Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Schematic Capture and Design interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Schematic Capture and Design Interview

Q 1. Explain the difference between a schematic and a PCB layout.

A schematic and a PCB layout are distinct but interconnected stages in electronic design. Think of a schematic as the blueprint of your circuit, a high-level representation showing the components and their connections using symbols. It’s like an architectural drawing for a house, detailing rooms and their interconnections. The PCB layout, on the other hand, is the physical implementation of that blueprint, showing the exact placement and routing of components and traces on a printed circuit board. It’s like the actual construction plan, specifying where each brick, pipe, and wire goes. The schematic focuses on functionality, while the layout concentrates on physical realization and manufacturability.

For example, a schematic might show a simple resistor-capacitor (RC) circuit with a resistor and capacitor connected in series. The PCB layout would then show the physical placement of these components on the board, along with the traces connecting them, considering factors like trace width, spacing, and layer assignment. The schematic is abstract; the layout is concrete.

Q 2. What are the common schematic capture software packages you are familiar with?

I’m proficient in several schematic capture software packages, including Altium Designer, Eagle, KiCad, and OrCAD. Each has its strengths and weaknesses. Altium Designer, for instance, is known for its robust features and advanced capabilities, particularly beneficial for complex designs. Eagle is popular for its relative simplicity and ease of use, making it a good choice for beginners or smaller projects. KiCad is a powerful, free and open-source option gaining significant traction, while OrCAD is a widely used industry standard, particularly in larger organizations. My experience spans using these tools across a variety of project types and scales.

Q 3. Describe your experience with component libraries and symbol creation.

Component libraries and symbol creation are crucial aspects of efficient schematic capture. I have extensive experience building and managing libraries, creating custom symbols for both common and specialized components. This involves not only drawing the visual representation of the component but also defining its properties, such as pin names, values, and footprints. A well-organized library is essential for design consistency and speed. For example, I once created a custom library of specialized RF components for a high-frequency communication project, ensuring accurate and consistent representation throughout the design process. If a component isn’t available in a standard library, I follow a rigorous process: carefully review datasheets, model the component’s electrical characteristics (if necessary), and design a schematic symbol that reflects these characteristics for use in simulations and PCB layout.

Q 4. How do you manage design revisions and version control in schematic capture?

Version control in schematic capture is vital for managing design revisions and collaboration. I utilize a combination of software-based version control systems, such as Git, and the built-in revision management features within the schematic capture software itself. Each significant design change is documented, allowing for easy rollback to previous versions if needed. This ensures traceability and helps to prevent errors. Think of it like tracking changes in a document using Google Docs or Microsoft Word’s revision history. For example, in a recent project, Git was employed to track all schematic changes, enabling seamless collaboration amongst the design team and effortless restoration of prior design iterations should problems arise.

Q 5. Explain your process for creating and verifying netlists.

Creating and verifying netlists is a critical step that bridges the gap between the schematic and the PCB layout. My process involves generating a netlist from the schematic using the software’s built-in capabilities. This netlist is essentially a textual representation of all connections within the design. I then verify the netlist’s accuracy by performing thorough checks and comparing it against the schematic to identify any discrepancies or errors. This often involves using specialized tools or features within the design software to automate the verification process. A good example would be comparing the generated netlist against the original schematic using a built-in netlist comparator feature to guarantee that the PCB layout will correctly reflect the intended circuit connectivity. If discrepancies are identified, I carefully trace and resolve them in the schematic before proceeding further.

Q 6. What are some common design rule checks (DRC) in schematic capture?

Design rule checks (DRCs) in schematic capture are automated checks that ensure the design adheres to specific rules and guidelines. Common DRCs include checking for inconsistencies in component designations, unconnected nets, and incorrect naming conventions. For instance, a DRC might flag an instance where a component is used with the wrong value or where a net is left floating without any connections. These checks help to catch potential errors early in the design process, preventing costly mistakes later on. Another example involves verifying that signals on different power planes are adequately separated to avoid interference. Regular DRC executions help ensure a cleaner, more robust and reliable design.

Q 7. How do you handle design changes during the schematic capture phase?

Handling design changes during schematic capture requires a systematic approach. I employ a change management process that involves documenting all changes, updating the schematic accordingly, and re-verifying the design using DRCs and netlist comparisons. All stakeholders are notified about updates and impact assessments are undertaken to ensure that downstream activities are not compromised. For example, if a component needs to be replaced, I systematically update the schematic, replace the component symbol, and re-run the DRC to check for any related issues. Thorough documentation ensures that future modifications and maintenance are straightforward and error-free.

Q 8. Describe your experience with hierarchical design in schematic capture.

Hierarchical design in schematic capture is a crucial technique for managing complexity in large electronic designs. Think of it like building with LEGOs: instead of working with thousands of individual bricks, you create sub-assemblies (smaller LEGO structures) and then combine those to build the final product. In schematics, this means breaking down a large circuit into smaller, manageable blocks or modules. Each module is a separate schematic sheet, potentially with its own hierarchy. This simplifies design, improves readability, and allows for easier reuse of components and sub-circuits.

For example, in designing a complex microcontroller-based system, you might create separate hierarchical blocks for the power supply, the microcontroller unit itself, sensor interfaces, and communication interfaces. Each of these would be a separate sheet, and they could even be further broken down. You then connect these higher-level blocks on a top-level schematic sheet, showing the overall system architecture. This modular approach dramatically reduces design time and significantly improves maintainability and error detection.

Q 9. How do you ensure schematic accuracy and consistency?

Ensuring schematic accuracy and consistency is paramount. It’s like following a precise recipe in cooking – even a small mistake can ruin the final dish. I employ several strategies:

- Design Rules Check (DRC): Utilizing built-in DRC features within the schematic capture software is essential. These tools automatically check for common errors such as unconnected nets, incorrect component values, and violations of design rules specified by the engineer (e.g., maximum voltage ratings).

- Component Libraries: Utilizing well-maintained and validated component libraries ensures consistent symbol usage and accurate component information. This prevents potential errors arising from incorrect values or mismatched components.

- Version Control: Implementing a robust version control system is critical for managing changes and ensuring that multiple designers can work collaboratively without conflicts. This allows for easy tracking of design iterations and a clear history of changes.

- Peer Reviews: Formal design reviews by other engineers or designers provide a fresh perspective and help catch errors that may have been overlooked. A second pair of eyes is invaluable.

Q 10. What are your strategies for debugging schematic errors?

Debugging schematic errors is akin to detective work. My approach is systematic and involves several steps:

- Utilize DRC: The first step is always to run a thorough Design Rules Check. This often highlights obvious issues like unconnected nets or missing components.

- Visual Inspection: Careful visual inspection of the schematic is necessary to identify any potential errors that the DRC might have missed. Looking for unusual wiring or component placements is essential.

- Netlist Review: Analyzing the generated netlist (a textual representation of the circuit connections) can help identify connectivity issues not readily apparent from the schematic diagram.

- Simulation: Circuit simulators (like SPICE) can be used to model the circuit’s behavior and check its functionality. This helps in verifying that the circuit meets the required specifications.

- Cross-Probing: If the error is related to a specific component, cross-probing to the PCB layout can quickly isolate the problem.

By following a structured approach, I can efficiently pinpoint the root cause of the error and implement the necessary corrections.

Q 11. Explain your understanding of electrical symbols and their usage.

Electrical symbols are the visual language of schematic capture. They represent electronic components and their connections in a standardized format. Just like road signs guide drivers, electrical symbols provide engineers with a universal way to communicate circuit design.

Understanding their usage is critical for efficient schematic creation. A thorough understanding of the symbols for common components such as resistors, capacitors, transistors, integrated circuits, and connectors is essential. Additionally, understanding less common components and being able to interpret manufacturer datasheets is a valuable skill. Incorrect symbol usage can lead to significant design errors, so adhering to established standards like ANSI/IEEE is critical.

For example, the symbol for a resistor is a zigzag line, while a capacitor is represented by two parallel lines, and transistors are shown with specific symbols representing their terminal structure (base, collector, emitter). The level of detail in the symbols can vary based on the design’s requirements. Simple schematics may only show the component’s function, while complex designs might incorporate detailed symbols that provide additional information.

Q 12. Describe your experience with cross-probing between schematic and PCB layout.

Cross-probing between schematic and PCB layout is a powerful feature that enables efficient design verification. Think of it as a two-way communication channel between the design intent (schematic) and its physical implementation (PCB). By selecting a component or a net on the schematic, cross-probing immediately highlights the corresponding component or trace on the PCB layout, and vice-versa.

This is invaluable for several reasons. It allows quick verification of component placement, net routing, and connectivity. If a problem is identified on the PCB, cross-probing to the schematic can quickly reveal the root cause in the design. This feature helps identify and resolve any discrepancies between the schematic and the layout, minimizing errors during the PCB design and manufacturing stages. For example, if a trace appears disconnected on the PCB, cross-probing can quickly identify if this is a layout issue or if a net is incorrectly connected in the schematic.

Q 13. How do you manage multiple sheets in a large schematic design?

Managing multiple sheets in a large schematic design requires a well-structured approach. Similar to organizing a large project, it demands careful planning and organization.

- Hierarchical Design: As discussed previously, hierarchical design plays a critical role in managing complexity. Breaking down the design into smaller, manageable blocks reduces the number of components on any single sheet.

- Sheet Naming Conventions: Consistent and descriptive sheet naming conventions are crucial for navigation and organization. Using a logical system, such as a naming convention that indicates the module function or its location within the overall design, helps greatly.

- Sheet Index: Maintaining a clear sheet index is essential. This index acts as a roadmap of the entire design, making it easier to find specific components and modules.

- Schematic Management Software Features: Utilizing the sheet management features provided by the schematic capture software, such as sheet cross-referencing and sheet searching, is essential for efficient navigation.

By employing these strategies, even very large designs can be handled efficiently and maintained easily.

Q 14. What are some best practices for creating clear and well-organized schematics?

Creating clear and well-organized schematics is crucial for ease of understanding, maintenance, and collaboration. It’s like writing a well-structured essay – clear organization improves comprehension. Here are some best practices:

- Use a Consistent Design Style: Adhering to a consistent style guide ensures uniformity throughout the schematic, improving readability and reducing errors. This includes consistent use of symbols, line widths, text sizes, and placement of components.

- Logical Component Placement: Arrange components logically, grouping related components together and placing them in a manner that improves understanding of the circuit’s function. This makes the schematic easier to interpret and simplifies tracing signals.

- Clear Signal Flow: Design the schematic so that signals flow in a consistent direction, typically from left to right or top to bottom. This helps to improve the readability of the schematic.

- Use Busses Effectively: Utilize buses to represent groups of interconnected signals, reducing the clutter and complexity of the schematic.

- Add Clear Annotations and Labels: Use clear and concise labels for components and nets, and add notes to explain any complex circuitry or unusual design choices. This makes the design easier to understand.

- Use a Hierarchy to Reduce Complexity: Employ hierarchical design, as described previously, to manage complex designs and enhance readability.

By following these practices, you ensure that your schematics are not only functional but also easily understandable by anyone reviewing or maintaining the design. This is critical for collaboration, debugging, and the long-term success of any electronic product.

Q 15. Explain your process for annotating and documenting schematics.

Annotating and documenting schematics is crucial for clarity, maintainability, and successful manufacturing. My process involves a multi-step approach ensuring comprehensive information is readily available. First, I meticulously label all components with clear, consistent designations following a well-defined naming convention (e.g., using prefixes to indicate component type and function). Second, I add designators to every net (signal line) for easy traceability throughout the design process and PCB layout. Third, I create a comprehensive bill of materials (BOM) directly linked to the schematic, automatically updating as the design evolves. This ensures accuracy and avoids potential errors. Fourth, I include detailed annotations explaining design choices, such as the rationale behind specific component selections or critical signal routing. Finally, I generate a set of thorough design specifications documenting component parameters, tolerances, operating conditions, and test procedures. This detailed documentation minimizes ambiguity, facilitates collaboration, and simplifies debugging during both the design and production phases. For example, in a recent project involving a high-speed data acquisition system, I used a hierarchical approach, annotating sub-circuits within the main schematic for better organization and clarity. This made the design far easier to understand and modify.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle signal integrity issues in schematic design?

Signal integrity is paramount, particularly in high-speed designs. I proactively address potential issues during the schematic design phase itself. This starts with careful component selection – choosing components with appropriate characteristics (e.g., low impedance, controlled inductance, minimized capacitance) for the intended signal frequencies. I then strategically place components to minimize trace lengths and loop areas, reducing parasitic inductance and capacitance. I also employ techniques such as using controlled impedance traces and incorporating termination resistors where necessary. Furthermore, I use simulation tools, such as SPICE, to verify signal integrity early in the design cycle, identifying and resolving potential issues before proceeding to the PCB layout stage. For instance, in a recent project involving a 10 Gigabit Ethernet interface, I used SPICE simulations to optimize the termination scheme, ensuring reliable signal transmission at high data rates. Early simulation uncovered a potential reflection issue which was resolved by adjusting trace impedance and adding a termination network.

Q 17. What are your experiences with different types of components (passive, active, integrated)?

My experience encompasses a wide range of components, including passive (resistors, capacitors, inductors), active (transistors, operational amplifiers), and integrated circuits (ICs). I understand the nuances of each type and their impact on circuit performance. For example, I’m familiar with different resistor technologies (e.g., thin-film, thick-film, metal-film), understanding their precision, power handling, and temperature coefficients. Similarly, I’m adept at selecting appropriate capacitors based on factors such as ESR (Equivalent Series Resistance) and ESL (Equivalent Series Inductance) for high-frequency applications. With active components, I carefully consider parameters such as gain, bandwidth, and noise figure for optimal circuit behavior. My IC selection is always informed by careful evaluation of datasheets, including considerations like package type, pinouts, operating voltages, and power consumption. Experience has shown me that a deep understanding of component limitations and trade-offs is crucial for robust design.

Q 18. How do you ensure the schematic is manufacturable?

Ensuring manufacturability is a critical aspect of schematic design. I achieve this by adhering to several key principles. Firstly, I use components readily available from reputable suppliers and choose packages that are commonly used in PCB manufacturing to prevent delays and ensure cost-effectiveness. Secondly, I limit the number of unique component types and values to simplify the assembly process and reduce the risk of errors. Thirdly, I avoid placing components too close together, providing sufficient space for component placement and soldering. Fourthly, I pay close attention to thermal considerations, making sure components with high power dissipation have adequate heat sinking. Finally, I avoid the use of obsolete or hard-to-source components. In one project, utilizing readily available surface mount components resulted in a 20% reduction in manufacturing costs compared to a previous design that included less common through-hole components.

Q 19. Explain your experience with design for manufacturability (DFM) principles.

Design for Manufacturability (DFM) is an integral part of my design workflow. I understand and apply key DFM principles from the initial schematic stages to minimize manufacturing challenges. This includes considering aspects such as component placement, trace routing, thermal management, and testability. For example, I ensure that components are placed in locations that are easily accessible for automated assembly processes. I prioritize standardized and widely available component packages that are compatible with industry-standard automated assembly equipment. Furthermore, I carefully design the PCB layout to incorporate sufficient clearances to prevent shorts and other manufacturing defects. I utilize design rules checking (DRC) tools to identify potential manufacturing issues early in the design process. My experience has taught me that proactive consideration of DFM leads to significant cost and time savings, and greatly reduces the risk of design iterations during manufacturing.

Q 20. How familiar are you with SPICE simulation and its application in schematic design?

I’m highly proficient in SPICE simulation and its application in schematic design. SPICE (Simulation Program with Integrated Circuit Emphasis) is an invaluable tool for verifying circuit functionality, analyzing performance characteristics, and identifying potential issues before fabrication. I use it extensively for DC and AC analysis, transient analysis, and noise analysis. This helps me optimize circuit design for things like gain, bandwidth, noise levels, and power consumption. For instance, I used SPICE simulation to model the behavior of an operational amplifier circuit, ensuring its stability and accuracy before prototyping. I am also familiar with different SPICE simulators like LTSpice and Ngspice, allowing me to choose the best tool based on the complexity and specifics of the design. SPICE simulation allows me to explore design tradeoffs quickly and efficiently, leading to better circuit designs.

Q 21. Describe your experience using design collaboration tools.

I have extensive experience using various design collaboration tools, enabling efficient teamwork and streamlined workflows. I’m proficient in using cloud-based platforms such as Google Drive, Dropbox, and Altium 365 for sharing and version controlling schematic designs. I’m comfortable with revision control systems like Git for collaborative design development, ensuring that everyone is working on the most up-to-date version. This approach prevents conflicts and ensures consistent design iterations. For instance, in a recent project, the entire team used a shared cloud-based repository to manage and update schematics, reducing the risk of errors. The ability to track design changes and revert to previous versions if necessary is invaluable. This collaborative approach not only improves efficiency but also fosters better communication and knowledge sharing within the design team.

Q 22. How do you manage design changes from multiple engineers?

Managing design changes from multiple engineers requires a robust version control system and a clear communication strategy. Think of it like a collaborative document – everyone needs access, but we need to avoid chaos. We typically use a system like Git integrated with our schematic capture software. This allows for branching and merging of design changes, tracking revisions, and resolving conflicts effectively.

- Branching Strategy: Each engineer works on a separate branch for their specific tasks. This isolates their changes until they’re ready for integration.

- Regular Check-ins: Frequent commits and merges help prevent large, difficult-to-integrate changes. Think of it like saving your work often – you avoid losing too much progress if something goes wrong.

- Code Reviews/Schematic Reviews: Before merging changes, a review process ensures the quality and consistency of the design. This is like a peer editing process; a second pair of eyes catches errors and inconsistencies.

- Clear Naming Conventions: We establish a clear naming convention for branches and commits to easily track changes and understand their purpose.

- Communication Tools: We use project management software and regular meetings to coordinate efforts and address any conflicts that arise. This proactive communication is key to keeping everyone aligned.

For example, if one engineer is modifying the power supply section while another is working on the digital signal processing, their branches remain separate until both sections are complete and thoroughly tested individually before merging into the main branch.

Q 23. Explain your process for generating BOMs from schematics.

Generating a Bill of Materials (BOM) from schematics is a crucial step in the design process. Most modern schematic capture software automates this process, but it requires careful setup and attention to detail. My process involves these steps:

- Component Libraries: Maintaining accurate and up-to-date component libraries is paramount. Each component should have a unique identifier and all relevant information, including part numbers, manufacturer details, and cost. Think of this as a meticulously organized inventory database.

- Design Rules Check (DRC): Before generating the BOM, running a DRC helps catch errors, like missing components or incorrect part designations. This ensures data accuracy.

- BOM Generation: Most EDA software offers a built-in BOM generator. I typically configure it to include all necessary information like part number, quantity, description, and manufacturer. This exports the data in a standard format like CSV or Excel for easy use in procurement.

- BOM Review and Verification: I always manually review the generated BOM for accuracy and completeness. This catches any software errors or missed items. Imagine it as a final quality control check.

- Version Control: The BOM is saved and version controlled along with the schematic, maintaining a complete record of design revisions. This ensures traceability and accountability.

For instance, if we discover a component shortage after BOM generation, the process allows us to track back to the schematic, identify the part, and find potential substitutes while minimizing delays.

Q 24. What are some common challenges you face in schematic capture, and how do you overcome them?

Common challenges in schematic capture include managing complex designs, ensuring design rule compliance, and handling component library inconsistencies. Let’s look at how I tackle these:

- Complex Designs: For large, complex designs, hierarchical design is essential. Breaking down the schematic into manageable blocks simplifies design, review, and debugging. Imagine it like building with Lego bricks; smaller, manageable parts make the larger structure easier to manage.

- Design Rule Compliance: Using design rule checking (DRC) tools is crucial for identifying potential design flaws early. This includes checks for incorrect component placements, clearance violations, and netlist inconsistencies. Think of this as a spell-check for your electrical design.

- Component Library Inconsistencies: Maintaining a consistent and well-organized component library is key. This prevents errors arising from using outdated or conflicting parts. It’s like using a standard parts list to ensure everyone is using the same parts, avoiding compatibility issues.

To overcome these challenges, I emphasize clear documentation, systematic design methodologies, and regular verification steps. This ensures efficiency and reduces errors.

Q 25. Describe your experience with different design methodologies (top-down, bottom-up).

Both top-down and bottom-up design methodologies have their place in schematic capture. The choice depends on project complexity and requirements.

- Top-Down Design: This starts with the overall system architecture and progressively refines it into lower-level modules. It’s great for large, complex projects where the overall system behavior needs to be defined first. Imagine building a house – you start with the blueprints and then work on individual rooms.

- Bottom-Up Design: This starts with individual components or modules and integrates them to form the complete system. It’s suitable for projects where well-defined, reusable components already exist. Think of it as assembling a kit; you start with individual parts and build the larger model.

I have experience with both methodologies. Often, a hybrid approach is the most effective, combining aspects of both top-down and bottom-up design to leverage the strengths of each. For example, a project might start with a top-down approach to define the system architecture, but then switch to a bottom-up approach for implementing individual modules based on pre-existing designs.

Q 26. What are your strengths and weaknesses in schematic capture and design?

My strengths lie in my ability to design complex, robust, and maintainable schematics. I’m proficient in several EDA tools and possess a solid understanding of electrical engineering principles. I excel at troubleshooting and debugging schematic designs and am comfortable working both independently and collaboratively.

An area where I could improve is my experience with some of the more advanced features of newer schematic capture software. While I am quick to learn, staying completely abreast of every new tool and function is a constant process requiring ongoing development.

Q 27. How do you stay up-to-date with the latest advancements in schematic capture software and technologies?

Staying current involves a multi-pronged approach:

- Training Courses: I regularly attend webinars and training courses offered by EDA software vendors. This helps in staying up to date on the new features and efficient techniques.

- Online Resources: I actively participate in online forums, communities, and read industry publications. This allows for peer learning and exposure to new technologies.

- Conferences and Workshops: Attending industry conferences and workshops provides invaluable exposure to the latest advancements and best practices in schematic capture and design.

- Hands-on Experience: Working on various projects using different EDA tools constantly challenges me and expands my skillset.

For example, I recently attended a workshop focused on high-speed digital design techniques which incorporated new features in our company’s EDA software for signal integrity analysis – significantly enhancing my skillset.

Q 28. Describe a challenging schematic design project you worked on, and how you solved it.

One challenging project involved designing the schematic for a high-speed data acquisition system. The requirements included low noise, high bandwidth, and precise timing synchronization across multiple channels. The initial design faced significant challenges with signal integrity issues and timing jitter. To overcome these challenges, we employed a multi-pronged strategy:

- Careful Component Selection: We meticulously selected components optimized for high-speed applications, paying close attention to their specifications. We analyzed datasheets carefully to ensure compatibility and performance.

- Signal Integrity Simulation: We utilized advanced signal integrity simulation tools to model and analyze potential noise and interference sources. This allowed us to identify and mitigate potential problems early in the design process. We used simulations to optimize trace lengths and routing to reduce noise and jitter.

- Iterative Design and Testing: We implemented an iterative design and testing process, building and testing prototypes to validate the design at each stage. This provided feedback for iterative improvements.

- Collaboration: We collaborated closely with the PCB designers to ensure a seamless integration between the schematic and the PCB layout. This included early consultation on routing and component placement to optimize signal integrity.

By implementing this iterative approach, we successfully addressed the signal integrity issues and delivered a high-performance data acquisition system that met all design specifications. It’s a great example of how combining theoretical knowledge with practical implementation leads to successful outcomes in challenging projects.

Key Topics to Learn for Schematic Capture and Design Interview

- Fundamentals of Schematic Capture: Understanding the basic principles of schematic design, including component placement, netlisting, and hierarchical design.

- Component Libraries and Symbol Creation: Learn how to create and manage component libraries, ensuring accuracy and consistency in your designs. Practice creating custom symbols for unique components.

- Design Rules Checking (DRC) and Electrical Rules Checking (ERC): Master the use of DRC and ERC tools to identify and correct errors in your schematics before moving to PCB layout. Understand the importance of these checks in ensuring design integrity.

- Netlisting and Bill of Materials (BOM) Generation: Learn the process of generating netlists from schematics and how to extract accurate BOMs for manufacturing. Understand the different formats and their implications.

- Hierarchical Design Techniques: Practice creating and managing hierarchical schematics for large and complex projects. Understand the advantages and best practices for hierarchical design.

- Schematic Annotation and Documentation: Master the techniques for clearly annotating and documenting schematics to facilitate collaboration and maintainability. Understand industry best practices for clear and consistent documentation.

- Software Proficiency: Demonstrate hands-on experience with industry-standard schematic capture software (e.g., Altium Designer, Eagle, KiCad). Be prepared to discuss your experience with specific features and functionalities.

- Problem-Solving and Troubleshooting: Be ready to discuss how you approach and solve common schematic design challenges, such as resolving netlist errors or managing complex design hierarchies.

- Design for Manufacturing (DFM) Considerations: Understand how schematic design choices impact manufacturability. Be prepared to discuss DFM best practices.

Next Steps

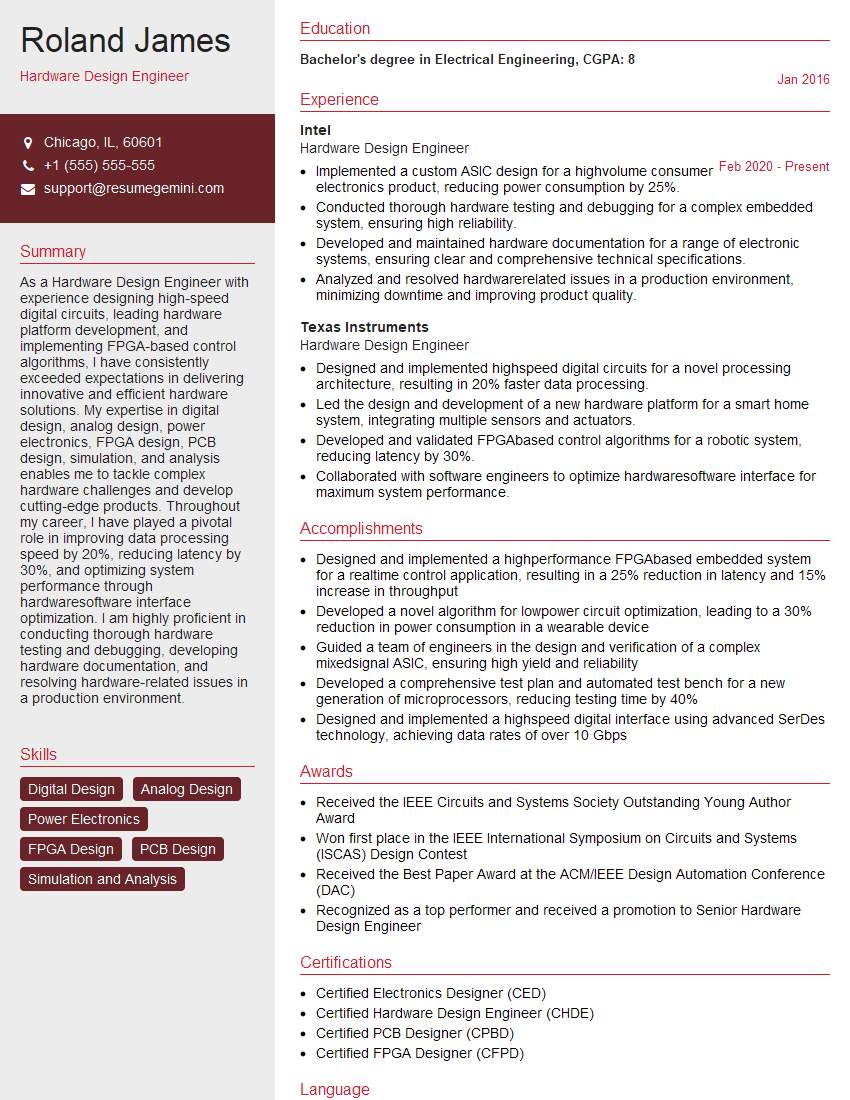

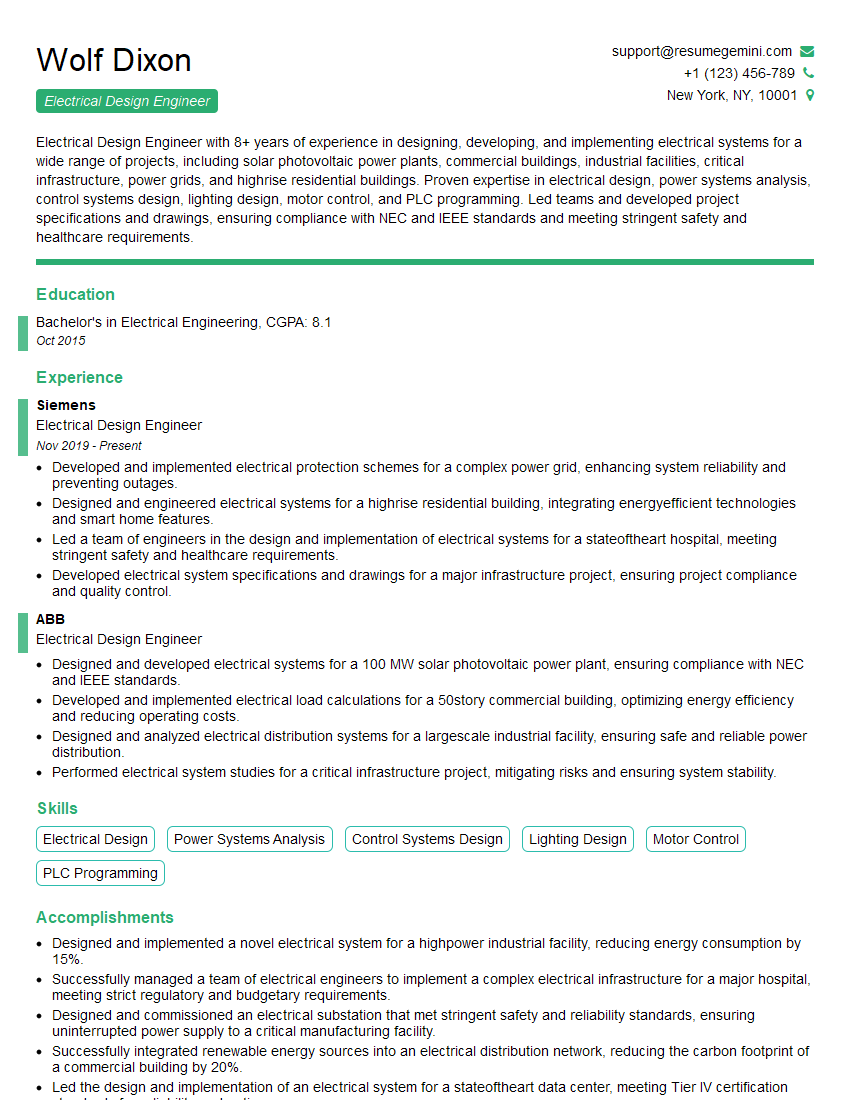

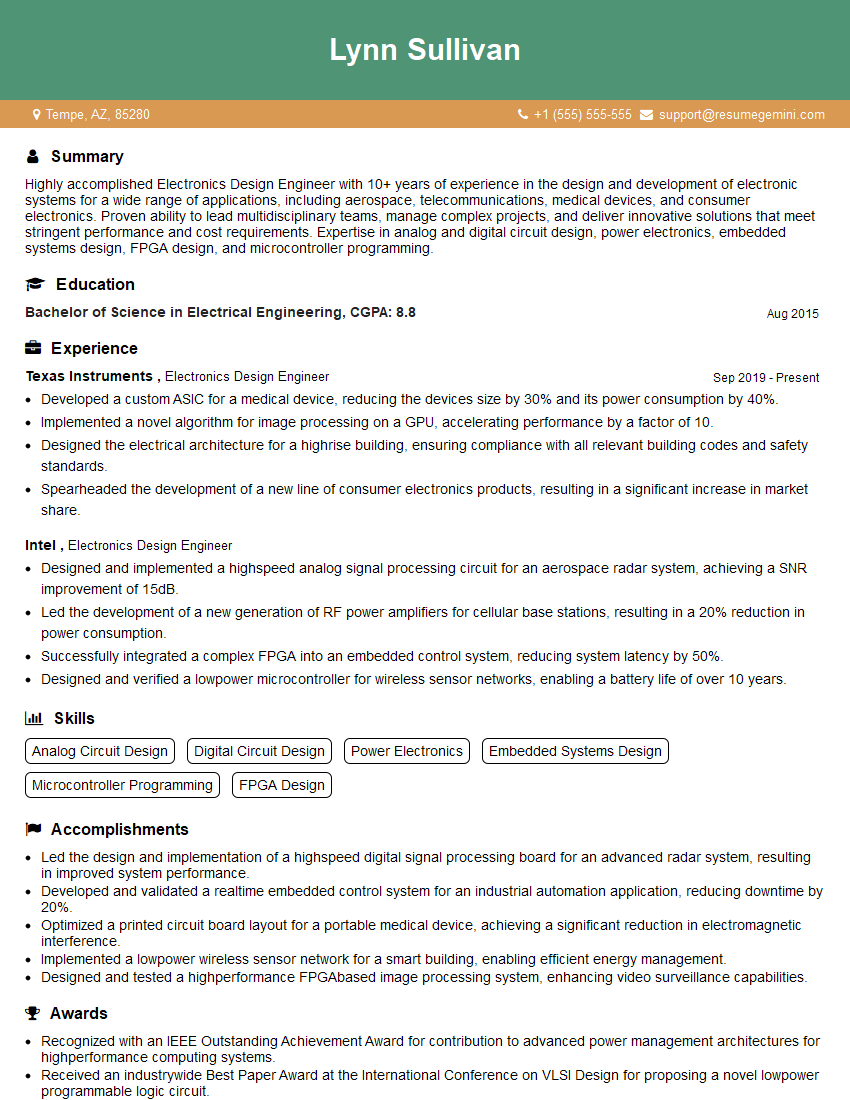

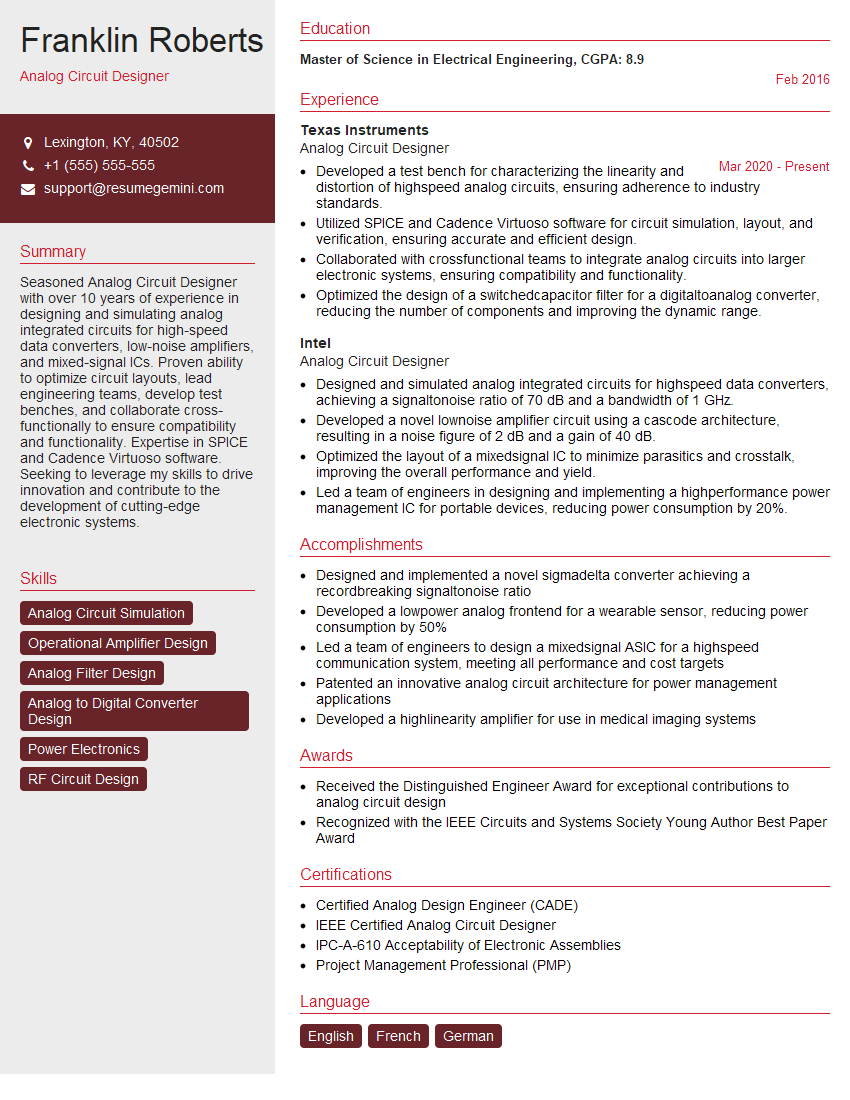

Mastering Schematic Capture and Design is crucial for career advancement in electronics engineering and related fields. It opens doors to exciting roles with significant responsibility and growth potential. To maximize your job prospects, focus on creating an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. They even provide examples of resumes tailored specifically to Schematic Capture and Design roles, giving you a head start in your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good