Cracking a skill-specific interview, like one for Solar Power Plant Maintenance, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Solar Power Plant Maintenance Interview

Q 1. Describe the process of performing a visual inspection of solar panels.

A visual inspection of solar panels is the first and most crucial step in maintaining a solar power plant. It’s like giving your panels a thorough ‘once-over’ to identify any potential problems early on. This involves systematically examining each panel for various defects.

- Checking for Physical Damage: Look for cracks, discoloration, broken glass, or any signs of physical impact. Imagine a small rock hitting a panel – you’d want to spot that quickly.

- Assessing Soiling: Bird droppings, dust, pollen, and other debris accumulate, reducing efficiency. You’ll be looking for significant soiling that requires cleaning. Think of it like cleaning your windows – the dirtier they are, the less light gets through.

- Inspecting Mounting Systems: Examine the mounting structures, bolts, and connections for corrosion, looseness, or damage. A loose bolt could compromise the entire system’s stability.

- Observing Wiring and Connections: Check for any exposed wires, damaged insulation, or loose connections. These are potential fire hazards and efficiency killers.

- Identifying Hotspots: Use an infrared camera (thermography) to detect hotspots, which indicate a cell or module malfunction and potential fire risk. Hotspots are like a fever in the panel – they need attention.

Documentation is key. I always take detailed photos and notes, noting the panel location and the nature of any issues found. This creates a comprehensive record for future reference and maintenance scheduling.

Q 2. Explain how you would troubleshoot a malfunctioning solar inverter.

Troubleshooting a malfunctioning solar inverter is like detective work. You need to systematically investigate the various components and parameters to pinpoint the source of the problem. Here’s my approach:

- Safety First: Always disconnect the inverter from the grid and the solar array before starting any troubleshooting.

- Check the obvious: Begin by verifying that the AC and DC disconnects are properly closed. Sometimes, the simplest solutions are overlooked.

- Inspect for Error Codes: Most inverters display error codes that provide valuable clues. Consulting the inverter’s manual to interpret these codes is crucial. Imagine these codes as error messages on your computer – they point you to the issue.

- Check the input voltage and current: Using a multimeter, measure the DC voltage and current from the solar array to ensure sufficient power is reaching the inverter.

- Verify the output voltage and current: Similarly, measure the AC output voltage and current to see if the inverter is generating power as expected. If the output is low or absent, this indicates an internal problem.

- Check for overheating: Inverters can overheat due to various reasons. Excessive heat can severely affect performance. Use a thermal camera to detect hotspots.

- Examine external connections: Check all wiring connections to the inverter, including grounding. Loose connections or corrosion can disrupt functionality.

- Consult the Inverter’s Manual: Always refer to the inverter’s manual for detailed troubleshooting steps and diagnostic procedures.

If the problem persists, I’d contact the inverter manufacturer or a qualified service technician for further assistance.

Q 3. What are the common causes of decreased solar panel efficiency?

Decreased solar panel efficiency is a common concern, and several factors can contribute to this issue. Think of it like a plant needing sunlight, water, and nutrients to grow optimally; similarly, solar panels require optimal conditions to perform their best. Here are some common causes:

- Soiling: Dust, dirt, bird droppings, and other debris accumulate on the panel’s surface, blocking sunlight and reducing energy production. This is easily fixed with regular cleaning.

- Shading: Even partial shading from trees, buildings, or other structures can significantly impact the overall performance of the entire array. It’s like covering part of a solar panel with your hand – less light gets through.

- Cell Degradation: Over time, solar cells degrade due to exposure to UV radiation and temperature fluctuations. This is a natural process, but the rate of degradation can be influenced by several factors, including the panel’s quality.

- Hot Spots: These are localized areas of high temperature on the panel’s surface, often due to cell defects or shading. Hotspots can damage cells and reduce overall performance.

- Bypass Diodes Failure: Bypass diodes protect individual cells within a panel from shading effects. If they fail, the whole panel may not function.

- Microcracks: Tiny cracks in the solar cells, often invisible to the naked eye, can reduce efficiency significantly. These can occur due to physical damage, thermal stress, or manufacturing defects. Think of cracks in a windscreen – they compromise its integrity.

- Module Mismatch: Different panels in a string may have slight differences in their power output, resulting in underperformance of the entire string.

Regular maintenance, including cleaning, shading mitigation, and thermal imaging, can help minimize the impact of these factors.

Q 4. How do you perform preventative maintenance on a solar power plant?

Preventative maintenance is key to maximizing the lifespan and efficiency of a solar power plant. It’s about proactively addressing potential issues before they become major problems. This is akin to regular checkups for your health – better to catch small issues before they become major illnesses.

- Regular Visual Inspections: Conducting frequent visual inspections to identify any physical damage, soiling, or loose connections. A simple walk-around can uncover many issues.

- Cleaning: Regularly cleaning the solar panels to remove dust, dirt, and other debris, improving energy output. Imagine washing your car – it shines brighter and performs better.

- Monitoring the SCADA System: Closely monitoring the performance data to identify any anomalies or trends that may indicate a potential problem. The SCADA system is your early warning system.

- Checking and Tightening Connections: Periodically inspecting and tightening all electrical connections, ensuring they are secure and corrosion-free.

- Thermal Imaging: Utilizing thermal imaging cameras to detect hotspots, indicating potential problems within the modules or inverters.

- Grounding Verification: Ensuring proper grounding to protect against electrical shocks and potential fire hazards.

- Inverter Maintenance: Regularly checking and maintaining the inverters to ensure optimal operation.

- Weed Control: Removing weeds and vegetation around the solar panels and mounting structures, preventing moisture damage and shading.

A well-defined preventative maintenance schedule, tailored to the specific plant conditions and equipment, is crucial for optimal performance and longevity.

Q 5. What safety precautions do you take when working on a solar array?

Safety is paramount when working on a solar array. High-voltage DC electricity is extremely dangerous. Here’s a list of the safety precautions I always take:

- Lockout/Tagout Procedures: Before starting any work, I always ensure that the DC and AC disconnects are locked out and tagged out to prevent accidental energization. This is a non-negotiable safety step.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including safety glasses, insulated gloves, and arc flash protection, to protect myself from potential hazards. Safety gear is my second skin.

- Grounding and Bonding: Proper grounding and bonding procedures are essential to prevent electrical shocks and protect against potential fire hazards. This is critical to prevent static electricity buildup.

- Awareness of Overhead Hazards: I’m always mindful of overhead power lines and other hazards during the inspection and maintenance process. Never work under overhead power lines.

- Fall Protection: When working at heights, I utilize appropriate fall protection equipment such as harnesses and safety lines. Height safety is of paramount importance.

- Fire Safety Measures: I am aware of the potential fire hazards associated with working on a solar array and have a fire extinguisher nearby.

- Weather Conditions: I never work during inclement weather such as thunderstorms or high winds. Weather can drastically affect safety and the work itself.

- Teamwork and Communication: When working with others, clear communication and teamwork are essential for ensuring safety.

Safety is not just a procedure; it’s a mindset. I treat every task with utmost caution and always prioritize safety over speed.

Q 6. Explain the difference between reactive and preventative maintenance.

Reactive and preventative maintenance are two distinct approaches to maintaining a solar power plant. They represent two sides of the same coin, and an effective maintenance strategy combines both.

- Reactive Maintenance: This involves fixing problems *after* they occur. Imagine waiting for your car to break down before fixing it. It’s often costly and disruptive to operations. Reactive maintenance addresses the immediate problem but doesn’t prevent future issues.

- Preventative Maintenance: This is a proactive approach that aims to prevent problems *before* they occur. Think of it as scheduling regular car servicing. It’s about proactively identifying potential issues and addressing them before they lead to failures. Preventative maintenance is more cost-effective in the long run.

An effective solar power plant maintenance strategy balances both approaches. Regular preventative maintenance helps minimize the need for reactive maintenance, leading to higher uptime, lower costs, and increased longevity of the system.

Q 7. How do you interpret data from a solar power plant’s SCADA system?

The SCADA (Supervisory Control and Data Acquisition) system is the brain of a solar power plant. It collects and displays real-time performance data, providing valuable insights into the system’s health and efficiency. Interpreting this data is crucial for effective maintenance and optimization.

I look for several key metrics:

- Power Output: I monitor the total power generated by the plant, comparing it to expected values based on weather conditions and system capacity. Significant deviations require investigation.

- Individual Panel/String Performance: I analyze the performance of individual panels or strings to identify underperforming units. This helps pinpoint problems quickly.

- Inverter Efficiency: I monitor the efficiency of the inverters, looking for any anomalies that could indicate a problem.

- Temperature Data: Monitoring the temperature of panels and inverters is crucial to detect hotspots or overheating. High temperatures can significantly reduce efficiency and create fire hazards.

- Voltage and Current: I review voltage and current readings to identify any issues with wiring, connections, or component failures.

- Environmental Data: Factors such as solar irradiance, ambient temperature, and wind speed impact power output. Considering these factors is essential to accurately assess system performance.

By analyzing these parameters, I can identify potential problems such as shading, soiling, faulty panels, or inverter issues. The SCADA system allows for early detection, facilitating timely intervention and minimizing downtime.

I use data visualization tools and trend analysis to identify patterns and make informed decisions. For example, a gradual decrease in power output over time might indicate cell degradation, while a sudden drop could signal a more serious fault. The data allows for proactive adjustments to operation and maintenance schedules.

Q 8. What are the key performance indicators (KPIs) for a solar power plant?

Key Performance Indicators (KPIs) for a solar power plant are crucial for monitoring its efficiency and identifying areas for improvement. They essentially tell us how well the plant is performing against its design and operational goals. Think of them as a plant’s vital signs.

- Energy Yield: This is arguably the most important KPI, measured in kWh or MWh. It represents the total energy produced by the plant over a specific period (daily, monthly, annually). A consistent decline in energy yield might indicate issues with soiling, shading, or equipment malfunction.

- Capacity Factor: This indicates how efficiently the plant is operating relative to its maximum capacity. It’s expressed as a percentage and shows the actual energy produced compared to the potential energy that could have been produced under ideal conditions. A lower capacity factor suggests potential losses.

- Performance Ratio (PR): PR takes into account various factors affecting energy production, such as solar irradiance, temperature, and system losses. It gives a more holistic view of the plant’s performance than simply looking at energy yield. A lower PR often signals problems requiring investigation.

- System Availability: This KPI measures the percentage of time the plant is operational. Downtime due to maintenance, repairs, or equipment failures directly impacts energy production and profitability. High system availability is key.

- Specific Yield: This measures energy production per kWp (kilowatt-peak) of installed capacity. It helps compare the performance of different plants or even different sections within a large plant. Variations here can point to performance inconsistencies.

Regular monitoring of these KPIs and trend analysis is critical for proactive maintenance and optimization of the solar power plant’s performance.

Q 9. How do you handle emergency repairs in a solar power plant?

Emergency repairs require a swift and organized response. The key is preparedness and a well-defined emergency response plan. Imagine a scenario where a critical inverter fails at peak sun. Time is of the essence.

- Immediate Assessment: Quickly identify the problem and its impact on the system. This usually involves checking safety parameters (e.g., voltage, current), identifying the faulty component, and determining the extent of the issue. Using specialized monitoring software provides real-time data that speeds up this process.

- Safety First: Prioritize safety procedures – lockout/tagout, ensuring isolation of affected components before commencing any work. This minimizes the risk of electrical shock or other hazards.

- Rapid Repair or Replacement: Depending on the nature of the fault, either immediate repair (if possible) or a temporary replacement of the faulty component is prioritized. Having readily available spare parts significantly reduces downtime.

- Reporting and Documentation: All emergency repairs must be meticulously documented, including the nature of the fault, repair actions taken, and the time taken. This data is invaluable for future maintenance planning and identifying potential systemic issues.

- Root Cause Analysis: Once the emergency is resolved, a thorough root cause analysis must be conducted to prevent similar incidents in the future. This is often done as a team exercise with the goal of continuous improvement.

Having a strong team, well-stocked spares inventory, and a comprehensive emergency plan are crucial for effective emergency repair management in a solar power plant.

Q 10. Describe your experience with cleaning solar panels.

Cleaning solar panels is essential for maintaining optimal energy production. Soiling from dust, bird droppings, and other contaminants significantly reduces the efficiency of panels. Think of it as washing the windows of a house to let in more light.

My experience encompasses various cleaning methods, including:

- Manual Cleaning: Using soft brushes, deionized water, and approved cleaning agents for smaller-scale cleaning or hard-to-reach areas. This ensures thorough cleaning without scratching the panel surfaces.

- Automated Cleaning Systems: Larger plants typically utilize automated robotic cleaning systems. These systems are programmed to clean the panels regularly, optimizing efficiency, and minimizing labor costs. Regular maintenance and adjustments are key for these systems.

- Water Management: Regardless of the method, responsible water management is crucial. Using deionized water minimizes water spots and reduces environmental impact. Appropriate water recycling systems are essential for larger plants.

The cleaning frequency depends on factors like environmental conditions (e.g., desert vs. coastal location). Regular inspection and monitoring of panel soiling levels dictate the cleaning schedule. For example, in dusty environments, more frequent cleaning might be required. We always document cleaning frequency, methods, and outcomes for trend analysis and improvement.

Q 11. Explain your understanding of different types of solar inverters.

Solar inverters are essential components that convert the DC (direct current) electricity produced by solar panels into AC (alternating current) electricity that can be used in homes and businesses. They’re the translators of solar energy.

Different types of inverters exist, each with its advantages and disadvantages:

- String Inverters: These are the most common and cost-effective type. They connect multiple solar panels in series (a ‘string’). While simple, a single fault in one string can affect the entire string’s output.

- Microinverters: Each panel has its own microinverter, converting DC to AC individually. This provides better energy harvesting since a single panel’s malfunction doesn’t affect the others. They are more expensive but offer higher efficiency and more granular monitoring capabilities.

- Power Optimizers: These devices are placed between the panels and the inverter and allow for individual panel monitoring and optimization of energy harvesting. This offers a balance between the string inverters’ cost-effectiveness and microinverters’ performance.

- Central Inverters: These large inverters are used in large-scale utility solar plants, converting the energy from multiple strings of panels. They require a strong grid connection and careful coordination.

The choice of inverter type depends on factors such as system size, budget, and desired performance characteristics. For instance, microinverters are better suited for rooftops with shading issues, while string inverters might be optimal for larger, uniform installations. I have experience working with all types, with a focus on preventive maintenance to ensure optimal performance and longevity.

Q 12. What are the common types of solar panel failures?

Solar panel failures, while infrequent with proper maintenance, can occur. Understanding the common types is crucial for effective troubleshooting and repair.

- Cell Degradation: Over time, solar cells lose efficiency due to exposure to environmental factors like UV radiation and temperature fluctuations. This is a gradual process and often not noticeable until performance significantly drops.

- Hot Spots: Partial shading or cell damage can cause localized overheating (hot spots), leading to reduced output and potential damage to neighboring cells. Regular visual inspection and thermal imaging are used to detect hot spots.

- Bypass Diodes Failure: Bypass diodes protect the panel from shading issues. Their failure can lead to complete panel shutdown or significant power reduction.

- Physical Damage: External factors such as hail, wind damage, or mishandling can cause cracks, breakage, or delamination of the panels. Regular visual inspections are essential to quickly address such damage.

- Wiring and Connection Issues: Corrosion, loose connections, or damaged wiring can significantly reduce output or cause complete system failure.

Proactive maintenance, including regular inspections, thermal imaging, and electrical testing, helps identify and address these issues early, preventing major failures and downtime. Knowing the symptoms of these failures is essential for fast and effective troubleshooting.

Q 13. Describe your experience with solar panel testing and diagnostics.

Solar panel testing and diagnostics are essential for ensuring the health and performance of the solar power plant. This involves a multi-faceted approach using various tools and techniques.

- Visual Inspection: This is the first step, checking for physical damage, soiling, or signs of hotspots. It is often followed by the use of thermal cameras for a more detailed assessment.

- I-V Curve Tracing: This involves measuring the current-voltage characteristics of the panels to determine their efficiency and identify potential issues like cell degradation or diode failures. Specialized equipment is used to generate the I-V curve.

- Electroluminescence (EL) Imaging: This technique uses a specialized camera to detect micro-cracks or other internal defects within the solar cells that may not be visible through visual inspection. It illuminates any faulty cells or areas within the panel.

- Infrared Thermography: Thermal imaging cameras detect temperature variations, pinpointing hot spots that might indicate cell degradation, shading issues, or damaged bypass diodes. These are typically captured in the evening for more accurate results.

- Data Acquisition and Analysis: Sophisticated monitoring systems gather real-time data on the system’s performance, identifying trends, and alerting to potential problems before they escalate. Software tools analyze these large datasets.

My experience involves using these techniques to diagnose and resolve issues ranging from minor cell degradation to major panel failures. This systematic approach ensures accurate diagnosis and facilitates efficient repairs, minimizing downtime and maximizing energy production.

Q 14. How do you manage a team during a large-scale maintenance project?

Managing a team during a large-scale maintenance project requires careful planning, clear communication, and strong leadership. Think of it as orchestrating a complex symphony – every instrument (team member) needs to play their part in harmony.

- Detailed Planning: Create a comprehensive project plan outlining all tasks, timelines, and resource allocation. This involves breaking down the large project into smaller, manageable tasks and assigning responsibilities.

- Clear Communication: Maintain constant communication with the team, providing regular updates, addressing concerns, and ensuring everyone is aligned on the project goals and timelines. This could include daily stand-up meetings or weekly progress reports.

- Delegation and Empowerment: Delegate tasks effectively to team members based on their skills and experience, empowering them to make decisions and take ownership of their work. This is key for team motivation and efficiency.

- Risk Management: Identify and mitigate potential risks throughout the project. This could include developing contingency plans to address unexpected issues or delays.

- Motivation and Recognition: Recognize and appreciate the team’s contributions, fostering a positive and collaborative work environment. This keeps team morale high throughout the potentially stressful maintenance project.

- Regular Monitoring and Evaluation: Track progress regularly against the project plan, addressing any deviations promptly. Regular evaluation helps maintain a trajectory towards success.

Effective team management during large-scale maintenance projects is paramount to ensure the project’s success, and minimizing delays and cost overruns.

Q 15. What are the environmental considerations in solar power plant maintenance?

Environmental considerations in solar power plant maintenance are crucial for minimizing the plant’s footprint and ensuring responsible energy production. This involves careful handling of materials, preventing soil erosion, and protecting local ecosystems.

- Waste Management: Proper disposal of damaged solar panels, batteries, and other components is vital. We follow strict protocols for recycling and hazardous waste management, ensuring compliance with all relevant environmental regulations. For example, we partner with certified recyclers who specialize in safely processing solar panel components to recover valuable materials like silicon and aluminum.

- Water Usage: Cleaning solar panels often involves water consumption. We employ techniques like dry cleaning or using minimal water with biodegradable cleaning solutions to conserve water resources. We also monitor water runoff from cleaning activities to prevent contamination.

- Wildlife Protection: During maintenance, we are careful to avoid disturbing local wildlife. This includes avoiding nesting areas, minimizing noise pollution, and following best practices for habitat preservation. For instance, we schedule maintenance activities during times of minimal animal activity whenever possible.

- Soil Erosion Prevention: Construction and maintenance activities can lead to soil erosion. We implement measures like revegetation, erosion control mats, and careful grading to minimize the impact on soil stability. Regular inspections help us identify and address any erosion problems promptly.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What software or tools do you use for monitoring and maintaining solar systems?

Monitoring and maintaining solar systems efficiently requires a combination of specialized software and hardware tools. The specific tools vary depending on the size and complexity of the system, but some common choices include:

- SCADA (Supervisory Control and Data Acquisition) systems: These systems provide real-time monitoring of key parameters like power output, voltage, current, temperature, and inverter performance. Examples include PVsyst, SolarAnywhere, and various proprietary SCADA solutions offered by inverter manufacturers. We use these to identify anomalies and potential problems early.

- Performance Monitoring Software: This software analyzes data from SCADA systems and provides detailed reports on energy production, system efficiency, and potential issues. Some common software options offer advanced analytics and predictive maintenance capabilities. We use this to track long-term performance trends and optimize plant output.

- Thermal Imaging Cameras: These cameras identify hotspots on solar panels, indicating potential cell failures or shading issues, allowing for targeted maintenance and repairs. This non-invasive technique allows for quick identification of problems.

- Multimeters and Clamp Meters: These basic electrical testing tools are essential for diagnosing electrical faults and measuring various parameters within the system. They are used for precise measurements in troubleshooting individual panels or strings.

- Drone technology: For large-scale plants, drones equipped with high-resolution cameras allow for efficient visual inspection of large areas. This minimizes the need for extensive manual inspections and helps identify faults faster.

Q 17. How do you ensure compliance with safety regulations during maintenance?

Ensuring safety is paramount in solar power plant maintenance. We adhere to strict safety protocols based on OSHA (Occupational Safety and Health Administration) standards and industry best practices.

- Lockout/Tagout Procedures: Before any maintenance work begins, we strictly follow lockout/tagout procedures to de-energize and isolate sections of the system, preventing accidental energization. This is a crucial step to ensure the safety of our team.

- Personal Protective Equipment (PPE): All personnel wear appropriate PPE, including safety glasses, gloves, arc flash suits (depending on the task), and insulated tools, to minimize the risk of electrical shock, burns, or other injuries.

- Fall Protection: Many maintenance tasks involve working at heights, so we utilize harnesses, safety lines, and appropriate fall protection equipment. Regular inspections of safety equipment are conducted to ensure they are in good working order.

- Training and Certifications: All our technicians receive comprehensive training on safety procedures, electrical safety, and proper use of equipment. Many possess specialized certifications, demonstrating their competency in performing safe maintenance operations.

- Regular Safety Audits: We conduct regular safety audits to identify and address any potential hazards. This proactive approach helps maintain a safe working environment for our team and reduces the likelihood of accidents.

Q 18. Describe your experience with troubleshooting ground faults in a solar array.

Troubleshooting ground faults in a solar array is a common task. It usually involves systematically isolating the faulty section and using specialized equipment to pinpoint the location of the fault.

Step-by-Step Approach:

- Isolate the Faulty String: We use a string combiner box to isolate each string of panels. By measuring the current and voltage of each string, we can identify the one with a ground fault.

- Identify the Faulty Panel: Once the faulty string is identified, we use a multimeter to isolate the faulty panel. This often involves checking the voltage across each panel in the string.

- Locate the Specific Fault: Once the panel is identified, the fault might be traced to a damaged diode, cracked cell, or a problem with the panel’s wiring or connection. Visual inspection and sometimes thermal imaging can help locate the problem area within the panel.

- Repair or Replace: The faulty component (diode, panel, or wiring) is either repaired or replaced, and the system is tested to confirm the ground fault has been resolved. Depending on the extent of the damage and the age of the equipment, we might choose to repair or replace the faulty component.

Example: I once encountered a ground fault in a large solar array. By systematically isolating strings, we identified the problem in a specific string. Further investigation pinpointed the fault to a single panel exhibiting a high ground current. After replacing this panel, the system’s performance was restored, and the ground fault was eliminated.

Q 19. What is your experience with different types of racking systems?

My experience encompasses various racking systems used in solar power plants. Racking systems are crucial for supporting solar panels and optimizing their orientation for maximum energy capture.

- Fixed-Tilt Mounting Systems: These are the simplest and most common, with panels mounted at a fixed angle optimized for the location’s latitude. They are cost-effective but less efficient than tracking systems. I’ve worked extensively with various ground-mounted and roof-mounted fixed-tilt systems.

- Single-Axis Tracking Systems: These systems rotate panels along a single axis (usually east-west) to follow the sun’s movement across the sky. They improve energy yield compared to fixed-tilt but are more complex and costly. I’ve been involved in the maintenance and troubleshooting of several single-axis tracking systems, addressing issues such as motor failures and alignment problems.

- Dual-Axis Tracking Systems: These systems provide even greater energy yield by tracking the sun’s movement along two axes, but are the most expensive and complex option. While I have less direct experience with dual-axis systems, I understand their operational principles and the associated maintenance challenges.

Each system requires specific maintenance protocols. For example, single-axis tracking systems require regular lubrication and inspection of motors and drive mechanisms. We use preventative maintenance schedules to address wear and tear, minimizing downtime and maximizing energy output.

Q 20. Explain your understanding of the different types of solar panel technologies.

Solar panel technologies have evolved significantly, each with its strengths and weaknesses. The main types I have worked with are:

- Crystalline Silicon Panels: These are the most common type, further categorized into monocrystalline and polycrystalline. Monocrystalline panels are more efficient but more expensive, while polycrystalline panels are more cost-effective but slightly less efficient. Their maintenance is relatively straightforward, focusing on cleaning and identifying damaged cells or hotspots.

- Thin-Film Solar Panels: These use thin layers of photovoltaic material deposited on a substrate (e.g., glass, plastic, or metal). They are flexible and can be integrated into various applications but generally have lower efficiency than crystalline silicon panels. Maintenance differs slightly, often requiring specialized cleaning techniques to prevent damage to the delicate thin-film layers.

- Perovskite Solar Cells: This emerging technology offers potential for high efficiency and low manufacturing costs. While I haven’t had direct experience maintaining large-scale Perovskite installations, I understand their sensitivity to moisture and temperature and the need for specialized maintenance protocols to address these vulnerabilities.

Understanding the specific characteristics of each technology is vital for effective maintenance. For instance, cleaning techniques must be adapted to prevent damage to the delicate surfaces of thin-film panels. Moreover, the failure modes of different technologies may differ, requiring different diagnostic procedures and repair strategies.

Q 21. How do you prioritize maintenance tasks in a solar power plant?

Prioritizing maintenance tasks in a solar power plant is crucial for maximizing efficiency and minimizing downtime. We use a combination of factors to establish our maintenance schedule:

- Predictive Maintenance: Analyzing data from SCADA systems and performance monitoring software helps predict potential failures and schedule preventative maintenance before problems occur. This approach minimizes unexpected downtime and extends the lifespan of the equipment.

- Preventative Maintenance: Scheduled inspections and cleaning are performed regularly to prevent minor issues from escalating into major problems. This includes tasks like cleaning panels, inspecting wiring, and lubricating moving parts in tracking systems. We have established a comprehensive preventative maintenance schedule that aligns with the manufacturer’s recommendations and our historical data.

- Corrective Maintenance: Addressing issues that arise unexpectedly, such as panel failures, inverter malfunctions, or ground faults. Our corrective maintenance process involves prompt diagnosis and repair to minimize the impact on energy production.

- Risk Assessment: We assess the potential risks associated with each component and prioritize maintenance tasks based on their criticality and potential impact on the system’s overall performance. High-risk components, such as inverters or major electrical connections, get higher priority in our maintenance schedule.

By combining predictive, preventative, and corrective maintenance strategies, we ensure that the solar power plant operates efficiently and reliably with minimal downtime. This approach is crucial for optimizing energy production and extending the lifespan of the equipment.

Q 22. Describe your experience with battery storage systems in solar power plants.

My experience with battery storage systems in solar power plants spans over eight years, encompassing various chemistries like Lithium-ion and Lead-acid. I’ve been involved in everything from initial system design and integration to ongoing maintenance and troubleshooting. This includes regular battery health checks, which involve monitoring voltage, current, temperature, and state of charge (SOC). We use sophisticated Battery Management Systems (BMS) to track this data and identify potential issues early on. For example, I once identified a faulty cell in a large Lithium-ion battery bank by analyzing subtle discrepancies in individual cell voltages detected by the BMS. This prevented a major system failure. Beyond routine checks, I’ve also handled battery replacements, thermal management system maintenance, and the implementation of advanced control strategies to optimize battery lifespan and performance.

I’m also familiar with safety protocols related to handling high-voltage DC systems and the proper disposal of spent batteries, ensuring environmental compliance. A key aspect of my work has been optimizing the charging and discharging cycles to maximize the storage system’s efficiency and longevity. This often involves fine-tuning the system’s parameters to balance energy storage needs with the overall power plant’s operational goals.

Q 23. What are the challenges associated with maintaining solar power plants in harsh weather conditions?

Maintaining solar power plants in harsh weather conditions presents numerous challenges. Extreme temperatures, for instance, can significantly impact the performance and lifespan of solar panels and other components. High temperatures can reduce panel efficiency, while freezing conditions can lead to cracking or damage. Similarly, strong winds can cause physical damage to the panels or mounting structures, while hail can result in significant damage requiring immediate repair. Heavy snowfall can reduce sunlight penetration, impacting power generation. Saltwater corrosion is a major factor near coastal areas, accelerating the degradation of metallic parts.

We mitigate these challenges through robust preventative maintenance schedules adapted to the specific climate. This involves regular inspections for any signs of damage, strengthening of mounting structures in high-wind areas, employing specialized cleaning techniques to remove snow, sand, or salt buildup, and using corrosion-resistant materials wherever possible. We also implement advanced monitoring systems that alert us to potential issues in real-time, allowing for prompt intervention before significant damage occurs. Think of it like a diligent home inspection, but on a massive scale, tailored to combat the specific weather threats.

Q 24. How do you ensure the accuracy of performance data collected from solar systems?

Ensuring the accuracy of performance data is crucial for optimizing solar plant operations and financial projections. We achieve this through a multi-layered approach. Firstly, we utilize high-quality monitoring equipment calibrated regularly. This includes sophisticated inverters, weather stations, and data loggers that capture detailed information on power generation, energy consumption, and environmental factors. We regularly cross-check the data from multiple sources to identify and correct any discrepancies. For example, we might compare the inverter’s reported energy output with the readings from a separate power meter.

Secondly, we employ data validation techniques to identify and filter out any anomalous readings caused by equipment malfunctions or other external factors. This often involves applying statistical methods to detect outliers and establish realistic performance benchmarks. Finally, we regularly perform site inspections to verify that the collected data accurately reflects the physical conditions of the plant. For example, we might physically inspect panel arrays to ensure there’s no shading or other issues impacting generation. This combination of technological precision and on-site verification allows us to maintain high confidence in the accuracy of our performance data.

Q 25. What is your experience with the use of drones in solar power plant inspections?

Drones have revolutionized solar power plant inspections, offering a safer, faster, and more cost-effective alternative to traditional methods. My experience includes utilizing drones equipped with high-resolution cameras and thermal imaging capabilities to conduct thorough inspections of large solar arrays. Drones allow us to quickly identify potential issues such as broken or damaged panels, shading, and hotspots, often in areas that are difficult or dangerous to access.

The thermal imaging feature is particularly useful for detecting faulty connections or cells that are overheating, allowing for early intervention and preventing cascading failures. We use specialized drone software to process the captured imagery, generating detailed reports with high-quality photos and thermal maps, accelerating the identification and prioritization of maintenance tasks. The data generated helps us optimize our maintenance schedules and reduce downtime. Safety protocols are paramount; we always operate within airspace regulations and employ experienced drone pilots.

Q 26. Explain the importance of regular preventative maintenance in maximizing solar power plant efficiency.

Regular preventative maintenance is paramount for maximizing solar power plant efficiency and extending the lifespan of its components. Think of it like servicing your car – regular checkups prevent major breakdowns. In solar plants, this involves routine cleaning of panels to remove dirt, debris, and bird droppings, which significantly reduce energy output. We also inspect all electrical connections for corrosion or loose wiring, which can cause energy loss or even fires. Regular checks on inverters, trackers, and other equipment ensure that they operate at peak performance.

Preventative maintenance also extends to the structural components, such as the mounting structures and grounding systems. Addressing minor issues early on can prevent major and costly repairs down the road. By following a structured preventative maintenance schedule, we proactively address minor problems before they escalate, saving significant costs in the long run and keeping the solar plant functioning optimally. The return on investment for a solid preventative maintenance program is substantial.

Q 27. How do you identify and address potential safety hazards during maintenance activities?

Safety is my utmost priority during all maintenance activities. We begin by conducting thorough risk assessments to identify potential hazards, such as high-voltage electrical systems, working at heights, and exposure to extreme weather conditions. We develop comprehensive safety plans that detail the necessary precautions, including lockout/tagout procedures for electrical systems, the use of appropriate personal protective equipment (PPE), and designated safety personnel on-site. We conduct regular safety training for all maintenance personnel, emphasizing safe work practices and emergency response procedures.

Before any work commences, a toolbox talk is conducted to ensure everyone understands the specific risks and procedures involved in that particular task. We use clear communication and standardized safety protocols to minimize the risk of accidents. For example, we use specialized tools for working on high-voltage systems and follow strict permit-to-work systems for potentially dangerous jobs. Continuous monitoring and evaluation of our safety procedures ensure we constantly improve and adapt our practices to maintain a safe working environment.

Q 28. Describe your experience with reporting and documenting maintenance activities.

Reporting and documenting maintenance activities are critical for tracking performance, identifying trends, and ensuring regulatory compliance. We utilize a computerized maintenance management system (CMMS) to meticulously record all maintenance tasks, including date, time, personnel involved, work performed, materials used, and any issues identified. This data is crucial for optimizing maintenance schedules and predicting future needs. We also generate detailed reports on maintenance costs, downtime, and equipment performance, which are used for budget planning and performance evaluation.

The CMMS allows us to generate customized reports to meet specific needs, such as reports detailing the performance of specific equipment over time or the total maintenance costs for a given period. We maintain digital records and photos of any repairs or maintenance undertaken, creating a comprehensive history of the plant’s maintenance activities. This detailed documentation is essential for audits, warranty claims, and troubleshooting future issues. The use of a CMMS ensures transparency, accountability, and a historical record to support decision-making.

Key Topics to Learn for Your Solar Power Plant Maintenance Interview

Ace your interview by mastering these essential areas of Solar Power Plant Maintenance. We’ve broken down the key concepts to help you shine.

- PV Panel Inspection and Cleaning: Understand different cleaning methods, frequency, and the impact of soiling on performance. Be prepared to discuss practical techniques and safety protocols.

- Inverter Maintenance and Troubleshooting: Know the common inverter faults, diagnostic procedures, and preventative maintenance strategies. Discuss your experience with different inverter technologies and their specific maintenance needs.

- Battery System Maintenance (if applicable): If the plant includes battery storage, be ready to discuss battery health monitoring, testing procedures, safety precautions, and common failure modes.

- Electrical Safety and Regulations: Demonstrate a thorough understanding of relevant safety standards and regulations, including lockout/tagout procedures and arc flash mitigation.

- Performance Monitoring and Data Analysis: Discuss your experience with SCADA systems, data interpretation, identifying performance bottlenecks, and using data to optimize plant operations.

- Preventive and Corrective Maintenance Schedules: Explain the importance of planned maintenance, developing effective schedules, and the use of CMMS (Computerized Maintenance Management Systems).

- Troubleshooting and Problem-Solving: Be prepared to discuss your approach to diagnosing and resolving issues in a solar power plant, highlighting your analytical and problem-solving skills.

- Health and Safety Regulations and Practices: Demonstrate awareness of relevant health and safety regulations, including working at heights, handling hazardous materials, and emergency response procedures.

Next Steps: Power Up Your Career

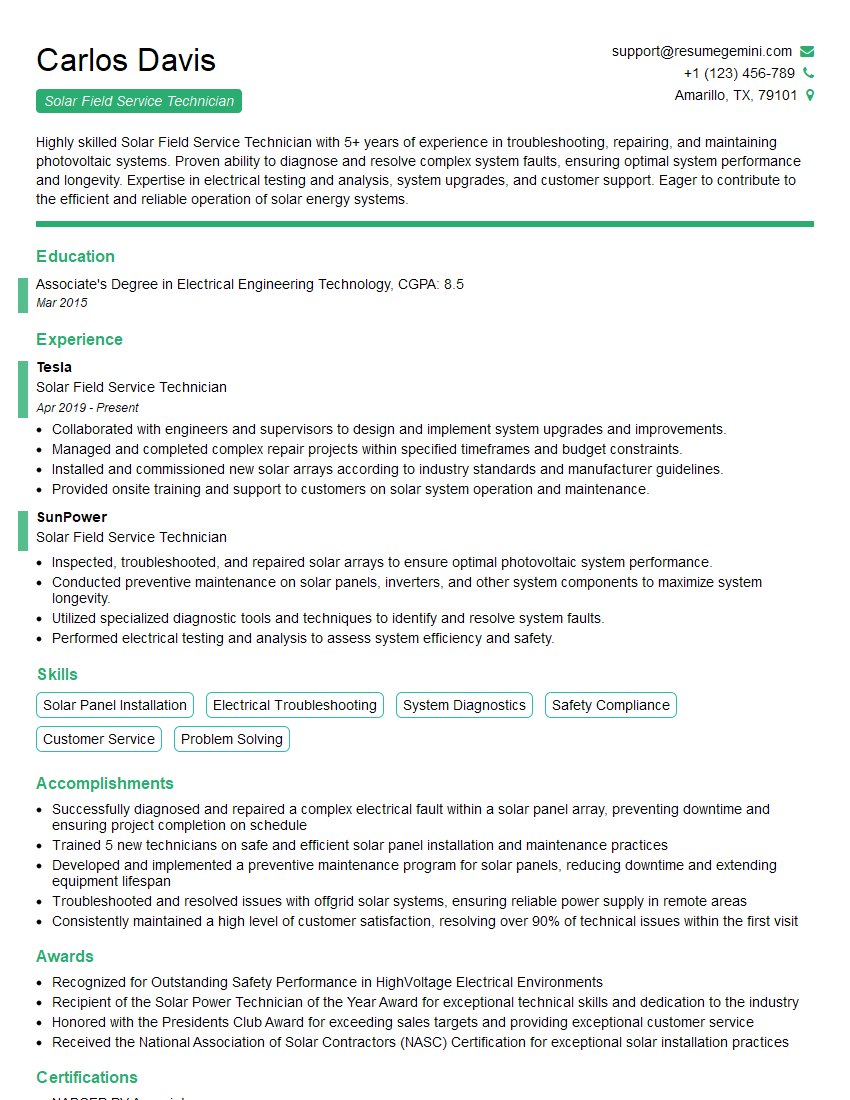

Mastering Solar Power Plant Maintenance is key to unlocking exciting career opportunities in a rapidly growing industry. A strong resume is your first step to landing your dream job. To maximize your chances, create an ATS-friendly resume that highlights your skills and experience effectively.

We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and resources to help you craft a compelling narrative that showcases your expertise. They even offer examples of resumes tailored specifically to Solar Power Plant Maintenance positions – check them out to see how you can best present your qualifications.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good