Unlock your full potential by mastering the most common Leather industry best practices interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Leather industry best practices Interview

Q 1. Explain the different types of leather and their characteristics.

Leather types are broadly classified based on the animal source, tanning method, and finishing processes. Think of it like choosing a wine – each type has unique characteristics impacting its feel, look, and suitability for different applications.

- Full-Grain Leather: The top layer of the hide, retaining its natural grain (the outer texture). It’s the strongest, most durable, and develops a beautiful patina over time. Think of a well-worn, luxurious leather jacket – that’s full-grain.

- Top-Grain Leather: The top layer after the grain has been sanded or buffed to create a smoother surface. It’s less durable than full-grain but more consistent in appearance. Many affordable leather goods use this type.

- Genuine Leather: Often a misleading term, it typically refers to split leather, the layer beneath the top grain. It’s thinner and less durable, often requiring a protective topcoat. It’s cheaper but sacrifices longevity.

- Nubuck Leather: A type of suede, with a napped finish. It’s soft and luxurious but requires more care and is less water-resistant. Consider those soft, velvety shoes – likely nubuck.

- Suede Leather: Similar to nubuck, but the napping is done on the flesh side of the hide. It offers a distinctive soft texture.

- Patent Leather: Leather coated with a high-gloss polyurethane finish. It’s highly resistant to water and scratches, but it lacks the natural breathability of other leather types. Think of shiny, formal shoes.

The choice of leather type significantly influences the final product’s quality, aesthetics, and price point.

Q 2. Describe the tanning process and its impact on leather quality.

Tanning is the crucial process that transforms perishable animal hides into durable leather. It involves preventing decomposition and improving the hide’s strength and flexibility. Imagine preserving a delicate piece of art – tanning is the preservation process for leather.

- Vegetable Tanning: Uses plant-based tannins like tree bark extracts. It’s an environmentally friendly method, resulting in leather that is strong and ages beautifully with a unique character. It’s often used for higher-end goods because it’s a slower, more labor-intensive process.

- Chrome Tanning: Uses chromium salts. This is a faster, more efficient process, producing leather that is soft and supple. It’s commonly used for mass production due to its speed and cost-effectiveness, but some environmental concerns exist regarding chromium waste.

- Combination Tanning: Combines both vegetable and chrome tanning methods to leverage the advantages of both. This often results in leather with good strength, suppleness, and a desirable aesthetic.

The tanning method significantly impacts the leather’s final properties, influencing its durability, feel, and environmental impact. For example, vegetable-tanned leather is typically stronger and more resistant to wear and tear over time but might be less supple than chrome-tanned leather.

Q 3. What are the common finishing techniques used in the leather industry?

Leather finishing is the final stage that determines the look, feel, and performance of the leather. It’s like adding the final touches to a painting, transforming the base material into something beautiful and functional.

- Dyeing: Applying color to the leather using various techniques like drum dyeing or spray dyeing.

- Pigmenting: Coating the leather with a pigmented finish for color and protection.

- Embossing: Impressing patterns or textures onto the leather’s surface.

- Finishing Coatings: Applying topcoats to enhance water resistance, scratch resistance, and overall durability.

- Buffing/Polishing: Enhancing the leather’s shine and smoothness.

The finishing techniques chosen significantly influence the leather’s final appearance, feel, and performance characteristics. For instance, a protective coating could make the leather more suitable for outdoor use, while embossing could add a decorative element.

Q 4. How do you assess the quality of leather hides?

Assessing leather hide quality requires a keen eye and experience. It’s similar to a gemologist assessing a diamond, looking for clarity, consistency, and absence of flaws.

- Visual Inspection: Checking for uniform grain, color, and texture. Are there any inconsistencies, scars, or holes?

- Feel and Texture: Assessing the leather’s suppleness, firmness, and overall hand feel. Is it smooth, soft, or firm?

- Thickness and Weight: Evaluating the hide’s thickness, ensuring consistency and appropriate weight for the intended application.

- Smell: A fresh, natural scent is preferable; off-odors might indicate defects or improper processing.

- Stretch Test: Gently stretching the leather to check for elasticity and resilience.

Careful assessment ensures the selection of high-quality hides, which directly impacts the final product’s quality and longevity.

Q 5. What are the different types of leather defects and how are they addressed?

Leather defects can arise at various stages of processing. Identifying and addressing these defects is crucial for quality control.

- Scars and Brandings: Marks from the animal’s life, often affecting the appearance.

- Insect Bites and Damage: Holes or imperfections caused by insects.

- Stretch Marks: Irregularities in the hide’s texture.

- Grain Cracks: Breaks in the leather’s surface.

- Imperfect Tanning: Uneven color or stiffness.

Addressing defects might involve trimming damaged areas, using fillers to repair minor imperfections, or selecting hides with fewer flaws. Severe defects might render the hide unsuitable for higher-grade products.

Q 6. Explain the importance of leather conditioning and care.

Leather conditioning and care are essential for maintaining its quality, appearance, and longevity. It’s like regular maintenance for a car – keeping it in good shape extends its life.

- Cleaning: Regular cleaning removes dirt and grime, preventing build-up and damage.

- Conditioning: Applying leather conditioners replenishes oils and moisturizers, keeping the leather supple and preventing cracking.

- Protection: Using protective sprays or creams shields the leather from water damage, UV rays, and scratches.

- Storage: Proper storage, away from direct sunlight and heat, helps prevent damage.

Proper care prevents premature wear and tear, ensuring that leather goods maintain their beauty and value for years.

Q 7. Describe your experience with different leather machinery and equipment.

My experience encompasses a wide range of leather machinery and equipment, from hide preparation to finishing. Think of it as a complete orchestra – each instrument plays its part in creating the final product.

- Hide Preparation Machines: I’ve worked with fleshing machines, splitting machines, and shaving machines for preparing hides.

- Tanning Equipment: Experience with drum tanneries, both chrome and vegetable, including knowledge of chemical handling and process control.

- Finishing Equipment: Proficient with dyeing machines, coating machines, embossing machines, and buffing machines, including their maintenance and troubleshooting.

- Cutting and Sewing Equipment: Familiar with various cutting dies and sewing machines for leather goods production.

My experience includes both traditional and modern machinery, ensuring efficiency and quality in leather production. I am also proficient in maintaining and troubleshooting these machines, which is critical for minimizing downtime and maximizing productivity.

Q 8. How do you ensure the consistency and quality of leather products throughout the manufacturing process?

Maintaining consistent leather quality throughout production is crucial. It’s like baking a cake – you need the right ingredients and precise steps every time to get the same delicious result. We achieve this through a multi-pronged approach:

Strict Raw Material Selection: We meticulously source hides, inspecting them for defects, thickness consistency, and overall quality. This includes carefully considering the breed of animal and its rearing conditions, as these greatly impact hide quality.

Standardized Processes: Each stage, from pre-tanning to finishing, follows precisely defined procedures documented in Standard Operating Procedures (SOPs). This ensures repeatability and minimizes variations.

Regular Quality Checks: At various points in the process, we conduct rigorous quality checks using standardized testing methods. This includes visual inspections, thickness measurements, tensile strength tests, and assessments of other physical properties. Any deviations from the standard are immediately addressed.

Calibration and Maintenance: Our equipment is regularly calibrated to maintain accuracy. This is particularly important for machines involved in processes like splitting, dyeing, and finishing.

Trained Personnel: Our skilled workforce undergoes continuous training on best practices and quality control. They are empowered to identify and report any inconsistencies immediately.

By combining these strategies, we ensure the final leather product meets our high quality standards consistently.

Q 9. What are the common challenges faced in leather production and how have you overcome them?

Leather production faces several challenges, some of which are:

Hide Quality Variability: Natural variations in animal hides can lead to inconsistencies in the final product. We overcome this by carefully selecting hides and using advanced sorting techniques to group them by quality.

Environmental Regulations: Stringent environmental regulations regarding waste management and chemical usage require careful planning and investment in eco-friendly technologies. We’ve implemented a closed-loop water system and switched to chrome-free tanning methods wherever feasible.

Fluctuating Raw Material Prices: The cost of raw hides can be unpredictable, impacting production costs. We mitigate this risk by securing long-term contracts with reliable suppliers and exploring alternative, sustainable sourcing options.

Skilled Labor Shortages: Finding and retaining skilled leather artisans is a challenge. We address this by offering competitive wages and benefits, providing robust training programs, and fostering a positive work environment.

Addressing these challenges requires a proactive and adaptable approach, involving continuous improvement, technological innovation, and a strong commitment to sustainability.

Q 10. Explain your understanding of leather sustainability and ethical sourcing.

Leather sustainability and ethical sourcing are paramount to our business. It’s about creating beautiful, durable products without compromising the well-being of animals or the environment. We adhere to the following principles:

Traceable Sourcing: We prioritize sourcing hides from tanneries that are certified by reputable organizations, guaranteeing ethical animal treatment and environmental responsibility. We maintain transparent records of our supply chain.

Reduced Environmental Impact: We utilize eco-friendly tanning methods that minimize water and chemical usage, reducing our carbon footprint. We invest in waste management systems to recycle and reuse byproducts, minimizing landfill waste.

Fair Labor Practices: We ensure fair wages and safe working conditions throughout our supply chain, supporting the livelihoods of those involved in leather production.

Sustainable Chemicals: We’re constantly researching and adopting less harmful chemicals in the tanning and finishing processes, striving towards a greener approach.

We believe sustainable practices are not just a trend, but essential for the long-term health of the leather industry and the planet.

Q 11. Describe your experience with different leather dyeing techniques.

Leather dyeing is an art and a science. Different techniques yield vastly different results. My experience spans several methods:

Vegetable Tanning Dyeing: This traditional method uses natural dyes derived from plants, yielding rich, earthy tones. The process is more time-consuming but produces environmentally friendly leather with a unique character. For example, we use quebracho and chestnut extracts for specific brown and tan shades.

Chrome Tanning Dyeing: This widely used method utilizes chromium salts, enabling faster and more consistent dyeing. Chrome-tanned leather is strong and durable, coming in a wide variety of colors. We employ this method while strictly adhering to environmental regulations for chromium waste disposal.

Aniline Dyeing: This delicate technique allows the leather’s natural grain to show through, producing a soft, supple finish. The colors are often subtle and translucent. This technique highlights the natural beauty of the hide.

Semi-aniline Dyeing: A blend of aniline and topcoat dyeing. This method offers more colorfastness and protection against wear while still maintaining some of the natural grain’s appearance.

The choice of technique depends on the desired aesthetic, the type of leather, and the intended application of the final product.

Q 12. How do you manage leather waste and minimize environmental impact?

Leather waste management is crucial for minimizing our environmental impact. We employ a multi-faceted approach:

Waste Reduction: Careful planning and optimized processes minimize waste generation from the outset. This includes precise cutting techniques and efficient material utilization.

Recycling and Reuse: Leather scraps are often reused in the production of lower-grade leather goods or as fillers in other industries. We also explore partnerships with companies specializing in recycling leather waste into other products.

Bioremediation: For certain types of waste, we utilize bioremediation techniques to break down organic matter and reduce environmental harm. This is particularly relevant for tannery wastewater treatment.

Energy Recovery: Certain leather waste can be used for energy generation through incineration, although this requires careful consideration of emission controls.

We are constantly exploring new technologies and partnerships to improve our waste management strategies and further minimize our environmental footprint. It’s a continual process of optimization and improvement.

Q 13. What are the key quality control measures you employ in leather manufacturing?

Quality control is an ongoing process, not a single event. We have several measures in place:

Incoming Inspection: Raw hides are rigorously inspected for defects upon arrival. Only hides meeting our strict quality criteria proceed to the next stage.

In-Process Control: Throughout the manufacturing process, we conduct regular checks at key stages (e.g., after tanning, dyeing, finishing). This allows for early detection and correction of any flaws.

Final Inspection: Each finished product undergoes a thorough final inspection, examining for defects, consistency of color and finish, and adherence to specifications.

Statistical Process Control (SPC): We employ statistical methods to monitor process variations and identify potential issues before they become significant problems. This proactive approach ensures consistency.

Testing and Analysis: We use various testing methods, including tensile strength tests, abrasion resistance tests, and colorfastness tests, to ensure the finished product meets the required standards.

These measures, when combined, form a robust quality control system that ensures the highest standards are consistently met.

Q 14. How do you ensure the durability and longevity of leather products?

Durability and longevity are hallmarks of high-quality leather. We ensure this through several practices:

Hide Selection: We select hides of appropriate thickness and strength based on the intended application of the final product. Thicker hides are typically more durable.

Tanning Process: The tanning process significantly influences the durability of the leather. We utilize tanning methods known for their strength and resistance to wear and tear.

Finishing Techniques: The finishing process protects the leather from environmental factors like moisture and UV radiation. We use high-quality finishes that enhance both durability and appearance.

Proper Care Instructions: We provide customers with clear instructions on how to care for and maintain their leather products, extending their lifespan. This includes cleaning, conditioning, and storage guidance.

Quality Materials: We select high-quality components for construction, ensuring the overall integrity and longevity of the finished product.

By focusing on all these aspects, we aim to create leather products that last for years, providing value and enjoyment to our customers.

Q 15. What are the different types of leather adhesives and their applications?

Choosing the right leather adhesive is crucial for the longevity and quality of a leather product. Different adhesives offer varying degrees of flexibility, strength, and resistance to water and chemicals. The selection depends heavily on the application and the types of leather being bonded.

- Contact Cement: This is a popular choice for many leather applications, offering strong bonds with quick setting times. It’s ideal for bonding leather to itself, or to other materials like wood or metal. Think of the strong bond needed in a leather handbag or wallet. However, it requires precise application to avoid visible glue lines.

- Hot Melt Adhesives: These are applied in a molten state and cool quickly, creating a strong bond. They are often used in automated processes for efficiency, such as attaching leather patches to garments. They’re less versatile than contact cement in terms of substrates.

- Water-Based Adhesives: Environmentally friendly and offering good flexibility, these adhesives are suitable for applications where flexibility is key, like leather upholstery. They have a longer drying time compared to contact cement.

- Solvent-Based Adhesives: These offer strong bonds and good resistance to solvents. They are used for applications requiring high durability and chemical resistance. They often have strong fumes and require careful ventilation.

The choice often involves weighing factors like speed of bonding, required strength, flexibility needed, environmental concerns, and the cost of the adhesive.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with leather pattern making and cutting.

My experience in leather pattern making and cutting spans over 15 years, encompassing both handcrafted and mass production techniques. I’m proficient in using various tools, from traditional hand-cutting knives to computerized cutting machines.

In my previous role, I was responsible for creating patterns for a wide range of leather goods, from simple wallets to complex motorcycle jackets. This involved understanding the grain direction of the leather, which is critical to prevent cracking or distortion of the final product. I’ve developed a keen eye for detail, ensuring that patterns are accurate and efficient, minimizing material waste. I’ve also worked with different leather types, understanding how their thickness and properties influence pattern design and cutting techniques. For example, heavier leathers like full-grain require more robust cutting tools and a more precise cutting technique than thinner, softer leathers.

My expertise extends to utilizing computer-aided design (CAD) software for creating and optimizing patterns, leading to improved efficiency and reduced waste. I’m also experienced in managing the entire cutting process, ensuring the efficient use of leather hides and optimizing yield.

Q 17. Explain your understanding of leather supply chain management.

Leather supply chain management is a complex process that involves careful coordination between various stakeholders, from raw material sourcing to the delivery of finished products. It’s crucial to ensure the quality, sustainability, and traceability of the leather throughout the entire chain.

My understanding includes sourcing high-quality raw hides from reputable tanneries, ensuring ethical and sustainable practices are followed. This involves tracking the origin of the hides, verifying compliance with environmental regulations, and ensuring animal welfare standards are met. Efficient logistics are also crucial, including timely transportation and storage of hides and finished goods, minimizing damage and spoilage. I’m familiar with managing inventory levels, forecasting demand, and collaborating with suppliers to ensure timely delivery of materials while optimizing costs. Transparency and traceability are paramount in today’s market; being able to track a product from raw material to finished good instills consumer confidence and allows for swift issue resolution if needed.

Q 18. How do you handle customer complaints related to leather product quality?

Handling customer complaints effectively is paramount for maintaining customer loyalty and brand reputation. My approach involves a systematic process, prioritizing empathy and swift resolution.

- Listen Actively: First, I listen carefully to understand the customer’s complaint, acknowledging their concerns and validating their feelings.

- Gather Information: I gather detailed information about the defect or issue, including photographs or videos if possible. This helps determine the root cause of the problem.

- Investigate: I investigate the complaint, checking production records, quality control reports, and examining the product itself to identify the cause of the defect.

- Offer a Solution: Depending on the nature of the complaint, I offer solutions such as repair, replacement, or refund. My goal is to find a fair and satisfactory solution for the customer.

- Follow-Up: After resolving the complaint, I follow up with the customer to ensure they are satisfied with the resolution. This demonstrates commitment to customer service and helps build trust.

This systematic approach ensures fairness, efficiency and customer satisfaction. A well-handled complaint can even turn a negative experience into a positive one, strengthening brand loyalty.

Q 19. What are the latest trends and innovations in the leather industry?

The leather industry is constantly evolving, driven by technological advancements and changing consumer preferences. Some notable trends include:

- Sustainable and Ethical Sourcing: Consumers are increasingly demanding leather produced ethically and sustainably, leading to a rise in demand for traceable, responsibly sourced leather.

- Technological Advancements: 3D printing and laser cutting technologies are revolutionizing pattern making and production, allowing for greater precision, efficiency, and customization.

- Innovation in Materials: We are seeing the emergence of innovative materials that mimic the look and feel of leather but are more sustainable and environmentally friendly, such as plant-based leathers or recycled materials.

- Customization and Personalization: Consumers are seeking more personalized leather products, leading to a growing demand for bespoke designs and customized options.

- Focus on Durability and Longevity: There is a growing trend towards purchasing high-quality, durable leather goods that are designed to last for years, rather than inexpensive, short-lived alternatives.

Staying ahead of these trends requires continuous learning and adaptation.

Q 20. How do you stay up-to-date with the latest leather industry best practices?

Staying updated in a dynamic industry like leather manufacturing is crucial. My approach involves a multi-faceted strategy:

- Industry Publications and Trade Shows: I regularly read industry publications and attend trade shows to learn about the latest trends, technologies, and best practices. This provides invaluable insights from leading experts.

- Professional Networks: I actively participate in professional networks and online communities to connect with other professionals in the field, share knowledge and learn from their experiences.

- Continuous Learning: I actively seek out opportunities for continuous learning through workshops, online courses, and industry certifications to keep my skills sharp and up-to-date.

- Competitor Analysis: By studying the innovations and strategies of competitors, I can identify areas for improvement and opportunities for innovation in my own work.

This proactive approach ensures I am equipped with the most current knowledge and best practices to consistently improve my work.

Q 21. Describe your experience with different leather stitching techniques.

My experience encompasses a wide range of leather stitching techniques, both by hand and machine. This includes understanding the importance of stitch selection for different applications and leather types.

- Hand Stitching: I’m proficient in various hand stitching techniques, including saddle stitching (known for its strength and durability), and decorative stitches for enhancing the aesthetic appeal of the product. Hand stitching is often preferred for high-end, bespoke items where precision and detail are paramount.

- Machine Stitching: I’m also experienced with various machine stitching techniques, including different stitch types and their respective applications. For example, a lockstitch is commonly used for its strength and neatness, while a chainstitch offers flexibility and is ideal for curved seams.

- Blind Stitching: This technique is used to create a nearly invisible stitch, commonly seen in high-end leather goods where a clean finish is crucial. It requires precision and practice.

The choice of stitching technique depends on factors like the desired aesthetic, the strength required, and the type of leather being used. For instance, thicker leathers may require stronger stitches and different needle sizes compared to thinner leathers.

Q 22. Explain your understanding of leather embossing and printing techniques.

Leather embossing and printing are crucial techniques for enhancing the aesthetic appeal and functionality of leather goods. Embossing is a process that creates a three-dimensional design on the leather’s surface by applying pressure using a heated die. This can range from subtle textures to intricate patterns. Printing, on the other hand, involves applying inks or pigments directly onto the leather to create designs, logos, or patterns. This can include various methods like screen printing, pad printing, or digital printing, each offering different levels of detail and cost-effectiveness.

Embossing: Think of it like stamping a design into the leather – you’re altering the surface itself. This results in a tactile element as well as a visual one. For instance, a crocodile pattern embossed on a handbag gives it a luxurious look and feel without the cost of using genuine crocodile skin. The depth and intricacy of the embossing depend on the pressure and temperature used, along with the die’s design.

Printing: Imagine painting a picture on the leather. The technique and inks used significantly impact the final product’s appearance and durability. A delicate floral print on a leather wallet might use a more refined screen printing method, while a bolder logo on a jacket might utilize a more resilient pad printing process. Digital printing offers the highest level of detail and customization but can be more expensive.

Selecting the right technique depends on factors like the leather type, the desired design complexity, the production volume, and the budget.

Q 23. How do you select appropriate leathers for different applications?

Leather selection for different applications requires careful consideration of several key factors: the desired aesthetic, durability requirements, budget constraints, and the intended use. For example, a supple, full-grain leather is ideal for luxury handbags, where quality and feel are paramount. Conversely, a durable, corrected-grain leather might be more suitable for work boots due to its resilience to wear and tear.

- Luxury Goods (Handbags, wallets): Full-grain or top-grain leathers are preferred for their superior quality, natural markings, and luxurious feel. The thickness and suppleness should be considered based on the design.

- Automotive Interiors: Strong, durable leathers with UV resistance are essential for automotive applications. Typically, corrected-grain or top-grain leathers treated with specialized coatings are chosen for their longevity and resistance to fading and cracking.

- Footwear: The choice depends on the type of footwear. For dress shoes, a smoother leather is common, while work boots require a more robust and resistant leather. Full-grain or corrected-grain leathers are frequent choices, sometimes combined with protective coatings.

- Clothing: Soft, supple leathers like lambskin or goatskin are often used for jackets and gloves, offering comfort and flexibility. Heavier leathers are suitable for outerwear that needs more durability.

The process involves evaluating samples, performing tests for strength, abrasion resistance, and water resistance, and considering the cost-effectiveness of each option.

Q 24. What are the different types of leather finishes and their properties?

Leather finishes significantly influence the leather’s look, feel, and performance. They’re applied after tanning and contribute to the leather’s protection and aesthetic appeal. Different finishes cater to specific needs and styles.

- Aniline Finish: This finish is minimal, allowing the leather’s natural grain and markings to show through. It provides a soft, supple feel but offers less protection against stains and scratches. This is commonly found in high-end goods where the natural beauty of the leather is emphasized.

- Semi-aniline Finish: A compromise between aniline and full-grain. A light pigment and a thin topcoat provide some protection while maintaining a relatively natural look and feel. This balance of aesthetics and practicality makes it popular for many applications.

- Topcoat Finish: A thicker topcoat provides significant protection against stains, scratches, and water damage. This results in a more uniform appearance and less visible natural markings. It’s frequently used in furniture and upholstery where durability is key.

- Corrected-Grain Finish: This is a more heavily processed finish. The natural grain is sanded down and a uniform pattern is embossed onto the surface, creating a consistent and less expensive leather. This is used frequently in more mass-produced items.

- Patent Leather Finish: A high-gloss finish created using a resin coating, giving the leather a shiny, almost lacquered look. This adds shine and durability but might feel less supple than other finishes. It is used to produce dressy accessories and shoes.

The choice of finish is dictated by the end product’s intended use, aesthetic requirements, and the desired level of durability.

Q 25. How do you ensure the compliance of your leather products with industry standards?

Ensuring compliance with industry standards is critical for maintaining quality and ethical practices within the leather industry. This involves adhering to regulations regarding chemical use, labor practices, and environmental impact. Specific standards vary by region, but common aspects include:

- Chemical Compliance: Following regulations on the use of restricted substances (e.g., REACH in Europe, Proposition 65 in California). This necessitates careful sourcing of tanning agents and other chemicals, along with regular testing to ensure compliance.

- Environmental Standards: Reducing waste, implementing efficient water usage systems, and managing wastewater properly. Certifications like Leather Working Group (LWG) audit help in achieving and demonstrating environmental responsibility.

- Social Responsibility: Adhering to fair labor practices, ensuring safe working conditions, and respecting workers’ rights. This often involves audits and certifications by organizations specializing in social responsibility in supply chains.

- Quality Control: Implementing rigorous quality control measures throughout the production process, from raw material selection to finished product inspection. This ensures the final product meets specified criteria for durability, appearance, and consistency.

Maintaining meticulous records, engaging in regular audits, and collaborating with certified suppliers are crucial for consistent compliance.

Q 26. What is your experience with leather costing and pricing strategies?

Leather costing and pricing strategies are complex, incorporating various factors to determine profitability. The process begins with understanding the raw material costs (hide prices, which fluctuate based on market conditions), processing costs (tanning, finishing, labor), and overhead (rent, utilities, equipment maintenance). Then there’s the costing of the specific design and manufacturing process.

Costing Methods: Accurate costing involves analyzing each stage of production, including material consumption, labor hours, and machine usage. Methods like activity-based costing or standard costing can be utilized for precise cost allocation.

Pricing Strategies: Pricing involves calculating the cost plus a desired profit margin. Market analysis is crucial to determine the right price point. Factors like brand positioning, competitor pricing, and customer perception influence final pricing decisions. Premium leather goods may use value-based pricing, while mass-produced items may rely on cost-plus pricing.

Example: A high-end handbag might have a high raw material cost, complex design and manufacturing processes, and a significant profit margin, justifying a premium price. In contrast, a simple leather belt might have a lower material cost, simpler production, and a smaller margin, resulting in a more affordable price.

Q 27. Explain your understanding of different leather grain types.

Leather grain refers to the outer surface of the hide, reflecting the natural texture and pattern. Different grain types result in varying leather characteristics and suitability for specific applications.

- Full-Grain Leather: This is the top layer of the hide, retaining its natural grain and imperfections. It’s the most durable and highest quality type, showing a unique texture and aging beautifully. The strength and natural resistance to wear and tear makes it ideal for premium products.

- Top-Grain Leather: The top layer after the very top layer (the grain) is removed. It is more uniform in appearance than full-grain but still retains some natural grain. It’s more affordable than full-grain while maintaining decent durability. It’s a good balance of cost and quality.

- Corrected-Grain Leather: The top layer is sanded down, and a uniform grain is stamped onto the surface. It’s consistent in appearance but less durable than full-grain or top-grain, meaning it’s frequently used for more affordable products that still require a leather-like appearance.

- Nubuck Leather: The top layer of the hide is sanded to create a velvety or suede-like finish. It’s soft to the touch but requires more care as it’s prone to staining and marking. This is ideal for premium, soft, and stylish products.

- Suede Leather: The underside of the leather, creating a soft, velvety finish. It’s delicate and requires careful handling, but its soft texture is highly desirable for specialized items.

Understanding these grain types helps select the appropriate leather for specific applications, considering factors like durability, appearance, and cost.

Q 28. Describe your experience with leather product development and design

My experience in leather product development and design spans several years, encompassing various stages from concept ideation to final production. I’ve been involved in projects ranging from luxury handbags to durable work boots.

Process: It starts with understanding the client’s needs and market trends. Design involves sketching, creating 3D models, and selecting suitable materials, considering factors like leather type, color, and finish. Prototyping is an essential step, ensuring the design is functional and aesthetically pleasing. This involves creating samples, testing their durability and comfort, and making necessary adjustments based on feedback. Collaboration with pattern makers, sample makers, and production teams is crucial to ensure a smooth transition from design to manufacturing.

Example: In one project, we developed a new line of sustainable leather travel bags. The design process involved sourcing eco-friendly leathers, implementing efficient manufacturing techniques to minimize waste, and designing durable but lightweight products. This involved extensive research into sustainable materials and manufacturing practices, prototyping and testing several different designs to ensure both functionality and durability.

Tools & Technology: I am proficient in using CAD software for design and prototyping, along with industry-standard pattern-making techniques. I’m comfortable working with different design tools and technologies to create innovative and functional leather products.

Key Topics to Learn for Leather Industry Best Practices Interview

- Sustainable Leather Sourcing and Production: Understand the environmental impact of leather production, explore sustainable tanning methods (vegetable tanning, chrome-free tanning), and discuss certifications like Leather Working Group (LWG). Consider the ethical implications of sourcing and the importance of traceability.

- Leather Finishing and Treatment: Learn about different finishing techniques (e.g., dyeing, embossing, glazing) and their effects on leather properties (durability, appearance, feel). Discuss quality control measures throughout the finishing process and how to identify and address defects.

- Leather Product Design and Manufacturing: Explore the design process for leather goods, considering factors like material selection, pattern making, cutting, stitching, and assembly. Understand different manufacturing processes and their suitability for various leather types and product applications. Analyze the importance of efficient production processes and waste reduction.

- Leather Quality Assessment and Testing: Familiarize yourself with methods for evaluating leather quality, including visual inspection, physical testing (e.g., tensile strength, tear strength), and chemical analysis. Understand how to interpret test results and ensure consistent quality throughout the production process.

- Health and Safety Regulations in Leather Manufacturing: Understand and be prepared to discuss relevant occupational health and safety regulations, including those related to chemical handling, personal protective equipment (PPE), and waste disposal. Discuss best practices for maintaining a safe and healthy work environment.

- Market Trends and Innovation in the Leather Industry: Stay updated on current trends in leather fashion, technology, and sustainability. Be ready to discuss innovative materials, processes, and technologies that are shaping the future of the industry.

Next Steps

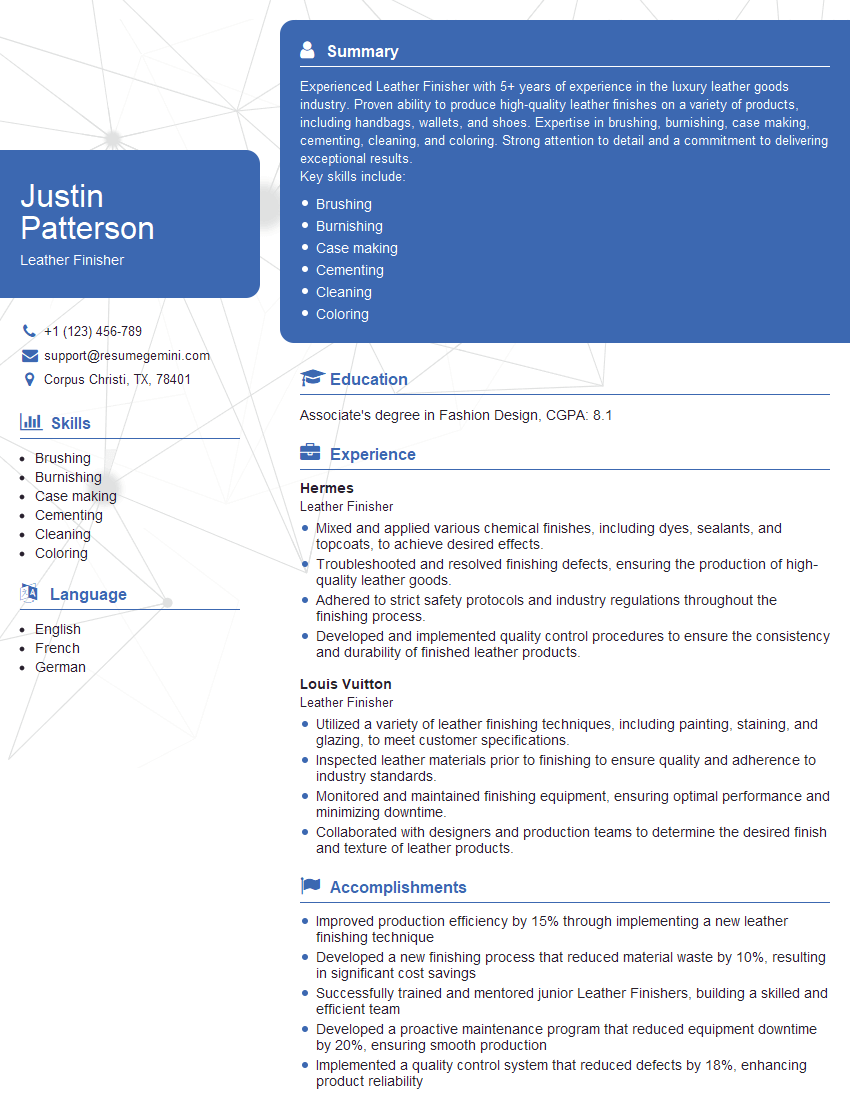

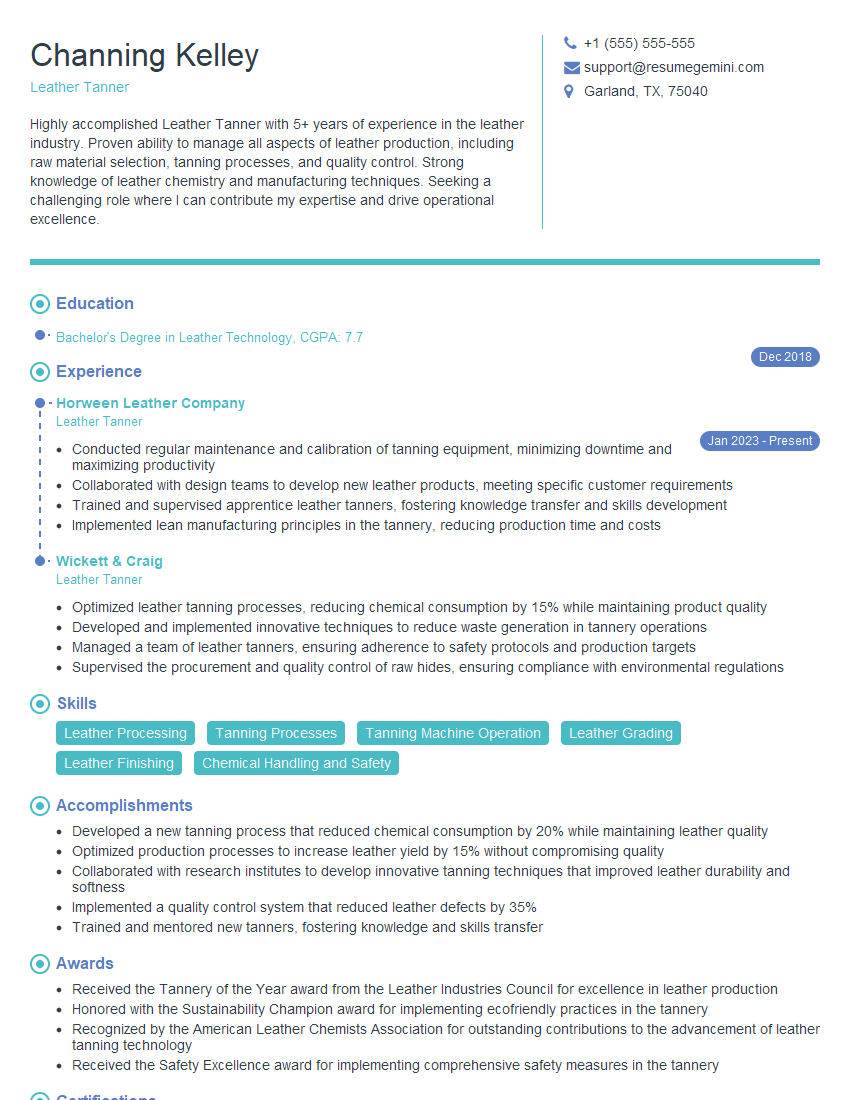

Mastering leather industry best practices is crucial for career advancement. A strong understanding of sustainable practices, quality control, and innovative techniques demonstrates commitment and expertise, making you a highly competitive candidate. To increase your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the leather industry. Examples of resumes tailored to these best practices are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good