Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Foil Stamping on Leather interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Foil Stamping on Leather Interview

Q 1. Describe the different types of foil used in leather stamping.

Foil stamping on leather utilizes various foil types, each offering unique characteristics. The choice depends on the desired aesthetic and project requirements. Common types include:

- Hot Stamping Foil: This is the most common type, available in a vast range of colors, finishes (matte, gloss, metallic), and textures. Think of the shimmering gold lettering on a luxury handbag – that’s likely hot stamping foil.

- Cold Foil: Unlike hot stamping, cold foil requires a separate process. It’s applied to the leather first, then overprinted with UV inks or other finishing techniques. This allows for more complex designs and color combinations. Imagine a subtle, embossed design with a pearlescent finish – this could use cold foil.

- Specialty Foils: This category encompasses foils with unique properties like holographic effects, textured surfaces (e.g., linen or crocodile), or even glow-in-the-dark options. They offer a premium look and feel, perfect for bespoke projects.

Selecting the right foil is crucial for achieving the desired effect. Factors such as leather type, design complexity, and budget all play a role in the decision-making process.

Q 2. Explain the process of setting up a foil stamping machine for a specific job.

Setting up a foil stamping machine for a specific job is a meticulous process requiring precision. It involves several key steps:

- Die Selection and Mounting: The correct die, matching the design and leather thickness, is carefully mounted onto the machine’s platen. This needs to be done securely to prevent misalignment.

- Foil Loading: The foil roll is loaded into the machine, ensuring it feeds smoothly and is correctly positioned relative to the die and the leather.

- Temperature and Pressure Adjustment: This is crucial. The temperature is adjusted based on the foil type and leather characteristics. Too low, and the foil won’t adhere; too high, and it can scorch the leather. Pressure needs to be carefully calibrated to ensure even stamping across the entire design without damage. We often start with test runs on scrap leather to fine-tune these settings.

- Machine Calibration: We check the timing and registration to ensure the die and foil align perfectly with the leather. Any misalignment will result in imperfect stamping.

- Test Run: Before commencing full-scale production, a test run is always done. This verifies the settings are correct and allows adjustments if necessary.

Each machine has its own interface and controls. Understanding the machine’s specifications and its operational nuances is essential for optimal results. Years of experience have made these steps second nature to me.

Q 3. What are the common causes of foil stamping defects, and how do you troubleshoot them?

Foil stamping defects can be frustrating, but identifying their causes often leads to quick solutions. Common issues include:

- Uneven Foil Transfer: This often points to inconsistent pressure or temperature settings. Adjusting these parameters usually resolves the problem.

- Foil Wrinkling or Creasing: This could indicate improper foil feeding, excessive pressure, or even the leather itself being too thick or uneven.

- Incomplete Impression: This can be due to insufficient pressure, incorrect temperature, or a damaged die. A thorough check of each component is necessary.

- Offsetting: This means the foil isn’t transferring directly onto the leather, often from misaligned components or a problem with the machine’s registration.

- Scorching or Burning of Leather: This is caused by excessive temperature. Reducing the heat setting is crucial.

Troubleshooting involves systematic checks: examining the machine’s settings, the condition of the die and foil, and the quality of the leather. A methodical approach, coupled with experience, allows for efficient identification and rectification of the problem. I often keep a detailed log to track issues and solutions.

Q 4. How do you ensure consistent pressure and temperature during foil stamping?

Maintaining consistent pressure and temperature is paramount for flawless foil stamping. This is achieved through:

- Precise Machine Calibration: Regular calibration and maintenance of the foil stamping machine are critical. This includes checking pressure gauges and temperature controllers frequently.

- Quality Control Checks: Throughout the process, regular test runs and visual inspections are done to ensure consistency. This proactive approach allows for early detection and correction of any variations.

- Using Appropriate Gauges and Thermometers: Precision instruments are essential for accurate measurement and adjustment of pressure and temperature.

- Experienced Operators: Skilled operators can feel subtle changes in pressure and temperature through touch and sight, which are vital for adjustments. My experience enables me to intuitively adapt to changes.

Consistent pressure and temperature not only guarantee the quality of the foil stamping but also extend the lifespan of the machine and the dies.

Q 5. How do you select the appropriate die for a given leather type and design?

Selecting the right die is crucial for successful foil stamping. The die’s design and material should be appropriate for the leather type and the desired design.

- Leather Type: Thicker leathers require sturdier dies capable of withstanding higher pressure. Delicate leathers might need softer dies to avoid damage.

- Design Complexity: Intricate designs demand more precise dies with sharper details. Simple designs can be done with simpler dies.

- Die Material: Dies are typically made from brass or steel. Brass is more commonly used for finer details, while steel is preferred for heavier-duty applications.

For example, a delicate calfskin leather might require a brass die with a smooth, polished surface, while a thicker, full-grain leather could use a steel die for more robust stamping. I always consult with the client about their requirements and the leather they’ve chosen before selecting the die.

Q 6. What safety precautions are necessary when operating foil stamping equipment?

Safety is paramount when operating foil stamping equipment. Essential precautions include:

- Proper Training: Thorough training on the specific machine’s operation and safety features is mandatory.

- Personal Protective Equipment (PPE): This includes safety glasses to protect against flying debris, hearing protection to reduce noise exposure, and heat-resistant gloves to avoid burns. I always make sure I and my team are properly equipped before starting a job.

- Machine Guards: Using all safety guards provided on the machine. Never operate the equipment with safety guards removed or compromised.

- Regular Maintenance: Regular machine inspections and maintenance help prevent accidents caused by malfunctioning equipment.

- Emergency Procedures: Familiarization with emergency shutdown procedures and the location of fire extinguishers is crucial.

I’ve always prioritized safety in my work, enforcing strict safety protocols to prevent accidents.

Q 7. Describe your experience with different types of leather and their suitability for foil stamping.

My experience spans various leather types, each with its own suitability for foil stamping. Some examples:

- Full-grain Leather: A premium leather with a natural surface, ideal for foil stamping as the foil adheres well and produces a sharp, clear impression. It can handle various pressure and heat levels.

- Top-grain Leather: A more affordable option, often smoother than full-grain. While suitable for foil stamping, it might be more prone to minor damage if pressure and temperature are not carefully controlled.

- Genuine Leather: A more varied category, including split-grain leather, which is generally less suitable for intricate foil stamping due to its more delicate nature.

- PU Leather (Polyurethane): This synthetic leather has different properties and requires different foil stamping techniques, parameters, and possibly specific foil types.

The choice of leather significantly affects the final result. For example, a full-grain leather will give a luxurious, high-quality feel, while PU leather could be suitable for mass-produced items where cost is a major factor. Understanding these characteristics allows for selecting the optimal leather and foil combination for each project.

Q 8. Explain the importance of proper die maintenance and cleaning.

Proper die maintenance and cleaning are absolutely crucial for consistent, high-quality foil stamping on leather. Think of your stamping die as a precision instrument; neglecting its care will lead to poor results and potentially damage the die itself. This translates to wasted materials, production delays, and ultimately, dissatisfied clients.

- Cleaning: After each use, the die needs thorough cleaning. This involves removing any excess foil, leather scraps, and adhesive residue. I typically use a soft brush, compressed air, and a specialized cleaning solution, ensuring I don’t scratch the die’s delicate surface.

- Inspection: A regular inspection for damage like burrs, dents, or wear is key. Minor imperfections can be addressed with polishing, but significant damage often requires professional repair or die replacement. Ignoring these issues leads to inconsistent stamping and potentially ruined leather pieces.

- Storage: Proper storage is equally important. I store dies in protective cases, away from moisture and extreme temperatures, to prevent corrosion and damage. This ensures their longevity and consistent performance.

For example, neglecting to clean adhesive residue from a die can lead to foil sticking unevenly, creating a messy and unprofessional finish. Regular maintenance, conversely, extends the die’s life, saving costs in the long run and ensuring consistent, high-quality output.

Q 9. How do you handle complex designs or intricate details in foil stamping?

Handling complex designs and intricate details in foil stamping requires a multi-faceted approach. It’s like creating a miniature work of art, requiring precision and patience. We utilize several techniques to achieve stunning results.

- Multiple Dies: For extremely intricate designs, I might use multiple dies to break down the design into smaller, manageable sections. This is particularly useful when dealing with fine lines or small details. Each die is then stamped sequentially to achieve the complete image.

- High-Precision Dies: Investing in high-quality, precisely engineered dies is non-negotiable. These dies are made with superior materials and craftsmanship, ensuring crisp, clean impressions, even on fine details.

- Precise Pressure Control: Achieving the right amount of pressure is critical. Too little, and the foil doesn’t fully transfer; too much, and it can damage the leather or the die. Experience allows for the fine-tuning of pressure for different types of leather and the complexity of the design.

- Material Selection: Using the correct foil type is also crucial. Some foils are thinner and more pliable, making them ideal for detailed designs. Thicker foils work better for larger, bolder designs.

Imagine trying to stamp a detailed floral pattern – it requires a different strategy than stamping a simple logo. By combining these techniques, we can tackle even the most challenging designs and deliver exceptional quality.

Q 10. What are the advantages and disadvantages of different foil stamping methods (e.g., hot vs. cold)?

Hot and cold foil stamping offer distinct advantages and disadvantages. The choice depends heavily on the project’s specific requirements and the type of leather being used.

- Hot Foil Stamping: This is the more traditional method, utilizing heat and pressure to transfer foil onto the leather.

- Advantages: Produces vibrant, deeply saturated colors, is well-suited to various leather types and thicknesses, and generally provides more durability.

- Disadvantages: Requires specialized equipment, may damage more delicate leathers if pressure isn’t carefully controlled, and can be less precise with intricate designs compared to cold foil.

- Cold Foil Stamping: This method utilizes an adhesive-backed foil and pressure, without heat.

- Advantages: Offers great precision and is ideal for intricate designs, reduces potential for damage to delicate leathers, and can be more cost-effective for smaller runs.

- Disadvantages: Colors may be less vibrant, the foil may be less durable, and is usually not as suitable for embossed designs.

For instance, a high-end leather handbag might benefit from hot foil stamping for its superior durability and vibrant color, while a delicate journal cover may be better suited to cold foil stamping to avoid damage.

Q 11. How do you manage production deadlines and prioritize tasks effectively?

Managing production deadlines and prioritizing tasks effectively in foil stamping requires a structured approach. I use a combination of techniques to ensure projects are completed on time and to the highest standard.

- Project Scheduling: I meticulously schedule projects, taking into account the complexity of the design, the quantity required, the type of leather, and the availability of materials and equipment. This involves breaking down larger projects into smaller, manageable tasks.

- Prioritization: I prioritize tasks based on deadlines, urgency, and client requirements. Using project management software helps me to track progress and identify potential bottlenecks.

- Communication: Open communication with clients and the team is essential. I regularly update clients on progress, address any concerns promptly, and ensure everyone is on the same page.

- Contingency Planning: Unforeseen issues can arise. Having a contingency plan helps mitigate the impact of delays or unexpected problems, ensuring we can stay on track.

For example, if a crucial material is delayed, I have alternate sources lined up to minimize downtime. This proactive approach ensures projects are delivered on time, reinforcing client trust and maintaining a professional reputation.

Q 12. Describe your experience with quality control procedures in foil stamping.

Quality control is paramount in foil stamping. It’s not just about the final product; it’s about ensuring every step of the process meets our stringent standards. We have a multi-stage quality control process.

- Pre-Production Checks: This involves inspecting dies for imperfections, verifying foil color accuracy, and carefully reviewing the design specifications to avoid any errors before the stamping process begins.

- In-Process Checks: During the stamping process, we conduct regular checks to ensure the foil is being applied correctly, the pressure is consistent, and the leather is not being damaged. This includes random sampling and visual inspection.

- Post-Production Inspection: Once stamping is complete, each piece undergoes a thorough final inspection. This focuses on foil adhesion, color consistency, and the overall appearance for any defects or inconsistencies. Defective pieces are immediately identified and either reworked or discarded.

- Documentation: Every step of the quality control process is carefully documented. This ensures traceability and accountability, aiding in identifying and resolving any quality issues that might arise.

This rigorous process helps us maintain a high level of consistency and ensures clients receive only top-quality products. Think of it as a quality assurance net, catching any issues before they reach the client.

Q 13. How do you identify and rectify inconsistencies in foil application or color transfer?

Identifying and rectifying inconsistencies in foil application or color transfer requires a systematic approach. It’s like detective work, carefully analyzing the issue to pinpoint the root cause.

- Visual Inspection: The first step is a thorough visual inspection of the affected pieces. This helps identify the nature and extent of the inconsistency, whether it’s uneven foil application, color variation, or other defects.

- Investigate the Process: Once the type of inconsistency is identified, I investigate the entire process to find the cause. This includes examining the die for damage, checking the foil type and its compatibility, reviewing the pressure settings, and inspecting the condition of the press itself.

- Adjustments and Corrections: Based on the findings, I make the necessary adjustments to correct the issue. This might involve cleaning or repairing the die, adjusting the pressure, replacing the foil, or even recalibrating the press.

- Retesting and Monitoring: After making corrections, I carefully monitor the process to ensure the problem is resolved. This involves retesting and conducting further quality control checks to confirm consistency.

For instance, if the foil is applying unevenly, I might check for debris on the die, adjust the pressure, or ensure proper alignment. A systematic approach is key to resolving inconsistencies quickly and effectively.

Q 14. How familiar are you with different types of foil stamping presses?

My experience encompasses a range of foil stamping presses, from smaller, manual presses to large, automated industrial machines. Each type has its strengths and weaknesses, and selecting the right one depends on the scale and type of project.

- Manual Presses: These are ideal for smaller projects, prototypes, or customized work where precise control and flexibility are critical. They allow for greater precision in pressure and placement for intricate designs.

- Semi-Automatic Presses: These offer a balance between manual control and automation, ideal for medium-sized projects. They often have features like automatic foil feeding and pressure adjustment, boosting efficiency.

- Automatic Presses: These are high-speed, high-volume machines perfect for mass production. While offering incredible speed, they usually offer less flexibility and precision compared to manual presses.

- Specific Press Types: I am familiar with various types, including platen presses (common for flat stamping), cylinder presses (better for larger areas), and rotary presses (for high-volume production). Each offers unique capabilities and is suitable for specific applications.

My knowledge allows me to select the most appropriate press for a given project, maximizing efficiency and ensuring optimal results. The right press is just as crucial as the quality of the die and foil to produce excellent work.

Q 15. Explain your experience with different types of dies (e.g., brass, steel).

My experience spans a wide range of dies used in foil stamping on leather, primarily brass and steel. Brass dies, known for their relative softness, are excellent for intricate designs and offer a more delicate impression. However, they tend to wear down faster than steel dies, requiring more frequent maintenance and potentially impacting the consistency of the stamped image over a large production run. Steel dies, on the other hand, are far more durable and better suited for high-volume projects where longevity is crucial. They can withstand significantly more impressions before showing signs of wear, resulting in cost savings in the long run. The choice between brass and steel often depends on the design complexity, the quantity needed, and the budget. For instance, for a small luxury goods run with a highly detailed logo, a brass die might be preferred for its superior detail. For a large corporate order requiring thousands of stamped items, a robust steel die would be the clear choice.

Beyond brass and steel, I’ve also worked with photopolymer dies, which offer a cost-effective alternative for short runs or prototypes. These dies are made using a photo-sensitive polymer material and are produced digitally, allowing for fast turnaround times and a greater degree of design flexibility. However, their durability is generally less than that of metal dies.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate the cost of a foil stamping job?

Calculating the cost of a foil stamping job involves several key factors. The most significant components are:

- Die cost: This includes the design, creation, and any potential repairs or remakes of the die. For high-volume jobs, amortizing the die cost over multiple runs reduces the per-unit cost.

- Foil cost: The type of foil, its color, and the amount needed heavily influence the overall price. Metallic foils generally cost more than pigmented foils.

- Labor cost: This encompasses the time spent on setting up the press, running the job, and quality control. More intricate designs and larger orders naturally increase labor costs.

- Material cost: The leather itself adds to the overall expense. The type of leather, its thickness, and its pre-treatment all affect the price.

- Setup and waste: There are associated costs with setting up the press and accounting for inevitable waste during the process. This is particularly relevant for small runs.

In practice, I use a detailed costing spreadsheet that takes all these factors into account. This allows me to provide accurate quotations and manage profitability effectively. The formula is essentially: Total Cost = Die Cost + Foil Cost + Labor Cost + Material Cost + Setup & Waste. The final price is then calculated by adding a markup percentage to cover overhead and profit.

Q 17. What is your experience with color matching and foil selection?

Color matching and foil selection are critical aspects of successful foil stamping. My experience involves working closely with clients to achieve the desired aesthetic. We typically start with a visual reference, such as a Pantone color or a sample, and then select a foil that closely matches the specified color. This often involves testing different foils and adjusting the pressure and temperature of the stamping process to fine-tune the final result. For example, achieving a specific shade of gold can require comparing several gold foils to find the one with the right undertones and reflectivity. Some projects demand perfect color consistency across a large batch, so I implement strict quality control checks throughout the process. This includes regularly checking the foil against the reference standard and making any necessary adjustments to maintain accuracy.

Q 18. Describe your experience working with different types of adhesives or coatings used in conjunction with foil stamping.

Adhesives and coatings play a crucial role in ensuring the foil adheres properly to the leather and enhances its durability and appearance. I have extensive experience with various adhesives, including those specifically designed for foil stamping on leather. Some common types are water-based adhesives, hot-melt adhesives, and UV-curable adhesives. The choice of adhesive depends on the type of leather, the foil, and the desired finish. For example, a water-based adhesive might be chosen for its environmentally friendly nature, while a hot-melt adhesive might offer faster processing times. Often, a protective coating, such as a clear UV-resistant varnish, is applied after the foil stamping process to protect the foil from abrasion and enhance its longevity. The selection of both adhesive and coating impacts the final feel and resistance to wear and tear, so this step needs careful consideration.

Q 19. What is your experience with pre- and post-production processes related to foil stamping?

Pre- and post-production processes are integral to a successful foil stamping project. Pre-production includes die creation and proofing. This step involves working with design teams to finalize the artwork, ensuring the design is suitable for foil stamping. We create a proof to show the client the expected final product, allowing for corrections before mass production. Post-production involves quality control checks, where every stamped item is inspected for imperfections such as uneven foil application, smudging, or misalignment. We also handle finishing touches such as trimming, edge finishing or additional treatments, dependent on the project requirements. Effective pre- and post-production procedures are crucial for meeting client expectations and maintaining high-quality standards.

Q 20. How do you maintain accurate records and tracking of materials and production?

Maintaining accurate records and tracking of materials and production is paramount for efficiency and accountability. I use a combination of digital and physical methods. A detailed inventory system tracks all materials, including different types of leather, foils, and adhesives. We use a bar-coding system to track materials throughout the production process, ensuring accurate usage reporting and minimizing waste. Production records are kept meticulously, noting details like the date, order number, quantity produced, and any quality control issues encountered. This data is vital for cost analysis, production planning, and identifying areas for process improvement. Regular inventory audits help verify the accuracy of our records.

Q 21. Describe your problem-solving skills as related to foil stamping malfunctions or errors.

Troubleshooting foil stamping malfunctions requires a systematic approach. I begin by identifying the specific problem, which could range from inconsistent foil adhesion to uneven stamping or die damage. My approach involves:

- Visual inspection: Carefully examining the stamped items and the press to identify any obvious issues, such as faulty die alignment or problems with the foil feed mechanism.

- Material analysis: Checking the quality of the foil, leather, and adhesive used. Degraded or improper materials can lead to various problems.

- Press settings review: Checking the pressure, temperature, and speed settings of the stamping press to ensure optimal operation. Incorrect settings are a frequent source of errors.

- Die condition assessment: Inspecting the die for damage or wear. A damaged die will produce inconsistent results.

For example, if I encounter inconsistent foil adhesion, I might check the temperature settings, the condition of the foil itself, or investigate the type and application of the adhesive. Through careful observation and a methodical approach, I can usually pinpoint the root cause and implement a corrective action to restore optimal performance. Documentation of these issues and their resolutions improves future efficiency and serves as valuable training material.

Q 22. How do you handle customer requests or special instructions?

Handling customer requests involves a meticulous process to ensure their vision translates perfectly onto the leather. I begin by carefully reviewing all specifications, paying close attention to details like foil type, color, design complexity, and leather characteristics. This includes analyzing provided artwork for potential issues like resolution or vector problems that might impact the final product. I then discuss these details with the client, clarifying expectations and identifying potential challenges proactively. For example, if a client requests a very fine detail in a metallic foil on a textured leather, I’ll advise them on potential limitations and explore alternative solutions to achieve the desired visual effect while ensuring a high-quality outcome. Open communication and clear expectations are key to client satisfaction.

If special instructions are provided, I meticulously document them, creating a checklist to ensure adherence throughout the production process. This detailed approach minimizes errors and ensures the final product precisely matches the client’s vision. For instance, if a client specifies a particular embossing technique alongside foil stamping, I make sure to clearly note this for the die-maker and press operator. This collaborative approach ensures a high level of precision and quality control.

Q 23. Describe your experience working in a fast-paced production environment.

My experience in fast-paced production environments has honed my ability to manage multiple projects concurrently while maintaining a high standard of quality. I thrive under pressure, prioritizing tasks effectively using techniques like time blocking and task prioritization matrices. Think of it like orchestrating a symphony – each instrument (task) needs to play its part precisely and in sync for a flawless performance. In one particular instance, we faced a tight deadline for a large order of personalized leather journals. By coordinating effectively with the team and streamlining the workflow, we not only met the deadline but also maintained our high quality standards. I am adept at identifying and resolving bottlenecks, keeping the production line moving smoothly. This efficiency also extends to problem-solving; I can quickly assess situations, identify the root cause of delays, and implement effective solutions without compromising quality.

Q 24. What software or programs are you familiar with related to design or production?

My software proficiency includes Adobe Illustrator for vector design work, essential for preparing artwork for foil stamping dies. I’m also adept at using CorelDRAW, which is another powerful vector graphics editor suitable for creating complex designs. Beyond design software, I’m familiar with various production management software commonly used in the industry, allowing me to seamlessly track projects, manage inventory, and monitor production timelines. Specific programs vary from company to company, but my experience is generally transferable. I am quick to learn new software as well, which is crucial in this ever-evolving field.

Q 25. How do you stay updated on industry trends and new technologies in foil stamping?

Staying updated on industry trends is critical in foil stamping. I actively engage in several strategies. This includes subscribing to trade publications like Leather World and attending industry conferences like the Leather & Fashion Technology Show. These events provide exposure to new foil types, embossing techniques, and innovative technologies. I also regularly explore online resources, including industry blogs and forums, to learn about new developments and best practices. Furthermore, networking with fellow professionals through industry associations provides valuable insights and collaborative opportunities. This multifaceted approach ensures I’m always abreast of the latest advancements and can adapt my skills accordingly.

Q 26. Explain your experience with troubleshooting die issues or mechanical problems.

Troubleshooting die issues is a crucial aspect of foil stamping. My experience spans a variety of problems, from minor adjustments to major repairs. For instance, if a die is producing inconsistent stamping, I systematically investigate possible causes: worn-out die components, improper pressure settings, or issues with the foil feeding mechanism. I’ll start by visually inspecting the die for any damage or wear, then check pressure settings and the alignment of the die with the press. If the problem persists, I might need to consult with a die-maker or engineer to diagnose more complex issues. I use a logical approach, ruling out simpler possibilities before moving to more complex ones. A systematic method is crucial in effectively resolving mechanical problems. My experience allows me to quickly identify and address problems, minimizing downtime and ensuring efficient production.

Q 27. What are your strengths and weaknesses in regards to foil stamping?

My strengths lie in my attention to detail, problem-solving abilities, and my collaborative approach. I have a keen eye for identifying even subtle imperfections and possess the technical expertise to correct them. My ability to calmly troubleshoot complex equipment issues under pressure is invaluable in a fast-paced production environment. I consider effective teamwork a key to success, valuing open communication and collaboration to ensure a smooth and efficient workflow. A weakness I’m actively working on is delegating tasks more effectively, as my focus on detail can sometimes lead to taking on more than is ideally manageable. I’m improving this by prioritizing tasks and proactively training colleagues, enhancing overall team efficiency.

Q 28. Describe your experience in maintaining the cleanliness and organization of your workspace.

Maintaining a clean and organized workspace is paramount for efficiency and safety in foil stamping. A cluttered workspace not only slows down production but also increases the risk of accidents. I strictly adhere to 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain), ensuring all tools and materials are properly stored, organized, and readily accessible. This includes regular cleaning of the press and surrounding areas, removing any debris or scrap materials immediately. This organized approach helps me locate needed items quickly, reduces downtime, and creates a safer working environment. The same meticulous attention to organization carries over to managing inventory and production materials, contributing to seamless workflow and overall production efficiency.

Key Topics to Learn for Foil Stamping on Leather Interview

- Foil Types and Properties: Understanding the various types of foil (hot stamp, cold foil, etc.), their characteristics (thickness, adhesion, colorfastness), and suitability for different leather types.

- Leather Preparation: Techniques for preparing leather hides for foil stamping, including cleaning, conditioning, and surface treatment to ensure optimal adhesion and a clean, crisp impression.

- Die Making and Design: Knowledge of die creation processes, material selection (brass, steel), and the importance of precise die design for achieving desired results on the leather.

- Foil Stamping Machines and Operation: Familiarity with different types of foil stamping machines (manual, automated), their operation, maintenance, and troubleshooting common issues.

- Temperature and Pressure Control: Understanding the critical role of temperature and pressure in achieving successful foil stamping, including how these factors affect foil adhesion and the final appearance.

- Quality Control and Inspection: Methods for inspecting stamped leather for defects (e.g., uneven foil application, poor adhesion, inconsistencies), and understanding industry quality standards.

- Troubleshooting and Problem Solving: Identifying and resolving common problems encountered during the foil stamping process, such as foil wrinkling, uneven stamping, or adhesion issues.

- Safety Procedures and Regulations: Understanding and adhering to relevant safety protocols and regulations associated with operating foil stamping equipment and handling materials.

- Sustainability and Environmental Considerations: Awareness of environmentally friendly practices in foil stamping, including waste reduction and responsible material sourcing.

- Advanced Techniques: Explore specialized techniques like blind embossing, debossing, and multi-color foil stamping.

Next Steps

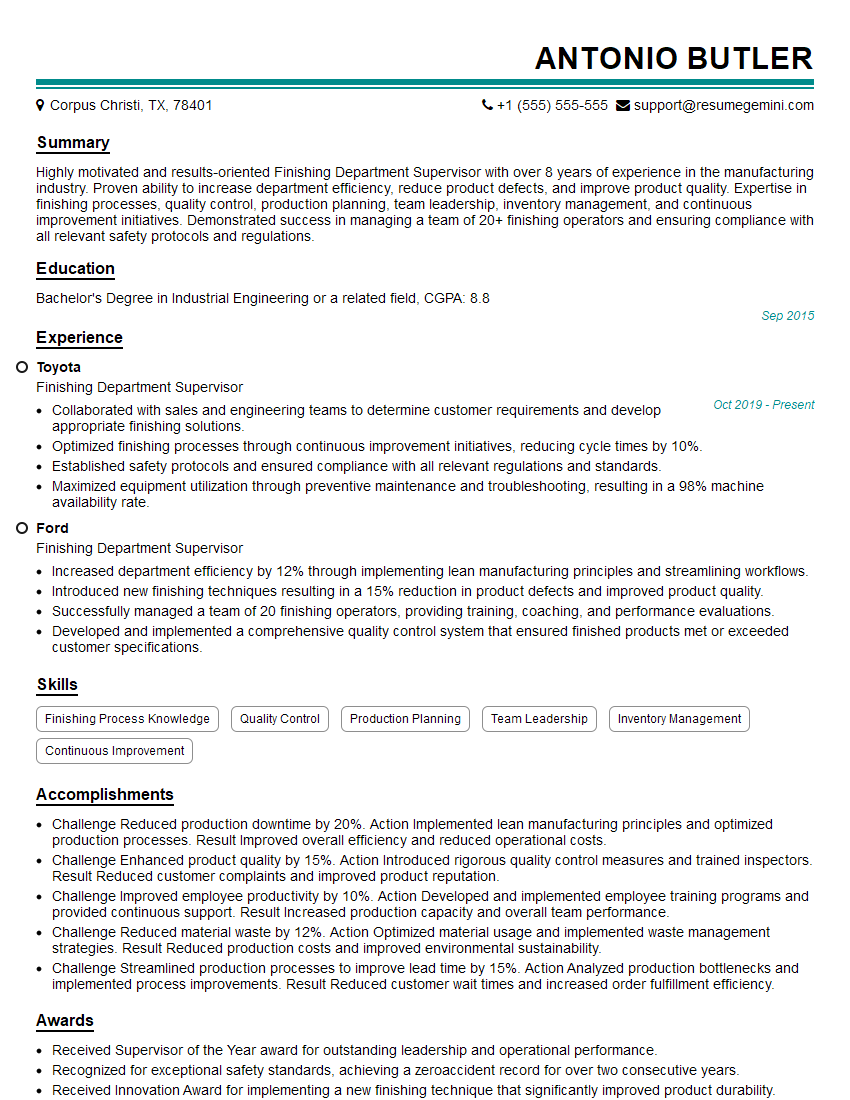

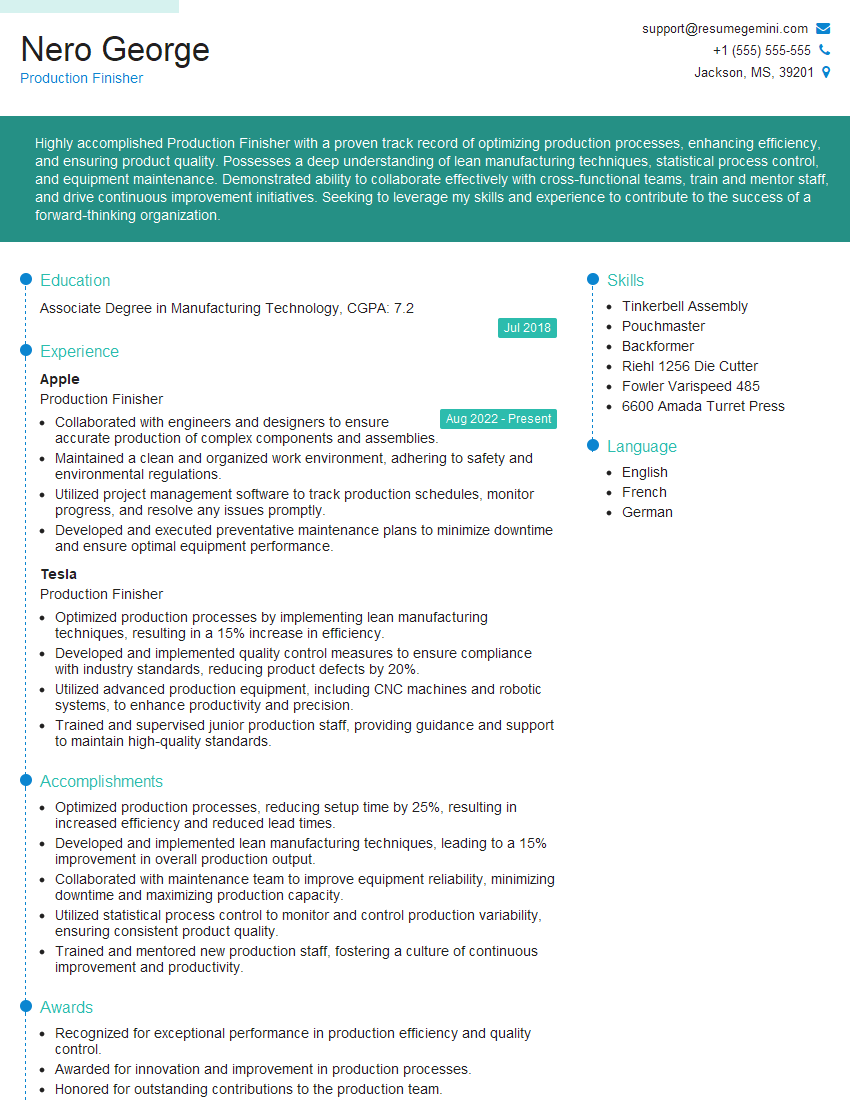

Mastering foil stamping on leather opens doors to exciting career opportunities in high-end fashion, luxury goods manufacturing, and custom design. A strong understanding of this specialized skill significantly enhances your value to potential employers. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to the Foil Stamping on Leather industry, giving you a head start in crafting a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good