Cracking a skill-specific interview, like one for NFPA 70 – National Electrical Code, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in NFPA 70 – National Electrical Code Interview

Q 1. Explain the difference between grounding and bonding.

Grounding and bonding, while often used interchangeably, are distinct electrical safety measures defined in NFPA 70. Grounding connects non-current-carrying metal parts of an electrical system to the earth, providing a path for fault currents to safely dissipate. Think of it as providing a low-resistance escape route for electricity if a fault occurs. Bonding connects non-current-carrying metal parts within an electrical system to each other, ensuring that they are at the same electrical potential. This prevents voltage differences between metal parts that could lead to shocks or electrical fires. Imagine bonding as creating a level playing field for all the metal parts, so no one part becomes dangerously charged relative to another.

Example: In a home, the metal water pipes are grounded to provide a path for fault current. Meanwhile, the metal conduit and boxes are bonded together to equalize the potential and prevent a shock hazard if a wire touches the conduit.

Q 2. What are the requirements for grounding electrode conductors?

Grounding electrode conductors (GECs) are the vital link between the grounding electrode system and the electrical service equipment. NFPA 70 outlines several requirements: they must be appropriately sized based on the ampacity of the system, usually copper or aluminum, and protected from physical damage. The material and size must ensure it can handle the fault currents without overheating or failing. Their installation must also comply with proper grounding techniques, avoiding sharp bends or kinks that can hinder conductivity. Common grounding electrodes include metallic underground water pipes (if suitable), ground rods driven into the earth, or a combination. The connection must be low-resistance and corrosion-resistant to ensure its long-term effectiveness.

Example: A typical residential installation might use a copper grounding electrode conductor, sized according to the service entrance’s ampacity, connecting the grounding electrode to the electrical panel’s grounding bus bar. The connection is usually made with a bolted, exothermic weld, or another approved method.

Q 3. Describe the purpose of arc-fault circuit interrupters (AFCIs).

Arc-fault circuit interrupters (AFCIs) are designed to protect against the dangers of arc-faults. An arc-fault is an unintentional electrical arc that can occur in branch wiring, potentially leading to fires. Unlike a short circuit, which is a direct, heavy current flow, arc-faults are characterized by a smaller current that generates intense heat, often unnoticed until a fire ignites. AFCIs detect these subtle changes in current and voltage, rapidly interrupting the circuit to prevent fire hazards. They are mandatory in certain locations in many jurisdictions.

Example: AFCIs are commonly required in bedrooms and hallways to protect against the risk of fire due to frayed wiring or faulty fixtures.

Q 4. What are the requirements for installing GFCIs?

Ground-fault circuit interrupters (GFCIs) protect against ground-fault electrical shocks. A ground fault occurs when a current intended to flow through a circuit takes an unintended path to the ground, often due to damaged insulation or a faulty appliance. GFCIs constantly monitor the current flowing in the hot and neutral conductors. If there’s an imbalance (indicating current is leaking to ground), the GFCI instantly trips to cut off the power, preventing electrocution.

Requirements for GFCI installation frequently involve locations where water or moisture is present (bathrooms, kitchens, outdoors) as well as in areas like garages, basements, and crawl spaces. They’re also required to protect specific outlets, such as those supplying outdoor lighting or power tools. The Code specifies the type of GFCI protection (e.g., outlet-type, circuit breaker-type) suitable for various applications. Installation requires proper wiring and adherence to the manufacturer’s instructions to ensure efficient and safe operation.

Example: In a kitchen, all countertop receptacles must be protected by GFCIs, regardless of whether they are specifically located above the countertop or not. Similarly, all outdoor receptacles must have GFCI protection.

Q 5. Explain the requirements for branch circuit calculations.

Branch circuit calculations are crucial for determining the appropriate size of conductors and overcurrent protection devices (circuit breakers or fuses). The calculations involve determining the total load (in amperes) on a branch circuit. This considers the wattage of appliances and lighting fixtures, taking into account the voltage and efficiency factors, along with a demand factor (which recognizes that not all loads operate simultaneously). The National Electrical Code provides tables and formulas to facilitate these calculations, ensuring circuits aren’t overloaded, preventing overheating and fire hazards. The calculated load must not exceed the ampacity of the conductors or the rating of the overcurrent protection device.

Example: A circuit powering several lights and a microwave requires careful calculation of the total amperage to choose the right gauge wire and breaker. A common method involves adding up the amperage of all loads and adding a safety factor.

Q 6. What are the requirements for wiring methods in different locations (e.g., wet locations, hazardous locations)?

Wiring methods must be selected based on the specific location’s environmental conditions. In wet locations (exposed to dripping or splashing water), wiring methods like Type NM (non-metallic sheathed cable) are generally prohibited unless within a raceway or conduit. Type UF (underground feeder) or other suitable types are instead required. In damp locations (subject to moisture), additional protection might be needed, but some types of NM may be allowed. Hazardous locations (containing flammable gases, liquids, or dust) require special wiring methods like Type MC (metal-clad cable) or conduit systems with explosion-proof fittings. This is determined by classifying the location according to the type of hazard present (Class I, II, or III, further subdivided into Divisions 1 and 2). The specific wiring method must be chosen to comply with the corresponding requirements from Article 500 and beyond in NFPA 70, to minimize the risk of ignition.

Example: Outdoor receptacles are typically installed using UF cable and weatherproof boxes. In an industrial facility with flammable solvents, wiring would need to conform to the relevant hazardous location standards.

Q 7. How do you determine the ampacity of a conductor?

Determining the ampacity of a conductor depends on several factors. The primary factor is the conductor’s size (measured in AWG or kcmil), material (copper or aluminum), and the installation conditions (ambient temperature, raceway type, number of conductors in a raceway). The ampacity rating is the maximum current-carrying capacity of the conductor under specified conditions without exceeding its temperature rating. These ratings are available in tables in the NEC. The installation environment and conditions can further affect the ampacity rating: if multiple conductors are bundled together, the ampacity rating is typically derated to account for the increased heat buildup. If conductors are installed in conduits, derating may also be necessary.

Example: A 12 AWG copper conductor in free air at 30°C might have an ampacity of 20 amps. However, if that same conductor is installed in a conduit with other conductors, its effective ampacity might be derated to 15 amps or less.

Q 8. Explain the requirements for overcurrent protection.

Overcurrent protection is crucial for preventing fires and equipment damage caused by excessive electrical current. The NEC mandates that all electrical circuits be protected by overcurrent devices like fuses or circuit breakers. These devices are sized to interrupt the flow of current when it exceeds a safe level, preventing overheating and potential hazards.

The selection of the appropriate overcurrent protection device is based on the circuit’s ampacity (the maximum current it can safely carry continuously) and the conductor’s ampacity. For instance, a 15-ampere circuit would typically use a 15-ampere circuit breaker. The NEC provides specific tables and calculations to determine the correct overcurrent protection based on wire size, installation methods, and ambient temperature. Incorrect overcurrent protection can lead to a fire hazard.

Furthermore, the NEC dictates the proper location and installation of overcurrent protection devices within the electrical panel. These devices should be readily accessible for inspection and maintenance. For example, you wouldn’t want to install them in a way that makes replacing a blown fuse difficult or dangerous.

Q 9. What are the requirements for installing and using surge protection devices?

Surge protection devices (SPDs) safeguard electrical equipment from voltage surges, which are sudden, high-energy spikes in voltage. These surges can be caused by lightning strikes, power grid switching, or even nearby equipment malfunctions. The NEC doesn’t mandate SPDs everywhere but strongly recommends their use in critical applications to protect sensitive electronics, prevent data loss, and extend the lifespan of expensive equipment.

The installation of SPDs typically involves placing them at the service entrance, main electrical panel, and potentially at individual branch circuits depending on the level of protection required. The SPDs must be properly sized for the system’s voltage and amperage rating and must be connected according to the manufacturer’s instructions and in compliance with the NEC. Improper installation can render the SPD ineffective or even create additional hazards.

Regular inspection and maintenance are also critical. SPDs have a limited lifespan and should be tested and replaced periodically to ensure they continue functioning effectively. Consider SPDs as a ‘sacrificial’ device that absorbs the surge to protect more valuable equipment.

Q 10. Describe the requirements for lighting fixtures in various locations.

Lighting fixture requirements vary widely based on location and application. For example, damp locations (like bathrooms or near pools) demand fixtures rated for damp or wet locations to prevent shock hazards. Similarly, fixtures in hazardous locations (like garages or workshops with flammable materials) need special certifications to prevent ignitions.

- Bathrooms and Wet Locations: Fixtures must be marked as suitable for damp or wet locations (e.g., ‘Damp’ or ‘Wet’ location ratings). These fixtures often feature additional seals and protections against moisture ingress.

- Hazardous Locations: The NEC’s Article 500 details requirements for fixtures in Class I, II, and III hazardous locations. These fixtures must be explosion-proof or intrinsically safe, preventing sparks or ignition sources.

- General Purpose Locations: In typical indoor areas, fixtures must be listed and labeled for their intended purpose and comply with general safety standards, including appropriate spacing from flammable materials.

Beyond location, other factors influence lighting fixture selection, including the type of lamp used (incandescent, fluorescent, LED), and the fixture’s mounting height and construction to ensure stable and safe installation.

Q 11. What are the requirements for electrical work in hazardous locations (Class I, II, III)?

Electrical work in hazardous locations (Class I, II, and III) requires specialized knowledge and equipment due to the presence of flammable or combustible materials. The NEC’s Article 500 meticulously outlines these requirements to prevent ignitions and explosions.

- Class I: Locations containing flammable gases or vapors (e.g., gasoline stations, chemical plants).

- Class II: Locations containing combustible dusts (e.g., grain elevators, woodworking shops).

- Class III: Locations containing easily ignitable fibers or flyings (e.g., textile mills).

Within these classes, Divisions 1 and 2 further specify the likelihood of flammable materials being present. Division 1 represents areas where flammable materials are regularly present, while Division 2 represents areas where flammable materials may occasionally be present. The required level of protection is higher in Division 1. Fixtures and equipment must be specially designed and installed to minimize ignition risks, frequently employing explosion-proof enclosures or intrinsically safe circuits.

Working in hazardous locations necessitates adherence to stringent safety protocols, including lockout/tagout procedures, appropriate personal protective equipment, and specialized training.

Q 12. Explain the requirements for installing and using transformers.

Transformers are essential components in electrical systems, stepping voltage up or down. Their installation and use must comply with the NEC to ensure safety and efficiency.

The NEC covers several aspects, including:

- Location: Transformers must be installed in suitable locations, free from excessive heat, moisture, or physical damage. Often, they are placed in dedicated enclosures or vaults.

- Overcurrent Protection: Transformers require overcurrent protection on both the primary and secondary sides to protect against short circuits and overloads. The size of these devices is dictated by the transformer’s rating.

- Grounding: Proper grounding is essential to protect against electrical shock and prevent damage to the transformer. This typically involves grounding the transformer’s case and other exposed metal parts.

- Clearances: Adequate clearances must be maintained around transformers to prevent accidental contact and to allow for proper ventilation.

Ignoring these requirements can lead to transformer failure, fires, or electrical shock. For example, a transformer improperly grounded may pose a serious shock hazard.

Q 13. What are the requirements for installing and maintaining service equipment?

Service equipment, encompassing the main electrical panel and associated components, is the critical entry point for electricity to a building. Its installation and maintenance are strictly regulated by the NEC to ensure safety and reliability.

Key requirements include:

- Accessibility: The service equipment must be readily accessible for inspection and maintenance, typically located in a designated area, such as a utility room or electrical closet.

- Grounding: The service equipment must be properly grounded to protect against electrical shock and to provide a path for fault currents. This typically involves a grounding rod driven into the earth.

- Overcurrent Protection: The main service panel must be equipped with appropriate overcurrent protection (e.g., main breakers or fuses) sized to match the service’s capacity.

- Clearances: Adequate clearances must be maintained around the service equipment to prevent accidental contact and ensure proper ventilation.

- Bonding: Metallic components within the service equipment must be properly bonded together to reduce the risk of electrical shock.

Regular inspection and maintenance, including testing of grounding and bonding, are crucial to prevent equipment failure and ensure electrical safety.

Q 14. Describe the requirements for electrical signs and lighting.

Electrical signs and lighting, often found outdoors, pose unique challenges requiring specific NEC compliance. These include considerations for weather protection, structural integrity, and safety to prevent shocks and potential hazards.

Requirements encompass:

- Weather Protection: Outdoor signs and lighting fixtures must be rated for outdoor use, offering sufficient protection against rain, snow, and other environmental factors. They should have appropriate enclosures and sealing to prevent moisture ingress.

- Structural Integrity: Fixtures and signs must be securely mounted and designed to withstand wind loads and other environmental stresses. They need to be robust enough to prevent damage or collapse.

- Accessibility: Access for maintenance and repairs should be considered during installation, ensuring that bulbs and other components can be safely replaced.

- Grounding and Bonding: Metal components of signs and lighting fixtures must be grounded and bonded to minimize the risk of electrical shock. This is particularly critical for illuminated signs.

- Clearances: Sufficient clearances must be maintained between signs and lighting fixtures and other building features to ensure safety and avoid potential hazards.

Failure to meet these requirements can lead to electrical hazards, structural failures, and damage to the sign or fixture itself. Regular inspections are vital for maintaining the integrity and safety of outdoor electrical installations.

Q 15. What are the requirements for installing and using motor controllers?

Installing and using motor controllers involves adhering to several key aspects of NFPA 70, the National Electrical Code (NEC). The NEC dictates requirements based on the motor’s horsepower, voltage, and the environment where it’s installed. Crucially, the controller must be properly sized to handle the motor’s starting current and running load. This prevents overheating and potential failure.

- Overcurrent Protection: The controller must include overcurrent protection, such as fuses or circuit breakers, sized appropriately per Article 430 of the NEC. This protects both the motor and the wiring from excessive current.

- Short Circuit Protection: The system should be protected against short circuits, often achieved through the use of a properly sized and coordinated protective device within the panelboard.

- Disconnecting Means: A readily accessible disconnecting means, such as a switch or circuit breaker, must be provided to isolate the motor from the power source for maintenance or emergencies. This is crucial for safety. Imagine needing to work on a motor – a readily available disconnect is essential.

- Enclosure Type: The enclosure type for the controller depends on the location’s environmental conditions. For example, a motor controller in a damp location would require a weatherproof enclosure (NEMA type rating).

- Wiring Methods: Wiring must adhere to NEC standards, including proper conductor sizing, insulation, and grounding. Incorrect wiring can lead to overheating, fire hazards, and equipment damage.

For instance, a 5-horsepower motor in a dry location might require a specific type of controller with a certain amperage rating and a specific NEMA enclosure type. Failing to adhere to these regulations can lead to fines and, more importantly, serious safety hazards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the requirements for grounding swimming pool equipment.

Grounding swimming pool equipment is paramount for safety, preventing electric shock. The NEC, specifically Article 680, outlines stringent requirements to minimize risk. The goal is to create a low-impedance path to the earth, ensuring that any fault current will flow to ground rather than through a person.

- Equipment Grounding Conductor: All metal parts of the pool equipment, including pumps, filters, and lights, must be bonded together and connected to a grounding electrode system. This creates a continuous ground path.

- Grounding Electrode: A reliable grounding electrode, such as a ground rod or the metallic water piping system, must be used. The connection to the electrode must be robust and corrosion-resistant.

- Ground Fault Circuit Interrupters (GFCIs): All 120-volt, single-phase, 15- and 20-ampere receptacles within 5 feet of the pool’s edge must be protected by GFCIs. These devices quickly interrupt the power if a ground fault is detected, preventing shock.

- Bonding: All metal parts within 5 feet of the pool’s edge must be bonded together, including fences, railings, and underwater lighting fixtures. This prevents voltage differences that could cause a shock.

Imagine a faulty underwater light. Proper grounding ensures that the current flows safely to ground, preventing electrocution. Failure to properly ground pool equipment can have fatal consequences.

Q 17. What are the requirements for working on energized electrical equipment?

Working on energized electrical equipment is extremely dangerous and should only be undertaken by qualified personnel using appropriate safety precautions. The NEC doesn’t explicitly describe *how* to work on energized equipment, as it strongly discourages it. The emphasis is on de-energizing equipment before working on it.

However, there might be rare instances (e.g., emergency repairs) where working on live equipment is unavoidable. In such cases, strict adherence to safety protocols, including:

- Permit-required confined space entry: This involves thorough safety planning, atmospheric testing, and having standby personnel available.

- Arc flash hazard analysis: This will determine the appropriate PPE (personal protective equipment), including arc-flash suits, insulated tools, and face shields.

- Use of appropriate tools: Tools must be rated for the voltage level and have insulated handles.

- Trained personnel: Only individuals with specific training and experience in working on energized equipment should be involved.

In essence, the NEC’s approach is to prioritize de-energization. Working on energized equipment is a last resort, requiring extensive safety precautions and highly trained personnel. The risk of severe injury or fatality is incredibly high.

Q 18. Describe the proper lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are critical safety measures designed to prevent the accidental energization of equipment during maintenance or repair. It involves physically locking and tagging the equipment’s power source to clearly indicate that it’s out of service.

- Preparation: Identify the energy sources to be controlled. This includes electrical, hydraulic, pneumatic, and other energy sources.

- Notification: Notify affected personnel about the planned lockout/tagout activity.

- Energy Isolation: Turn off the equipment and isolate the energy sources using appropriate methods, such as switches, circuit breakers, or valves.

- Lockout/Tagout: Apply a lock and tag to the energy isolating device. Each person involved should use their own lock and tag.

- Verification: Verify that the energy source is de-energized by performing a test, such as checking voltage with a voltmeter.

- Work Performance: Perform the work safely and efficiently.

- Lockout/Tagout Removal: Once the work is complete, the locks and tags are removed by the person who installed them, after verifying that it’s safe to do so.

Think of LOTO as a multi-layered security system. Each lock and tag acts as an independent barrier against accidental energization. It’s not just about turning off the power, but about ensuring that no one can accidentally turn it back on during maintenance.

Q 19. Explain the requirements for installing and using solar photovoltaic systems.

Installing and using solar photovoltaic (PV) systems involves adherence to Article 690 of the NEC. This article addresses safety and performance requirements for PV systems, covering aspects like grounding, overcurrent protection, and system grounding.

- Grounding: The system must be effectively grounded to prevent electric shock and safeguard against fault currents. This often involves grounding the array, the inverter, and the building’s electrical system.

- Overcurrent Protection: Appropriate overcurrent protection devices, like fuses or circuit breakers, are necessary to protect the PV system components from damage due to short circuits or overloads.

- Rapid Shutdown: The system must incorporate rapid shutdown capabilities to reduce the risk of firefighters being exposed to energized conductors during emergencies. These systems are designed to quickly de-energize sections of the array.

- Disconnecting Means: Readily accessible disconnecting means must be provided at various points in the system for maintenance and safety purposes.

- Wiring Methods: The wiring used in PV systems must meet specific requirements, ensuring that it’s suitable for the voltages and environmental conditions involved. This includes using appropriately rated and UV-resistant cables.

Consider a large-scale solar farm. The NEC’s requirements regarding grounding, overcurrent protection, and rapid shutdown are crucial for ensuring both the safety of workers and the longevity of the system itself. Improper installation can lead to system failures and potential fire hazards.

Q 20. What are the requirements for emergency power systems?

Emergency power systems, as outlined in Article 700 of the NEC, provide backup power during outages. These systems are crucial for maintaining essential functions in hospitals, data centers, and other critical facilities. The requirements emphasize reliability and safety.

- Reliability: The system must be designed to start automatically and supply power within a specified time frame. Regular testing and maintenance are essential to ensure its readiness.

- Capacity: The system’s capacity must be sufficient to power the critical loads it’s designed to support during an outage.

- Transfer Switches: Automatic transfer switches are commonly used to seamlessly switch from normal power to the emergency power source when a main power failure occurs.

- Overcurrent Protection: Emergency power systems must be protected by overcurrent devices, such as circuit breakers or fuses, sized appropriately for the system’s capacity.

- Grounding: The system’s grounding must meet the NEC’s requirements to ensure safety and prevent electric shock.

Imagine a hospital relying on an emergency power system during a power outage. The system’s reliability and capacity are not only crucial for maintaining critical life support equipment but also essential for maintaining the safety of patients and staff. Proper installation and regular testing are absolutely vital.

Q 21. How do you interpret electrical drawings and schematics?

Interpreting electrical drawings and schematics is a fundamental skill for electricians and electrical engineers. These drawings provide a visual representation of the electrical system, showing the layout of components, wiring paths, and connections. Understanding these drawings is crucial for installation, troubleshooting, and maintenance.

Key elements to understand:

- Symbols: Familiarize yourself with standard electrical symbols used to represent various components, such as switches, outlets, motors, and circuit breakers. These symbols are standardized to allow for consistent interpretation.

- Wiring Diagrams: Wiring diagrams show the connections between different components, illustrating the flow of electricity through the system.

- Panel Schedules: These schedules list the circuit breakers or fuses in a panelboard, along with the circuits they protect and the loads they serve.

- One-line Diagrams: One-line diagrams provide a simplified overview of the entire electrical system, showing major components and their interconnections.

- Reference Designations: Each component is typically assigned a reference designation, a unique identifier that links it to other parts of the drawing and relevant specifications.

For example, a symbol for a single-pole switch will be universally recognized, allowing for quick identification of its function in a drawing. Learning to interpret these drawings is like learning a language. The more experience you gain, the easier it becomes to understand the layout and purpose of an electrical system.

Q 22. Describe the different types of raceways and their applications.

Raceways are protective conduits for electrical wiring, providing mechanical protection and often fire resistance. Several types exist, each suited to different applications.

- Rigid Metal Conduit (RMC): Heavy-duty, durable steel conduit offering excellent protection against physical damage. Commonly used in industrial settings or where significant mechanical stress is expected.

- Intermediate Metal Conduit (IMC): Lighter and thinner than RMC, offering a balance between protection and cost. Suitable for many commercial and industrial applications.

- Electrical Metallic Tubing (EMT): Also known as thinwall conduit, it’s lightweight and flexible, easier to bend and install than RMC or IMC. Common in residential and light commercial work.

- Flexible Metal Conduit (FMC): Highly flexible, used for connecting equipment where movement is anticipated, like connecting a motor to a control panel.

- Plastic Conduit (PVC): Less expensive and lightweight than metal conduit. Suitable for dry locations, though its mechanical strength is less than metal options. Different types exist, offering varying degrees of fire resistance.

- Underfloor raceways: These systems are installed under floors and provide a pathway for power and data cables. They allow for easier access and reconfiguration than embedded wiring.

The choice of raceway depends on factors such as the environment (wet, dry, corrosive), the type of wiring, the mechanical stresses, and cost considerations. For example, RMC is preferred in corrosive environments while PVC might be suitable in dry, non-hazardous locations.

Q 23. What are the requirements for using different types of conductors (e.g., copper, aluminum)?

The NEC outlines specific requirements for using copper and aluminum conductors. The primary differences relate to their ampacity (current-carrying capacity), installation methods, and connection techniques.

- Ampacity: Aluminum conductors have lower ampacity than copper conductors of the same size. This means a larger aluminum conductor is needed to carry the same current as a smaller copper conductor. This is due to aluminum’s higher resistivity.

- Connections: Aluminum oxide forms on the surface of aluminum conductors, hindering electrical conductivity. Special anti-oxidant pastes or connectors are required to ensure reliable connections. These are designed to penetrate the oxide layer and create a good electrical contact. Over-tightening connections can also damage aluminum conductors, leading to failure.

- Installation: Aluminum conductors are generally more challenging to work with than copper, as they are softer and more prone to deformation during bending.

The NEC provides specific tables and rules (e.g., Table 310.15(B)(16)) detailing the ampacity of different conductor types and sizes. These tables take into account factors such as the type of insulation, ambient temperature, and installation method. Failure to adhere to these requirements can lead to overheating, fire hazards, and premature equipment failure.

For example, if you are designing a circuit that requires a 100-ampere rating, you would consult the ampacity tables to determine the appropriate size of copper or aluminum conductor necessary to meet the required amperage while complying with NEC requirements for the type of installation and ambient temperatures.

Q 24. Explain the concept of voltage drop and how to calculate it.

Voltage drop is the reduction in voltage between the source and the load in an electrical circuit. It’s caused by the resistance of the conductors themselves. Excessive voltage drop can lead to inefficient operation of equipment and even damage.

Voltage drop is calculated using Ohm’s Law: Voltage Drop = I * R, where:

Iis the current in amperes.Ris the resistance of the conductor in ohms.

The resistance of a conductor depends on its length, cross-sectional area, and material resistivity (e.g., copper has lower resistivity than aluminum). The formula for resistance is:

R = (ρ * L) / A

ρ(rho) is the resistivity of the conductor material.Lis the length of the conductor.Ais the cross-sectional area of the conductor.

To calculate voltage drop in a circuit, you need to know the current, the length of the conductors, and the material and size of the conductors. The NEC provides tables and formulas to simplify these calculations. A 3% voltage drop is generally considered acceptable for branch circuits. Higher voltage drops can lead to reduced efficiency, dimmer lights, or malfunctioning equipment. For example, a motor might overheat or not have enough torque if the voltage drop is excessively high.

Q 25. What are the requirements for identifying and labeling conductors?

Conductors must be clearly identified and labeled to ensure safety and facilitate troubleshooting. The NEC specifies requirements for conductor identification and labeling, especially within raceways and panels.

- Color-coding: The NEC uses specific color codes for grounded conductors (typically green or green with yellow stripes) and ungrounded conductors (black, red, blue, etc.). These color codes help distinguish between different phases and the neutral.

- Marking: Conductors that are not color-coded must be marked using tags or labels. These labels must clearly identify the conductor’s function (e.g., phase A, phase B, neutral, ground).

- Terminal markings: Terminals in panels and switchboards must be clearly marked to indicate their function and the corresponding circuit.

- Conduit markings: Large conduit systems often require labeling to identify the circuits contained within.

Proper identification is crucial for safety during maintenance and repairs. Incorrectly identified conductors can lead to accidental shock, equipment damage, or incorrect circuit operation. For instance, if a neutral and a hot conductor are inadvertently switched, it could lead to dangerous situations for electricians or equipment malfunction.

Q 26. Describe your experience with electrical code inspections.

I have extensive experience with electrical code inspections, spanning both residential and commercial projects. My inspections focus on ensuring adherence to the NFPA 70 (NEC) and relevant local codes. I review wiring methods, grounding techniques, overcurrent protection, and equipment installations. I use a systematic approach, carefully examining plans, drawings, and the actual installations. This typically involves detailed walkthroughs, visual inspections, testing with specialized equipment (like a multimeter to verify grounding), and documentation of any observed discrepancies.

I’ve worked on projects ranging from small renovations to large-scale commercial buildings. My experience includes identifying and documenting various code violations, such as improper grounding, insufficient overcurrent protection, inadequate wiring methods, and incorrect labeling. I work closely with contractors to help them understand and rectify any identified violations, ensuring that installations are safe and comply with code requirements. I prepare detailed inspection reports and follow up to ensure corrections have been implemented.

Q 27. How do you stay up-to-date with changes to the NFPA 70 (NEC)?

Staying current with changes to the NFPA 70 (NEC) is crucial for maintaining expertise in electrical safety. I employ a multi-pronged approach:

- NFPA membership and publications: I am an active member of the NFPA, receiving regular updates and notifications on code changes.

- Professional development courses: I regularly attend seminars, workshops, and online courses focused on the NEC and related electrical codes.

- Industry publications and journals: I subscribe to professional journals and publications that cover changes and updates in electrical codes and standards.

- Online resources and networking: I actively participate in online forums and networking groups for electrical professionals to share information and discuss code interpretations.

This ongoing learning process ensures that my knowledge and skills remain aligned with the latest safety standards and best practices.

Q 28. Explain a situation where you had to resolve a code violation.

During an inspection of a new commercial building, I discovered a significant code violation involving the grounding system. The contractor had used improper grounding electrodes, resulting in inadequate fault current protection. This could have caused severe electrical shock hazards.

To resolve the issue, I first documented the violation with photographs and detailed descriptions in my inspection report. Then, I met with the contractor to explain the code requirements, showcasing the specific sections of the NEC that were violated. I worked collaboratively with the contractor to develop a remediation plan that involved replacing the existing grounding electrodes with correctly sized and spaced electrodes that met NEC requirements. I conducted a follow-up inspection after the corrections were made to verify that the grounding system was compliant with the code. The issue was resolved efficiently and safely through communication and a focus on remediation. The outcome ensured the safety of the building’s occupants and electrical systems.

Key Topics to Learn for NFPA 70 – National Electrical Code Interview

- Wiring Methods and Materials: Understanding various cable types (e.g., NM, BX, MC), their applications, and installation requirements is crucial. Practice identifying appropriate cable choices for different scenarios.

- Overcurrent Protection: Mastering the concepts of fuses, circuit breakers, and their coordination is essential. Be prepared to discuss fault current calculations and the selection of appropriate overcurrent protection devices.

- Grounding and Bonding: Thorough understanding of grounding electrode systems, equipment grounding, and bonding requirements is vital for safety. Be ready to explain the purpose and application of each.

- Branch Circuits and Feeders: Know the rules governing branch circuit calculations, sizing, and protection. Understand the difference between branch circuits and feeders and their respective requirements.

- Motors and Motor Circuits: Learn about motor control circuits, overload protection, and starting methods. Be prepared to discuss different types of motors and their associated NEC requirements.

- Lighting and Appliances: Understand the NEC requirements for lighting systems, including fixture installation, wiring, and load calculations. Be familiar with appliance connection requirements and safety considerations.

- Special Occupancies: Familiarize yourself with the specific requirements for hazardous locations (e.g., Class I, II, III), and other special occupancies like healthcare facilities or industrial settings.

- Troubleshooting and Problem Solving: Practice applying your knowledge to solve practical problems related to electrical systems. Develop your ability to identify code violations and propose safe and compliant solutions.

Next Steps

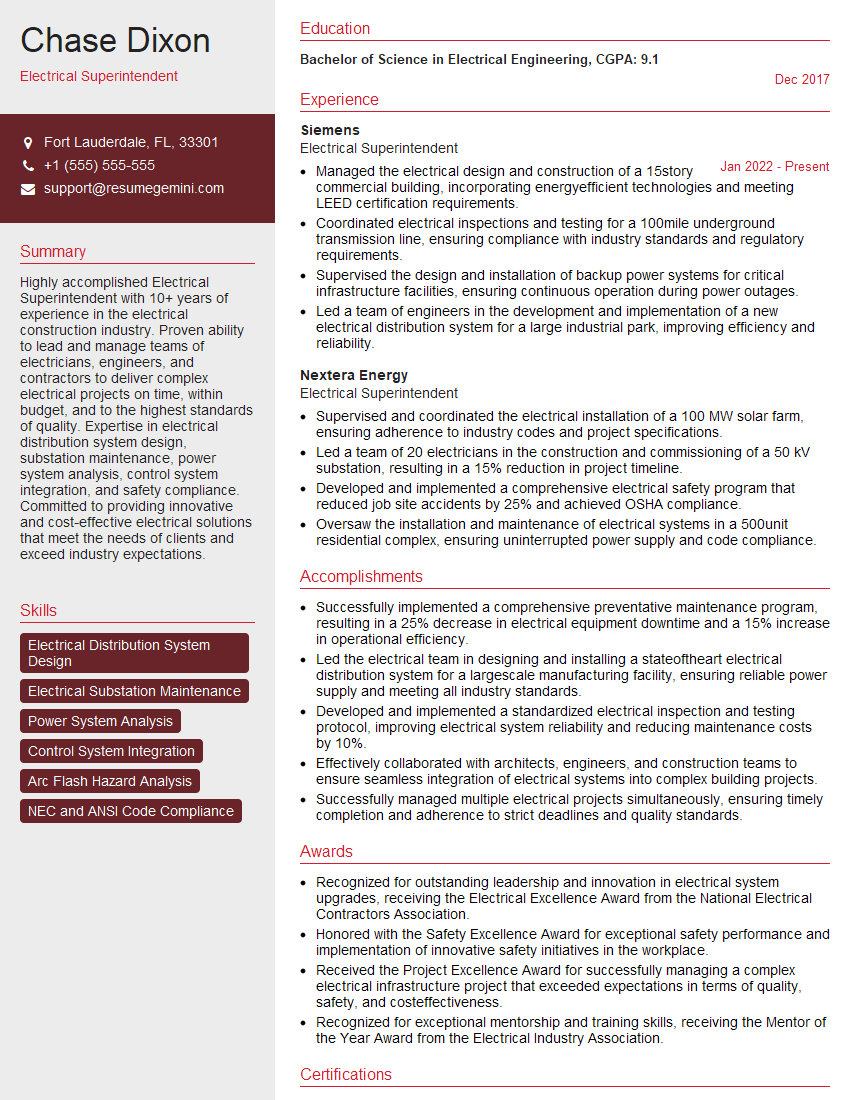

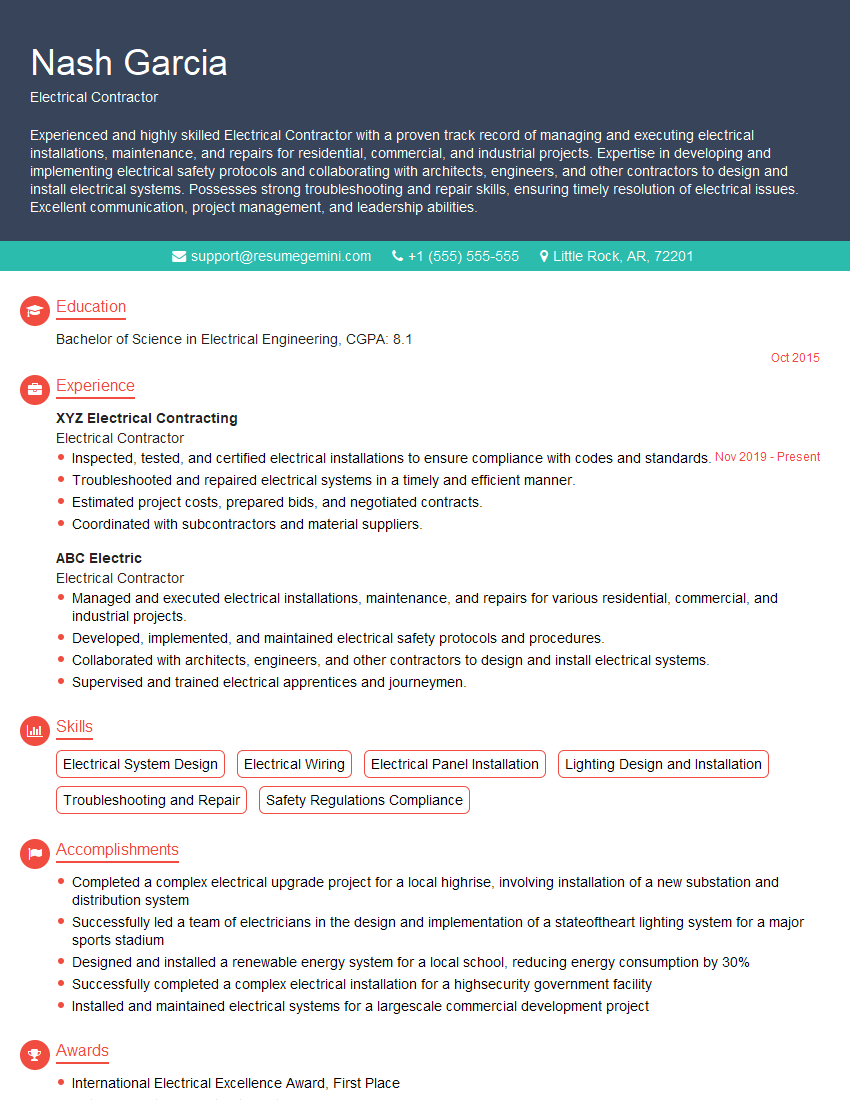

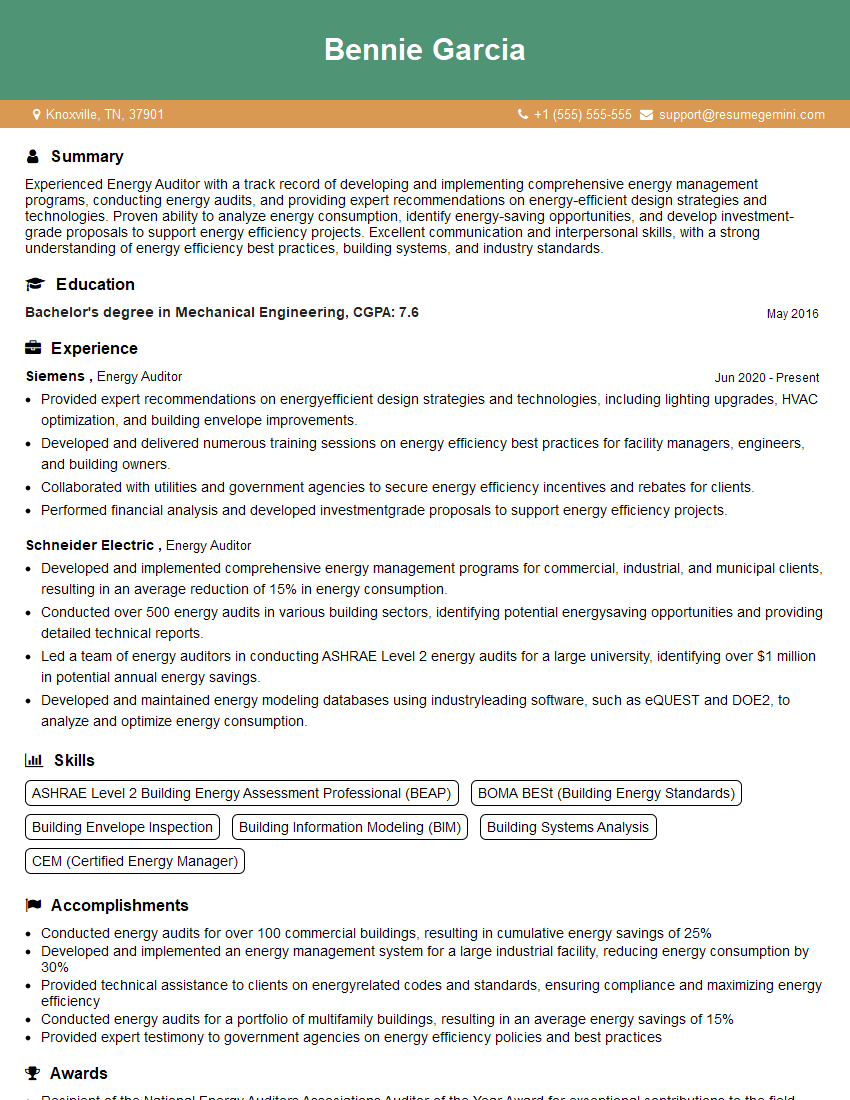

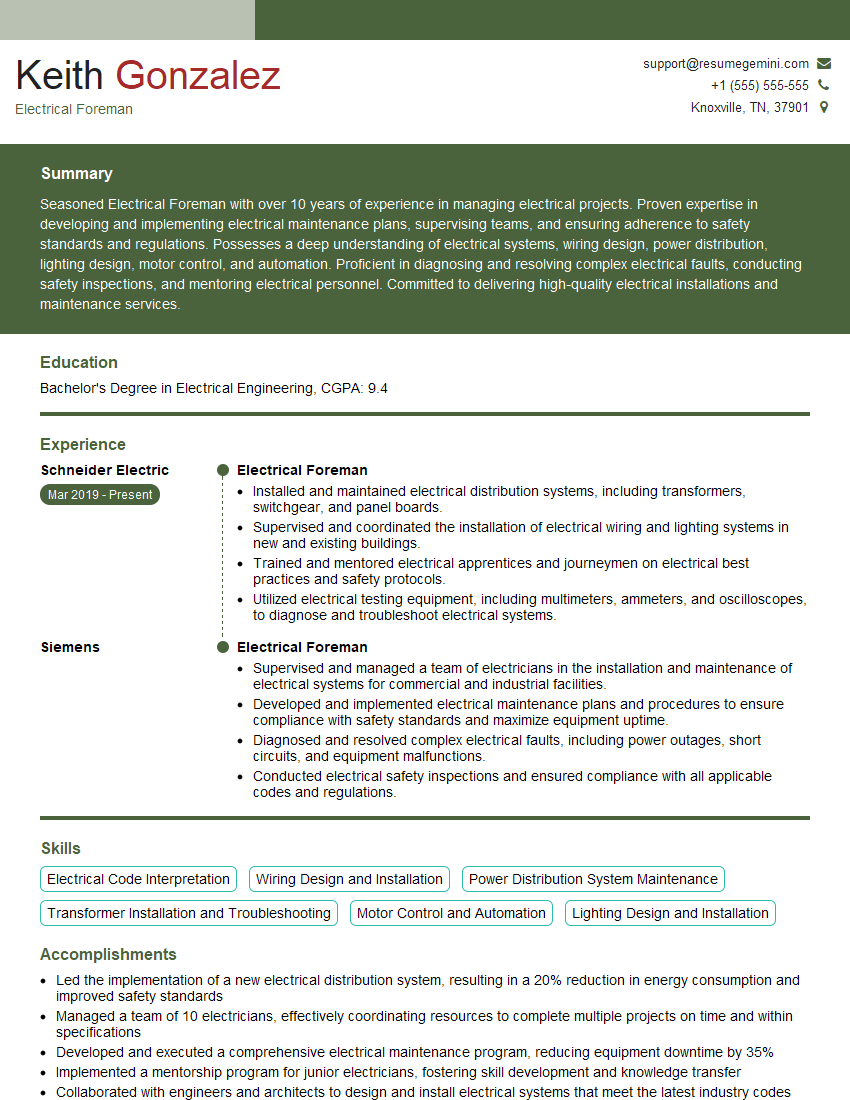

Mastering the NFPA 70 – National Electrical Code is paramount for career advancement in the electrical field, opening doors to higher-paying roles and increased responsibility. A strong understanding of the code demonstrates your commitment to safety and professionalism. To significantly improve your job prospects, create an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource to help you build a professional and impactful resume, showcasing your NFPA 70 knowledge effectively. Examples of resumes tailored to NFPA 70 – National Electrical Code expertise are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good