The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Specification and Standards Compliance interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Specification and Standards Compliance Interview

Q 1. Explain the difference between a specification and a standard.

While often used interchangeably, specifications and standards differ significantly. A specification is a detailed description of the requirements for a product, process, or service. It outlines what needs to be achieved, focusing on the ‘what’. Think of it as a blueprint. A standard, on the other hand, is a documented agreement on technical specifications or other criteria established by a recognized body. It sets out how to meet the requirements defined in the specification, focusing on the ‘how’. Standards often provide a consistent, repeatable approach, facilitating interoperability and reducing ambiguity.

Example: A specification for a car might detail its required speed, fuel efficiency, and safety features. A standard, like those set by the SAE (Society of Automotive Engineers), would then specify the exact procedures and tests to verify that the car meets these specifications. The specification defines the goal, while the standard provides the path to reach it.

Q 2. Describe your experience with ISO 9001.

I have extensive experience with ISO 9001, having been involved in the implementation and maintenance of quality management systems (QMS) for several organizations across various industries. This includes leading internal audits, participating in external audits, and developing and implementing corrective actions. In one particular project, I helped a manufacturing company transition from an outdated QMS to ISO 9001:2015, leading a team that revamped their documentation, training procedures, and internal audit programs. This involved thorough analysis of their existing processes, identifying gaps, and developing an implementation plan aligned with ISO 9001 requirements. The successful implementation resulted in improved efficiency, reduced waste, and enhanced customer satisfaction, as evidenced by a significant decrease in customer complaints and an increase in on-time delivery.

My experience goes beyond mere implementation; I understand the importance of continuous improvement, the Plan-Do-Check-Act (PDCA) cycle, and the role of management commitment in achieving and maintaining ISO 9001 certification.

Q 3. How do you ensure compliance with industry regulations?

Ensuring compliance with industry regulations is a multi-faceted process that begins with thorough identification of all applicable regulations. This involves regularly reviewing legislation, industry-specific guidelines, and contractual obligations. Once identified, we translate these regulations into specific requirements, creating internal processes and procedures to ensure adherence. This includes meticulous documentation, regular training for employees, and the establishment of a robust monitoring and auditing system. For instance, in a medical device company, we’d need to follow regulations like FDA 21 CFR Part 820 and EU MDR, ensuring stringent controls throughout the design, manufacturing, and distribution process.

We use a combination of proactive measures, such as risk assessments, and reactive measures, like investigating non-conformances, to maintain compliance. Proactive measures help prevent issues, while reactive ones enable us to correct and improve upon any deviations.

Q 4. What methods do you use to identify and manage compliance risks?

Identifying and managing compliance risks requires a systematic approach. We employ a risk-based thinking methodology, starting with a comprehensive risk assessment that identifies potential areas of non-compliance. This assessment considers internal and external factors, legal changes, and evolving industry best practices. We use tools like Failure Mode and Effects Analysis (FMEA) to evaluate potential risks, assigning severity, probability, and detectability scores to each risk.

Once identified, we prioritize risks based on their impact and likelihood, developing mitigation strategies to address them. These strategies may include implementing new procedures, providing additional training, or investing in new technologies. We continually monitor the effectiveness of our mitigation strategies and update our risk assessment on a regular basis to adapt to changing circumstances. This ensures that our compliance program remains current and effective.

Q 5. How do you interpret and apply technical specifications?

Interpreting and applying technical specifications involves a thorough understanding of the language used, and often requires collaborating with subject matter experts. I start by carefully reviewing the document, identifying key requirements, and clarifying any ambiguities. This may involve cross-referencing with other relevant documents or consulting with the specification’s authors for clarification. Once the requirements are fully understood, I translate them into actionable steps, defining clear roles, responsibilities, and deadlines.

Consider a situation where we’re working with a material specification that details specific chemical composition and tolerances. I wouldn’t just look at the numbers; I’d examine the test methods to be used, ensure our testing equipment is calibrated correctly and understand the consequences of deviations from the specifications. This ensures we’re not only meeting the letter of the specification but also its intent.

Q 6. Describe your experience with auditing compliance processes.

My auditing experience covers both internal and external compliance audits across numerous industries. I’m proficient in conducting audits against various standards, including ISO 9001, ISO 14001, and industry-specific regulations. I utilize a structured approach, developing audit plans, selecting appropriate sampling techniques, and documenting findings thoroughly. During an audit, I verify the existence and effectiveness of implemented processes and controls.

For instance, in an audit of a software development company’s compliance with ISO 27001 (Information Security Management), I would examine their information security policies, procedures, and controls, ensuring they adequately protect sensitive data. I would then document any findings, both positive and negative, and report them to management. The reporting phase is crucial, offering constructive feedback to help improve the management system.

Q 7. How do you handle non-compliance issues?

Handling non-compliance issues requires a systematic and proactive approach. First, we investigate the root cause of the non-compliance to prevent recurrence. This involves interviewing staff, reviewing documentation, and analyzing data to understand why the deviation occurred. Once the root cause is identified, we implement corrective actions to address the immediate issue. Simultaneously, we develop preventive actions to avoid similar situations in the future. These actions are documented, implemented, and verified.

For example, if a product fails to meet a critical specification, we’d immediately initiate a non-conformance report, investigate the failure’s origin (faulty material, process error, etc.), correct the defect, and potentially implement new quality control checks to prevent future occurrences. Effective communication throughout the process, especially to affected stakeholders, is vital to maintain transparency and trust.

Q 8. What is your experience with developing or revising specifications?

Developing and revising specifications is a crucial part of ensuring products or services meet defined requirements. My experience encompasses the entire lifecycle, from initial concept and needs analysis to final document approval and implementation. This involves collaborating with cross-functional teams (engineering, quality, marketing) to gather input, define unambiguous requirements, and create specifications that are clear, concise, and measurable. I’m proficient in various specification writing styles, including formal standards (e.g., ISO, IEEE) and internal company documents.

For example, in a previous role, I led the revision of our software development specifications. We transitioned from a vague, narrative style to a structured format using a requirements management tool. This improvement significantly enhanced traceability, reduced ambiguities, and ultimately improved the efficiency of our development process. The new specifications incorporated detailed acceptance criteria for each requirement, minimizing misunderstandings and rework. Another example involves creating detailed specifications for a new manufacturing process, encompassing everything from raw material selection to quality checks at each stage.

Q 9. How do you stay up-to-date on changes in relevant standards and regulations?

Staying current with evolving standards and regulations is paramount in my field. I employ a multi-faceted approach to ensure I’m always abreast of the latest changes. This includes subscribing to relevant industry publications and journals, actively participating in professional organizations (like ASME or IEEE), and attending industry conferences and webinars. I also leverage online resources, such as government agency websites and standard-setting bodies’ official publications. Regularly reviewing and updating internal compliance documentation is critical. Finally, I maintain a network of contacts within the industry to exchange information and discuss emerging trends.

For example, when new environmental regulations were implemented, I proactively researched their implications, updated our internal procedures, and conducted training sessions for the relevant teams to ensure full compliance. This proactive approach minimizes risks and ensures we maintain a robust compliance posture.

Q 10. Explain your experience using a quality management system (QMS).

My experience with Quality Management Systems (QMS) is extensive. I’ve worked within organizations using ISO 9001, and I understand the principles behind other frameworks like AS9100 (aerospace) and IATF 16949 (automotive). A QMS provides a structured framework to ensure consistent product quality and customer satisfaction. My responsibilities have encompassed participating in internal audits, developing and maintaining quality procedures, and implementing corrective actions to address non-conformances. I’m experienced with document control, process mapping, and the continuous improvement cycle (Plan-Do-Check-Act).

In a past project, I spearheaded the implementation of a new QMS within our department, leading to a significant reduction in defects and improved customer satisfaction. This involved a thorough gap analysis of our existing processes against the ISO 9001 standard, followed by the development and implementation of new procedures, training of staff, and ongoing monitoring of effectiveness. The improved quality control reduced rework by 20% and increased on-time delivery by 15%.

Q 11. How familiar are you with different quality control tools and methodologies?

I’m well-versed in various quality control tools and methodologies. My experience includes using tools like control charts (Shewhart, CUSUM), Pareto charts, cause-and-effect diagrams (Ishikawa), and statistical process control (SPC) techniques. I understand the application of methodologies such as Six Sigma and Lean manufacturing principles in improving processes and reducing waste. I’m also familiar with Failure Mode and Effects Analysis (FMEA) and Design of Experiments (DOE). Selecting the appropriate tool depends on the specific context and the type of data available.

For instance, when investigating a recurring defect in a manufacturing process, I used a Pareto chart to identify the most significant contributing factors. This allowed us to focus our improvement efforts on the root causes, leading to a more effective and targeted solution. In another instance, I utilized control charts to monitor process stability and prevent defects proactively. I can adapt to and select the most fitting method dependent on the given challenge.

Q 12. Describe a situation where you had to resolve a compliance conflict.

In one project, we encountered a conflict between a customer’s specific requirement and a relevant industry standard. The customer requested a feature that wasn’t explicitly compliant with the standard, potentially compromising safety and reliability. To resolve this, I facilitated a collaborative discussion involving engineers, the customer, and legal counsel. We explored alternative solutions that would meet the customer’s needs while remaining compliant with the standard. This involved presenting a risk assessment to the customer outlining potential consequences of non-compliance. Ultimately, we proposed a modified design that satisfied the customer’s request without sacrificing safety or standard compliance.

This experience highlighted the importance of open communication, clear documentation, and thorough risk assessment in resolving compliance conflicts. It’s essential to understand the context of each requirement and to find mutually beneficial solutions that maintain integrity and meet all regulatory requirements.

Q 13. How do you ensure traceability in your compliance processes?

Traceability in compliance processes is crucial for demonstrating compliance and facilitating efficient investigation of any non-conformances. I ensure traceability through a combination of methods. This includes using uniquely identifiable documents and records, establishing a clear chain of custody for all materials and processes, and implementing a robust document control system. This system incorporates version control, approval workflows, and access control measures to maintain the integrity of our records. We also use traceability matrices to map requirements to design specifications, test plans, and final products. Digital tools and systems significantly help in tracking and maintaining this traceability.

For example, in software development, we use version control systems (e.g., Git) to track code changes, linking them to specific requirements and test results. This allows us to easily identify the root cause of any defects and trace the impact of changes across the entire system.

Q 14. What are the key performance indicators (KPIs) you track in compliance management?

Key Performance Indicators (KPIs) in compliance management vary depending on the context, but some common metrics include the number of non-conformances, the rate of corrective actions completed, audit findings, and customer satisfaction scores related to quality. We also track metrics like the effectiveness of our training programs, the timeliness of compliance updates, and the cost of non-compliance. The specific KPIs we track are aligned with our strategic goals and regularly reviewed to ensure they remain relevant and effective. Dashboards and reporting tools are utilized to monitor these KPIs and identify areas for improvement.

By tracking these KPIs, we can identify trends, proactively address potential issues, and demonstrate continuous improvement in our compliance management system. Regular reporting on these metrics to management helps to ensure accountability and transparency within the organization.

Q 15. How do you communicate compliance requirements to different stakeholders?

Communicating compliance requirements effectively requires tailoring the message to each stakeholder’s level of understanding and their role within the organization. I employ a multi-faceted approach.

- For Executive Leadership: I focus on the high-level risks and opportunities associated with non-compliance, presenting data on potential financial penalties, reputational damage, and impact on strategic goals. I use executive summaries and key performance indicators (KPIs) to demonstrate the program’s effectiveness.

- For Management Teams: I provide clear, concise guidelines and procedures, emphasizing their responsibilities for ensuring compliance within their teams. This often includes training materials and regular updates on relevant changes in regulations or standards.

- For Employees: Communication is simple, direct, and easily accessible. This may involve interactive training modules, easily digestible guides, and frequently asked questions (FAQs) addressing common concerns. I ensure that communication is consistent with organizational tone and language.

- For External Stakeholders (e.g., Auditors): My communication is formal, detailed, and evidence-based. I provide comprehensive documentation, including audit trails, demonstrating our adherence to relevant standards and regulations.

For example, when communicating PCI DSS compliance to a development team, I’d focus on secure coding practices and data protection. With executive leadership, I’d highlight the financial implications of a data breach.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with gap analysis in compliance management.

Gap analysis is a crucial part of compliance management. It involves comparing your current state of compliance against the requirements of a specific standard or regulation. I’ve extensively used this process to identify areas needing improvement. My approach typically involves:

- Defining the scope: Clearly identifying the specific standard or regulation (e.g., ISO 27001, HIPAA) and the areas of the organization to be assessed.

- Gathering information: Collecting data on current practices, policies, procedures, and systems using audits, questionnaires, interviews, and document reviews.

- Comparing current state to required state: This often involves creating a matrix comparing the requirements of the standard against the existing controls. Any gaps are clearly identified.

- Prioritizing gaps: Risks associated with each gap are assessed and prioritized based on likelihood and impact, focusing on critical vulnerabilities first.

- Developing a remediation plan: Creating a plan of action to close the identified gaps, including timelines, responsibilities, and resource allocation.

In a recent project involving ISO 9001 compliance, we used a gap analysis to reveal deficiencies in our internal audit program. This led to enhancements in our audit schedule and a more robust internal audit process, improving overall quality management.

Q 17. Describe a time you identified a potential compliance issue before it caused a problem.

During a review of our data backup procedures for a financial institution, I noticed a potential vulnerability. Our backups were being stored in the same physical location as our primary servers. While seemingly standard practice, I realized that a significant disaster, such as a fire, could impact both the primary data and the backups, leading to total data loss.

I flagged this as a potential compliance issue (violating business continuity requirements) and presented my findings to the IT team and management. We implemented an offsite backup solution, preventing a significant compliance failure and potential business disruption. This proactive identification of a vulnerability saved the company significant time and financial resources that would have been spent on recovery after a data loss.

Q 18. How do you use data analysis to improve compliance performance?

Data analysis is vital for improving compliance performance. I leverage data to monitor trends, identify areas of weakness, and measure the effectiveness of compliance initiatives. For example:

- Monitoring key performance indicators (KPIs): Tracking metrics like the number of compliance incidents, the time taken to resolve incidents, and the effectiveness of training programs helps me identify areas for improvement.

- Analyzing audit findings: By analyzing the findings of internal and external audits, recurring issues can be identified and addressed to prevent future non-compliance events.

- Using data visualization: Dashboards and reports allow for easy monitoring of compliance performance and identifying trends.

- Predictive analytics: Sophisticated techniques can forecast potential risks based on historical data, allowing for proactive mitigation.

For instance, by analyzing incident reports, I might discover a pattern of non-compliance related to a particular software application, prompting the development of enhanced training or improved system controls.

Q 19. How familiar are you with root cause analysis (RCA) for compliance issues?

Root cause analysis (RCA) is a critical methodology for understanding the underlying reasons behind compliance issues. It helps move beyond treating symptoms and addresses the root problem, preventing recurrence. I’m proficient in various RCA techniques, including the ‘5 Whys’ and Fishbone diagrams.

The ‘5 Whys’ method involves repeatedly asking ‘why’ to uncover the root cause. For example, if an employee fails a compliance training test, we might ask: Why did they fail? Because they didn’t study. Why didn’t they study? Because they didn’t have enough time. Why not? Because of excessive workload. Why? Because of inadequate staffing. This process helps to expose a root cause (inadequate staffing) that can then be addressed.

Fishbone diagrams visually map out potential causes and effects, aiding in identifying the main contributing factors. Both approaches are powerful tools for systematically investigating compliance issues.

Q 20. How do you measure the effectiveness of your compliance programs?

Measuring the effectiveness of a compliance program requires a multi-faceted approach. I rely on several key methods:

- Key Performance Indicators (KPIs): Metrics like the number and severity of compliance incidents, the cost of non-compliance, employee training completion rates, and the time to remediate issues provide valuable insights.

- Internal audits: Regular internal audits assess adherence to policies and procedures, identifying areas for improvement.

- External audits: External audits provide an independent evaluation of compliance posture, strengthening credibility.

- Employee feedback: Gathering feedback through surveys and focus groups reveals challenges and areas of uncertainty, aiding in program enhancement.

- Management review: Regular reviews of compliance performance, incorporating data from various sources, facilitate continuous improvement.

Ultimately, effectiveness is assessed by a reduction in non-compliance incidents, improved employee awareness, stronger organizational resilience, and a culture of compliance.

Q 21. Describe your experience with corrective and preventive actions (CAPA).

Corrective and Preventive Actions (CAPA) are crucial for addressing compliance issues and preventing recurrence. My experience with CAPA involves:

- Incident identification and reporting: Establishing clear processes for identifying, documenting, and reporting compliance failures.

- Root cause analysis (RCA): Employing techniques like the ‘5 Whys’ and Fishbone diagrams to understand the root causes of compliance issues.

- Corrective action: Implementing immediate actions to fix the immediate problem, often involving changes to procedures, systems, or training.

- Preventive action: Developing and implementing measures to prevent similar incidents from occurring in the future. This might involve policy changes, process improvements, or employee training.

- Verification and validation: Confirming that corrective and preventive actions have been effective in resolving the issue and preventing recurrence. This often involves follow-up audits or monitoring.

- Documentation: Maintaining detailed records of the entire CAPA process, including the initial incident, root cause analysis, actions taken, and verification/validation results.

For example, if a data breach occurs, the CAPA process would include immediate containment of the breach (corrective action), followed by review of security policies and procedures, employee training updates, and implementing stronger security measures (preventive action).

Q 22. What is your approach to training employees on compliance requirements?

My approach to employee compliance training is multifaceted and focuses on creating a culture of compliance, not just rote memorization. I begin by identifying the specific standards and regulations relevant to each employee’s role and responsibilities. This targeted approach ensures training is relevant and avoids overwhelming employees with unnecessary information.

- Modular Training: I break down complex compliance requirements into smaller, manageable modules, making it easier for employees to digest and retain the information. For example, a module on data privacy might cover different aspects like data handling, storage, and breach response separately.

- Interactive Sessions: I incorporate interactive elements like quizzes, case studies, and role-playing exercises to make the training engaging and effective. This helps employees apply their knowledge in realistic scenarios and identify potential pitfalls.

- Regular Refresher Courses: Compliance regulations frequently evolve. Therefore, I schedule regular refresher courses and updates to ensure employees remain current on the latest requirements. This prevents outdated knowledge from becoming a compliance risk.

- Assessment and Feedback: Post-training assessments are crucial to measure comprehension and identify areas needing further clarification. Constructive feedback ensures employees understand their responsibilities and feel supported.

For instance, in my previous role at a medical device company, we implemented a tiered training system based on employee roles and responsibilities. This ensured that Quality System Regulation (QSR) training was tailored to each individual’s tasks, leading to a significant improvement in compliance adherence.

Q 23. How do you ensure compliance during a product lifecycle?

Ensuring compliance throughout a product lifecycle requires a proactive and systematic approach, integrating compliance considerations into every stage, from concept to end-of-life. This includes:

- Design and Development: Compliance requirements must be incorporated from the initial design phase, ensuring the product meets all relevant standards and regulations before it’s even built. This might involve conducting thorough risk assessments, performing design reviews to identify potential non-compliance issues, and documenting all design decisions.

- Manufacturing and Production: Stringent quality control measures throughout the manufacturing process are vital to maintain compliance. This can involve regular audits of manufacturing facilities, adhering to strict procedures for materials handling and testing, and maintaining meticulous records.

- Testing and Verification: Thorough testing and verification are essential to ensure the product meets all specified requirements and complies with applicable regulations. This might include conducting functional testing, performance testing, and safety testing. All test results should be thoroughly documented.

- Distribution and Sales: Compliance extends to how the product is distributed and sold. This includes ensuring proper labeling, complying with import/export regulations, and providing accurate information to customers.

- End-of-Life Management: Even after the product’s useful life is over, compliance considerations persist. This could involve proper disposal or recycling of the product to minimize environmental impact and comply with waste management regulations.

Think of it like building a house – you wouldn’t start construction without blueprints (design), inspections during construction (manufacturing), and final inspections before moving in (testing). Compliance is built into each stage of the process.

Q 24. How would you improve compliance processes in an organization?

Improving compliance processes involves a strategic approach that focuses on people, processes, and technology. I would implement the following improvements:

- Centralized Compliance Management System: Implement a centralized system to manage all compliance-related documents, training materials, and audit reports. This ensures easy access to information and improves efficiency.

- Risk-Based Approach: Conduct regular risk assessments to identify potential compliance vulnerabilities and prioritize efforts to mitigate those risks. This ensures resources are allocated effectively.

- Automated Compliance Monitoring Tools: Utilize software tools to automate tasks like document management, compliance reporting, and data analysis. This reduces manual effort and improves accuracy.

- Enhanced Employee Training and Awareness: Regular and targeted employee training is essential to maintain a culture of compliance. Gamification and interactive training modules can improve engagement and retention.

- Regular Audits and Reviews: Conduct internal and external audits to identify areas for improvement and ensure the effectiveness of compliance programs. Regular reviews of policies and procedures ensure they remain relevant and effective.

- Establish Clear Accountability: Clearly define roles and responsibilities for compliance within the organization. This helps prevent gaps in responsibility and promotes accountability.

For example, in a previous role, we implemented a software solution that automated the tracking of certifications and licenses, which significantly reduced the administrative burden and prevented expirations from becoming a compliance issue.

Q 25. What is your experience with compliance reporting and documentation?

My experience with compliance reporting and documentation is extensive. I’m proficient in creating and maintaining comprehensive records, ensuring accuracy and traceability. This includes:

- Developing and Implementing Reporting Systems: I have experience designing and implementing reporting systems that track compliance metrics, identify trends, and generate reports for management and regulatory bodies. These systems are often tailored to specific regulatory requirements.

- Maintaining Accurate Records: I understand the importance of meticulously maintaining accurate records, ensuring all relevant information is documented and easily accessible. This often includes electronic document management systems.

- Preparing Compliance Reports: I have a proven ability to prepare concise and accurate compliance reports for internal and external audits, regulatory inspections, and management reviews. These reports are tailored to the specific audience and highlight key findings and recommendations.

- Utilizing Reporting Software: I am experienced in utilizing various reporting software and tools to generate standardized reports, track compliance progress, and identify areas requiring attention.

For instance, in a previous project, I developed a customized reporting system for a pharmaceutical company that automated the generation of regulatory reports, resulting in significant time savings and improved accuracy.

Q 26. Explain your understanding of different types of audits (internal, external, etc.).

Different types of audits serve distinct purposes and provide different perspectives on an organization’s compliance posture.

- Internal Audits: These are conducted by internal teams to assess the effectiveness of the organization’s compliance program. They provide an internal perspective, allowing for early identification and remediation of potential issues before they escalate. Internal audits are crucial for continuous improvement and proactive risk management.

- External Audits: These are conducted by independent third-party organizations to verify the organization’s compliance with specific standards or regulations. External audits provide an objective assessment and offer increased credibility to stakeholders. Examples include ISO certifications audits or regulatory inspections.

- First-Party Audits: These are essentially self-assessments conducted by the organization itself to evaluate compliance. They’re often used as a precursor to more formal audits, aiding in identifying potential weaknesses and preparing for external assessments.

- Second-Party Audits: These are conducted by a customer or other stakeholder to assess the supplier’s or partner’s compliance with their specific requirements. This is common in supply chains.

- Third-Party Audits: These are performed by an independent certification body or auditing firm to verify compliance with industry standards or regulatory requirements.

Imagine an annual health checkup – an internal audit is like regularly monitoring your own health; an external audit is like a doctor’s check-up, providing an independent and objective assessment.

Q 27. How do you balance compliance with efficiency and cost-effectiveness?

Balancing compliance with efficiency and cost-effectiveness requires a strategic approach. It’s not a matter of choosing one over the other, but rather optimizing both simultaneously.

- Prioritize Risks: Focus resources on the highest-risk areas, rather than trying to achieve 100% compliance across all areas. A risk-based approach allows for efficient allocation of resources.

- Automation and Technology: Leverage technology to automate compliance tasks, such as document management, reporting, and monitoring. This reduces manual effort and costs.

- Streamline Processes: Continuously evaluate and improve processes to eliminate unnecessary steps and reduce inefficiencies. Process optimization can significantly improve productivity and lower costs.

- Employee Training and Engagement: Invest in effective training programs to empower employees to understand and adhere to compliance requirements. Well-trained employees are less likely to make mistakes that lead to compliance issues and associated costs.

- Outsourcing: Consider outsourcing specific compliance tasks or functions to specialized firms if it is more cost-effective than managing them in-house.

For example, implementing a streamlined document control system with automated workflows can drastically reduce the time and resources required for managing compliance documents, improving efficiency and reducing administrative costs.

Q 28. Describe your experience with implementing a new compliance system or process.

In a previous role, I led the implementation of a new ISO 9001:2015 quality management system. The process involved several key steps:

- Gap Analysis: We began by conducting a gap analysis to compare our existing processes with the ISO 9001:2015 requirements, identifying areas needing improvement.

- Policy and Procedure Development: We developed new policies and procedures aligned with the ISO 9001:2015 standards, ensuring clarity and consistency.

- Employee Training: Comprehensive training was provided to all employees, focusing on the new system and its implications for their roles.

- System Implementation: The new system was implemented in phases, ensuring a smooth transition and minimizing disruption to operations.

- Internal Audits: Regular internal audits were conducted to monitor progress and identify any areas needing further attention.

- Certification Audit: Finally, we underwent a third-party certification audit to verify compliance with ISO 9001:2015 requirements. We successfully achieved certification, demonstrating the effectiveness of the implementation process.

This project involved close collaboration with various departments, strong communication, and meticulous planning. The successful implementation resulted in enhanced quality control, improved efficiency, and enhanced customer satisfaction.

Key Topics to Learn for Specification and Standards Compliance Interview

- Understanding Standards Organizations: Familiarize yourself with key organizations like ISO, IEEE, ANSI, etc., and their respective roles in defining standards within your field. Consider exploring the history and impact of specific standards relevant to your target roles.

- Interpreting and Applying Standards: Practice interpreting technical specifications and standards documents. Focus on translating abstract requirements into practical implementation steps. Consider working through example scenarios where you need to apply a standard to a specific problem.

- Compliance Testing and Verification: Understand the methods and tools used to verify compliance with specific standards. This includes both theoretical knowledge of testing methodologies and practical experience with relevant software or hardware.

- Risk Management and Compliance: Explore how non-compliance can lead to risks (e.g., legal, safety, financial). Learn about strategies for mitigating these risks and ensuring ongoing compliance. Consider the ethical implications of non-compliance.

- Documentation and Traceability: Understand the importance of meticulous documentation in demonstrating compliance. Explore techniques for maintaining traceability throughout the product lifecycle, from design to implementation and testing.

- Continuous Improvement and Auditing: Learn about processes for continuous improvement of compliance practices and the role of internal and external audits. Consider the principles of effective quality management systems.

- Specific Standards Relevant to Your Field: Research and understand the specific standards most relevant to your area of expertise. This shows initiative and a deep understanding of your chosen field.

Next Steps

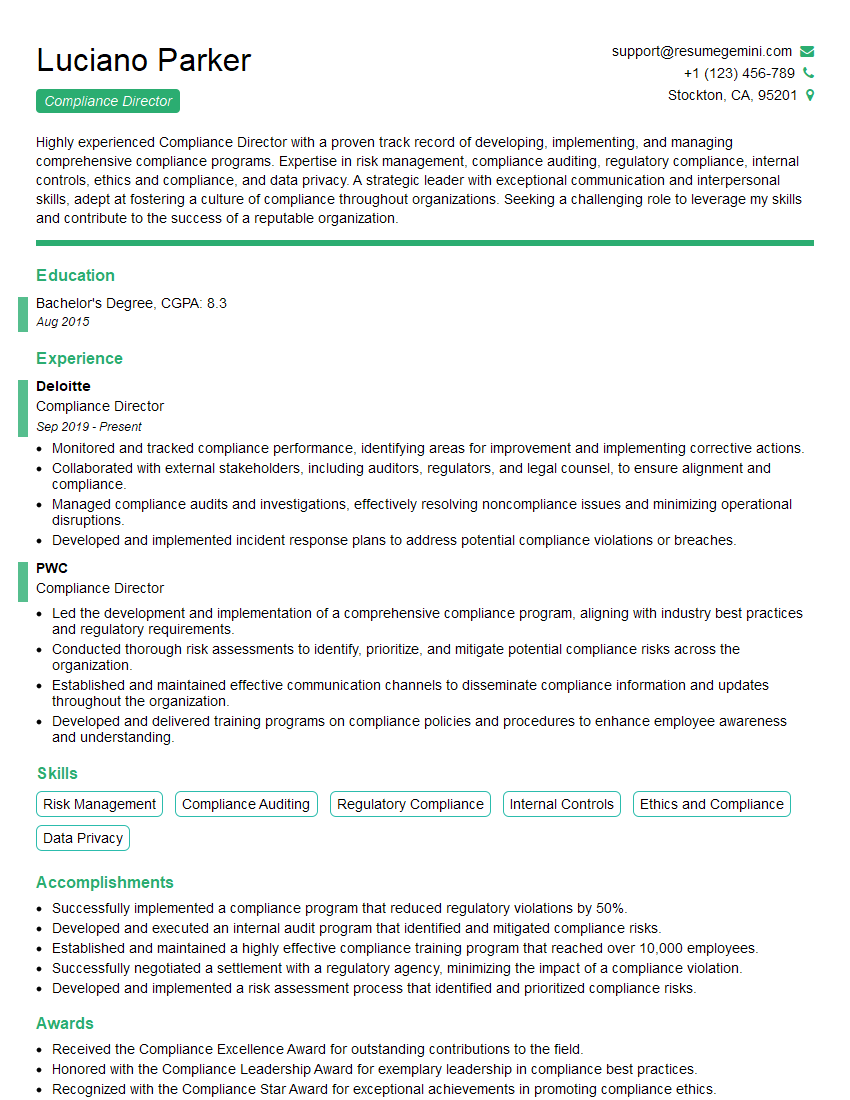

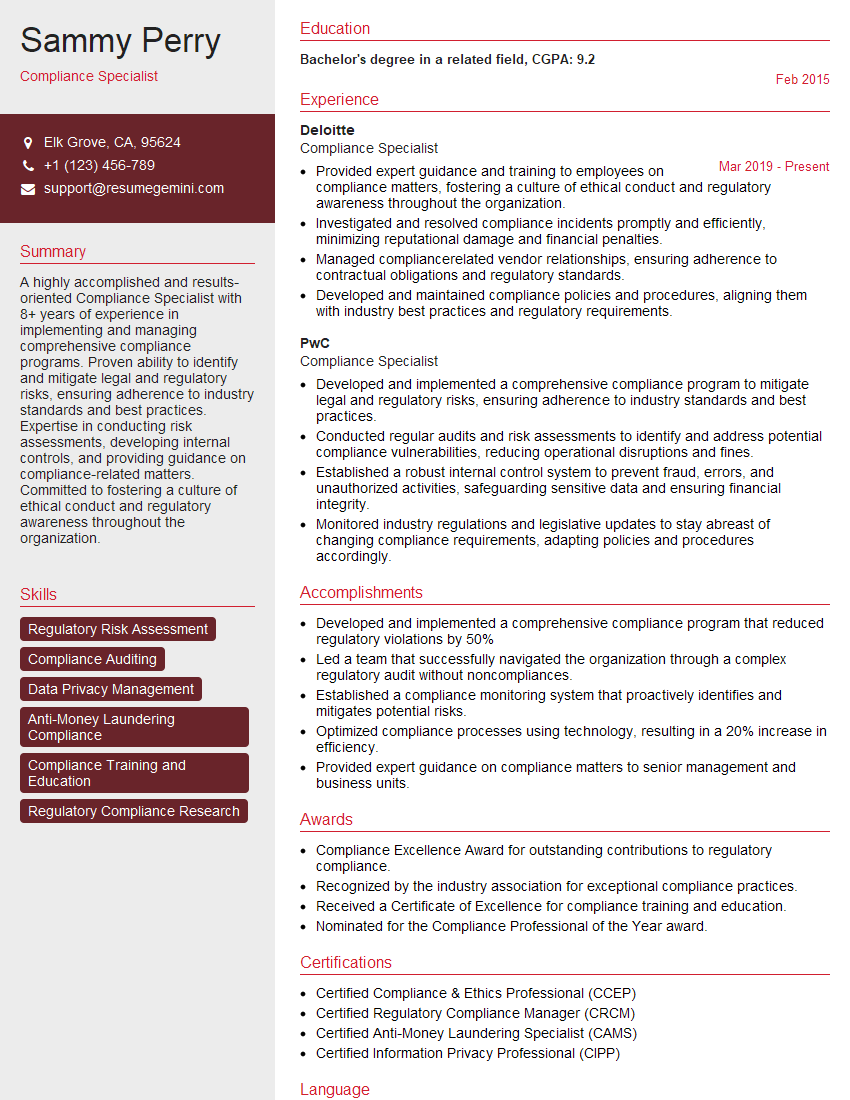

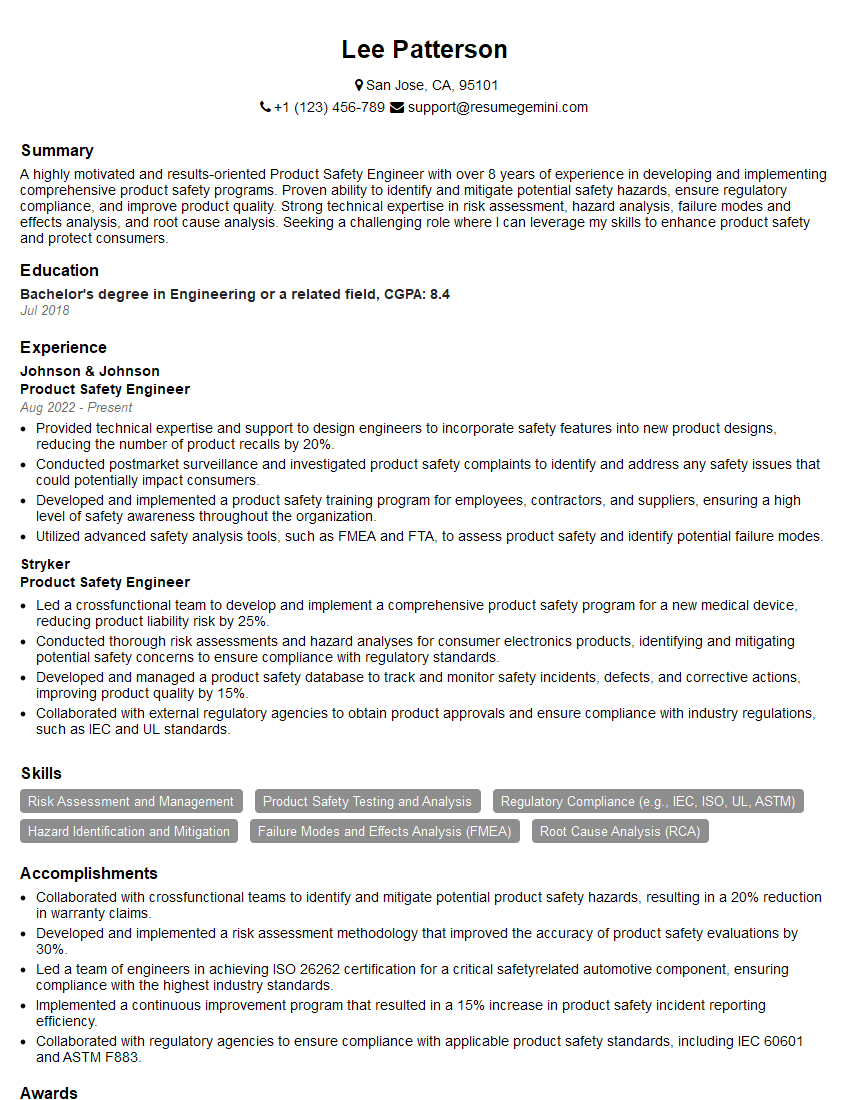

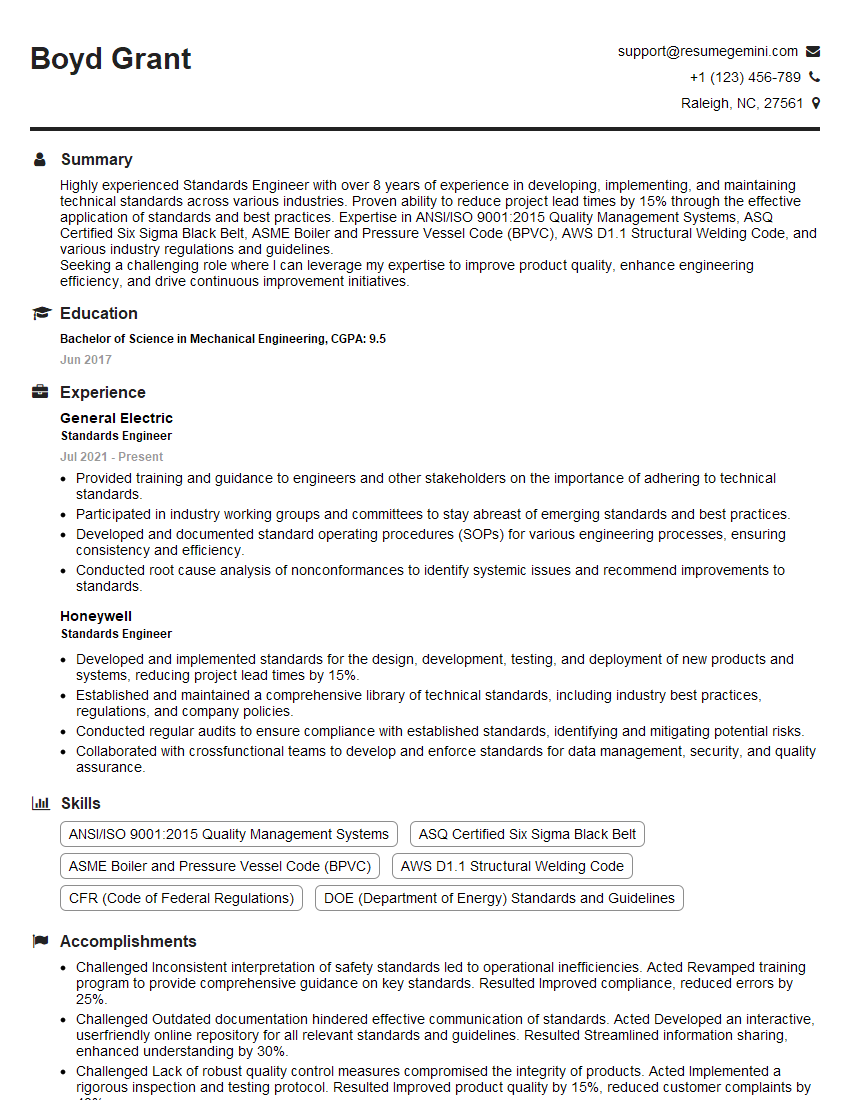

Mastering Specification and Standards Compliance is crucial for career advancement in many technical fields. It demonstrates a commitment to quality, safety, and adherence to best practices, making you a valuable asset to any organization. To significantly boost your job prospects, crafting a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you create a professional and impactful resume, highlighting your skills and experience in Specification and Standards Compliance. Examples of resumes tailored to this specialization are available within ResumeGemini, allowing you to tailor your own application effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good