Are you ready to stand out in your next interview? Understanding and preparing for Advanced Rigging and Load Handling interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Advanced Rigging and Load Handling Interview

Q 1. Explain the different types of rigging hardware and their applications.

Rigging hardware is the backbone of any safe and efficient lift. It encompasses a wide array of components, each designed for specific purposes. Understanding their applications is crucial for selecting the right equipment and preventing accidents.

- Shackles: These are U-shaped metal connectors with a screw pin or bolt for securing a load. They’re incredibly versatile, used for connecting slings to hooks or other rigging points. Different shackle types (bow, screw pin, etc.) offer varying strengths and applications. For example, a screw pin shackle provides better security against accidental opening compared to a bow shackle.

- Slings: These are the primary load-bearing components, coming in various materials (nylon, polyester, wire rope) and configurations (round, endless, choker). The choice depends on the load’s characteristics (weight, shape, fragility) and the environment. A wire rope sling is suitable for heavy, durable loads, while a synthetic sling might be preferred for delicate items to prevent scratching.

- Hooks: These are essential for connecting slings to cranes or other lifting mechanisms. They come in various designs, such as single, double, or grab hooks, each with its specific load capacity and application. Always check for hook damage before use; a bent hook is a serious safety hazard.

- Eye Bolts: These are threaded bolts with a ring at one end, providing a secure attachment point for slings or other rigging components. Their use is often critical when lifting from pre-existing attachment points on the load itself. Ensure the eye bolt’s capacity is sufficient for the load.

- Turnbuckles: These are adjustable connectors that allow for fine-tuning the length of a sling or other rigging component. They’re essential for achieving proper tension and alignment before a lift. Never exceed the manufacturer’s specified tension limit.

Choosing the right hardware is not just about strength; it also considers factors like corrosion resistance, material compatibility, and ease of use. A thorough understanding of each piece and its limitations is paramount for safe rigging operations.

Q 2. Describe the process of calculating safe working loads for various rigging configurations.

Calculating safe working loads (SWLs) for rigging configurations requires a methodical approach, factoring in numerous variables. The process isn’t a simple formula; it demands an understanding of physics, material properties, and the limitations of equipment.

Step 1: Determine the weight of the load. This might seem obvious, but accurately weighing or estimating the load’s mass is fundamental. Overestimating is always safer than underestimating.

Step 2: Account for rigging configuration. The way slings are arranged significantly affects the load distribution. A single sling directly supports the load’s weight. However, with multiple slings, angle of slings becomes critical. The load is shared, but the angle reduces the effective load-bearing capacity of each sling. Trigonometric calculations are typically employed to determine the load on each sling.

Step 3: Consider the SWL of individual components. Each piece of rigging hardware—shackles, slings, hooks—has a clearly defined SWL. The overall system’s SWL is limited by the weakest component. A comprehensive inspection of all hardware is vital before any lifting operation.

Step 4: Apply safety factors. Safety factors are critical. These are multipliers applied to the calculated load to account for uncertainties and potential unforeseen stresses. The specific factor varies depending on the application, regulations, and risk assessment but generally ranges from 5 to 10, and often higher for critical operations.

Example: Consider lifting a 10,000 lb load with two slings at a 60-degree angle to the vertical. We’d use trigonometry to find the load on each sling, and then apply appropriate safety factors to ensure each component can handle the resulting stress. Any calculations should always be documented.

Software tools and engineering calculations are often used for complex configurations to ensure accuracy and safety. Consulting with qualified professionals is crucial, especially for high-risk or unusual lifting arrangements.

Q 3. What are the critical safety considerations when planning a complex rigging operation?

Safety is paramount in complex rigging operations. Overlooking even seemingly minor details can have catastrophic consequences. A comprehensive risk assessment is essential, encompassing these critical considerations:

- Load Securement: Proper load securing is fundamental. The load must be evenly distributed, preventing shifting or swaying during the lift. Consider using appropriate securing devices like load binders or straps in addition to the primary lifting slings.

- Environmental Factors: Wind, rain, and temperature can significantly impact the lift’s safety. High winds can make a load unstable, while rain or snow can increase its weight or reduce grip. Environmental conditions must be carefully assessed and appropriate precautions implemented.

- Personnel Safety: A clear communication plan is vital. Designated signal persons and a robust system for communicating instructions are needed. Exclusion zones around the lift should be established and maintained to protect personnel from falling objects or swinging loads. All personnel must wear appropriate PPE (Personal Protective Equipment).

- Equipment Inspection: A meticulous pre-lift inspection of all rigging equipment is mandatory. Look for signs of wear, damage, or corrosion. Any questionable equipment must be immediately replaced. Certificates of compliance and inspection records should be readily available and reviewed.

- Emergency Planning: A detailed emergency plan should be in place, addressing potential scenarios like equipment failure or unexpected load movement. Emergency procedures and escape routes should be clearly defined and practiced.

- Regulatory Compliance: All rigging operations must comply with relevant industry standards and regulations. Understanding and adhering to these requirements is non-negotiable.

A rigorous approach to safety isn’t just about following procedures; it’s about fostering a safety-conscious culture within the entire team. Regular training, clear communication, and a proactive approach to hazard identification are essential for preventing accidents.

Q 4. How do you determine the appropriate type of crane and lifting equipment for a specific load?

Selecting the appropriate crane and lifting equipment is crucial for a successful and safe lift. The choice depends on several factors:

- Load Weight and Dimensions: The crane’s lifting capacity must exceed the load’s weight, including any rigging hardware. The crane’s reach and the load’s dimensions must also be considered to ensure proper stability and maneuverability.

- Load Characteristics: The load’s center of gravity, shape, and fragility influence the choice of lifting equipment. Delicate loads require specialized lifting attachments to prevent damage.

- Work Environment: The site’s terrain, obstructions, and accessibility impact crane selection. Limited space might necessitate a smaller, more maneuverable crane, while difficult terrain may require a crane with specialized undercarriage.

- Lifting Height and Reach: The crane’s boom length and lifting height must be sufficient to reach the required height and position the load accurately.

For example, lifting a heavy, bulky piece of machinery in a confined space would require a crane with high lifting capacity and a short boom, maybe even a mobile crane. Conversely, lifting a lighter load to a high altitude requires a crane with a long reach and sufficient height capability. Detailed load charts provided by the crane manufacturer must be consulted to ensure the selected equipment is appropriate for the job.

The selection process often involves detailed calculations and risk assessments. Consulting with experienced crane operators and engineers is recommended to ensure the correct equipment is chosen and used safely.

Q 5. Explain the importance of pre-lift inspections and what they entail.

Pre-lift inspections are not merely a formality; they’re a critical safety measure that can prevent accidents and equipment damage. A thorough inspection should be performed before every lift, regardless of its complexity. It’s a systematic check that verifies everything is in good working order.

What a pre-lift inspection entails:

- Visual Inspection of Rigging Equipment: This includes checking slings, shackles, hooks, and other hardware for wear and tear, corrosion, damage, and proper lubrication. Any signs of damage, including fraying, cracks, or deformation, necessitate immediate replacement.

- Verification of Load Securement: Confirming that the load is properly secured and balanced is vital to prevent shifting or dropping during the lift. Proper load distribution and securing devices should be inspected.

- Crane Inspection: A thorough check of the crane’s components is necessary, paying close attention to hydraulics, brakes, controls, and structural integrity. Confirming operational checks and inspection logs are crucial.

- Ground Conditions: The lifting area needs to be assessed for stability and potential hazards. Ensure the ground is level and firm, free from obstructions or soft spots that could compromise the crane’s stability.

- Weather Conditions: Check for wind speeds, rain, and other weather factors that could affect the lift’s safety. Wind speeds beyond the operational limits of the equipment should halt the lift.

- Documentation: A comprehensive checklist should be used to record all inspection findings. Any discrepancies or issues should be documented and addressed before proceeding.

A pre-lift inspection isn’t just about ticking boxes; it’s about ensuring a safe work environment for everyone involved. It’s a proactive approach to hazard identification and mitigation.

Q 6. Describe your experience with different types of slings and their limitations.

I have extensive experience with various types of slings, each having its own advantages and limitations. The right choice depends on the load’s characteristics and the lifting environment.

- Wire Rope Slings: These are strong and durable, ideal for heavy, durable loads. However, they can be susceptible to kinking or damage if improperly handled. Their relatively high stiffness can also cause damage to delicate loads.

- Synthetic Web Slings: These slings (nylon or polyester) are lighter and more flexible than wire rope slings, offering better protection for delicate loads and easier handling. They are resistant to abrasion but can be vulnerable to sharp edges and chemicals.

- Chain Slings: These are exceptionally strong and resistant to abrasion, making them suitable for lifting heavy, rough loads. However, they can be heavier and less flexible than synthetic slings, and improper handling can lead to damage.

Limitations: Each sling type has specific limitations. Wire rope slings can be damaged by kinking or crushing. Synthetic slings can be weakened by UV exposure or chemical contact. Chain slings can be damaged by overloading or impact. Knowing these limitations and using slings appropriate to the application, including understanding the safe working load (SWL) for specific sling angles, is crucial for safe lifting operations.

For example, in a situation involving a delicate piece of equipment with sharp corners, a synthetic web sling would be a safer choice than a wire rope sling, which would likely cause damage. Always check sling condition before each use and retire them when they show signs of wear or damage.

Q 7. How do you handle unexpected challenges or equipment malfunctions during a rigging operation?

Unexpected challenges and equipment malfunctions are inherent risks in rigging operations. A well-trained rigger is prepared to handle these situations calmly and effectively. My approach involves a combination of experience, problem-solving skills, and adherence to safety protocols.

Steps to address unexpected challenges:

- Assess the Situation: The first step is to accurately assess the nature and severity of the problem. This includes identifying the malfunctioning equipment, the extent of the risk, and any immediate dangers.

- Implement Immediate Safety Measures: The immediate priority is to ensure the safety of personnel. This might involve securing the load, evacuating the area, or activating emergency procedures.

- Diagnose the Problem: Try to determine the root cause of the malfunction or challenge. This may involve inspecting the equipment, consulting manuals, or seeking assistance from colleagues.

- Develop a Solution: Based on the diagnosis, develop a plan to address the issue. This might include replacing faulty equipment, modifying the rigging configuration, or implementing alternative lifting methods.

- Implement the Solution Safely: Execute the solution methodically and safely, ensuring compliance with all safety protocols. Any changes to the initial plan require careful consideration and may necessitate additional safety measures.

- Post-Incident Review: After resolving the issue, conduct a thorough review to identify any underlying causes that contributed to the challenge and to implement preventative measures for future operations.

For example, if a sling breaks during a lift, the immediate priority is to secure the load to prevent it from falling. Then, assess the damage, replace the sling with a suitable alternative, and ensure the rest of the equipment is safe before resuming the lift. Documentation of the entire process is crucial.

Effective communication is critical during such situations. Maintaining clear communication with all team members is vital for ensuring everyone understands the situation and the steps being taken to address it.

Q 8. What are your preferred methods for communicating safety procedures to a rigging crew?

Effective communication is paramount in rigging, where a single misunderstanding can lead to serious consequences. My preferred methods involve a multi-pronged approach. Firstly, I conduct thorough pre-lift briefings, utilizing clear and concise language, avoiding jargon unless absolutely necessary and ensuring everyone understands their roles and responsibilities. I use visual aids like diagrams and sketches of the rigging plan to complement verbal instructions. Secondly, I emphasize hands-on demonstrations, allowing the crew to physically practice procedures under supervision. This ensures everyone understands the practical application of safety protocols. Finally, I encourage open communication throughout the operation. I establish a clear chain of command, with designated personnel responsible for reporting concerns or potential hazards immediately. For instance, during a recent petrochemical plant project, a pre-lift briefing with a detailed diagram of the lifting configuration, followed by a hands-on demonstration of the crane hook-up procedure, prevented potential miscommunication and ensured a safe lift.

Q 9. Explain the concept of load stability and how to maintain it.

Load stability refers to the ability of a suspended load to remain balanced and controlled throughout the lift. Maintaining it is crucial to prevent swinging, tipping, or accidental release. Key factors include the load’s center of gravity, the rigging configuration, and environmental factors like wind. To ensure stability, we begin with a thorough load assessment, determining its weight, dimensions, and center of gravity. The rigging configuration is meticulously planned to center the load and distribute the weight evenly. For example, using spreader beams prevents loads from twisting or shifting during the lift. Proper tensioning of slings and straps also plays a vital role. Finally, we consider environmental factors, such as wind speed and direction, and adjust the lift plan accordingly, perhaps postponing the lift if conditions are too hazardous. Remember, a well-planned lift considers all these elements; an improperly secured load is a recipe for disaster.

Q 10. How do you ensure compliance with relevant safety regulations and standards (e.g., OSHA)?

Compliance with safety regulations is non-negotiable. I maintain compliance by staying updated on the latest OSHA (or equivalent) standards, attending relevant training courses, and actively incorporating these standards into all aspects of my work. This includes meticulous record-keeping, ensuring all permits and inspections are completed and documented. We also conduct regular toolbox talks to refresh the crew on safety protocols, address any specific concerns, and discuss lessons learned from past incidents, both ours and industry-wide. For example, a recent project involving a particularly heavy load required us to obtain specialized permits and adhere to stringent load testing procedures, going beyond the minimum OSHA requirements to ensure complete safety and compliance.

Q 11. Describe your experience with different rigging techniques, such as chokering, bridling, and spreader beams.

My experience encompasses a wide range of rigging techniques. Chokering involves using a sling to secure a load around a single point, often requiring careful consideration of the load’s shape and weight distribution. Bridling uses multiple slings attached to a single load, distributing weight more evenly and providing greater stability, especially useful for oddly shaped objects. Spreader beams are essential for large and bulky objects; they distribute the weight across multiple points, minimizing stress on individual slings and preventing load instability. I have extensive experience using each technique, selecting the appropriate method based on the load’s characteristics, the lifting equipment available, and the environmental conditions. For instance, in one project, we used a complex bridling system with multiple load cells for a particularly delicate piece of machinery, guaranteeing its safe transport. For another, moving large steel beams required the use of spreader beams to prevent damage and ensure a smooth lift.

Q 12. What is your experience with load monitoring and control systems?

Load monitoring and control systems are vital for ensuring safe and efficient lifts, particularly in high-risk environments. My experience includes utilizing both basic load indicators, such as shackles with load pins, and advanced systems that provide real-time data on load weight, tension, and movement. I’m proficient in interpreting this data, making necessary adjustments to the lift plan, and ensuring that the load remains within the safe working limits of the equipment. Modern systems integrate with crane control systems, providing automatic alerts when safety thresholds are approached. I can not only operate these systems but also troubleshoot them and determine whether they are suitable for a given project. A recent project involving the precise positioning of a reactor vessel benefited greatly from real-time load monitoring. Any deviation from the planned trajectory was immediately detected and corrected, preventing potential damage and injuries.

Q 13. How do you develop a rigging plan for a complex project?

Developing a rigging plan for a complex project requires a systematic approach. It begins with a thorough site survey and risk assessment, identifying all potential hazards and constraints. The next step involves gathering detailed information about the load, including its weight, dimensions, center of gravity, and any fragility considerations. We then select appropriate rigging equipment based on load characteristics, considering factors like sling type, length, and capacity. This is followed by the development of detailed lift plans, including lift diagrams, load calculations, and safety procedures. All calculations are checked and rechecked, and the plan is reviewed by multiple team members to ensure safety and efficiency. For instance, a recent project to lift a large transformer required careful coordination with the crane operator, the placement of the lifting points, and the timing of movements. The detailed plan mitigated any risks and ensured a flawless operation.

Q 14. Describe your experience with risk assessments related to rigging operations.

Risk assessments are an integral part of every rigging operation. My approach involves a systematic process using established methodologies, identifying potential hazards during each stage of the lift. This includes assessing the equipment’s condition, the competence of the crew, environmental factors, and potential interactions with other operations on the site. For each hazard identified, we determine the likelihood and severity of the consequences and implement appropriate control measures. These measures can range from simple procedural changes, such as additional spotters or more detailed checklists, to more significant interventions such as specialized equipment or work method adjustments. We always document these assessments and mitigation strategies, making them readily available to the crew. For example, a project involving a lift near high-voltage power lines necessitated a detailed risk assessment, including measures like establishing a safety exclusion zone and appointing a dedicated electrical safety officer. Thorough risk assessment prevents accidents and ensures a safe working environment.

Q 15. What are your experience with different types of lifting equipment?

My experience encompasses a wide range of lifting equipment, from basic chain hoists and lever blocks to sophisticated crane systems and specialized lifting beams. I’m proficient in using both manual and powered equipment, including hydraulic jacks, air hoists, and various types of cranes – tower cranes, mobile cranes, and overhead cranes. My experience extends to assessing the suitability of equipment for specific lifting tasks, considering factors such as load capacity, reach, and operational environment. For instance, I’ve worked extensively with magnetic lifters for handling steel plates in a shipyard setting, and I’ve used vacuum lifters for delicate glass panels in a construction project. A key aspect of my expertise is understanding the limitations of each piece of equipment and implementing appropriate safety measures.

- Chain hoists: Used frequently for lighter loads requiring precise vertical movement.

- Lever blocks: Simple, manual devices ideal for situations without power.

- Hydraulic jacks: Powerful for lifting heavy objects in controlled increments.

- Mobile cranes: Versatile for lifting various loads in diverse locations.

- Overhead cranes: Efficient for lifting loads within a confined area, like a factory.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle emergency situations during lifting operations?

Emergency situations during lifting operations require immediate, decisive action. My approach follows a structured protocol: Assess, Alert, Act, Analyze.

- Assess: Quickly determine the nature of the emergency (e.g., load shifting, equipment malfunction, structural failure). Is there an immediate danger to personnel or property?

- Alert: Immediately activate emergency procedures, including notifying all personnel in the area, ceasing operations, and contacting emergency services if necessary.

- Act: Based on the assessment, take appropriate actions. This may involve lowering the load slowly and cautiously, securing loose components, or evacuating the area. Using the right communication methods is crucial.

- Analyze: Once the immediate danger is mitigated, conduct a thorough investigation to identify the root cause of the emergency. This is crucial for preventing future incidents. Detailed documentation is vital during this phase.

For example, if a load starts to swing unexpectedly, I would immediately signal the crane operator to stop lifting and carefully lower the load. If a cable snaps, I would prioritize personnel safety, ensuring a safe distance from the falling load before addressing the situation.

Q 17. Explain the importance of proper documentation and record keeping in rigging operations.

Proper documentation and record-keeping are paramount for safety, legal compliance, and continuous improvement in rigging operations. Detailed records provide a critical audit trail, enabling traceability for any incidents and facilitating investigations. Documentation should include:

- Pre-lift inspection reports: Detailing the condition of all equipment, including slings, chains, hooks, and the lifting device.

- Lifting plans: Outlining the procedure, including the load weight, center of gravity, lifting points, and rigging configuration.

- Risk assessments: Identifying potential hazards and mitigation strategies.

- Incident reports: Documenting any unforeseen events, near misses, or accidents, along with corrective actions.

- Maintenance logs: Tracking equipment maintenance and inspections.

These records are invaluable for demonstrating adherence to safety regulations, identifying trends, and improving operational efficiency. They are also crucial in case of legal disputes or insurance claims.

Q 18. How do you determine the proper angle of lift for a load?

Determining the proper angle of lift is crucial to maintain stability and prevent load instability. An ideal angle keeps the load’s center of gravity directly under the lifting point, minimizing stress on the rigging and reducing the risk of tipping or swinging. Factors to consider include:

- Load geometry: The shape and dimensions of the load significantly affect the appropriate angle of lift.

- Load weight distribution: Uneven weight distribution requires careful consideration of the angle to maintain balance.

- Lifting equipment capacity: The chosen equipment’s capacity and limitations influence the permissible lift angle.

- Environmental conditions: Wind and other environmental factors may need adjustments to the lifting angle.

Using load charts and calculations, one must ensure the stresses imposed by the angle do not exceed the lifting equipment’s capacity. A large angle can create excessive side loads on the lifting points, while a very small angle might cause excessive stress on other parts of the system.

Example: Lifting a long, slender beam requires a near-vertical lift to prevent swaying and potential damage. Conversely, lifting a wide, flat object may allow for a slight angle, provided calculations confirm it’s within the safe operating limits.

Q 19. What is your experience with different types of knots and hitches used in rigging?

My experience with knots and hitches is extensive, covering a wide range appropriate for various rigging applications. I’m proficient in both basic and advanced knots, ensuring the selection aligns with the load’s characteristics and the rigging configuration. Some commonly used knots and hitches include:

- Bowline: A versatile, reliable knot forming a fixed loop that will not slip.

- Clove hitch: A simple knot easily adjustable around a post or other object.

- Figure-eight knot: Used to prevent ropes from running through a pulley.

- Running bowline: Creates a sliding loop for adjustable rigging.

- Carrick bend: Connects two ropes of similar diameter.

The choice of knot depends greatly on the specific application, the type of rope, and the load requirements. Incorrect knot selection can lead to serious accidents. I always double-check each knot and confirm its security before commencing any lift.

Q 20. Describe your understanding of load center and its significance in lifting operations.

The load center is the point on a load where its total weight is considered to be concentrated. It’s crucial for safe lifting because it determines the stability of the load during the lift. If the load center isn’t properly positioned, there’s a significant risk of the load swinging, tilting, or otherwise becoming unstable, potentially causing an accident. Knowing the load center helps determine the correct rigging configuration to maintain stability.

Determining the load center: This is often done by visually inspecting the load and its weight distribution, or through calculations based on detailed load dimensions and weight information. For complex loads, specialized software or engineering analysis may be required.

Significance in Lifting: Accurate load center determination allows for:

- Proper sling placement: Ensuring even weight distribution to avoid stress concentration.

- Stable lift: Minimizing the risk of swinging or tilting during the lift.

- Appropriate crane operation: Allowing for precise control of the load during movement.

Failing to properly account for the load center can lead to significant hazards, including equipment damage, load instability, and injury to personnel.

Q 21. Explain how environmental factors affect rigging operations.

Environmental factors significantly impact rigging operations, potentially compromising safety and efficiency. These factors require careful consideration and appropriate mitigation strategies. Key environmental concerns include:

- Wind: High winds create significant forces on suspended loads, increasing the risk of instability and swaying. Wind speed and direction must be carefully assessed, and lifting operations may need to be suspended or modified in strong winds.

- Temperature: Extreme temperatures can affect the strength and properties of rigging materials, such as steel and synthetic ropes. Cold temperatures can embrittle steel, while heat can weaken synthetic fibers. Appropriate material selection and adjustments to operating procedures are crucial.

- Precipitation: Rain, snow, or ice can increase the weight of the load, reduce friction, and make surfaces slippery. This can increase the risk of accidents and necessitate adjustments to lifting techniques and safety precautions.

- Visibility: Poor visibility due to fog, rain, or darkness can hinder communication and make it difficult to monitor the lift. Additional lighting or other safety measures might be required.

Proper risk assessments that take into account these environmental factors are vital for planning safe and effective rigging operations. Flexibility in adjusting lifting procedures is a must to compensate for the ever-changing environmental conditions.

Q 22. How do you identify potential hazards associated with different rigging configurations?

Identifying potential hazards in rigging configurations requires a systematic approach. It starts with a thorough understanding of the load – its weight, center of gravity, dimensions, and any inherent instability. Then, we analyze the rigging plan itself, considering the type and condition of the equipment (slings, shackles, hooks, etc.), the angles of the lift, and the structural integrity of the lifting points on the load and the supporting structure.

For example, a high-angle lift using a single sling can create significant stress on the sling and potentially cause it to fail. Conversely, using too many slings with unequal loading can create an unbalanced lift, leading to instability and potential damage. We also consider environmental factors like weather conditions (wind, rain) that might affect the stability of the lift. A checklist approach, coupled with experience and careful observation, is crucial. We might use a risk assessment matrix to quantify potential risks.

- Analyze Load Characteristics: Weight, center of gravity, shape, fragility.

- Evaluate Rigging Hardware: Type, capacity, condition, certification.

- Assess Lifting Points: Strength, suitability, and secure attachment.

- Consider Environmental Factors: Wind, rain, temperature, ground conditions.

- Check for Obstructions: Overhead power lines, nearby personnel, or equipment.

Q 23. What are the common causes of rigging accidents, and how can they be prevented?

Rigging accidents stem from a variety of causes, many stemming from human error. Common causes include improper rigging techniques, using damaged or overloaded equipment, inadequate planning, and a lack of training. Prevention hinges on rigorous adherence to safety protocols.

- Improper Rigging Techniques: Incorrect sling angles, improper hitching, insufficient support points, leading to unbalanced loads and sling failure. Prevention: Thorough training, clear and detailed rigging plans, and rigorous supervision.

- Damaged or Overloaded Equipment: Using equipment beyond its rated capacity or with visible damage (such as frayed wire rope or cracked shackles). Prevention: Regular inspections, adherence to equipment capacity ratings, and immediate removal of damaged equipment from service.

- Inadequate Planning: Failure to adequately assess the load, the environment, or potential hazards. Prevention: Detailed risk assessments, comprehensive rigging plans developed by experienced personnel, and pre-lift meetings.

- Lack of Training: Personnel unfamiliar with safe rigging practices and emergency procedures. Prevention: Mandatory and regular safety training for all involved, including hands-on practice and competency assessments.

Think of it like building a house – if you skip steps or use inferior materials, the whole structure is at risk. Rigging is no different; meticulous planning and execution are critical for safety.

Q 24. What is your experience with different types of load securing devices?

My experience encompasses a wide range of load securing devices, including various types of slings (chain, wire rope, synthetic), shackles, hooks, and specialized lifting attachments. I’m proficient in selecting the appropriate device for a given task, considering factors such as load weight, material compatibility, and environmental conditions. For instance:

- Chain slings: Durable, versatile, suitable for heavy loads and high temperatures. I understand the importance of proper lubrication and inspecting for wear and elongation.

- Wire rope slings: Strong, but susceptible to corrosion and fatigue. I know how to inspect for broken wires, kinks, and correct fitting procedures.

- Synthetic slings: Lightweight, easy to handle, but susceptible to abrasion and UV degradation. I’m experienced in recognizing signs of wear and tear and selecting appropriate slings for the environment.

- Shackles: Crucial connecting links, requiring thorough inspection for cracks and proper pin engagement. I understand the various types (bow, screw pin) and their appropriate applications.

My experience also involves the use of specialized devices like spreader beams, which improve stability during lifts and reduce stress on individual slings. I always prioritize the correct selection of equipment based on load specifications and safety regulations.

Q 25. Describe your knowledge of different types of wire rope and their applications.

Wire rope comes in various constructions, each with its own properties and applications. The core, strands, and wires all impact the rope’s strength, flexibility, and resistance to wear. For example:

- 6×19 Construction: Offers a good balance of flexibility and strength, commonly used in general-purpose applications.

- 6×7 Construction: More resistant to abrasion than 6×19, but less flexible, suitable for applications with higher wear and tear.

- 6×36 Construction: Higher flexibility and better fatigue resistance, ideal for applications requiring frequent bending.

- Improved Plow Steel (IPS): A high-strength construction often used in demanding applications where maximum strength is needed.

Material also plays a crucial role. Galvanized wire rope offers corrosion resistance, while stainless steel wire rope provides superior corrosion protection but at a higher cost. Selecting the right wire rope involves considering the load, operating conditions (e.g., environment), and the required lifespan. I’ve worked extensively with all these types and understand their limitations.

Q 26. Explain the importance of regular maintenance and inspection of rigging equipment.

Regular maintenance and inspection are paramount to ensuring the safety and longevity of rigging equipment. Neglecting this can lead to catastrophic failures. Inspections should be conducted before each use and following any significant event (e.g., a near miss). Regular maintenance ensures early detection of problems, preventing accidents.

- Visual Inspection: Checking for visible damage, such as broken wires, corrosion, kinks, cuts, or deformations. This includes checking for proper lubrication of chain slings.

- Load Testing: Periodic load testing of equipment verifies its ability to handle rated loads. This is particularly important for critical lifts.

- Documentation: Maintaining thorough records of inspections, maintenance, and repairs is essential for tracking equipment history and ensuring compliance with regulations.

- Retirement Criteria: Establishing clear criteria for retiring damaged or worn-out equipment. This prevents the use of compromised equipment.

Think of it like a car – regular servicing extends its life and prevents breakdowns. Similarly, regular maintenance on rigging equipment minimizes the risk of failure and ensures safe operation.

Q 27. What are your experience with using rigging software for planning and analysis?

I have extensive experience using rigging software for planning and analysis. These programs allow for the simulation of complex lifts, providing crucial insights into stress levels, stability, and potential hazards. Software can help optimize rigging configurations, minimizing risks and ensuring safe operation.

For example, I’ve used software to model the lift of a large transformer, analyzing the stresses on each sling and the overall stability of the lift. The software helped determine the optimal number and placement of slings, minimizing stress concentrations and preventing potential failures. It allowed for ‘what-if’ scenarios, enabling the evaluation of various rigging configurations before commencing the actual lift, improving the safety and efficiency of the operation.

Specific software packages I’m familiar with include [mention specific software names if comfortable; otherwise omit this sentence] – these provide detailed analysis including finite element analysis for complex scenarios.

Q 28. Describe a challenging rigging situation you’ve encountered and how you resolved it.

One challenging situation involved lifting a massive, irregularly shaped piece of industrial equipment into a tight space with limited access. The initial rigging plan, based on readily available information, proved inadequate due to the equipment’s unexpected weight distribution and the restricted clearance.

The problem was the risk of the load swaying dangerously close to nearby structures. My solution involved a multi-pronged approach:

- Detailed on-site assessment: I conducted a thorough inspection of the equipment, precisely determining its center of gravity and overall dimensions.

- Revised rigging plan: I created a new plan that utilized a combination of spreader beams and multiple slings arranged to better distribute the load and maintain stability. This minimized the chance of swaying.

- Communication and coordination: Close collaboration with the crane operator and ground crew was vital in executing the modified plan smoothly and safely.

- Real-time adjustments: During the lift, we made minor adjustments based on real-time observation, ensuring that the load remained stable and clear of obstructions.

The successful execution of this modified plan highlighted the importance of adaptability, problem-solving, and effective teamwork in complex rigging operations. The situation underscores the need for flexibility and on-the-spot decision-making in challenging rigging scenarios.

Key Topics to Learn for Advanced Rigging and Load Handling Interview

- Rigging Hardware & Components: Understanding the strengths, weaknesses, and limitations of various shackles, slings, wire ropes, and other equipment. Consider practical applications like selecting appropriate hardware for different load types and environmental conditions.

- Load Calculations & Analysis: Mastering load distribution principles, center of gravity calculations, and stress analysis techniques. Practical application includes designing safe rigging plans for complex lifts and analyzing potential failure points.

- Lifting Techniques & Procedures: Familiarize yourself with various lifting methods (e.g., crane lifts, specialized lifting devices), safety protocols, and emergency procedures. Consider practical scenarios requiring efficient and safe execution of lifts.

- Risk Assessment & Mitigation: Developing a strong understanding of hazard identification, risk assessment methodologies, and implementing control measures to minimize potential accidents. Practical application involves creating pre-lift checklists and conducting thorough site surveys.

- Regulations & Compliance: Thorough knowledge of relevant safety regulations, industry best practices, and compliance standards. Practical application includes ensuring all rigging operations adhere to legal and ethical guidelines.

- Troubleshooting & Problem Solving: Ability to identify and resolve issues related to rigging equipment, load instability, and unexpected situations. Consider practical scenarios involving equipment malfunction or changing weather conditions.

- Communication & Teamwork: Effective communication with crane operators, ground crew, and other team members is crucial. This includes clear signaling, concise instructions, and maintaining open communication channels.

Next Steps

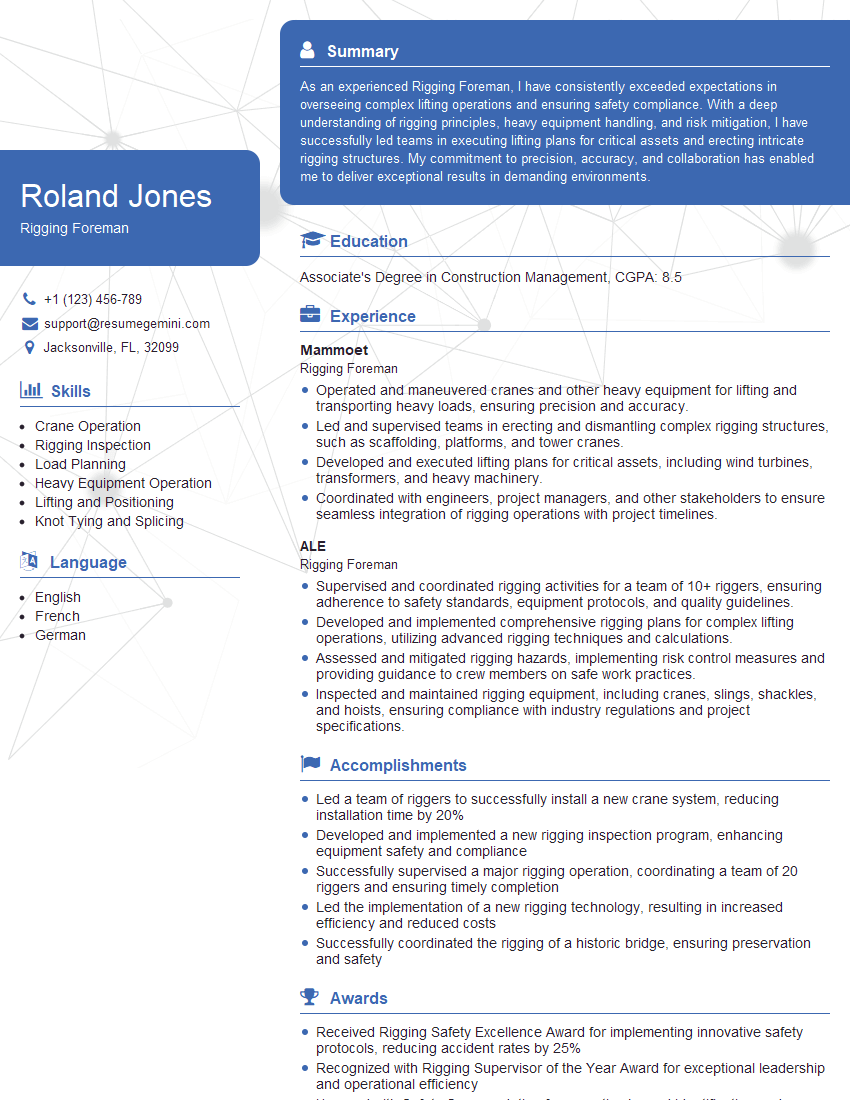

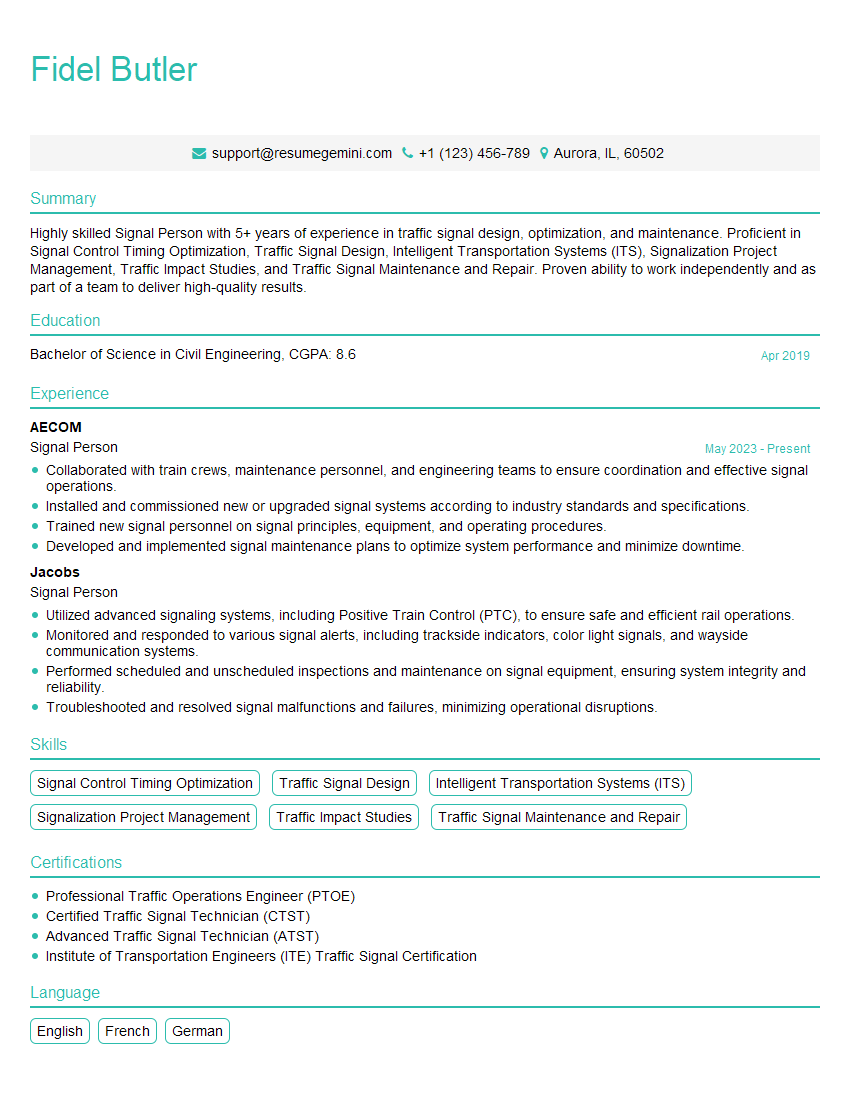

Mastering Advanced Rigging and Load Handling is crucial for career advancement in this high-demand field. It demonstrates a commitment to safety, efficiency, and technical expertise, opening doors to higher-paying roles and increased responsibility. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional resumes, and we offer examples specifically tailored to the Advanced Rigging and Load Handling industry to help you present your qualifications in the best possible light. Take the next step toward your dream career – build your winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good