Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential ElectroOptical System Maintenance interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in ElectroOptical System Maintenance Interview

Q 1. Explain the principles of optical alignment and collimation.

Optical alignment and collimation are crucial for ensuring that light from a source travels in a precisely controlled manner to its intended destination. Think of it like aiming a laser pointer – you need to adjust it so the beam hits exactly where you want it.

Alignment refers to the process of ensuring all optical components (like lenses, mirrors, and detectors) are positioned correctly relative to each other and the light path. Misalignment leads to reduced signal strength, image distortion, or even complete signal loss. We use tools like precision mounts, adjustable stages, and alignment telescopes to achieve accurate positioning.

Collimation, on the other hand, focuses on ensuring that light rays are parallel to each other. A collimated beam remains focused over long distances, which is vital in applications like laser ranging or long-haul fiber optic communication. We use collimating lenses to achieve parallelism, often verified using specialized techniques like beam profiling to measure beam divergence.

For example, in a telescope, alignment ensures the eyepiece is perfectly centered with the objective lens and the light path, while collimation guarantees a sharp, clear image by ensuring the incoming light rays are parallel before reaching the focal point.

Q 2. Describe your experience troubleshooting malfunctioning electro-optical systems.

My experience in troubleshooting malfunctioning electro-optical systems spans various scenarios, from laser rangefinders to fiber optic communication networks. A systematic approach is key. I start by thoroughly inspecting the system for any obvious physical damage or loose connections. Next, I’ll perform a series of tests, starting with simple checks like verifying power supply voltage and signal levels, then progressing to more complex measurements using oscilloscopes, optical power meters, and spectrum analyzers.

For instance, I once worked on a malfunctioning laser scanner in a manufacturing plant. After checking the power and control signals, I discovered a misaligned laser diode. Using a precision alignment tool, I corrected the misalignment, and the system resumed working flawlessly. Another instance involved a fiber optic link with a significant signal attenuation. By using an optical time-domain reflectometer (OTDR), I pinpointed a micro-bend in the fiber cable that was causing the signal loss. This systematic approach, combined with experience, enables efficient diagnosis and repair.

Q 3. How do you diagnose and repair faulty lasers or laser diodes?

Diagnosing and repairing faulty lasers or laser diodes requires a careful approach, as they are sensitive components. The initial steps are similar to general troubleshooting: check the power supply, inspect for physical damage, and measure the output power with a power meter. A faulty laser might exhibit low power, unstable output, or even complete failure.

To diagnose the problem more precisely, I might use specialized equipment like a laser beam profiler to check beam quality and divergence. If the laser diode itself is faulty, replacing it is often the solution; this requires careful handling to avoid electrostatic discharge (ESD) damage. If the issue is related to the driving circuitry, I would investigate the control signals and check for shorts, open circuits, or incorrect bias currents. Specific tests depend on the type of laser and its application. For instance, in a laser diode used for telecommunications, a spectrum analyzer helps to ensure it’s emitting at the correct wavelength and bandwidth.

Q 4. What are the common causes of signal degradation in fiber optic systems?

Signal degradation in fiber optic systems can stem from several factors, broadly categorized as attenuation and dispersion.

- Attenuation refers to the loss of signal strength as light travels through the fiber. Common causes include fiber imperfections, bending losses (especially micro-bends), and absorption by the fiber material.

- Dispersion is the spreading of the optical pulse as it travels, blurring the signal and reducing its quality. This can be caused by chromatic dispersion (different wavelengths traveling at different speeds) and modal dispersion (different light paths within a multi-mode fiber).

Other causes include connector losses (due to poor polishing or misalignment), splice losses (poor fusion), and external factors like environmental temperature fluctuations. For example, a poorly spliced fiber joint can significantly increase attenuation, while a sharp bend in the fiber can introduce both attenuation and increased dispersion.

Q 5. Explain different types of optical detectors and their applications.

Optical detectors convert light signals into electrical signals, forming the core of many electro-optical systems. Several types exist, each with specific applications:

- Photodiodes: These are highly sensitive devices used in various applications, from light detection and ranging (LiDAR) to optical communication. They’re known for speed and sensitivity. For instance, a PIN photodiode is common in high-speed data communication.

- Phototransistors: Simpler than photodiodes, they offer good sensitivity but are slower. They’re often used in less demanding applications like light switches or simple light sensors.

- Photomultiplier tubes (PMTs): These are highly sensitive detectors capable of detecting even single photons. They are used in low-light applications like astronomy, medical imaging, and scientific research. However, they require a high voltage power supply.

- Avalanche photodiodes (APDs): These offer internal gain, increasing sensitivity, making them suitable for long-haul fiber optic communication where weak signals need amplification.

The choice of detector depends heavily on the specific application’s requirements, considering factors like sensitivity, speed, operating wavelength, and cost.

Q 6. Describe your experience with optical metrology techniques.

My experience with optical metrology techniques involves using precision instruments to measure various optical properties. I have used interferometers for high-precision measurements of surface roughness, optical path differences, and refractive indices. I’ve also used optical power meters and spectrum analyzers to measure light intensity and spectral characteristics respectively.

For example, I used an interferometer to measure the flatness of an optical component during the alignment process of a high-precision laser system. In another project, I employed a spectrum analyzer to ensure that a laser source was emitting at the correct wavelength for a specific communication system. These techniques are essential for ensuring the quality and performance of electro-optical systems.

Q 7. How do you perform routine maintenance on electro-optical equipment?

Routine maintenance of electro-optical equipment is crucial for ensuring its long-term performance and reliability. It typically involves a combination of visual inspections, cleaning, and functional tests.

Visual Inspection checks for any signs of damage, dust accumulation, or loose connections. Cleaning involves carefully removing dust and debris from optical surfaces using appropriate cleaning materials and techniques. This is critical to prevent signal degradation. Functional Tests involve verifying the performance of the system using appropriate test equipment and comparing the results with specifications. This ensures the system meets the required parameters. For example, regular cleaning of optical lenses in a microscope is vital for maintaining image clarity, and periodic checks of the output power of a laser system are necessary to prevent unexpected failures.

The specific maintenance procedures vary depending on the type of equipment and its operating environment, but a consistent and documented maintenance schedule is essential for optimal performance and longevity.

Q 8. What safety precautions do you take when working with lasers?

Laser safety is paramount. My approach is based on the acronym LASER itself: Laser safety glasses are always worn, appropriate to the laser’s wavelength and power. Access to the laser area is strictly controlled; unauthorized personnel are prohibited. Safety protocols, including emergency shut-off procedures, are thoroughly understood and practiced. Enclosures and beam paths are meticulously checked for any damage or misalignment that could cause uncontrolled beam escape. Regular safety training and updates ensure my knowledge remains current and effective. For example, working with a high-power Nd:YAG laser requires specific eye protection rated for 1064 nm, whereas a HeNe laser demands different eyewear. Any maintenance involving laser alignment necessitates the use of beam blockers to prevent accidental exposure.

Q 9. Describe your experience with thermal imaging systems and their maintenance.

I have extensive experience maintaining various thermal imaging systems, from handheld units to large, sophisticated systems used for building inspections or even research. My work includes preventative maintenance, such as cleaning lenses and sensor elements with appropriate cleaning solutions to avoid scratching. I regularly check the system’s calibration and perform adjustments as needed, often using blackbody calibration sources. Troubleshooting involves analyzing thermal images for anomalies like inconsistent temperature readings or image artifacts which can signal sensor degradation or problems within the electronics. For example, I once resolved an issue with a thermal camera that exhibited banding in its images by tracing the problem to a faulty cooling system component. Replacing that component restored the image quality.

Q 10. How do you ensure the accuracy and precision of electro-optical measurements?

Accuracy and precision in electro-optical measurements are crucial. This is achieved through a multi-pronged approach. Firstly, proper calibration is essential, using traceable standards and following strict procedures. This includes using certified calibration equipment and documenting every step of the process. Secondly, environmental factors like temperature and humidity can impact measurements, therefore, these factors are carefully controlled or compensated for. Thirdly, the use of appropriate measurement techniques and instrumentation is vital; choosing the correct sensors and ensuring they are properly configured and maintained. Finally, thorough data analysis and uncertainty estimation help determine the reliability of the measurements. For instance, when measuring the intensity of a light source, I’d use a calibrated photometer under controlled lab conditions and perform multiple measurements to reduce the impact of random errors.

Q 11. Explain your understanding of different types of optical lenses and their properties.

Optical lenses are the heart of many electro-optical systems. They come in various types, each with unique properties.

- Refractive lenses, like those found in cameras, use the bending of light to focus images. Their properties include focal length, aperture, and refractive index.

- Diffractive lenses use diffraction to focus light, offering advantages in miniaturization and aberration correction.

- Aspheric lenses have non-spherical surfaces to reduce aberrations and improve image sharpness.

- Achromatic lenses are designed to minimize chromatic aberration, ensuring color accuracy.

Q 12. What is your experience with optical filters and their application?

Optical filters are essential components, selectively transmitting or blocking certain wavelengths of light. I have experience with various types, including

- Bandpass filters, which transmit a narrow range of wavelengths.

- Longpass and shortpass filters, which transmit wavelengths above or below a specific cutoff.

- Neutral density filters, which reduce light intensity across the spectrum.

Q 13. How do you troubleshoot issues related to image quality in electro-optical systems?

Troubleshooting image quality problems in electro-optical systems requires a systematic approach. I begin by visually inspecting the system for obvious issues like dirt or scratches on lenses. Then I proceed to check the focus and alignment of optical components, often using collimation tools and test targets. If the problem persists, I evaluate the system’s electronics, checking for faulty sensors, signal processing issues, or data acquisition errors. Software settings also play a key role; I’ll check exposure time, gain, and other parameters to ensure optimal image acquisition. For example, a blurry image might indicate a defocused lens or a problem with the image stabilization mechanism. A noisy image could be due to a high gain setting or a faulty sensor.

Q 14. Describe your experience with calibration procedures for electro-optical instruments.

Calibration procedures are critical for maintaining the accuracy of electro-optical instruments. This usually involves using traceable standards, following manufacturer’s instructions meticulously, and maintaining detailed records. The calibration process varies significantly depending on the instrument. A spectrometer, for example, requires calibration using known emission lines from a light source, whereas a thermal camera uses a blackbody source of known temperature. I’m proficient in using both automated and manual calibration methods and understand the importance of using appropriate calibration tools and software. Documenting all calibration activities ensures traceability and compliance with relevant standards. I have a strong understanding of the statistical methods used to analyze calibration data and determine the uncertainty of measurements.

Q 15. What software and tools are you proficient in using for electro-optical system maintenance?

My proficiency in electro-optical system maintenance relies heavily on a suite of software and tools. For data acquisition and analysis, I’m adept at using specialized software packages like LabVIEW, MATLAB, and specialized vendor-specific software for controlling and monitoring specific equipment. These tools allow me to capture, process, and interpret data from various sensors and instruments within the system.

On the hardware side, I’m experienced with optical power meters, optical spectrum analyzers, oscilloscopes, multimeters, and fiber optic test equipment such as OTDRs (Optical Time-Domain Reflectometers) and light sources. I also utilize specialized tools for cleaning and aligning optical components, including fiber optic cleaning kits and precision alignment tools. My experience also extends to using CAD software to understand and troubleshoot system designs. For example, I’ve used SolidWorks to visualize and diagnose alignment issues in a complex laser system.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the difference between coherent and incoherent light sources.

The core difference between coherent and incoherent light sources lies in the phase relationship between the emitted light waves. Incoherent sources, like incandescent bulbs or LEDs, emit light waves with random phases. This means the waves are not synchronized, leading to a less focused and less intense beam. Think of it like many people shouting at once – the sound is loud but lacks direction.

Coherent sources, such as lasers, emit light waves with a fixed phase relationship. These waves are synchronized, resulting in a highly focused and intense beam. Imagine a perfectly synchronized choir – the sound is powerful and directed. This coherence allows for applications like holography and high-precision measurements, which are impossible with incoherent light. This difference significantly impacts the performance and applications of electro-optical systems.

Q 17. How do you interpret and analyze electro-optical system data?

Interpreting and analyzing electro-optical system data involves a systematic approach. First, I examine the raw data from various sensors, looking for trends, anomalies, and deviations from expected values. This could involve analyzing power levels, spectral characteristics, signal-to-noise ratios, and temporal variations. For example, a sudden drop in optical power might indicate a fiber break or connector issue.

Next, I correlate this data with system parameters, environmental conditions, and operational logs to pinpoint the root cause. I might use statistical methods to identify patterns or employ signal processing techniques to isolate specific signals from noise. Finally, I document my findings, propose solutions, and validate the effectiveness of those solutions using further data analysis. A strong understanding of the system’s design and expected behavior is essential to making accurate interpretations.

Q 18. Describe your experience with different types of optical fibers and their characteristics.

I have experience working with various types of optical fibers, each with unique characteristics: Single-mode fibers carry only one optical mode, resulting in low signal attenuation and high bandwidth, making them ideal for long-distance communication. Multi-mode fibers, on the other hand, can support multiple optical modes, leading to higher attenuation and lower bandwidth, but are generally easier and cheaper to connect.

Furthermore, I’m familiar with different fiber types based on their material composition, such as silica fibers (most common), polymer fibers (used for short-distance applications), and specialty fibers like photonic crystal fibers which offer unique properties. The choice of fiber depends heavily on the application – for instance, a long-haul telecommunications system would demand single-mode fiber for its low loss, while a short-distance sensor network might use multi-mode fibers due to their cost-effectiveness. Understanding these distinctions is crucial for optimizing system performance and avoiding compatibility issues.

Q 19. What are the common failure modes of electro-optical components?

Electro-optical components are susceptible to a range of failures. For example, lasers can suffer from degradation of output power, beam divergence, or mode instability. Photodetectors may experience reduced sensitivity, increased noise, or even complete failure. Optical fibers can be damaged by bending, micro-bending, or physical cuts, resulting in signal attenuation or loss. Connectors can degrade due to contamination or misalignment, leading to increased insertion loss.

Other common failures include damage to optical coatings, causing scattering or reflection losses. Thermal effects can also cause significant issues in sensitive components. Identifying the precise failure mode often requires a careful analysis of symptoms, a thorough understanding of the system architecture, and the appropriate testing procedures. For example, a sudden increase in bit-error rate in a fiber optic communication system could point towards a connector problem or fiber damage, which can be diagnosed using OTDR measurements.

Q 20. How do you handle emergency situations involving malfunctioning electro-optical equipment?

Handling emergency situations involving malfunctioning electro-optical equipment requires a calm and methodical approach. My first priority is safety – ensuring the equipment is isolated to prevent further damage or injury. This might involve shutting down power supplies, disconnecting optical connections, or evacuating the area if necessary.

Next, I assess the situation, identifying the specific problem and its potential impact. I rely on my knowledge of the system, historical data, and diagnostic tools to quickly determine the cause. Then I prioritize the actions to mitigate the problem. This might involve switching to redundant systems, performing emergency repairs, or contacting specialized support teams. Throughout the process, I maintain detailed records of my actions and observations to aid in future troubleshooting and prevent similar occurrences.

Q 21. Explain your understanding of optical power budgeting.

Optical power budgeting is a crucial aspect of electro-optical system design and maintenance. It involves meticulously accounting for all optical power losses throughout the system, from the source to the detector. This involves carefully considering losses from various components: fiber attenuation, connector losses, coupler losses, and detector sensitivity.

By accurately calculating these losses, we can determine the required source power to ensure sufficient signal strength at the detector. This is critical to achieving the desired system performance and avoiding signal degradation. I use specialized software and calculations to create a power budget, predicting potential losses and ensuring sufficient margin for variations or unexpected events. An accurate power budget is essential for preventing system failures and ensuring the system operates within its specified parameters. Insufficient power budget can lead to poor signal quality, high error rates, and system instability.

Q 22. What is your experience with the repair and maintenance of infrared cameras?

My experience with infrared (IR) camera repair and maintenance spans over eight years, encompassing various models from different manufacturers. This includes troubleshooting malfunctions, replacing faulty components like detectors, lenses, and cooling systems, and performing calibrations to ensure accurate thermal imaging. For example, I once successfully repaired a damaged IR camera used in a high-stakes industrial inspection by identifying a loose connection in the cryocooler circuit, avoiding a costly replacement.

My work involves diagnosing issues based on symptoms like noisy images, poor image quality, or complete system failure. This often involves using specialized test equipment such as thermal imaging cameras, oscilloscopes, and multimeters to pinpoint the root cause. I’m proficient in using manufacturer’s service manuals and diagnostic software to guide the repair process. Once repairs are complete, I rigorously test the camera’s performance against established specifications to ensure its reliability before returning it to service.

Q 23. Describe your experience with the alignment and testing of optical assemblies.

Aligning and testing optical assemblies requires precision and specialized tools. My experience includes working with various optical systems, from simple lenses to complex assemblies involving mirrors, prisms, and filters. Alignment typically involves adjusting the position of optical components using micro-adjusters to achieve optimal performance, often measured using interferometry or autocollimators for high precision. Testing includes verifying parameters like focal length, spot size, and image clarity.

For instance, I recently aligned a laser rangefinder, using an autocollimator to ensure perfect collimation of the laser beam. Misalignment in this case could lead to significant errors in distance measurement. Following alignment, I conducted rigorous testing using targets at various distances to confirm accurate performance within the manufacturer’s specifications. The process involved meticulous documentation of the alignment parameters at each step to enable repeatability and troubleshooting if needed.

Q 24. How familiar are you with various types of optical sensors?

I am highly familiar with a wide range of optical sensors, including:

- Photomultiplier Tubes (PMTs): Excellent for low-light applications.

- Charge-Coupled Devices (CCDs): Widely used for imaging in various spectrums.

- Complementary Metal-Oxide-Semiconductor (CMOS) sensors: Cost-effective and rapidly evolving technology.

- Infrared detectors: Such as microbolometers and quantum well infrared photodetectors (QWIPs), used for thermal imaging.

- Photodiodes: Used in various applications from light detection to laser power measurements.

My experience involves understanding the strengths, weaknesses, and operational characteristics of each type, allowing me to select the appropriate sensor for a given application and effectively troubleshoot related issues. Choosing the wrong sensor can drastically impact the system’s overall performance and accuracy.

Q 25. Explain the principle of operation of a photomultiplier tube.

A photomultiplier tube (PMT) is a highly sensitive light detector that converts photons into an electrical signal. Its principle of operation relies on the photoelectric effect: when a photon strikes the photocathode, it ejects an electron. This electron is then accelerated towards a series of dynodes, each held at an increasingly higher voltage.

At each dynode, the electron collides and generates multiple secondary electrons through secondary emission. This cascading effect results in a significant amplification of the initial signal. The amplified electron pulse is then collected at the anode, producing a measurable electrical current proportional to the incident light intensity. PMTs are exceptionally sensitive, capable of detecting single photons, making them crucial in applications requiring extremely low-light detection, such as astronomy and medical imaging.

Q 26. Describe your experience with preventive maintenance scheduling for electro-optical systems.

Preventive maintenance scheduling is crucial for maximizing the lifespan and performance of electro-optical systems. My approach involves creating a customized schedule based on the specific system, its operating conditions, and manufacturer recommendations. This often includes a combination of regular inspections, cleaning, calibration, and component replacements.

For example, a system operating in harsh environmental conditions would require more frequent maintenance than one in a controlled environment. I use Computerized Maintenance Management Systems (CMMS) software to track maintenance activities, generate reports, and alert technicians about upcoming tasks. This ensures that potential problems are identified and addressed before they lead to system failures, reducing downtime and maintaining optimal system performance.

Q 27. How do you ensure the proper grounding and shielding of electro-optical equipment?

Proper grounding and shielding are essential for protecting electro-optical equipment from electromagnetic interference (EMI) and electrostatic discharge (ESD), which can damage sensitive components and lead to inaccurate readings. My experience encompasses implementing various grounding and shielding techniques, including:

- Using shielded cables to minimize EMI pickup.

- Employing conductive enclosures to protect sensitive circuitry from external electromagnetic fields.

- Implementing grounding straps and connecting the equipment to a dedicated earth ground point.

- Using ESD mats and wrist straps to prevent static electricity from damaging components during handling and maintenance.

Ignoring these precautions can lead to erroneous data, system malfunctions, and even catastrophic failures. I always prioritize safety and adherence to best practices to ensure the long-term reliability and accuracy of the systems I maintain.

Q 28. Explain your experience with documentation and reporting of maintenance activities.

Meticulous documentation and reporting are paramount in electro-optical system maintenance. I maintain detailed records of all maintenance activities, including dates, performed tasks, parts used, test results, and any observations. This includes utilizing both electronic and paper-based documentation systems, depending on client requirements.

Reports are generated to provide a clear overview of the maintenance performed, highlighting any significant findings or issues. This documentation is crucial for troubleshooting, tracking equipment history, ensuring compliance with regulatory requirements, and providing valuable data for predictive maintenance strategies. For example, using trend analysis on maintenance data might reveal a pattern indicative of an impending failure, allowing for proactive intervention.

Key Topics to Learn for ElectroOptical System Maintenance Interview

- Optical Components & Principles: Understanding lenses, mirrors, prisms, fibers, detectors (photodiodes, CCDs), and their properties. This includes knowledge of optical aberrations and their correction.

- Laser Systems: Familiarize yourself with laser types (HeNe, diode, solid-state), operation principles, safety procedures, alignment techniques, and common troubleshooting issues.

- Detector Technologies: Deepen your understanding of various detector types, their performance characteristics (sensitivity, noise, response time), and how to interpret detector output signals.

- Electronic Circuits & Signal Processing: Gain proficiency in analyzing and troubleshooting electronic circuits associated with electro-optical systems. This includes amplifiers, filters, and analog-to-digital converters.

- Optical Alignment & Calibration: Master the techniques for precise alignment and calibration of optical components, ensuring optimal system performance. Understand the use of alignment tools and procedures.

- Troubleshooting & Diagnostics: Develop strong problem-solving skills to identify and resolve malfunctions in electro-optical systems. This involves using diagnostic tools and interpreting error messages.

- Maintenance Procedures & Preventative Maintenance: Learn about standard maintenance protocols, cleaning procedures, and preventative measures to prolong system lifespan and performance.

- Safety Regulations & Procedures: Understand and adhere to all relevant safety regulations and procedures associated with working with lasers and high-voltage equipment.

- Data Acquisition & Analysis: Develop skills in collecting, analyzing, and interpreting data from electro-optical systems to assess performance and identify areas for improvement.

- Specific System Architectures: Research common architectures used in electro-optical systems relevant to your target roles (e.g., lidar, imaging systems, fiber optic communication systems).

Next Steps

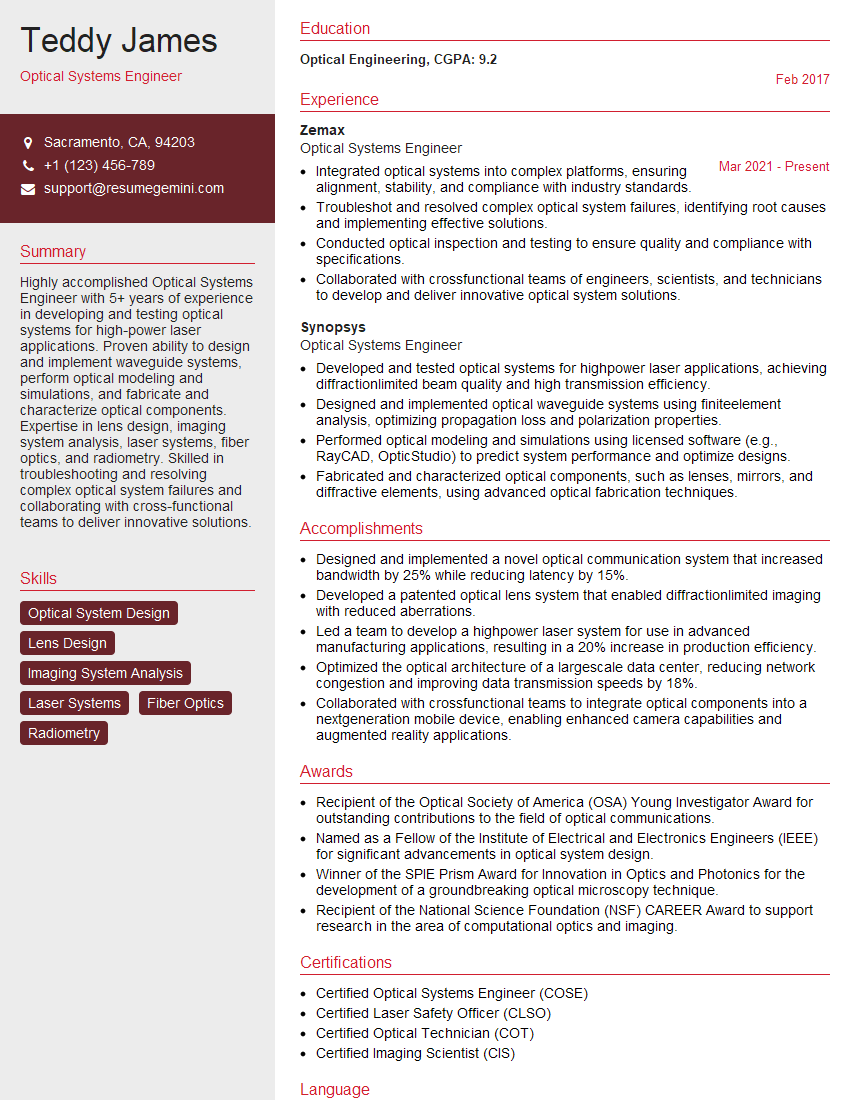

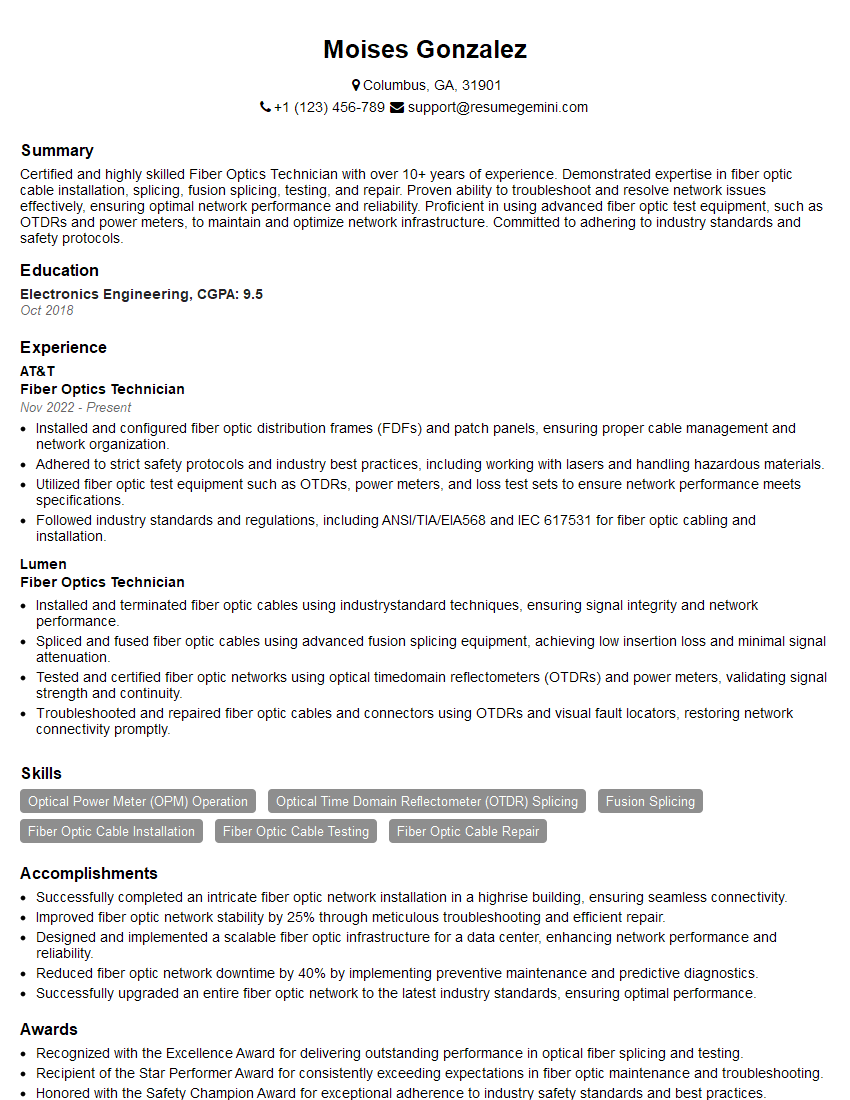

Mastering ElectroOptical System Maintenance opens doors to exciting and rewarding careers in diverse fields, offering excellent growth potential and competitive salaries. To maximize your job prospects, creating an ATS-friendly resume is crucial. A well-structured resume highlights your skills and experience effectively, ensuring your application gets noticed by recruiters. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to ElectroOptical System Maintenance, helping you present your qualifications in the best possible light. Invest the time to craft a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good