detailed assessment of the forest, defining harvesting objectives, and outlining the operational plan.

Inventory and Assessment: We start by determining the volume and species composition of timber, assessing the terrain, identifying environmentally sensitive areas, and evaluating potential risks (e.g., slope instability).

Harvesting Design: Based on the assessment, we design the layout of harvesting units, considering factors like road access, equipment limitations, and desired regeneration patterns. Different harvesting methods will influence this significantly.

Environmental Considerations: Crucial to this is identifying and protecting sensitive habitats, waterways, and endangered species. This may involve implementing measures to minimize erosion, sediment control, and water quality impacts.

Road Network Planning: A well-designed road network is crucial for efficient timber extraction and minimizes damage to the forest. We aim to keep road construction to the minimum necessary.

Risk Assessment and Mitigation: We must consider potential risks, like weather events, equipment failure, and worker safety. We put mitigation plans in place to address these risks proactively.

Thorough pre-harvest planning is crucial for maximizing timber yield, minimizing environmental impact, and ensuring worker safety. It’s a vital step to achieving economic viability and ecological responsibility.

Q 3. What are the key considerations for road construction in a logging operation?

Road construction in logging operations presents unique challenges. We need to balance the need for efficient access to timber with minimizing environmental damage. Key considerations include:

Environmental Protection: Minimizing disturbance to soil, water bodies, and sensitive ecosystems is vital. This often involves using techniques like erosion and sediment control measures during and after construction.

Slope Stability: Roads on steep slopes require careful design and construction to prevent erosion and landslides. This might involve terracing, retaining walls, and appropriate drainage systems.

Water Quality: Proper drainage systems are essential to prevent contamination of waterways with sediment or chemicals. We frequently use culverts and other water management structures.

Accessibility: Roads need to be suitable for the size and weight of logging equipment. The quality and durability of roads affect operational efficiency.

Cost-Effectiveness: While efficient access is vital, we must ensure the road construction is cost-effective and doesn’t outweigh the value of the timber being harvested. Road design must be optimized.

Poorly constructed roads can result in significant environmental damage and economic losses, highlighting the critical nature of these design choices.

Q 4. How do you ensure the safety of logging crews and equipment on a job site?

Safety is paramount in logging operations. It’s not just a matter of compliance; it’s a fundamental ethical and operational necessity. We implement a comprehensive safety program that covers various aspects:

Pre-shift meetings: Daily meetings to review the day’s tasks and potential hazards, emphasizing safe work practices.

Equipment maintenance: Regular checks and maintenance of all equipment to ensure it’s in optimal working condition and free of defects.

Personal Protective Equipment (PPE): Mandatory use of appropriate PPE, including helmets, safety glasses, high-visibility clothing, and appropriate footwear.

Training and certification: Comprehensive training programs for all crew members on safe operation of machinery, hazard recognition, and emergency procedures. Certifications are often required for operating specialized equipment.

Emergency Response Plan: Developing and regularly practicing an emergency response plan to address accidents, injuries, and other unforeseen events.

Communication Systems: Clear and reliable communication systems among crew members, supervisors, and emergency services.

We treat safety as a shared responsibility. Every member of the crew is accountable for their safety and that of their colleagues. A strong safety culture minimizes risks and fosters a work environment where everyone can go home safe at the end of the day.

Q 5. Explain your experience with different types of harvesting equipment.

My experience encompasses a range of harvesting equipment, from traditional to highly mechanized systems.

Feller bunchers: These machines cut and gather trees into bundles, significantly improving efficiency in harvesting operations. I’m proficient in operating several models, from smaller, more maneuverable units for selective harvesting to larger, high-capacity machines for clear-cutting operations.

Harvesters: These advanced machines combine felling, delimbing, and bucking functions in a single unit, maximizing productivity and reducing manual labor. My experience includes various harvester heads and control systems, enabling me to adapt to different tree sizes and species.

Forwarders: Forwarders are responsible for transporting felled trees from the harvesting site to designated landing areas. I have expertise in operating forwarders in varied terrain conditions, ensuring efficient log transportation and minimizing ground damage.

Skidders: While less common now in mechanized operations, I also have experience operating skidders, particularly in more challenging terrains where larger machines may not be suitable. Skidders are valuable for smaller-scale operations or selective harvesting in difficult terrain.

My experience with various equipment allows me to choose the most suitable machines for each harvesting project, considering factors such as terrain, tree species, and operational objectives. I am also well versed in their maintenance and safety procedures.

Q 6. What are the environmental regulations relevant to timber harvesting in your region?

Environmental regulations governing timber harvesting vary by region, but generally focus on minimizing environmental impact. In my region, key regulations include:

Water Quality Protection: Strict guidelines to prevent erosion, sedimentation, and pollution of waterways, often requiring the implementation of best management practices (BMPs).

Protection of Endangered Species and Habitats: Regulations to protect threatened and endangered species and their habitats, often requiring site-specific surveys and mitigation measures.

Forest Practices Act: A comprehensive set of rules and regulations designed to ensure sustainable forest management practices are followed, including requirements for reforestation, road construction standards, and harvesting methods.

Air Quality Regulations: Regulations concerning dust and emissions from equipment, often necessitating the use of dust suppression techniques and environmentally friendly fuels.

Permitting and Reporting Requirements: Procedures for obtaining necessary permits before commencing operations, submitting regular reports on progress and compliance, and conducting post-harvest assessments.

Staying current on these regulations is critical for ensuring compliance and achieving environmentally sound harvesting operations. We regularly attend workshops and training to stay up-to-date on the latest regulations.

Q 7. How do you assess and mitigate risks associated with slope instability during harvesting?

Slope instability is a significant risk in timber harvesting, potentially causing accidents and environmental damage. Assessing and mitigating this risk involves a multi-step process:

Slope Assessment: A detailed assessment of the terrain, including slope angle, soil type, and presence of any previous landslides. This often involves using topographic maps, aerial imagery, and on-site inspections by qualified professionals.

Soil Testing: Analyzing soil properties to determine its stability and susceptibility to erosion. This provides a crucial understanding of the ground conditions.

Risk Mapping: Creating a map identifying areas with high risk of slope failure. This helps in planning harvesting operations and selecting appropriate methods and routes.

Mitigation Measures: Implementing appropriate measures to reduce the risk of slope failure. These may include:

Restricting equipment access: Restricting equipment operation in high-risk areas.

Terracing: Creating level platforms on slopes to reduce the gradient and increase stability.

Drainage systems: Installing drainage systems to manage water flow and prevent erosion.

Revegetation: Planting vegetation to enhance soil stability and reduce erosion.

Monitoring and Inspections: Regular monitoring of slopes during harvesting operations to identify and address any emerging instability issues. Regular inspections help in early detection.

Ignoring slope instability can have catastrophic consequences. Proactive risk assessment and mitigation are essential for safe and sustainable harvesting operations.

Q 8. Describe your experience with timber cruising and volume estimation techniques.

Timber cruising, the process of assessing the volume and value of timber in a stand, is fundamental to sustainable harvesting. My experience encompasses various techniques, from traditional methods like fixed-radius plots and variable-radius plots using angle gauges (e.g., the Bitterlich method), to modern approaches leveraging GPS and GIS data. Volume estimation then utilizes this data, often employing species-specific volume equations (derived from tree diameter and height measurements) and statistical analysis to project the total merchantable volume. For instance, in a recent project involving a mixed hardwood stand, we used a combination of fixed-radius plots and a prism cruise to efficiently assess the volume of oak, maple, and hickory trees, accounting for differences in merchantability standards for each species. This allowed us to accurately estimate the total volume of each species, providing critical information for operational planning and sales projections.

Furthermore, I’m proficient in using specialized software such as Forest Growth and Yield simulators that integrate cruising data to predict future timber growth and help optimize harvest schedules for maximum sustainable yield. For example, I’ve used such software to model the impact of different thinning regimes on the growth of Douglas fir stands, ensuring long-term forest health and productivity.

Q 9. Explain how you would develop a sustainable harvesting plan for a specific forest type.

Developing a sustainable harvesting plan requires a holistic approach, considering ecological, economic, and social factors. It begins with a thorough assessment of the specific forest type – identifying dominant species, age classes, site productivity, and existing wildlife habitat. Key steps include:

- Inventory and Analysis: Accurate timber cruising (as described above) provides the baseline data for volume estimation and species composition.

- Silvicultural Considerations: The plan must align with the desired future forest structure and composition. This might involve selecting cutting methods (e.g., shelterwood, selection, clearcutting) appropriate for the species and site conditions to promote regeneration and long-term forest health. For example, a shelterwood system would be ideal for shade-tolerant species, ensuring sufficient seed trees remain to facilitate natural regeneration.

- Environmental Protection: The plan must incorporate measures to minimize impacts on water quality, soil erosion, and wildlife habitat. This includes buffer strips along waterways and careful consideration of road placement.

- Economic Feasibility: The plan should outline the harvesting methods, transportation logistics, and projected costs and revenues to ensure economic viability.

- Stakeholder Engagement: Consultation with relevant stakeholders – landowners, local communities, and regulatory agencies – is crucial to ensure buy-in and address any potential conflicts.

For instance, developing a plan for a mature Douglas fir forest in the Pacific Northwest might involve a combination of shelterwood and selection cutting methods to promote regeneration and maintain biodiversity, coupled with riparian buffer zones to protect water quality and salmon habitat.

Q 10. How do you address erosion and sediment control during and after harvesting?

Erosion and sediment control are paramount concerns in timber harvesting. My approach involves implementing preventative measures during harvesting and restorative measures after harvesting. During operations, this involves:

- Proper Road Construction and Maintenance: Well-designed and maintained roads minimize soil disturbance. Techniques such as water bars, culverts, and proper drainage systems are essential.

- Minimizing Soil Disturbance: Using directional felling techniques and careful skidding practices help reduce soil compaction and erosion.

- Stream Buffer Strips: Maintaining vegetated buffers along waterways protects water quality and prevents sedimentation.

Post-harvest, measures include:

- Revegetation: Planting native species helps stabilize the soil and reduce erosion.

- Erosion Control Structures: Check dams and other structures can be used to manage water flow and prevent erosion in particularly vulnerable areas.

- Monitoring: Regular monitoring of water quality and erosion levels is crucial to assess the effectiveness of control measures.

For example, I’ve successfully implemented these measures on steep slopes by using a combination of cable logging (to reduce ground disturbance) and planting fast-growing erosion-control vegetation immediately after harvesting.

Q 11. What are the best practices for minimizing damage to residual trees during harvesting?

Minimizing damage to residual trees is critical for maintaining forest health and productivity. This requires skilled operators and careful planning. Best practices include:

- Skilled Operators: Experienced operators are crucial in maneuvering equipment and avoiding collisions with residual trees.

- Directional Felling: Trees are felled in a specific direction to minimize impacts on surrounding trees.

- Proper Equipment Use: Appropriate equipment selection for the terrain and tree size minimizes damage.

- Pre-harvest Planning: Careful planning identifies trees to be retained and routes for machinery to avoid collisions.

- Buffer Zones: Establishing buffer zones around high-value or sensitive trees protects them from damage during operations.

For instance, in a recent project involving a high-value timber stand, we employed highly trained operators and used advanced GPS systems to guide the machinery, minimizing damage to residual trees designated for future growth or seed production. This resulted in far fewer damaged trees and a much healthier, more productive stand after harvesting.

Q 12. Describe your experience with GPS and GIS technology in timber harvesting.

GPS and GIS technologies are now indispensable in timber harvesting. My experience encompasses using GPS for precise location mapping of trees, roads, and boundaries. This enhances accuracy in timber cruising, improves operational efficiency by optimizing harvest layouts, and facilitates accurate tracking of timber extraction. GIS software is used to integrate this data, generating maps that visualize terrain, vegetation, and other critical information, guiding harvesting operations and minimizing environmental impact.

For example, in one project, we used GIS to create a detailed map incorporating terrain data, tree locations, and sensitive environmental features (like streams and wetlands). This allowed us to plan efficient logging roads that minimized environmental impact and avoided sensitive areas. We also used GPS-enabled machinery to precisely follow pre-planned harvest routes, improving operational efficiency and reducing waste.

Q 13. How do you manage conflicts between logging operations and other forest users (e.g., recreation, wildlife)?

Managing conflicts between logging operations and other forest users requires proactive communication and planning. It starts with understanding the needs and concerns of all stakeholders. This often involves:

- Public Consultation: Early and open communication with local communities, recreational users, and wildlife agencies is essential to address concerns and identify potential conflicts.

- Spatial Planning: Using GIS, we can identify areas with high recreational use or significant wildlife habitat and plan logging operations to minimize impacts on these areas, potentially scheduling work around peak usage times.

- Mitigation Measures: Implementing mitigation measures (e.g., creating wildlife corridors, designated recreation areas, timed closures) can minimize conflicts and ensure the continued enjoyment of the forest by multiple user groups.

- Monitoring and Adaptive Management: Continuous monitoring of the effects of logging operations on other forest users allows for adjustments to the harvesting plan to minimize negative impacts.

For example, in a project near a popular hiking trail, we coordinated with local authorities to schedule logging during the off-season, minimizing disruption to hikers. We also established designated buffer zones around the trail to ensure hiker safety and maintain the aesthetic appeal of the area.

Q 14. What is your experience with various harvesting techniques for different tree species?

My experience spans various harvesting techniques tailored to different tree species and site conditions. For example:

- Clearcutting: Suitable for fast-growing, even-aged stands of species like lodgepole pine, but requires careful planning to minimize environmental impacts.

- Shelterwood Cutting: Ideal for shade-tolerant species such as Douglas fir and maple, where seed trees are retained to facilitate natural regeneration.

- Selection Cutting: Suited for uneven-aged stands and valuable hardwoods, allowing for selective removal of mature trees while maintaining a diverse forest structure.

- Seed-Tree Cutting: Retaining a few seed trees to regenerate the stand, often used for species with good natural regeneration capabilities.

- Commercial Thinning: Removing smaller trees to improve growth of remaining trees, beneficial for increasing the value and volume of high-value timber.

The choice of harvesting method depends on various factors including species characteristics, stand density, site conditions, ecological objectives, and economic considerations. For instance, harvesting mature redwoods might require specialized techniques like cable logging due to their size and the often steep terrain. In contrast, harvesting a younger, less dense pine plantation might employ more conventional methods like skidding.

Q 15. Explain how you ensure compliance with relevant environmental and safety regulations.

Ensuring compliance with environmental and safety regulations is paramount in timber harvesting. It’s not just about avoiding penalties; it’s about responsible stewardship of our forests and protecting the well-being of our workforce. My approach is multifaceted and proactive.

- Pre-harvest Planning: Before any tree is felled, we conduct thorough site assessments, identifying environmentally sensitive areas like wetlands, endangered species habitats, and steep slopes. We then tailor our harvesting plan to minimize impact, potentially employing selective logging techniques or adjusting skid trails to avoid these areas. We also obtain all necessary permits and licenses from relevant authorities.

- On-site Monitoring: During harvesting operations, we have dedicated personnel overseeing compliance. This includes regular checks on equipment maintenance to prevent fuel spills or mechanical failures, ensuring adherence to faller safety protocols (e.g., proper felling techniques, designated escape routes), and monitoring soil erosion control measures.

- Post-harvest Inspections: After the operation, we conduct a thorough inspection to evaluate the effectiveness of our mitigation strategies. This includes assessing water quality, checking for erosion, and confirming the absence of damage to non-target vegetation. Any necessary remediation actions are immediately implemented.

- Record Keeping: Meticulous record-keeping is essential. We document all aspects of the operation, from pre-harvest planning documents and permits to daily work logs and post-harvest inspections. This ensures traceability and transparency.

- Training and Education: Continuous training for all personnel on safety regulations and environmental best practices is crucial. Regular refresher courses, safety meetings, and the use of updated guidelines are standard practice.

For instance, in a recent project near a protected stream, we implemented a riparian buffer zone of 50 feet, using specialized equipment to minimize disturbance. We also employed water quality monitoring throughout the operation to ensure compliance with water quality standards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a situation where you had to troubleshoot a problem with harvesting equipment.

During a large-scale operation, our primary feller buncher experienced a hydraulic failure. The machine was immobilized, halting the entire harvesting process, and potentially delaying the project schedule. My approach involved a systematic troubleshooting process.

- Safety First: We immediately secured the area, ensuring the safety of all personnel involved. The machine was completely shut down and isolated.

- Initial Assessment: I examined the machine for obvious causes: leaks, damaged lines, or unusual noises. A preliminary visual inspection indicated a potential failure in the main hydraulic pump.

- Diagnostics: With the help of our mechanic, we used diagnostic equipment to pinpoint the exact nature of the problem. This confirmed our suspicion of a failed pump. We also checked the hydraulic oil levels and quality for potential contamination.

- Repair or Replacement: Given the extent of the damage, a repair was deemed impractical. We ordered a replacement hydraulic pump from the supplier, prioritizing a fast delivery.

- Preventative Maintenance: While waiting for the replacement, we used the downtime to implement preventative maintenance on other machines to prevent similar failures. We also reviewed our maintenance schedule to improve early detection of potential problems.

- Operational Adjustments: In the interim, we re-allocated resources to other parts of the operation to minimize productivity loss. We prioritized smaller tasks and focused on areas that didn’t rely heavily on the feller buncher.

The entire process, from failure to resumption of full operation, took approximately 36 hours. The quick response and systematic troubleshooting avoided significant delays and cost overruns.

Q 17. How do you monitor and evaluate the effectiveness of your harvesting operations?

Monitoring and evaluating harvesting operations involves a comprehensive approach encompassing several key areas. We use a combination of quantitative and qualitative data to ensure efficiency and effectiveness.

- Production Tracking: We closely monitor daily production rates (cubic meters or board feet harvested), machine utilization, and labor hours. This data provides insights into productivity and identifies potential bottlenecks.

- Cost Analysis: We track all costs, including labor, equipment, fuel, maintenance, and transportation. This data allows us to calculate costs per unit of volume and identify areas for improvement.

- Quality Control: We inspect harvested timber for damage and defects, ensuring it meets the specified quality standards. This helps to minimize waste and maintain product value.

- Environmental Monitoring: We monitor environmental impacts, such as soil erosion, water quality, and habitat disturbance. Post-harvest assessments help us measure the effectiveness of our environmental mitigation strategies.

- Safety Records: We meticulously track safety incidents, near-misses, and lost-time injuries. This data helps to identify safety hazards and improve our safety programs.

- Data Analysis & Reporting: We use data analysis software to generate reports and visualize key performance indicators (KPIs). This helps us to identify trends, track progress, and make data-driven decisions.

For example, by analyzing production data, we were able to identify that a specific harvesting crew was consistently underperforming. Further investigation revealed a lack of training on a new piece of equipment. After additional training, their productivity significantly improved.

Q 18. What are your strategies for managing harvesting costs and maximizing profitability?

Managing harvesting costs and maximizing profitability requires a strategic approach that integrates several key elements.

- Efficient Planning and Scheduling: Careful planning reduces downtime and improves resource allocation. This includes optimizing the harvesting sequence, selecting the right equipment for the job, and minimizing transportation distances.

- Equipment Selection and Maintenance: Choosing appropriate equipment is crucial. Well-maintained equipment minimizes downtime and reduces repair costs. A preventative maintenance schedule is essential.

- Negotiating favorable contracts with suppliers: Securing competitive pricing for fuel, parts, and services can significantly reduce operational costs.

- Labor Management: Efficiently managing labor resources, including training and incentivizing productivity, optimizes workforce performance.

- Waste Reduction: Minimizing waste during harvesting by using precise felling and extraction techniques translates to increased profitability.

- Market Analysis: Understanding market demand and pricing ensures that harvested timber is sold at optimal prices.

- Value-Added Products: Exploring the possibility of creating value-added products from by-products (e.g., wood chips for bioenergy) increases revenue streams.

For example, we implemented a new scheduling system that reduced travel time between harvesting sites by 15%, leading to a considerable saving in fuel and labor costs.

Q 19. How do you incorporate riparian buffer zones into your harvesting plans?

Riparian buffer zones are critical for protecting water quality and aquatic habitats. Their incorporation into harvesting plans requires careful consideration and precise execution.

- Identification and Delineation: The first step is to accurately identify and delineate riparian areas. This often involves using topographic maps, aerial imagery, and on-site surveys. We use GPS technology to map the precise boundaries.

- Buffer Zone Width: The width of the buffer zone depends on several factors, including the slope of the land, soil type, and the sensitivity of the aquatic ecosystem. We adhere to all relevant regulations and best management practices in establishing buffer zone width. It is often wider than the minimum legally required width.

- Harvesting Techniques: Within the buffer zone, we may employ selective harvesting techniques, avoiding any heavy machinery operations. We might use hand felling or cable logging, which minimizes ground disturbance.

- Erosion and Sediment Control: We implement measures to prevent erosion and sediment from entering waterways. This can involve constructing sediment basins, stabilizing banks, and using erosion control blankets.

- Leave Trees: To provide shade and maintain biodiversity, we often leave strategically placed trees within the buffer zone.

In one project near a sensitive river, we created a 100-foot buffer zone, using only hand felling within the zone. We also installed sediment fences to prevent soil erosion and carefully monitored water quality throughout the operation.

Q 20. What are your skills in using harvesting simulation software?

I am proficient in using several harvesting simulation software packages, including TimberMatic and ForestPro. These tools are indispensable for optimizing harvesting operations and predicting outcomes.

- Planning and Design: The software allows me to create detailed harvesting plans, including road layout, skid trail design, and felling patterns, using high-resolution terrain data.

- Resource Allocation: I can simulate different harvesting scenarios and assess the optimal allocation of machinery and labor resources to maximize efficiency and minimize costs.

- Yield Estimation: The software accurately estimates timber volume and quality, helping with accurate forecasting and more efficient procurement planning.

- Environmental Impact Assessment: Simulations can assess the potential environmental impacts of various harvesting strategies, including soil erosion and habitat fragmentation, enabling informed decision-making regarding mitigation strategies.

- Risk Assessment: The software can be used to assess potential risks associated with the operation, such as safety hazards and equipment malfunctions, enabling proactive risk mitigation.

For example, using TimberMatic, I recently simulated different harvesting layouts for a steep slope site. The simulations identified the optimal layout to minimize erosion risk while maintaining high productivity.

Q 21. Describe your experience with forest inventory and assessment methods.

My experience with forest inventory and assessment methods is extensive. I’m proficient in various techniques, from traditional ground-based surveys to advanced remote sensing methods.

- Ground-based Inventories: I have conducted numerous ground-based inventories, using techniques such as fixed-radius plots, variable-radius plots (using angle gauges), and line-plots. This involves measuring tree diameter at breast height (DBH), tree height, and species identification. I understand the importance of proper sampling design and statistical analysis to ensure accurate estimates.

- Remote Sensing: I am experienced in using LiDAR (Light Detection and Ranging) data and aerial photography for forest inventory. This technology allows for rapid and accurate assessment of forest structure, volume, and biomass over large areas.

- Data Analysis: I am proficient in using statistical software packages such as

RandSASto analyze inventory data. This includes calculating forest growth and yield, creating growth and yield models, and developing volume and biomass estimation models. - GIS (Geographic Information Systems): I utilize GIS software to map forest inventory data, create thematic maps illustrating different forest attributes, and visualize spatial patterns in forest structure and composition.

In a recent project, we used LiDAR data to create a highly detailed 3D model of a forest stand. This allowed us to accurately assess the volume and assess the potential for selective harvesting, minimizing environmental impact.

Q 22. How do you assess the health and condition of a forest before harvesting?

Assessing forest health before harvesting is crucial for ensuring sustainable operations and minimizing environmental impact. It’s like giving a patient a thorough check-up before surgery. My assessment involves a multi-faceted approach:

Stand Examination: I visually inspect the stand for tree health, assessing for signs of disease, insect infestation (e.g., bark beetle damage), and stress from environmental factors like drought or fire. This includes looking at crown density, branching patterns, and stem form.

Sampling and Analysis: I employ techniques like increment boring to determine tree age, growth rate, and overall health. Soil sampling helps assess nutrient levels and soil compaction. This data informs decisions on thinning strategies and appropriate harvesting methods.

Species Identification and Inventory: A detailed inventory using various tools, from traditional methods to LiDAR (Light Detection and Ranging) for larger areas, is crucial. This tells us the species composition, diameter distribution, and volume of timber, helping us make efficient harvesting plans.

Wildlife Habitat Assessment: I consider the presence of endangered species or sensitive habitats. This might involve consultation with wildlife biologists to identify key areas to protect during harvesting.

Risk Assessment: We identify potential hazards like unstable slopes, waterways, or proximity to infrastructure to plan safe and efficient logging operations. This includes developing site-specific safety plans.

For example, in a recent project, we identified a significant infestation of pine bark beetles in a specific area. This led us to prioritize harvesting that section to prevent further spread and protect the remaining healthy trees. The data collected informed a carefully planned harvesting approach minimizing damage to the surrounding healthy forest.

Q 23. What is your experience with training and supervising logging crews?

I have over 15 years of experience training and supervising logging crews, emphasizing both safety and productivity. My approach is built on a foundation of clear communication, practical demonstrations, and ongoing feedback.

Safety Training: Safety is paramount. Training focuses on the proper use of equipment (chainsaws, feller bunchers, skidders), hazard identification (e.g., unstable trees, slopes), and emergency response procedures. I use a combination of classroom instruction, practical demonstrations, and regular safety meetings.

Technical Skills Development: I train crews in efficient harvesting techniques, including felling, bucking, and skidding. This includes instruction on proper tree selection and minimizing damage to remaining trees and the environment. I conduct regular skills assessments to identify areas for improvement.

Supervision and Mentoring: I provide on-site supervision, offering guidance and addressing issues as they arise. I mentor crew members, encouraging teamwork and problem-solving. Regular feedback sessions ensure continuous improvement and address any performance concerns.

Compliance and Regulations: I ensure all crew members are aware of and comply with all relevant safety regulations and environmental protection laws. This includes maintaining accurate records and reporting.

For instance, I once successfully implemented a new felling technique that reduced the risk of tree damage and improved the efficiency of the crew by 15%. This involved hands-on training, regular feedback, and encouragement of continuous improvement.

Q 24. How do you incorporate principles of biodiversity conservation into harvesting operations?

Biodiversity conservation is integral to sustainable forestry. We don’t just harvest trees; we manage ecosystems. My approach involves several key strategies:

Retain Riparian Buffers: Protecting streamside vegetation is vital for water quality and wildlife habitat. We leave wide buffer zones along waterways untouched during harvesting.

Leave Wildlife Trees and Snags: Leaving behind trees of different species, sizes, and ages provides habitat for various species. This includes leaving standing dead trees (snags) which are crucial nesting and foraging sites.

Create Habitat Diversity: Strategic retention of various forest structures, including varied canopy cover, creates diverse habitats supporting a wider range of species.

Minimize Soil Disturbance: Using directional felling and careful skidding techniques minimizes soil compaction and erosion, protecting delicate habitats.

Consider Connectivity: We plan harvesting operations to maintain connectivity between forest patches, allowing wildlife to move freely between habitats.

In a recent project, we collaborated with ecologists to identify critical habitat areas for an endangered bird species. We adjusted our harvesting plan to protect these areas, leaving behind specific tree species and structural features that provided optimal habitat.

Q 25. Explain your understanding of carbon sequestration and its relevance to forest management.

Carbon sequestration is the process by which carbon dioxide from the atmosphere is absorbed and stored in trees and soil. It’s crucial for mitigating climate change. In forest management, understanding carbon sequestration is essential for sustainable practices.

Forest Growth and Carbon Storage: Growing trees absorb CO2, storing carbon in their biomass (wood, leaves, roots). Well-managed forests act as significant carbon sinks.

Soil Carbon: Healthy forest soils store large amounts of carbon. Sustainable harvesting practices help maintain soil health and carbon storage.

Harvesting Impacts: Harvesting releases some stored carbon, but responsible practices can minimize this and enhance long-term carbon sequestration through reforestation and forest regeneration.

Carbon Accounting: We use various techniques to quantify carbon stocks and fluxes in forests, enabling informed management decisions for carbon mitigation.

For example, we might choose harvesting methods that minimize soil disturbance to maintain soil carbon stocks. We can also consider the carbon footprint of transportation and processing to optimize the overall carbon balance of our operations.

Q 26. How do you ensure the long-term productivity and sustainability of the harvested area?

Ensuring long-term productivity and sustainability requires a holistic approach:

Site Preparation: Proper site preparation after harvesting promotes regeneration. This might involve scarification, planting, or natural regeneration techniques tailored to the site’s conditions.

Silvicultural Treatments: Appropriate silvicultural practices, such as thinning and pruning, promote healthy growth and maximize timber yield over time.

Regeneration Strategies: We choose regeneration methods (e.g., planting seedlings, allowing natural regeneration) based on species, site conditions, and management goals.

Monitoring and Adaptive Management: Regular monitoring of growth and forest health allows us to adapt our management strategies based on observed results.

Rotation Lengths: Selecting appropriate rotation lengths (the time between harvests) ensures both sustainable timber yield and ecosystem health.

For instance, we might use a combination of shelterwood cutting and planting to regenerate a stand after harvesting, ensuring a continuous supply of timber while maintaining biodiversity.

Q 27. Describe your experience with post-harvest site preparation techniques.

Post-harvest site preparation is crucial for successful regeneration. Techniques vary depending on the site’s conditions and regeneration goals:

Scarification: This involves disturbing the soil surface to create seedbeds and improve germination. Methods include using specialized equipment or controlled burning (under specific conditions).

Planting: Planting seedlings of desirable species is often necessary, especially when natural regeneration is slow or unreliable. We use appropriate planting techniques to ensure seedling survival.

Natural Regeneration: In some cases, encouraging natural regeneration through techniques like shelterwood cutting is more sustainable and cost-effective.

Fertilization: In some cases, soil fertilization might be necessary to enhance nutrient availability and promote growth.

I’ve used various techniques depending on the context. In one project, we used controlled burning to prepare the site for natural regeneration of pines, while in another, we planted hardwoods after clear-cutting using specialized planting equipment to maximize survival rates.

Q 28. What are your strategies for managing slash and debris after harvesting?

Slash (logging debris) management is crucial for safety, reducing fire risk, and improving site conditions for regeneration. Strategies include:

Pile and Burn: Slash is piled and burned under controlled conditions, meeting all relevant regulations and safety protocols. This reduces fuel load and can improve site conditions.

Chipping: Slash is chipped and used as mulch or biomass fuel, providing an alternative to burning and utilizing the waste material.

Leave on Site: In some cases, leaving slash on the site can enhance wildlife habitat and contribute to soil nutrient cycling. This is carefully considered and implemented strategically.

Baling: Slash is baled and removed from the site, reducing fire hazard and providing a usable product.

The choice of method depends on several factors, including fire risk, environmental regulations, and the availability of processing facilities. For example, in areas with high fire risk, chipping or removal are preferred, while in areas with low risk, leaving some slash on-site might be a suitable option.

Key Topics to Learn for Timber Harvesting Principles Interview

- Sustainable Harvesting Practices: Understanding and applying principles of sustainable forest management, including selective cutting, shelterwood systems, and clear-cutting with regeneration plans. Consider the environmental impact of different harvesting methods.

- Harvest Planning & Design: Developing harvesting plans that incorporate terrain analysis, timber volume estimation, road network design, and considerations for minimizing environmental damage. Practical application includes creating a harvesting plan for a specific site considering slope, soil type, and species composition.

- Harvesting Equipment & Operations: Familiarize yourself with various harvesting machines (feller bunchers, skidders, forwarders, harvesters) and their applications. Understand operational safety procedures and maintenance requirements. Be prepared to discuss the advantages and disadvantages of different equipment choices based on site conditions.

- Log Transportation & Handling: Knowledge of efficient and safe log transportation methods, including trucking, rafting, and other techniques. Understand the importance of minimizing damage during transportation and storage. Be ready to discuss cost-effective approaches.

- Health & Safety Regulations: Demonstrate a thorough understanding of relevant safety regulations and best practices in timber harvesting. This includes personal protective equipment (PPE), hazard identification, and risk mitigation strategies.

- Economic Considerations: Analyze the economic aspects of timber harvesting, including cost estimation, profit maximization, and the impact of market fluctuations on harvesting operations. Consider factors like timber pricing, labor costs, and equipment expenses.

- Environmental Impact Assessment: Be prepared to discuss the environmental impact of timber harvesting and mitigation strategies. This includes water quality, soil erosion, and biodiversity conservation.

Next Steps

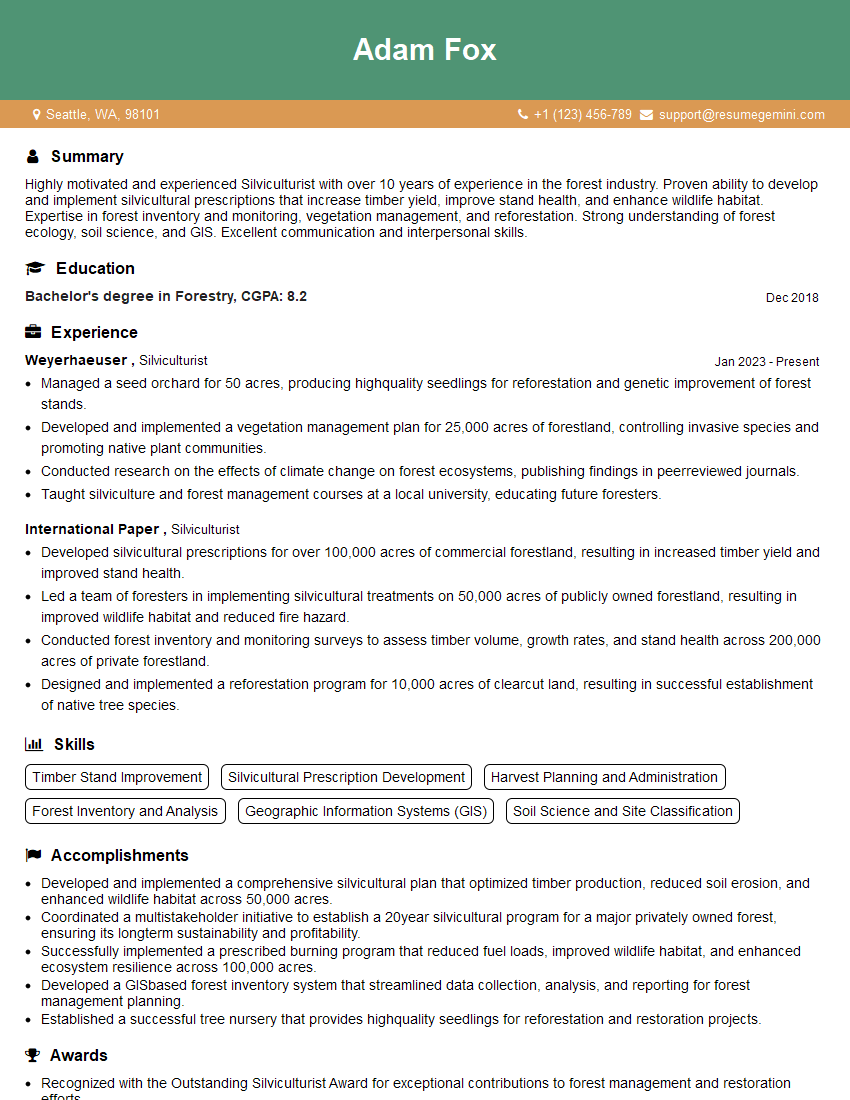

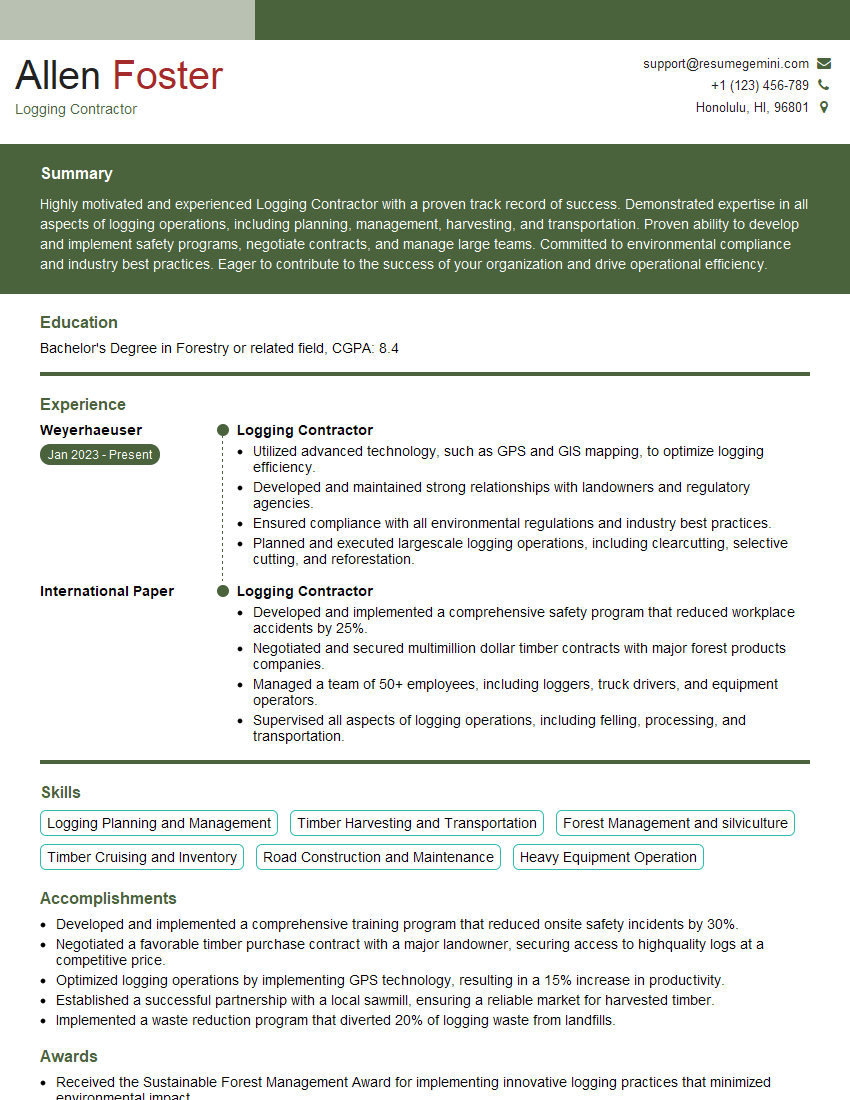

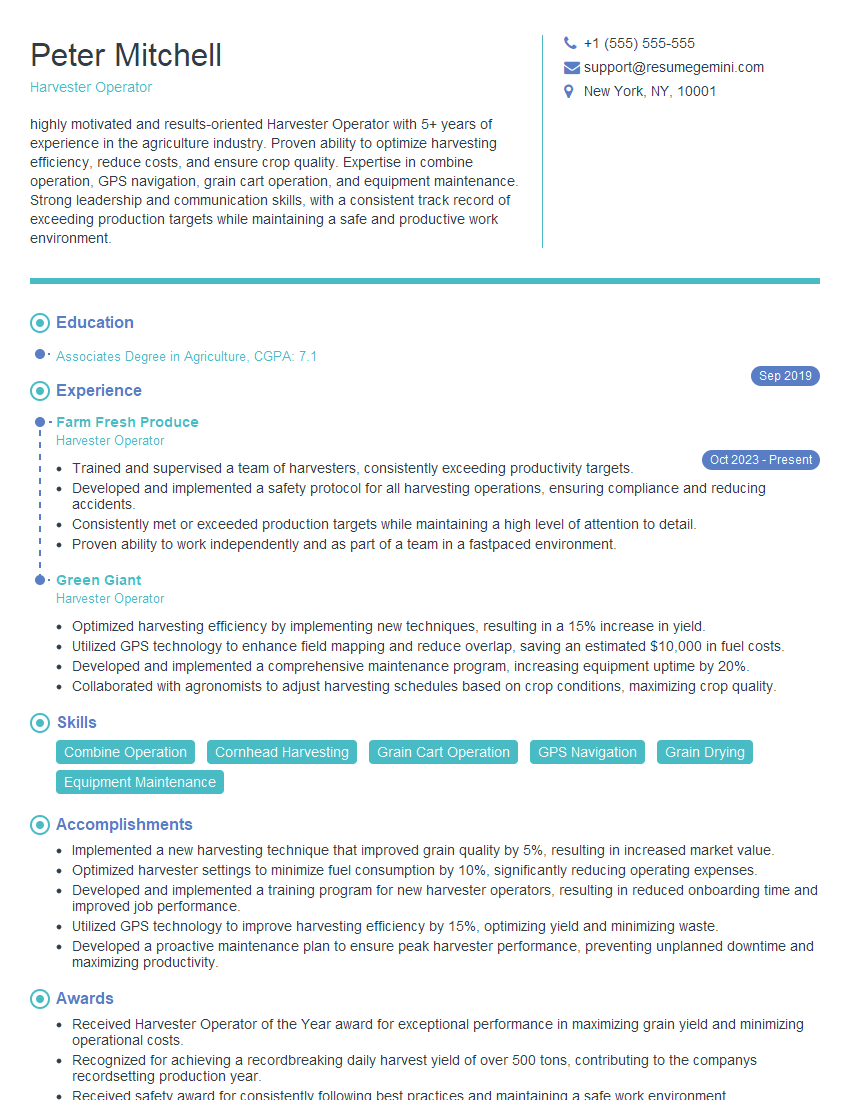

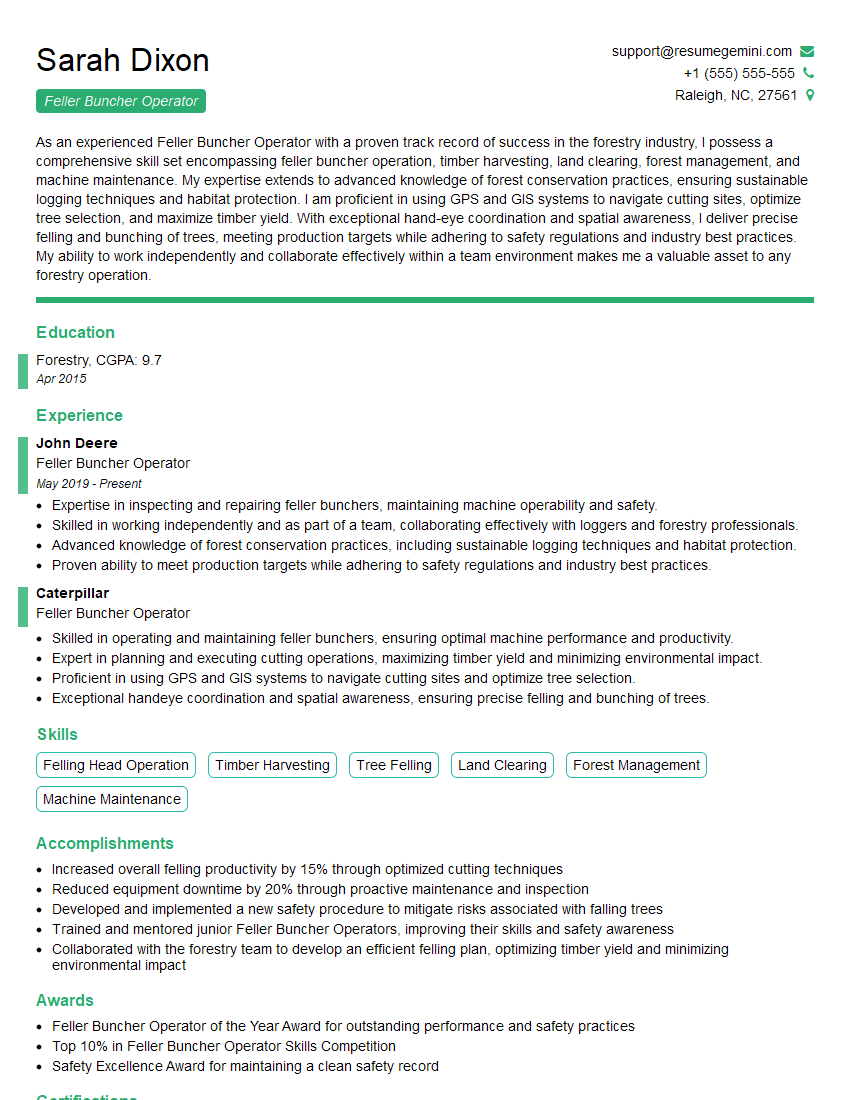

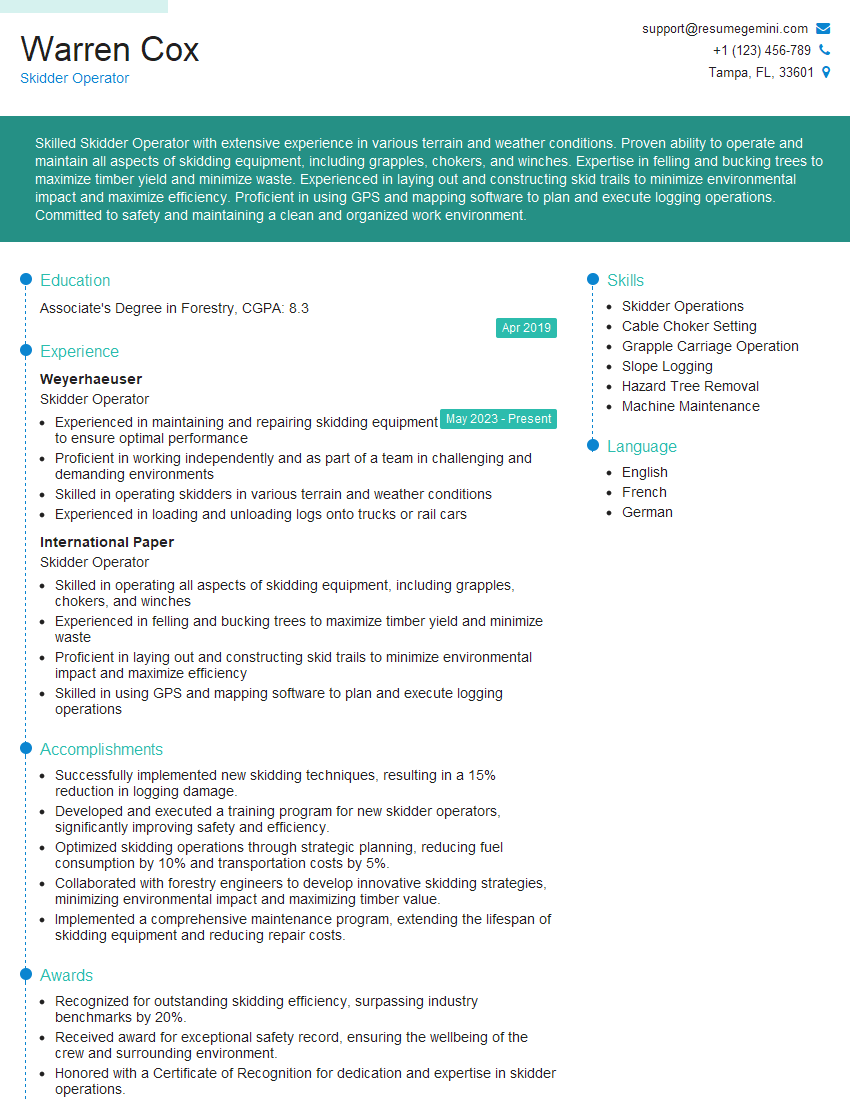

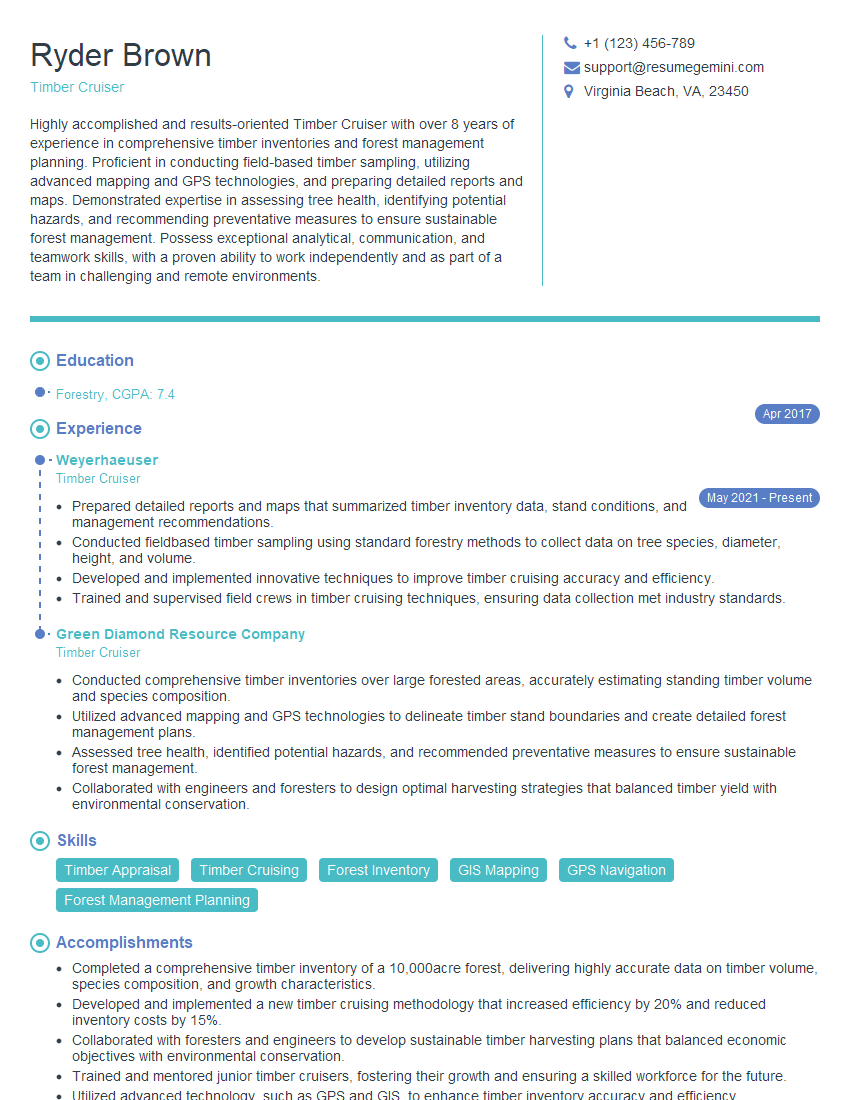

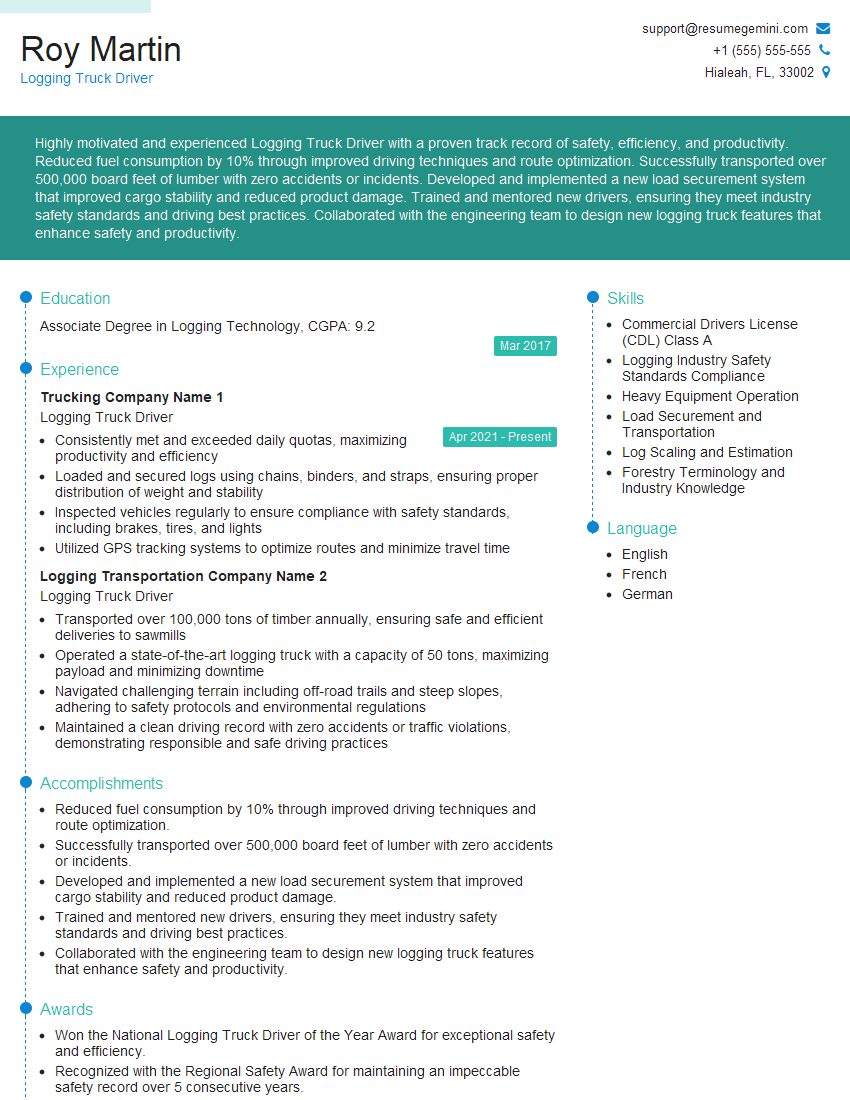

Mastering Timber Harvesting Principles is crucial for career advancement in the forestry industry, opening doors to leadership roles and specialized positions. To significantly improve your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you craft a professional and effective resume tailored to the forestry sector. Examples of resumes specifically designed for candidates with expertise in Timber Harvesting Principles are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good