Are you ready to stand out in your next interview? Understanding and preparing for Operating Chainsaws and Other Timber Harvesting Equipment interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Operating Chainsaws and Other Timber Harvesting Equipment Interview

Q 1. Describe the different types of chainsaws and their applications.

Chainsaws come in various types, each designed for specific applications. The primary categories are based on engine type and bar length.

- Gasoline-powered chainsaws: These are the most common type, offering high power and versatility for various tasks, from felling large trees to limbing and bucking. Their power-to-weight ratio makes them ideal for professional use. Subcategories include professional, homeowner, and farm models, differing mainly in engine size and features.

- Electric chainsaws: These are quieter and cleaner than gasoline models, making them suitable for residential use and smaller projects. However, their power is limited by the cord length, making them less suitable for extensive felling work in remote locations. They are further divided into corded and cordless (battery-powered) varieties.

- Pneumatic chainsaws: These are primarily used in industrial settings, often for specialized applications requiring high power and continuous operation. They are powered by compressed air and are commonly found in sawmills or large-scale timber operations.

Bar length is another crucial factor. Shorter bars (under 16 inches) are ideal for pruning and smaller tasks, while longer bars (20 inches and above) are necessary for felling large trees and processing larger logs. The choice of chainsaw depends heavily on the type of work, the size of trees, and the working environment.

Q 2. Explain the proper techniques for felling a tree.

Felling a tree safely and efficiently involves a systematic process. Think of it like a surgical operation – precise and planned.

- Assess the tree: Check for lean, dead branches, decay, and surrounding obstacles. Wind direction and speed are crucial considerations.

- Plan the escape route: Always identify two escape routes at a 45-degree angle from the planned fall line. Clear the area around the tree of obstacles.

- Make the felling cut: Begin with the notch cut – a V-shaped cut made on the side of the tree where you want it to fall. This provides a hinge to guide the tree’s direction. Follow this with the felling cut, made on the opposite side of the notch, leaving a hinge of sufficient width.

- Control the fall: As the tree begins to fall, step back along your escape route. Never stand directly behind the felling cut.

- Limbing and Bucking: After the tree falls, limb the branches and cut the trunk into manageable lengths (bucking).

Proper technique ensures a clean and controlled fall, minimizing risk to the operator and surrounding property.

Q 3. How do you assess the risk of tree fall and ensure worker safety?

Risk assessment in tree felling is paramount. It’s not just about looking at the tree; it’s about understanding the entire environment.

- Tree inspection: Look for signs of decay, disease, lean, dead branches, and insect infestation. A damaged tree is more likely to fall unpredictably.

- Site assessment: Consider the terrain, proximity to power lines, buildings, or other obstacles. Strong winds can greatly increase the risk.

- Weather conditions: Wind speed and direction are critical. High winds can make a tree fall uncontrollably.

- Soil conditions: Wet or unstable soil can increase the risk of the tree uprooting and falling unexpectedly.

Worker safety is ensured by using proper personal protective equipment (PPE) including helmets, eye protection, chaps, gloves, and steel-toed boots. Clear communication among the felling crew is vital, ensuring everyone understands their roles and responsibilities.

Using a qualified arborist for complex situations, especially those involving large or potentially dangerous trees, is highly advisable.

Q 4. What are the safety regulations and procedures for operating chainsaws?

Chainsaw safety regulations and procedures are stringent and vary by region but generally include:

- Training and certification: Many jurisdictions require training and certification for professional chainsaw operators.

- PPE: Always wear appropriate PPE, including chaps, helmets, eye and ear protection, and gloves.

- Proper maintenance: Ensure the chainsaw is properly maintained and in good working order.

- Safe operating practices: Follow all manufacturer’s instructions, maintain a firm grip on the saw, and never operate it while fatigued or under the influence of drugs or alcohol.

- Emergency procedures: Have a plan in place in case of an accident or emergency, and ensure first-aid supplies are readily available.

- Environmental considerations: Be mindful of the environment and follow regulations for tree felling and waste disposal.

Ignoring these procedures can lead to severe injury or death.

Q 5. Describe the maintenance procedures for chainsaws and other harvesting equipment.

Regular maintenance is essential for optimal performance and safety.

- Chain sharpening: Sharpen the chain regularly using a chainsaw file or sharpening tool. A dull chain requires more force, increases kickback risk, and reduces cutting efficiency.

- Bar lubrication: Ensure the bar is properly lubricated to prevent overheating and damage.

- Air filter cleaning: Clean or replace the air filter regularly to ensure proper engine combustion.

- Spark plug inspection: Check and clean or replace the spark plug as needed. A fouled spark plug can lead to poor engine performance.

- Fuel and oil levels: Always maintain proper fuel and oil levels to prevent engine damage.

For other harvesting equipment (e.g., feller bunchers, skidders), maintenance schedules are often more complex and usually outlined in the equipment’s manual. These often involve regular inspections of hydraulic systems, tracks or wheels, and engine components.

Q 6. How do you identify and address potential mechanical issues with a chainsaw?

Identifying and addressing chainsaw mechanical issues requires a systematic approach.

- Difficult starting: This could indicate a problem with the spark plug, fuel system, or air filter.

- Poor performance: Check the air filter, spark plug, fuel mixture, and chain sharpness.

- Excessive vibration: This might signal a loose component, worn bearings, or chain tension problems.

- Chain kickback: This is often caused by a dull chain or improper cutting technique.

- Engine overheating: This could be due to insufficient bar lubrication or a clogged air filter.

Always refer to the chainsaw’s manual for troubleshooting guidance. For more complex issues, consult a qualified chainsaw mechanic.

Q 7. Explain the different types of harvesting equipment and their uses.

Timber harvesting equipment encompasses a range of specialized machines designed for various stages of the process.

- Feller bunchers: These machines cut and gather trees, creating bundles for easier processing.

- Harvesters: These combine felling, limbing, and bucking operations into a single machine, significantly increasing efficiency.

- Skidders: These machines are used to transport felled trees from the harvesting site to a landing area.

- Forwarders: These machines are used to transport the harvested timber from the landing area to the roadside.

- Processors: These machines further process the logs, such as debarking or cutting them into specific lengths.

The choice of equipment depends on factors such as terrain, tree size, timber volume, and operational scale. Large-scale operations often utilize a combination of machines for optimized productivity.

Q 8. What are the advantages and disadvantages of different felling techniques?

Felling techniques vary depending on tree size, location, and surrounding obstacles. The most common techniques are the open face felling, the hinged felling, and the directional felling. Each has its advantages and disadvantages.

- Open Face Felling: This involves cutting a notch on one side of the tree and then making a back cut to fell it in a chosen direction. Advantages: Relatively straightforward for smaller trees. Disadvantages: Less control over felling direction, especially with larger trees, and increased risk of kickback.

- Hinged Felling: This method involves creating a hinge on the back of the tree, allowing for more precise control over the direction of the fall. Advantages: Offers greater control and precision, reducing the risk of kickback and tree damage. Disadvantages: Requires more skill and experience to execute correctly.

- Directional Felling: This is a more advanced technique, often utilizing wedges and specialized equipment to control the felling direction with extreme precision, crucial when working near obstacles. Advantages: Maximum control in challenging situations. Disadvantages: Requires specialized equipment and high level of expertise.

The choice of technique depends on a risk assessment which involves evaluating the tree, its surroundings, and the prevailing weather conditions. For example, in a dense forest, hinged felling is preferred to minimize damage to neighboring trees.

Q 9. How do you determine the appropriate felling direction for a tree?

Determining the appropriate felling direction is crucial for safety and efficiency. It’s a process involving several considerations.

- Assess the Tree: Examine the tree for lean, wind sway, and potential weaknesses. A leaning tree should be felled in the direction of its lean whenever possible.

- Analyze the Surroundings: Identify potential obstacles such as other trees, power lines, buildings, or bodies of water. The felling direction should avoid these obstacles.

- Consider Wind Direction and Speed: Wind can significantly influence the tree’s fall, so felling direction should account for this. Ideally, fell downwind to minimize the risk of the tree being blown unexpectedly.

- Escape Path Planning: Plan a clear escape route—45 degrees to the rear of the felling direction—to quickly get away from the falling tree.

- Use Felling Indicators: Utilize markers (paint, flagging tape) to clearly indicate the intended felling direction.

I always prioritize safety. For example, if there’s a risk of the tree falling on a power line, I would immediately contact the utility company and halt the operation until it’s declared safe.

Q 10. Describe your experience with using personal protective equipment (PPE) in forestry operations.

Personal Protective Equipment (PPE) is non-negotiable in forestry operations. My experience includes consistent and rigorous use of:

- Hard Hat: Protecting against falling branches and debris.

- Safety Glasses/Face Shield: Shielding my eyes and face from flying debris and sawdust.

- Hearing Protection: Chainsaws are incredibly loud, and hearing loss is a real risk. I always use earplugs or earmuffs.

- Chainsaw Chaps/Protective Clothing: These garments protect my legs and torso from chainsaw cuts. Regular checks for damage and replacements when needed are crucial.

- Gloves: Protecting my hands from cuts and blisters.

- Steel-Toed Boots: Protecting my feet from falling objects and sharp debris.

I always inspect my PPE before each shift to ensure it’s in good condition. If any item is damaged or shows signs of wear, it’s immediately replaced. This proactive approach to PPE significantly reduces risk of injury.

Q 11. Explain your experience with pre-harvest planning and site preparation.

Pre-harvest planning and site preparation are crucial for efficient and safe timber harvesting. My experience includes:

- Site Assessment: This detailed evaluation includes tree species identification, tree size and density, terrain analysis, and identification of hazards such as streams, wetlands, power lines and other obstacles.

- Layout Planning: Determining the most effective harvesting methods and creating detailed maps indicating felling directions, skid trails, and landing areas.

- Road and Trail Construction/Maintenance: Building or improving access roads and skid trails to safely move timber out of the harvesting area. This planning takes into account the terrain to minimize environmental impact and erosion.

- Environmental Protection Planning: Measures to protect water quality, sensitive ecosystems, and wildlife are incorporated into all plans.

- Hazard Identification and Mitigation: Identifying and mitigating potential hazards, such as unstable trees, difficult terrain, and weather conditions, are critical components of safety planning.

For instance, in one project, careful planning of skid trails minimized soil erosion by strategically positioning them to avoid sensitive areas. This resulted in a significantly lower environmental impact.

Q 12. How do you handle unexpected situations or emergencies during timber harvesting?

Unexpected situations are part of forestry work. My approach is based on preparedness and rapid response. Examples include:

- Tree Falling Unexpectedly: Immediate evacuation to the pre-planned escape route. Following the incident, a thorough investigation to identify and correct the cause.

- Equipment Malfunction: Secure the immediate area, shut down the equipment, and conduct a careful inspection. Minor repairs may be attempted, but for significant issues, contacting support/maintenance is critical.

- Weather-Related Emergencies: Immediate evacuation of the site if severe weather (e.g., thunderstorms, high winds) develops. Operations are only restarted after confirming the weather is safe.

- Injury: First aid is administered immediately, and emergency medical services are contacted. The incident is reported, and a thorough investigation is undertaken to prevent recurrence.

Regular training and communication are key to handling emergencies. My team and I regularly practice emergency procedures.

Q 13. Describe your experience with using GPS and mapping technology in forestry operations.

GPS and mapping technologies have revolutionized forestry operations. My experience includes using GPS devices and GIS software for:

- Precise Location Mapping: Mapping trees for efficient harvesting and minimizing waste.

- Inventory Management: Tracking timber volume and species for accurate reporting and sales.

- Planning and Layout: Creating precise harvesting plans, including road layouts, felling directions, and skid trails.

- Boundary Determination: Precisely defining property boundaries to avoid accidental harvesting on neighboring land.

- Post-Harvest Assessment: Assessing the effectiveness of harvesting operations and evaluating environmental impacts.

For example, using GIS, I’ve created detailed maps showing the optimal route for skid trails, minimizing environmental damage and maximizing harvesting efficiency. This resulted in lower operational costs and less disturbance to the forest ecosystem.

Q 14. How familiar are you with different types of wood and their properties?

Knowledge of different wood types and their properties is fundamental. My experience encompasses the identification and properties of numerous species, including their:

- Strength and Durability: Different woods are suited for various applications (e.g., construction, furniture).

- Workability: Some woods are easier to cut, shape, and finish than others.

- Density: Affecting weight and strength.

- Grain Patterns: Influencing appearance and workability.

- Susceptibility to Decay and Pests: Choosing appropriate species for specific outdoor applications.

This knowledge is vital for selecting appropriate harvesting techniques and ensuring the timber is used effectively. For instance, knowing the different properties of Douglas Fir versus Pine allows me to determine the most suitable cutting techniques and recommend the best applications for the harvested timber.

Q 15. Describe your experience with using skidders and forwarders.

My experience with skidders and forwarders spans over 15 years, encompassing various terrains and timber types. Skidders, primarily used for dragging logs, require a keen understanding of terrain management to prevent ground damage and maximize efficiency. I’m proficient in operating both cable and grapple skidders, adapting my technique to the specific conditions – using a cable skidder for steeper slopes and dense undergrowth, and a grapple skidder for easier terrain and larger log volumes. Forwarders, on the other hand, are used for loading and transporting logs directly to a landing area, minimizing ground disturbance compared to skidders. I’m experienced in operating both wheeled and tracked forwarders, understanding the benefits and limitations of each type. For example, wheeled forwarders are faster on well-maintained roads, while tracked forwarders excel in challenging, muddy conditions. My expertise lies in optimizing the coordinated use of skidders and forwarders to create a smooth and efficient logging workflow. This includes strategic placement of landing areas, planning routes to minimize damage, and effective communication with the felling crew to ensure a steady supply of logs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with log loading and transportation?

Log loading and transportation are critical components of timber harvesting, demanding precision and safety. My experience involves operating various types of loading equipment, including loaders, grapple cranes, and knuckleboom loaders. I understand the importance of load distribution and securing logs to prevent shifting during transportation. This includes proper lashing techniques and compliance with weight limits. I’ve worked with various transportation methods, from truck trailers to specialized log trucks, and have experience in managing the logistical aspects of getting logs from the harvesting site to the mill. For example, in one project, we had to navigate challenging mountain roads, requiring careful planning of truck routes and load sizes to maintain safety and avoid delays. Accurate load planning and efficient communication with drivers are paramount to prevent accidents and maximize transport efficiency.

Q 17. How do you ensure the efficiency and productivity of timber harvesting operations?

Efficiency and productivity in timber harvesting are achieved through careful planning and execution. This starts with meticulous pre-harvest planning, including site assessments, road design, and the selection of appropriate harvesting techniques. Effective crew management is crucial; clear communication, proper training, and the right equipment assignments are essential. Regular equipment maintenance is non-negotiable. Preventive maintenance prevents downtime and ensures optimal performance. Real-time data tracking is another key component. Using technology to monitor productivity, fuel consumption, and machine performance helps identify areas for improvement. For instance, implementing GPS tracking on equipment allows for better route planning, minimizing travel time and fuel consumption. Finally, continuous evaluation and adaptation are key. Regularly reviewing performance metrics and adjusting strategies based on data analysis is critical for achieving continuous improvement.

Q 18. What are the environmental considerations in timber harvesting?

Environmental considerations are paramount in modern timber harvesting. Minimizing soil disturbance is key; this involves careful planning of roads and skid trails, using appropriate equipment, and employing erosion control measures. Protecting water quality is critical. We must avoid contaminating streams and rivers, and implement buffer zones around sensitive waterways. Maintaining biodiversity is another important factor. Selective cutting techniques and the retention of key habitat features can help mitigate the impact on wildlife and plant communities. Carbon sequestration is also becoming increasingly important, considering the role forests play in climate change mitigation. Sustainable harvesting practices, such as minimizing waste and promoting forest regeneration, contribute to this goal. Proper waste management procedures must be in place to deal with debris and unwanted materials.

Q 19. Describe your experience with complying with environmental regulations.

Compliance with environmental regulations is a top priority. I’m thoroughly familiar with federal, state, and local regulations concerning timber harvesting. This includes obtaining all necessary permits and licenses, adhering to strict guidelines on water quality and soil protection, and following procedures for endangered species protection. I’m proficient in using various environmental assessment tools and have extensive experience in preparing and submitting required documentation to regulatory agencies. Maintaining detailed records of harvesting activities, including GPS data and environmental monitoring reports, is crucial for demonstrating compliance. Regularly reviewing and updating my knowledge of evolving regulations ensures our operations remain compliant. For example, I was instrumental in developing and implementing a detailed erosion control plan for a recent project that helped us exceed compliance standards.

Q 20. How do you maintain accurate records and documentation of harvesting activities?

Accurate record-keeping is fundamental for efficient and compliant timber harvesting. I use a combination of digital and paper-based systems to maintain detailed records of all harvesting activities. This includes GPS data from harvesting equipment, daily progress reports, timber volume measurements, and environmental monitoring data. Dedicated logging software and field data collection apps are instrumental for efficient data entry and storage. All records are regularly reviewed and archived to ensure data integrity and facilitate compliance audits. Maintaining clear documentation allows for effective analysis of harvesting operations, identifies areas for improvement, and enables accurate reporting to clients and regulatory agencies. Accurate and comprehensive records are essential for ensuring transparency and accountability throughout the harvesting process. A detailed chain of custody must be followed to track timber from the forest to the mill.

Q 21. What is your experience with different types of cutting techniques?

My experience encompasses a variety of cutting techniques, each tailored to specific forest conditions and objectives. I’m proficient in clearcutting, shelterwood cutting, selection cutting, and seed-tree cutting. Clearcutting, while sometimes controversial, is appropriate in certain situations, and when done properly minimizes the risk of future fires and maximizes efficiency. Shelterwood and selection cutting are better suited for preserving forest biodiversity and maintaining ecological balance. Seed-tree cutting involves leaving a small number of seed-bearing trees to promote natural regeneration. The choice of technique is dictated by factors such as the age and type of forest, desired regeneration patterns, and environmental considerations. In all cases, safety is paramount, and proper planning is crucial to minimize damage to the surrounding environment and maintain the overall health of the forest.

Q 22. How do you manage fuel and lubrication for chainsaws and other equipment?

Proper fuel and lubrication are paramount for chainsaw and equipment longevity and safe operation. Think of it like keeping a car running smoothly – neglecting it leads to breakdowns and potential danger.

Fuel: I always use fresh, high-quality fuel, specifically designed for two-stroke engines. Mixing fuel and oil in the correct ratio according to the manufacturer’s specifications is crucial. Using the wrong mix can severely damage the engine. I meticulously check the fuel level before each use and avoid storing fuel for extended periods, as it can degrade.

Lubrication: Chainsaws require regular bar and chain lubrication. This is achieved through an automatic oiler system which needs regular inspection and adjustments. I make sure there’s sufficient oil in the reservoir and that the oiler is functioning correctly; a poorly lubricated chain can overheat, break, or cause kickback. I also lubricate all moving parts of other equipment as per the manufacturer’s maintenance schedule, using the recommended lubricants.

Storage: I store fuel and oil in properly sealed containers away from heat sources and sparks, to prevent fire hazards. Equipment is stored in a dry, clean place, protected from the elements.

Regular cleaning and maintenance, including checking air filters and spark plugs, are also integral parts of fuel and lubrication management.

Q 23. Explain your understanding of bucking and limbing techniques.

Bucking and limbing are essential techniques in timber harvesting, each requiring precision and safety. Think of bucking as cutting the felled tree into manageable lengths and limbing as removing the branches.

Bucking: I use a combination of cuts to fell the tree safely and efficiently, always considering the tree’s lean and the direction of fall. I employ accurate measurements to cut the tree to the desired lengths. Safety is always paramount, and I’m mindful of potential hazards like kickback and pinched saws.

Limbing: Limbing involves removing branches safely and efficiently. It’s essential to make cuts close to the trunk without damaging the valuable part of the log. I use controlled cuts to prevent the saw from getting pinched. I work methodically, starting with the lower branches and working my way up.

Experience allows for rapid assessment of the best bucking and limbing strategies based on tree size, species, terrain and the intended final product. Proper technique minimizes waste and improves efficiency.

Q 24. Describe your experience with working in different terrain conditions.

Working in diverse terrain conditions requires adaptability and specialized techniques. Safety procedures change significantly depending on the slope, undergrowth, and soil type.

Steep Slopes: On steep slopes, I use extra caution, employing felling techniques that consider the direction of the tree’s fall to prevent it from rolling. I always maintain a stable footing, often using safety harnesses and anchor points. I avoid working alone in challenging terrain.

Rocky Terrain: Rocky ground requires careful positioning to avoid stumbling or damaging equipment. I select my cutting position strategically, being mindful of unseen hazards like rocks hidden beneath the leaf litter.

Swampy Areas: Working in swampy areas poses challenges with stability and visibility. I use specialized footwear and may utilize additional support such as platforms or walkways to maintain balance.

My experience enables me to quickly assess risks associated with different terrain conditions and apply appropriate safety measures and operational adjustments.

Q 25. How do you handle and manage waste materials during timber harvesting?

Waste management is critical for environmental responsibility and efficient timber harvesting. It involves the careful handling and disposal of all materials left after harvesting, minimizing environmental impact.

Debris Removal: I collect and remove debris from the harvesting site in an environmentally conscious manner, separating valuable material from waste. Where possible, branches are chipped or shredded for use as mulch or biomass fuel.

Disposal: All waste is disposed of according to local regulations and best practices. This might include burning (under strict permits and safety conditions), chipping, or transporting to a designated disposal site.

Slash Piles: In many situations, creating organized slash piles is more efficient. These are carefully built and monitored to minimize the risk of wildfire. They allow for a more controlled burn or more effective removal in line with local regulations.

Minimizing waste ensures operational efficiency and respects environmental sensitivities.

Q 26. What are your strategies for preventing accidents and injuries?

Accident prevention is the highest priority in timber harvesting. This requires meticulous planning, adherence to safety protocols and a proactive approach.

Personal Protective Equipment (PPE): I consistently use all necessary PPE, including helmets, safety glasses, ear protection, gloves, chainsaw chaps and sturdy boots. This is non-negotiable and forms the foundation of my safety practices.

Pre-Operational Checks: Before starting any work, I meticulously inspect all equipment to ensure it’s in perfect working order, with the chainsaw chain properly sharpened and lubricated.

Safe Work Practices: I adhere strictly to safe work practices, including maintaining awareness of my surroundings, avoiding distractions, and working with a partner whenever possible for mutual support and assistance.

Emergency Preparedness: I am familiar with emergency response procedures and have readily available communication devices.

Constant vigilance and a commitment to safety protocols are essential for preventing accidents and injuries.

Q 27. Describe your experience with using tree climbing equipment (if applicable).

While not always required, my experience includes using tree climbing equipment for specific tasks such as accessing hard-to-reach areas or performing specialized pruning or felling in delicate situations. Safety is paramount when using climbing equipment.

Equipment: I’m proficient in using climbing gear including ropes, harnesses, ascenders, descenders and other specialized equipment.

Techniques: I understand proper climbing techniques such as proper knot tying, safe ascents and descents, and fall arrest systems.

Inspections: Regular inspection and maintenance of all climbing gear is crucial. Any damaged or worn equipment is immediately replaced.

This specialized skill provides versatility and enables me to handle various timber harvesting challenges.

Q 28. How do you ensure the quality of harvested timber?

Ensuring the quality of harvested timber is a multi-stage process that begins before the felling and continues through the extraction and transportation stages. It impacts the final value and usability of the wood.

Selection: Careful selection of trees to be harvested, considering species, size, and quality, is the first step. Damaged or diseased trees are avoided.

Felling and Bucking: Precise felling and bucking techniques minimize damage to the logs. Proper cuts ensure straight, clean logs.

Handling and Transport: Logs are handled carefully to avoid damage during extraction and transport. This includes utilizing proper equipment and minimizing drops or impacts.

Grading: After harvesting, logs are often graded according to size and quality, to determine their best use.

Quality timber is a valuable commodity; careful attention to detail throughout the process maximizes its value.

Key Topics to Learn for Operating Chainsaws and Other Timber Harvesting Equipment Interview

- Chainsaw Operation and Maintenance: Understanding different chainsaw types, safety protocols (including PPE), proper starting and stopping procedures, maintenance schedules (chain sharpening, bar lubrication), and troubleshooting common mechanical issues.

- Felling Techniques: Mastering safe felling techniques for various tree sizes and conditions, including proper notch cuts, felling direction considerations, and hazard tree assessment. Practical application involves understanding the impact of tree lean, wind, and surrounding obstacles.

- Timber Harvesting Equipment: Familiarity with different types of harvesting equipment (feller bunchers, skidders, forwarders, processors) – their operational principles, safety features, and limitations. Understanding the role of each machine within a complete harvesting operation.

- Safety Regulations and Procedures: A comprehensive understanding of relevant safety regulations, emergency procedures, and first aid in relation to chainsaw operation and timber harvesting. This includes knowing how to respond to equipment malfunctions and potential accidents.

- Environmental Considerations: Awareness of sustainable harvesting practices, environmental impact assessments, and adherence to regulations concerning forest management and conservation.

- Log Handling and Transportation: Safe and efficient methods for loading, securing, and transporting logs, considering load stability and relevant transportation regulations.

- Problem-Solving and Decision-Making: Demonstrate the ability to analyze situations, identify potential hazards, and make sound decisions under pressure, especially in unpredictable field conditions.

Next Steps

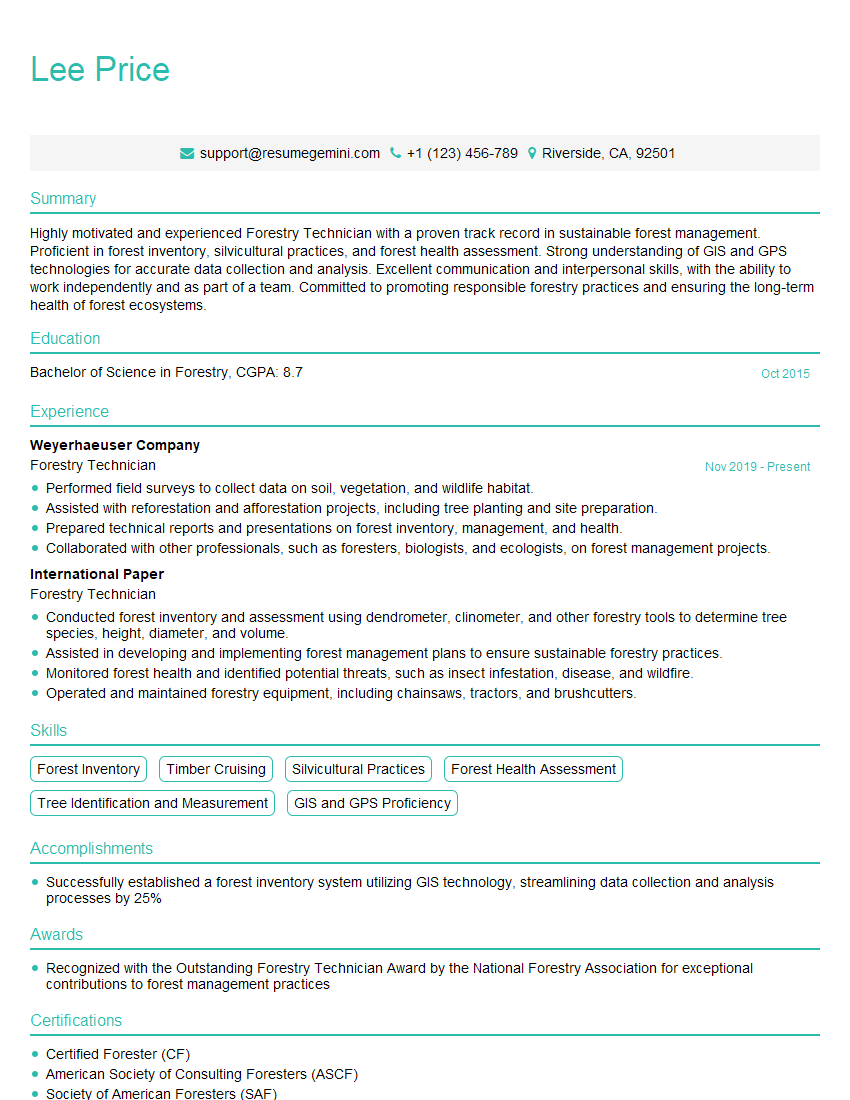

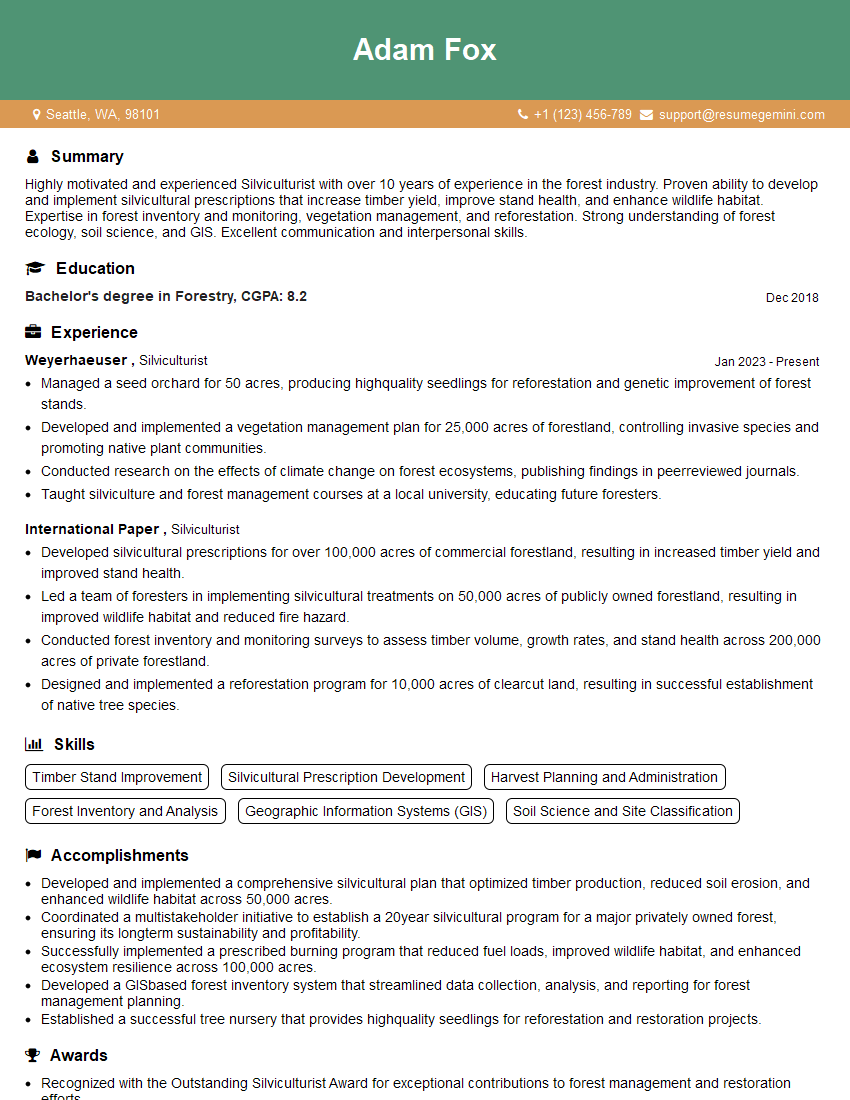

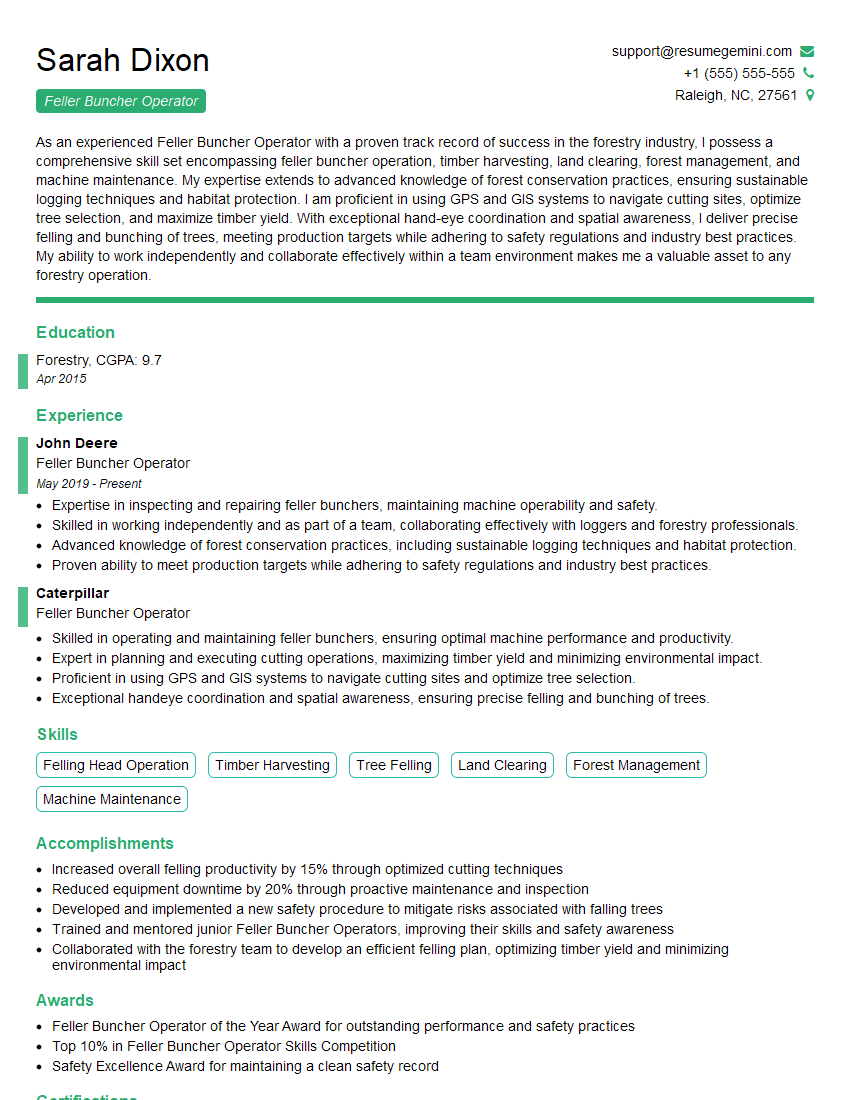

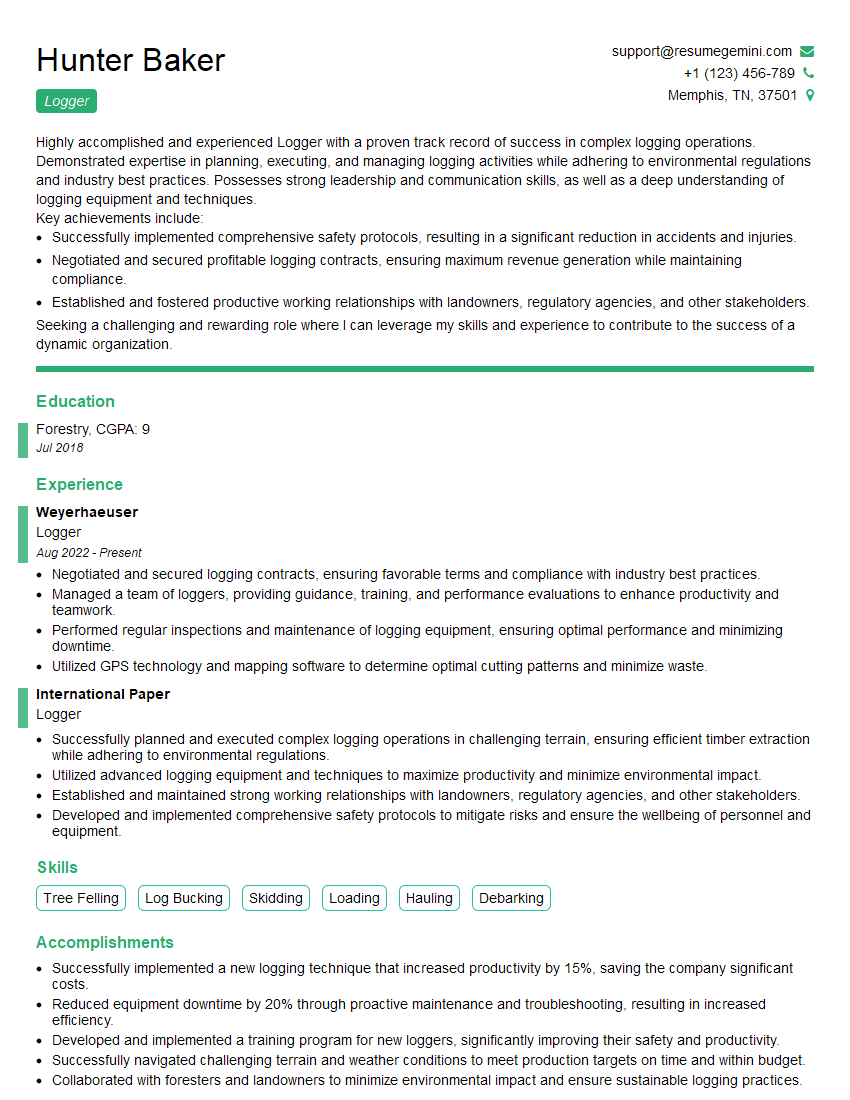

Mastering the operation of chainsaws and other timber harvesting equipment is crucial for career advancement in the forestry and logging industries. It opens doors to higher-paying positions with increased responsibility and opportunities for specialization. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to the Operating Chainsaws and Other Timber Harvesting Equipment field, giving you a head start in presenting your qualifications to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good