Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Leather Treating interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Leather Treating Interview

Q 1. Explain the different types of leather and their suitability for various treatments.

Leather types vary greatly in their structure, affecting how they absorb and react to treatments. Understanding this is crucial for successful leather care.

- Full-grain leather: The highest quality, with the top layer of the hide intact. It’s durable and develops a beautiful patina over time. It accepts treatments well, but requires less aggressive cleaning due to its strength. Example: High-end handbags, furniture.

- Top-grain leather: The top layer is sanded to remove imperfections, then coated. It’s more affordable but less durable than full-grain. It needs more gentle treatments as the coating can be damaged. Example: Many furniture and clothing items.

- Genuine leather: This is a split-leather (the lower layers of the hide) often coated with polyurethane or other materials for strength and appearance. It’s highly sensitive to certain chemicals and requires specialized care. Example: Wallets, belts, cheaper furniture.

- Bonded leather: Made from leather scraps bonded with glue and other materials. It’s the least durable and requires the most cautious approach; many harsh treatments will damage it quickly. Example: Cheap furniture, book covers.

The suitability of a treatment depends on the leather type. For example, harsh chemicals suitable for cleaning full-grain may damage genuine or bonded leather.

Q 2. Describe the process of leather dyeing, including pre-treatment and finishing steps.

Leather dyeing is a multi-step process involving pre-treatment, dyeing, and finishing.

- Pre-treatment: This prepares the leather for dye absorption. It might involve cleaning, degreasing to remove natural oils, and possibly neutralizing the pH. This step ensures even dye penetration and prevents blotchiness.

- Dyeing: This involves immersing the leather in a dye bath. Different dyes exist, including:

- Aniline dyes: Penetrate deeply, enhancing the natural grain, but are less lightfast.

- Semi-aniline dyes: A compromise between aniline and pigmented dyes, providing a balance between color depth and protection.

- Pigmented dyes: Sit on the surface, providing more durable and lightfast colors but hiding the leather’s natural texture.

- Finishing: This protects the dyed leather, enhances its appearance, and improves its performance. It might involve sealing, applying topcoats, and buffing to achieve the desired look and feel. This could include embossing, glazing, or other techniques.

Imagine dyeing a piece of fabric: pretreatment is like pre-washing to ensure the dye sets properly; dyeing is like applying the color, and finishing is like ironing and pressing for a smooth, professional finish.

Q 3. What are the common challenges faced during leather finishing and how do you address them?

Leather finishing presents several challenges: uneven color, cracking, scratching, and poor water resistance are common.

- Uneven color: This can result from inconsistent pre-treatment or dyeing. Solution: Careful pre-treatment, proper dye mixing and application, and using even pressure during dyeing.

- Cracking: This happens when the leather is too dry or hasn’t been properly treated. Solution: Conditioning the leather with a suitable leather conditioner to restore suppleness and flexibility.

- Scratching: This can be caused by rough handling or poor finishing. Solution: Proper handling during processing and using protective coatings.

- Poor water resistance: This is often due to insufficient finishing. Solution: Apply a high-quality water-resistant finish.

Troubleshooting often involves careful observation. A cracked leather might need conditioning; uneven color requires re-evaluation of the dyeing process.

Q 4. How do you identify and address common leather defects?

Identifying and addressing leather defects requires a keen eye and understanding of the manufacturing process.

- Scars and brands: Natural markings from the animal’s life; they are often left intact in higher-grade leathers, adding character.

- Insect bites: Small holes, usually clustered. They cannot be fully repaired, but the area may be concealed during finishing.

- Stretch marks: Visible lines indicating the hide’s natural growth. They are mostly cosmetic.

- Cuts and tears: These can be repaired using specialized leather repair kits, involving patching and coloring.

Addressing defects depends on severity and the type of leather. Minor imperfections may be acceptable, while major flaws might require repair or rejection.

Q 5. Explain the different types of leather finishes and their properties.

Leather finishes significantly impact the look, feel, and durability of the leather.

- Waxed finishes: Provide water resistance and a soft, supple feel. They are commonly used on boots and outdoor apparel.

- Glazed finishes: Give a smooth, shiny surface with a high-gloss sheen, often seen in dress shoes or handbags.

- Suede finishes: Provide a velvety, soft texture. They are more sensitive to dirt and water, requiring specialized cleaning products.

- Nubuck finishes: Similar to suede but with a slightly more durable and tougher surface, still requiring careful cleaning.

The choice of finish depends on the intended use and desired aesthetic. A waxed finish might be ideal for work boots, while a glazed finish would be more suitable for dress shoes.

Q 6. Describe the process of leather cleaning and conditioning.

Cleaning and conditioning leather maintains its appearance and prolongs its lifespan.

- Cleaning: Start with a soft brush or cloth to remove loose dirt. Then, use a leather cleaner specifically designed for the leather type. Apply sparingly, following the manufacturer’s instructions, and gently wipe clean with a damp cloth.

- Conditioning: Once cleaned, apply a leather conditioner to moisturize the leather and restore its suppleness. Use a small amount and rub it in gently using a circular motion. Allow the conditioner to absorb before buffing with a soft cloth.

Think of it like caring for your skin: cleaning removes dirt and grime, and conditioning replenishes moisture for softness and health.

Q 7. What are the safety precautions involved in handling leather treating chemicals?

Leather treating chemicals can be hazardous if mishandled. Always prioritize safety.

- Personal Protective Equipment (PPE): Wear gloves, eye protection, and a respirator when working with chemicals. This protects your skin, eyes, and respiratory system from fumes and potential irritants.

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes. Consider working outdoors or using exhaust fans.

- Proper storage: Store chemicals in a cool, dry place, away from children and pets, following the manufacturer’s instructions.

- First aid: Have a first aid kit readily available, and know what to do in case of accidental exposure. Consult a Safety Data Sheet (SDS) for specific handling procedures and first aid instructions.

Safety isn’t optional; it’s essential when working with chemicals. Proper precautions protect your health and ensure a safe working environment.

Q 8. How do you determine the appropriate treatment for a specific type of leather?

Determining the right leather treatment hinges on understanding the leather’s type, its intended use, and the desired final aesthetic. Think of it like choosing the right paint for a project – you wouldn’t use house paint on a delicate watercolor painting.

- Leather Type: Full-grain, top-grain, genuine, and bonded leather all have different structures and require different treatments. Full-grain, for instance, is more durable and needs less protection than bonded leather, which is more prone to damage.

- Intended Use: Leather for a handbag needs different treatment than leather for a car seat. A handbag needs to resist scratches and stains, while a car seat needs to withstand abrasion and UV exposure.

- Desired Finish: Do you want a matte, glossy, or distressed look? The treatment will vary depending on the desired outcome. A glossy finish might require a sealant, while a distressed finish would need specific techniques to achieve the desired effect.

For example, I once worked on restoring a vintage leather jacket. Careful inspection revealed it was full-grain leather, slightly dried out. The treatment involved a deep conditioning oil followed by a protective balm to restore its suppleness and prevent further drying.

Q 9. Explain the difference between aniline and semi-aniline leather finishes.

Aniline and semi-aniline finishes represent different levels of leather processing and resulting aesthetics. Imagine aniline as the ‘natural’ look and semi-aniline as a slight enhancement.

- Aniline Leather: This is minimally processed, showcasing the natural grain and imperfections of the hide. It’s incredibly soft and breathable but also more susceptible to scratches and staining. It’s like wearing a fine, unlined cashmere sweater – beautiful, but needs careful handling.

- Semi-Aniline Leather: This undergoes a light surface coating to improve its durability and water resistance while still preserving much of its natural appearance. It offers a balance between the natural look of aniline leather and the added protection of a fully finished leather.

The key difference lies in the level of pigment and protective coating. Aniline has minimal or no coating, while semi-aniline has a thin, subtle coat. This impacts durability, stain resistance, and the overall aesthetic. Semi-aniline often offers a more consistent color than aniline, which might show slight variations in tone due to its natural markings.

Q 10. What are the environmental considerations involved in leather treating?

Environmental consciousness is paramount in leather treating. We must minimize the impact of our processes on the environment throughout the entire lifecycle, from sourcing materials to waste disposal.

- Sustainable Sourcing: Using leather from tanneries committed to environmentally responsible practices is crucial. This involves looking for certifications and audits that ensure minimal water pollution, reduced energy consumption, and ethical animal husbandry.

- Chemical Selection: Choosing eco-friendly chemicals and dyes is vital. This involves researching and using products with low VOCs (volatile organic compounds) and biodegradable formulations. Many water-based dyes are now available that significantly reduce environmental impact.

- Waste Management: Proper disposal of chemical waste, leather scraps, and packaging is essential. This requires strict adherence to local and international regulations and working with responsible waste management companies.

For example, in my current work, we’ve transitioned to a water-based dyeing system, significantly reducing our water and energy consumption while minimizing the release of harmful chemicals into the environment.

Q 11. How do you maintain the quality and consistency of leather treatments?

Maintaining quality and consistency in leather treatments involves rigorous quality control measures at every stage. Think of it as baking a cake – precise measurements and consistent procedures ensure a perfect result every time.

- Batch Consistency: We meticulously document and control every step of the treatment process, from the formulation of chemicals to the application methods. This ensures each batch of treated leather maintains the same quality and color.

- Regular Calibration: Equipment used in the process, such as dyeing machines and spray guns, are regularly calibrated and maintained to prevent variations in application.

- Quality Checks: At each stage, samples are tested for color consistency, durability, and other relevant properties. This allows for immediate correction of any deviations from the standard.

- Documentation: Detailed records of each batch, including the raw materials used, the processes followed, and the final quality test results, are carefully maintained. This provides a valuable history for troubleshooting and continuous improvement.

One instance where this was vital was when we identified a slight color variation in a large order. Our detailed batch records allowed us to pinpoint the exact source of the problem, a slight adjustment in a dye component, and rectify it for subsequent batches.

Q 12. Describe your experience with various leather treating equipment.

My experience encompasses a wide range of leather treating equipment, from traditional hand tools to sophisticated automated systems.

- Hand Tools: I’m proficient in using various hand tools like sponges, brushes, and scrapers for applying treatments and finishing. These are invaluable for detailed work and smaller projects.

- Spray Systems: I have extensive experience with automated spray systems for even application of dyes, finishes, and protective coatings. These allow for efficient treatment of large quantities of leather while ensuring consistency.

- Dyeing Machines: My expertise includes operating and maintaining various dyeing machines, including paddle dyeing systems and drum dyeing machines. The choice of machine depends on the leather type and the desired dyeing effect.

- Finishing Machines: I’m also familiar with different finishing machines, such as glazing and embossing machines, used to enhance the leather’s appearance and provide specific textures.

For instance, working on a large upholstery order required the use of an automated spray system for applying a protective coating, ensuring uniform protection across all pieces. In contrast, hand-tool application was essential for a smaller, high-end handbag project that required meticulous detail and a specific finish.

Q 13. Explain your knowledge of color matching in leather dyeing.

Color matching in leather dyeing requires a keen eye for detail and a thorough understanding of color theory and the dyeing process. It’s like being a painter who needs to perfectly match the colors on a canvas.

- Color Measurement Tools: We utilize spectrophotometers to accurately measure the color of the leather and the dye. This provides objective data for precise color matching.

- Dye Formulation: Skilled dye technicians blend different dyes to achieve the desired color, taking into account the leather’s inherent characteristics and the desired shade.

- Test Dyes: Small test batches are dyed before proceeding with the main order to ensure the color matches the requirements. Any adjustments can be made at this stage.

- Lightfastness Testing: After dyeing, the color’s resistance to fading due to light exposure is tested to ensure long-lasting results.

I once had a project requiring a precise shade of burgundy, and using a spectrophotometer ensured that our final product was an exact match to the customer’s sample. It was crucial for the overall quality of their high-end leather goods.

Q 14. How do you troubleshoot issues related to leather cracking or fading?

Troubleshooting cracking or fading in leather requires careful investigation and understanding of the root cause.

- Cracking: This often stems from dryness or inadequate conditioning. The solution involves deep conditioning treatments to restore the leather’s suppleness. Over-stretching or improper handling during manufacturing may also contribute, requiring careful preventative measures in subsequent production runs.

- Fading: This can result from prolonged UV exposure, improper storage, or using inappropriate cleaning products. Protecting the leather from sunlight and using specialized leather cleaners can mitigate this. The type of dye used can also impact fading; some dyes are inherently more lightfast than others.

I remember a case where customer leather goods showed significant cracking. Our investigation determined it was due to a poorly formulated conditioning agent used during manufacturing. We changed the agent and revised the treatment protocol to prevent similar occurrences.

Addressing both issues requires a systematic approach: identifying the cause (sun exposure, dryness, chemical damage etc.), treating the damage with appropriate products (conditioners, dyes, sealants), and implementing preventive measures (UV protection, proper storage, correct cleaning).

Q 15. Describe the process of leather restoration, including repair and refinishing.

Leather restoration is a multi-step process encompassing repair and refinishing to revitalize damaged or aged leather. Repair focuses on addressing physical imperfections, while refinishing aims to improve the leather’s appearance and protect it from further deterioration.

Repair: This stage involves addressing tears, scratches, and other physical damage. It might include techniques like patching using matching leather, carefully filling in scratches with specialized fillers, and stitching up tears. The choice of repair method depends heavily on the type of leather and the extent of the damage. For example, a small scratch on a supple lambskin might be handled differently than a large tear in a thick, full-grain hide.

Refinishing: After repairs are completed, refinishing begins. This usually involves cleaning the leather to remove dirt and grime, followed by conditioning to restore its suppleness and hydration. Then, color restoration may be necessary to blend repairs or even out fading. Finally, a protective topcoat is applied to safeguard the leather from future wear and tear and to enhance its sheen and durability. This might involve a variety of finishes, from matte to high-gloss, depending on the desired aesthetic.

For example, restoring a vintage leather handbag might involve patching a torn seam, filling small scratches with a leather filler matching the bag’s color, cleaning the entire bag with a specialized cleaner, applying a leather conditioner to moisturize the leather, and finishing with a protective sealant to preserve the color and texture.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different methods for waterproofing leather?

Waterproofing leather involves applying a protective barrier to repel water and prevent moisture absorption. Several methods exist, each with varying effectiveness and longevity:

- Leather Waterproofing Sprays: These are readily available and convenient. They form a temporary barrier, offering short-term protection. Reapplication is usually necessary, especially after washing or exposure to heavy rain. Effectiveness varies depending on the spray’s formulation.

- Leather Waterproofing Creams or Waxes: These penetrate the leather’s surface more deeply, offering more durable water resistance than sprays. They also nourish and condition the leather, improving its overall health. Creams are generally better for softer leathers, while waxes are suitable for tougher, more durable hides.

- Leather Sealants: These create a more substantial barrier compared to sprays or creams. They provide excellent water resistance but can alter the leather’s breathability and appearance (potentially leading to a less natural look). It’s crucial to select a sealant specifically designed for leather.

- Professional Waterproofing Treatments: Some leather goods can be professionally treated with specialized waterproof coatings. These often provide the most durable protection, but are usually more expensive.

The best method depends on the leather type, intended use, and desired level of protection. For instance, a frequently used outdoor jacket would benefit from a durable sealant or professional treatment, while a delicate handbag might only require a gentle waterproofing spray.

Q 17. What is the importance of pre-treatment in leather dyeing?

Pre-treatment in leather dyeing is crucial for ensuring even color penetration, maximizing dye uptake, and preventing uneven results. It prepares the leather surface and fibers to receive the dye effectively.

The importance stems from leather’s inherent variability in porosity and structure. Pre-treatment addresses this variability by:

- Cleaning: Removing dirt, oils, and other residues that may hinder dye absorption. This ensures the dye adheres uniformly to the fibers.

- Neutralizing: Balancing the leather’s pH to optimize dye interaction. Different dyes perform optimally under specific pH conditions.

- Opening the Pores: Processes like retanning (using a secondary tanning agent) or using specific pre-treatment chemicals can open the pores of the leather, allowing for better dye penetration. This enhances the intensity and evenness of the final color.

- Improving Dye Affinity: Some pre-treatments improve the leather’s ability to bond with the dye molecules. This is particularly important with specific dye types that might otherwise have poor affinity with the leather.

Without proper pre-treatment, the dye may not adhere consistently, resulting in blotchy or uneven coloration. This can significantly reduce the quality and value of the finished leather product.

Q 18. How do you ensure the durability of your leather treatments?

Ensuring the durability of leather treatments requires a multifaceted approach focusing on both the treatment itself and the subsequent care:

- High-Quality Products: Using reputable brands and formulations specifically designed for leather ensures that the ingredients are effective and long-lasting. Cheap products often lack the necessary components for true protection.

- Proper Application: Following the manufacturer’s instructions precisely is critical. Correct application methods – whether it’s even spreading, optimal drying time, or multiple coats – significantly impacts durability.

- Appropriate Aftercare: Regular cleaning and conditioning after treatment maintains the integrity of the leather and the applied protective layers. This prevents premature wear and tear.

- Environmental Protection: Protecting the leather from excessive sun exposure, moisture, and harsh chemicals extends its lifespan and the longevity of treatments. Storing leather goods appropriately is vital.

- Selection of Treatment: Choosing the right treatment for the specific type of leather and its intended use is paramount. A delicate suede will need a different approach than a tough, full-grain leather.

Think of it like protecting a wooden fence. Using quality paint, applying it correctly, and regularly maintaining the fence ensures a long-lasting finish. The same principle applies to leather treatments.

Q 19. Explain the principles of leather chemistry.

Leather chemistry is a complex field dealing with the chemical composition, properties, and reactions of leather. It’s crucial to understand these aspects for effective treating and processing. The basic principles revolve around the transformation of animal hides into leather through various chemical processes:

- Tanning: This is the primary chemical process that converts the hide into leather, making it durable and resistant to decay. Various tanning methods exist, such as chrome tanning (using chromium salts), vegetable tanning (using plant extracts), and aldehydes tanning, each influencing the leather’s final properties.

- Retanning: This secondary tanning process is often used to modify the leather’s properties, such as fullness, softness, or grain appearance. This step often uses synthetic tanning agents.

- Dyeing: This process imparts color to the leather using various dyes that interact with the leather fibers based on their chemical affinity. The process’s chemistry depends on the dye type (acid, basic, direct, etc.) and the leather’s characteristics.

- Finishing: This is a final step which can involve applying coatings, pigments, and other chemicals to achieve the desired look and feel. The interactions of these coatings with the underlying leather are crucial for the final product’s appearance and durability.

Understanding these aspects allows for the selection of appropriate treatment methods, considering factors such as leather type, tanning method, and intended end-use. It’s the foundation of effective and responsible leather processing.

Q 20. What are the different types of leather preservatives?

Several types of leather preservatives protect leather from deterioration and damage. These preservatives work through various mechanisms to maintain the leather’s quality and appearance:

- Leather Conditioners: These moisturize the leather, replacing lost oils and maintaining its suppleness and flexibility. They prevent cracking and dryness.

- Waterproofers: These create a protective barrier against water and moisture, preventing damage from rain, spills, or humidity.

- Leather Cleaners: These remove dirt, grime, and stains, preventing these from damaging the leather’s surface and causing discoloration.

- UV Protectants: These shield the leather from the harmful effects of ultraviolet radiation (sunlight), preventing fading and deterioration.

- Leather Protectors/Sealants: These create a protective layer that prevents scratches, scuffs, and other surface damage. These often include water resistance as well.

The choice of preservative depends on the specific needs of the leather and the intended environment. For example, a leather jacket used outdoors requires waterproofer and UV protectant, while a leather sofa inside a home may primarily need a conditioner and cleaner.

Q 21. Describe your experience with various leather finishing techniques (e.g., buffing, glazing).

My experience with various leather finishing techniques is extensive. I’ve worked with a wide range of leathers and finishes, achieving diverse aesthetics and levels of durability.

Buffing: I’ve used buffing extensively to achieve a smooth, even surface. This process involves using rotary buffing wheels with various compounds to remove imperfections, create a sheen, and enhance the leather’s appearance. The choice of buffing compound is crucial; a fine compound creates a subtle sheen, while coarser compounds achieve a higher gloss. I’ve found that the technique requires a careful balance to avoid removing too much leather or creating unevenness.

Glazing: Glazing produces a high-gloss, reflective finish. It often involves applying multiple thin coats of glazing compounds and then carefully buffing between each coat to build a smooth, even layer. Precise control over the application and buffing is vital to prevent streaks or unevenness. I’ve worked with various glazing compounds, from water-based to solvent-based, each resulting in slightly different effects.

Other Techniques: My experience extends beyond buffing and glazing. I’m also proficient in techniques like embossing (creating textured patterns), stamping (applying logos or designs), and applying various topcoats for different levels of sheen and protection. Each technique requires a thorough understanding of the leather’s properties and the chemical interactions of the various finishing materials. A deep understanding of leather chemistry underpins my success in these areas.

Q 22. How do you handle different types of leather damage (e.g., scratches, stains)?

Handling leather damage requires a nuanced approach, varying based on the type of leather and the severity of the damage. Scratches, for instance, can often be minimized using leather conditioners that plump the leather and reduce the visibility of surface imperfections. For deeper scratches, a careful application of a matching leather dye followed by a top coat might be necessary. Stains, on the other hand, necessitate a more targeted approach. Water-based stains often respond well to gentle cleaning with a damp cloth and mild soap. Oil-based stains, however, might require specialized solvents or professional cleaning. Always test any cleaning solution on an inconspicuous area first.

- Scratches: Minor scratches can often be buffed out with a soft cloth and leather conditioner. Deeper scratches may require professional repair or dye application.

- Water Stains: These can often be removed with a damp cloth and mild saddle soap. Avoid harsh scrubbing.

- Oil Stains: These are more challenging and may require the use of specialized leather cleaners or professional intervention. Absorbent materials can help draw out some of the oil initially.

- Ink Stains: Depending on the type of ink, specialized stain removers may be necessary. Isopropyl alcohol can sometimes work, but always test it in an inconspicuous area first.

Remember, the key is to work gently and patiently, avoiding aggressive scrubbing that could further damage the leather.

Q 23. What are the common issues with pigmented leather finishes?

Pigmented leather finishes, while offering durability and color consistency, present their own set of challenges. One common issue is cracking or flaking, often caused by excessive dryness or exposure to harsh chemicals. Another concern is color transfer, where the pigment rubs off onto clothing or other surfaces, particularly during the initial break-in period. Finally, scratches can be more visible on pigmented leather compared to aniline leather, as they expose the underlying color layer. Regular conditioning and protection from harsh elements are essential to mitigate these issues.

For example, I once worked on a high-end handbag made with pigmented leather. The client complained about color transfer. After a thorough examination, we determined the leather wasn’t properly sealed post-dyeing. This was a manufacturing defect. In such cases, mitigating the damage is often the best solution and replacing the item may be the only option.

Q 24. How do you assess the quality of treated leather?

Assessing the quality of treated leather involves a multi-sensory approach. Visual inspection is crucial, checking for evenness of color, absence of blemishes, and consistent texture. The leather’s suppleness and feel are also important indicators; high-quality leather should feel smooth and supple, not stiff or brittle. Finally, the durability and resistance to scratches and water are key factors. I would perform a series of tests, including a scratch test, a water resistance test and a dye rub test. These would be documented with photographs and notes, providing a complete record of the leather’s qualities.

Think of it like tasting wine; you assess it visually (clarity, color), by smell (aroma), and finally, by taste (flavor, body). Similarly, assessing leather’s quality requires careful consideration of its visual appearance, tactile feel, and performance under stress.

Q 25. Describe your experience with quality control procedures in a leather treating environment.

In my experience, quality control in leather treating involves rigorous adherence to standardized procedures. This includes meticulous documentation of every step in the treatment process, from initial inspection to final quality check. We use a detailed checklist for each stage. This checklist ensures consistent results and allows us to trace any issues back to their source. Regular calibration of equipment is also crucial, especially when using machines for cleaning or dyeing. Furthermore, we conduct regular staff training and competency checks to ensure consistent application of techniques and adherence to safety protocols.

For example, we recently implemented a new color matching system. Through rigorous testing and documentation, we established precise color standards and verified the system’s accuracy. This prevented inconsistencies in color throughout batches of treated goods.

Q 26. What are the most common mistakes in leather treating and how to prevent them?

One of the most common mistakes is using the wrong products or applying them incorrectly. This can lead to discoloration, damage, or even irreversible harm to the leather. Another common error is applying too much product, which can leave a sticky residue or clog the leather’s pores. Finally, ignoring the type of leather is a critical mistake. Different leathers require different treatments and products. Prevention involves thorough research and understanding of the leather’s type, performing patch tests before full application, and following product instructions meticulously.

For example, using a harsh chemical cleaner on delicate suede would severely damage the material. Always start with the gentlest approach possible, and only escalate to stronger solutions if necessary.

Q 27. Explain the importance of maintaining detailed records of treatments.

Maintaining detailed records of leather treatments is essential for several reasons. First, it allows for traceability, enabling us to identify the source of any problems that arise later. Second, it facilitates consistency; we can reproduce successful treatments with high accuracy and avoids repeated trial and error. Third, comprehensive records are important for managing inventory and resources efficiently. Finally, detailed documentation can be invaluable for troubleshooting and resolving complex issues. It provides an auditable trail of the leather’s history, allowing for future analysis and improvement of treatment methods.

Imagine trying to recreate a complex recipe without notes. It would be nearly impossible! Similarly, maintaining records is critical for ensuring consistent, high-quality results in leather treating.

Q 28. Describe your problem-solving approach in a leather treating context.

My problem-solving approach in leather treating is systematic and methodical. I begin by carefully examining the issue, noting the type of leather, the nature of the damage, and any relevant history. I then consult my reference materials, including product specifications and treatment guidelines. I may perform further tests to better understand the problem. Next, I develop a plan, prioritizing safe and effective solutions. Finally, I execute the plan carefully, meticulously documenting each step, and evaluate the results. If the initial approach fails, I iterate, refining my approach based on the lessons learned. My goal is always to find a solution that minimizes further damage while achieving the best possible outcome.

For example, I once faced a challenging case involving a valuable antique leather-bound book with water damage. After a thorough analysis, I combined gentle cleaning with a specialized leather conditioner and a controlled drying process to restore the book to its original condition. The detailed notes and photographs from this process were instrumental in assisting with similar issues subsequently.

Key Topics to Learn for Leather Treating Interview

- Leather Chemistry: Understanding the chemical composition of different leather types (e.g., full-grain, top-grain, split) and their impact on treatment processes. This includes knowledge of collagen structure and its interaction with various chemicals.

- Pre-Treatment Processes: Familiarize yourself with cleaning, degreasing, and conditioning techniques. Understand the purpose and impact of each step on the final product quality and its practical application in a production setting.

- Dyeing and Finishing Techniques: Explore various dyeing methods (e.g., aniline, semi-aniline, pigmented) and finishing techniques (e.g., glazing, embossing, buffing). Be prepared to discuss the advantages and disadvantages of each method and their suitability for different leather types and end-uses.

- Leather Defects and Repair: Gain knowledge of common leather defects (e.g., scratches, wrinkles, scars) and effective repair techniques. Understanding how to identify and address these issues is crucial for quality control.

- Environmental Considerations: Understand the environmental impact of leather treating chemicals and processes. Be prepared to discuss sustainable practices and environmentally friendly alternatives.

- Quality Control and Testing: Learn about different quality control methods used in leather treating, including visual inspection, physical testing (e.g., tensile strength, abrasion resistance), and chemical testing. Be able to discuss how to ensure consistent quality and meet industry standards.

- Troubleshooting and Problem-Solving: Develop your ability to identify and solve common problems encountered during the leather treating process. This might involve understanding color variations, uneven finishes, or other defects and formulating solutions.

Next Steps

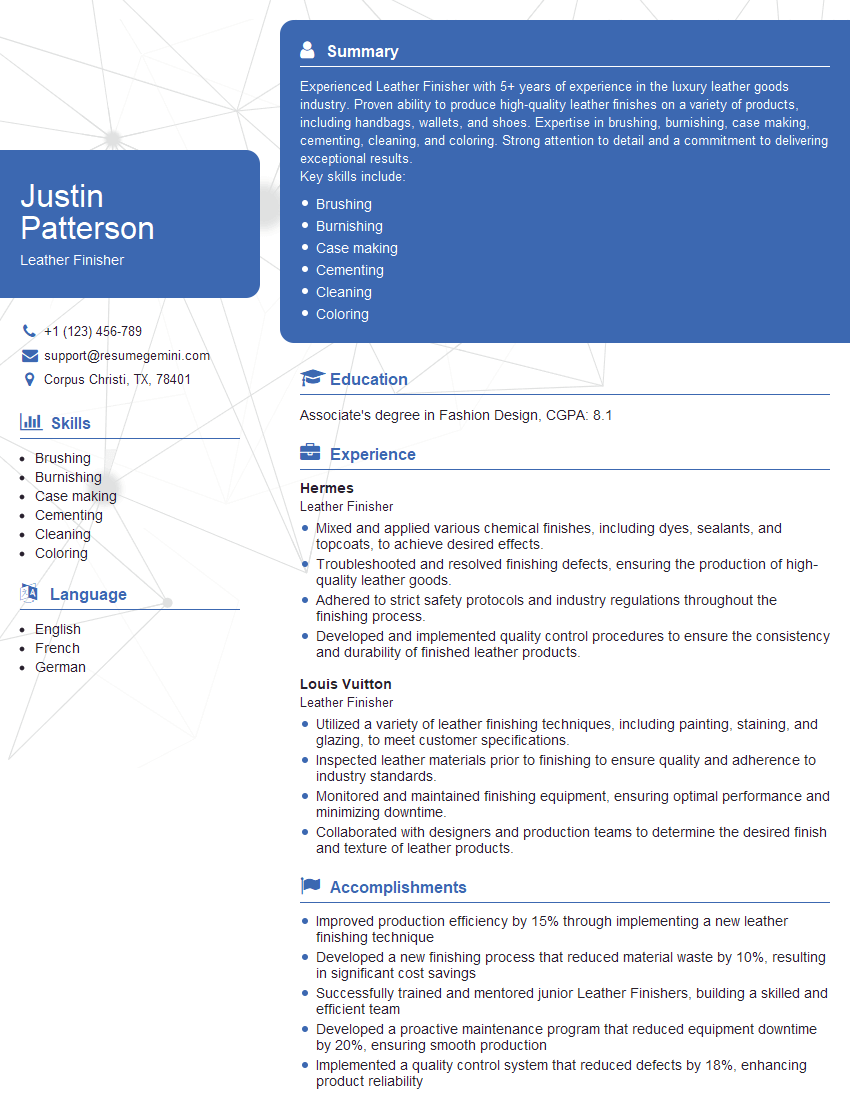

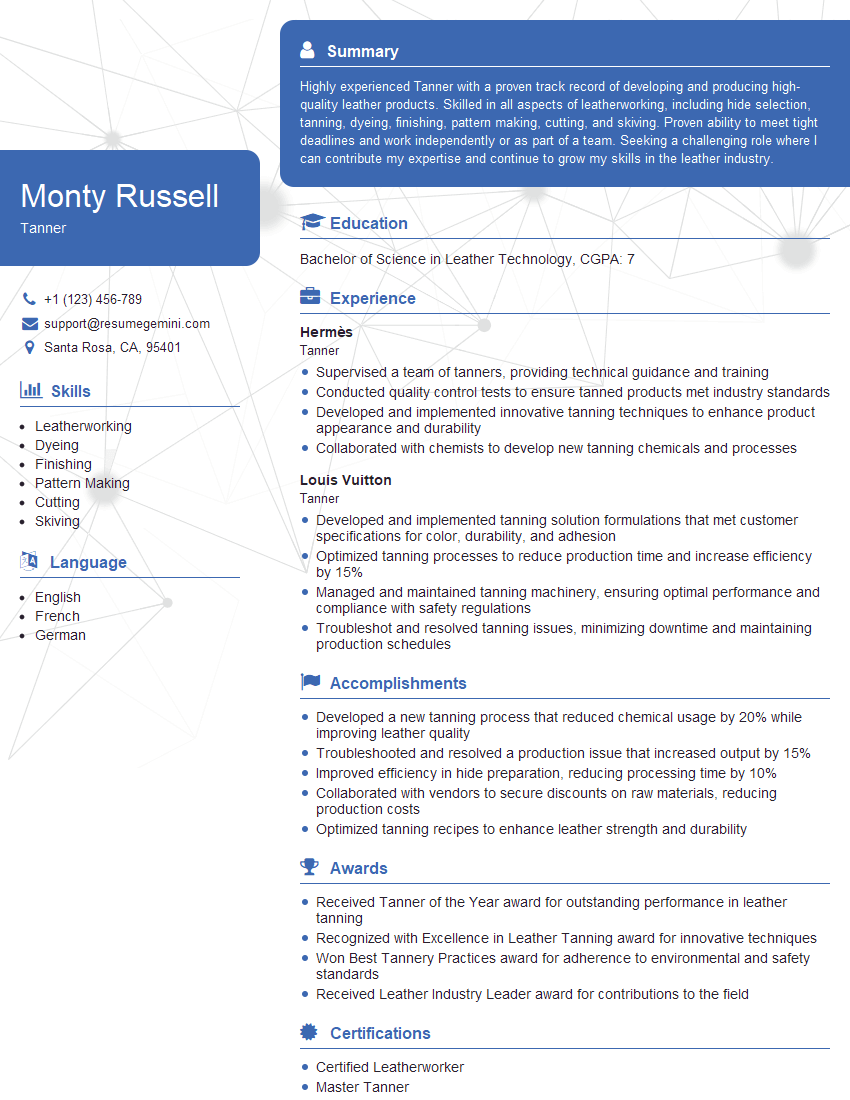

Mastering leather treating techniques opens doors to exciting career opportunities in the fashion, automotive, and furniture industries, offering rewarding roles with excellent growth potential. To maximize your chances of landing your dream job, focus on creating a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your application stands out from the competition. Examples of resumes tailored to the leather treating industry are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good