Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential NEC 2017 interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in NEC 2017 Interview

Q 1. Explain the difference between a grounded and ungrounded conductor.

The key difference between a grounded and an ungrounded conductor lies in its connection to earth. A grounded conductor, also known as a neutral conductor, is intentionally connected to earth at the service equipment. This connection provides a safe path for fault currents to flow back to the source, minimizing the risk of electric shock. Think of it like a safety valve – if something goes wrong, the current has a designated escape route. An ungrounded conductor, or hot conductor, is not intentionally connected to earth. It carries the electrical current to the load. It’s crucial to remember that ungrounded conductors are at a higher potential voltage and should be treated with extra caution.

Example: In a standard 120/240-volt residential system, the neutral conductor is grounded, while the two hot conductors are ungrounded.

Q 2. Describe the requirements for grounding electrode conductors.

Grounding electrode conductors (GEC) connect the grounding electrode system to the electrical service equipment. NEC 2017 outlines specific requirements for their installation to ensure effective grounding. These requirements include:

- Material: GECs must be of sufficient size and made of a corrosion-resistant material like copper or copper-clad steel. Their ampacity rating is not typically considered in this context, as their main function is not current-carrying, but rather, establishing a low-impedance path to earth.

- Size: The minimum size is dictated by Table 250.66 of the NEC, and it depends on the size of the grounding electrode and the type of grounding electrode used (e.g., grounding rod, metal water pipe).

- Protection: GECs must be protected from physical damage. This often involves using conduit or other protective measures.

- Connections: Connections must be made using approved methods, such as exothermic welding, to ensure a low-resistance connection.

- Number: Multiple GECs may be needed depending on the size of the system and grounding electrode resistances.

Practical Application: A properly sized and installed GEC is critical for ensuring the safety of electrical systems by providing a low-impedance path for fault currents, preventing dangerous voltage buildup, and protecting against electric shock.

Q 3. What are the ampacity requirements for different types of conductors?

Ampacity, or the current-carrying capacity of a conductor, is determined by several factors, including the conductor material, insulation type, installation method, and ambient temperature. The NEC provides tables (Table 310.15(B)(16) and others) to look up ampacity ratings for different conductor types and conditions. For instance, a copper conductor with THHN insulation will have a different ampacity rating than an aluminum conductor with XHHW insulation under the same conditions.

Example: A 12 AWG copper THHN conductor might have an ampacity of 20 amps in free air, but this could be reduced if installed in conduit or in high ambient temperatures. Always consult the NEC tables and any relevant manufacturer’s data to ensure you are using the correct ampacity ratings for the specific conditions of your project. Using conductors with inadequate ampacity can lead to overheating, fire hazards, and equipment failure.

Q 4. Explain the requirements for installing and sizing branch circuits.

Branch circuits are the portion of the wiring system extending beyond the final overcurrent device to the outlets. NEC 2017 provides detailed requirements for installing and sizing them:

- Sizing: Branch circuits are sized based on the anticipated load, which is determined by adding the load of all connected devices and appliances. The circuit breaker or fuse protects the wiring from overcurrent. You must select a conductor size with sufficient ampacity to handle the calculated load.

- Overcurrent Protection: Each branch circuit must have an overcurrent protective device (circuit breaker or fuse) sized appropriately to protect the conductors from overheating. The overcurrent protection device’s rating cannot exceed the conductor’s ampacity.

- Wiring Methods: Wiring methods must comply with the NEC’s requirements for installation methods, such as using appropriate conduits or cable types, proper grounding, and securing the wiring. They must be routed to avoid damage and adhere to spacing requirements for safety.

- Outlet Spacing: Outlets must be spaced appropriately to meet the NEC’s requirements for convenient use.

- Number of Outlets per Circuit: The NEC limits the number of outlets on a single branch circuit to prevent overloading.

Practical Application: A poorly sized or installed branch circuit can lead to overloaded circuits, causing overheating, fire hazards, and equipment damage. For example, plugging too many appliances into a single 15-amp circuit can trip the breaker, while improper wiring can lead to a fire. Proper sizing and installation are key to safety and reliability.

Q 5. What are the requirements for arc-fault circuit interrupters (AFCIs)?

Arc-fault circuit interrupters (AFCIs) are designed to protect against electrical fires caused by arcing faults. NEC 2017 mandates their use in specific locations:

- Bedrooms: AFCIs are required in all 120-volt, single-family dwelling unit branch circuits supplying outlets and lighting in bedrooms.

- Other Locations: AFCIs may be required in other areas of a dwelling unit depending on local regulations or as specified by the building codes.

- Types: There are two main types of AFCIs: combination-type (combining AFCI and GFCI protection) and dedicated AFCI breakers/receptacles.

- Testing: AFCIs require periodic testing and the test button should be routinely pressed to ensure the device functions correctly.

Important Note: AFCIs can sometimes trip on harmless arc events but still provide a valuable measure of safety by reducing the potential for electrical fires due to arcing faults.

Q 6. Describe the requirements for grounding and bonding.

Grounding and bonding are crucial for electrical safety. Grounding connects non-current-carrying metal parts of equipment and wiring to earth, providing a low-impedance path for fault currents. Bonding connects non-current-carrying metal parts to each other, equalizing electrical potentials and preventing voltage differences that could cause dangerous shocks or arcing. NEC 2017 covers both in detail:

- Grounding Electrode System: A grounding electrode system, consisting of interconnected electrodes (ground rods, metal water pipes, etc.), provides a path for fault currents to earth.

- Equipment Grounding Conductor: Connects the metal enclosures of equipment to the grounding electrode system, providing a path for fault currents to earth.

- Bonding: Connects metal enclosures and other non-current-carrying metal parts together, equalizing potentials and minimizing voltage differences.

- Bonding Jumper: A conductor used to connect metal parts for bonding.

Practical Application: Imagine a faulty appliance – if it’s properly grounded, a fault current will flow safely to earth through the grounding conductor, preventing a dangerous voltage from appearing on the appliance’s metal case. If not grounded, the case could become energized, posing a serious shock hazard. Bonding ensures that multiple metal enclosures are at the same potential, preventing arcing between them.

Q 7. Explain the requirements for installing and using GFCIs.

Ground Fault Circuit Interrupters (GFCIs) protect against electrical shock by detecting small current imbalances between the hot and neutral conductors. If a ground fault occurs, such as someone touching a live conductor, the GFCI trips, quickly interrupting the power and minimizing the risk of electrocution. NEC 2017 dictates their use in various locations:

- Bathrooms: GFCIs are required in all 120-volt, single-family dwelling branch circuits supplying receptacles in bathrooms.

- Kitchens: GFCIs are required in kitchens for receptacles on countertops.

- Garages: GFCIs are usually required in garages.

- Outdoor Receptacles: GFCIs are required for all outdoor receptacles.

- Other Locations: GFCIs may be required in other damp or wet locations.

- Testing: GFCIs must be tested regularly using their built-in test button to ensure they are functioning correctly.

Practical Application: GFCIs are a life-saving device, crucial for preventing electrocution in areas where the risk of contact with water or moisture is higher. The quick trip of the GFCI significantly reduces the duration of the shock, minimizing the danger.

Q 8. What are the requirements for overcurrent protection?

Overcurrent protection in NEC 2017 is crucial for preventing damage to equipment and ensuring safety. It involves using devices like fuses and circuit breakers to interrupt the flow of electricity when current exceeds safe levels. The requirements depend heavily on the type and size of the circuit and the equipment being protected.

- Sizing: Overcurrent protection devices must be sized to protect the conductors and equipment they serve, not exceeding their ampacity ratings. For example, a 15-amp circuit requires a 15-amp breaker, not a 20-amp one, to prevent wire overheating.

- Coordination: In systems with multiple levels of protection (e.g., panelboard breakers and branch circuit breakers), proper coordination is essential. Smaller breakers need to trip before larger ones to isolate the fault quickly and efficiently, preventing cascading failures.

- Specific Equipment: Certain equipment, like motors, transformers, and other specific loads, might require special consideration in choosing the correct overcurrent protection devices. NEC provides specific tables and calculations for these cases. This ensures appropriate protection without unnecessary nuisance tripping.

- Location: Overcurrent protection devices must be readily accessible and clearly marked. They should be located as close as practical to the load they protect.

Imagine a kitchen circuit overloaded by too many appliances. Without appropriate overcurrent protection, the wires could overheat, potentially causing a fire. A correctly sized and properly located breaker prevents this by tripping and cutting the power before things get dangerous.

Q 9. Explain the requirements for installing and using surge protection devices.

Surge protection devices (SPDs) are essential for protecting sensitive electronic equipment from voltage spikes or surges. The NEC 2017 outlines specific requirements for their installation and use to ensure effectiveness and safety.

- Location: SPDs should be installed as close as possible to the service entrance to divert surges before they reach sensitive equipment. They are typically placed in the electrical panel or a dedicated surge protection enclosure.

- Type Selection: The type of SPD (e.g., Type 1, Type 2, Type 3) needs to be chosen appropriately based on its location in the electrical system and the level of protection required. Type 1 SPDs are used at the service entrance, while Type 3 SPDs are often used at the point of use (e.g., protecting individual equipment).

- Grounding: Proper grounding of the SPD is critical to ensure that surges are diverted safely to the earth. Improper grounding can negate the protection offered by the SPD.

- Coordination: Similar to overcurrent protection, coordination between different SPDs in the system is necessary to ensure that the surge is effectively handled and directed to ground without damage to the system itself.

- Inspection and Maintenance: SPDs should be regularly inspected and tested to ensure they are functioning correctly. Many SPDs have built-in indicators to signal when they have been activated and may need replacement.

Think of an SPD as a lightning rod for your electrical system, diverting destructive voltage spikes away from your computers, appliances, and other sensitive equipment, preventing costly repairs or data loss.

Q 10. Describe the requirements for installing and using transformers.

Transformers are used to step up or step down voltage levels in electrical systems. The NEC 2017 covers various aspects of their installation and use, focusing on safety and proper operation.

- Location: Transformers should be installed in suitable locations that are dry, well-ventilated, and free from combustible materials. This prevents overheating and potential fire hazards.

- Overcurrent Protection: Transformers require proper overcurrent protection, often using fuses or circuit breakers sized according to the transformer’s rating. This protects against overload and short circuits.

- Grounding: Transformers must be properly grounded to protect against electric shock and to ensure safe operation. The grounding method depends on the transformer’s type and size.

- Clearances and Spacing: Appropriate clearances must be maintained around transformers to prevent accidental contact and to allow for adequate ventilation. These clearances are specified in the NEC based on voltage levels.

- Marking and Identification: Transformers must be clearly marked with their voltage ratings, kVA rating, and other relevant information for safe operation and maintenance.

Consider a distribution transformer on a utility pole. It steps down the high-voltage transmission line electricity to the lower voltage used in homes. Proper installation and maintenance, as per NEC guidelines, are critical to ensure its safe and reliable operation.

Q 11. What are the requirements for installing and using motors?

Motors are widely used in various applications and require specific considerations for safe installation and operation according to NEC 2017.

- Overload Protection: Motors require overload protection to prevent damage from excessive current draw. This is typically achieved through thermal protectors built into the motor or external overload relays. Overload protection should be sized to match the motor’s full-load current.

- Disconnecting Means: A readily accessible disconnecting means, such as a switch or circuit breaker, must be provided to isolate the motor from the power source for maintenance or emergency situations. This allows safe access for repair or maintenance.

- Grounding: Motors need proper grounding to protect against electric shock. This ensures that any faults will be grounded and that the motor’s metallic parts don’t become energized.

- Wiring Methods: The wiring methods for motor circuits must comply with NEC requirements, ensuring proper sizing of conductors, proper conduit, and protection against damage. This guarantees safe and reliable operation of the circuit.

- Enclosures: Motors may require specific enclosures based on their location and the environment. This protects the motor from dust, moisture, or other environmental factors.

Think of a large motor in a factory. Without proper overload protection, a jammed bearing or other problem could lead to excessive current, causing the motor windings to burn out. The NEC requirements ensure that the system will safely shut down in such a scenario.

Q 12. Explain the requirements for installing and using lighting fixtures.

Lighting fixtures, while seemingly simple, require careful installation and adherence to NEC 2017 to prevent hazards.

- Wiring and Connections: Wiring to lighting fixtures must comply with NEC requirements for conductor sizing, insulation types, and connection methods. This ensures that the circuits are adequately protected from overheating and that the connections are secure.

- Support and Mounting: Fixtures need to be securely mounted to support their weight and withstand normal vibrations. This prevents the fixtures from falling and causing injury or damage.

- Accessibility: Fixtures and their associated wiring must be readily accessible for maintenance and repairs. This allows easy inspection and replacement of components.

- Specific Fixture Types: Different types of lighting fixtures have specific requirements for installation, such as those for damp locations or outdoor applications. Using the wrong type of fixture in an inappropriate environment could lead to hazards like electric shock.

- Overcurrent Protection: Lighting circuits must be protected by overcurrent devices sized to prevent overheating. This prevents fire hazards and damage to the lighting circuits.

Imagine a bathroom fixture. Using a fixture not rated for damp locations could lead to a dangerous short circuit. The NEC’s requirements are there to prevent this and other potential issues.

Q 13. Describe the requirements for installing and using receptacles.

Receptacles, being commonly used outlets, have specific NEC 2017 requirements for installation that prioritize safety and accessibility.

- GFCI Protection: Receptacles in locations prone to moisture, such as bathrooms, kitchens, and outdoor areas, often require Ground Fault Circuit Interrupter (GFCI) protection to prevent electric shock. GFCIs quickly detect ground faults and shut off power before causing harm.

- Grounding: All receptacles must be properly grounded to ensure that a ground fault will not result in a shock. This protects people from electrical hazards.

- Spacing and Location: Receptacles must be appropriately spaced around a room for convenience and to avoid overloading circuits. They should also be located to avoid hazards, such as being obstructed or near water.

- Types and Ratings: Different types of receptacles exist (e.g., 15-amp, 20-amp, tamper-resistant), and the proper type must be selected to match the appliance and circuit requirements. Incorrect receptacle choice could cause overheating or failure.

- Accessibility: Receptacles must be easily accessible and not obstructed by furniture or other items.

Consider a kitchen countertop. Having GFCI protection on the receptacles is vital to prevent electric shocks if a person drops a wet appliance into the outlet.

Q 14. What are the requirements for installing and using switchboards?

Switchboards are central distribution points in electrical systems, and their installation is strictly governed by NEC 2017 for safety and reliability.

- Location: Switchboards must be installed in accessible, dry locations that are properly ventilated. This allows for easy maintenance and minimizes the risk of damage from moisture or heat.

- Clearances and Space: Sufficient clearances around the switchboard are required for safe access and maintenance. This allows electricians to work safely around the energized components.

- Overcurrent Protection: Switchboards contain overcurrent protection devices, such as circuit breakers or fuses, to protect the circuits and equipment they serve. These breakers are crucial for safety in case of a fault.

- Grounding: The switchboard must be properly grounded to ensure safety and proper operation. Grounding provides a path for fault currents to flow to ground, preventing electric shock and damage to equipment.

- Bonding: Metallic parts of the switchboard and its enclosure should be bonded together to prevent voltage differences and ensure electrical safety.

- Enclosures: Switchboards are usually housed in metal enclosures to provide protection against accidental contact with live parts. The enclosure type depends on the environment and application.

Think of the main electrical panel in a house. It’s the heart of the electrical system. The NEC’s strict requirements for switchboards ensure reliable and safe distribution of power.

Q 15. Explain the requirements for installing and using panelboards.

Panelboards, essentially the distribution centers of your electrical system, are governed by strict NEC 2017 guidelines. Their installation and usage hinge on safety and proper functionality. Key aspects include:

- Location: Panelboards must be readily accessible for maintenance and inspection, typically in dry, clean locations away from excessive heat or moisture. Imagine trying to work on a panelboard drenched in rain – a safety hazard!

- Clearances: Sufficient clearances must be maintained around the panelboard for ventilation and safe working space. NEC 2017 specifies minimum distances from walls, other equipment, and obstructions.

- Mounting: Secure mounting is crucial. They must be firmly attached to a structurally sound surface to prevent damage or accidental falls. Think of it like anchoring a ship – a sturdy foundation is vital.

- Overcurrent Protection: Each circuit within the panelboard needs proper overcurrent protection (circuit breakers or fuses) sized appropriately for the load. This prevents overheating and potential fires – a critical safety measure.

- Wiring: All wiring entering and exiting the panelboard must be properly supported and secured, using appropriate connectors and ensuring no loose connections. Think of it like neatly organizing cables in a computer – loose wires can create chaos.

- Marking: Clear labeling of circuits is mandatory for identification and maintenance purposes. Properly labeled circuits prevent confusion during troubleshooting and repairs.

Example: In a commercial kitchen, the panelboard supplying high-power appliances like ovens and fryers would require larger circuit breakers and more robust wiring compared to a panelboard for lighting in an office.

Career Expert Tips:

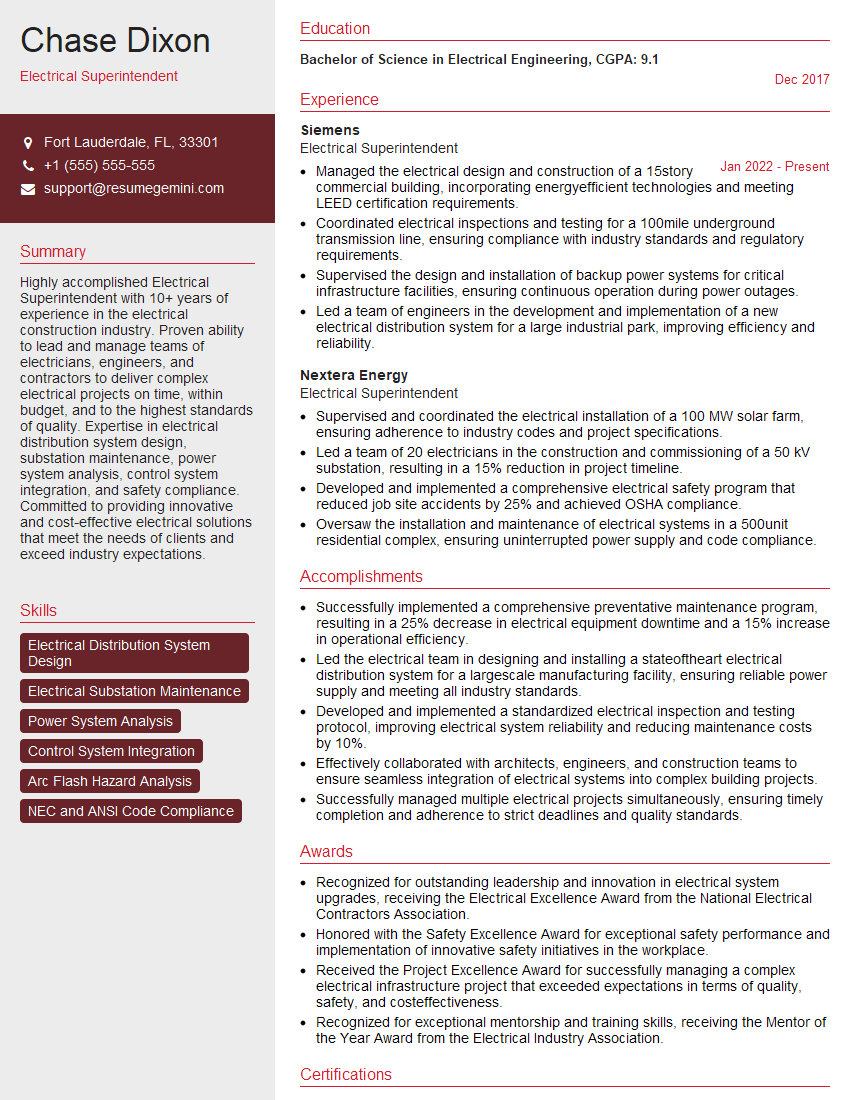

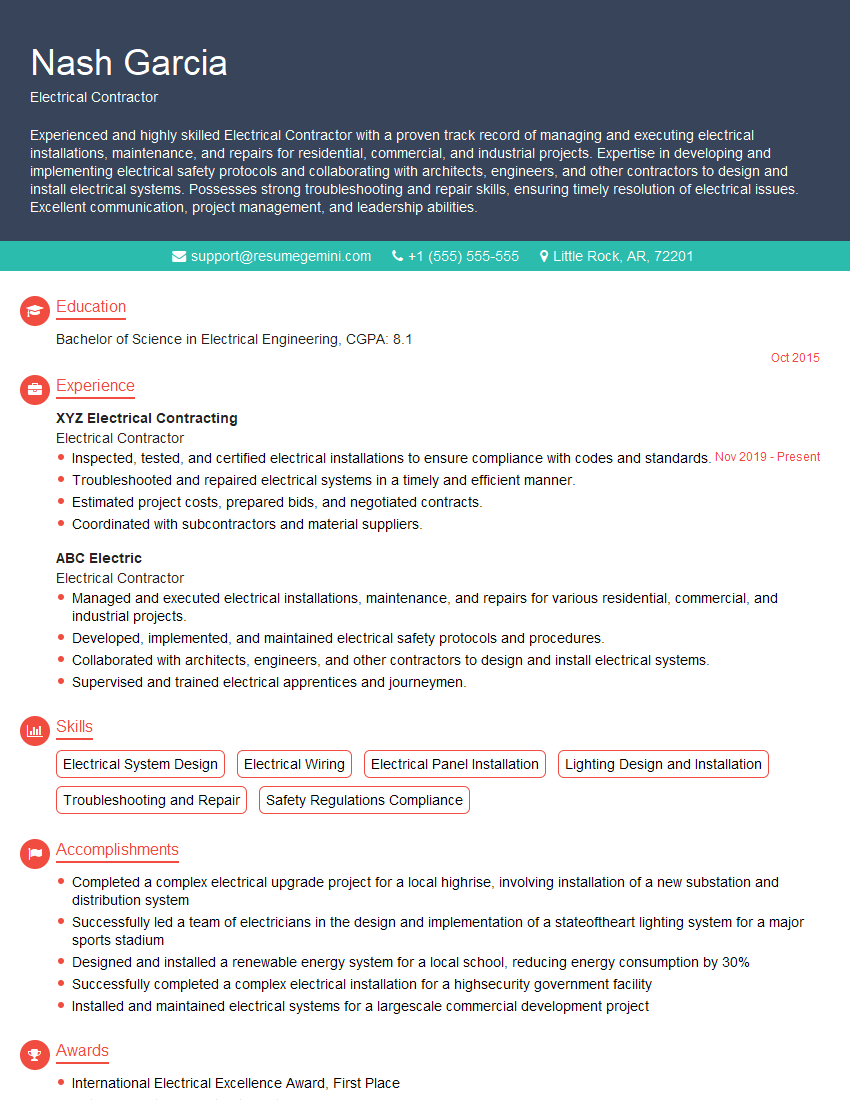

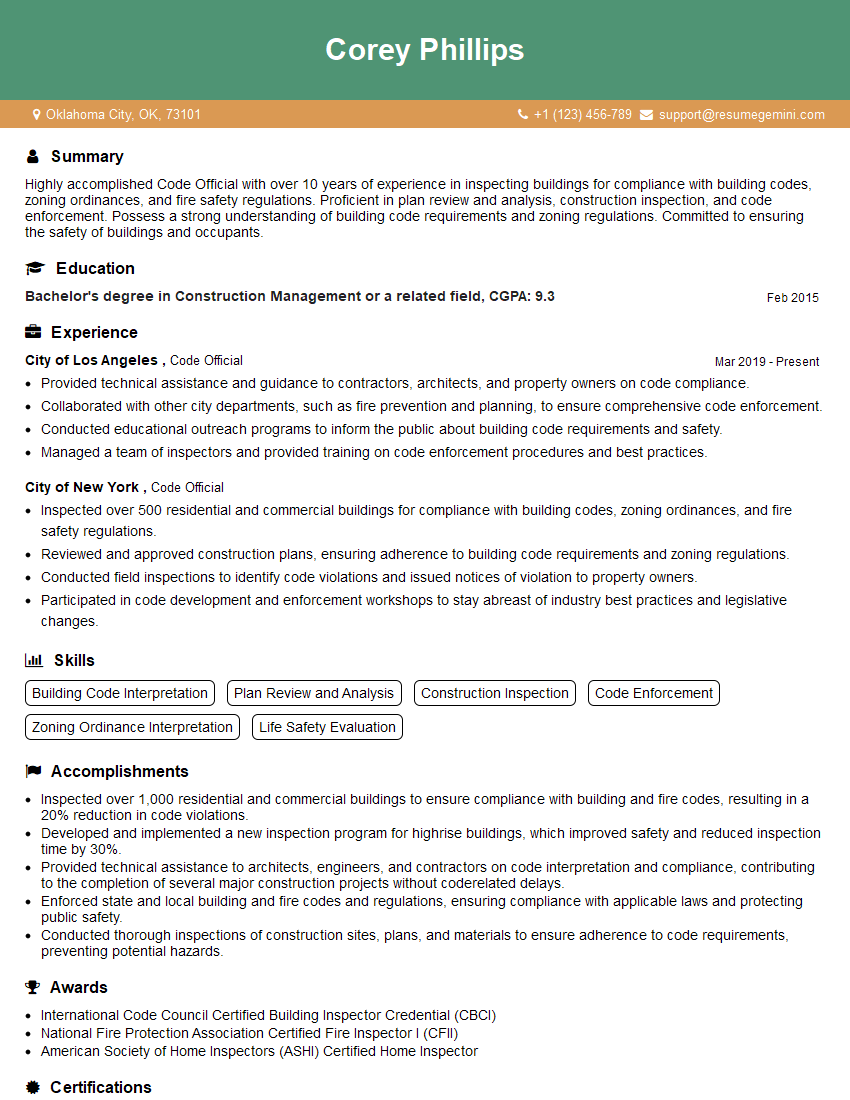

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the requirements for installing and using raceways.

Raceways, the pathways for electrical conductors, are subject to several crucial NEC 2017 requirements. These regulations focus on safety and efficient cable management.

- Type Selection: The type of raceway (conduit, tubing, etc.) is dictated by the environment and the type of conductors it contains. For example, metallic conduit provides better protection in harsh environments than PVC.

- Support and Securing: Raceways must be properly supported and secured at appropriate intervals to prevent sagging, damage, and accidental contact. Imagine a heavy cable hanging loosely – a tripping hazard and potential for damage.

- Bends and Radius: Bends in raceways must meet minimum radius requirements to prevent damage to the conductors inside. Sharp bends can damage conductors and reduce their effective lifespan.

- Fill: The amount of conductors within a raceway must not exceed the allowable fill percentage specified in NEC 2017. Overfilling can impede heat dissipation and increase fire risk.

- Grounding: Metal raceways must be properly grounded to ensure safety and protect against electrical shock. Grounding is like providing an escape route for electricity – preventing dangerous buildups.

- Boxes and Fittings: Proper boxes and fittings must be used at junctions, terminations, and points of entry/exit. These components ensure safe and organized connections.

Example: In a commercial setting, using rigid metal conduit (RMC) may be required in areas with potential physical damage, while EMT conduit might be suitable for less demanding environments.

Q 17. What are the requirements for installing and using cables?

Cable installation under NEC 2017 necessitates adherence to several crucial aspects that prioritize safety and performance. These requirements are integral to a safe and functional electrical system.

- Type Selection: The appropriate cable type must be selected based on voltage, current carrying capacity, environmental conditions, and installation methods. Choosing the wrong cable can lead to overheating or failure.

- Installation Methods: Cables must be installed in accordance with the approved methods, like in raceways, cable trays, or direct burial (if permitted). The method impacts the safety and longevity of the cables.

- Support and Securing: Similar to raceways, cables need to be supported and secured to prevent sagging, damage, and accidental contact. Imagine loose cables – a tripping hazard and potential for damage.

- Splices and Connections: All splices and connections must be made properly and protected against moisture and mechanical damage. Improper connections can lead to overheating, arcing, and fires.

- Overcurrent Protection: Cables must be protected by overcurrent devices sized appropriately for their current-carrying capacity to prevent overheating and damage. This is the primary defense against electrical faults.

- Marking and Identification: Cables should be properly marked and identified to allow for easy tracing and maintenance. Clear labeling is essential for maintenance and troubleshooting.

Example: Using THHN (Thermoplastic High Heat-resistant Nylon) wire for high-temperature applications is critical. Using the wrong cable type could lead to insulation failure and potential fire hazards.

Q 18. Explain the requirements for installing and using wiring methods.

Wiring methods in NEC 2017 encompass a wide range of techniques for installing electrical conductors. The choice depends heavily on environmental factors, safety considerations, and building construction.

- Conduit Systems: These systems provide superior protection against physical damage and environmental hazards. Types include rigid conduit, intermediate metal conduit (IMC), and electrical metallic tubing (EMT).

- Cable Trays: Often used in commercial and industrial settings for organizing and supporting large cable bundles. They allow for easy cable access and expansion.

- Surface Metal Raceway Systems: These provide a sleek aesthetic and are suitable for surface mounting. Easy to install, they’re useful for adding circuits without significant construction changes.

- Concealed Wiring Methods: Wiring is run within walls or ceilings, requiring careful planning and installation to ensure proper support and protection. They offer a cleaner, more integrated look.

- Direct Burial: This method is used for underground wiring, requiring specific cable types and installation techniques to protect against moisture and mechanical damage.

Example: In a remodel, surface metal raceways can be used to neatly add new circuits without the hassle of tearing down walls. In a new high-rise building, cable trays are commonly used to manage the vast number of cables.

Q 19. Describe the requirements for installing and using electrical equipment in hazardous locations.

Installing electrical equipment in hazardous locations demands stringent adherence to NEC 2017 guidelines, primarily Article 500 and subsequent articles covering specific hazardous materials (e.g., Article 501 for Class I locations). The goal is to prevent ignition of flammable gases, vapors, or dusts.

- Classification of Hazardous Locations: Locations are classified based on the type and presence of flammable materials (Class I, II, III). This dictates the type of equipment permitted.

- Equipment Enclosures: Equipment must be housed in explosion-proof or intrinsically safe enclosures designed to prevent ignition. These enclosures are specifically rated to prevent sparks or heat from igniting hazardous materials.

- Wiring Methods: Specific wiring methods, often employing conduit and explosion-proof fittings, are mandatory to prevent sparking or arcing.

- Special Precautions: Additional measures such as purging, pressurization, or other specialized techniques may be required depending on the level and type of hazard.

Example: In a petroleum refinery (Class I, Division 1 location), intrinsically safe equipment with special wiring methods would be mandatory to prevent potential explosions. Standard equipment is not suitable here.

Q 20. What are the requirements for electrical installations in special occupancies?

Special occupancies, such as healthcare facilities, correctional facilities, and theaters, require extra precautions and specific electrical installation requirements under NEC 2017. These are designed for the unique safety and operational needs of these settings.

- Healthcare Facilities (Article 517): These locations necessitate provisions for critical power systems, equipment grounding, and specific requirements for medical equipment and patient care areas. Reliability and safety are paramount.

- Educational Occupancies (Article 518): These facilities focus on protection against shock hazards, the proper grounding of equipment, and safety considerations for both students and staff.

- Assembly Occupancies (Article 519): These include theaters and auditoriums, requiring special attention to emergency lighting and egress illumination, ensuring safe exits during emergencies.

- Correctional Facilities (Article 520): These locations involve security considerations and requirements for safeguarding equipment from vandalism and damage. Robust construction and tamper-resistance are crucial.

Example: A hospital operating room will need dedicated, uninterrupted power supplies for critical medical equipment, significantly different from standard electrical installations in an office building.

Q 21. Explain the requirements for emergency systems.

Emergency systems, as detailed in NEC 2017 Article 700 and subsequent articles, are crucial for ensuring life safety and operational continuity during power outages. Reliability and swift response are critical.

- Power Sources: Emergency systems must have dedicated power sources, such as generators or batteries, to provide power when the main power fails.

- Capacity: Sufficient capacity is required to meet the load demands of the designated emergency circuits.

- Transfer Switches: Automatic transfer switches are typically employed to seamlessly transfer power from the normal source to the emergency source when a power outage occurs.

- Testing and Maintenance: Regular testing and maintenance of emergency systems are mandatory to ensure reliability and operational readiness. Regular testing verifies proper function and allows for timely repairs.

- Emergency Lighting: Emergency lighting systems must provide illumination for egress in case of a power outage. The paths to exits need to be clearly illuminated.

- Emergency Power for Critical Equipment: In certain occupancies, emergency power may be required for critical equipment such as fire alarms, elevators (in some cases), and security systems.

Example: A hospital’s emergency power system must be able to support life-sustaining medical equipment, ensuring continued operation during power failures. This system requires robust design, redundancy, and regular testing.

Q 22. Describe the requirements for fire alarm systems.

The NEC 2017 outlines rigorous requirements for fire alarm systems to ensure life safety and property protection. These systems must be designed, installed, and maintained according to specific codes to reliably detect and signal fires, facilitating prompt evacuation and emergency response.

System Design: The system must be designed to provide adequate coverage throughout the building, considering occupancy type, building layout, and potential fire hazards. This includes specifying the appropriate number, type, and placement of smoke detectors, heat detectors, and manual pull stations.

Notification Appliances: Audible and visual notification appliances, such as horns and strobe lights, must meet specific sound levels and visibility requirements to alert occupants effectively, even in high-noise environments or for individuals with hearing impairments. These must be strategically placed to ensure audibility in all areas.

Power Supply: The system must have a reliable power supply, typically including a primary power source and a secondary backup power source (battery) to ensure continuous operation during power outages. The battery backup must meet specific runtime requirements, usually at least 24 hours.

Testing and Maintenance: Regular testing and maintenance are crucial. The NEC mandates periodic inspections, testing of components, and documentation of these activities to ensure the system’s ongoing functionality and reliability. This might include weekly testing of the system, monthly visual inspections, and annual thorough testing by qualified personnel.

Specific Locations: Special considerations apply to specific areas such as high-rise buildings, healthcare facilities, and industrial settings. These often require more sophisticated systems, potentially including addressable systems with advanced monitoring capabilities.

Q 23. What are the requirements for lightning protection systems?

Lightning protection systems aim to mitigate the risks associated with lightning strikes, safeguarding lives, property, and sensitive equipment. The NEC 2017 provides detailed guidelines on designing and installing effective lightning protection systems, focusing on proper grounding and bonding to safely divert electrical current.

Air Terminals: These are strategically placed to intercept lightning strikes and provide a conductive path to the grounding system. The number and placement depend on the building’s size, shape, and surroundings. Consideration is given to potential strike points and the building’s height.

Down Conductors: These conductors provide the path for the lightning current from the air terminals to the grounding system. They must be made of a durable, corrosion-resistant material with adequate cross-sectional area to handle the expected current. Proper bonding is crucial.

Grounding Electrode System: This is the final stage, dispersing the lightning current safely into the earth. The size and type of grounding electrode (e.g., ground rods, buried conductors) depend on soil resistivity and the building’s size. Ground resistance testing is required to verify effectiveness.

Bonding: All components of the lightning protection system (air terminals, down conductors, grounding electrode system) must be effectively bonded together to ensure a continuous, low-impedance path for the lightning current. This prevents potential voltage differences and dangerous arcing.

Proper design requires considering the specific characteristics of the building and its environment. For example, a tall building in a thunderstorm-prone area would require a more extensive and robust system than a small residential building in a region with infrequent lightning activity.

Q 24. Explain the requirements for photovoltaic systems.

Photovoltaic (PV) systems are becoming increasingly prevalent, and the NEC 2017 provides detailed requirements for their safe and efficient installation. The focus is on preventing electrical hazards, ensuring proper grounding and bonding, and protecting both the system and personnel.

Overcurrent Protection: PV systems must have appropriate overcurrent protection devices, such as fuses or circuit breakers, to protect the system and prevent damage from short circuits or overloads. These need to be sized correctly for the system’s capacity.

Grounding and Bonding: All metal components of the PV system, including the array, wiring, and racking, must be grounded and bonded to prevent electrical shocks and ensure a safe path for fault currents. This is particularly important for preventing dangerous voltages.

System Voltage: PV systems can operate at high DC voltages, posing a significant shock hazard. The NEC mandates adherence to strict safety guidelines for managing these voltages, including proper labeling and warnings.

Wiring Methods: PV wiring must be installed using approved methods, typically in conduit or raceways, to protect the wiring from damage and ensure a safe and neat installation. Proper wire sizing and insulation are also critical.

Disconnects: The NEC requires readily accessible disconnect means to de-energize the PV system during maintenance or emergencies. This allows for safe work on the system.

Code compliance is paramount, ensuring the safety and longevity of the system. Ignoring these guidelines can lead to system failure, fire hazards, and potentially injury.

Q 25. Describe the requirements for electric vehicle charging systems.

Electric vehicle (EV) charging systems are rapidly gaining popularity, and the NEC 2017 addresses their unique electrical requirements, emphasizing safety and proper installation practices. The focus is on managing high currents, ensuring adequate grounding, and preventing overheating.

Overcurrent Protection: EV chargers draw substantial current, necessitating appropriately sized overcurrent protection devices (circuit breakers or fuses) to protect the wiring and the charger itself. Incorrect sizing can lead to overheating and fire hazards.

Grounding: The charger must be properly grounded to prevent electrical shocks and ensure a safe path for fault currents. This is critical for safety, particularly in wet or damp environments.

Wiring: Wiring for EV chargers must be sized to handle the high currents involved, using conductors with adequate ampacity. The type and insulation of the wiring must also meet NEC requirements.

Location and Installation: The NEC specifies requirements for the location and installation of EV chargers, considering factors such as proximity to flammable materials, ventilation, and accessibility.

Communication and Monitoring: Some systems incorporate communication protocols to monitor the charging process and provide data on energy consumption. The NEC addresses considerations for this aspect as it becomes more common.

Compliance with these guidelines ensures a safe and reliable EV charging infrastructure.

Q 26. How do you determine the proper size of a conductor based on voltage drop?

Determining the proper conductor size to mitigate voltage drop involves several steps. Excessive voltage drop leads to inefficient operation and potential equipment damage. The NEC provides tables and formulas to help calculate this.

Calculate the total voltage drop: This is determined by calculating the voltage drop in each section of the circuit. The NEC allows for a maximum percentage voltage drop, typically 3% for branch circuits and 5% for feeders.

Determine the load current: This is the total current the circuit will draw. This can be determined by adding the amperage ratings of all connected devices.

Calculate the circuit length: This is the total length of the conductor run, considering both the hot and neutral conductors. This should include the distance from the panel to the load and back again.

Determine the conductor material and resistivity: This will be either copper or aluminum. Tables in the NEC provide the resistance values for different sizes of wire for each material.

Use the voltage drop formula (or NEC tables): The formula

VD = 2KIL/CMcalculates voltage drop (VD), where:- K is the constant for the conductor material (from NEC tables)

- I is the current in amps

- L is the length of the conductor in feet

- CM is the circular mil area of the conductor

By applying this formula or using the NEC tables, the appropriate conductor size to meet the maximum allowable voltage drop can be determined. If the calculated voltage drop is too high, then a larger conductor must be selected to reduce the resistance and hence the voltage drop.

Q 27. Explain the importance of proper conductor sizing to prevent overheating.

Proper conductor sizing is crucial to prevent overheating, a major fire hazard. Undersized conductors carry more current than they’re designed for, causing excessive heat generation. This can lead to insulation damage, melting of the conductor, and ultimately, a fire. Think of it like a water pipe – too small a pipe for a high-volume water flow causes excessive pressure and potential damage.

Ampacity: Each conductor has a specific ampacity rating, which is the maximum amount of current it can carry continuously without overheating. Selecting a conductor with an ampacity equal to or greater than the expected current is essential.

Derating Factors: The NEC incorporates derating factors to account for ambient temperature, number of conductors in a raceway, and other conditions that can affect the conductor’s ampacity. Failure to apply these factors can result in overheating.

Overload Protection: Even with properly sized conductors, overcurrent protection devices (circuit breakers or fuses) are necessary to protect against short circuits and overloads that could still cause excessive heat. These need to be sized correctly to operate before a conductor can overheat.

Heat Build-up: Conductors enclosed in conduit or raceways can experience increased heat buildup. Adequate ventilation and proper installation practices are crucial in these cases to avoid overheating.

Ignoring proper conductor sizing can lead to catastrophic consequences. The NEC’s provisions ensure safety by providing guidelines for selecting appropriately sized conductors for various applications and environmental conditions.

Q 28. Describe a scenario where you had to interpret a complex section of the NEC 2017 and how you resolved it.

During a recent commercial project, we encountered a complex scenario involving the application of Article 725 (Class 2 Circuits) and Article 726 (Class 3 Circuits) to a building’s low-voltage data and communications cabling systems. The specific challenge arose in differentiating when Class 2 versus Class 3 circuits should be applied to various components of the data infrastructure. The NEC doesn’t explicitly state which to use for every scenario. This requires careful consideration of voltage, power, and application.

The problem was compounded by the building’s unique layout and the mix of older and newer communication systems. We found the existing infrastructure didn’t completely conform to either Class 2 or Class 3, creating compliance challenges.

To resolve the issue, we embarked on a systematic approach:

Thorough review of Articles 725 and 726: We painstakingly examined the detailed definitions, requirements, and permissible uses of both Class 2 and Class 3 circuits.

Careful analysis of the existing systems: We meticulously mapped the existing cabling and equipment to determine the voltage, current, and power levels of each circuit segment.

Consultation with industry experts: We sought guidance from experienced electrical engineers and code authorities to interpret ambiguous sections of the NEC and ensure compliance with the relevant standards. We also checked for manufacturer recommendations for their cabling and equipment.

Development of a hybrid solution: Based on our analysis, we devised a solution that involved selective upgrading of specific circuit segments to meet the stricter requirements of either Class 2 or Class 3. For some circuits, an approved modification was determined. This ensured compliance while minimizing unnecessary upgrades.

Detailed documentation: We documented our entire decision-making process, including calculations, justifications, and references to relevant NEC articles and industry standards.

This meticulous process allowed us to comply with the NEC and develop a safe and functional system. This exemplifies the importance of a thorough understanding of the code and the ability to apply critical thinking to resolve complex electrical scenarios.

Key Topics to Learn for NEC 2017 Interview

- Contract Administration: Understand the roles and responsibilities of the Project Manager, Supervisor, and Contractor under the NEC2017 contract. Practice applying clauses related to compensation events, early warnings, and dispute resolution.

- Risk Management: Learn how to identify, assess, and mitigate risks throughout the project lifecycle using the NEC2017 framework. Be prepared to discuss practical examples of risk allocation and management strategies.

- Planning & Programming: Master the principles of project planning and scheduling within the NEC2017 context. Understand how the contract influences the planning process and the importance of accurate baseline programs.

- Early Warning & Compensation Events: Develop a thorough understanding of the procedures for raising early warnings and claiming compensation events. Practice applying these procedures to hypothetical scenarios.

- Dispute Resolution: Familiarize yourself with the various dispute resolution mechanisms outlined in NEC2017. Understand the steps involved in resolving disputes efficiently and effectively.

- Key Clauses & Definitions: Become familiar with the crucial clauses and definitions within the NEC2017 contract. Be able to explain their significance and practical implications.

- Project Control & Reporting: Understand the importance of accurate and timely reporting within the NEC2017 framework. Be prepared to discuss different reporting methods and their effectiveness.

- Variations & Change Management: Learn how to manage variations and changes effectively under NEC2017. Understand the procedures for initiating, assessing, and implementing changes.

Next Steps

Mastering NEC 2017 is crucial for career advancement in construction project management. A strong understanding of this widely used contract demonstrates your expertise and increases your value to potential employers. To significantly boost your job prospects, create an ATS-friendly resume that highlights your NEC2017 skills and experience. We strongly recommend using ResumeGemini, a trusted resource for crafting professional and effective resumes. ResumeGemini provides examples of resumes tailored specifically to NEC 2017, helping you present your skills and experience in the best possible light. Take the next step towards your dream job by investing in your resume today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good