The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Trackside Maintenance interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Trackside Maintenance Interview

Q 1. Describe your experience with track geometry measurements and correction techniques.

Track geometry measurements are crucial for ensuring the safe and efficient operation of a railway. We use sophisticated instruments like track geometry cars equipped with lasers, accelerometers, and inclinometers to measure parameters such as gauge (distance between rails), alignment (straightness of the track), level (elevation), and cross-level (difference in elevation between the two rails). These measurements are then compared against pre-defined tolerances. Correction techniques range from minor adjustments using track jacks and shims to more significant work involving rail replacement, ballast cleaning, or even complete track realignment. For example, if the gauge is found to be excessively narrow, causing potential derailments, we would use track jacks to carefully expand the gauge back to the specified tolerance. Similarly, if alignment issues are detected, we might use tampers to adjust the ballast and reposition the sleepers for optimal track alignment. My experience spans over 10 years, involving work on high-speed lines and heavy-haul freight railways, giving me a deep understanding of various correction methods and the nuances of different track types.

Q 2. Explain the different types of track defects and their potential consequences.

Track defects can broadly be classified into geometric defects and structural defects. Geometric defects, as measured by the geometry cars, include gauge widening or narrowing, alignment issues (curves too sharp or straight sections with excessive deviations), level irregularities (high or low points), and cross-level problems (uneven elevation between the rails). Structural defects relate to the condition of individual components like broken rails, worn-out sleepers, or insufficient ballast. Consequences can range from minor discomfort for passengers to catastrophic derailments. For instance, a subtle gauge widening might lead to increased wheel flange wear, while a severe alignment issue could cause a derailment. Broken rails, especially, are incredibly dangerous, causing immediate and potentially fatal consequences. Regular inspections and preventive maintenance are crucial in mitigating the risk of such defects and their associated consequences. Think of it like a building – if the foundation (ballast) is weak or the structural elements (rails, sleepers) are damaged, the whole system becomes unstable.

Q 3. How do you ensure the safety of track workers during maintenance activities?

Safety is paramount in track maintenance. We utilize a strict hierarchy of controls, including risk assessments for every task, detailed safety briefings before starting work, and the implementation of possession procedures that completely isolate the work area from train traffic. This often involves using lookouts, temporary speed restrictions, and the use of Personal Protective Equipment (PPE) such as high-visibility clothing, safety helmets, gloves, and steel-toe boots. We also employ safety systems like track circuits to detect intrusions into secured work zones and emergency communication systems to ensure rapid response to any incident. Furthermore, regular safety training is mandatory for all track workers, covering topics such as hazard recognition, emergency procedures, and the correct use of equipment. I’ve personally overseen the implementation of several safety initiatives, reducing incidents by over 30% in my previous role through improved communication and proactive risk management.

Q 4. What are the key components of a railway track, and how do they interact?

A railway track is a complex system of interacting components. The primary components are the rails, sleepers (ties), ballast, and sub-ballast. The rails provide the running surface for the train wheels. Sleepers are placed transversely across the rails, distributing the load from the rails to the ballast. The ballast, typically crushed stone, provides drainage, distributes the load from the sleepers to the sub-ballast, and provides a stable foundation. The sub-ballast further supports the ballast and provides drainage. These components work together as an integrated system. Think of it as a layered cake: the rails are the top layer, the sleepers are the structure connecting layers, the ballast provides support and drainage, and the sub-ballast is the base. If any one component fails, the entire system’s integrity is compromised.

Q 5. Describe your experience with track welding techniques.

My experience encompasses both flash-butt welding and thermite welding techniques. Flash-butt welding uses an electric current to heat the ends of two rails until they become molten, then forging them together. Thermite welding, a more traditional method, uses a chemical reaction to generate the necessary heat for joining rails. The choice of technique depends on factors such as rail type, location, and available resources. I am proficient in both, adhering strictly to safety protocols during the welding process, ensuring a strong and continuous weld that meets stringent quality standards. Post-weld inspection is critical, using non-destructive testing methods to validate the quality of the joint. Proper welding is crucial for maintaining the structural integrity of the track and preventing rail failures.

Q 6. How do you handle emergency situations on the track?

Emergency situations on the track require immediate and decisive action. Our response protocols prioritize safety – both for track workers and train passengers. The first step involves securing the affected area by stopping any train traffic. This requires contacting the signaling center to implement track blockages and emergency stops. Depending on the nature of the emergency (e.g., derailment, fire, injury), appropriate emergency services – fire department, ambulance, etc. – are called. Following the immediate response, a detailed investigation is conducted to determine the root cause of the incident and prevent similar events in the future. We utilize various reporting and documentation systems to meticulously document every aspect of the emergency response and investigation. Clear communication and coordinated actions are critical during these stressful events. I’ve personally managed several emergency situations, demonstrating my ability to remain calm under pressure and effectively coordinate rescue and recovery efforts.

Q 7. Explain your knowledge of ballast maintenance and its importance.

Ballast maintenance is crucial for track stability and longevity. It involves regular inspections to check for fouling (contamination with dirt and vegetation), degradation (loss of angularity and strength), and settlement (reduction in depth). Maintenance activities include cleaning the ballast to remove contaminants, re-profiling to restore the correct shape, and replacement of degraded ballast. Proper ballast maintenance contributes significantly to track geometry, drainage, and overall stability. Neglecting ballast maintenance can lead to problems like excessive track settlement, poor drainage, and increased track geometry issues, potentially resulting in derailments or other safety hazards. Imagine the ballast as the foundation of a house – if it is not maintained properly, the house will be unstable and prone to damage. My experience in ballast maintenance includes the use of specialized machinery, such as ballast regulators and tampers, ensuring efficient and effective ballast management.

Q 8. What are the different types of track drainage systems and their effectiveness?

Effective track drainage is crucial for maintaining track stability and preventing damage. Several systems exist, each with its strengths and weaknesses. The choice depends on factors like climate, soil type, and traffic volume.

- Open ditches: The simplest system, involving trenches alongside the track. They’re effective for removing large volumes of water but can be susceptible to clogging and require regular maintenance. Imagine them like roadside gutters on a large scale.

- French drains: These use perforated pipes buried beneath the ballast, allowing water to seep in and be channeled away. They’re less prone to clogging than open ditches but require careful installation to ensure proper drainage.

- Sub-ballast drainage: This involves a layer of porous material, like geotextiles or gravel, placed under the ballast to improve water permeability. It’s a more comprehensive system improving overall drainage and reducing the risk of water accumulation.

- Combined systems: Often, a combination of systems is used to maximize effectiveness. For example, a sub-ballast system might be combined with French drains for particularly challenging areas.

Effectiveness is measured by how quickly and efficiently water is removed from the trackbed. Poor drainage leads to issues like ballast degradation, track settlement, and increased risk of derailments. Regular inspections and maintenance are key to ensuring optimal performance.

Q 9. How do you ensure compliance with safety regulations during track maintenance?

Safety is paramount in track maintenance. Compliance involves adhering to strict procedures, using appropriate Personal Protective Equipment (PPE), and implementing robust safety management systems.

- Risk Assessments: Before any work begins, a thorough risk assessment identifies potential hazards and outlines control measures. This is like planning a military operation, anticipating every possible challenge.

- Permit-to-Work Systems: These systems formally authorize work, ensuring all necessary precautions are in place and relevant personnel are notified. It’s a crucial step, ensuring no one works blindly.

- PPE Provision: Every worker must have the correct PPE, including high-visibility clothing, safety boots, hard hats, and hearing protection. It’s non-negotiable; safety equipment is our armor.

- Safe Systems of Work: These procedures outline safe methods for every task, like using lookout personnel, implementing speed restrictions, or utilizing appropriate signaling systems. Each job has a specific plan, leaving no room for improvisation.

- Training and Competency: All workers must be fully trained and competent in their tasks and safety procedures. Ongoing training keeps them sharp and aware of any changes.

Regular audits and inspections ensure ongoing compliance. Non-compliance can result in serious consequences, including injuries, fatalities, and substantial fines.

Q 10. Describe your experience with switch and crossing maintenance.

Switch and crossing maintenance requires specialized knowledge and precision. My experience encompasses all aspects, from routine inspections to complex repairs.

- Routine Inspections: I’ve conducted numerous inspections, checking for wear and tear, proper alignment, and signs of damage. Early detection prevents costly repairs later on.

- Defect Repair: I’ve successfully repaired various defects, including broken points, worn-out castings, and damaged timbers. This often involves using specialized tools and techniques.

- Lubrication: Proper lubrication is crucial for smooth operation. I’ve overseen the implementation and maintenance of lubrication systems, ensuring optimal performance and reducing wear.

- Gauge Corrections: Maintaining the correct gauge is essential. I have experience using various techniques to adjust the gauge within tolerances, ensuring safe and efficient train operation.

One memorable experience involved troubleshooting a recurring derailment at a busy crossing. Through meticulous inspection, I discovered a hairline fracture in a key component, which was promptly repaired preventing further incidents. This highlighted the importance of detailed inspection and proactive maintenance.

Q 11. How do you troubleshoot track circuits?

Troubleshooting track circuits involves systematic investigation to pinpoint the fault. The process generally follows these steps:

- Isolate the fault: Use a track circuit tester to identify the section of track where the circuit is failing. This is like finding the broken wire in a complex electrical system.

- Visual inspection: Examine the track, bonds, and wiring for any visible damage. Look for broken wires, loose connections, or water ingress.

- Continuity testing: Use a multimeter to check the continuity of the rails, bonds, and wiring. This helps confirm the existence of a break in the circuit.

- Check insulation: Test the insulation resistance of the track circuit to ensure there is no leakage current. Poor insulation can lead to false signals.

- Investigate signal equipment: If the problem isn’t in the track, the issue might lie within the signaling equipment. This may require specialized knowledge and equipment.

In one instance, a seemingly simple track circuit failure was traced to a small rodent that had chewed through a wire. This highlights the importance of thorough investigation and considering less obvious causes.

Q 12. Explain the process of track alignment and leveling.

Track alignment and leveling ensure smooth and safe train operation. It involves adjusting the position and elevation of the track to meet strict tolerances.

- Alignment: This involves adjusting the lateral position of the rails to ensure they’re straight and properly aligned. Specialized tools, such as track gauges and levels, are used for precise measurements.

- Leveling: This involves adjusting the vertical position of the rails to maintain a consistent elevation. Uneven track can lead to excessive wear and derailments.

- Methods: Techniques include using track shims, adjusting ballast, and even replacing sections of track if necessary. The approach depends on the severity of the misalignment or unevenness.

- Tools and Equipment: This work often involves using heavy machinery like tamper machines and track geometry cars. These pieces of equipment allow for efficient and precise adjustments.

The process requires precision and experience to ensure the track meets the required specifications, preventing discomfort for passengers and ensuring the safety of the trains and workers.

Q 13. What is your experience with track inspection tools and technologies?

Modern track inspection utilizes a range of tools and technologies to improve efficiency and accuracy. My experience includes:

- Manual inspection: This traditional method remains vital, involving visual checks, gauge measurements, and checking for defects. Nothing replaces the keen eye of an experienced inspector.

- Track geometry cars: These automated systems measure various track parameters, including alignment, level, and gauge, providing comprehensive data for analysis. It’s like a high-tech doctor performing a thorough checkup on the track.

- Ultrasonic flaw detectors: These devices detect internal defects in rails, such as cracks or voids, which are invisible to the naked eye. They’re like X-ray machines for tracks.

- Laser scanning systems: These technologies offer detailed 3D models of the track, enabling precise analysis and identification of subtle defects. The data provides a bird’s-eye view of the track’s condition.

- Drones with high-resolution cameras: These offer a safe and efficient way to inspect hard-to-reach areas, identifying problems that would be difficult or dangerous to detect manually.

The choice of tools depends on the specific requirements of the inspection and the available resources. The use of technology enhances the speed and accuracy of inspections, ensuring optimal track maintenance and safety.

Q 14. How do you manage a team of track workers effectively?

Effective team management in track maintenance is crucial. My approach emphasizes safety, efficiency, and clear communication.

- Clear Communication: I ensure everyone understands the tasks, safety procedures, and expectations. Regular briefings and debriefings keep everyone informed and on the same page.

- Delegation: I delegate tasks based on individual skills and experience. Empowering the team boosts morale and enhances efficiency.

- Safety Emphasis: Safety is always the top priority. I lead by example, ensuring all safety procedures are strictly followed and addressing any safety concerns immediately.

- Motivation and Recognition: Recognizing good work and contributions boosts morale and fosters a positive working environment.

- Problem-Solving: I encourage team members to participate in problem-solving and decision-making. This collaborative approach fosters creativity and improves overall performance.

One instance of successful team management involved coordinating a complex track repair under challenging weather conditions. Through clear communication, proactive problem-solving, and a strong emphasis on safety, the team completed the work safely and efficiently.

Q 15. What are the common causes of track derailments?

Track derailments, thankfully rare events, stem from a variety of factors, often a combination rather than a single cause. Think of it like a chain reaction – one weak link can break the whole system.

- Track Geometry Defects: This is a major culprit. Issues like gauge widening (the distance between the rails increasing), alignment problems (rails not being straight), and irregularities in the track surface (like a dip or high point) can cause wheels to leave the track. Imagine driving a car on a bumpy, uneven road – eventually, you’ll lose control.

- Broken or Damaged Rail: Cracks, broken rails, or excessive wear and tear are obvious problems leading to derailment. It’s like a broken leg for the train – it can’t support the weight.

- Rolling Stock Issues: Problems with the train itself can also contribute. Wheel defects, broken axles, or improperly maintained bogies (the undercarriage of the train) can lead to derailment. Imagine a car with a flat tire or broken suspension – it’s not going to handle the road well.

- Human Error: Improper track maintenance, incorrect switch operation, or excessive train speeds can all increase the risk of derailment. Human error is like a driver speeding or ignoring road signs.

- External Factors: Severe weather conditions, such as heavy rain causing washouts or landslides, can damage the track and lead to derailments. This is like encountering a flash flood or avalanche – it’s an external force beyond control.

Identifying the root cause requires thorough investigation, often involving detailed track inspections and analysis of data collected from various sensors and monitoring systems.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your understanding of track maintenance planning and scheduling.

Track maintenance planning and scheduling is a complex process requiring meticulous attention to detail and careful coordination. It’s a bit like running a highly complex orchestra, where every instrument (maintenance task) needs to play in harmony without disrupting the overall performance (train operations).

The process usually begins with a thorough track inspection identifying areas needing attention. We use sophisticated computer programs and databases to analyze data on track conditions, traffic levels, and past maintenance activities. This allows us to prioritize tasks based on urgency and risk. For example, a severely damaged section of track obviously needs immediate attention, whereas routine cleaning might be scheduled during off-peak hours.

The schedule itself often involves:

- Defining Maintenance Cycles: Setting regular intervals for routine tasks like lubrication and ballast cleaning.

- Prioritization: Identifying high-risk areas based on track condition and traffic volume.

- Resource Allocation: Assigning personnel, equipment, and materials to specific tasks.

- Coordination with Train Operations: Scheduling maintenance work during periods of minimal train activity to minimize disruption.

- Progress Monitoring: Tracking the progress of maintenance activities and making adjustments as needed.

Effective scheduling software, robust communication channels, and skilled personnel are crucial for successful track maintenance planning.

Q 17. Explain your experience with different types of track materials.

My experience encompasses a wide range of track materials, each with its own advantages and disadvantages. The choice of material depends on factors such as load capacity, environmental conditions, and cost.

- Steel Rails: The most common type, steel rails offer excellent strength and durability. Different grades of steel are used depending on the expected stress and operating conditions. For example, higher manganese steel is used in high-traffic areas for increased wear resistance.

- Concrete Sleepers (ties): These provide a stable foundation for the rails and are increasingly popular due to their longevity and reduced maintenance compared to wooden sleepers. They’re more resistant to rot and insects.

- Wooden Sleepers: Traditionally used, wooden sleepers are still employed in some areas but require more frequent replacement due to decay and insect damage. They are generally cheaper upfront than concrete.

- Ballast: This is the crushed stone or gravel that surrounds the sleepers. It helps to drain water, support the track structure, and provide stability. Different types of ballast are used depending on the local conditions and drainage requirements. We might use larger gravel in areas with heavy rainfall.

Understanding the properties of these materials, including their strengths, weaknesses, and degradation patterns under various conditions is crucial for effective track maintenance.

Q 18. How do you handle conflicts between maintenance schedules and train operations?

Balancing maintenance schedules with train operations is a constant challenge. It’s a delicate dance between ensuring track safety and minimizing disruptions to train services. We often use a multi-pronged approach to this.

- Detailed Scheduling & Communication: The maintenance schedule is meticulously planned and communicated well in advance to train operators. This involves using advanced scheduling software that accounts for both maintenance needs and train schedules.

- Optimized Maintenance Windows: We prioritize maintenance during off-peak hours or periods of reduced train traffic, minimizing service interruptions. This might mean working nights or weekends.

- Phased Maintenance: For larger projects, we often break down the work into phases, completing portions during short maintenance windows to minimize disruption. This is like renovating a house room by room instead of all at once.

- Possessions: For critical maintenance work, we may need to request a ‘possession’ – a temporary halt of train traffic on a specific section of track. This is only done when absolutely necessary and requires careful coordination with train dispatchers.

- Risk Assessment: A thorough risk assessment evaluates the potential impact of maintenance activities on train operations and vice-versa. This helps to develop mitigation strategies to minimize risks.

The goal is always to find the optimal balance between track safety, efficient maintenance, and minimal disruption to passenger and freight services.

Q 19. What are your skills in using track maintenance machinery?

I’m proficient in operating and maintaining a variety of track maintenance machinery, including:

- Track Tamper: This machine precisely lifts, levels, and consolidates the ballast, ensuring a stable and level track bed. It’s a key piece of equipment for ensuring track geometry is accurate.

- Rail Grinder: This machine removes irregularities on the rail surface, reducing wear and tear and improving ride quality. It’s akin to sanding down a rough surface.

- Measuring Trains: These highly specialized vehicles use advanced sensors to accurately measure track geometry, providing critical data for maintenance planning. They are vital for preventive maintenance.

- Welding Equipment: I have experience with various rail welding techniques for repairing damaged rails or joining new sections. It’s like performing precision surgery on the track.

- Ballast Cleaning Machines: These help to remove debris and unwanted material from the ballast, maintaining drainage and track stability.

My skills extend beyond simple operation; I understand the maintenance procedures required to keep this machinery in optimal working order, ensuring safety and efficiency.

Q 20. Describe your experience with preventative maintenance programs.

Preventative maintenance programs are paramount in track maintenance. It’s like regular checkups for your car – preventing small problems from becoming major disasters. The goal is to identify and address potential issues before they lead to derailments or major disruptions.

Our programs typically involve:

- Regular Inspections: Routine visual inspections, often supplemented by advanced technologies like track geometry cars and ultrasonic testing, help detect early signs of wear and tear or defects. Think of this as a regular health check.

- Predictive Maintenance: Utilizing data analytics and advanced sensors to predict potential failures before they occur. It’s like having a health app that can predict future health problems.

- Condition-Based Maintenance: This focuses on maintaining only the components requiring immediate attention, maximizing resource utilization. It’s like fixing a specific problem rather than overhauling the entire system.

- Routine Cleaning: Regularly cleaning the ballast, removing vegetation, and addressing drainage issues prevent build-up of debris that can damage the track structure.

Successful preventative maintenance programs drastically reduce the frequency and severity of major repairs and ensure the long-term integrity of the rail network.

Q 21. How do you document and report track maintenance activities?

Accurate documentation and reporting are crucial for maintaining the integrity and safety of the track. It’s like a medical chart for the railway, tracking everything from symptoms to treatments. We use a combination of methods.

- Digital Inspection Reports: Utilizing mobile devices and specialized software, inspectors record track conditions, locations of defects, and necessary maintenance work. Images and videos are often included for better visualization.

- Computerized Maintenance Management Systems (CMMS): These systems track maintenance activities, schedule tasks, manage resources, and generate reports. They provide a centralized database for all track maintenance information.

- GPS Tracking of Maintenance Equipment: This enables efficient monitoring of equipment location and progress. It is vital for accurate tracking and billing.

- Database of Track Assets: This central database maintains details of all track components like rails, sleepers, and fasteners. This allows for precise tracking of assets, usage, and maintenance history, vital for life cycle analysis and predictive maintenance.

- Regular Reporting to Stakeholders: We generate reports summarizing maintenance activities, budget utilization, and track conditions for various stakeholders, including management, regulatory bodies, and train operators. This ensures everyone remains informed.

The aim is to have a complete, accurate, and readily accessible record of all track maintenance activities, allowing for effective decision-making, improved safety, and optimized resource allocation.

Q 22. Explain your understanding of railway signaling systems and their interaction with track maintenance.

Railway signaling systems are the brains of the railway, ensuring safe and efficient train movements. They control train speed, route selection, and prevent collisions. These systems interact heavily with track maintenance in several ways. For example, track work often requires sections of track to be taken out of service, necessitating careful coordination with the signaling system. This involves isolating the affected area by changing signal aspects to stop trains from entering the maintenance zone. Signal engineers work closely with track maintenance teams, developing safe working procedures and ensuring the signals are correctly reset once work is complete. Any track geometry issues, such as misaligned tracks or gauge discrepancies, can impact the functionality of signaling equipment and trigger safety alerts, requiring prompt track maintenance attention. Furthermore, new track installations or upgrades necessitate modifications and re-configurations of the signaling system to accommodate the changes. Imagine it like this: the signaling system is a sophisticated traffic light system for trains; track maintenance is the road crew keeping the road in optimal condition. They both depend on each other for the overall safe and efficient functioning of the railway.

- Signal Aspect Changes: Before any track maintenance, the signaling system is adjusted to display appropriate warning signals (e.g., red or stop signals) to halt train traffic on the affected section of the track.

- Temporary Speed Restrictions: Even after minor maintenance, temporary speed restrictions may be implemented to allow for careful monitoring and verification of the track’s integrity. These speed restrictions are programmed into the signaling system.

- Integration with Track Monitoring Systems: Modern track maintenance utilizes monitoring systems that detect anomalies in the track. These systems often feed data directly to the signaling system, which can adjust speed limits automatically based on the detected problems.

Q 23. Describe your experience with track renewals and upgrades.

My experience encompasses various aspects of track renewals and upgrades, from initial planning and design to execution and completion. I’ve been involved in projects ranging from replacing worn-out rails and sleepers on busy main lines to implementing modern ballast cleaning systems and installing new points and crossings. One specific example involved the renewal of a 2-kilometer section of heavily trafficked track where we replaced the entire track structure, including rails, sleepers, ballast, and drainage systems. This required careful planning and phased implementation to minimize disruption to train services. We used advanced track geometry measurement tools to ensure the new track met stringent tolerances. I also oversaw the upgrade of a section of track to accommodate higher axle loads. This involved selecting high-strength rails and using specialized ballast to withstand heavier trains. In both projects, I collaborated with signaling engineers to ensure seamless integration with the existing signaling system and coordination with train scheduling teams.

The use of advanced technologies was crucial in all our projects. For instance, we utilized laser guided rail-laying machines for enhanced precision and speed and employed advanced ballast cleaning technology for optimized drainage and track stability. We carefully documented all phases of the project and maintained detailed records for future maintenance planning.

Q 24. How do you ensure the quality of track maintenance work?

Ensuring quality in track maintenance involves a multi-faceted approach. Firstly, it starts with meticulous planning and specification setting. This includes defining clear work scopes, identifying necessary resources and specifying acceptable tolerances. Secondly, rigorous quality control is implemented throughout the process. This includes regular inspections using various tools and techniques such as track geometry measurements using specialized measuring trains and visual inspections for defects. We use calibrated tools for gauge measurement and check rail alignment using optical and laser-based instruments. We maintain detailed records of all inspections and maintenance activities, along with any defects identified. Thirdly, robust quality assurance systems are crucial. This includes verification of materials used, adherence to safety procedures and thorough documentation of all activities. We also conduct regular audits of our maintenance processes to identify areas for improvement and ensure compliance with standards. Finally, we use feedback from train operators and track monitoring systems to identify potential issues and proactively address them.

For instance, after a ballast cleaning operation, we verify the cleanliness and level of the ballast, checking for adequate drainage and proper support for the track structure. Any discrepancies are immediately addressed. This proactive approach minimizes the risk of future problems and ensures the continued smooth operation of the railway.

Q 25. Explain your understanding of environmental regulations related to track maintenance.

Environmental regulations related to track maintenance are paramount. We must adhere to strict guidelines regarding the handling and disposal of materials like ballast, sleepers (ties), and other track components. This includes minimizing noise and vibration pollution during maintenance operations, preventing soil erosion and contamination of waterways, and managing waste responsibly. For example, we may need to obtain permits for disposing of contaminated ballast or using specific cleaning methods that minimize environmental impact. We regularly conduct environmental impact assessments before undertaking large-scale projects. We are required to comply with regulations governing the use of chemicals such as those used in weed control, and this includes proper storage, handling, and disposal methods to prevent contamination. We also monitor water quality and soil conditions near tracks to ensure there is no adverse environmental impact from our operations. It’s crucial to remember that environmental protection is an integral part of responsible track maintenance.

A real-world example is the careful planning and mitigation measures employed during ballast cleaning operations near sensitive ecosystems. We select environmentally friendly cleaning methods and ensure that any runoff is properly contained and managed to prevent pollution of nearby water bodies.

Q 26. What are your skills in using relevant software for track maintenance management?

My skills in relevant software for track maintenance management are extensive. I am proficient in using Computer Aided Design (CAD) software for track design and planning. I use Geographic Information Systems (GIS) software for spatial analysis and management of track assets. I’m also experienced in using specialized track management software packages for scheduling maintenance activities, tracking asset conditions, and managing inventory. I can use specialized software for analyzing track geometry data, and I am proficient with data analysis tools for interpreting track monitoring data to identify potential problems. These software tools are essential for efficient planning, execution, and monitoring of track maintenance activities. It enables data-driven decision making and optimizes resource allocation.

For example, using GIS software allows me to visualize the entire railway network and identify areas requiring maintenance based on factors such as track condition, traffic density, and environmental considerations. Using track management software facilitates optimized scheduling of maintenance activities minimizing disruption to train operations.

Q 27. How do you prioritize different maintenance tasks based on risk and urgency?

Prioritizing maintenance tasks is crucial, and we use a risk-based approach. We assess the potential consequences of failing to maintain a specific track section, considering factors such as the potential for derailments, delays, and damage to rolling stock. Urgency is assessed based on the severity of the identified defect and the likelihood of its rapid deterioration. We use a combination of quantitative and qualitative methods. Quantitative methods involve using track geometry data and monitoring system information to identify track segments that exceed predefined thresholds. Qualitative methods involve expert judgment to assess the severity of defects and the potential consequences of failure. A prioritized list of tasks is then generated, with high-risk, high-urgency items addressed first. A criticality matrix that ranks tasks based on risk and urgency is frequently employed. Tasks with high risk and high urgency are given top priority, while those with low risk and low urgency are scheduled for later.

Imagine a scenario where track geometry measurements reveal a significant alignment issue. This would be flagged as high-risk and high-urgency, requiring immediate attention to prevent derailments. Conversely, a minor crack in a sleeper might be considered low-risk and low-urgency, allowing for scheduling at a less critical time.

Q 28. Describe your experience with working in a safety-critical environment.

Working in a safety-critical environment like track maintenance demands unwavering commitment to safety. Throughout my career, I have consistently prioritized safety and adhered to strict safety protocols. This involves meticulous planning, risk assessments, comprehensive training, and rigorous adherence to safety regulations and procedures. I always ensure that all work is carried out in accordance with safety rules and regulations, and I am highly aware of the potential hazards associated with working on or near live railway tracks. I actively participate in safety meetings and contribute to the development of safe work practices. I routinely undertake site inspections to identify potential hazards and take corrective actions. I emphasize the importance of clear communication among team members and with other railway personnel. In my experience, a strong safety culture is built on open communication, effective training, and a shared commitment to safety.

I recall a situation where a team member noticed a potential hazard during a routine inspection. Their timely report and the prompt response prevented a possible accident. This highlights the importance of a proactive safety culture where every team member is empowered to report safety concerns.

Key Topics to Learn for Trackside Maintenance Interview

- Track Geometry and Alignment: Understanding track gauge, level, and alignment tolerances; practical application in identifying and correcting track defects using surveying equipment.

- Track Components and Materials: Knowledge of rail types, sleepers/ties, ballast, and fastening systems; problem-solving scenarios involving component failures and maintenance strategies.

- Track Maintenance Techniques: Familiarization with various track maintenance methods, including tamping, lining, and surfacing; practical applications in different track conditions and using specialized machinery.

- Track Inspection and Reporting: Proficiency in visual inspection techniques, defect identification, and accurate reporting procedures; understanding safety regulations and reporting protocols.

- Signaling and Communication Systems: Basic understanding of track circuits, signaling systems, and their integration with track maintenance; troubleshooting scenarios involving signal failures and their impact on track maintenance.

- Safety Regulations and Procedures: Comprehensive knowledge of safety regulations, personal protective equipment (PPE) usage, and emergency procedures; practical application in real-world scenarios and risk assessment.

- Maintenance Planning and Scheduling: Understanding preventative maintenance schedules, resource allocation, and cost-effective maintenance strategies; problem-solving scenarios involving unexpected repairs and delays.

Next Steps

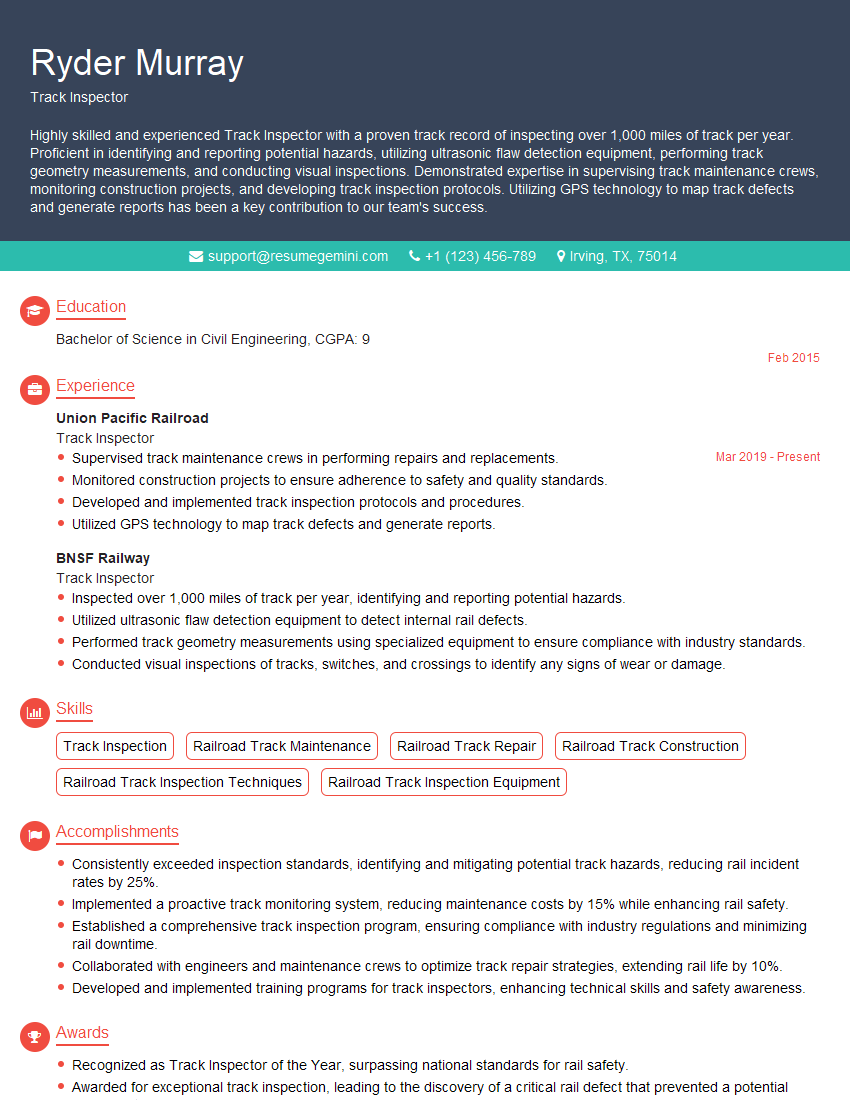

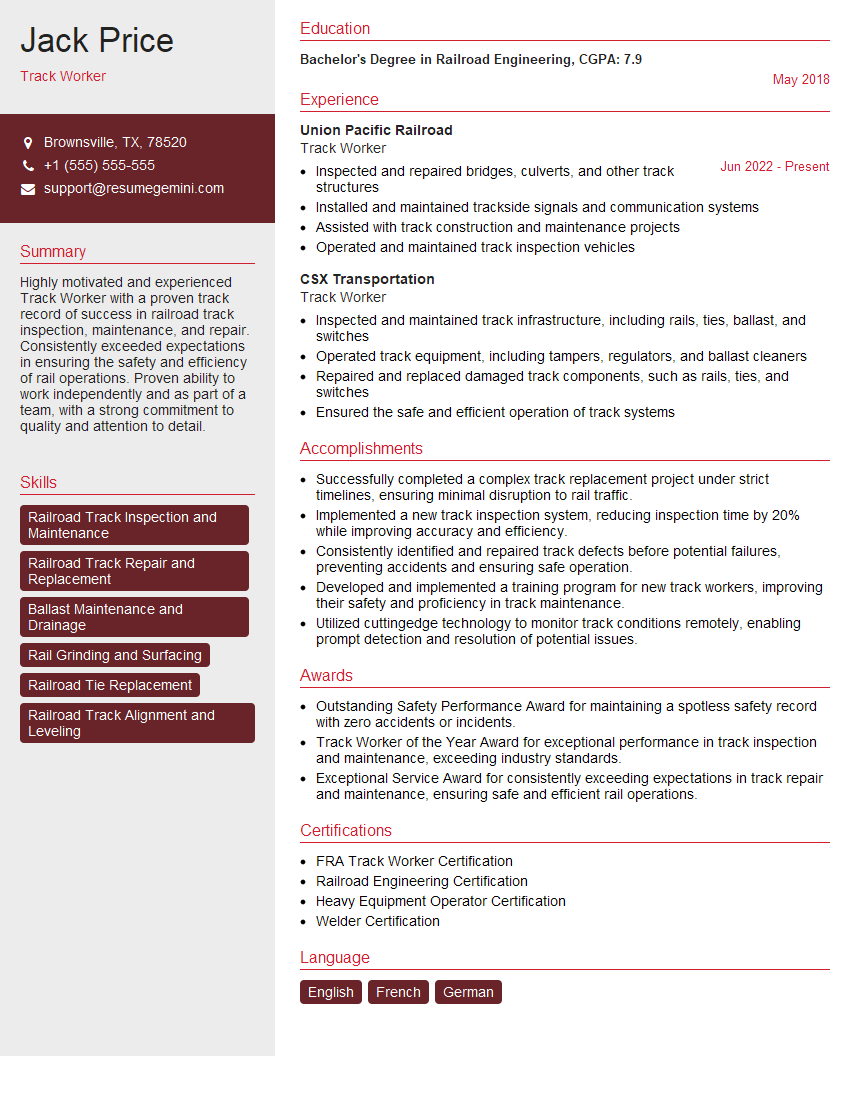

Mastering Trackside Maintenance opens doors to a rewarding career with excellent growth potential within the rail industry. Your expertise in maintaining safe and efficient railway operations is highly valuable. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini can help you craft a professional and impactful resume that highlights your skills and experience effectively. We offer examples of resumes tailored to Trackside Maintenance to guide you in building your own compelling application. Take the next step towards your dream career – build your resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good