Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Fabrication and Assembly Knowledge interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Fabrication and Assembly Knowledge Interview

Q 1. Explain the difference between MIG and TIG welding.

MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding are both arc welding processes that use a non-reactive gas to shield the weld pool from atmospheric contamination, ensuring a strong and clean weld. However, they differ significantly in their techniques and applications.

- MIG Welding: Uses a consumable electrode (wire) that feeds continuously into the weld pool, acting as both the electrode and the filler material. This makes it a fast, relatively easy-to-learn process, ideal for mass production and joining thicker materials. Think of it like a hot glue gun, but instead of glue, it’s molten metal. The wire feeds automatically, simplifying the process for the welder.

- TIG Welding: Employs a non-consumable tungsten electrode to create the arc, and a separate filler rod is manually fed into the weld pool. This allows for precise control and cleaner welds, making it suitable for thin materials, intricate designs, and applications where high-quality finishes are critical. It’s a bit more akin to using a delicate paintbrush— requiring more skill and precision but offering superior results.

In short, MIG is for speed and efficiency, TIG for precision and quality. The choice depends on the project’s requirements. I’ve used both extensively, from MIG welding large structural components in a shipyard to TIG welding intricate stainless steel parts for medical equipment.

Q 2. Describe your experience with blueprint reading and interpretation.

Blueprint reading and interpretation are fundamental to my work. My experience encompasses interpreting various types of engineering drawings, including orthographic projections, isometric views, sectional drawings, and assembly drawings. I’m proficient in understanding different annotation symbols, dimensioning techniques, material specifications, and tolerance levels.

For instance, I recently worked on a project where the blueprint specified a complex assembly with tight tolerances. By carefully analyzing the dimensions and tolerances on the drawing, I was able to accurately fabricate and assemble the parts, ensuring the final product met the specified design requirements. I am comfortable using both physical blueprints and digital CAD drawings and can utilize various software to interpret 3D models.

Beyond the technical aspects, I believe the key to effective blueprint reading is to understand the ‘why’ behind the design. Knowing the function of each component helps in identifying potential issues and finding efficient solutions.

Q 3. What types of assembly tools are you proficient with?

My proficiency with assembly tools is extensive. I am skilled in using a wide range of hand tools such as:

- Screwdrivers (Phillips, flathead, Torx)

- Wrenches (open-ended, box-end, socket)

- Pliers (needle-nose, slip-joint)

- Hammers

- Chisels

- Riveting tools

Furthermore, I’m experienced with various power tools, including:

- Electric drills

- Impact wrenches

- Pneumatic tools (air ratchets, rivet guns)

I am also adept at using specialized assembly equipment like torque wrenches, which are crucial for ensuring consistent and accurate tightening of fasteners to prevent damage or failure. My experience covers various applications, from delicate electronics assembly to heavy machinery construction.

Q 4. How do you ensure quality control during the fabrication process?

Quality control is paramount in fabrication and assembly. My approach is multifaceted and begins even before the fabrication process starts.

- Material Inspection: I thoroughly inspect incoming materials for defects, ensuring they meet the specified requirements. This includes checking dimensions, surface finish, and material properties.

- Process Monitoring: During fabrication, I meticulously monitor every step of the process. This includes checking weld quality (using visual inspection and sometimes destructive testing), ensuring proper alignment of parts, and verifying dimensions at critical stages. For instance, I utilize calibrated measuring tools such as calipers and micrometers.

- In-process Inspection: Regular checks are done to ensure the parts are being produced within the specified tolerances. If any discrepancies are found, immediate corrective actions are implemented.

- Final Inspection: Before assembly completion, a comprehensive inspection is carried out to ensure all components meet specifications. This includes functional testing where applicable.

- Documentation: Maintaining detailed records of each step of the process, including measurements, inspection results, and any corrective actions, is crucial for traceability and continuous improvement.

I believe in a proactive approach—preventing defects rather than just detecting them. By adhering to these procedures, I consistently deliver high-quality work that meets or exceeds client expectations.

Q 5. Describe your experience with different types of fasteners (bolts, screws, rivets).

My experience with fasteners is broad, covering various types, materials, and applications. I understand the strengths and limitations of each type and can select the appropriate fastener for a given application considering factors such as load, vibration, corrosion resistance, and ease of assembly.

- Bolts: I’m experienced with different bolt types such as machine bolts, carriage bolts, and eye bolts, understanding the nuances of their use in different applications. For instance, I know that choosing a bolt with the correct grade and tensile strength is critical for structural applications.

- Screws: I have experience with various screw types including machine screws, wood screws, self-tapping screws, and set screws. The selection depends on the materials being joined and the desired level of clamping force.

- Rivets: I’m proficient in using solid rivets, blind rivets, and other specialized types, understanding the critical factors such as rivet diameter, material, and proper setting techniques for a secure and reliable joint.

In each instance, I prioritize safety and reliability, ensuring proper torque is applied and any required coatings or treatments are utilized to increase lifespan and functionality.

Q 6. What is your experience with different joining methods (welding, brazing, soldering)?

My experience encompasses a range of joining methods, each with its own strengths and weaknesses.

- Welding: As discussed earlier, I’m proficient in MIG and TIG welding, understanding the importance of proper joint preparation, shielding gas selection, and post-weld cleaning for optimal results.

- Brazing: This is a joining process that uses a filler metal with a lower melting point than the base metals. I’ve used brazing for joining dissimilar metals where welding might be difficult or undesirable.

- Soldering: This technique uses a filler metal with an even lower melting point than brazing, often used for joining smaller components and electronic assemblies. I have experience with both soft soldering and hard soldering, understanding the difference in material and application.

Selecting the appropriate joining method depends on the materials being joined, the required strength of the joint, the aesthetic requirements, and the cost-effectiveness of each method.

Q 7. How do you handle discrepancies between assembly drawings and actual components?

Discrepancies between assembly drawings and actual components are a common challenge in fabrication. My approach involves a systematic investigation to identify the root cause and implement a solution.

- Verification: First, I verify the accuracy of the drawings and the components. I use multiple methods, including direct measurement of the components and comparison with the drawings, and checking the revision levels of both the drawings and bill of materials to ensure they are current.

- Root Cause Analysis: If a discrepancy is confirmed, I investigate the potential causes. This might involve checking for errors in the design, manufacturing tolerances, or human error during fabrication or component sourcing.

- Communication: Clear and immediate communication with the engineering team and procurement department is crucial. It’s essential to document the findings clearly and propose solutions.

- Solution Implementation: Depending on the nature of the discrepancy, the solution might involve modifying the existing components, creating new components, or revising the assembly drawings. For minor discrepancies, I may be able to make adjustments on-site. For more significant ones, collaboration with the design team is needed.

- Documentation: All discrepancies, investigations, corrective actions, and approved revisions are meticulously documented to prevent future occurrences and maintain a record for traceability.

A proactive approach, strong communication, and attention to detail are vital in effectively resolving these issues and ensuring the project’s success.

Q 8. Describe your troubleshooting skills in a fabrication or assembly setting.

Troubleshooting in fabrication and assembly is like being a detective for mechanical problems. It involves systematically identifying the root cause of a malfunction or defect, not just treating the symptom. My approach involves a structured process:

- Identify the Problem: Clearly define the issue. Is it a functional failure, a dimensional inaccuracy, or a cosmetic defect? For example, if a robotic arm isn’t welding properly, I’d note the inconsistent weld bead, the specific robot arm involved, and the time of failure.

- Gather Information: Collect data points. Check logs, review work instructions, interview operators, and inspect the faulty component. In the welding example, I’d check the welding parameters (voltage, current, speed), examine the weld joint for contamination, and review the robot’s maintenance log.

- Analyze the Data: Look for patterns and correlations. Is the problem occurring consistently, intermittently, or only under certain conditions? In our example, if the problem only happens after a specific production run, the problem could lie in the material batch.

- Develop and Test Solutions: Formulate hypotheses and test them systematically. This could involve adjusting parameters, replacing parts, or modifying the process. For the welding problem, I might adjust the welding parameters, clean the welding tip, or replace a faulty sensor on the robot arm.

- Implement and Verify: Once a solution is found, implement it and verify that it resolves the problem effectively and doesn’t introduce new issues. Post-implementation monitoring is crucial to ensure long-term stability. We’d monitor the weld quality post-adjustment to ensure the solution is sustainable.

Through this process, I’ve successfully resolved issues ranging from misaligned parts to faulty sensors in automated systems, consistently improving efficiency and reducing downtime.

Q 9. How familiar are you with lean manufacturing principles?

Lean manufacturing principles are central to efficient production. My familiarity extends to the core concepts of Value Stream Mapping, 5S, Kaizen, and Kanban. I understand how these principles reduce waste (muda) in all forms – overproduction, waiting, transportation, over-processing, inventory, motion, and defects.

For example, I’ve used Value Stream Mapping to identify bottlenecks in assembly lines by visually mapping the entire process, from raw materials to finished goods. This helped pinpoint areas where excessive inventory built up, leading to improvements in material flow and reduced lead times. Implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) in a previous role significantly improved workspace organization, reducing search time and improving safety. Finally, applying Kaizen (continuous improvement) is a constant process of observing for small, incremental adjustments to the process that create big results. We once reduced assembly time by 15% by improving the ergonomics of the workstation, a small adjustment that had a big impact.

Q 10. What safety precautions do you follow during fabrication and assembly?

Safety is paramount in fabrication and assembly. My adherence to safety protocols is unwavering and includes:

- Proper Personal Protective Equipment (PPE): Always wearing appropriate PPE such as safety glasses, hearing protection, gloves, and steel-toed boots, depending on the task.

- Lockout/Tagout Procedures: Strictly following lockout/tagout procedures before performing maintenance or repairs on machinery to prevent accidental starts.

- Ergonomic Practices: Maintaining proper posture and using lifting aids to prevent musculoskeletal injuries.

- Machine Guarding: Ensuring that all machinery is properly guarded to prevent accidental contact.

- Hazard Identification and Risk Assessment: Actively participating in hazard identification and risk assessment processes to identify and mitigate potential hazards before they become incidents. I have extensive experience completing Job Safety Analyses (JSAs).

- Housekeeping: Maintaining a clean and organized workspace to prevent trips, falls, and other accidents.

I believe safety is a shared responsibility, and I actively encourage my colleagues to adhere to safety procedures.

Q 11. Explain your experience with different types of materials (metals, plastics, composites).

I possess extensive experience working with a variety of materials, each with its own unique characteristics and challenges:

- Metals: I’m proficient in working with steel, aluminum, stainless steel, and various alloys. I understand the different machining techniques for each, including milling, turning, welding, and forming. Experience includes working with sheet metal, bar stock, and castings.

- Plastics: I have experience with thermoplastics (such as ABS, polycarbonate, and nylon) and thermosets (like epoxy and polyester). I’m familiar with injection molding, extrusion, and other plastic fabrication techniques. I understand the importance of material selection based on thermal and mechanical requirements.

- Composites: My experience extends to working with fiber-reinforced polymers (FRP), such as carbon fiber and fiberglass. I understand the unique handling and processing requirements of these materials, including layup techniques and curing processes.

This experience allows me to select the appropriate material and manufacturing process for a given application, ensuring optimal performance and cost-effectiveness.

Q 12. What is your experience with automated assembly equipment?

I have significant experience with automated assembly equipment, including robotic arms, automated guided vehicles (AGVs), and various automated assembly machines. My experience encompasses:

- Programming and Operation: I’m proficient in programming and operating various robotic systems, including those using industrial robotic languages such as RAPID (ABB) or KRL (KUKA). This includes setting up and debugging automated assembly cells.

- Troubleshooting and Maintenance: I can troubleshoot and perform basic maintenance on automated equipment, minimizing downtime and maximizing productivity. I’m capable of identifying and resolving issues ranging from sensor failures to programming errors.

- Integration: I’ve been involved in the integration of new automated equipment into existing assembly lines, ensuring seamless operation and compatibility with other systems. This includes understanding and resolving communication protocols between different machines.

For example, in a previous role, I successfully integrated a new robotic welding cell into an automotive assembly line, resulting in a 20% increase in welding efficiency and improved weld quality.

Q 13. How do you manage your time effectively in a fast-paced production environment?

Managing time effectively in a fast-paced production environment requires a proactive and organized approach. My strategies include:

- Prioritization: I use prioritization techniques to focus on the most critical tasks first, ensuring that deadlines are met and bottlenecks are avoided. Techniques include using a task management system, assigning tasks based on urgency and impact, and reviewing task lists daily.

- Time Blocking: I allocate specific time blocks for different tasks, minimizing distractions and promoting focused work. For example, I might allocate an hour in the morning for reviewing production reports and an afternoon block for resolving production issues.

- Proactive Planning: I anticipate potential delays and bottlenecks proactively, allowing me to adjust my schedule and resources accordingly. Regularly checking material stock levels and machinery maintenance schedules falls under this strategy.

- Communication: Maintaining clear and concise communication with my team and supervisors, ensuring everyone is aware of my progress and any potential roadblocks, is also vital for effective time management. This keeps everyone informed and allows for collaborative problem solving.

This structured approach ensures that I consistently meet deadlines, even in high-pressure situations.

Q 14. Describe your experience with error proofing and preventing defects.

Error proofing and defect prevention are crucial for maintaining high-quality production. My approach focuses on:

- Process Improvement: Analyzing the assembly process to identify potential points of failure and implement preventative measures. This could involve redesigning work instructions, improving tooling, or implementing Poka-Yoke (error-proofing) devices. For example, we designed a simple jig to ensure proper alignment of components, virtually eliminating misalignment defects.

- Statistical Process Control (SPC): Using SPC techniques to monitor process variables and identify trends that could lead to defects. This involves collecting data, creating control charts, and analyzing the data to identify potential problems before they cause significant issues. For example, a control chart of weld depth could signal a problem with the welding machine before multiple bad welds were produced.

- Root Cause Analysis: Conducting thorough root cause analyses to determine the underlying reasons for defects and implement corrective actions to prevent recurrence. Tools like fishbone diagrams and 5 Whys are useful here.

- Regular Audits: Conducting regular audits of the assembly process to identify potential issues and ensure adherence to quality standards. This allows for early detection and correction of problems.

- Training and Documentation: Ensuring that all personnel are properly trained and that clear and concise work instructions are available to minimize errors caused by lack of knowledge or understanding.

My proactive approach to error proofing has consistently resulted in a reduction in defects and improved overall product quality.

Q 15. Explain your understanding of tolerance and dimensional accuracy.

Tolerance and dimensional accuracy are fundamental in fabrication and assembly. Tolerance refers to the permissible variation in a dimension, essentially the acceptable range of error. Dimensional accuracy, on the other hand, describes how closely a manufactured part or assembly conforms to its specified dimensions. Think of it like baking a cake: the recipe specifies exact measurements, but you have a little leeway (tolerance) – a cake that’s slightly under or over the weight isn’t necessarily unusable. However, if it’s significantly off, it impacts the final quality (dimensional accuracy). In manufacturing, tolerances are expressed using various methods, often including plus/minus values (e.g., 10mm ± 0.1mm) or limits of size (e.g., 10mm – 10.2mm).

For example, a bolt designed to fit into a specific hole has a tolerance; the bolt diameter can’t be too small (it would be loose), nor too large (it wouldn’t fit). Maintaining dimensional accuracy is crucial for ensuring proper fit, function, and interchangeability of components. Stricter tolerances usually mean higher manufacturing costs but result in better quality and reliability.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy of your work using measuring instruments?

Ensuring accuracy relies heavily on the correct selection and proficient use of measuring instruments. This starts with calibration – verifying the instrument against a known standard. I regularly calibrate my tools, typically using traceable standards, and document the calibration process. For instance, micrometers, calipers, and height gauges are regularly checked against certified master gauges. Beyond calibration, proper measurement techniques are crucial. This includes understanding instrument limitations (resolution, accuracy), ensuring the instrument is clean and properly handled, and taking multiple measurements at different orientations to minimize errors. I always record measurements meticulously in a log, including the instrument used, date, and the part’s identifier. For complex geometries, I might utilize coordinate measuring machines (CMMs) or optical comparators for higher precision and detailed analysis.

For example, when measuring the diameter of a cylindrical part, I’d take at least three measurements at different positions along the axis and average them to account for any slight variations in the part. If inconsistencies exceed the acceptable tolerance, I’d investigate the root cause, such as machine wear or improper machining parameters.

Q 17. What experience do you have with different types of assembly processes (manual, automated)?

My experience spans both manual and automated assembly processes. Manual assembly requires dexterity, precision, and a deep understanding of the product design. I’ve worked extensively on projects involving intricate hand-assembly of electromechanical devices, ensuring proper alignment and secure fastening of delicate components. This involves following detailed work instructions, performing quality checks at each stage, and employing appropriate tools and jigs. I’m adept at using various hand tools, fasteners, and adhesives.

On the other hand, I’m also proficient in automated assembly. This includes experience with robotic assembly lines where components are automatically fed, positioned, and assembled using robotic arms and specialized tooling. My experience with automated systems involves programming and troubleshooting robotic cells, optimizing assembly sequences for efficiency, and understanding the limitations and capabilities of automated equipment. For example, I worked on a project where we automated the assembly of a small electronic circuit, resulting in a significant increase in throughput and reduction in human error.

Q 18. Describe your experience with using CAD software for fabrication design.

I’m proficient in several CAD software packages, including SolidWorks, AutoCAD, and Inventor. My experience encompasses using these tools to create 2D and 3D models of fabricated parts and assemblies, generate detailed drawings including tolerances and annotations, and perform simulations to verify design functionality and manufacturability. I’m adept at creating and modifying designs based on design reviews and feedback. I also utilize CAD software to generate cutting lists, material estimates, and production documentation, streamlining the entire fabrication process. For instance, in a recent project, I used SolidWorks to design a custom fixture for an automated assembly line, optimizing its geometry and material selection for strength and cost-effectiveness.

Furthermore, my CAD proficiency extends to utilizing design for manufacturing (DFM) principles. I always consider the limitations of available manufacturing processes during design to ensure cost-effective and efficient production. This includes selecting appropriate materials, tolerances, and features that are easily achievable using the selected manufacturing processes.

Q 19. How do you handle unexpected issues or delays in the production process?

Handling unexpected issues or delays requires a systematic approach. My first step is always to identify the root cause of the problem. This might involve reviewing production logs, inspecting the faulty components, and consulting with the team. Once the root cause is understood, I develop a contingency plan. This could involve adjusting the production schedule, sourcing alternative materials or components, or implementing corrective actions to prevent recurrence. Effective communication is critical; I keep all stakeholders informed about the issue, the proposed solution, and the expected impact on the project timeline.

For example, I once encountered a delay due to a supplier’s failure to deliver critical components on time. My response involved identifying alternative suppliers, expediting the delivery process, and negotiating a revised delivery schedule. Simultaneously, I worked with the engineering team to explore alternative design solutions that could utilize readily available components, minimizing the impact on the overall project.

Q 20. What are your preferred methods for documenting assembly procedures?

My preferred methods for documenting assembly procedures are clear, concise, and readily accessible. I typically use a combination of visual aids and textual descriptions. Detailed illustrated work instructions, using software like Adobe Illustrator or specialized assembly instruction software, are commonly used. These instructions include step-by-step procedures, diagrams, images, and parts lists. I also incorporate videos or animated sequences to demonstrate complex assembly steps. This ensures that even those unfamiliar with the product can easily understand and follow the assembly process. Furthermore, I ensure that all documentation is version-controlled and readily accessible to all relevant personnel.

For example, when documenting the assembly of a complex mechanical device, I’d create a series of numbered steps, each with a clear image or diagram showing the correct component placement and orientation. I’d include torque specifications for fasteners, wiring diagrams for electrical connections, and any special tooling or safety precautions required.

Q 21. What is your experience with testing and inspecting finished products?

Testing and inspecting finished products are essential to ensure quality and adherence to specifications. My experience includes performing various tests, including functional tests (verifying the product’s functionality), dimensional inspections (checking for accuracy and tolerances), and performance testing (evaluating the product’s performance under various conditions). I’m familiar with various testing equipment and methodologies, including automated testing systems and statistical process control (SPC) techniques. I use data from testing and inspection to identify any defects, analyze root causes, and implement corrective actions to prevent future issues. This includes using data analysis tools to identify trends and patterns in defect rates.

For example, in a recent project, we implemented an automated testing system to check the functionality of electronic devices after assembly. This enabled us to quickly identify and rectify any faulty units, minimizing rework and improving overall product quality. This system also collected data which helped us identify systematic issues in the assembly process leading to higher defect rates.

Q 22. How do you ensure the safety of yourself and others in a manufacturing setting?

Safety in a manufacturing environment is paramount. It’s not just about following rules; it’s about cultivating a safety-first mindset. My approach is multi-faceted and begins with rigorously adhering to all company safety policies and procedures. This includes proper use of Personal Protective Equipment (PPE), such as safety glasses, hearing protection, steel-toe boots, and any other specialized gear required for the specific task.

Beyond PPE, I proactively identify and report any potential hazards. This might involve noticing a loose wire, a spill, or a malfunctioning piece of equipment. I firmly believe in the power of teamwork in safety; I actively participate in safety meetings, contribute to hazard assessments, and readily assist colleagues in ensuring they are working safely. I’m also trained in emergency procedures, including first aid and evacuation protocols, and I’m comfortable acting quickly and responsibly in emergency situations. Finally, I constantly strive to improve my own safety knowledge through continuous training and by staying updated on industry best practices.

For instance, during a project involving heavy machinery, I noticed a colleague wasn’t using the safety guard correctly. Instead of simply ignoring it, I politely approached them, explained the potential risks, and showed them the proper procedure. This proactive approach, focused on both individual and collective safety, is fundamental to my work ethic.

Q 23. Explain your understanding of ergonomics in fabrication and assembly.

Ergonomics in fabrication and assembly focuses on designing workstations and tasks to minimize physical strain and discomfort. It’s about creating a work environment that’s comfortable and efficient, leading to increased productivity and reduced risk of injury. Understanding ergonomics involves considering factors such as posture, repetitive motions, and the weight and reach of tools and materials.

In practice, this means advocating for adjustable workstations, proper tool placement, and the use of ergonomic tools that reduce strain on the body. For example, using anti-fatigue mats to reduce strain on the legs, implementing proper lifting techniques to prevent back injuries, and ensuring that tools are readily accessible to minimize awkward reaching are crucial. I always assess my workspace to identify potential ergonomic issues. If I notice something uncomfortable or inefficient, I’ll suggest improvements, such as adjusting the height of my workbench or using a different tool to reduce repetitive movements. A poorly designed workspace not only impacts efficiency but also significantly increases the risk of musculoskeletal disorders such as carpal tunnel syndrome or back pain.

Q 24. What is your experience with preventative maintenance of equipment?

Preventative maintenance is crucial for ensuring equipment reliability and preventing costly downtime. My experience involves performing routine inspections, lubricating moving parts, replacing worn components, and documenting all maintenance activities. This is often a scheduled routine, but also involves being vigilant for any signs of wear or malfunction during daily operation. I’m familiar with a variety of equipment, including welding machines, cutting tools, and assembly robots, and I understand the specific maintenance needs of each.

For instance, in a previous role, I was responsible for the preventative maintenance of our CNC milling machine. This included daily checks of coolant levels, weekly lubrication of moving parts, and monthly inspections of the cutting tools. By diligently following the manufacturer’s recommendations and carefully monitoring the machine’s performance, I was able to avoid several potential breakdowns and ensure consistent production output. A proactive approach to maintenance saves money in the long run by avoiding costly emergency repairs and extending the lifespan of equipment.

Q 25. Describe your experience with working from technical drawings and specifications.

I have extensive experience interpreting and working from technical drawings and specifications. This includes understanding various drawing types, such as orthographic projections, isometric views, and schematics. I can decipher dimensions, tolerances, materials specifications, and manufacturing processes indicated in the drawings. My skills extend beyond simply reading the drawings; I can effectively translate the design into a physical product. I can identify potential design flaws or ambiguities and communicate them effectively to the design team.

For example, I recently worked on a project that involved fabricating a complex metal bracket from a detailed engineering drawing. The drawing specified tight tolerances and specific surface finishes. Using my skills, I was able to accurately fabricate the bracket to meet all the specifications, ensuring a precise fit and function within the final assembly. My experience working with various CAD software allows me to easily interpret 3D models and extract relevant information for the fabrication and assembly processes.

Q 26. What are your strengths and weaknesses in a fabrication and assembly role?

My strengths lie in my meticulous attention to detail, my problem-solving abilities, and my commitment to quality. I’m a highly efficient worker who consistently meets deadlines. I’m also a quick learner and adapt readily to new technologies and processes. My experience working on complex projects has honed my ability to manage multiple tasks simultaneously and work effectively under pressure.

One area I’m actively working to improve is my delegation skills. While I’m comfortable taking on a lot of responsibility, I recognize the importance of delegating tasks effectively to optimize team productivity and development. I’m actively seeking opportunities to develop this skill and improve my leadership capabilities within team environments.

Q 27. How do you prioritize tasks in a high-volume production setting?

Prioritizing tasks in a high-volume production setting requires a systematic approach. I typically use a combination of methods to ensure the most efficient workflow. Firstly, I identify tasks with the shortest lead times and the most significant impact on the overall production schedule. This is often determined by analyzing the Bill of Materials (BOM) and the production schedule. Secondly, I consider the urgency and dependencies between tasks. Some tasks might be critical prerequisites for subsequent stages of the production process, and these take precedence. Finally, I assess the resources required for each task, including manpower, equipment, and materials, to ensure a balanced workload and prevent bottlenecks.

I often use Kanban or similar visual management systems to track progress and identify potential roadblocks. This allows for real-time adjustments and ensures that the most important tasks are always at the forefront. Flexibility and adaptability are key in such environments, allowing me to react swiftly to unexpected changes in priorities.

Q 28. Describe a time you had to solve a complex problem in a fabrication or assembly project.

In a previous project involving the assembly of a complex electronic device, we encountered a recurring problem: a high failure rate in a specific sub-assembly. The initial troubleshooting efforts focused on individual components, but the problem persisted. I decided to take a step back and systematically analyze the entire assembly process, including the sequence of operations, the tools used, and the environmental factors.

Through careful observation and data collection, I discovered that the problem wasn’t with the components themselves, but with the sequence of assembly steps. A slight change in the order of operations, combined with the use of a different jig, significantly reduced the failure rate. This solution, born from a methodical approach to problem-solving, demonstrated the importance of considering the bigger picture and not just focusing on individual components.

Key Topics to Learn for Fabrication and Assembly Knowledge Interview

- Blueprint Reading and Interpretation: Understanding technical drawings, schematics, and specifications to accurately interpret assembly instructions and identify components.

- Material Selection and Properties: Knowledge of various materials (metals, plastics, composites) and their properties (strength, durability, machinability) to choose the right materials for specific applications. Practical application: Justifying material choices based on project requirements and cost-effectiveness.

- Assembly Processes and Techniques: Familiarity with various assembly methods (welding, soldering, riveting, bolting, adhesive bonding) and their appropriate applications. Understanding quality control measures at each stage.

- Quality Control and Inspection: Implementing and adhering to quality control procedures to ensure the accuracy and precision of fabricated and assembled products. Identifying and troubleshooting defects.

- Safety Procedures and Regulations: Understanding and adhering to all relevant safety regulations and procedures within a fabrication and assembly environment. This includes the safe use of tools and equipment.

- Tools and Equipment: Demonstrating proficiency in using a variety of hand tools, power tools, and machinery commonly used in fabrication and assembly (e.g., measuring instruments, welding equipment, CNC machines). Understanding preventative maintenance procedures.

- Lean Manufacturing Principles: Understanding and applying lean manufacturing principles to optimize efficiency, reduce waste, and improve overall productivity in the fabrication and assembly process.

- Problem-Solving and Troubleshooting: Ability to identify, analyze, and resolve problems that may arise during the fabrication and assembly process. This includes utilizing problem-solving methodologies.

- Production Planning and Scheduling: Understanding the basics of production planning and scheduling to ensure timely completion of projects and efficient resource allocation.

Next Steps

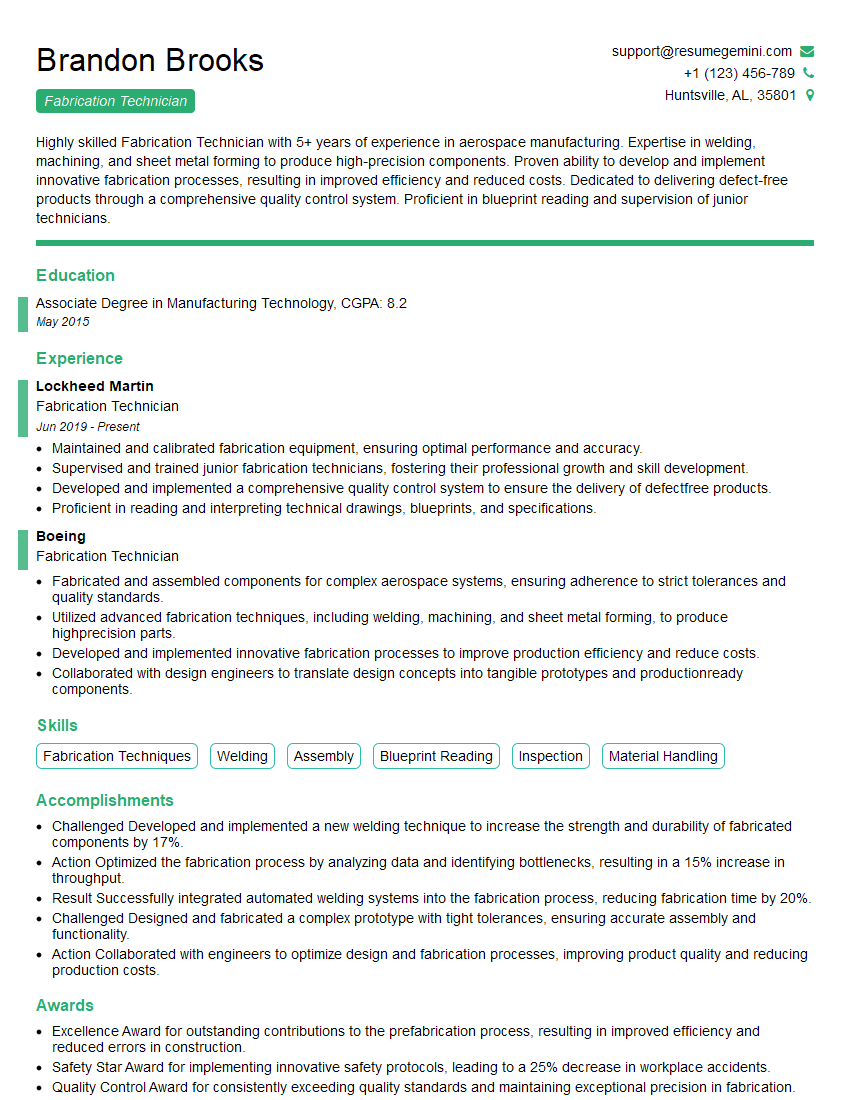

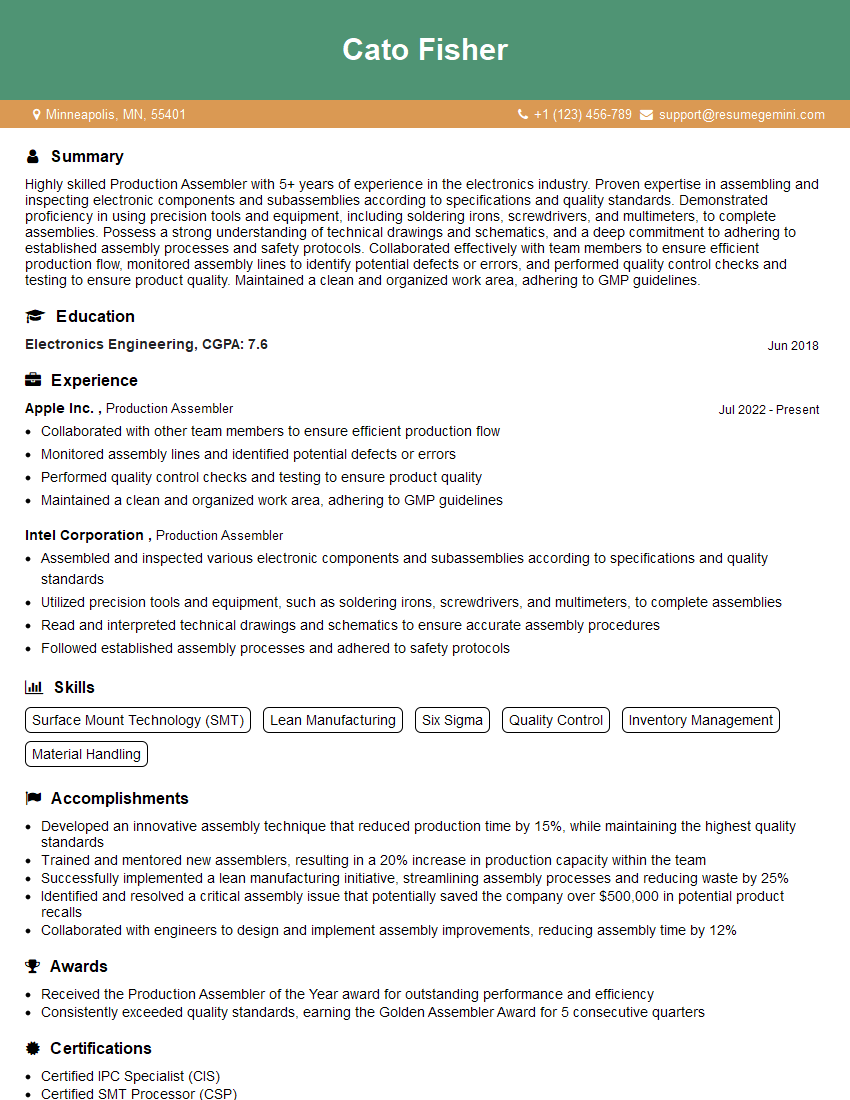

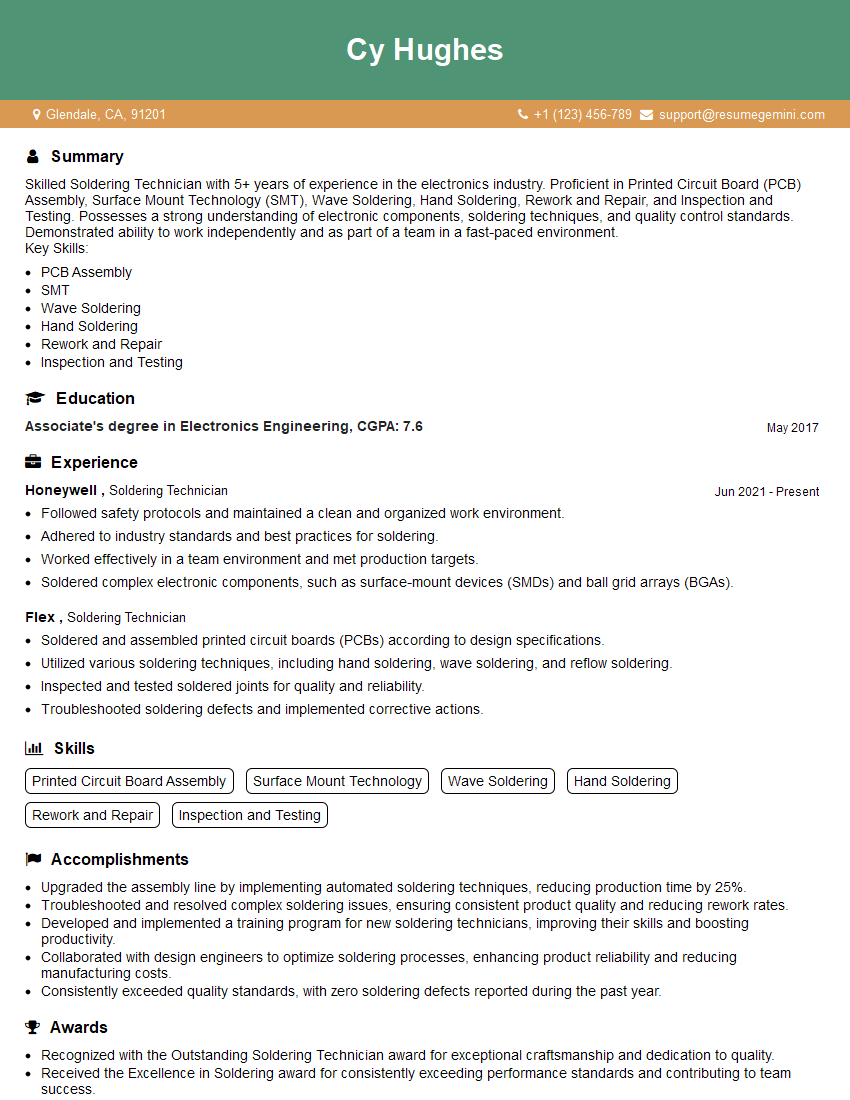

Mastering Fabrication and Assembly Knowledge is crucial for career advancement in this dynamic field. A strong understanding of these concepts will significantly improve your job prospects and allow you to contribute meaningfully to a team. To maximize your chances of landing your dream role, creating an ATS-friendly resume is vital. This ensures your qualifications are effectively highlighted to potential employers. We recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini offers a streamlined process and provides examples of resumes tailored to Fabrication and Assembly Knowledge to help you showcase your skills effectively. Take the next step towards your career success today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good