Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Felling and Bucking Trees interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Felling and Bucking Trees Interview

Q 1. Describe your experience with different felling techniques (e.g., directional felling, hinge cuts).

Felling a tree involves strategically cutting it down in a controlled manner. I’m proficient in several techniques, primarily directional felling and hinge cutting. Directional felling is crucial for guiding the tree’s fall away from hazards like power lines or buildings. This involves creating a carefully planned notch and back cut to direct the tree’s fall. Imagine it like gently nudging a large domino to fall in a specific direction. The hinge, a portion of the tree left uncut, acts as a pivot point.

Hinge cutting is a critical aspect of directional felling. The hinge’s size and placement dictate the direction and speed of the fall. An improperly placed hinge can lead to unpredictable falls. My experience includes working with various tree sizes and slopes, adjusting my techniques accordingly. For example, in a heavily wooded area with limited space, precise hinge cuts and careful consideration of surrounding trees become paramount. In contrast, a more open area might allow for a less precise approach.

Beyond these, I’m also experienced with other techniques like open-face felling, which is typically used for smaller trees, or felling with a wedge, used to alter the fall path if unexpected problems arise.

Q 2. Explain the importance of proper tree assessment before felling.

Proper tree assessment is the cornerstone of safe and efficient felling. It’s not just about looking at a tree; it’s about understanding its complete profile – its health, structural integrity, lean, and the surrounding environment. I begin by visually inspecting the tree for signs of decay, disease, or stress. Look for cracks, leaning, dead branches, or unusual growth patterns. These can indicate weaknesses that might affect its fall path.

I then consider the surrounding environment: are there power lines, buildings, other trees, or slopes nearby? How close are these obstacles to the tree? The wind speed and direction are also critical factors. A strong wind can drastically alter a tree’s fall path, even with a perfectly executed cut. Using tools like a clinometer to measure lean and assessing soil conditions adds an extra layer of precision to my analysis, ensuring I create the safest possible plan for felling the tree.

For example, a seemingly healthy tree with a hidden internal rot could unexpectedly break during felling, leading to injury or damage. A thorough assessment would have identified this risk. Experienced judgment is key.

Q 3. How do you identify and mitigate potential hazards during felling operations?

Identifying and mitigating hazards is an ongoing process, starting with the initial tree assessment and extending throughout the entire felling operation. This includes identifying potential fall zones, clearing debris from around the tree to prevent obstructions and creating a safe escape path for myself and anyone else on the site.

Potential hazards include: leaning trees that might pull down other trees during the fall, snags that might cause kickback, and hidden obstacles like rocks or stumps that could interfere with the fall. Understanding the wind conditions and the potential for unexpected changes in those conditions is also essential. I always establish clear communication with my crew and ensure everyone understands the felling plan and potential hazards.

Mitigation strategies involve choosing the correct felling technique, setting up a safe working zone and using appropriate personal protective equipment (PPE). I’ll frequently use wedges to help guide the fall and employ extra caution when operating near potential hazards. If the risk is too high or the situation is unclear, I’m prepared to cease work and reassess or seek expert advice. Safety always comes first.

Q 4. Describe your experience using various chainsaw safety equipment (e.g., chaps, helmets, eye protection).

I consistently utilize all the necessary safety equipment when working with chainsaws. This includes chainsaw chaps (protective trousers that defend against chain saw cuts), a hard hat to protect against falling debris, and safety glasses or a face shield to protect my eyes from flying wood chips and debris. I also use hearing protection to mitigate the significant noise generated by chainsaws. Gloves and sturdy boots further complete my safety attire, offering protection from cuts, scrapes, and slips.

The quality of my safety equipment is paramount. I regularly inspect my PPE for any signs of damage or wear and replace items as needed. My gear is essential to my safety, so maintaining it properly and ensuring it fits correctly is a daily habit.

For example, I once narrowly avoided a significant injury due to my chaps when a saw unexpectedly kicked back. The chaps stopped the saw chain, preventing a severe leg injury. This experience reinforced the importance of wearing proper safety gear at all times. It is non-negotiable.

Q 5. What are the common causes of chainsaw kickback and how do you prevent it?

Chainsaw kickback is a dangerous occurrence that can result in serious injury. It happens when the upper portion of the guide bar unexpectedly contacts an object, causing the saw to recoil towards the operator. The most frequent causes are pinching, which happens when the chain is trapped between the wood and the guide bar, and also contact of the tip of the guide bar with an object. Another major cause is when the saw is bucking a tree and the chain gets bound up.

Prevention involves several steps. Maintaining a firm grip on the saw with both hands, avoiding using the saw above shoulder height (which decreases control and increases the likelihood of kickback), ensuring the chain is sharp and properly tensioned, keeping the saw clear of obstacles while cutting and using a proper cutting technique are all crucial. Never let the cutting chain encounter the wood at too steep an angle; rather, keep it as close to a horizontal plane as possible.

Kickback prevention is a continuous process that requires awareness, proper technique, and regularly maintained equipment.

Q 6. Explain the process of bucking a felled tree into logs of specific lengths.

Bucking refers to cutting a felled tree into smaller logs of desired lengths. The process begins with assessing the tree’s size and desired log lengths. I’ll then use my chainsaw to make precise cuts along the tree’s length, creating logs that meet the required dimensions. This frequently involves making cuts on both sides of the log, creating a clean cut with little to no waste.

Safety is key in bucking. For example, before making each cut, I carefully inspect the area to ensure no obstructions or hazards are present. I always check for potential kickback, ensuring my body position remains at a safe distance from the cutting line. Using the correct technique for each type of cut is also crucial to control the fall direction of the log.

Bucking might require different techniques depending on the size and shape of the felled tree and the type of equipment being used. For example, large logs might require multiple cuts from several angles to ensure safe and efficient bucking.

Q 7. How do you ensure the safety of yourself and others during bucking operations?

Safety during bucking operations is paramount. It begins with a thorough assessment of the felled tree to identify potential hazards. I’ll ensure the tree is stable, and clear any obstacles around it before beginning the bucking process. I then use a consistent, safe bucking technique for each cut, maintaining a secure and balanced stance at all times. This ensures that the logs fall in a controlled manner, preventing unexpected movement or kickback.

Maintaining situational awareness during bucking is critical. If another person is assisting, I always ensure they’re maintaining a safe distance from the cutting area. Clear communication and defined roles are important. I’ll also regularly inspect my chainsaw and safety equipment, ensuring they are in top condition. If a situation arises where safety is compromised, I immediately stop work, reassess, and take corrective action. Safety is a priority that cannot be overlooked.

Q 8. What are the different types of wood you have experience felling and bucking?

My experience encompasses a wide variety of wood species, each presenting unique challenges in felling and bucking. I’ve worked extensively with hardwoods like oak, maple, and hickory, known for their density and strength, requiring precise cuts and powerful equipment. Conversely, I’ve also handled softwoods such as pine, fir, and spruce, which are generally easier to fell but can present challenges with their tendency to lean or have hidden defects. Working with hardwoods requires more consideration for the grain direction and potential for kickback, while softwoods often necessitate careful assessment of branch weight and potential for wind-related movement. I’ve also had experience with specialty woods like cherry and walnut, understanding the high value and requiring extra care to avoid damage.

- Hardwoods (Oak, Maple, Hickory): High density, strong, require precise cuts.

- Softwoods (Pine, Fir, Spruce): Easier to fell, but prone to leaning and hidden defects.

- Specialty Woods (Cherry, Walnut): High value, require extra care to prevent damage.

Q 9. Describe your experience working with different types of terrain and weather conditions.

Terrain and weather are significant factors influencing felling and bucking operations. I’ve worked on everything from flat, open fields to steep, mountainous slopes, each demanding different techniques and safety precautions. Steep slopes increase the risk of uncontrolled tree movement, necessitating careful planning and potentially specialized equipment like rigging systems. Weather conditions are equally important; high winds can make felling extremely dangerous, and rain or snow can affect the ground conditions, leading to slips and falls. I’ve adapted my techniques to handle these varying conditions, emphasizing safety and planning in every situation. For example, on steep slopes, I’ll use wedges to help control the fall direction and employ extra safety measures.

- Steep Slopes: Require careful planning, rigging systems, and wedges for fall control.

- High Winds: Postpone felling operations if winds are too strong.

- Rain/Snow: Assess ground conditions and increase safety precautions to prevent slips and falls.

Q 10. How do you handle unexpected situations or emergencies during felling and bucking?

Unexpected situations are part of the job, and preparedness is key. This includes having a thorough understanding of the felling site before beginning work, identifying potential hazards like hidden obstacles or unstable trees. If a tree falls unexpectedly, or a chainsaw malfunctions, my training kicks in. I’m trained in emergency procedures, including using a safety zone, communicating effectively with my team, and knowing how to quickly assess and mitigate the situation. A recent example involved a large branch unexpectedly snapping during a cut, which required immediate action to secure the remaining parts of the tree to prevent further hazards. I quickly reassessed the situation, repositioned myself for safety and proceeded with a modified plan.

- Unexpected Fall: Establish a safety zone and communicate with the team.

- Equipment Malfunction: Follow emergency procedures for safe shutdown and repair/replacement.

- Unforeseen Hazards: Adapt techniques and reassess the situation, prioritizing safety.

Q 11. What safety procedures do you follow when operating a chainsaw?

Chainsaw safety is paramount. I always start by performing a pre-operational check ensuring the chain is sharp, properly tensioned, and the safety features are functioning correctly. I wear appropriate personal protective equipment (PPE), including chainsaw chaps, safety helmet with face shield, gloves, and safety boots. Before each cut, I assess the tree for potential hazards, considering factors such as lean, wind direction, and surrounding obstacles. I always use the proper felling technique, making controlled cuts, and maintaining a safe distance from the falling tree. After each use, I clean and maintain my equipment.

- PPE: Chainsaw chaps, helmet with face shield, gloves, safety boots.

- Pre-operational Check: Chain sharpness, tension, safety features.

- Felling Technique: Controlled cuts, safe distance from falling tree.

- Post-operational Check: Cleaning, maintenance.

Q 12. Describe your experience with different types of felling tools and equipment.

My experience extends to a variety of felling tools and equipment. I’m proficient with various sizes of gas-powered chainsaws, adapted to different tree sizes and felling conditions. I also have experience with hand saws for smaller trees or delicate work. Beyond chainsaws, I utilize wedges and felling levers to aid in controlling the direction of the fall. For larger operations, I’m experienced in utilizing rigging equipment, including ropes, pulleys, and winches for safe and efficient felling.

- Chainsaws: Various sizes and power levels, adapted to different tree sizes and conditions.

- Hand Saws: Used for smaller trees or delicate work.

- Wedges and Levers: Help control the direction of the tree fall.

- Rigging Equipment: Ropes, pulleys, and winches for larger operations.

Q 13. How do you maintain your chainsaw and other equipment?

Regular maintenance is crucial for the longevity and safety of chainsaws and other equipment. After each use, I clean the saw, removing sawdust and debris from the bar and chain. I regularly sharpen the chain using a filing guide to ensure optimal cutting performance and safety. I lubricate the bar and chain with appropriate oil to reduce friction and wear. For larger equipment, I follow manufacturer’s recommendations for maintenance, including regular inspections and servicing. This preventative maintenance ensures the tools are functioning efficiently and safely.

- Cleaning: Remove sawdust and debris.

- Sharpening: Maintain chain sharpness using a filing guide.

- Lubrication: Use appropriate oil for bar and chain.

- Inspections and Servicing: Follow manufacturer’s recommendations.

Q 14. What are your experience levels with different types of saws (e.g., gas, electric)?

I have extensive experience with both gas-powered and electric chainsaws. Gas-powered saws offer more power and are generally preferred for larger trees and demanding conditions, while electric saws are suitable for smaller jobs where noise and emissions are a concern. I’m comfortable with the operational nuances of both types, understanding their strengths and limitations. My familiarity extends to maintaining and troubleshooting issues with both types of saws. I choose the appropriate saw based on the job’s requirements, considering factors like tree size, terrain, and environmental concerns.

- Gas-powered Chainsaws: More power, suitable for larger trees and demanding conditions.

- Electric Chainsaws: Quieter, less emissions, better for smaller jobs.

- Maintenance and Troubleshooting: Experienced in maintaining and troubleshooting both types.

Q 15. What are the key considerations when determining the best felling direction for a tree?

Determining the felling direction is crucial for safe and efficient tree felling. It involves assessing several factors to ensure the tree falls predictably and avoids damage to property or personnel. We consider the tree’s lean, the prevailing wind, obstacles (other trees, power lines, buildings), and the desired landing zone.

- Lean: If a tree leans significantly, the felling direction should be in the direction of the lean. This minimizes the risk of the tree falling the wrong way.

- Wind: Wind can influence the fall path, potentially causing the tree to deviate from the intended direction. Felling should account for wind speed and direction, often choosing a direction that counters the wind’s effect.

- Obstacles: Thorough assessment is critical. A safety zone should be established, free from any obstacles that could be struck by the falling tree or its branches. This often involves a significant distance, depending on the tree’s size and the surrounding terrain.

- Landing Zone: Identifying a safe landing zone is paramount. This zone should be clear, level, and free of obstacles. Consider the terrain—a steep slope might require a different approach than a flat area.

For example, I once had to fell a large oak leaning slightly to the east. A strong westerly wind was blowing. I chose to fell it slightly west of its lean to counter the wind, ensuring it fell safely into a pre-cleared landing area.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the appropriate size and type of wedge for a difficult felling operation?

Selecting the right wedge for a difficult felling operation hinges on understanding the tree’s characteristics and the specific challenges presented. The size and type of wedge depend on factors such as the tree’s diameter, lean, and the presence of any obstacles.

For example, a large, heavily leaning tree might require the use of multiple wedges to assist in guiding the fall. We might start with a small, blunt wedge to create an initial opening, then gradually introduce larger, sharper wedges to encourage the controlled fall.

- Size: The wedge’s size should be proportional to the tree’s diameter. A wedge that’s too small will be ineffective, while one that’s too large might damage the tree’s bark unnecessarily or cause it to split unpredictably.

- Type: Different types of wedges are available, each serving a specific purpose. Blunt wedges are used for initial opening, while sharper wedges provide more precise control of the felling direction. For instance, we could use a combination of a blunt wedge and a pair of ‘dutchman’ wedges to effectively direct the fall.

Proper wedge placement is crucial. Improper placement can lead to unpredictable results, and in severe cases, could cause the tree to fall unexpectedly and dangerously.

Q 17. Explain your understanding of felling and bucking regulations and safety standards.

Felling and bucking regulations and safety standards are paramount in our industry, focusing on the safe handling of powered equipment and the prevention of accidents. These regulations are governed at both the national and local levels, often incorporating guidelines from organizations like OSHA (Occupational Safety and Health Administration). Key aspects include:

- Personal Protective Equipment (PPE): This includes helmets, safety glasses, hearing protection, high-visibility clothing, chainsaw chaps, and steel-toe boots.

- Safe Operating Procedures for Chainsaws: Proper use, maintenance, and pre-operational checks are strictly enforced.

- Pre-felling Assessment: A thorough assessment of the tree, surrounding terrain, and potential hazards must be conducted before each felling operation.

- Emergency Procedures: Emergency response plans and communication protocols are crucial in case of accidents.

- Debris Management: Regulations address safe removal and disposal of brush, branches, and other debris resulting from felling and bucking operations.

- Environmental Regulations: These vary by location and might concern matters like erosion control and protection of sensitive habitats.

Non-compliance can lead to severe penalties, including fines and operational shutdowns. Regular training and adherence to safety protocols are integral to minimizing risks and ensuring a safe work environment.

Q 18. What is your experience with timber scaling and measurement techniques?

My experience with timber scaling and measurement techniques is extensive. Accurate scaling is essential for determining timber volume and value. I’m proficient in various methods, including:

- Scribing (or scaling): This involves marking the log’s dimensions on its surface before calculating its volume. This approach can vary based on the species and the intended use.

- Using a scaling stick or diameter tape: I use these to measure the diameter of logs at both ends to calculate volume using appropriate formulas, such as Smalian’s formula.

- Volume tables: These pre-calculated tables utilize species-specific factors to estimate the volume based on diameter and length. They provide a quick way to make an estimate.

- Electronic scaling tools: I am familiar with advanced electronic tools that automate the measurement and calculation process, increasing efficiency and precision.

The choice of method depends on the situation, the available equipment, and the desired level of accuracy. In practice, I often combine multiple methods to verify measurements and ensure accuracy. For instance, I might use a diameter tape to measure the log and then cross-reference my findings using a volume table to validate the estimated timber quantity.

Q 19. Describe your experience working in a team environment.

Teamwork is essential in felling and bucking. I’ve worked extensively in collaborative environments, both in small crews and larger logging operations. My role often involves coordinating tasks, providing guidance to less experienced team members, and ensuring everyone adheres to safety protocols.

I’m adept at communicating effectively, listening attentively to team members’ concerns and suggestions, and making sure everyone feels heard and respected. A shared understanding of the tasks, hazards, and our collective roles are crucial. In the past, this has involved daily safety briefings, sharing of knowledge, and mutual support during complex operations. For instance, on one project, my experience with advanced felling techniques allowed me to guide the team in safely felling a particularly challenging cluster of trees near power lines.

Clear communication, mutual respect, and collaborative problem-solving are crucial ingredients to ensure the safe and effective execution of logging operations.

Q 20. How do you prioritize safety during both felling and bucking operations?

Safety is my top priority. It’s a non-negotiable aspect of every felling and bucking operation. My approach emphasizes a proactive, multi-layered safety system:

- Pre-operation planning: This begins with a thorough risk assessment of the area, including the tree’s condition, surrounding obstacles, and weather conditions.

- Proper PPE: Wearing appropriate personal protective equipment is mandatory.

- Safe operating practices: Following prescribed procedures for chainsaw operation, including proper starting and stopping techniques and the use of safety devices like the chain brake.

- Clear communication: Maintaining clear communication among team members during operations is paramount to avoid accidents. This is done through designated hand signals and vocal communication.

- Emergency preparedness: Having a well-defined emergency response plan and the necessary emergency equipment.

- Regular maintenance: Ensuring all equipment, including chainsaws, is properly maintained and checked before each use.

Safety isn’t just a checklist; it’s a mindset. I consistently assess and adjust my approach to mitigate potential risks, fostering a culture of safety within the team.

Q 21. How do you communicate effectively with your team members during logging operations?

Effective communication is crucial for safe and efficient logging operations. It involves a combination of methods tailored to the situation. I primarily use a combination of:

- Visual Communication: Hand signals are essential, especially in noisy environments, to convey information quickly and unambiguously. We use a standardized set of hand signals for communicating directions, warnings, and status updates.

- Verbal Communication: Clear and concise verbal instructions are essential, especially during complex felling operations. I use simple, direct language, avoiding jargon whenever possible, ensuring everyone understands their roles and responsibilities.

- Pre-Operation Briefings: Before commencing work, we conduct briefings to review the day’s plan, potential hazards, and communication procedures. This ensures everyone is on the same page.

- Regular Check-ins: During prolonged operations, frequent check-ins ensure everyone’s safety and morale, enabling swift problem-solving and prompt response to unforeseen circumstances.

Open communication, mutual respect, and active listening contribute to building trust and ensuring everyone feels comfortable raising concerns or reporting potential hazards. It is imperative that everyone feels empowered to raise safety concerns.

Q 22. What is your experience with first aid and emergency response procedures?

First aid and emergency response are paramount in forestry. I’m certified in Wilderness First Responder, and I’ve refreshed my training annually for the past ten years. This includes handling various injuries, from minor cuts and sprains to more serious situations like broken bones or traumatic injuries. My training encompasses stabilizing patients, calling for emergency medical services, and providing immediate care until professional help arrives.

For example, I once had to treat a colleague who suffered a severe laceration to his leg from a falling branch. I immediately applied pressure to stop the bleeding, cleaned the wound as best I could, and splinted his leg to prevent further injury before calling for emergency assistance. Knowing how to effectively manage a scene, communicate clearly with emergency services, and provide basic life support is crucial for the safety of the team.

- Emergency response protocol: Includes assessing the situation, prioritizing injuries, securing the scene, communicating with emergency services, providing first aid and monitoring until professionals arrive.

- First Aid Kits: Always carry a fully stocked, and regularly inspected, first-aid kit on my person, including tourniquets, bandages, antiseptic wipes, and pain relievers.

Q 23. How do you handle challenging or difficult trees?

Challenging trees require careful assessment and a tailored approach. Factors like leaning trees, trees with defects (rot, cavities), or trees in confined spaces necessitate advanced techniques. I utilize a combination of visual inspection, specialized tools, and appropriate felling strategies.

For instance, when dealing with a leaning tree near a power line, I’d first assess the lean, wind direction, and the tree’s structural integrity. I’d then use directional felling techniques, employing wedges and possibly a winch to control the fall and prevent damage to the power line. This may involve using a specific felling cut to direct the tree’s fall away from the power line, or cutting the tree in sections to reduce its weight and improve control.

- Specialized techniques: These include using wedges, felling levers, winches, and specialized rigging equipment for complex situations.

- Hazard tree assessment: Thorough evaluation of the tree’s condition, surroundings, and potential risks before commencing any felling operation.

Q 24. Describe your knowledge of different tree species and their properties.

Knowing tree species is fundamental. Different species have varying wood densities, grain patterns, and branching structures, which significantly impact felling techniques. For example, a brittle species like a Pine is more prone to breakage during felling compared to a more flexible species like an Oak. I have extensive knowledge of various species native to this region, including their strength, susceptibility to decay, and growth habits. This knowledge influences my choice of cutting techniques, safety precautions, and equipment selection.

- Hardwoods vs. Softwoods: Understanding the difference in wood density and structure is essential in choosing appropriate cutting methods and equipment.

- Species identification: Ability to identify various tree species by their bark, leaves, and overall shape.

- Wood properties: Understanding how different wood properties, such as grain orientation and moisture content, affect felling and bucking operations.

Q 25. How do you assess the risk of falling limbs or debris during felling operations?

Assessing risk involves a systematic approach. I visually inspect the tree for dead or weak branches, signs of decay, and potential hazards like broken limbs hanging precariously. I also assess the surrounding area for obstacles that may be impacted by falling debris, such as buildings, power lines, or other trees. Weather conditions, like wind speed and direction, are also crucial factors that influence risk assessment.

For instance, before felling a large tree near a residential area, I would inspect the canopy carefully for any loose or dead branches. I would then determine a safe fall zone, clearing the area of obstructions and ensuring a safe escape route for myself and my team.

- Visual inspection: A thorough examination of the tree and surrounding area to identify potential hazards.

- Weather monitoring: Checking wind speed and direction to mitigate the risk of unpredictable falls.

- Fall zone assessment: Identifying and clearing the fall zone of any obstacles that could be damaged or cause injury.

Q 26. Explain the importance of pre-felling planning and site preparation.

Pre-felling planning is non-negotiable for safety and efficiency. This involves a thorough site assessment, determining the felling direction, planning escape routes, and communicating with the team. Site preparation includes clearing the fall zone of any obstacles and marking the felling direction. For large operations, this might even include creating access roads and designating staging areas.

For example, before felling a large group of trees, I would first create a detailed map of the area, identifying each tree’s location, size, and lean. I would then determine the safest felling direction for each tree, considering potential hazards and obstructions. I would ensure that my team and I have designated safe zones and escape routes, clearly communicated with each other, and followed all safety procedures before commencing work.

- Site survey and mapping: Detailed assessment of the work area to identify potential hazards.

- Escape route planning: Pre-planning escape routes in case of emergency.

- Communication plan: Establishment of a clear communication strategy between team members.

Q 27. What measures do you take to prevent damage to surrounding property during felling operations?

Preventing property damage involves careful planning and execution. This includes choosing the appropriate felling direction, utilizing specialized equipment like winches or grapples for precise control, and taking extra precautions near structures. I’d use directional felling techniques to control the tree’s fall away from buildings, fences, or other valuable property.

Suppose I needed to fell a tree near a house. I would carefully choose the felling direction to ensure the tree falls away from the house, and I would use wedges or a winch to fine-tune the tree’s path. I would also ensure the area around the house is clear of any debris that could be dislodged during the fall.

- Directional felling: Using specific techniques to control the direction of the falling tree.

- Equipment use: Using appropriate equipment such as winches or grapples for added control and precision.

- Protective measures: Using protective barriers, such as tarps or mats, to shield property from damage.

Q 28. Describe your experience with using any specialized equipment for felling and bucking (e.g., grapple, winch)

I’m proficient in using various specialized equipment, including grapples, winches, and felling heads. Grapples are invaluable for handling bucked logs, ensuring safe and efficient movement of timber. Winches provide precise control during felling, particularly when dealing with large or leaning trees in confined spaces. Felling heads are highly efficient for rapid bucking and processing, significantly increasing productivity.

For example, when working on a steep slope, a grapple is crucial for safely moving logs to a loading area without endangering personnel or causing further ground instability. A winch can be essential for controlling the fall of a large leaning tree near power lines, allowing for gradual and precise lowering.

- Grapple operation: Safe and efficient use of grapples for moving logs and timber.

- Winch operation: Precise control of tree falls using winches.

- Felling head operation: Efficient use of felling heads for processing timber.

Key Topics to Learn for Felling and Bucking Trees Interview

- Tree Identification and Assessment: Understanding different tree species, their growth patterns, and identifying potential hazards (disease, decay, etc.) before felling.

- Felling Techniques: Mastering various felling methods (e.g., directional felling, notch cuts, back cuts) based on tree size, location, and surrounding obstacles. Practical application includes understanding the importance of escape routes and safe working distances.

- Safety Regulations and Procedures: Deep understanding of OSHA (or relevant regional) safety standards for tree felling, including personal protective equipment (PPE) use and hazard identification/mitigation.

- Bucking Techniques: Efficient and safe methods for cutting felled trees into manageable lengths for transport, considering wood grain and potential hazards.

- Equipment Operation and Maintenance: Safe and proficient use of chainsaws, wedges, and other relevant equipment. Understanding preventative maintenance and troubleshooting common issues.

- Environmental Considerations: Minimizing environmental impact through responsible felling practices, including considerations for soil erosion and wildlife habitats.

- Problem-Solving and Decision-Making: Ability to assess complex situations, identify potential risks, and make sound, timely decisions in dynamic work environments. This includes adapting techniques to unpredictable situations (e.g., unforeseen obstacles, changing weather conditions).

Next Steps

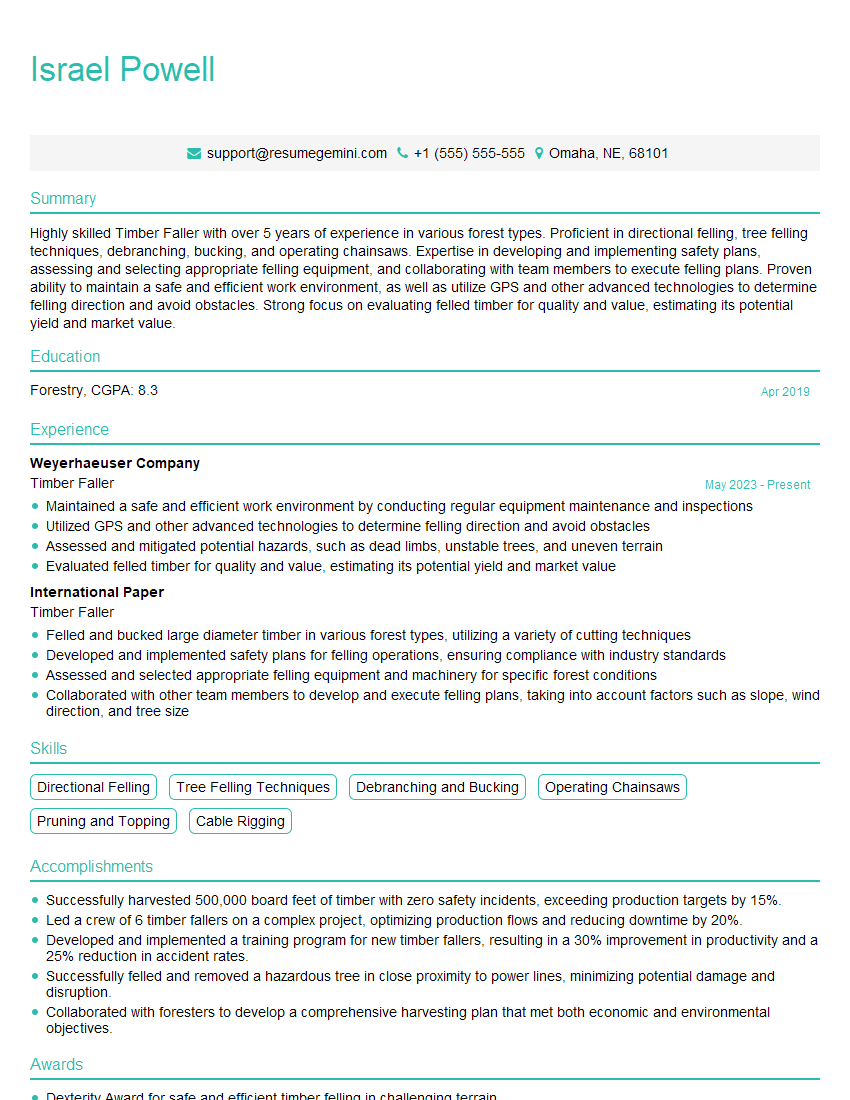

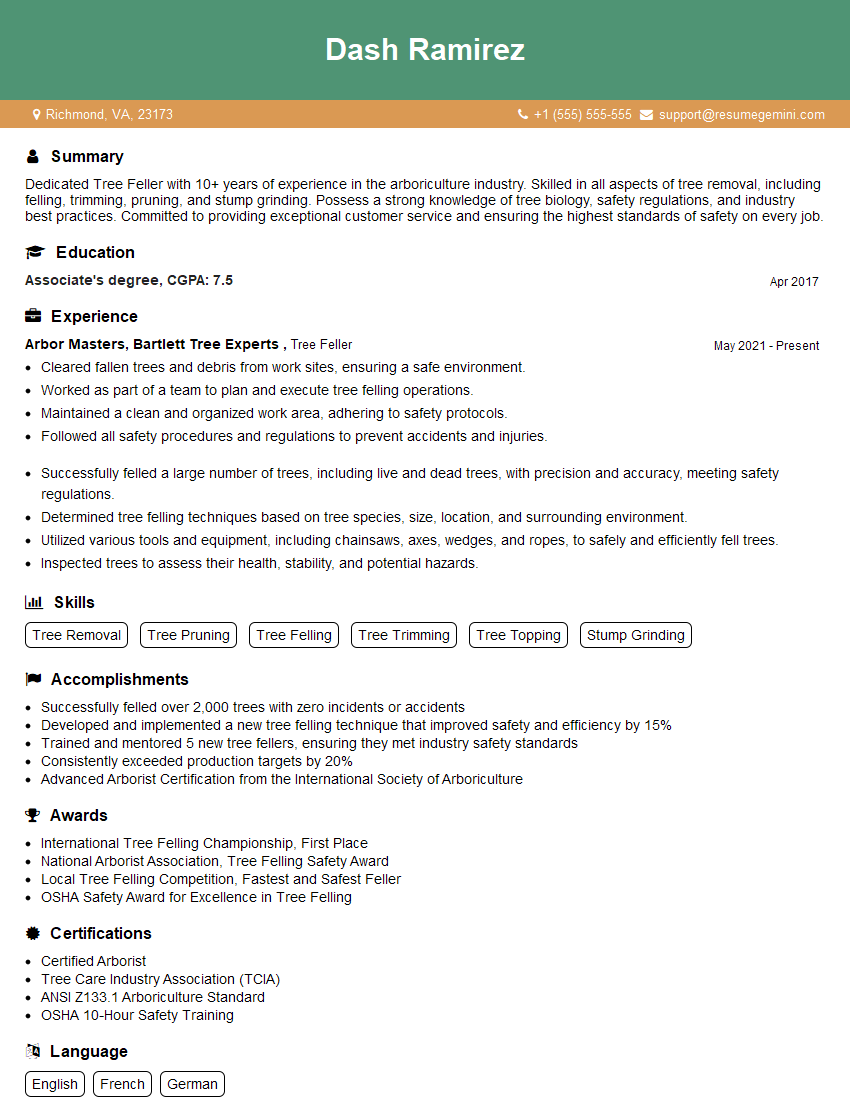

Mastering the skills of felling and bucking trees opens doors to a rewarding and challenging career in forestry, arboriculture, or related fields. A strong understanding of these techniques will significantly enhance your job prospects and earning potential. To maximize your chances of securing your ideal role, creating a professional, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you craft a compelling resume that highlights your skills and experience effectively. Examples of resumes tailored to Felling and Bucking Trees are available within ResumeGemini to help guide your creation of a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good