Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Fabric Cutting Techniques interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Fabric Cutting Techniques Interview

Q 1. Explain the difference between a single-ply and multi-ply fabric cut.

The key difference between single-ply and multi-ply fabric cutting lies in the number of layers of fabric cut simultaneously. Single-ply cutting involves cutting one layer of fabric at a time, offering greater precision and control, especially with intricate patterns or delicate fabrics. Multi-ply cutting, on the other hand, involves cutting multiple layers of fabric stacked together. This method is significantly faster and more efficient for large-scale production runs of simpler designs, but requires careful alignment and attention to ensure consistent cuts across all layers.

Think of it like this: single-ply is like carefully crafting a single intricate cake layer, while multi-ply is like efficiently baking a stack of simpler, identical sheet cakes at once. The choice depends on the design complexity, fabric type, and production volume.

Q 2. Describe your experience with various fabric cutting tools and machinery.

My experience encompasses a wide range of fabric cutting tools and machinery. I’m proficient with manual cutting tools such as rotary cutters, shears (both straight and pinking), and pattern shears. I’ve also extensively used various automated cutting systems, including computer-aided cutting (CAC) machines with both oscillating and straight knives. My experience also includes working with different spreading machines for efficiently layering fabric before cutting. I am adept at selecting the appropriate tool or machine based on the fabric type, design complexity, and production volume. For example, delicate silks benefit from sharp shears and careful manual cutting, whereas heavy-duty denim is well-suited to the power and speed of a CAC machine.

Q 3. How do you ensure accurate fabric cutting based on patterns?

Accurate fabric cutting based on patterns demands meticulous attention to detail and a methodical approach. I begin by carefully studying the pattern pieces, noting the grainlines, notches, and markings. Next, I precisely lay out the pattern pieces on the fabric, ensuring proper alignment with the grain and minimizing waste. I utilize weights or pins to secure the patterns in place, preventing any shifting during the cutting process. I always double-check my work before cutting, and for multi-ply cutting, I meticulously align and secure the fabric layers to guarantee consistent cuts throughout. Finally, I carefully cut along the pattern lines using the appropriate tools, maintaining a steady hand and ensuring sharp blades for clean cuts.

For particularly complex designs, I may use a laser projector to display the pattern directly onto the fabric for precise alignment and to reduce any potential human error.

Q 4. What methods do you use to minimize fabric waste during cutting?

Minimizing fabric waste is crucial for efficient production and cost-effectiveness. I employ several strategies, including efficient nesting techniques to maximize the number of pattern pieces that can be cut from a single fabric spread. I use specialized software for computer-aided cutting to optimize nesting layouts and reduce waste. I also carefully consider the fabric layout, taking into account the pattern orientation and grain direction to minimize the use of fabric. Additionally, I frequently reuse fabric scraps whenever possible for smaller components or design details. It’s all about strategic planning and thoughtful execution from the initial pattern design and spreading to the final cutting process.

Q 5. Explain your experience with different cutting layouts (e.g., nesting, spreading).

My experience with cutting layouts includes both traditional manual methods and advanced computer-aided systems. I am proficient in various nesting techniques, adapting the method to the specific requirements of each project. For instance, ‘block nesting’ is effective for simple patterns and large-scale production, while more complex layouts, such as ‘auto-nesting’ via specialized software, are employed for intricate designs to optimize material usage. I also understand the importance of proper fabric spreading, ensuring uniform tension and minimizing wrinkles to prevent distortion during the cutting process. My experience includes using both manual and automated spreading machines, selecting the best technique depending on fabric type and volume.

Q 6. How do you handle challenging fabric types (e.g., slippery, bulky)?

Handling challenging fabrics requires adapting techniques and utilizing specialized tools. For slippery fabrics like silk or satin, I use specialized pins or weights to secure the pattern pieces and prevent shifting. I also opt for sharp, fine-tipped rotary cutters or shears to minimize slippage. For bulky fabrics like velvet or heavy wool, I might adjust the cutting pressure or use specialized blades designed for thick materials. In some cases, using multiple thin layers instead of one thick layer can facilitate easier cutting and improved accuracy. Understanding the properties of different fabrics is key to selecting the appropriate tools and techniques to produce clean, accurate cuts.

Q 7. Describe your process for inspecting cut fabrics for defects.

Fabric inspection is a critical step in ensuring quality. After cutting, I carefully examine each piece for defects such as holes, tears, inconsistencies in the weave, or miscuts. I use a strong light source to detect minor flaws and I run my hands across the fabric to check for any irregularities in the texture. Any defective pieces are immediately set aside and documented, and if necessary, adjustments to the cutting process are made. Thorough inspection ensures that only high-quality fabrics proceed to the next stage of production, minimizing potential problems later in the garment construction.

Q 8. How do you maintain quality control throughout the cutting process?

Maintaining quality control in fabric cutting is paramount to producing high-quality garments. It’s a multi-faceted process starting even before the cutting begins.

Pre-cutting Inspection: Before any cutting, I meticulously inspect the fabric rolls for flaws like imperfections, inconsistencies in color or weave, and damage. This helps prevent faulty garments down the line. Think of it like a chef checking the quality of ingredients before starting a dish.

Accurate Pattern Placement: Precise placement of patterns on the fabric is crucial. We use spread sheets or automated systems to ensure minimal waste and consistent placement, avoiding distortions or misalignments. This minimizes fabric loss and ensures uniform garment sizes.

Sharp Blades and Regular Maintenance: Dull blades create frayed edges and inaccurate cuts, leading to poor quality. Regular sharpening and replacement of cutting tools is vital. Imagine trying to cut bread with a blunt knife—the result is messy and uneven.

Regular Calibration: Automated cutting systems require regular calibration to maintain accuracy. This involves checking the cutting pressure, blade alignment, and sensor readings to ensure consistent cuts. This is akin to regularly tuning a musical instrument to ensure it’s in perfect harmony.

Post-cutting Inspection: After cutting, a final inspection checks for any defects or mistakes. This final check ensures that only perfectly cut pieces proceed to the next stage of production. This is like a final proofreading of a document before printing.

Q 9. What experience do you have with automated cutting systems?

I have extensive experience with automated cutting systems, including Gerber and Lectra machines. My expertise encompasses operating, maintaining, and troubleshooting these sophisticated systems. I’m proficient in programming cutting parameters, managing nesting software, and optimizing cutting layouts for maximum efficiency and minimal waste. For instance, I’ve successfully implemented a new nesting algorithm on a Gerber cutter, resulting in a 15% reduction in fabric waste in a large-scale production run for a major denim brand. I also possess hands-on experience with various software interfaces, including the creation and modification of cutting sequences, which allows for flexibility in handling diverse fabric types and garment styles.

Q 10. How familiar are you with different types of cutting knives and blades?

My familiarity with cutting knives and blades extends across various types, each suited for specific fabrics and applications.

Rotary blades: Ideal for smooth, consistent cuts on woven fabrics like cotton, linen, and silk. They are used in both manual and automated cutting systems.

Oscillating blades: Excellent for cutting multiple layers of fabric and are particularly effective on layered knit fabrics or materials that might stretch during cutting. The oscillating motion minimizes stretching.

Straight knives: Primarily used for manual cutting, especially on thicker, heavier fabrics like leather or denim, where precision is key.

Die cutting blades: Used for intricate shapes, particularly on thinner, more delicate fabrics. These offer very accurate cuts for designs requiring complex details.

Understanding the characteristics of each blade type and its suitability for different fabrics is crucial for achieving optimal cutting performance and quality. Choosing the wrong blade can lead to damaged fabrics or inaccurate cuts.

Q 11. Explain your understanding of fabric grain and its impact on cutting.

Fabric grain refers to the direction of the yarns in a woven fabric—the warp (lengthwise) and weft (crosswise) yarns. Understanding fabric grain is fundamental in cutting because it dictates how the fabric will drape, stretch, and behave during wear. Cutting with or against the grain directly impacts the final garment’s fit and appearance.

Cutting with the grain: Results in a stable, less likely to stretch or distort garment. This is typically preferred for most garments.

Cutting on the bias: Cutting at a 45-degree angle to the grain creates draping and stretch which is often desired for tailored garments or flowy dresses.

Cutting across the grain: Can lead to more stretching or distortion, typically avoided except in specific design situations.

Ignoring fabric grain can lead to ill-fitting garments, uneven seams, and a distorted final product. Consider how a wrongly placed seam on a shirt will be more noticeable and uncomfortable when worn. Proper grain alignment is a matter of professional pride and customer satisfaction.

Q 12. How do you manage and organize large fabric quantities in a cutting room?

Managing large fabric quantities requires a systematic approach. This includes using efficient storage systems, implementing clear labeling, and maintaining a well-organized cutting room.

Organized Storage: Fabric rolls are stored according to type, color, and quantity. We use a combination of vertical racking and horizontal shelving, maximizing space while ensuring easy accessibility. Think of it as a well-stocked library, where each book is easy to find.

Clear Labeling: Each roll is clearly labeled with details such as fabric type, color, quantity, and date received. This allows for quick identification and efficient inventory management. Clear labeling ensures everyone on the team works from the same information.

FIFO System: Implementing a First-In, First-Out (FIFO) system ensures that older fabrics are used first, minimizing storage time and preventing fabric degradation. This prevents fabric from becoming obsolete and reduces storage costs.

Inventory Management Software: Using dedicated software to manage fabric inventory ensures an accurate record of stock levels, helps to plan future purchasing, and assists in managing costs.

Q 13. Describe your experience with using computerized pattern-making software.

I am proficient in using various computerized pattern-making software, including industry-standard programs such as Gerber Accumark and Optitex. My expertise includes creating and modifying patterns, grading patterns for different sizes, and generating marker layouts for efficient fabric utilization. For example, I recently used Gerber Accumark to develop a new pattern for a complex jacket design which was then graded across multiple sizes, resulting in a more efficient and streamlined production process, saving significant time and reducing errors.

Q 14. What safety measures do you employ during fabric cutting?

Safety is of paramount importance in the cutting room. I strictly adhere to all safety regulations and implement several measures to prevent accidents.

Proper Blade Handling: Always using appropriate safety guards on blades, and avoiding direct contact with blades when possible. Proper blade handling is basic safety training for anyone working with cutting machinery.

Personal Protective Equipment (PPE): Wearing appropriate PPE such as cut-resistant gloves, safety glasses, and closed-toe shoes is mandatory at all times. This protects against accidental injuries from sharp blades and flying fabric scraps.

Machine Guards: Ensuring that all machine guards are properly secured and functioning correctly before operating automated cutting systems. Regular machine maintenance is paramount to ensuring these guards remain effective.

Regular Maintenance Checks: Performing routine inspections on equipment to identify and address any potential hazards before they cause accidents. Regularly inspecting all cutting equipment is integral to creating a safe working environment.

Cleanliness: Keeping the cutting room floor clear of fabric scraps to minimize tripping hazards. Regular cleanup contributes to a safer work environment, and this is a shared responsibility of the team.

Q 15. How do you address inconsistencies or errors in cut fabric pieces?

Addressing inconsistencies in cut fabric pieces requires a multi-pronged approach focusing on prevention and correction. Prevention starts with meticulous attention to detail during the layout process, ensuring accurate measurements and proper alignment of patterns. However, errors can still occur. When inconsistencies are detected, the first step is to identify the root cause. This might involve inspecting the cutting equipment for malfunctions, checking the sharpness of the blades, or evaluating the quality and consistency of the fabric itself. Was the fabric warped or stretched? Was there a problem with the cutting machine’s settings?

For minor inconsistencies, like slight variations in seam allowance, adjustments can often be made during the sewing process. However, for significant errors, such as a piece cut incorrectly or damaged, the only option is to recut the piece from a new section of fabric. A detailed record-keeping system, tracking fabric usage and any discrepancies, helps avoid repeating mistakes and ensures accountability. For example, if consistent errors occur on one particular cutting table, we’d investigate that table’s condition and calibrate it as needed. Think of it like baking – if your cakes are consistently overcooked, you adjust the oven temperature. In this instance, we adjust the machine settings or equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your process for creating and maintaining cutting layouts.

Creating and maintaining efficient cutting layouts is crucial for minimizing fabric waste and maximizing productivity. My process begins with a thorough understanding of the garment design and the required number of pieces. I then use specialized software, or manual techniques for smaller projects, to create a layout that optimizes fabric placement, minimizing waste. This involves considering the fabric’s grain direction, pattern orientation, and the arrangement of individual pattern pieces to reduce the number of sheets required. For example, I’d group similar shapes together to make cutting smoother. Efficiency is key – wasted fabric means wasted money and resources.

The layout is meticulously documented, usually digitally and saved for future reference. This documentation includes the cutting sequence, material specifications, and any notes regarding fabric manipulation during cutting. Regular updates are made to improve efficiency; we might track how many pieces we manage to get out of a fabric roll, allowing us to refine layouts over time and minimize waste. This is an iterative process, improving over each cut run. The layout is then transferred onto the fabric, using markers or chalk to ensure accurate placement. This entire process needs to be consistently followed to ensure that the cutting room produces high-quality, consistent results.

Q 17. What are the key factors to consider when choosing a cutting method?

Choosing the right cutting method depends on several key factors. The first is the type of fabric. Delicate fabrics like silk require gentler methods, such as manual cutting with sharp shears, to avoid damage. Sturdier fabrics, such as denim or canvas, can withstand more robust methods like automated cutting with a computer-controlled cutting machine. Secondly, consider the volume of production. Small-scale projects might be best suited to manual cutting, while mass production necessitates automated systems.

The complexity of the pattern is another crucial factor. Intricate designs with many small pieces are better suited to automated cutting, which ensures accuracy and consistency. Finally, budget and available resources heavily influence the method choice. Automated cutting systems require a significant upfront investment but offer higher efficiency in the long run. A cost-benefit analysis, considering initial investment, operational costs, and potential waste reduction, is essential in determining which method provides the best return on investment.

Q 18. How do you ensure consistent cutting quality across different team members?

Ensuring consistent cutting quality across different team members requires a combination of training, standardized procedures, and quality control measures. Thorough training is crucial, focusing on proper use of cutting equipment, accurate pattern placement, and adherence to established cutting techniques. We’ll use examples and demonstrate best practice techniques, reinforcing concepts through practical exercises. A standardized cutting instruction guide, with detailed diagrams and clear instructions, must be readily available to all team members.

Regular quality checks are essential to catch and correct any inconsistencies. This may include random sampling of cut pieces to verify measurements and accuracy, and feedback sessions where the team can discuss challenges and best practices. Clear communication is key, ensuring that every team member understands the expectations, and performance feedback will help to identify areas for improvement. A well-trained and motivated team, empowered to take ownership of their work, is the foundation for consistent quality. Imagine it like a sports team – consistent practice and coaching is key to consistent performance.

Q 19. How familiar are you with different types of fabric cutting tables?

My experience encompasses various types of fabric cutting tables, from basic manual tables to sophisticated, automated systems. I’m proficient with standard cutting tables, which provide a stable surface for manual cutting with shears or rotary cutters. These are well-suited for smaller projects and less intricate designs. I have extensive experience with electric cutting tables, which offer motorized cutting capabilities, increasing productivity and reducing operator fatigue. These are more efficient but require a slightly different skillset. Finally, I’m familiar with computerized cutting systems, often used in mass production environments. These systems offer the highest levels of precision and speed, allowing for complex patterns and minimal material waste. These systems require specialized software and training.

Understanding the strengths and limitations of each type allows me to select the most appropriate equipment for any given project. For example, a delicate lace fabric would warrant manual cutting on a standard table, while a large-scale denim production run would benefit from automated cutting. Each system offers unique advantages and the right choice is heavily dependent on both project requirements and available resources.

Q 20. Describe your experience with different types of cutting equipment maintenance.

Regular maintenance is crucial for ensuring the longevity and accuracy of cutting equipment. For manual cutting tools, this includes regular sharpening of shears and rotary cutters, ensuring they remain sharp and precise, which leads to cleaner cuts and reduced fabric waste. For electric cutting tables, maintenance involves checking the blade alignment, lubrication of moving parts, and regular cleaning to remove fabric scraps and debris. This minimizes friction and prolongs equipment lifespan. For computerized cutting systems, maintenance is more complex and often involves software updates, calibration checks, and periodic servicing by qualified technicians. These steps are essential for accurate cutting and avoiding downtime. It’s like maintaining a car – regular servicing prevents bigger, more costly issues later.

My experience includes preventative maintenance schedules, troubleshooting minor malfunctions, and coordinating repairs with specialized technicians. Detailed records are maintained for all maintenance activities, including dates, tasks performed, and any issues encountered. This helps ensure that maintenance protocols are followed diligently and problems are addressed proactively, minimizing downtime and ensuring the equipment’s continued efficiency and accuracy.

Q 21. How do you prioritize tasks and manage your time in a fast-paced cutting room?

In a fast-paced cutting room, effective task prioritization and time management are crucial. My approach involves utilizing a combination of strategies. I start by creating a detailed cutting schedule, prioritizing orders based on deadlines and production needs. This schedule usually maps out the day or week and is then broken down into smaller, manageable tasks. This might include preparing the fabric, creating the layout, and cutting the fabric itself. I often utilize tools like Kanban boards to visually track progress and identify any potential bottlenecks. This helps to prevent delays and keep the workflow moving smoothly.

Time management also includes assessing available resources, and allocating them effectively. This may involve assigning tasks to team members based on their skills and experience, which is essential for maximizing efficiency and ensuring the consistent quality of the output. Effective communication is crucial – regular briefings with the team, identifying any unforeseen challenges and adjusting the schedule accordingly, will ensure smooth workflow and meet deadlines.

Q 22. What are your strategies for improving efficiency in the cutting process?

Improving efficiency in fabric cutting hinges on meticulous planning and employing the right techniques. My strategies focus on optimizing material usage, streamlining the cutting process, and leveraging technology where possible.

Nesting Optimization: I utilize computer-aided design (CAD) software to create efficient nesting patterns, minimizing fabric waste. This involves strategically arranging pattern pieces to reduce the number of cuts and maximize yield from each fabric bolt. Think of it like a jigsaw puzzle – the goal is to fit as many pieces as possible without overlap.

Sharp Tools and Equipment: Dull blades lead to inaccurate cuts and increased material waste. Regularly maintaining and replacing cutting tools – including rotary cutters, shears, and electric cutting machines – is crucial for efficiency and precision. A sharp blade is like a surgeon’s scalpel; it makes clean, precise cuts.

Batch Processing: When possible, I prioritize batch cutting of similar garments or components. This allows for streamlined workflows and minimizes setup time for changing patterns or fabrics. It’s like an assembly line – focusing on one task before moving to the next.

Teamwork and Collaboration: Efficient cutting often involves a team. Clear communication and collaboration ensure that everyone understands the cutting instructions and works together smoothly. A well-coordinated team is far more efficient than individual efforts.

Q 23. How do you interpret and follow cutting instructions accurately?

Accurately interpreting and following cutting instructions requires careful attention to detail and a thorough understanding of pattern making principles. I approach this by following a structured process:

Pattern Study: Before commencing cutting, I thoroughly examine the pattern pieces, noting grainlines, notches, markings, and any special instructions. This helps me anticipate potential challenges and ensure correct placement.

Fabric Preparation: Proper fabric preparation – including pre-washing and ironing – is essential for accuracy. Wrinkles and uneven fabric can lead to inaccurate cuts. I always ensure the fabric is smooth and free of creases.

Precise Measurement and Alignment: I use accurate measuring tools like rulers and measuring tapes to verify measurements and ensure precise alignment of pattern pieces on the fabric. This step is critical for accurate garment construction.

Consistent Cutting Technique: I use consistent cutting techniques, maintaining a straight line and avoiding uneven cuts. This includes maintaining consistent pressure on the cutting tool and making slow, deliberate cuts.

Double-Checking: After cutting, I always double-check my work, ensuring all pieces are cut accurately and that all markings and notches are intact.

Q 24. Explain your experience with fabric handling and storage best practices.

Proper fabric handling and storage are crucial for maintaining the quality and integrity of the material. My experience encompasses these best practices:

Clean and Organized Storage: Fabrics are stored in a clean, dry environment, away from direct sunlight and moisture. I use appropriate shelving and storage containers to prevent damage and maintain order. Think of it like a well-stocked pantry – everything has its place.

Proper Folding and Stacking: Fabrics are folded neatly and stacked to prevent creasing and damage. I avoid over-stacking, which can crush or distort the fabric. This keeps the fabric pristine and ready for use.

Protective Measures: Delicate fabrics might require additional protection, such as acid-free tissue paper between layers. This protects against abrasion and color transfer. It’s like using bubble wrap for fragile items.

Inventory Management: Maintaining an accurate inventory helps to track fabric usage and minimize waste. This involves regularly checking stock levels and documenting fabric details (type, quantity, etc.).

Q 25. Describe your problem-solving skills when encountering unexpected challenges during cutting.

Problem-solving is inherent to fabric cutting. Unexpected challenges arise, requiring quick thinking and resourcefulness. My approach involves:

Identifying the Problem: Carefully assess the situation. What went wrong? Is it a faulty pattern, a damaged fabric, a malfunctioning machine, or a simple error?

Assessing the Impact: How significant is the problem? Can it be easily rectified, or does it require a major adjustment to the cutting plan?

Creative Solutions: Brainstorm possible solutions. Can parts be salvaged? Can the pattern be adjusted? Sometimes, a minor alteration saves a whole piece of fabric.

Seeking Assistance: If the problem is beyond my immediate expertise, I consult with colleagues or supervisors. Two heads are better than one.

Documentation and Prevention: Document the problem and its solution to learn from the experience and prevent similar issues in the future. This is crucial for continuous improvement.

Q 26. How do you ensure accurate measurements when cutting fabrics?

Ensuring accurate measurements is paramount in fabric cutting. My methods include:

Calibration of Tools: Regularly check and calibrate measuring tools (rulers, tapes) to ensure accuracy. A slightly off ruler can cause significant errors.

Precise Marking: Use precise marking tools like tailor’s chalk, marking pens, or pattern weights to accurately mark pattern pieces on the fabric. Clear markings minimize errors.

Multiple Measurements: Take multiple measurements to verify accuracy, especially for crucial dimensions. This minimizes mistakes due to oversight.

Square and Straight Cutting Surface: Use a large, flat, and clean cutting surface to ensure accurate alignment of pattern pieces and prevent skewed cuts. A stable surface is crucial for precise cuts.

Proper Fabric Handling: Ensure the fabric is lying flat and smooth to prevent distortions that affect measurements.

Q 27. What are your preferred methods for marking and numbering cut pieces?

My preferred methods for marking and numbering cut pieces aim for clarity and efficiency:

Clear and Consistent Numbering: Use a numbering system that’s easy to understand and consistently applied to all pattern pieces. A logical system prevents confusion.

Durable Marking: Use marking tools that are durable and won’t easily fade or smudge during the cutting and sewing process. Sharpie markers are usually adequate for most fabrics.

Placement of Markings: Mark numbers and other important information (grainlines, notches) in a clear and visible location on each piece. It’s useful to note the direction of grainline for accurate sewing.

Fabric Labels: For large projects, using labels with detailed information helps streamline the identification and organization of cut pieces. This simplifies the assembly process.

Digital Documentation: For complex designs, I use digital images or spreadsheets to record the markings and piece identification. It’s especially useful for projects with hundreds of pieces.

Q 28. Explain your understanding of different fabric finishes and their impact on cutting.

Different fabric finishes significantly influence cutting techniques and require specific considerations. My understanding encompasses:

Woven Fabrics: Woven fabrics (cotton, linen, silk) have a distinct grain and require careful attention to grainlines. Cutting against the grain can affect the final garment’s drape and fit. Consider the bias when cutting.

Knit Fabrics: Knit fabrics (jersey, rib knit) are more stretchy and require less precise cutting. However, careful handling is crucial to prevent distortion. Stretchy materials require a gentler approach.

Pile Fabrics: Pile fabrics (velvet, corduroy) need to be cut in one direction to maintain a consistent nap. Cutting against the nap can create an uneven appearance.

Pattern Adaptation: The choice of cutting tools and techniques depends on the fabric’s weight and texture. Heavy fabrics may require specialized shears, while delicate fabrics need sharp, lightweight rotary cutters.

Pre-cutting Considerations: Fabrics with finishes like water-repellent or stain-resistant coatings require understanding potential impacts on cutting tools and maintaining blade sharpness to avoid clogging.

Key Topics to Learn for Fabric Cutting Techniques Interview

- Fabric Properties and Selection: Understanding different fabric types (woven, knit, non-woven), their drape, and how these properties influence cutting methods and pattern adjustments.

- Pattern Making and Grading: Mastering the principles of pattern construction, including understanding seam allowances, grainlines, and the process of grading patterns for different sizes.

- Cutting Techniques: Proficiency in various cutting methods, including hand cutting, using electric shears, and employing automated cutting systems. Understanding the advantages and disadvantages of each method.

- Spread Planning and Lay Planning: Optimizing fabric usage by efficiently arranging patterns on fabric spreads to minimize waste and maximize yield. This includes understanding marker making and its impact on efficiency.

- Quality Control and Inspection: Identifying and addressing common cutting defects, implementing quality control checks throughout the cutting process to ensure accuracy and consistency.

- Safety Procedures and Equipment Maintenance: Understanding and adhering to safety regulations related to cutting equipment, and performing basic maintenance on cutting tools to ensure optimal performance.

- Problem-solving and Troubleshooting: Identifying and resolving issues related to pattern discrepancies, fabric imperfections, and equipment malfunctions during the cutting process. This includes understanding how to adapt cutting techniques based on unexpected challenges.

- Industry Best Practices and Technology: Staying updated with the latest advancements in fabric cutting technology and industry best practices for efficiency and quality.

Next Steps

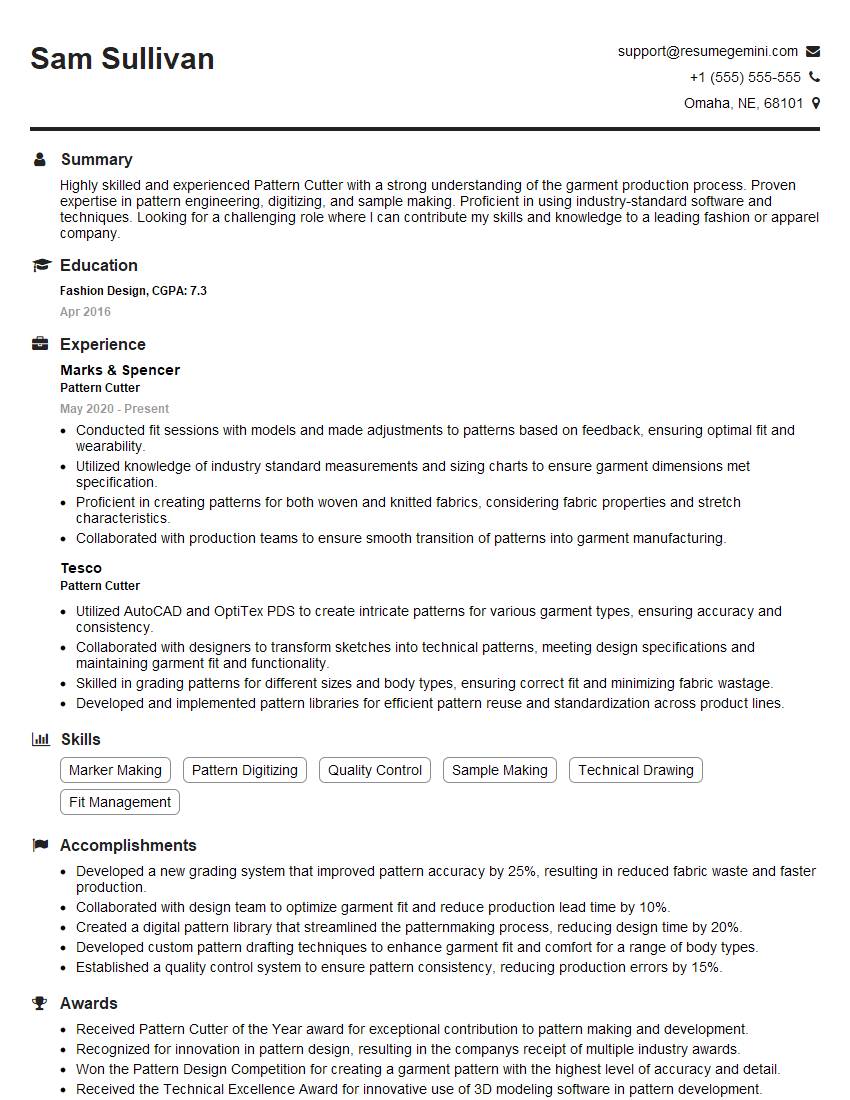

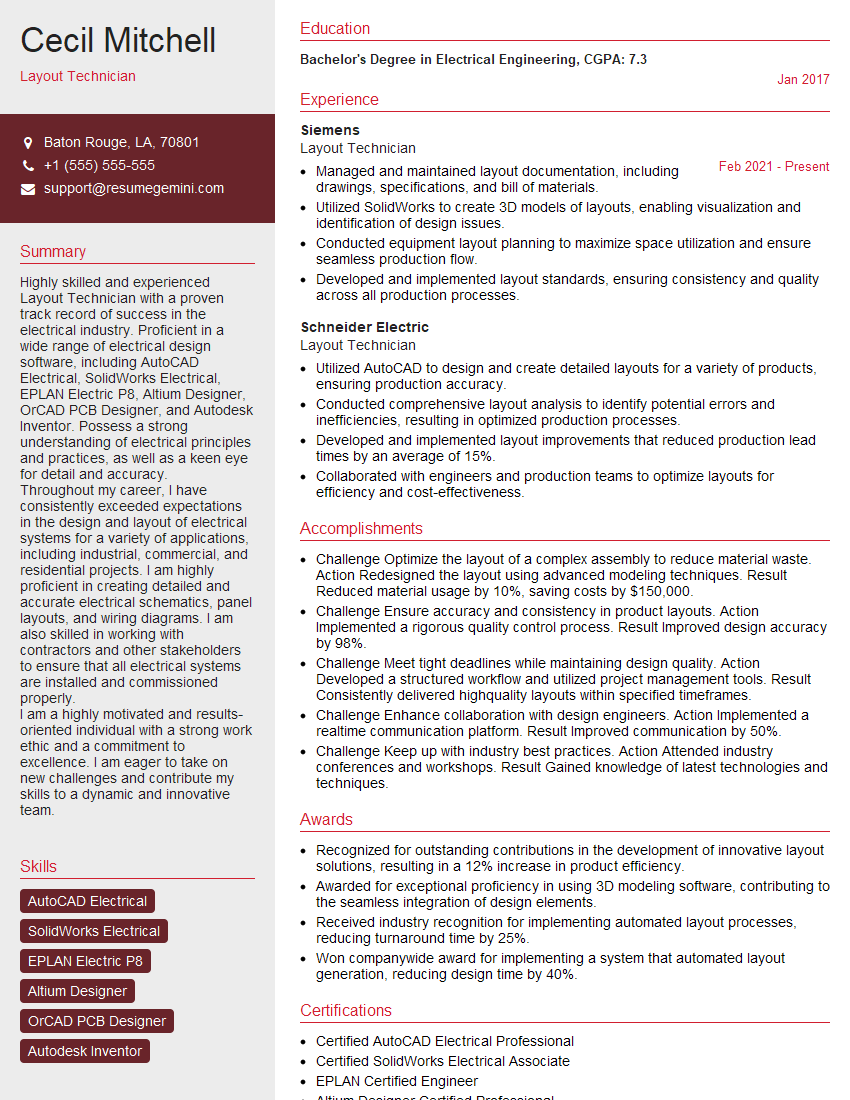

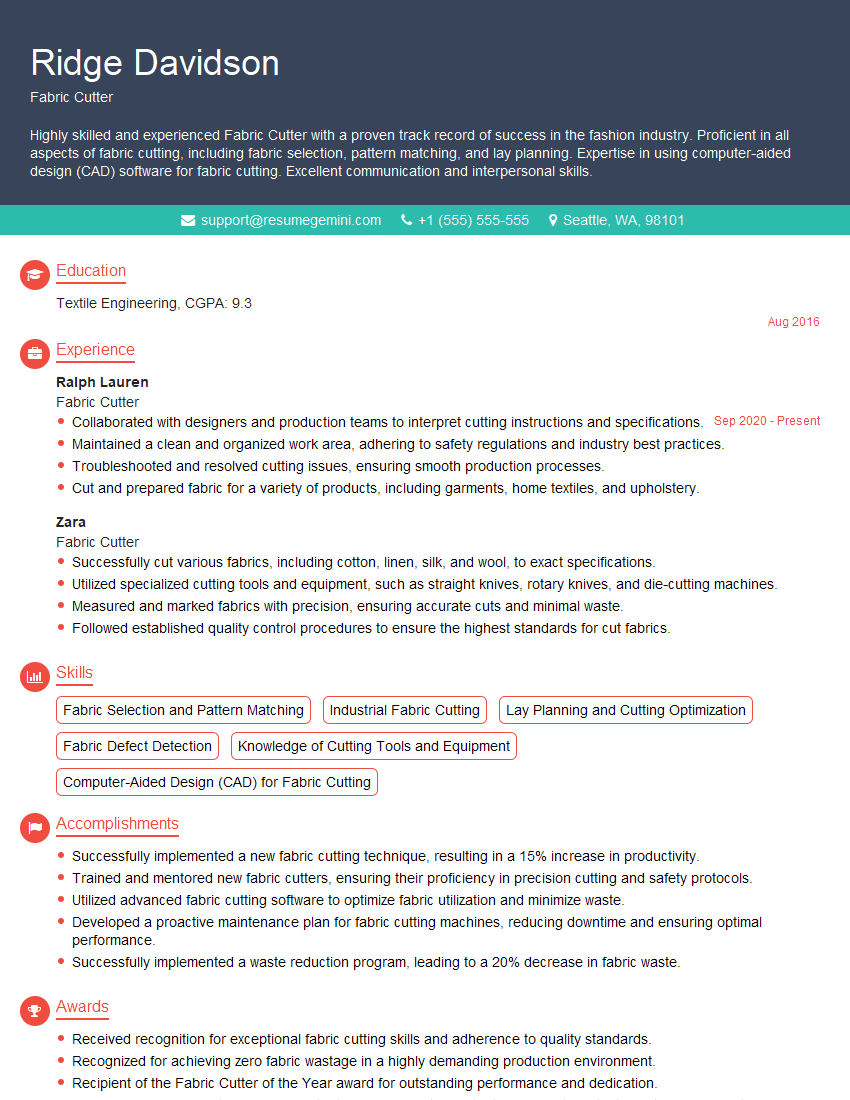

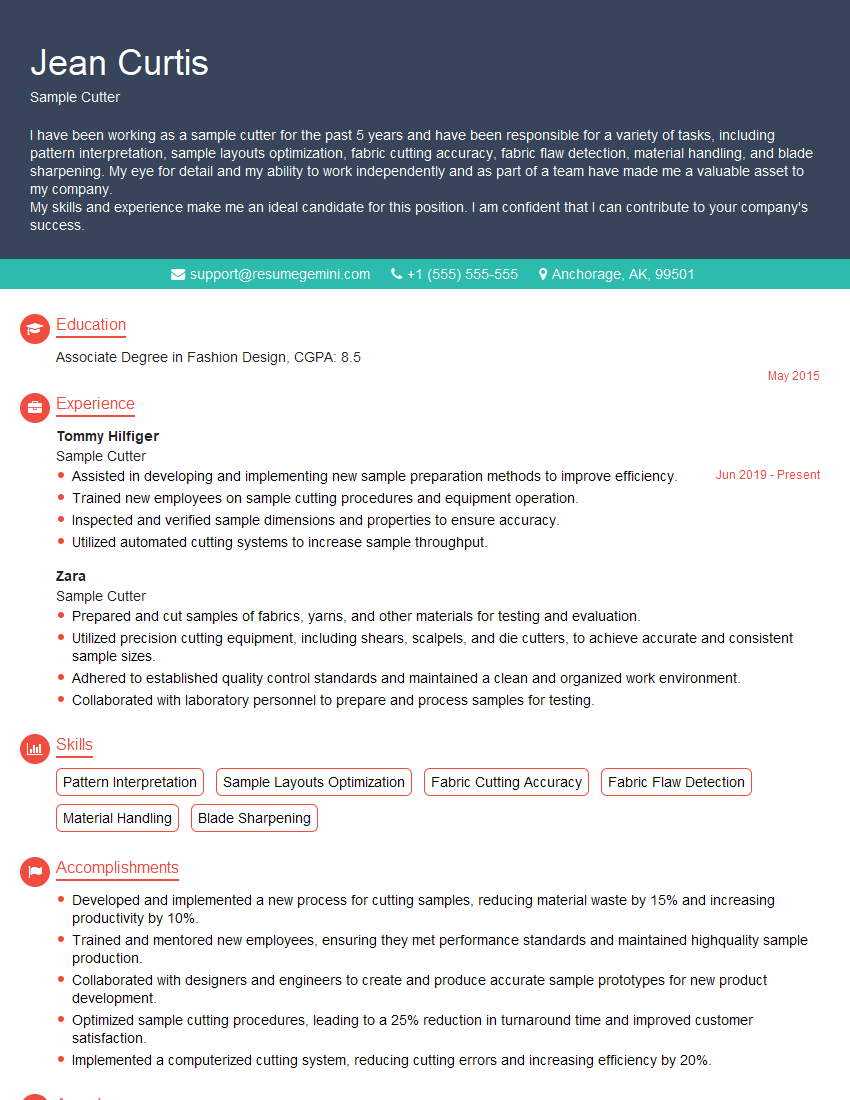

Mastering fabric cutting techniques is crucial for career advancement in the fashion and textile industries. A strong understanding of these techniques demonstrates your value to potential employers and opens doors to higher-level positions and increased earning potential. To maximize your job prospects, it’s vital to present your skills effectively. Create an ATS-friendly resume that highlights your expertise and accomplishments. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your application stands out. Examples of resumes tailored to Fabric Cutting Techniques are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good