Cracking a skill-specific interview, like one for Heavy Equipment Operation (e.g., skidders, loaders), requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Heavy Equipment Operation (e.g., skidders, loaders) Interview

Q 1. Describe your experience operating a skid steer loader.

My experience with skid steer loaders spans over eight years, encompassing various applications from landscaping and construction to agricultural tasks. I’m proficient in operating a wide range of models, including Bobcat and Case brands. I’ve worked on projects ranging from small-scale residential renovations to large-scale commercial developments. For instance, on a recent landscaping project, I used a skid steer with a grapple attachment to efficiently clear and sort brush, significantly speeding up the process compared to manual labor. My skills extend beyond basic operation; I’m adept at utilizing the machine’s capabilities to optimize efficiency and precision in various terrains and material handling tasks. I understand the nuances of operating different attachments, ensuring safe and effective application.

Q 2. Explain the safety procedures you follow when operating heavy equipment.

Safety is paramount in heavy equipment operation. My procedures always begin with a thorough pre-operational inspection, checking fluid levels, tire pressure, and the overall condition of the machine. I always wear the appropriate personal protective equipment (PPE), including a hard hat, safety glasses, gloves, and steel-toed boots. Before starting the engine, I ensure the area is clear of obstructions and personnel. During operation, I maintain a safe speed, keeping a clear view of my surroundings and being mindful of potential hazards like overhead power lines or uneven terrain. Communication is crucial; I utilize hand signals or radios to coordinate with other workers on the site. If I encounter any mechanical issues, I immediately shut down the equipment and report the problem to the supervisor. Regular training and adherence to company safety protocols are a fundamental part of my work ethic.

Q 3. How do you perform pre-operational checks on a wheel loader?

Pre-operational checks on a wheel loader are vital for ensuring safe and efficient operation. My routine begins with a visual inspection of the entire machine, checking for any leaks, damage, or loose components. Then, I check the fluid levels: engine oil, transmission oil, hydraulic fluid, coolant, and fuel. Tire pressure is crucial; I ensure all tires are properly inflated. I test the brakes, steering, and the functionality of all controls, including the bucket and lift arms. I operate the horn and lights to ensure they are working correctly. Finally, I check the safety devices, such as the emergency shut-off switch and seatbelt. This systematic approach helps identify potential problems before they lead to accidents or downtime. It’s like giving your machine a thorough health check before starting a long journey.

Q 4. What are the different types of loaders and their applications?

Loaders are categorized by their design and application. Wheel loaders are the most common, ideal for loading and transporting materials over relatively smooth terrain. They are highly versatile, used in construction, agriculture, and material handling. Skid steer loaders offer excellent maneuverability in tight spaces, making them suitable for landscaping, demolition, and smaller construction projects. Backhoe loaders combine a front-end loader with a rear-mounted backhoe, providing digging and loading capabilities in a single machine. Telehandlers extend their reach vertically, useful for high-reach applications like placing materials on upper floors of buildings. The choice depends heavily on the specific job requirements, the terrain, and the material being handled.

Q 5. Describe your experience with different attachments for loaders (e.g., buckets, forks).

My experience with loader attachments is extensive. I’m proficient with various buckets, from general-purpose buckets to specialized ones for handling specific materials like rocks or sand. I frequently use forks for pallet handling, which requires precision and understanding of weight distribution. I’ve also used other attachments such as grapples for handling logs or brush, snow blowers, and augers for drilling. Each attachment requires specific operating techniques to ensure safety and effectiveness. For example, using forks requires a different approach to lifting and maneuvering than using a bucket. Understanding the limitations and capabilities of each attachment is crucial for efficiency and safety. I regularly adapt my operating technique depending on the type of attachment I’m using.

Q 6. How do you handle challenging terrain while operating a skid steer?

Handling challenging terrain with a skid steer requires experience and careful judgment. I adjust my speed to match the terrain conditions, avoiding sudden movements that could cause loss of control. When encountering inclines or declines, I maintain a slow and steady pace, avoiding excessive tipping risks. I use my understanding of the machine’s weight distribution to optimize traction. On loose or uneven surfaces, I adjust my driving style to prevent wheel spin or getting stuck. If necessary, I use counterweights or adjust the load to improve stability. Before tackling difficult terrain, I assess the area carefully, planning a route that minimizes risk. Experience has taught me to anticipate potential problems and react accordingly to ensure both safety and efficiency. I’d rather take a more cautious approach than risk damaging the machine or causing an accident.

Q 7. Explain your experience with maintaining and troubleshooting heavy equipment.

Maintaining and troubleshooting heavy equipment is an integral part of my role. I conduct regular maintenance checks, including lubrication, fluid top-offs, and inspections for wear and tear. I’m familiar with common maintenance procedures, such as changing filters, greasing components, and performing minor repairs. If I encounter a mechanical issue, I systematically troubleshoot the problem, starting with a visual inspection and checking obvious causes before moving to more complex diagnostic steps. I’m adept at identifying common problems and have a good working knowledge of the operating systems of different types of machinery. I keep detailed records of maintenance and repairs, aiding in preventative maintenance and future troubleshooting. This proactive approach minimizes downtime and extends the life of the equipment. For complex problems, I know when to call a qualified mechanic to avoid potentially damaging the equipment further.

Q 8. What are the common causes of equipment malfunctions and how do you address them?

Equipment malfunctions stem from various sources, broadly categorized as mechanical, hydraulic, and electrical issues. Mechanical problems can include worn parts like bearings, chains, or belts, often due to lack of maintenance or excessive wear and tear. Hydraulic failures frequently result from leaks, contaminated fluid, or pump malfunctions, leading to reduced power or complete system failure. Electrical problems may involve faulty wiring, damaged sensors, or issues with the control system, often resulting in erratic operation or complete shutdown.

Addressing these issues requires a systematic approach. Firstly, a thorough visual inspection is crucial, checking for obvious signs of damage or leaks. Secondly, diagnostic tools, such as pressure gauges for hydraulic systems and multimeters for electrical circuits, may be needed to pinpoint the exact problem. Thirdly, appropriate repairs must be made, which may involve replacing faulty components, cleaning or repairing hydraulic lines, or tracing and repairing electrical wiring. Regular preventative maintenance, such as scheduled oil changes, lubrication, and inspections, significantly reduces the likelihood of these malfunctions. For example, I once diagnosed a skidder’s sluggish response to the throttle by identifying a worn throttle cable; a simple replacement solved the problem.

Q 9. How do you ensure the safety of yourself and others while operating heavy equipment?

Safety is paramount in heavy equipment operation. It’s a multifaceted approach encompassing pre-operation checks, safe operating procedures, and awareness of surroundings. Before starting any equipment, I meticulously conduct a pre-start inspection, ensuring all fluid levels are correct, there are no obvious mechanical issues (leaks, loose bolts), and safety devices like seatbelts and emergency stops are functional. During operation, I maintain a safe distance from other personnel and equipment, using hand signals or radios for clear communication. I am always mindful of my surroundings, avoiding overhead hazards and unstable ground conditions. I never operate equipment while fatigued or under the influence of drugs or alcohol.

I also emphasize situational awareness – anticipating potential hazards and adapting my actions accordingly. For instance, I might reduce speed when approaching blind corners or adjust my path to avoid obstacles. Furthermore, I believe in regularly reviewing safety procedures and participating in any safety training provided by my employer. The wellbeing of myself and others is non-negotiable, and I always prioritize safe work practices.

Q 10. Describe your experience working with GPS or other guidance systems on heavy equipment.

I possess extensive experience utilizing GPS and other guidance systems in heavy equipment, primarily for precision grading and earthmoving tasks. These systems significantly improve efficiency and accuracy. For example, I’ve utilized GPS-guided bulldozers to achieve precise land leveling across large areas, reducing rework and material waste. These systems typically employ satellite signals to determine the machine’s position and compare it against a pre-programmed design or target grade. This information is relayed to the operator through a display, providing real-time guidance on machine positioning and adjustments needed to maintain accuracy.

My experience also encompasses working with machine control systems that integrate GPS with other sensors, such as tilt sensors and laser levels, to provide more comprehensive control and feedback. This enhanced precision is invaluable in applications demanding high accuracy such as road building, pipeline installation, and site preparation for construction.

Q 11. How do you calculate the weight capacity of a loader and ensure safe operation?

Calculating a loader’s weight capacity is crucial for safe operation and prevents overloading, which can lead to equipment damage or accidents. The rated capacity is usually specified by the manufacturer and is based on the loader’s design and structural limits. This information is usually found in the operator’s manual and should be clearly understood before operation.

To ensure safe operation, I always consult the manufacturer’s specifications for the maximum load capacity for both the loader and the specific attachment being used. Furthermore, I consider the material’s density and the loader’s reach. Operating within the recommended weight limits helps extend the lifespan of the loader and avoids structural damage. For instance, if I am loading heavy rock with a bucket, I’ll use the loader’s load charts to determine the appropriate bucket size and ensure the total weight remains well below the machine’s rated capacity. It’s better to make multiple smaller loads than risk exceeding the limit.

Q 12. What are the legal and regulatory requirements for operating heavy equipment in your area?

Legal and regulatory requirements for operating heavy equipment vary by location, but generally include licensing, certification, and adherence to safety standards. In my area, a valid operator’s license specific to the type of equipment being operated is mandatory. This license is usually obtained after completing a course on safe operating procedures and demonstrating competency through practical examinations. Furthermore, regular safety training and compliance with relevant health and safety regulations established by governmental bodies and industry organizations are compulsory. This includes regular machine inspections, reporting of accidents or near misses, and adherence to safe working practices. Ignoring these requirements can lead to significant fines or legal action.

I am always up-to-date on all relevant regulations and actively participate in any required safety training. This proactive approach ensures not only my safety but also the safety of those around me and the compliance of my operations with all relevant laws and industry best practices.

Q 13. Explain your experience with different types of excavator attachments (e.g., breakers, thumbs).

I have experience with a variety of excavator attachments, including breakers, thumbs, and various buckets. Hydraulic breakers are used for demolition and rock breaking, requiring careful control to avoid damaging the excavator or surrounding structures. I understand the importance of selecting the right breaker size for the task and operating it within its specified parameters to prevent damage. Thumbs, or grapple attachments, are essential for handling awkward materials, logs, or scrap metal. They improve efficiency and precision in material handling, especially in tight spaces.

Different buckets are used for specific applications. I am proficient in using a variety of buckets, from general-purpose buckets to specialized buckets designed for specific materials or tasks, like trenching or clean-up. The selection of the correct attachment is critical, ensuring the correct tool is used for each specific job and operated safely and efficiently. Selecting the wrong attachment can lead to poor productivity, machine damage, or safety hazards.

Q 14. How do you perform routine maintenance on a bulldozer?

Routine maintenance on a bulldozer is crucial for its longevity and safe operation. It involves regular inspections and servicing, focusing on key components. This typically begins with a visual inspection, checking for any leaks, loose bolts, or damage. Next, I check and change the engine oil, transmission fluid, and hydraulic fluid according to the manufacturer’s recommended intervals. Filters (air, fuel, hydraulic) should also be changed or cleaned regularly. Track tension is critical; it needs to be adjusted to the correct specifications to prevent premature wear and tear.

Furthermore, regular greasing of various components, including pins, bushings, and linkages, is necessary to reduce friction and wear. The undercarriage, including tracks, rollers, and sprockets, needs to be inspected for wear and damage. Finally, I would inspect the blade and other cutting edges for wear and tear, and perform any necessary sharpening or replacement. A well-maintained bulldozer runs smoothly, is more efficient, and significantly reduces the risk of breakdowns or accidents. This preventative approach minimizes downtime and extends the machine’s lifespan considerably.

Q 15. What are the safety considerations when operating near power lines?

Operating heavy equipment near power lines is extremely dangerous. The biggest risk is accidental contact between the equipment and the lines, leading to electrocution or equipment damage. To mitigate this, the cardinal rule is to maintain a safe distance. This distance varies depending on the voltage of the power lines, and you should always consult the site-specific safety plan and relevant regulations. Before starting any work, I always thoroughly assess the area, identifying power lines and calculating the necessary clearance. I’d never rely on visual estimation alone; I’d use measuring tools or even call the utility company to confirm the exact location and voltage of the lines if unsure. If the operation requires me to get near power lines, I’d employ spotters, use insulated equipment (where feasible), and rigorously follow the detailed safety procedures outlined in the job safety analysis (JSA).

For instance, during a logging operation near a high-voltage line, we established a designated exclusion zone, marked it clearly with safety cones and flagging tape, and had a spotter constantly monitoring the position of the skidder’s boom and grapple. This extra layer of caution significantly reduced the chances of an accident.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle unexpected equipment failure in the field?

Unexpected equipment failure in the field demands a calm and methodical response. My first step is to ensure the immediate safety of myself and anyone nearby. This includes switching off the equipment, exiting the machine safely, and warning others in the vicinity of the potential hazard. I then conduct a visual inspection of the equipment to identify the apparent cause of the failure. Is it a hydraulic leak? An engine malfunction? Electrical fault? The nature of the failure dictates the next steps. For minor issues, I might attempt a simple repair if my skills and the circumstances allow (e.g., tightening a loose bolt). However, for significant failures, I’d immediately report the incident to my supervisor, following the established company protocols. Depending on the situation, this might involve using a two-way radio, satellite phone, or even activating an emergency beacon. I would never attempt a repair beyond my skill level to avoid potential further damage or injury.

For example, during a road-building project, the loader’s hydraulic system failed. After ensuring safety, I conducted a preliminary inspection, noting a significant leak. I immediately reported the incident to my supervisor via radio and waited for assistance. This immediate reporting ensured prompt repairs and minimized project downtime.

Q 17. Describe your experience with operating in confined spaces.

Operating in confined spaces presents unique challenges related to maneuverability, visibility, and safety. I have experience operating skid steers and compact loaders in tight spaces such as construction sites with limited access and confined areas within warehouses or industrial facilities. This necessitates a more cautious approach and increased awareness of surroundings. Before starting work in such areas, I always thoroughly assess the space, checking for obstacles, overhead hazards, and potential pinch points. I’ll utilize mirrors or cameras (if available) to compensate for reduced visibility. I also ensure that there is adequate ventilation to prevent the build-up of hazardous gases or fumes. Communication with colleagues and supervisors is crucial to ensure everyone is aware of the operation and to prevent accidents. I operate at a slower speed and make frequent checks to avoid collisions or damage. In one instance, I had to use a smaller skid steer to move materials within a very narrow passageway of an old industrial building – the careful assessment and slow, deliberate operation were critical in that confined space.

Q 18. How do you ensure the proper stability of a loader during operation?

Ensuring loader stability is paramount for safe operation. This depends on several factors, primarily the load’s weight and distribution, the ground conditions, and the loader’s design and operating characteristics. I always follow the manufacturer’s guidelines for load capacity and center of gravity. I avoid overloading the loader and make sure the load is evenly distributed to prevent tipping. When lifting heavy loads, I’ll operate on level ground or, if not possible, carefully assess the terrain. I avoid sharp turns or sudden movements while carrying a load. Before lifting, I check the ground for soft spots or uneven surfaces which might affect stability. Using the loader’s stabilizers (if equipped) is a very important aspect of stability, particularly on uneven ground or when handling very heavy loads. Always keeping my eye on where the center of gravity of the machine and the load is going to be helps me to maintain equilibrium, and never overestimate the terrain’s capacity.

Q 19. What are the signs of operator fatigue and how do you mitigate them?

Operator fatigue is a serious safety risk. Signs include decreased alertness, slower reaction times, poor judgment, and physical exhaustion. I am aware of these signs and take proactive measures to mitigate them. I ensure I get adequate rest before and during long shifts. Taking regular breaks, including short rest periods throughout the day and longer breaks for meals, is vital. Staying hydrated by drinking plenty of water, avoiding caffeine and alcohol, and having proper nutrition all contribute to maintaining alertness and preventing fatigue. I’m also mindful of the working environment; excessive noise, heat, or cold can significantly increase fatigue. Reporting any feelings of fatigue to my supervisor and requesting a break are crucial, as is ensuring adequate breaks and sleep during off-duty times.

Q 20. Explain your experience with different types of ground conditions and how they affect equipment operation.

Ground conditions significantly influence heavy equipment operation. Soft ground, such as mud or sand, reduces traction and increases the risk of getting stuck. In such conditions, I use lower gears and reduce speed to maintain control and prevent wheel spin. On rocky terrain, I choose a slower speed to avoid damage to the equipment’s undercarriage and ensure better control, and often make use of ground-engaging tools specifically designed for such conditions. Hard surfaces like paved roads or concrete slabs offer good traction but may damage the tires if not handled properly. I adjust my operating style depending on the type of ground. For instance, when working on a steep incline or slope, I take extra precautions to maintain stability and use the machine’s features designed for working in these conditions. Furthermore, I always evaluate the ground’s load-bearing capacity to make sure I am not exceeding its limits – thus protecting the machine and the environment.

For example, during a logging operation in a swampy area, I adjusted the tire pressure on the skidder to optimize traction and selected a gear appropriate for the soft ground to avoid getting stuck. My experience in handling these different soil types and terrain characteristics makes me an efficient and safe operator.

Q 21. How do you handle emergency situations during heavy equipment operation?

Emergency situations require a rapid and decisive response. My primary concern is always safety. My immediate actions depend on the nature of the emergency: fire, equipment malfunction, injury, or environmental hazard. If a fire occurs, I’d shut down the equipment, evacuate the area, and activate the emergency procedures, including contacting the fire department. For equipment malfunctions leading to immediate risks, I’d first shut down the machine safely, followed by communication with my supervisor and emergency response team. In case of injury, I’d provide first aid if qualified, contact emergency services, and secure the area to prevent further incidents. Environmental hazards, such as fuel spills, would necessitate immediate containment measures and reporting to the relevant authorities. Regardless of the emergency, thorough documentation of the incident is essential for investigation and preventative actions. I frequently review and practice emergency procedures to ensure quick reaction times during real-life scenarios.

Q 22. What is your experience with load charts and capacity limits?

Load charts and capacity limits are paramount to safe and efficient heavy equipment operation. They detail the maximum weight an equipment can lift or carry at various reach distances and configurations. Ignoring these limits can lead to equipment damage, injury, or even death.

My experience involves meticulously consulting load charts before every lift. I’ve worked with various machines including skid steers, wheel loaders, and excavators, each with its unique chart. For instance, when operating a wheel loader moving large logs, I carefully check the chart to ensure the weight and reach are within the safe operating parameters. If the load is near the limit, I’ll take additional precautions like using a spotter and ensuring the ground is stable. Failure to adhere to load charts directly impacts the longevity and operational safety of the equipment, significantly impacting project timelines and budgets if a machine suffers damage due to overload.

I also understand that load charts are not static; factors like ground conditions and the condition of the machine (e.g., tire pressure) can affect carrying capacity. Therefore, I always account for these variables and operate with a margin of safety. Think of it like this: a load chart is like a speed limit – following it ensures a safe and predictable journey.

Q 23. How do you ensure proper visibility while operating heavy equipment?

Maintaining proper visibility is critical for heavy equipment operation. It’s about more than just seeing; it’s about anticipating potential hazards. My approach is multi-faceted.

- Pre-Operational Checks: Before starting any machine, I meticulously inspect all mirrors, windows, and lights to ensure they are clean and functioning correctly.

- Strategic Positioning: I always position the equipment strategically to maximize visibility. This might involve repositioning the machine for optimal line of sight or using a spotter to cover blind spots, especially when working in confined spaces or near other equipment.

- Awareness of Surroundings: I constantly scan my surroundings, paying close attention to pedestrians, other equipment, and potential obstacles. This includes checking blind spots using mirrors frequently during maneuvers.

- Back-Up Cameras and Sensors: I utilize back-up cameras and sensors whenever available, particularly when working in reverse or in areas with limited visibility. These are invaluable tools for enhancing safety.

For example, during a recent logging operation, I used a spotter to guide my skidder through a dense section of trees where visibility was extremely limited. The spotter’s help significantly reduced the risk of accidents by ensuring a clear understanding of our surrounding environment and possible obstructions.

Q 24. Describe your experience with working in a team environment on heavy equipment projects.

Teamwork is essential in heavy equipment projects. I’ve consistently demonstrated the ability to collaborate effectively within teams of varying sizes. This involves clear communication, mutual respect, and shared responsibility for project success and safety.

- Communication: I actively participate in pre-job briefings and communicate effectively with operators, spotters, and supervisors about the tasks, potential hazards, and strategies for mitigating those risks. I’m not afraid to ask questions and I value input from others.

- Coordination: I coordinate my actions with other equipment operators to avoid collisions or interference. This involves signaling appropriately and maintaining a safe distance. A recent project involving simultaneous excavation and loading required precise timing and coordination to prevent equipment conflicts and maximize efficiency.

- Collaboration: I assist other team members when needed, sharing my expertise and offering support. This is a team effort, and every member contributes to the overall outcome. For instance, I once helped another operator troubleshoot a machine malfunction, which enabled us to resume the project more quickly.

My approach to teamwork is built on the principle of shared responsibility and clear, respectful communication. It’s about understanding that everyone plays a vital role in completing the project safely and efficiently.

Q 25. What are your strategies for minimizing wear and tear on equipment?

Minimizing wear and tear on heavy equipment is crucial for maintaining productivity and reducing operational costs. My strategy is proactive and preventative.

- Regular Maintenance: I adhere strictly to the manufacturer’s recommended maintenance schedule, including regular fluid changes, lubrication, and inspections. This prevents small problems from escalating into costly repairs.

- Proper Operation: I operate the equipment within its designed limits and avoid unnecessary stress. This includes avoiding sudden stops and starts, overloading, and operating in unsuitable conditions.

- Careful Handling: I take care to avoid damaging the equipment during transportation and storage. This includes using appropriate tie-down techniques and ensuring the equipment is stored on level ground.

- Reporting Issues: I promptly report any mechanical issues or signs of wear and tear to the supervisor, ensuring that problems are addressed before they worsen.

For example, I noticed a slight leak in a hydraulic line during a routine inspection. Reporting it immediately prevented the leak from becoming larger, saving hours of downtime and considerable repair costs. Thinking long-term reduces short-term expenses.

Q 26. How do you adapt to different types of heavy equipment?

Adapting to different types of heavy equipment is a key aspect of my expertise. I approach this through a combination of formal training and hands-on experience.

- Formal Training: I actively seek out training and certifications on new equipment types. This ensures that I am fully aware of the machine’s capabilities and limitations before operating it.

- Hands-on Experience: I am confident in my ability to quickly learn new machines through practical application. I begin by closely studying the operator’s manual and undergoing a supervised training session.

- Simulators: I have utilized simulators to gain proficiency with new equipment models, allowing me to practice in a safe and controlled environment before handling the actual machine.

- Understanding Common Principles: I understand that despite their differences, all heavy equipment shares underlying operational principles related to hydraulics, mechanics, and safety protocols. This foundation speeds up the learning curve for new machines.

Recently, I transitioned from operating skid steers to operating a large excavator. Through a combination of training and hands-on experience, I rapidly became proficient in operating the excavator, successfully completing the assigned tasks within the project timeline.

Q 27. How do you communicate effectively with other workers on the site?

Effective communication on a job site is crucial for safety and efficiency. My approach emphasizes clarity, conciseness, and respect.

- Clear and Concise Language: I use clear, concise language, avoiding jargon and ensuring everyone understands the message. This is particularly important when giving instructions or communicating about potential hazards.

- Non-Verbal Communication: I utilize hand signals and other non-verbal cues when necessary, especially in noisy environments or situations where vocal communication is difficult.

- Active Listening: I actively listen to others, ensuring I understand their concerns and input. This fosters teamwork and prevents misunderstandings.

- Two-Way Communication: I encourage two-way communication, making sure that information flows smoothly both from me to others and vice-versa.

For example, when working near a powerline, I ensured everyone understood the proximity risks, using both hand signals and verbal instructions to emphasize the importance of safety. Clear and precise communication in such situations is critical to preventing accidents.

Key Topics to Learn for Heavy Equipment Operation (e.g., skidders, loaders) Interview

- Machine Operation Fundamentals: Understanding basic controls, hydraulic systems, and engine operation for both skidders and loaders. Practice explaining your experience with different models and their unique features.

- Safety Procedures and Regulations: Demonstrate knowledge of OSHA standards, pre-operational checks, and emergency procedures. Be prepared to discuss your experience with maintaining a safe work environment.

- Maintenance and Troubleshooting: Explain your ability to perform basic maintenance tasks, identify common malfunctions, and describe your approach to troubleshooting issues on the job. Highlight preventative maintenance strategies.

- Terrain and Load Management: Discuss your understanding of working safely in various terrains and effectively managing load weight and distribution to prevent accidents. Provide examples from your experience.

- Efficiency and Productivity: Explain your strategies for optimizing work processes, maximizing efficiency, and achieving production goals. Be ready to discuss how you’ve improved productivity in past roles.

- Communication and Teamwork: Highlight your ability to communicate effectively with supervisors and colleagues, work collaboratively within a team, and follow instructions accurately.

- Environmental Awareness: Show understanding of environmentally responsible practices in heavy equipment operation, including minimizing ground disturbance and fuel consumption.

Next Steps

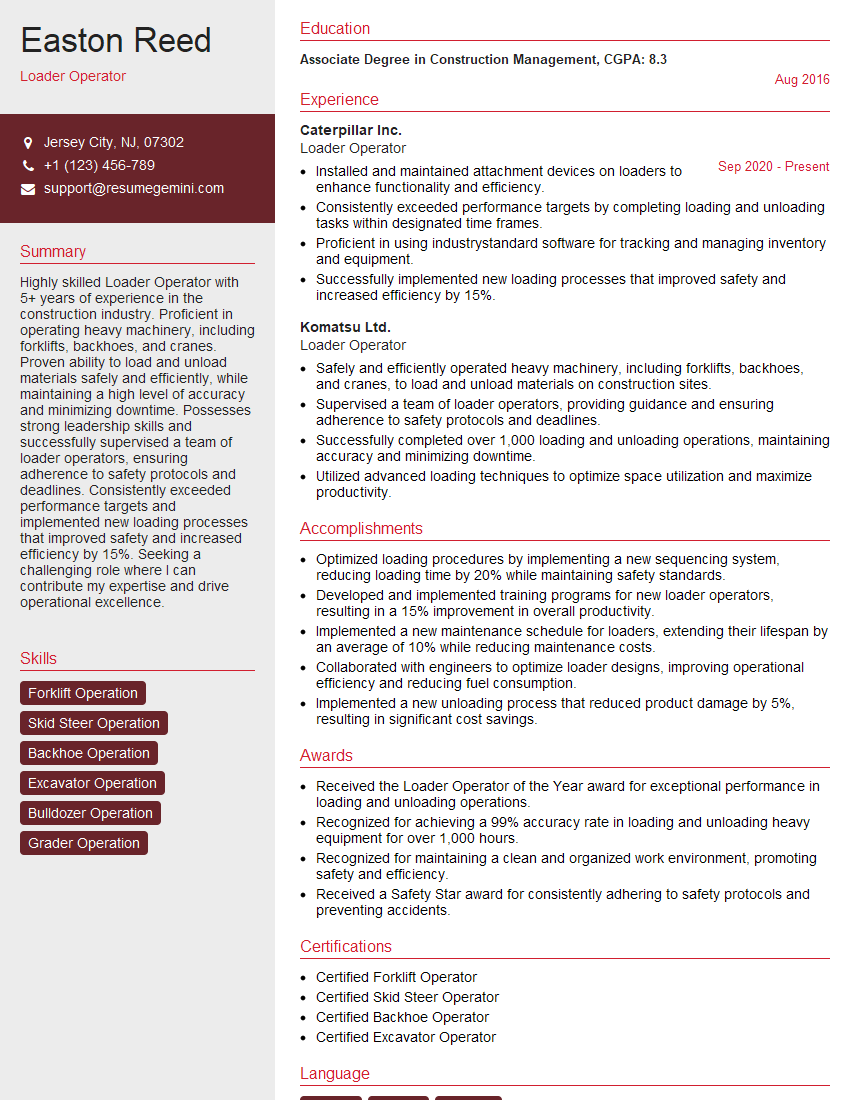

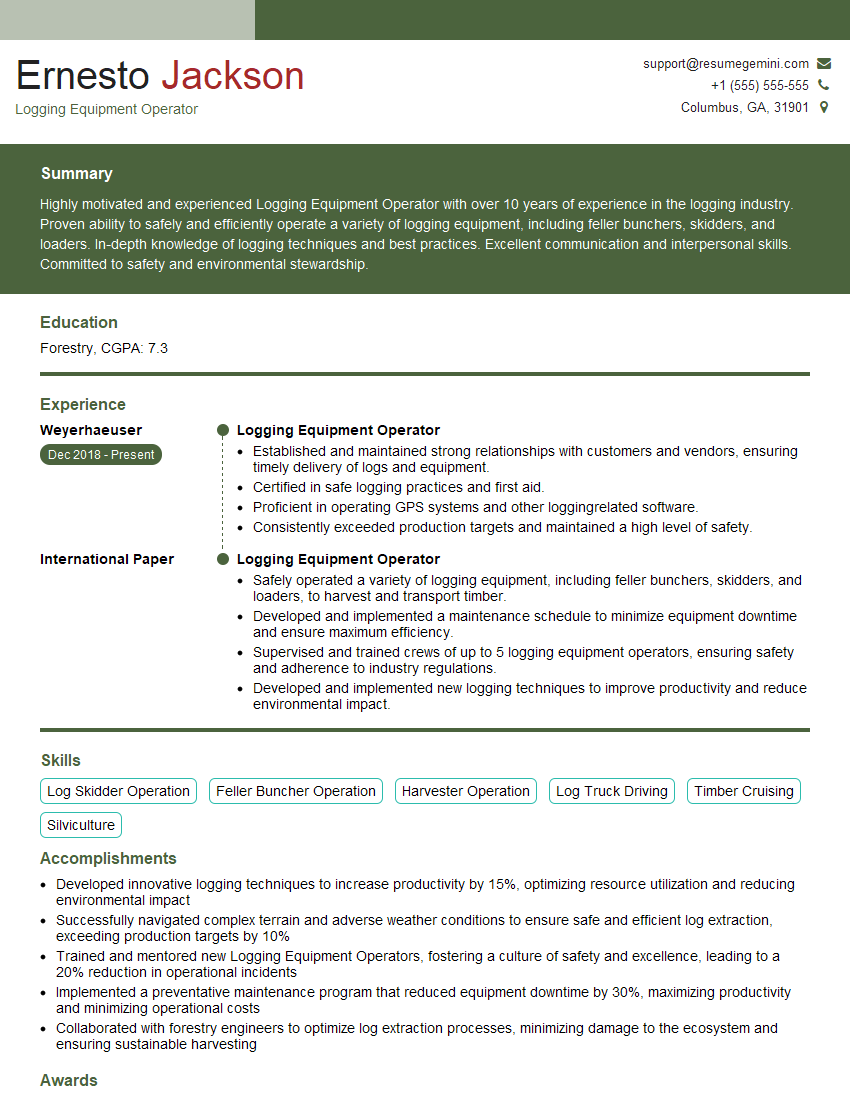

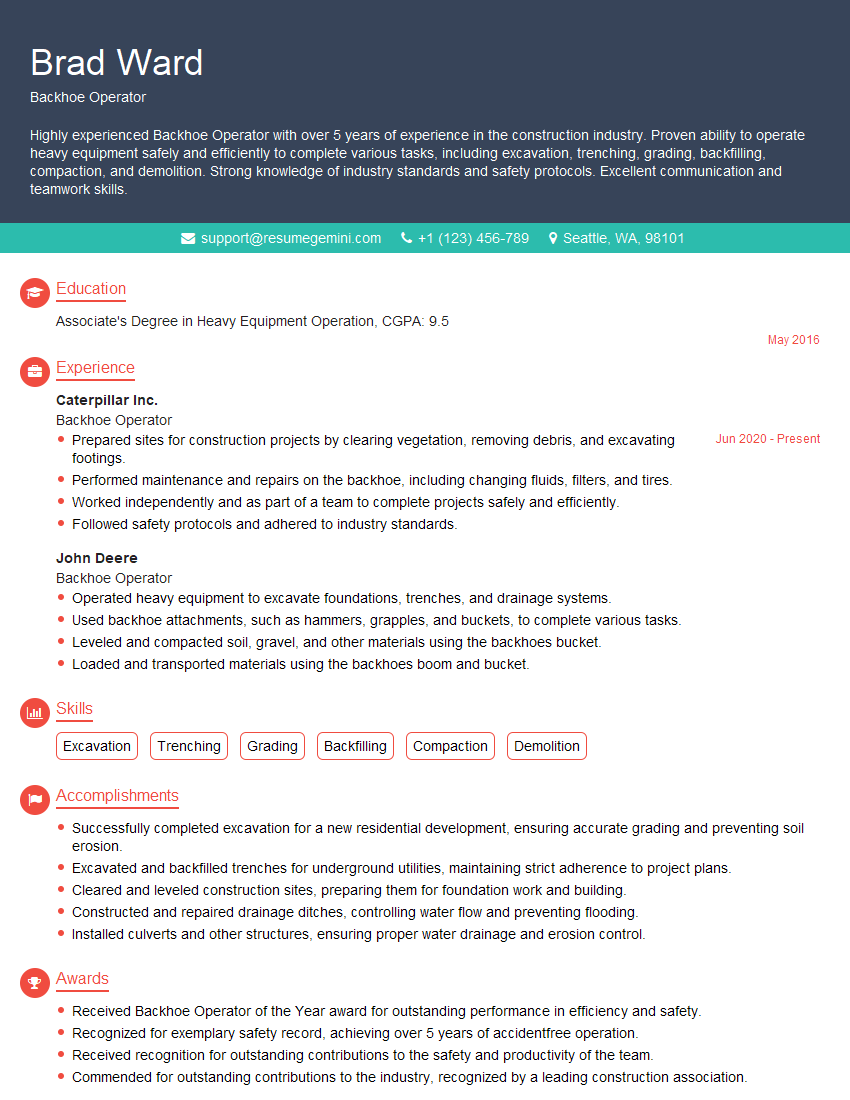

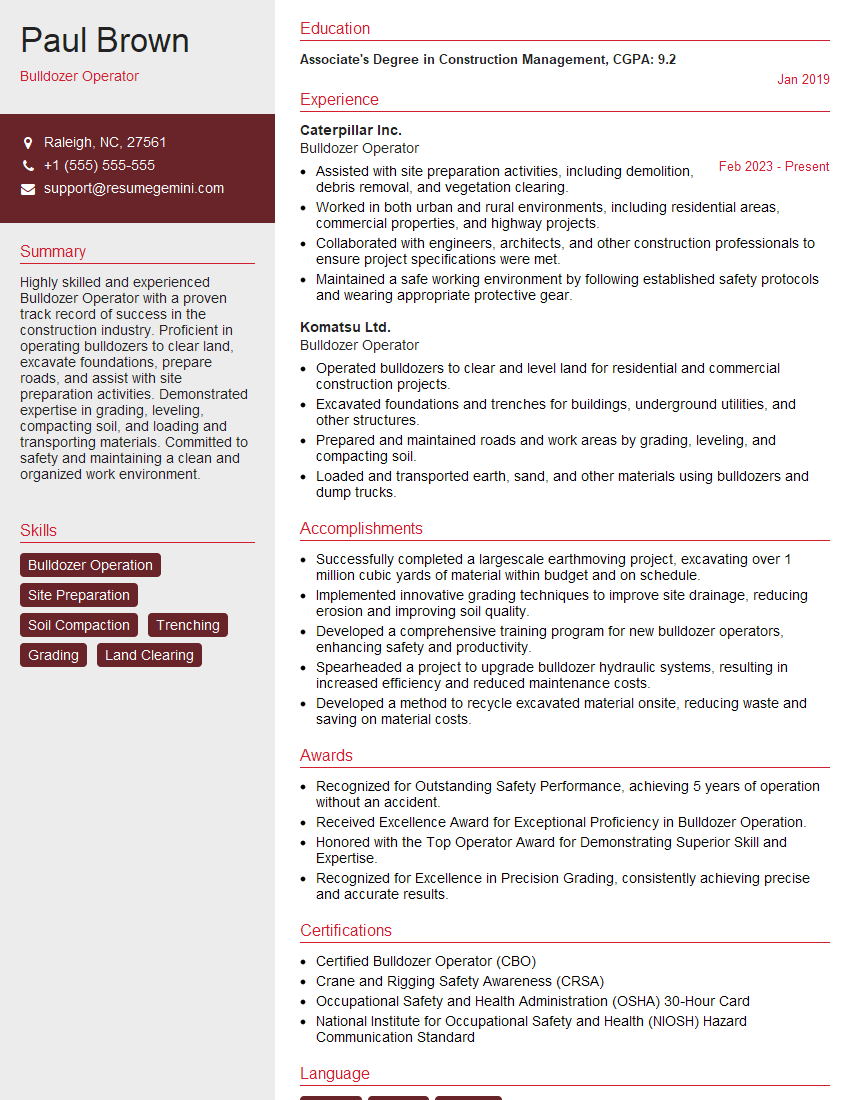

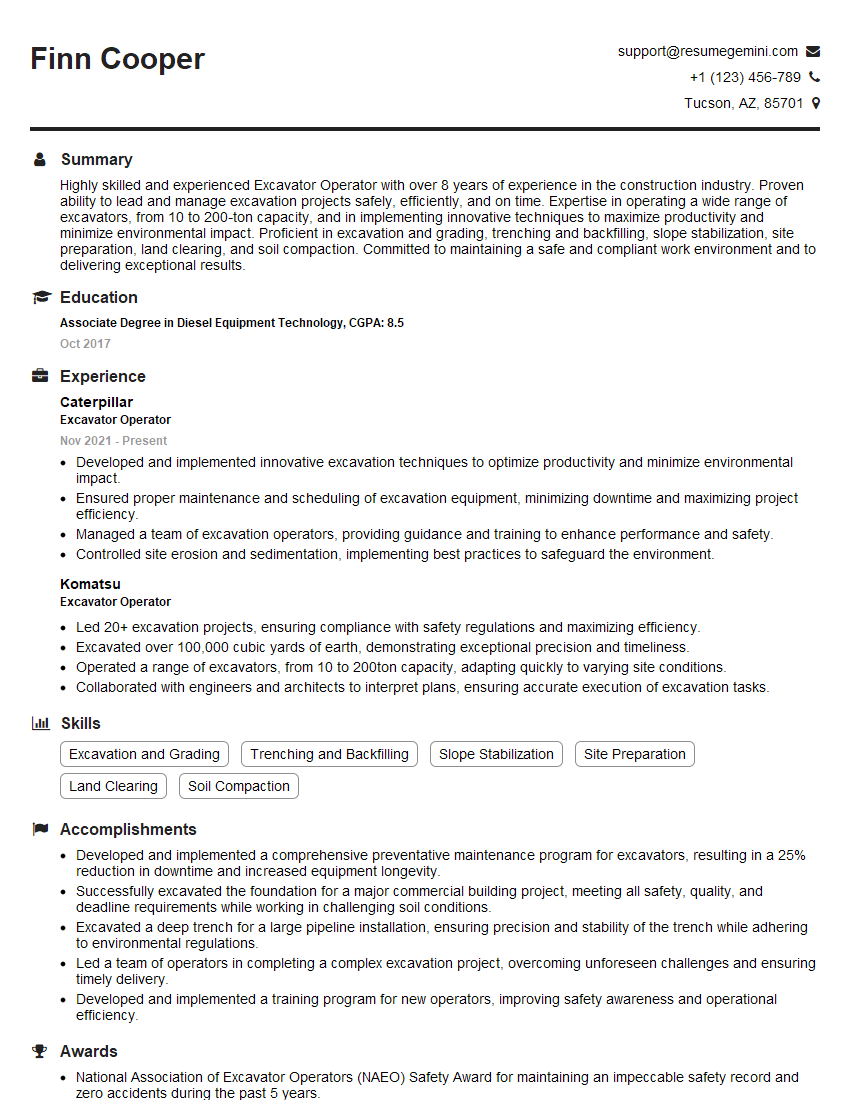

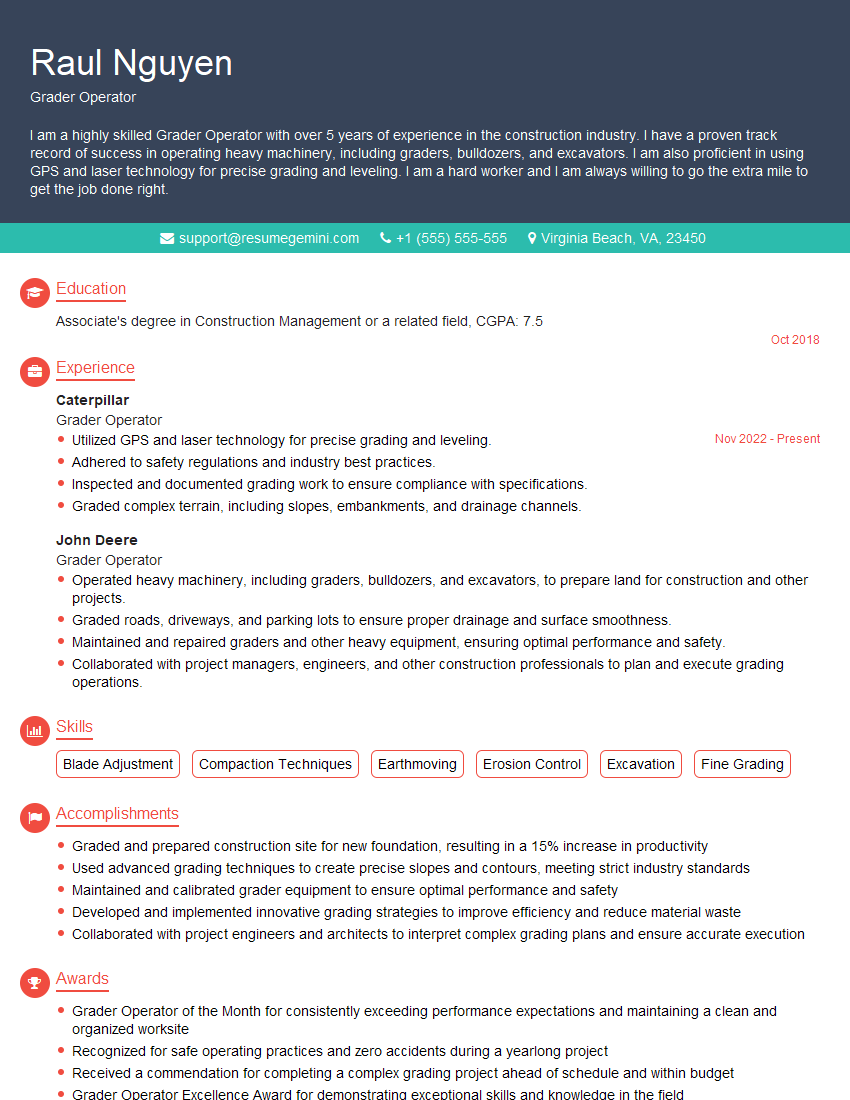

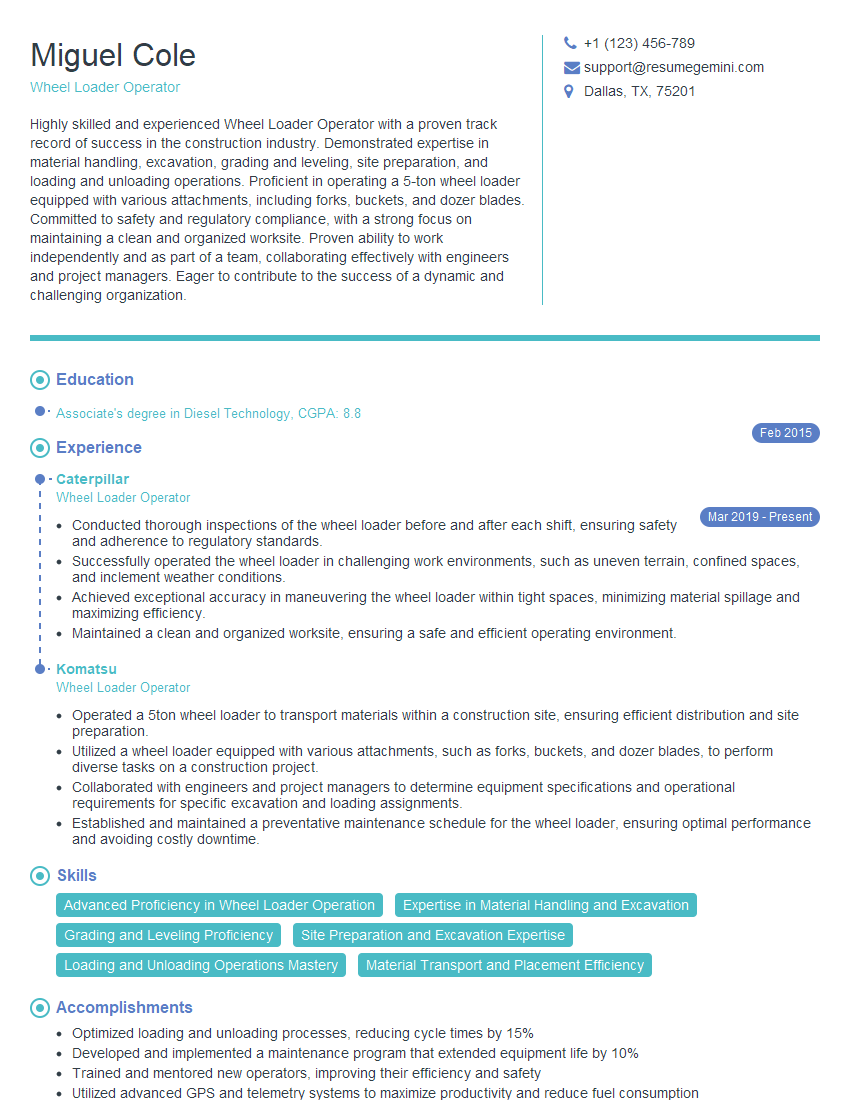

Mastering heavy equipment operation, particularly skilled use of skidders and loaders, opens doors to rewarding and well-compensated careers in forestry, construction, and mining. These roles are essential to many industries and offer excellent opportunities for growth and advancement. To significantly improve your job prospects, focus on creating an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that stands out to recruiters. We offer examples of resumes tailored to heavy equipment operation (e.g., skidders and loaders) to help guide you in crafting your own compelling application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good