Cracking a skill-specific interview, like one for Knowledge of Die Manufacturing Equipment, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Knowledge of Die Manufacturing Equipment Interview

Q 1. Explain the different types of dies used in manufacturing.

Die types in manufacturing are incredibly diverse, categorized primarily by the forming process they facilitate. Think of it like a toolbox – each tool designed for a specific job. We have:

- Progressive Dies: These are workhorses, performing multiple operations – blanking, punching, forming – in a single stroke. Imagine a factory line where a sheet metal goes in, and a fully formed part comes out in one go. They are highly efficient for mass production but complex to design and maintain.

- Compound Dies: Similar to progressive dies, but all operations occur within a single die set. A great choice when complexity isn’t high and you need a robust solution.

- Single-Stage Dies: These perform only one operation per stroke – think punching a hole or simply cutting a shape. Simpler than compound or progressive, these are often used in smaller batch production runs or for specific operations within a larger process.

- Transfer Dies: Designed for high-volume production, transfer dies move the workpiece between stations, allowing for very intricate and multiple operations in a fully automated process. They are extremely precise and efficient, used in creating highly complex parts.

- Bending Dies: These are specialized to precisely bend sheet metal or wire into specific shapes. The design focuses on achieving the desired angle and radius while avoiding buckling or fracturing.

- Drawing Dies: Used to form cups, shells, or other hollow shapes from sheet metal by pulling the material through a shaped opening. These dies need to carefully control the material’s flow to prevent tearing or wrinkling.

The choice of die type heavily depends on the part’s complexity, required production volume, and available resources.

Q 2. Describe the process of die design and development.

Die design and development is a meticulous process blending engineering, artistry, and precision manufacturing. It typically starts with a thorough understanding of the final part’s specifications and materials. Think of it as creating a blueprint for a tiny, incredibly precise factory within a larger factory. The steps typically involve:

- Part Design Analysis: Evaluating the part’s geometry, tolerances, and material properties to determine the feasibility of the design and necessary operations.

- Process Planning: Deciding which operations are necessary (blanking, punching, forming, etc.) and their sequence, ultimately choosing the best die type.

- Die Layout Design: Creating detailed drawings showing the die’s components, including punch and die geometry, stripper plates, and guides. This requires expertise in CAD/CAM software and a deep understanding of material flow and stress distribution.

- Tooling Selection: Choosing appropriate materials for punches, dies, and other components, considering factors like wear resistance, strength, and cost.

- Manufacturing of Die Components: Precision machining or electrical discharge machining (EDM) is used to create the individual components with extremely tight tolerances.

- Die Assembly and Tryout: Carefully assembling the die components, followed by rigorous testing to verify functionality and identify any necessary adjustments. This often involves trial and error, iterative refinements, and close monitoring of the part quality.

The entire process demands expertise in material science, metallurgy, and manufacturing processes. A single mistake in the design stage can be incredibly costly in terms of time and resources.

Q 3. What are the key considerations for selecting the appropriate die material?

Selecting the right die material is crucial for die longevity, precision, and ultimately, the cost-effectiveness of the manufacturing process. It’s like choosing the right tool for a job; using a hammer to tighten a screw won’t work. The main considerations include:

- Wear Resistance: The die material must withstand repeated impacts and friction without significant wear or deformation. Tool steels like high-speed steel (HSS) or powder metallurgy tool steels are popular choices.

- Strength and Toughness: The material must resist fracture and deformation under high stress, especially in demanding applications like deep drawing or forging.

- Thermal Conductivity: For high-speed processes or those involving heat generation, a material with good thermal conductivity can prevent overheating and improve die life.

- Cost: Die materials vary significantly in cost. The choice requires balancing performance requirements with budget constraints. Using expensive materials for a low-volume application is inefficient.

- Machinability: The material must be easily machinable to allow for precise creation of complex die geometries.

For example, a die used for stamping high-strength steel might require a high-wear-resistant tool steel, whereas a die for stamping aluminum might use a less expensive but still sufficiently durable material.

Q 4. How do you troubleshoot common die-related problems?

Troubleshooting die problems requires systematic approach, combining experience with a logical process of elimination. Common issues include:

- Broken Punches or Dies: This is often due to excessive force, material defects, or poor die maintenance. Examine the broken components carefully to identify the root cause – Was it fatigue, overload, or a flaw in the material?

- Poor Part Quality: This can manifest as burrs, cracks, or dimensional inaccuracies. Carefully analyze the part defects to determine if the problem is with the die geometry, material flow, or the press parameters.

- Die Wear: Progressive wear on punches and dies is inevitable. Regular inspections and timely maintenance are crucial to prevent premature failure. Use precision measuring instruments to monitor wear patterns and determine the need for replacement or repair.

- Misalignment: Misaligned die components can lead to poor part quality or die damage. Precise alignment checks are essential, often using alignment pins or gauges.

Troubleshooting involves careful observation, data collection (measuring dimensions, forces etc.), and a methodical approach to isolating and correcting the problem. Often, it requires using specialized measuring instruments and understanding the principles of material flow under stress.

Q 5. Explain the process of die maintenance and repair.

Die maintenance and repair are critical for extending die life and maintaining part quality. Regular maintenance prevents unexpected downtime and reduces production costs. The process involves:

- Regular Inspections: Conduct visual inspections for wear, cracks, or other damage after a predetermined number of strokes or at set intervals. Precise gauging to monitor critical dimensions is essential.

- Cleaning and Lubrication: Regularly clean the die to remove chips and debris and apply appropriate lubricants to reduce friction and wear. This is like oiling a machine to keep it running smoothly.

- Sharpening and Reprofiling: Worn punches and dies can be sharpened or reprofiled to restore their original geometry. This requires specialized equipment and expertise.

- Repair and Replacement: Damaged or severely worn components may need to be repaired or replaced. Repairs may involve welding, grinding, or other techniques. Careful selection of replacement components is crucial to ensure proper fit and functionality.

- Storage: Proper storage of dies is important to prevent rust and damage. Dies are often stored in climate-controlled environments or coated with protective compounds.

Preventive maintenance is far more cost-effective than dealing with unexpected failures. A well-maintained die will produce high-quality parts for much longer, saving time, money, and material.

Q 6. What are the safety precautions involved in working with dies?

Working with dies involves significant safety risks, primarily due to the high forces and sharp edges involved. Safety precautions are paramount and should never be compromised:

- Lockout/Tagout Procedures: Always follow proper lockout/tagout procedures before performing any maintenance or repair on a die or press. This is crucial to prevent accidental activation.

- Personal Protective Equipment (PPE): Use appropriate PPE, including safety glasses, hearing protection, gloves, and steel-toed shoes. Dies can easily cause serious eye or hand injuries.

- Proper Handling Techniques: Use appropriate lifting equipment for heavy dies and follow safe handling procedures to prevent injuries.

- Machine Guards: Ensure all machine guards are in place and functioning correctly before operating the press.

- Emergency Shut-off Procedures: Be familiar with the location and operation of emergency shut-off devices and be prepared to react quickly in case of an accident.

- Training: All personnel working with dies should receive thorough training on safe operating procedures and emergency response protocols.

Safety is not optional. Strict adherence to safety protocols is crucial to prevent serious accidents and injuries.

Q 7. How do you ensure the quality and precision of manufactured parts?

Ensuring the quality and precision of manufactured parts requires a multifaceted approach, starting from the design phase and continuing throughout the manufacturing process. Think of it as a quality control loop.

- Precise Die Design and Manufacturing: The accuracy of the die directly impacts the quality of the part. Precise machining, thorough inspections, and robust design are critical. Employing advanced techniques such as EDM for complex geometries is a key ingredient.

- Material Selection: The properties of the material being formed directly impact the final part quality. Careful selection of materials that match the design requirements is crucial. The correct material will ensure the part meets specifications and has the necessary durability.

- Process Monitoring and Control: Monitoring critical process parameters, such as press tonnage, speed, and temperature, is essential to ensure consistent part quality. This is often achieved through automation and real-time data acquisition.

- Quality Control Inspections: Regular inspection of parts using dimensional measuring equipment (calipers, CMMs, etc.) ensures adherence to design specifications and tolerances. Statistical Process Control (SPC) can help to monitor and control part quality over time.

- Preventive Maintenance: Regular maintenance of the die and press prevents unexpected downtime and ensures consistent part quality. Regular cleaning, sharpening and lubrication of the tooling all contribute to consistent and high-quality output.

A robust quality management system, which involves all the above measures and a culture of attention to detail, is essential for achieving consistent and precise manufacturing.

Q 8. What is the role of CNC machining in die manufacturing?

CNC machining is absolutely crucial in die manufacturing. It allows for the precise creation of intricate die components, far beyond the capabilities of traditional methods. Think of it as a highly sophisticated sculpting tool controlled by a computer. Instead of relying on manual processes prone to error, CNC machines use computer-aided design (CAD) data to precisely guide cutting tools, creating complex shapes and geometries with exceptional accuracy and repeatability. This is vital for the creation of dies used in processes such as stamping, forging, and casting, where even minor imperfections can lead to significant defects in the final product.

For example, a progressive die for automotive parts requires incredibly precise punches and dies. CNC machining ensures consistent hole sizes, perfect alignment of features, and complex shapes impossible to achieve manually. This results in higher quality parts, reduced scrap, and increased production efficiency.

Q 9. Describe your experience with different die manufacturing processes (e.g., stamping, forging).

My experience spans a wide range of die manufacturing processes, primarily focusing on stamping and forging. In stamping, I’ve worked extensively with progressive dies, which perform multiple operations in a single stroke, and blanking dies, used to cut sheet metal into specific shapes. I’m proficient in designing, building, and troubleshooting these dies, from initial CAD modeling through final assembly and tryout. I understand the nuances of material selection for different stamping applications, including considerations of material ductility and springback.

With forging, my experience includes both open-die and closed-die forging. I’ve been involved in designing and optimizing forging dies for various applications, accounting for factors such as metal flow, die cavity design, and thermal stress. This often involves close collaboration with metallurgists and materials engineers to ensure optimal die life and part quality. For instance, in one project involving a titanium forging, we needed to carefully account for the material’s high temperature strength and potential for cracking. The die design incorporated specialized cooling channels and features to address these challenges.

Q 10. How do you interpret engineering drawings related to dies?

Interpreting engineering drawings for dies requires a keen eye for detail and a thorough understanding of manufacturing processes. I start by carefully reviewing the overall layout of the die, noting the dimensions, tolerances, and material specifications. This includes understanding the relationship between different components, such as punches, dies, and strippers. I pay close attention to surface finish requirements, ensuring they align with the desired part quality.

Next, I examine the details of individual components. This involves checking for critical dimensions, identifying specific features (e.g., radii, angles, and draft angles), and verifying that they are manufacturable. I look for potential issues, such as interference between components or areas prone to stress concentration. Finally, I verify that the drawing reflects the required functionality of the die, ensuring it accurately represents the intended process and part geometry. This might involve consulting related documents, such as material specifications or process parameters, to fully grasp the requirements.

Q 11. What software programs are you proficient in for die design and simulation?

I’m proficient in several software programs crucial for die design and simulation. My expertise includes CAD software such as SolidWorks and AutoCAD, allowing me to create detailed 3D models of dies. I utilize CAM software like Mastercam and FeatureCAM to generate CNC machining programs, optimizing toolpaths for efficient and precise machining. Furthermore, I’m experienced in using finite element analysis (FEA) software such as ANSYS to simulate die performance under various loading conditions, predicting potential failures and optimizing designs for improved durability. This predictive capability saves time and resources by identifying design flaws early in the process.

For example, using FEA, I recently identified a potential stress concentration point in a forging die that was missed during the initial design. By modifying the die design based on the simulation results, we avoided a costly failure during the production process.

Q 12. How do you manage die inventory and optimize its utilization?

Effective die inventory management is key to efficient production. I utilize a combination of techniques, including a well-organized database to track die availability, condition, and usage history. This database provides a clear overview of our inventory, facilitating easy identification of available dies for specific jobs. Regular inspections are critical, identifying potential problems before they lead to downtime. This includes visual inspections for wear, damage, and proper lubrication.

Optimization strategies include preventative maintenance schedules and proactive replacement of worn components. We prioritize dies with high utilization rates and strategically allocate resources to maintain their performance. A lean methodology is applied to reduce storage space and streamline die retrieval, minimizing downtime. We also employ a system of standardized die storage and handling to minimize damage during transportation and storage.

Q 13. What are the common causes of die wear and tear?

Die wear and tear are inevitable, but understanding the common causes allows for preventative measures. Abrasion from the workpiece material is a significant factor, particularly in processes involving abrasive materials. Adhesion, where workpiece material sticks to the die surface, can cause tearing and pitting. Excessive forces and impacts can lead to cracks and fractures in the die, especially in forging. Finally, thermal cycling, particularly in processes with high temperatures, can cause fatigue and eventually die failure.

Improper lubrication can exacerbate many of these issues, leading to increased friction and accelerated wear. Incorrect die design, such as insufficient draft angles or stress concentration points, can also contribute to premature failure. Regular maintenance, including proper lubrication, timely repair, and proactive replacement of worn components, can significantly extend die life.

Q 14. Explain the process of die tryout and validation.

Die tryout and validation are critical steps to ensure the die meets specifications and produces parts to the required quality. The process starts with a trial run using the actual production material, closely monitoring part dimensions, surface finish, and any signs of die failure. We gather data on critical parameters, such as force, stroke, and speed, to optimize the process and ensure it falls within acceptable tolerances. This is often followed by dimensional inspections of the produced parts, comparing them against the CAD model to verify conformity.

If modifications are necessary, they’re implemented, followed by further testing and validation. This iterative process continues until the die consistently produces parts that meet the required quality standards. Documentation of the entire process, including adjustments and results, is crucial for quality control and future reference. After successful validation, the die is approved for production, and detailed documentation supports ongoing maintenance and troubleshooting.

Q 15. How do you measure the accuracy and precision of a die?

Measuring the accuracy and precision of a die involves a multifaceted approach, focusing on both dimensional accuracy and surface finish. Accuracy refers to how close the die’s dimensions are to the intended design, while precision refers to the consistency of those dimensions across multiple parts. We employ a combination of methods:

Coordinate Measuring Machines (CMMs): These highly precise machines use probes to measure the die’s three-dimensional geometry. Data collected is compared to the CAD model to identify any deviations. This is crucial for ensuring the overall shape and features of the die are within tolerance.

Optical Comparators: These tools use projected images to compare the die’s profile against a master drawing or template. They are particularly useful for checking the finer details and ensuring consistent feature sizes and locations.

Surface Roughness Measurement: Techniques like profilometry are used to assess the surface texture of the die. A smoother surface is often preferred for better part quality and reduced wear on the die. This helps prevent defects in the final product. Ra (average roughness) and Rz (maximum peak-to-valley height) are common parameters measured.

Functional Testing: The ultimate test is often functional testing. We’ll run sample parts through the die and measure their dimensions, comparing them to the design specifications. This verifies the overall performance and catches any errors not detected by dimensional checks alone. This is vital for ensuring the die performs its intended function.

For example, in manufacturing a progressive die for stamping automotive parts, CMM measurements ensure the punch and die cavities are within microns of the specified dimensions, while functional testing validates that the stamped parts meet the required tolerances for assembly.

Career Expert Tips:

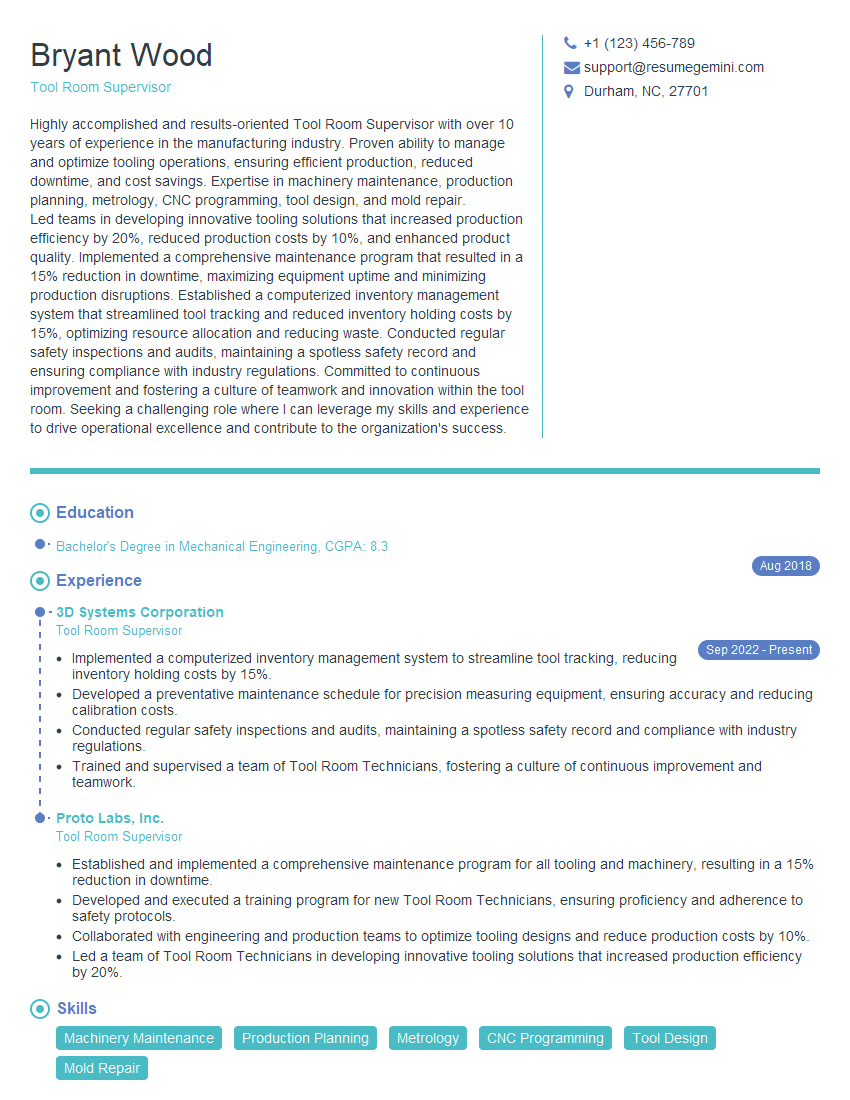

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different die materials and their properties.

My experience encompasses a wide range of die materials, each with unique properties influencing their application and lifespan. The selection depends on factors like the material being stamped, the complexity of the die, and the production volume.

Tool Steel (e.g., A2, D2, O1): These are workhorses in die manufacturing, offering excellent hardness, wear resistance, and toughness. A2 is a good general-purpose steel, while D2 provides enhanced wear resistance for high-volume applications. O1 is often chosen for its ease of heat treatment. I’ve extensively used tool steel for dies in automotive and electronics manufacturing.

Powder Metallurgy Tool Steels: These offer superior dimensional stability and consistency, reducing the need for extensive finishing. They are more expensive but can be cost-effective in high-precision applications.

Carbide: Carbide dies are exceptionally durable and wear-resistant, making them ideal for very high-volume production and the processing of hard-to-work materials. Tungsten carbide is commonly used. The high cost is offset by extended lifespan. We used carbide dies in a project making dies for extremely hard metals.

Ceramics: Certain ceramic materials are finding increasing use in specialized dies where extreme temperatures or chemical resistance is needed. Their use in die-casting and certain high-temperature applications is common, although they’re more brittle and require careful handling.

Choosing the right material is critical. A poorly chosen material can lead to premature die failure, resulting in downtime, scrap, and increased costs. This decision is always made carefully considering the specific project requirements and cost-benefit analysis.

Q 17. How do you improve the efficiency and productivity of the die manufacturing process?

Improving die manufacturing efficiency and productivity involves a holistic approach focusing on process optimization, technology integration, and workforce training. Here are some key strategies:

Lean Manufacturing Principles: Implementing lean methodologies like 5S (Sort, Set in Order, Shine, Standardize, Sustain) and Kaizen (continuous improvement) helps eliminate waste and streamline the manufacturing flow. This minimizes unnecessary movement, storage, and waiting times.

CAD/CAM Integration: Using advanced CAD/CAM software allows for optimized die design, reducing material waste and machining time. Simulation tools can predict potential problems before they occur, saving rework and minimizing delays. This also simplifies communication across the manufacturing process.

Automation: Automating processes such as material handling, machining, and inspection increases speed and consistency. CNC machining centers are essential for producing complex die geometries with high precision. Robotics can significantly improve efficiency and reduce human error.

Improved tooling and fixtures: High-quality tooling and fixtures minimize downtime, improve accuracy, and reduce manufacturing errors. Properly designed fixtures aid in consistent die placement and workpiece handling.

Regular Maintenance and Preventative Maintenance Programs: A proactive approach to maintenance prevents unplanned downtime and keeps equipment running smoothly. This reduces disruptions and improves predictability in scheduling.

For instance, implementing a preventative maintenance schedule on our CNC machines reduced downtime by 20%, directly impacting production output. The implementation of a robust CAD/CAM system allowed us to reduce material waste by 15% and machining time by 10% on a recent project.

Q 18. What are the different types of die coatings and their applications?

Die coatings play a crucial role in enhancing die performance and lifespan. The choice of coating depends on the application and the material being processed.

Chromium Plating: This is a common coating that provides excellent wear resistance and corrosion protection. It’s suitable for a wide range of die applications but can be brittle and prone to cracking under stress.

Nickel Plating: Offers good corrosion resistance and acts as a base for other coatings. It’s often used under chrome plating to improve adhesion and reduce porosity.

Titanium Nitride (TiN): A PVD (Physical Vapor Deposition) coating that provides exceptional hardness and wear resistance. It also reduces friction, leading to improved surface finish and extended die life. This is widely used in high-speed stamping applications.

Diamond-Like Carbon (DLC): DLC coatings offer a combination of hardness, lubricity, and chemical inertness. They are particularly useful for dies processing abrasive materials or where reduced friction is critical.

PTFE (Polytetrafluoroethylene): A self-lubricating coating used to reduce friction and prevent galling (welding of metal surfaces). This is beneficial when dealing with sticky materials or under high pressure.

For example, a progressive die used in high-speed stamping of aluminum parts might benefit from a TiN coating for its wear resistance and reduced friction. A die used to form a part from a corrosive material may benefit from a Chromium plating for better corrosion resistance.

Q 19. How do you handle and resolve conflicts related to die manufacturing?

Conflict resolution in die manufacturing often involves addressing technical issues, scheduling conflicts, or communication breakdowns. My approach is always collaborative and focuses on finding mutually beneficial solutions.

Open Communication: I encourage open communication among all stakeholders, including engineers, machinists, and quality control personnel. This helps to identify the root cause of the conflict quickly and prevents misunderstandings.

Data-Driven Analysis: We rely heavily on data to support decision-making. By analyzing process data, dimensional measurements, and quality reports, we can pinpoint problems and track their impact.

Problem-Solving Frameworks: We often utilize structured problem-solving methods like the 5 Whys technique or fishbone diagrams to get to the root cause of the conflict. This is extremely effective in isolating the core problem.

Mediation and Facilitation: In case of conflicts between different departments, I act as a mediator, ensuring respectful communication and helping the team find common ground. My role is to guide the group to the solution, not impose one.

For instance, a recent conflict involved a scheduling conflict between the machining and heat treatment departments. Through open communication and data analysis showing the impact of delays on production, we found a compromise that adjusted the scheduling and met the production demands.

Q 20. Describe your experience with different types of presses used in die manufacturing.

My experience with various types of presses used in die manufacturing includes both mechanical and hydraulic presses. The choice of press depends on the application and the required force and speed.

Mechanical Presses: These presses utilize a crankshaft and connecting rod mechanism to generate force. They are generally suitable for high-speed, repetitive stamping operations with relatively lower tonnage. They’re efficient and well-suited for high-volume production of smaller parts. I’ve used many mechanical presses throughout my career in large-scale manufacturing.

Hydraulic Presses: Hydraulic presses use hydraulic cylinders to generate force. They are capable of producing higher tonnage and are more versatile for complex forming operations, including deep drawing and bending. They offer greater flexibility in terms of force control and are often chosen for larger, more intricate dies. We used hydraulic presses in manufacturing dies for larger automotive components requiring substantial force.

Transfer Presses: These automated presses integrate several operations into a single machine, increasing production efficiency and reducing handling time. This type is commonly found in high-volume production lines.

Progressive Presses: These presses perform a series of operations in a single stroke, greatly increasing production speed. Each station performs a different operation on the workpiece, leading to efficient production of complex parts.

The selection of the press is crucial. A mismatch between the die and the press can lead to die damage, poor part quality, or safety hazards. The tonnage capacity, speed, and stroke length are among the key factors to consider.

Q 21. What are your preferred methods for quality control in die manufacturing?

Quality control in die manufacturing is paramount. My preferred methods incorporate a multi-stage approach ensuring high-quality dies that meet specifications and industry standards.

Incoming Material Inspection: This involves verifying the quality of raw materials (tool steel, carbide, etc.) before they are used in die production. This minimizes the risk of defects originating from poor quality materials.

Process Monitoring: Throughout the manufacturing process, we monitor key parameters such as machining tolerances, heat treatment cycles, and surface finish. This ensures consistent quality and allows for prompt correction of any deviations.

Dimensional Inspection: As mentioned earlier, CMMs and optical comparators play a crucial role in verifying the accuracy and precision of the die’s dimensions. This is a critical stage for ensuring dimensional compliance with the design specifications.

Surface Finish Inspection: We inspect the die surface for defects such as scratches, pitting, and cracks. This ensures a smooth surface that reduces friction and enhances part quality.

Functional Testing: Running sample parts through the die and testing their properties ensures the die performs as intended. This is the most crucial check to ensure that the finished die performs its intended role.

Statistical Process Control (SPC): SPC charts help to monitor process variability and identify trends that may indicate potential quality issues. This is vital for proactive identification and correction of process deviations.

For example, using SPC charts in our heat treatment process allowed us to detect and rectify a slight variation in temperature that was impacting the die’s hardness, preventing potential future quality problems and associated scrap.

Q 22. Explain your understanding of statistical process control (SPC) in relation to dies.

Statistical Process Control (SPC) in die manufacturing is crucial for maintaining consistent quality and minimizing defects. It involves using statistical methods to monitor and control the manufacturing process. We collect data on key characteristics of the dies, such as dimensions, surface finish, and hardness, at various stages of production. This data is then plotted on control charts, like X-bar and R charts, or individuals and moving range charts, allowing us to identify trends, patterns, and deviations from the target values. For example, if we notice a consistent drift in die dimensions beyond the control limits, it signals a potential problem with the machining process, prompting an investigation into the root cause—be it tool wear, machine misalignment, or even changes in raw material properties.

By applying SPC, we can detect variations early, preventing the production of faulty dies and reducing scrap. The key is to establish robust control limits based on historical data and continuously monitor the process. Out-of-control signals trigger corrective actions to bring the process back within acceptable limits, and regular process capability studies ensure the process is meeting the required specifications consistently over time.

Q 23. How do you manage and reduce die manufacturing costs?

Managing and reducing die manufacturing costs requires a multifaceted approach. It begins with careful planning and design, employing techniques like Design for Manufacturability (DFM) to optimize the die design for efficient production. This includes selecting appropriate materials, minimizing complexity, and considering tooling standardization to reduce setup times and costs.

Secondly, efficient process optimization is critical. This involves streamlining workflows, reducing waste (material, time, and energy), and improving machine utilization. We implement techniques like lean manufacturing principles, such as 5S and Kaizen events, to eliminate waste and improve overall productivity. Regular preventative maintenance on equipment is vital for preventing costly downtime and extending the life of expensive tools. Furthermore, rigorous quality control measures, as discussed earlier with SPC, minimize scrap and rework, directly impacting costs. Finally, careful sourcing of raw materials and efficient inventory management contribute to minimizing expenses.

For example, in one project, by implementing a lean manufacturing initiative focused on reducing setup times, we achieved a 20% reduction in overall production costs.

Q 24. How do you integrate automation in die manufacturing processes?

Automation plays a vital role in modern die manufacturing. It enhances precision, consistency, and efficiency while reducing labor costs and human error. Integration can be incremental or comprehensive, depending on the complexity and budget. Examples of automated processes include:

- Computer Numerical Control (CNC) machining: This allows for precise and repeatable machining of intricate die components.

- Robotic systems: Robots can handle material handling, loading and unloading of machines, and even perform some assembly tasks.

- Automated inspection systems: These systems use vision systems and other sensors to automatically inspect die dimensions and surface finish, providing immediate feedback and eliminating manual inspection bottlenecks.

- Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) integration: This seamlessly connects the design process with the manufacturing process, ensuring accuracy and minimizing errors.

Implementing automation necessitates careful planning and consideration of factors like cost, return on investment (ROI), and the need for skilled personnel to operate and maintain automated systems. The key is to prioritize automation in areas where it provides the greatest benefit and aligns with the overall production strategy.

Q 25. What are the latest trends and technologies in die manufacturing?

The die manufacturing industry is constantly evolving. Some of the latest trends and technologies include:

- Additive Manufacturing (3D Printing): This offers the potential for rapid prototyping and the creation of complex die geometries that are difficult or impossible to produce using traditional methods. This allows for faster turnaround times and customization of dies for specialized applications.

- Advanced Materials: The use of advanced materials like high-strength steels, composites, and ceramic materials provides enhanced wear resistance, durability, and performance in demanding applications.

- Digital Twins and Simulation: Creating digital representations of the dies and the manufacturing process allows for optimization and prediction of performance before physical production begins.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML can be used to optimize processes, predict equipment failures, and improve quality control.

- Industry 4.0 Technologies: The integration of various technologies, such as IoT sensors, data analytics, and cloud computing, allows for better real-time monitoring, data-driven decision-making, and improved overall efficiency.

These technologies are transforming die manufacturing, leading to increased efficiency, improved quality, and reduced lead times.

Q 26. Describe your experience with lean manufacturing principles in die production.

Lean manufacturing principles have been instrumental in improving efficiency and reducing waste in our die production processes. We’ve implemented several key aspects of lean manufacturing, including:

- 5S methodology: This focuses on workplace organization, improving flow, and reducing waste through sorting, setting in order, shining, standardizing, and sustaining.

- Value stream mapping: This technique helps identify and eliminate non-value-added steps in the die manufacturing process. By mapping out the entire process, we can pinpoint bottlenecks and areas for improvement.

- Kaizen events: These are focused improvement events where teams work together to identify and implement process improvements. We’ve successfully used Kaizen events to reduce setup times and improve overall cycle times.

- Kanban systems: This helps manage workflow and inventory more effectively, reducing waste and ensuring just-in-time production.

Through the consistent application of these principles, we have achieved significant improvements in lead times, reduced waste, and improved overall productivity. For instance, one of our Kaizen events resulted in a 15% reduction in lead time for a specific type of die.

Q 27. How do you handle urgent die repairs and downtime?

Handling urgent die repairs and downtime requires a well-defined emergency response plan. This plan involves having readily available spare parts, skilled technicians on call, and a streamlined repair process. Upon encountering a problem, the first step is a rapid assessment of the situation to determine the severity and potential impact on production. If the issue is critical, we immediately activate the emergency response plan, mobilizing the necessary resources to restore operation as quickly as possible.

We use a combination of techniques, including root cause analysis, to identify the cause of the failure and prevent recurrence. For routine maintenance or repairs, we have established a preventative maintenance schedule to minimize unexpected downtime. Detailed records are kept to track repairs, maintenance activities, and parts usage, allowing us to identify trends and improve our response procedures over time. Our goal is to minimize downtime and maintain production continuity.

Q 28. What are your salary expectations for this role?

My salary expectations for this role are in the range of $120,000 to $150,000 per year, depending on the specific benefits package and overall compensation structure. This is based on my extensive experience and expertise in die manufacturing, encompassing design, production, automation, and lean manufacturing principles. I am confident that my skills and experience align perfectly with the requirements of this position and that my contributions will significantly benefit your organization.

Key Topics to Learn for Knowledge of Die Manufacturing Equipment Interview

- Die Design and Construction: Understanding various die types (progressive, compound, etc.), materials selection, and design principles for optimal performance and durability. Consider the impact of design choices on manufacturing efficiency and product quality.

- Manufacturing Processes: Familiarize yourself with the complete die manufacturing process, from initial design and material procurement to machining, heat treatment, and final inspection. Be prepared to discuss different machining techniques and their applications.

- Troubleshooting and Maintenance: Develop a strong understanding of common die failures, their causes, and effective troubleshooting strategies. Discuss preventative maintenance techniques and their importance in maximizing die lifespan and minimizing downtime.

- Quality Control and Inspection: Learn about quality control measures implemented throughout the die manufacturing process. Be able to explain different inspection methods and their significance in ensuring the production of high-quality dies.

- Materials Science: Gain a solid grasp of the properties of various materials used in die construction, their behavior under stress, and how to select appropriate materials based on application requirements.

- Safety Procedures and Regulations: Understand and be able to discuss relevant safety regulations and procedures within a die manufacturing environment. This demonstrates your commitment to workplace safety.

- CAD/CAM Software: Demonstrate familiarity with common CAD/CAM software used in die design and manufacturing. Be ready to discuss your experience with specific software packages if applicable.

- Cost Optimization and Efficiency: Discuss strategies for optimizing die manufacturing processes to reduce costs while maintaining quality and efficiency.

Next Steps

Mastering knowledge of die manufacturing equipment is crucial for career advancement in this highly specialized field. A strong understanding of these processes and technologies will significantly enhance your job prospects and open doors to more challenging and rewarding opportunities. To maximize your chances of success, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that showcases your expertise. Examples of resumes tailored to Knowledge of Die Manufacturing Equipment are available to guide you, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good