Unlock your full potential by mastering the most common Bucking and Limbing Techniques interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Bucking and Limbing Techniques Interview

Q 1. Describe the proper techniques for bucking a tree.

Bucking a tree involves cutting it into manageable sections after felling. Proper technique is crucial for safety and efficiency. It begins with assessing the tree’s lean and identifying potential hazards like other trees or obstacles. You then make your cuts, starting with a notch (a V-cut or a notch-and-back cut) on the side you want the tree to fall. This directs the fall. Then, make the felling cut on the opposite side, a few inches above the notch. Ensure the felling cut is wide enough to avoid binding the saw. Once the tree is down, you proceed with bucking it into lengths suitable for transport or processing. Always ensure your cuts are in line and avoid twisting the chainsaw.

Example: Imagine bucking a large oak. I’d start by creating a precise V-notch on the side of the fall and carefully ensure the felling cut is several inches above, leaving a hinge. This keeps control over the fall. I’d then buck the tree into 8-10 foot lengths, depending on transportation needs.

Q 2. Explain the different types of limbing cuts.

Limbing involves removing branches from a felled tree. There are several types of cuts:

- Push Cut: Used for smaller branches. The saw is pushed through the branch, away from the operator.

- Pull Cut: Used for larger branches where a push cut might bind. The saw is pulled through the branch, towards the operator, usually needing the support of a limbing bar.

- Bore Cut: Employed to remove limbs flush with the trunk. A notch is made on the top of the branch, then the cut is completed from the underside to avoid snags.

Choosing the correct cut depends on the branch size, its position, and the overall safety of the operation. A skilled arborist will use a combination of techniques to efficiently and safely remove all branches.

Example: When limbing a pine tree, I often use push cuts for the smaller branches and pull cuts for the larger ones near the trunk to avoid damaging the log during removal.

Q 3. What safety precautions must be taken when performing bucking and limbing?

Safety is paramount when bucking and limbing. Key precautions include:

- Proper Personal Protective Equipment (PPE): This is non-negotiable and includes chainsaw chaps, safety helmet with face shield, gloves, steel-toed boots, and hearing protection.

- Safe Working Area: Ensure a clear area around the tree, free of obstacles and people. Consider the direction of the fall and potential kickbacks.

- Sharpened Chain: A dull chain increases the chance of kickback and requires more force, increasing the risk of accidents.

- Check for Tension: Before cutting, check if the tree or branch is under tension. This is crucial to avoid injuries from sudden movement.

- Never Overreach: Always maintain a firm stance and avoid overreaching. A good strategy is to take multiple cuts instead of overextending and using full power.

- Appropriate Technique: Always use the correct bucking and limbing techniques based on the size and type of branch or tree.

Q 4. How do you assess tree risk before bucking and limbing?

Assessing tree risk before starting work involves a thorough visual inspection of the tree and its surroundings. I look for:

- Tree Health: Signs of disease, decay, or insect infestation significantly impact the stability of the tree.

- Lean: Note the tree’s lean and the direction it is most likely to fall.

- Branch Structure: Examine the branches for weaknesses, broken limbs, or signs of stress.

- Surrounding Environment: Assess any obstacles such as other trees, power lines, or buildings in the potential fall path.

- Soil Conditions: The stability of the soil beneath the tree is crucial; loose or wet soil can lead to unexpected falls.

- Weather Conditions: High winds or rain can increase risks; work should be suspended if conditions are unsafe.

This assessment helps determine the appropriate techniques, the use of additional safety measures, and ultimately, whether it’s safe to proceed with the work.

Q 5. What are the common hazards associated with bucking and limbing?

Common hazards associated with bucking and limbing include:

- Kickback: The chainsaw unexpectedly recoiling towards the operator.

- Pinch: The saw blade becoming trapped between two pieces of wood.

- Falling Branches or Trees: Unforeseen tree movement during cutting.

- Injury from Sharp Objects: Contact with branches, chainsaws, or other tools.

- Exposure to Hazardous Materials: Certain trees might contain allergenic sap or other substances.

A thorough risk assessment and adherence to safety precautions are essential in mitigating these hazards.

Q 6. Explain your experience with different types of chainsaws.

My experience encompasses a wide range of chainsaws, from smaller homeowner models to large professional saws. I’m proficient with various brands such as Stihl, Husqvarna, and Echo. I understand the differences in engine size, bar length, and power output and can select the appropriate saw for a specific task. For example, a smaller saw is ideal for limbing while a larger, more powerful saw is necessary for bucking large trees. I am also familiar with the maintenance requirements for each, including chain sharpening and lubrication. Regular maintenance is key to safety and efficient operation.

Q 7. Describe your experience with various bucking and limbing tools.

Beyond chainsaws, I’m experienced with various bucking and limbing tools. This includes limbing bars for improved leverage and control, wedges for managing tree falls, and various types of felling axes for precise cuts in specific situations. I’m also adept at using specialized equipment such as climbing gear if the tree needs to be accessed from above, and mechanical aids such as winches to control larger falls. Selecting the right tool for the job is vital for efficiency and safety.

Example: In a recent job, I utilized a limbing bar extensively when working on a dense canopy, as it allowed me to cleanly and precisely remove limbs with improved control compared to relying solely on a chainsaw.

Q 8. How do you maintain your chainsaw and other equipment?

Maintaining my chainsaw and other equipment is paramount to safety and efficiency. It’s not just about keeping them running; it’s about preventing accidents and ensuring optimal performance. My routine involves several key steps:

- Daily Inspection: Before each use, I meticulously check the chain for sharpness, damage, and proper tension. I also inspect the bar for wear and tear, ensuring it’s lubricated adequately. I examine the fuel and oil levels, ensuring they are topped off. A quick visual check of all bolts and nuts for tightness is also crucial.

- Regular Maintenance: This includes sharpening the chain with a quality file, using a chain gauge to maintain the correct depth. I clean the air filter regularly, replacing it as needed. I change the bar oil and fuel filter at recommended intervals, based on usage. I also lubricate moving parts like the chain tensioner.

- Professional Servicing: Annually, I take my chainsaw to a certified professional for a thorough service. This ensures all components are in peak condition, and it identifies any potential issues early on. This often includes a full carb cleaning and any necessary adjustments.

- Proper Storage: When not in use, my chainsaw is stored in a dry, secure location, away from flammable materials. I always ensure the fuel tank is empty to prevent issues with fuel degradation.

This systematic approach ensures my equipment is always reliable and safe, minimizing the risk of breakdowns or accidents in the field.

Q 9. How do you handle unexpected situations during bucking and limbing?

Unexpected situations are inevitable in bucking and limbing. My response relies on a combination of preparation, experience, and quick thinking. For example, if a tree falls unexpectedly, I immediately assess the situation to ensure my safety and then proceed with the necessary cleanup and further felling adjustments. If I encounter a hidden snag or rot in a log, I will immediately reassess my cutting technique, likely using wedges to control the split, ensuring a safe and controlled separation. I always have a well-defined escape route planned before beginning work. If a limb catches or binds unexpectedly, I’ll use wedges, or if the situation requires it, I’ll back away and reassess my approach with a more precise cut to free the trapped limb. Communication is also vital; if working in a team, clear communication regarding potential risks and the next steps is crucial. The key is to remain calm, assess the situation, and employ the safest and most effective solution.

Q 10. Describe your experience working in different terrain conditions.

I have extensive experience working across diverse terrains. From steep slopes to swampy ground, each environment presents unique challenges. On steep slopes, I always work uphill, preventing the log from rolling back towards me. I use extra caution and secure footing, sometimes employing additional safety measures like a climbing harness and anchor points. In swampy areas, I assess ground stability before proceeding, using wider stances and strategically placed supports to prevent the equipment from sinking or becoming unstable. Working on rocky terrain requires careful foot placement and mindful chainsaw handling to avoid impacts. I always adapt my techniques and safety precautions based on the specific conditions, prioritizing safety above all else. Experience has taught me the importance of environmental awareness and adaptability in maintaining safe and efficient working practices.

Q 11. What are the proper techniques for felling a tree in confined spaces?

Felling trees in confined spaces demands meticulous planning and precision. The primary concern is controlling the direction and trajectory of the falling tree. I begin by carefully assessing the space and identifying a safe escape route before making any cuts. A proper notch, appropriately sized for the tree’s diameter, is essential. The back cut must be carefully positioned to ensure the tree falls within the safe zone. Wedges are often invaluable in guiding the fall. The use of a felling line, strategically placed to direct the tree’s fall, is critical in very confined situations. If a crane or other lifting equipment is available it will be used. The entire process must be systematic and precise, making small cuts and constantly assessing the tree’s response. Safety is always the paramount consideration, and in extremely confined spaces, professional assistance might be necessary.

Q 12. Explain the importance of proper tree felling direction.

Proper tree felling direction is crucial for safety and efficiency. The direction should be selected to minimize hazards and maximize the ease of bucking and limbing. Factors to consider include the tree’s lean, obstructions, and the prevailing wind direction. Falling a tree into an open area minimizes the risk of damage to property or injury to personnel. By considering factors like slope and the presence of other trees or structures, it is possible to strategically choose the safest possible direction. Failing to carefully consider the direction can have disastrous results, leading to damage or even injury.

Q 13. How do you determine the best bucking and limbing strategy for a specific tree?

Determining the best bucking and limbing strategy involves a comprehensive assessment of the tree. Factors such as the tree’s species, size, shape, and the presence of defects (rot, knots) heavily influence the approach. For example, a large, leaning tree might require specific cuts to control its fall and prevent it from damaging nearby trees. For smaller trees, simple bucking and limbing methods may suffice. I always start with limbing the smaller branches first and then move up to larger ones, ensuring stability for each step. Bucking should be done in a controlled manner, considering the size and weight of each section. Experienced judgment is essential in selecting the most effective approach for a safe and efficient operation. I always prioritize safety and employ the least risky cutting methods.

Q 14. Explain your understanding of wedge usage in bucking and limbing.

Wedges are invaluable tools in bucking and limbing, especially when dealing with difficult situations. They are used to help control the direction of a cut, prevent binding, and help split logs. Wooden or metal wedges can be inserted into cuts to help control the direction of a fall. For example, if a tree is leaning, wedges can be used to guide its fall in a specific direction. If a log is hung up on another tree, wedges can help to split the log and free it. Proper placement of wedges is critical for effectiveness and safety. Overdriving wedges can lead to equipment damage or injury. The selection of the wedge depends on the type of wood and the force required.

Q 15. What are the different types of wood and how do they affect bucking and limbing?

Different wood species possess varying characteristics that significantly impact bucking and limbing. Hardness, grain pattern, and moisture content are key factors. Hardwoods like oak and hickory are incredibly dense and require more power and precision to cut through cleanly, potentially leading to increased tool wear and fatigue. Softwoods like pine and fir are generally easier to work with, but can be more prone to splitting if not handled carefully. For example, a dull chain on a chainsaw will struggle more with dense hardwoods, leading to binding and kickback. Conversely, a sharp saw can easily overcut softwoods, leading to waste and less efficient work.

- Hardwoods (e.g., Oak, Hickory): Dense, strong, challenging to cut, more prone to tool wear.

- Softwoods (e.g., Pine, Fir): Less dense, easier to cut, but potentially prone to splitting.

- Decayed Wood: Weak, unstable, requires extra caution to avoid injury and equipment damage.

Understanding these differences is crucial for selecting the appropriate tools and techniques for efficient and safe operation. I always assess the wood type before beginning any bucking or limbing operation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the safety of yourself and others during bucking and limbing operations?

Safety is paramount in bucking and limbing. My approach is multifaceted and starts with a thorough risk assessment of the worksite. This includes checking for hazards like unstable ground, overhead hazards (hanging limbs, power lines), and weather conditions. Personal protective equipment (PPE) is mandatory, including safety glasses, hearing protection, chainsaw chaps, steel-toe boots, and a helmet. I always ensure the chainsaw is properly maintained and fueled, and I never operate it when tired or under the influence of anything that could impair my judgment.

- Pre-Cut Assessment: Thorough inspection of the tree and surroundings before making any cuts.

- Proper Technique: Utilizing correct bucking and limbing methods to avoid kickback and other accidents.

- Communication: Clear communication with fellow workers, especially when working in a team.

- Emergency Preparedness: Knowing the location of first aid supplies and having a plan for dealing with emergencies.

I’ve had several near misses over the years, and these experiences have reinforced the importance of strict adherence to safety protocols. For instance, once a large limb unexpectedly shifted during limbing, narrowly missing me. That reinforced the importance of always securing my footing and being aware of potential movement in the tree.

Q 17. What are the legal and regulatory requirements for bucking and limbing in your area?

Legal and regulatory requirements vary depending on location, but generally involve adherence to workplace safety regulations, licensing requirements for operating heavy equipment, and environmental protection laws. In my area, we must obtain permits for any logging operations, especially on public or protected land. This often involves submitting detailed plans outlining the work area, methods, and waste disposal strategies. We are also required to maintain detailed records of all work performed, including equipment maintenance and safety inspections. Failure to comply can result in significant fines and legal repercussions. We also need to be aware of and follow all relevant regulations on endangered species or protected habitats.

For instance, we’re required to have specific training and certifications to operate certain types of equipment like chainsaws or skidders. Environmental regulations mandate responsible disposal of logging debris to minimize impact on local ecosystems.

Q 18. Describe your experience with first aid and emergency procedures in forestry.

I hold a current First Aid and CPR certification, and I am proficient in treating common forestry injuries like lacerations, sprains, and fractures. I’m trained in stabilizing patients for evacuation and know the emergency contact numbers and procedures for our region. I’ve used these skills on several occasions, including treating a minor chainsaw injury to a colleague and assisting a hiker who had fallen and broken their leg. My experience has underscored the importance of having a comprehensive first aid kit accessible at all times and conducting regular safety briefings to ensure all team members are aware of emergency procedures. Knowing how to quickly assess a situation, provide immediate first aid, and communicate effectively with emergency services is critical in remote forestry settings.

Q 19. How do you manage waste and debris after bucking and limbing?

Waste management is a crucial aspect of responsible forestry. After bucking and limbing, we typically separate the waste into different categories for efficient disposal or reuse. Larger pieces of wood are often used for firewood or other purposes, reducing landfill waste. Smaller branches and debris are chipped and used as mulch or biomass fuel. Any remaining waste is transported to an approved disposal site according to local regulations. Proper waste management not only helps protect the environment but also demonstrates our commitment to sustainable forestry practices. Failure to do so can lead to significant fines and environmental damage.

Q 20. Describe your experience with different types of logging equipment.

My experience encompasses a range of logging equipment, including chainsaws (various sizes and models), skidders, feller bunchers, and forwarders. I’m proficient in operating and maintaining each type, understanding their capabilities and limitations. I know how to choose the right equipment for each task, considering factors such as terrain, tree size, and accessibility. For example, a smaller chainsaw might suffice for limbing smaller trees, while a larger one is necessary for bucking larger logs. Skidders are useful for moving felled timber out of the woods, whereas feller bunchers are more efficient in larger-scale operations.

Regular maintenance is key to safe and efficient operation. I perform daily checks on all equipment, ensuring they are in proper working condition. This includes inspecting the chain brakes, oil levels, and other critical components.

Q 21. How do you read and interpret a felling plan?

A felling plan is a crucial document that outlines the details of a logging operation. I’m adept at reading and interpreting these plans, understanding the designated felling zones, the direction of each tree’s fall, and any special considerations (e.g., proximity to power lines, water bodies, or roads). I’ll look for details like the tree species, diameter, and location, along with any specific safety instructions or environmental protection measures. The plan typically also includes a map of the area, which is very important for navigation and to avoid mistakes.

Understanding a felling plan is critical for ensuring the safe and efficient execution of a logging operation. It helps us minimize risks and maximize productivity. I always thoroughly review the plan before beginning any work and ensure everyone on my team understands its contents.

Q 22. Explain your experience with pre-harvest planning and assessments.

Pre-harvest planning is crucial for efficient and safe logging operations. It involves a thorough assessment of the area, including the species and size of trees, terrain, accessibility, and potential hazards. This assessment informs decisions about the best felling techniques, equipment needed, and the overall logging strategy.

My experience includes conducting detailed site surveys using GIS mapping and tree diameter measurements to determine timber volume and assess potential risks like steep slopes or proximity to water bodies. I then develop a detailed harvesting plan, outlining road layout, tree marking for felling, and skid trail routes, ensuring minimal environmental impact. For example, I’ve worked on projects where pre-harvest planning significantly reduced soil erosion by strategically positioning skid trails and avoiding sensitive areas.

This process also involves consulting with stakeholders such as landowners, environmental agencies, and local communities to address their concerns and ensure compliance with regulations. A well-executed pre-harvest plan directly translates into a safer and more productive logging operation.

Q 23. How do you contribute to a safe and productive work environment?

Safety and productivity go hand-in-hand in logging. I contribute to a safe work environment by consistently adhering to and enforcing safety protocols, including daily equipment inspections, proper use of personal protective equipment (PPE) like helmets, chaps, and safety glasses, and maintaining clear communication among crew members. I actively participate in safety training and briefings, ensuring everyone understands the risks associated with bucking and limbing.

My approach to productivity emphasizes efficiency without compromising safety. I teach and demonstrate best practices in felling techniques, proper use of chainsaws, and effective limbing strategies. This not only improves output but also minimizes the risk of accidents. For instance, I’ve implemented a system of regular tool sharpening and maintenance, leading to improved cutting efficiency and reduced fatigue-related accidents.

Moreover, I foster a culture of safety by reporting hazards immediately, encouraging peer-to-peer safety observations, and participating in regular safety meetings. A safe work environment leads to improved morale and higher productivity.

Q 24. Explain your understanding of environmental considerations in logging operations.

Environmental considerations are paramount in modern logging. My understanding encompasses minimizing soil disturbance, protecting water quality, and preserving biodiversity. This involves careful planning of logging roads and skid trails to minimize erosion and sedimentation. I’m adept at using techniques like directional felling to avoid damaging adjacent trees and employing riparian buffers to protect waterways.

I understand the importance of proper slash disposal techniques, such as chipping or piling, to reduce wildfire risks. Knowing which species are sensitive and where they are located allows me to avoid harming them. This often involves working with environmental consultants and adhering to strict guidelines set by regulatory agencies. For example, on one project, we used specialized equipment to avoid disturbing a rare wetland species by keeping machinery a safe distance from the sensitive area.

Sustainable forestry practices are not just a regulatory requirement; they are crucial for long-term ecological health and the viability of the logging industry itself.

Q 25. Describe your problem-solving skills in relation to bucking and limbing challenges.

Problem-solving is a daily occurrence in bucking and limbing. Challenges can range from difficult terrain to unforeseen tree defects. My approach is systematic and involves a careful assessment of the situation, considering all available resources and safety precautions. I prioritize safety above all else.

For example, if a tree falls unexpectedly, I immediately assess the situation to ensure no one is injured. Then, I determine the safest way to clear the obstacle, possibly involving additional equipment or personnel. If encountering a tree with significant internal defects, I carefully adjust my cutting techniques to prevent kickback or uncontrolled felling.

My experience also encompasses creative problem-solving. I’ve devised rigging systems to safely remove fallen trees from difficult locations, developed alternative bucking strategies to avoid damaging adjacent trees, and even used innovative techniques like felling wedges to steer trees in specific directions, minimizing risks and maximizing resource utilization.

Q 26. How do you stay up-to-date with industry best practices and safety regulations?

Staying current with industry best practices and safety regulations is essential for maintaining proficiency and ensuring compliance. I achieve this through continuous professional development, including attending workshops, seminars, and industry conferences. I actively participate in professional organizations, accessing their resources and networking with other professionals.

I also regularly review updates to relevant safety regulations and standards, such as those published by OSHA (in the US context – adapt as needed for other countries) and other relevant bodies. I subscribe to industry publications and online resources to stay abreast of technological advancements and new techniques. This ongoing learning ensures I maintain the highest level of expertise and safety standards in my work.

Furthermore, I regularly seek feedback from colleagues and supervisors, embracing opportunities for mentorship and skill development.

Q 27. Describe a time you had to make a quick decision to ensure safety during a bucking and limbing operation.

During a particularly windy day, I was bucking a large pine tree when a sudden gust caused a significant limb to shift unexpectedly. It threatened to fall towards a nearby worker. Instead of continuing with the cut, I immediately yelled a warning and signaled the worker to move to safety. I then used my chainsaw to quickly cut the limb away from the worker, securing it in a controlled manner to prevent further hazards.

This rapid decision-making, based on years of experience recognizing potential hazards, prevented a possible serious accident. It underscores the importance of constant vigilance, situational awareness, and the ability to make quick, sound judgments to protect the safety of the entire crew.

Key Topics to Learn for Bucking and Limbing Techniques Interview

- Safety Procedures and Regulations: Understanding and applying relevant safety protocols for bucking and limbing operations, including personal protective equipment (PPE) requirements and hazard identification.

- Tree Anatomy and Physiology: Knowledge of wood grain, stress points, and growth patterns to inform efficient and safe cutting techniques.

- Cutting Techniques: Mastering various bucking and limbing cuts, including proper saw handling, felling techniques, and limb removal strategies to minimize damage and risk.

- Equipment Operation and Maintenance: Demonstrating proficiency in operating chainsaws and other relevant equipment, including proper maintenance and safety checks.

- Environmental Considerations: Understanding the environmental impact of bucking and limbing and applying best practices for minimizing harm to the ecosystem.

- Problem-Solving and Decision-Making: Analyzing challenging situations, such as unexpected tree conditions or equipment malfunctions, and applying effective problem-solving skills to ensure safety and efficiency.

- Emergency Procedures: Knowledge of emergency response protocols in case of accidents or injuries, including first aid and communication procedures.

- Legal and Regulatory Compliance: Understanding and adhering to all relevant local, state, and federal regulations related to bucking and limbing operations.

Next Steps

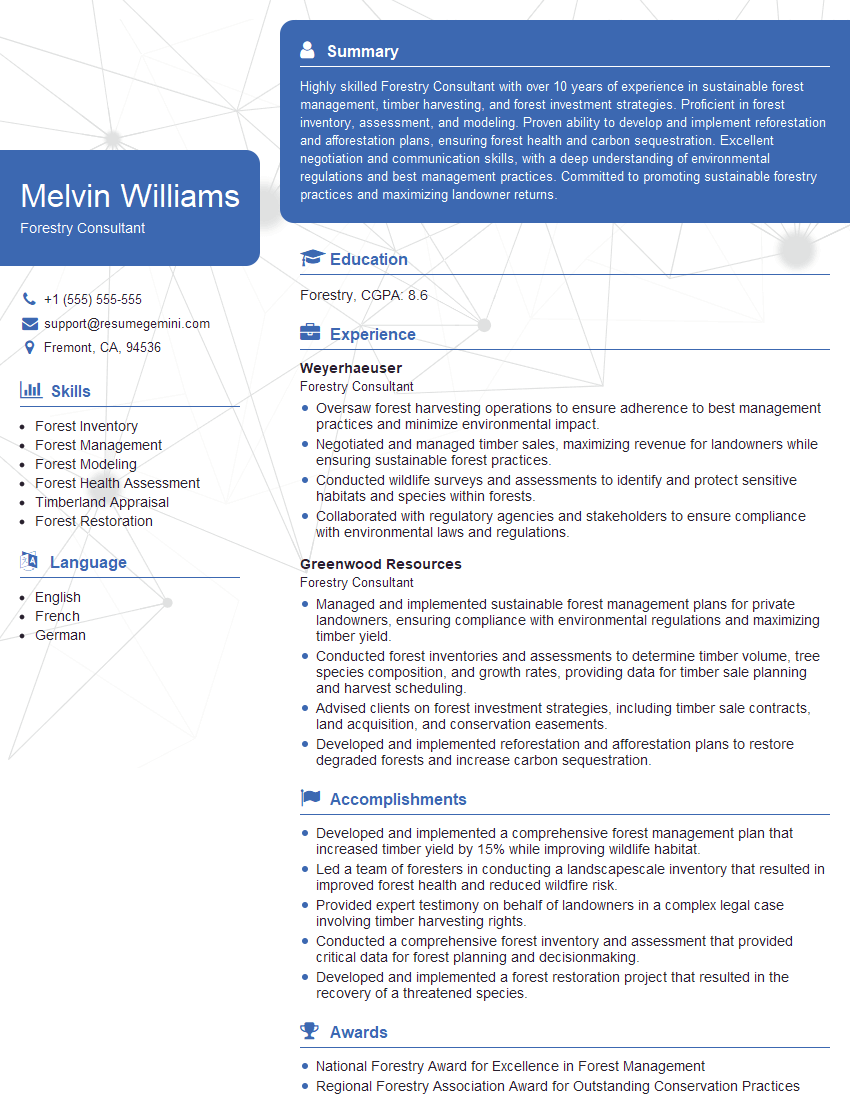

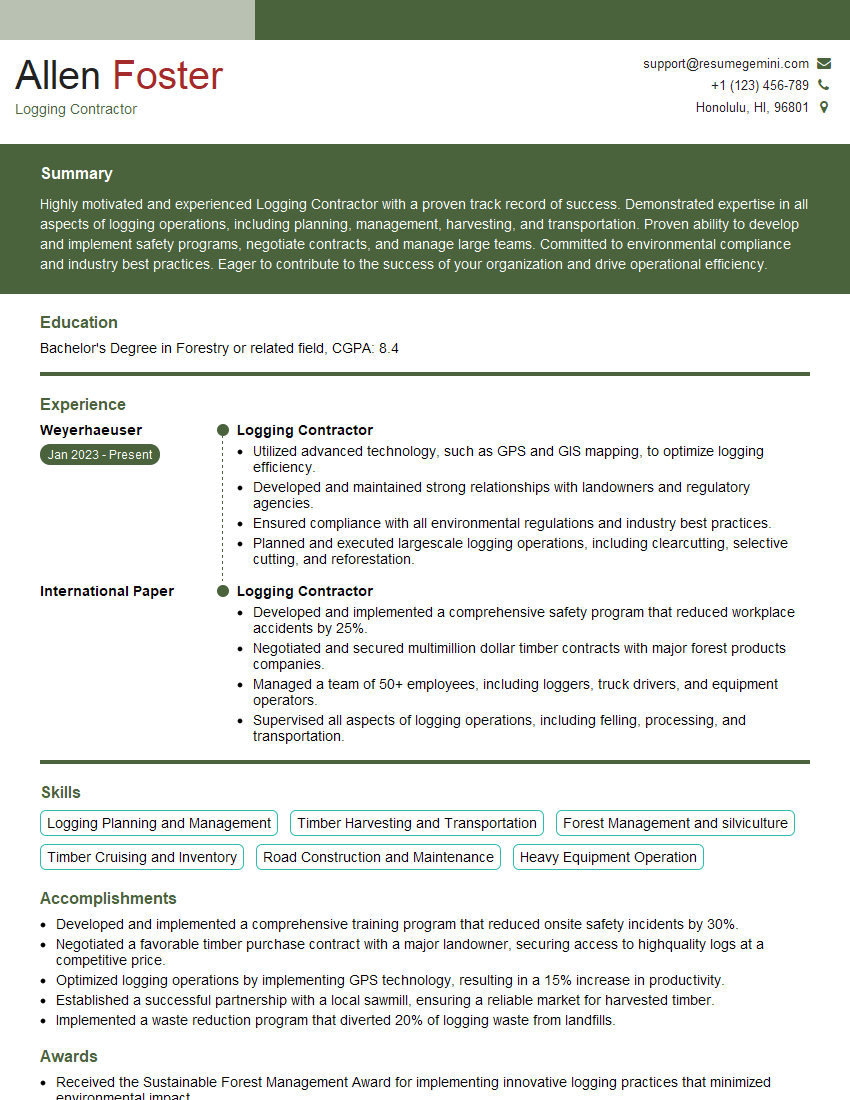

Mastering Bucking and Limbing Techniques is crucial for career advancement in forestry, arboriculture, and related fields. It demonstrates a commitment to safety, skill, and efficiency, making you a highly valuable asset to any team. To maximize your job prospects, focus on creating an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource to help you build a professional and impactful resume that showcases your skills and experience effectively. Examples of resumes tailored to Bucking and Limbing Techniques are available to guide you through the process. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good