Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Chainsaw Operation and Maintenance interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Chainsaw Operation and Maintenance Interview

Q 1. What are the different types of chainsaws and their applications?

Chainsaws come in various types, each suited for different applications. The key distinctions lie in engine size (and thus power), bar length (cutting capacity), and features.

- Top-Handle Chainsaws: These are lightweight and compact, ideal for one-handed operation in tree pruning, limbing, and smaller cutting tasks. Think of them as precision tools for detailed work in the upper branches.

- Rear-Handle Chainsaws (farm saws): These offer a more powerful engine and longer bar length, perfect for larger felling and bucking operations. They are more robust, for longer continuous operation.

- Professional Chainsaws: These are high-performance machines, boasting high power, durability, and often advanced features like automatic chain lubrication and anti-vibration systems. These are the workhorses for professional arborists and loggers.

- Electric Chainsaws: These are quieter and require less maintenance, suitable for smaller jobs and those in noise-sensitive areas. However, they are typically less powerful than gas-powered counterparts and limited by cord length.

- Battery-Powered Chainsaws: These combine the quiet operation of electric saws with the freedom of cordless use. They are becoming increasingly powerful and are a great option for many tasks.

Choosing the right type depends heavily on the scale and nature of the work. A homeowner pruning a small tree might opt for a lightweight top-handle saw, while a logging crew would need heavy-duty professional models.

Q 2. Explain the process of selecting the correct chainsaw for a specific task.

Selecting the correct chainsaw involves careful consideration of several factors:

- Engine Displacement (cc): Larger engines provide more power for felling larger trees and cutting through thicker wood. Smaller engines are more suitable for lighter tasks like pruning.

- Bar Length (inches): This determines the maximum length of wood the saw can cut. Longer bars are for larger trees, shorter bars for more precise cuts and smaller jobs.

- Power Source: Gas-powered saws offer greater power and mobility but require more maintenance. Electric and battery-powered saws are quieter and require less maintenance, but may have less power.

- Weight: Heavier saws offer more power and stability but can lead to fatigue. Lighter saws are easier to handle but might lack power for larger tasks.

- Features: Consider features like anti-vibration systems, automatic chain lubrication, and chain brakes for increased safety and efficiency.

For example, felling a large oak tree would require a powerful gas-powered chainsaw with a long bar, while trimming branches on a fruit tree would be better suited to a lightweight, shorter bar saw.

Q 3. Describe the proper procedures for starting and stopping a chainsaw.

Starting and stopping a chainsaw safely are crucial for preventing injury. Always follow the manufacturer’s instructions.

- Starting: Ensure the chain brake is engaged. For gas-powered saws, prime the carburetor (if necessary), half-choke the saw, pull the starter cord firmly, then disengage the choke once it starts. For electric saws, simply plug them in and engage the power switch.

- Stopping: Release the throttle, allowing the engine to idle down. Once idle, use the chain brake to stop the chain. Turn off the ignition switch for gas saws or simply unplug electric saws. Never stop a chainsaw by jamming the bar into the ground.

Remember, always start and stop the saw in a clear area, away from bystanders or obstacles.

Q 4. How do you maintain the chain tension and lubrication of a chainsaw?

Maintaining proper chain tension and lubrication is essential for safe and efficient chainsaw operation.

- Chain Tension: The chain should be taut but not overly tight. There should be slight sag visible when looking at the underside of the bar. Adjust tension using the adjusting mechanism, usually a nut or bolt on the side of the saw. Refer to your manual for specifics.

- Lubrication: Chainsaws use an automatic oiler to lubricate the chain and bar. Ensure the oil reservoir is always full and that the automatic oiler is functioning correctly. Check for oil dripping onto the bar regularly – insufficient lubrication leads to rapid chain and bar wear.

Neglecting these aspects can lead to premature wear, chain breakage, kickback, and other safety hazards.

Q 5. What safety precautions should be taken before, during, and after using a chainsaw?

Safety is paramount when working with chainsaws. Follow these precautions:

- Before Use: Inspect the saw for damage, ensure the chain is sharp and properly tensioned, wear appropriate personal protective equipment (PPE) including safety glasses, hearing protection, chainsaw chaps, steel-toe boots, and gloves.

- During Use: Maintain a firm grip on the saw, keep both hands on the handles, avoid reaching over the chain, and never cut above shoulder height. Keep a clear cutting area free from obstructions. Use proper cutting techniques.

- After Use: Turn the saw off, engage the chain brake, and allow the saw to cool before cleaning or maintenance. Store the saw securely and out of reach of children.

Regular safety training and a cautious approach are crucial for safe chainsaw operation.

Q 6. What are the signs of a dull chainsaw chain, and how do you sharpen it?

A dull chain will require more force to cut, increasing the risk of kickback and causing significant strain on the saw’s engine. Signs of a dull chain include:

- Slow cutting: Noticeably slower cutting speed compared to a sharp chain.

- Increased vibration: More vibrations felt during operation.

- Rough cuts: Uneven cuts and ragged edges indicate a dull chain.

- Chain grabbing or binding: The chain might bind or grab the wood, requiring extra force.

Sharpening: This can be done using a chainsaw file or a sharpening tool designed for chainsaws. Proper sharpening technique involves filing each tooth to the correct angle and depth, ensuring even filing across all teeth. Using a guide tool is recommended for uniform sharpening.

Regular chain sharpening is essential for maintaining performance and safety.

Q 7. Explain the proper techniques for felling a tree using a chainsaw.

Felling a tree safely and efficiently requires planning and skill. Always plan your escape route before beginning.

- Assess the tree: Check for dead branches, leaning, and surrounding obstacles.

- Determine the felling direction: Choose a felling direction that avoids hazards and allows for a safe escape route.

- Cut the notch: Make a notch on the side of the tree facing the felling direction. This notch guides the tree’s fall.

- Make the back cut: Make a back cut slightly higher than the notch, leaving a hinge for controlled felling. This hinge is crucial to guide the tree in the desired direction.

- Felling: Carefully monitor the tree’s fall. If the tree starts to fall in an unexpected direction, immediately retreat along your planned escape route.

Improper felling techniques can lead to tree damage, property damage, or serious injury.

Note: Felling large trees often requires professional expertise. If you lack experience, it is best to seek professional assistance.

Q 8. How do you handle kickback when operating a chainsaw?

Kickback is a dangerous reaction where the chainsaw’s guide bar suddenly rises and snaps back toward the operator. It’s usually caused by pinching the bar, hitting a foreign object, or improper cutting technique. The key to preventing kickback is to always maintain a firm grip, use proper cutting techniques (keeping the saw’s nose pointed down and avoiding contact with the wood as much as possible), and wear appropriate safety gear, including a helmet and chaps. Imagine trying to cut a log that’s wedged between two other logs; this pinching action is a major kickback risk. Always anticipate potential kickback scenarios and adjust your grip and cutting angle accordingly. If a kickback does occur, release the throttle immediately and let the saw stop before attempting to regain control.

A practical example: When felling a large tree, you should always aim to make the initial cut on the side away from your body to reduce the risk of kickback if the tree falls differently than anticipated. Proper technique and anticipation are critical factors in preventing this dangerous event.

Q 9. Describe the different types of chainsaw bars and their characteristics.

Chainsaw bars are the metal rails that guide the chain. There are several types, each suited to different applications:

- Full-Compensated (Full-Skip): These bars have a wide, flat profile designed for smooth cutting and superior performance in larger diameter wood. The skip teeth provide a more efficient cutting action and better chip removal.

- Semi-Skip Tooth: A balance between skip-tooth and round-tooth, providing a blend of performance and longevity. Good all-around choice for a variety of cutting tasks.

- Round-Tooth: Ideal for thinner woods, branch trimming, and pruning. Offers more durability at the expense of speed in large logs.

- Low-Profile Bars: Designed for increased maneuverability in tighter spaces, particularly useful for arborists working in confined areas. However, they often have a shorter lifespan due to increased stress on the bar.

The choice of bar depends on the task. For felling large trees, a full-compensated bar is recommended, while for detailed work, like pruning, a round-tooth bar might be preferable. The bar’s length is also crucial, longer bars suitable for larger logs and shorter bars for smaller ones. You’d never want to use a short bar to fell a large tree as this would put a lot of stress on the bar and could increase the chance of kickback.

Q 10. What are the common maintenance tasks for a chainsaw?

Regular chainsaw maintenance is crucial for safety and efficiency. Key tasks include:

- Chain sharpening: This ensures optimal cutting performance and reduces the risk of kickback. Dull chains require more force, leading to fatigue and increased risk.

- Bar lubrication: Proper lubrication prevents friction and extends the lifespan of both the bar and the chain. Adequate lubrication minimizes the risk of overheating and potential damage.

- Air filter cleaning: A clean air filter ensures the engine receives the proper amount of air for optimal performance. Clogged filters restrict airflow, leading to poor engine performance and reduced power.

- Spark plug inspection and cleaning/replacement: Ensures proper ignition and smooth engine operation. A fouled spark plug can lead to misfiring and reduced engine power.

- Tensioning the chain: A loose chain will increase the risk of derailment and kickback. The chain should be taut but not over-tightened.

- Inspection of all nuts and bolts: Prevent accidental loss and ensure safe chainsaw operation.

Think of it like maintaining a car: regular checks and cleaning prevent costly repairs and ensure reliable performance.

Q 11. How often should a chainsaw be serviced?

The frequency of chainsaw servicing depends on usage. For professional use, chainsaws should be inspected after every day’s work and should receive a thorough service every 25-50 hours of operation, or every 6 months, whichever comes first. For homeowners who occasionally use chainsaws, a yearly service should suffice, provided that the maintenance tasks mentioned previously are performed after each use.

Regular servicing is a vital part of preventative maintenance. It is significantly cheaper than repairing a damaged saw and prevents potential injury.

Q 12. What are the signs of a malfunctioning chainsaw?

Several signs indicate a malfunctioning chainsaw:

- Difficult starting: Could indicate issues with the spark plug, air filter, or fuel system.

- Reduced power: May be due to a dull chain, clogged air filter, or fuel issues.

- Excessive vibration: Suggests potential problems with the chain, bar, or engine bearings.

- Chain derailment: Often caused by a loose chain, damaged bar, or incorrect chain tension.

- Unusual noises: Grinding, knocking, or squealing sounds indicate significant problems that need attention.

- Excessive fuel consumption: Indicative of carburetor problems or other internal engine issues.

Ignoring these signs can lead to serious damage or injury, therefore they should be addressed immediately

Q 13. How do you troubleshoot common chainsaw problems?

Troubleshooting involves systematic investigation. For example, if the chainsaw won’t start, check the fuel, spark plug, and air filter first. If it lacks power, examine the chain’s sharpness and the air filter’s cleanliness. Excessive vibration might point to worn bearings or a damaged bar. Always consult the owner’s manual for specific troubleshooting steps. If you are unable to solve the problem yourself, always take it to a qualified chainsaw mechanic.

A step-by-step approach is key. For instance, if you suspect a carburetor problem, cleaning or replacing it might solve the issue. Addressing one problem at a time prevents further complications.

Q 14. What are the safety regulations regarding chainsaw operation?

Chainsaw operation requires strict adherence to safety regulations:

- Personal Protective Equipment (PPE): Always wear safety glasses, hearing protection, chainsaw chaps, gloves, and a helmet with face shield.

- Proper training: Ensure you have thorough training on chainsaw operation and maintenance before starting any work.

- Clear the work area: Remove all obstacles and ensure adequate space for safe maneuverability.

- Check for hazards: Be aware of overhead obstructions, underground utilities, and other potential hazards.

- Maintain control: Keep a firm grip on the chainsaw and avoid reaching over or around the blade.

- Refuel safely: Turn off the chainsaw and allow it to cool completely before refueling, in a well ventilated area, away from ignition sources.

- Follow all manufacturer instructions: Carefully read and understand the chainsaw’s manual and adhere to its safety guidelines.

Safety should always be the top priority when working with a chainsaw. Failure to adhere to these guidelines can result in serious injury or even death.

Q 15. What personal protective equipment (PPE) is required when using a chainsaw?

Chainsaw operation is inherently dangerous, so proper Personal Protective Equipment (PPE) is paramount. Think of PPE as your armor against potential injuries. It’s not just about following regulations; it’s about protecting your life and well-being. The minimum required PPE includes:

- Helmet with visor or face shield: Protects your head and face from flying debris.

- Eye protection: Safety glasses or goggles are essential to prevent eye injuries from sawdust or chain throw.

- Hearing protection: Earplugs or earmuffs are crucial to reduce the significant noise generated by a chainsaw.

- Gloves: Provides hand protection and enhances grip.

- Chainsaw chaps or trousers: These are specifically designed to protect your legs from chain cuts. They are crucial and significantly reduce the severity of leg injuries.

- High-visibility clothing: Essential, particularly when working near others or in low-light conditions.

- Sturdy, closed-toe boots with steel toes (recommended): To protect your feet from rollovers and debris.

Remember, using the right PPE is not optional; it’s a crucial aspect of safe chainsaw operation. I’ve seen firsthand the devastating consequences when this is neglected.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of proper chain sharpening techniques.

Proper chain sharpening is essential for safety and efficiency. A dull chain requires more force to cut, increasing the risk of kickback (a sudden, uncontrolled movement of the chainsaw) and causing fatigue. It also leads to poor cuts, more vibration and damage to the bar and chain itself.

The goal is to maintain a sharp, consistent cutting edge. You need a file that matches the chain’s gauge (thickness), and a depth gauge tool. The process involves filing each cutter to the correct angle and depth, ensuring an even sharpness across all teeth. There are numerous techniques: circular filing, flat filing, and using a sharpening tool with guides. Each needs practice for achieving consistent results.

Imagine trying to cut wood with a dull knife; it’s difficult, inefficient, and risky. Regular sharpening, ideally after every few tanks of fuel, ensures a smooth, efficient cut and minimizes the chances of accidents. Sharp chains require less effort, resulting in less operator fatigue and a safer working environment.

Q 17. Describe the different types of chainsaw cutting techniques.

Several chainsaw cutting techniques exist, each suited for different situations. Choosing the wrong technique can lead to inefficiency or even dangerous kickback. Mastering each is crucial for a professional.

- Hinge Cut: This creates a controlled felling direction, crucial for directing the tree’s fall. It involves making a notch (back cut and face cut) to create a hinge, then a back cut to fell the tree.

- Bore Cut (or Bucking): Used to cut through a log while it is supported, usually with the chainsaw positioned horizontally. This requires careful positioning to prevent the bar from pinching.

- Open Cut (for Limbing): For removing branches, this involves a single cut, usually with the chainsaw positioned vertically, careful to keep the chain running and to avoid pinching.

- Push Cut: The chainsaw is pushed through the wood using the weight of the saw. This is used mainly when cutting from the top. It is essential to maintain firm control.

Each technique requires practice and understanding of wood grain, tree structure, and the chainsaw’s handling characteristics. A poorly executed hinge cut can lead to unexpected tree falls, while an incorrectly performed bore cut can bind the chain, resulting in kickback.

Q 18. How do you assess the risk associated with a specific tree felling operation?

Assessing the risk of a tree felling operation is paramount. Neglecting this can lead to serious accidents and property damage. The process involves a systematic evaluation of various factors:

- Tree condition: Look for diseases, decay, lean, cracks, and deadwood that might affect stability.

- Surrounding environment: Identify obstacles like other trees, buildings, power lines, or slopes. Consider the ground condition, and the possibility of things like loose rocks.

- Weather conditions: Strong winds, rain, or snow significantly increase the risk.

- Operator experience: The skill level of the operator influences the assessment; advanced operators can handle more complex situations.

- Equipment condition: Ensure the chainsaw is properly maintained and functioning correctly.

A detailed risk assessment helps determine the necessary safety measures. This might include choosing a different felling technique, using extra support equipment, or employing additional personnel. Remember: A thorough risk assessment is not merely a formality; it’s a life-saving step.

Q 19. What are the emergency procedures in case of a chainsaw accident?

Immediate response is critical in chainsaw accidents. Timely action can significantly impact the outcome.

- Stop the chainsaw immediately: Ensure it’s completely switched off and away from the injured person.

- Assess the injury: Determine the severity, and prioritize life-threatening injuries (severe bleeding or breathing difficulties).

- Call for emergency medical services: Provide clear details of the location and the nature of the injury.

- Provide first aid: If you have the appropriate training, provide first aid, focusing on controlling bleeding and preventing further injury. Do not attempt to move the injured person unless absolutely necessary.

- Secure the area: Prevent unauthorized access to the accident site.

Remember, prompt action and professional medical attention are crucial. Knowing your limitations and acting appropriately is vital.

Q 20. How do you dispose of used chainsaw bar oil responsibly?

Used chainsaw bar oil should be disposed of responsibly to protect the environment. It’s usually a mixture of mineral oil and additives, and is hazardous waste. Simply pouring it on the ground is illegal and environmentally damaging.

Proper disposal methods vary by location; some areas might have designated collection centers for used oil. Check with your local waste management authorities. In some cases, you may be able to take it to an auto parts store or other designated facility. You may have to pay a fee for proper handling. Never dispose of it down the drain or with regular household waste.

Environmental responsibility is key. Follow local regulations and always look for the environmentally sound option.

Q 21. What are the legal requirements for operating a chainsaw in your area?

Legal requirements for operating a chainsaw vary significantly by location. These laws often cover things like operator age, training requirements, and safety regulations.

You must check your local, state/provincial and possibly even federal regulations. Some jurisdictions mandate specific training certifications before you can legally operate a chainsaw, especially in commercial settings. They may also define regulations regarding the type of PPE required and the permissible work areas. Ignoring these regulations can result in hefty fines or even legal repercussions.

Always research and understand the relevant laws in your specific area before operating a chainsaw. This demonstrates responsibility and protects both you and the environment.

Q 22. Describe your experience with different chainsaw brands and models.

My experience spans a wide range of chainsaw brands and models, from Stihl and Husqvarna – industry leaders known for their reliability and power – to smaller brands like Poulan and Echo. I’ve worked extensively with professional-grade saws designed for felling large trees, as well as lighter models suitable for pruning and smaller jobs. For example, I’ve used the Stihl MS 661 for large-scale timber harvesting, appreciating its power and durability, and the Husqvarna 450 Rancher for more general-purpose work, valuing its versatility and ease of handling. My experience includes both petrol and battery-powered models, allowing me to adapt to different job requirements and environmental concerns.

Each model presents its own unique characteristics. Stihl saws, in my experience, tend to have a more robust build, while Husqvarna models often emphasize ergonomics and user-friendliness. Understanding these nuances is crucial for choosing the right tool for the task. For instance, a lightweight saw is ideal for pruning high branches, whereas a heavier, more powerful saw is necessary for felling large trees.

Q 23. Explain your understanding of chainsaw safety regulations.

Chainsaw safety regulations are paramount, and my understanding encompasses local, state, and potentially federal regulations depending on the location and type of work. These regulations typically cover areas such as personal protective equipment (PPE), safe operating procedures, and emergency response. Essential PPE includes safety helmets with visors or face shields, chainsaw chaps or trousers, gloves, and hearing protection. Safe operating procedures emphasize factors like proper tree assessment before felling, maintaining a safe working distance from others, avoiding kickback, and using proper felling techniques to control the direction of the falling tree. Emergency response protocols include having a first-aid kit on hand and knowing how to communicate for emergency assistance.

Ignoring these regulations can lead to severe injury or fatality. For example, failing to wear appropriate PPE could result in serious eye, leg, or head injuries during operation. Regular training and adherence to best practices are crucial for safe operation.

Q 24. What is your experience with preventative maintenance on chainsaws?

Preventative maintenance is fundamental to chainsaw longevity and safe operation. My routine includes several key steps: Firstly, I regularly inspect the chain for sharpness and damage. A dull or damaged chain reduces cutting efficiency and increases the risk of kickback. I sharpen or replace chains as needed, ensuring proper tension. Secondly, I clean the air filter regularly, as a clogged filter restricts airflow, reducing engine performance and potentially causing damage. Thirdly, I check and lubricate the chain frequently using a high-quality bar and chain oil. Sufficient lubrication prevents premature wear and tear of the bar and chain. Finally, I inspect and clean the spark plug, ensuring it’s properly gapped, and I change the bar oil and fuel as recommended by the manufacturer.

Neglecting these steps can lead to costly repairs, reduced efficiency and even increase the risk of accidents. For instance, a poorly lubricated chain is more likely to break or become damaged, resulting in a dangerous situation.

Q 25. Describe a time you had to troubleshoot a chainsaw issue in the field.

During a large-scale logging operation, a Stihl MS 660 experienced a sudden loss of power. Initially, I suspected fuel issues. However, after checking the fuel supply and filter, the problem persisted. I then systematically checked the air filter (clean), spark plug (good spark), and finally, the carburetor. I discovered a small piece of debris lodged in the carburetor’s jet, restricting fuel flow. After careful cleaning, I reassembled the carburetor. The chainsaw started immediately and operated normally. This experience highlighted the importance of methodical troubleshooting and the need to check all potential causes before jumping to conclusions.

This incident reinforced the value of carrying a basic tool kit including screwdrivers, wrenches, and cleaning supplies, directly in the field to address minor issues promptly.

Q 26. How do you ensure the safety of yourself and others while operating a chainsaw?

Ensuring safety while operating a chainsaw involves a multi-faceted approach. Before starting any work, I conduct a thorough site assessment, identifying potential hazards and planning the cutting sequence carefully. I always wear the appropriate PPE and ensure it is in good condition. I maintain a safe working distance from others, establishing clear communication and designated safe zones. I follow proper felling techniques, considering factors like tree lean, wind direction, and potential obstacles. When cutting, I keep a firm grip on the chainsaw, avoid reaching over obstacles, and maintain control at all times. I never operate a chainsaw when fatigued or under the influence of alcohol or drugs. Finally, regular maintenance and timely repairs contribute significantly to overall safety.

Safe operation is a continuous process, not just a set of rules. Regular training, awareness, and a commitment to safety protocols are essential for reducing risks.

Q 27. How do you maintain your chainsaw to keep it in optimal working condition?

Maintaining a chainsaw for optimal working condition involves a regular maintenance schedule. This includes daily checks of the chain tension, lubrication, and air filter cleanliness. Weekly, I’ll perform a more thorough inspection, checking for any damage to the bar, chain, or other components. Monthly maintenance might include cleaning the carburetor and replacing the spark plug (depending on usage). Regular sharpening of the chain is crucial for efficiency and safety, typically every few hours of operation depending on the wood type and cutting conditions. Finally, annual servicing by a qualified technician ensures the saw is in peak condition and identifies any potential issues before they become major problems.

Thinking about maintenance as a preventative measure rather than a reactive one saves time, money, and potential injury in the long run.

Q 28. Explain your experience in using different types of cutting attachments for a chainsaw.

My experience extends to various chainsaw attachments beyond the standard cutting bar and chain. I’ve used pruning bars for precise cuts on smaller branches, allowing for better control and minimizing damage to surrounding vegetation. I’ve also utilized different chain types, such as skip-tooth chains for cutting hardwoods, and chipper attachments for smaller-scale wood chipping projects. Specific attachments can significantly increase versatility and efficiency. For instance, a pruning bar allows for safer and more precise cuts in dense foliage, while a chipper can quickly process smaller branches and brushwood on site.

Choosing the right attachment depends heavily on the specific task. Incorrect attachment usage can damage both the saw and the work itself; understanding the capabilities and limitations of each attachment is crucial.

Key Topics to Learn for Chainsaw Operation and Maintenance Interview

- Chainsaw Safety Procedures: Understanding and applying all relevant safety regulations, including personal protective equipment (PPE) usage and emergency procedures. This includes theoretical knowledge of safety standards and practical application in various work scenarios.

- Chainsaw Mechanics and Components: Detailed knowledge of chainsaw components (engine, chain, bar, carburetor, etc.), their functions, and potential malfunctions. This includes understanding how these components interact and troubleshooting common issues.

- Chainsaw Maintenance and Repair: Proficiency in performing routine maintenance tasks such as chain sharpening, bar lubrication, air filter cleaning, and spark plug replacement. Understanding preventative maintenance schedules and the ability to diagnose and repair minor mechanical problems.

- Proper Cutting Techniques: Mastering various cutting techniques (e.g., felling, limbing, bucking) for different tree types and terrain. This includes understanding the impact of different techniques on safety and efficiency.

- Fuel and Lubricant Handling: Safe and responsible handling, storage, and usage of fuel and lubricants, adhering to all safety regulations. Understanding the environmental impact of fuel and lubricant spills and proper cleanup procedures.

- Troubleshooting and Diagnostics: Ability to identify and diagnose common chainsaw problems, using systematic troubleshooting methods to determine the root cause of malfunctions and implement effective solutions.

- Environmental Awareness: Understanding the environmental impact of chainsaw operation, including best practices for minimizing damage to surrounding vegetation and soil.

Next Steps

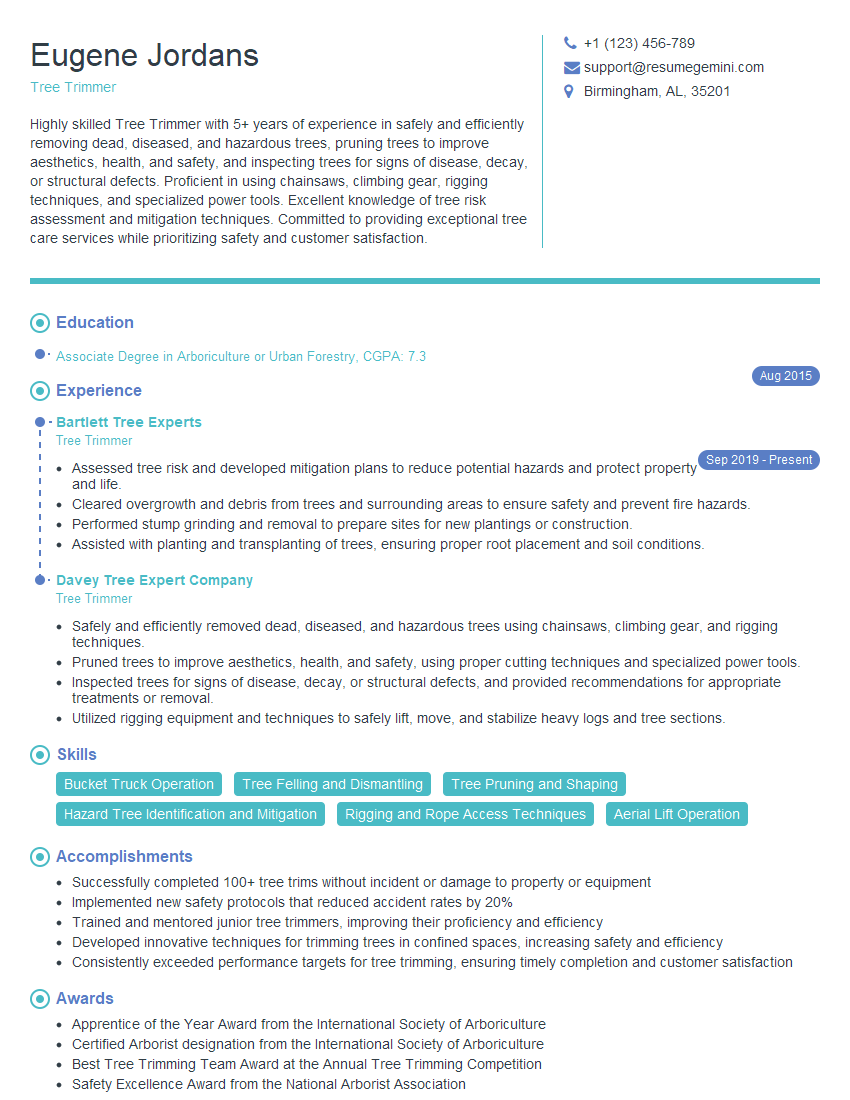

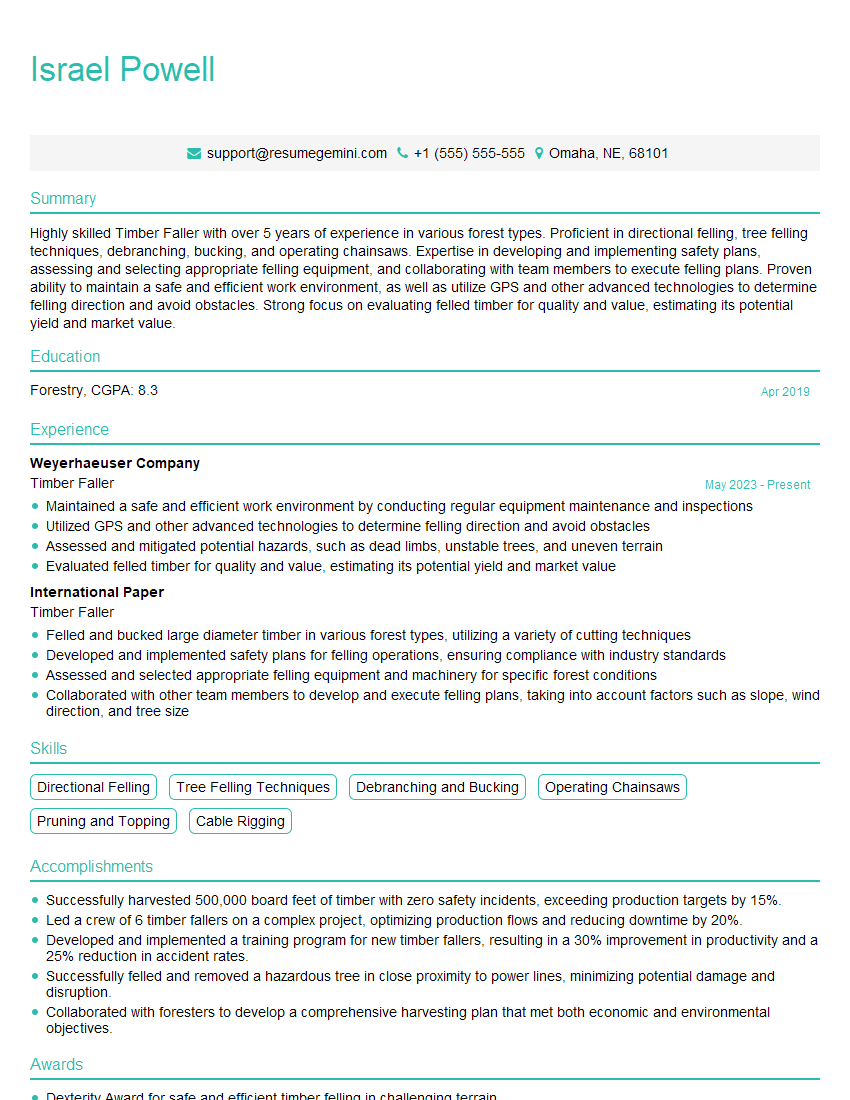

Mastering Chainsaw Operation and Maintenance opens doors to exciting career opportunities in forestry, landscaping, arboriculture, and more. A strong understanding of these skills demonstrates commitment to safety, efficiency, and environmental responsibility – highly valued qualities in any employer. To significantly boost your job prospects, create an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. Examples of resumes tailored to Chainsaw Operation and Maintenance are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good