The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Forest Product Identification and Utilization interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Forest Product Identification and Utilization Interview

Q 1. Describe the different types of wood grain patterns and their implications for product suitability.

Wood grain patterns are formed by the arrangement of wood fibers during tree growth. These patterns significantly influence a wood’s aesthetic appeal and its suitability for specific applications. Different patterns exhibit varying strength and workability.

- Straight Grain: Fibers run parallel to the tree’s length, resulting in strong, uniform wood ideal for structural purposes like beams and flooring. Imagine the straight, consistent lines you’d see in a well-grown pine plank.

- Spiral Grain: Fibers spiral around the tree’s axis, impacting strength and causing warping during drying. It’s less desirable for structural use but can offer interesting visual effects.

- Interlocked Grain: Fibers are angled in alternating directions, producing a wavy appearance. This pattern provides excellent resistance to splitting but can be challenging to work with.

- Diagonal Grain: Fibers run at an angle to the tree’s axis, resulting in a more visually striking pattern. Strength properties are generally intermediate.

- Curly Grain: Fibers grow in tight curls, often creating beautiful figures like flame or fiddleback. This pattern is valuable for decorative applications but can be brittle.

- Birdseye Grain: Small, circular knots on the surface create a distinctive pattern. It’s prized for its unique look and is commonly used in veneers.

Understanding grain patterns helps determine which species and boards are best for different projects. For instance, straight grain wood is preferred for furniture requiring strength and stability, while curly or birdseye grain is chosen for aesthetically pleasing veneers or decorative elements.

Q 2. How do you identify different species of wood using macroscopic and microscopic techniques?

Identifying wood species requires a combination of macroscopic and microscopic techniques. Macroscopic examination focuses on visible characteristics, while microscopic analysis delves into the wood’s cellular structure.

- Macroscopic Identification: This involves observing features like color, texture, odor, grain pattern, growth rings, and the presence of knots or other abnormalities. For example, the distinct reddish-brown color and straight grain of mahogany are easily recognizable. A magnifying glass can aid in this process.

- Microscopic Identification: This method utilizes a microscope to analyze the wood’s cellular structure, including the size, shape, and arrangement of cells. Key features like the presence of rays, vessel elements (in hardwoods), and tracheids (in softwoods) are crucial for species identification. Microscopic analysis provides more precise identification, especially for species with similar macroscopic features.

Professional wood identification often involves using both methods in conjunction with reference guides and databases. Experienced woodworkers frequently develop an intuitive sense for species identification through years of practice, similar to how a sommelier identifies wines.

Q 3. Explain the process of determining the moisture content of wood and its importance.

Determining wood moisture content is crucial for predicting its behavior and ensuring quality in wood products. Excess moisture can lead to warping, shrinkage, and fungal decay, while insufficient moisture can result in cracking and brittleness.

Moisture content is measured as the percentage of water in wood relative to its dry weight. The most common method is using a moisture meter, which uses electrical resistance or pin-type sensors to determine moisture content. Another method involves oven-drying a sample to constant weight. The formula is:

Moisture Content (%) = [(Wet Weight - Dry Weight) / Dry Weight] x 100For example, if a wood sample weighs 100g wet and 80g dry, its moisture content is [(100-80)/80] x 100 = 25%. The acceptable moisture content varies depending on the wood species and intended application. Understanding and controlling moisture content is critical for effective wood processing and preventing defects.

Q 4. What are the key physical and mechanical properties of wood and how do they affect its utilization?

Wood’s physical and mechanical properties are vital in determining its suitability for different applications. These properties vary significantly between species and even within a single species, depending on growth conditions and wood density.

- Density: Heavier woods are generally stronger and more durable. Density affects strength, stiffness, and resistance to wear.

- Strength: This includes compressive, tensile, shear, and bending strength. Strength is crucial for structural applications like beams and framing.

- Hardness: Measured by the Janka hardness scale, hardness indicates resistance to dents and wear. Hardwoods are generally harder than softwoods.

- Stiffness: The ability to resist bending or deformation under load. This is important for applications requiring stability and dimensional accuracy.

- Durability: Resistance to decay, insects, and weathering. Durability is influenced by factors like density, extractive content, and permeability.

For instance, oak’s high density and hardness make it suitable for flooring and furniture, while pine’s lighter weight and greater availability make it suitable for construction framing. These properties are considered during the design and selection processes for various wood products.

Q 5. Discuss the various wood defects and their impact on the quality and use of wood products.

Wood defects are imperfections that reduce the quality and value of wood products. These can be caused by various factors including genetics, environmental conditions, disease, and processing techniques.

- Knots: Branches embedded in the wood, which reduce strength and can complicate processing.

- Checks: Cracks in the wood that run across the grain, often due to rapid drying.

- Splits: Long cracks extending along the grain, weakening the wood.

- Shakes: Separations between the growth rings, indicating poor wood formation.

- Decay: Decomposition of wood due to fungal or bacterial activity.

- Wane: The presence of bark or lack of wood on the edges of a piece.

The impact of defects varies depending on their severity and location. Small knots in a piece of furniture may not affect its functionality, but extensive decay will render the wood unusable. Understanding wood defects is vital for quality control, grading, and determining appropriate end-uses of wood products.

Q 6. Explain the different methods used for wood preservation and their effectiveness.

Wood preservation methods aim to extend the lifespan of wood by protecting it from decay, insect attack, and other forms of degradation. Various techniques are used, depending on the type of wood, intended application, and environmental conditions.

- Pressure Treatment: Wood is placed in a pressure vessel and impregnated with preservatives under high pressure. This method is effective for protecting wood from ground contact applications. Common preservatives include chromated copper arsenate (CCA), although less toxic alternatives like copper azole are now preferred.

- Surface Treatment: Preservatives are applied to the wood surface, offering a less durable but simpler method than pressure treatment. This includes paints, stains, and oil-based treatments that may provide some protection against moisture and insects.

- Thermal Modification: Wood is heated to high temperatures, altering its chemical structure and improving its durability and dimensional stability. This increases resistance to decay and makes the wood less prone to shrinking and swelling.

- Incising: Creating shallow cuts in the wood surface to facilitate deeper penetration of preservatives. This method is often used in conjunction with pressure treatment to enhance preservative effectiveness.

The choice of preservation method is crucial in ensuring the longevity and safety of wood products. For instance, pressure-treated lumber is essential for outdoor structures exposed to the elements, whereas surface treatments may suffice for indoor applications.

Q 7. How do you assess the sustainability of different forest products?

Assessing the sustainability of forest products requires a holistic approach, considering environmental, social, and economic factors throughout the entire product lifecycle, from forest management to end-of-life disposal.

- Forest Management Practices: Sustainable forestry involves managing forests in a way that maintains biodiversity, protects ecosystems, and ensures long-term productivity. Certification schemes like the Forest Stewardship Council (FSC) provide assurance of sustainable forest management.

- Harvesting and Processing Methods: Minimizing waste, utilizing efficient processing techniques, and reducing energy consumption are critical for sustainability.

- Transportation and Distribution: Optimizing transportation routes and reducing emissions associated with product transport contribute to a lower environmental impact.

- Product Design and Durability: Designing durable and long-lasting products reduces the need for frequent replacements and minimizes resource consumption.

- End-of-Life Management: Promoting recycling, reuse, or responsible disposal of wood products minimizes waste and environmental impacts.

A life cycle assessment (LCA) can be used to quantify the environmental impact of a forest product, allowing for comparisons between different products and management practices. By considering all these factors, we can make informed decisions to support truly sustainable forest products.

Q 8. Describe the different types of wood processing techniques (e.g., sawing, drying, treating).

Wood processing involves a series of steps to transform raw timber into usable products. These techniques can be broadly categorized into sawing, drying, and treating, each with its own nuances and importance.

- Sawing: This initial step involves cutting logs into smaller pieces, like lumber (boards, planks, beams) or veneers (thin sheets). Different sawing methods, such as plain sawing, quarter sawing, and rift sawing, affect the appearance and properties of the final product. Plain sawing is the most common and cost-effective but can result in more pronounced wood grain variations, while quarter sawing produces more stable and visually appealing boards, albeit at a higher cost.

- Drying: Freshly cut wood contains significant moisture content, leading to shrinkage and warping if not properly dried. Drying methods include air drying (slow, natural process), kiln drying (accelerated using controlled temperature and humidity), and solar drying. The choice of method depends on the wood species, product requirements, and cost considerations. Kiln drying is faster but requires specialized equipment, while air drying is slower but more environmentally friendly.

- Treating: Wood treatment involves applying chemicals to enhance its durability and resistance to decay, insects, and fire. Pressure treatment is a common method where wood is immersed in preservatives under high pressure. Common preservatives include chromated copper arsenate (CCA) – now largely phased out due to environmental concerns – and more environmentally friendly alternatives such as copper azole (CA) and micronized copper quat (MCQ). The type of treatment depends on the intended use of the wood, e.g., outdoor applications require more robust treatments than indoor uses.

Imagine building a deck – you’d likely choose pressure-treated lumber for its resistance to rot and insects, ensuring its longevity. In contrast, furniture might use kiln-dried lumber that’s been carefully selected for appearance and stability.

Q 9. What are the common uses of various hardwood and softwood species?

Hardwoods and softwoods, categorized by their botanical characteristics (broadleaf vs. coniferous), find diverse applications based on their properties.

- Hardwoods: Known for strength, durability, and often beautiful grain patterns. Examples include:

- Oak: High strength, durable, used in flooring, furniture, cabinetry, and barrels.

- Maple: Hard, strong, and stable, commonly used in flooring, furniture, and musical instruments (especially drums).

- Walnut: Rich color and texture, favored for high-end furniture, veneers, and gunstocks.

- Mahogany: Beautiful reddish-brown color, used in fine furniture and veneers.

- Softwoods: Generally less dense and often easier to work with than hardwoods. Examples include:

- Pine: Versatile, used in construction (framing, decking), furniture, and paper production.

- Spruce: Lightweight, strong, often used in construction (framing, plywood), musical instruments, and paper pulp.

- Fir: Strong and lightweight, used in construction, plywood, and pulp and paper.

- Cedar: Aromatic, decay-resistant, used in outdoor construction, fencing, and chests.

The choice between hardwood and softwood often comes down to the intended use. A sturdy hardwood floor demands durability, while a simple wooden shelf might suffice with a less expensive softwood.

Q 10. Explain the principles of wood anatomy and its relevance to product properties.

Wood anatomy, the study of the microscopic structure of wood, is fundamental to understanding its properties. Wood is composed of cells arranged in a complex structure.

- Cells: The basic building blocks of wood, including tracheids (in softwoods), vessels (in hardwoods), fibers, and parenchyma cells. These cells’ size, shape, arrangement, and wall thickness determine the wood’s characteristics.

- Growth Rings: Visible concentric rings representing annual growth, reflecting seasonal variations in cell size and density. The width of these rings influences wood strength and appearance.

- Grain: The arrangement of wood fibers, significantly impacting strength and aesthetic qualities. Straight grain is stronger than irregular grain.

The anatomy directly relates to product properties. For instance, denser wood with thicker cell walls (e.g., oak) is stronger and more durable than wood with thinner walls (e.g., pine). The grain pattern influences the workability and appearance of the wood; straight grain is easier to work with and yields more stable products. Understanding wood anatomy is crucial for selecting appropriate species for specific applications and optimizing processing techniques.

Q 11. How do you identify and classify different types of wood decay?

Wood decay is caused by fungi and is categorized into several types, primarily based on the pattern of decay and the type of fungi involved.

- Brown rot: This type of decay primarily affects the cellulose component of wood, leaving behind a brown, crumbly residue. The wood loses its strength significantly, and it becomes easy to crumble between the fingers.

- White rot: This decay affects all components of wood (cellulose, hemicellulose, and lignin), resulting in a white, spongy, or stringy texture. Although the wood often looks paler, its strength might be affected to varying degrees depending on the stage of decay.

- Soft rot: This decay is typically caused by fungi that thrive in moist environments. Soft rot produces a characteristic pitting or erosion on the wood’s surface, resulting in a softened, weakened texture.

Identifying wood decay often involves visual inspection, but more detailed analysis might require microscopic examination or laboratory testing. The color, texture, and strength loss, coupled with knowledge of the wood species and its environment, aid in determining the type and extent of decay. For instance, seeing a crumbly brown residue in a structural beam strongly indicates brown rot, raising safety concerns.

Q 12. Discuss the environmental impact of forest product harvesting and utilization.

Forest product harvesting and utilization have significant environmental impacts, both positive and negative. Sustainable practices are crucial to mitigate negative effects.

- Deforestation and Habitat Loss: Unsustainable logging practices can lead to deforestation, loss of biodiversity, and disruption of ecosystems. Selective logging and reforestation efforts help minimize this impact.

- Soil Erosion and Water Pollution: Removal of trees can expose soil to erosion, leading to sediment runoff into waterways and water pollution from chemical treatments. Careful planning and management can reduce erosion.

- Greenhouse Gas Emissions: Forest products can act as carbon sinks, but harvesting and processing can release stored carbon. Sustainable forest management and responsible wood utilization, including using wood as a renewable building material, can minimize greenhouse gas emissions.

- Waste Generation: Wood processing generates waste, including sawdust, bark, and wood residues. Efficient waste management and utilization of by-products in products like biofuel or particleboard help minimize waste.

The forest products industry is increasingly adopting sustainable practices such as certification schemes (e.g., Forest Stewardship Council – FSC) to ensure responsible forest management and minimize environmental impact. The adoption of circular economy principles, promoting reuse and recycling, also minimizes waste and environmental damage.

Q 13. What are the different methods used for measuring wood strength and stiffness?

Measuring wood strength and stiffness is crucial for structural applications and product design. Several methods exist, ranging from simple tests to sophisticated laboratory procedures.

- Static Bending Test: This standard test measures the wood’s bending strength (flexural strength) and modulus of elasticity (stiffness) by applying a load to a specimen until failure. The load at failure and deflection are used to calculate strength and stiffness properties.

- Compression Test: This test measures the wood’s resistance to compressive forces. A specimen is loaded along the grain or across the grain until failure.

- Tensile Test: Measures the wood’s resistance to tensile forces (pulling apart). This is particularly important for applications requiring high tensile strength.

- Shear Test: Determines the wood’s resistance to shear forces (forces that cause sliding along planes). This is important for assessing the strength of joints.

The choice of test depends on the intended use. For example, a structural beam might require bending and compression tests, while a wood panel might require shear and tensile tests. These tests generate data vital for ensuring product safety and performance.

Q 14. Explain the role of wood chemistry in the utilization of forest products.

Wood chemistry plays a crucial role in forest product utilization, impacting properties like durability, treatability, and reactivity.

- Lignin: A complex polymer that provides rigidity and strength to wood. Its chemical structure influences wood’s resistance to decay and its response to chemical treatments. Modifying lignin can improve properties like pulpability for paper production.

- Cellulose and Hemicellulose: These carbohydrates are major components of wood, responsible for its strength and structure. Understanding their chemical properties is crucial for processes like pulping and the production of biofuels and biomaterials.

- Extractives: Natural compounds found in wood, such as resins, oils, and tannins, influence properties like color, odor, decay resistance, and treatability. Extractives can be beneficial (e.g., cedar’s natural resistance to decay) or detrimental (e.g., resins interfering with adhesion).

For example, knowing the chemical composition allows for the selection of appropriate preservatives. Pressure treatment relies on the chemical interaction between the preservative and the wood’s components. Similarly, pulping processes are tailored to the chemical composition of wood to separate cellulose fibers efficiently. Understanding wood chemistry allows for the development of new products and improves the efficiency and sustainability of existing processes.

Q 15. How do you select the appropriate wood species for a given application?

Selecting the right wood species for a specific application is crucial for ensuring both functionality and longevity. It’s like choosing the right tool for a job – a screwdriver wouldn’t work well as a hammer! The process involves considering several key properties of the wood:

- Strength and Durability: For structural applications like building beams or furniture frames, hardwoods like oak, ash, or maple are preferred due to their high strength-to-weight ratio. Softer woods like pine are better suited for less demanding applications.

- Workability: Some woods are easier to work with than others. Pine is relatively easy to cut and shape, making it ideal for carpentry projects. Hardwoods can be more challenging to work with but offer superior durability.

- Appearance: Aesthetic considerations often play a major role. The grain, color, and texture of the wood can significantly influence the final product. For example, cherry wood is prized for its rich color and is often used in high-end furniture.

- Resistance to Decay and Insects: For outdoor applications, choosing naturally durable species like cedar or redwood is essential to prevent rot and insect damage. These woods contain natural oils and resins that provide inherent protection.

- Cost: The price of different wood species varies greatly. Exotic hardwoods like mahogany can be very expensive, while readily available softwoods are more economical.

For example, if I’m building a deck, I’d choose a durable, rot-resistant wood like cedar or redwood. For a fine piece of furniture, I might select oak or cherry for its strength and beauty. The selection process often involves a trade-off between different properties, based on the specific requirements of the project and budget constraints.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the different types of wood-based panels (e.g., plywood, MDF, particleboard).

Wood-based panels are engineered materials offering cost-effective and versatile alternatives to solid wood. They are composed of wood particles or veneers bonded together with adhesives. Here are some common types:

- Plywood: Made from thin layers (plies) of wood veneer glued together with the grain of adjacent plies oriented at right angles. This cross-layering enhances strength and stability. Plywood is strong, relatively inexpensive, and widely used in construction and furniture making.

- Medium-Density Fiberboard (MDF): Manufactured from wood fibers mixed with resin and pressed under high temperature and pressure. MDF has a smooth, uniform surface, making it ideal for painting and finishing. It’s frequently used in furniture, cabinetry, and molding.

- Particleboard (Chipboard): Made from wood particles (chips) bound together with resin and pressed into panels. Particleboard is less dense and strong than plywood or MDF but is still cost-effective for applications where high strength isn’t critical, such as shelving or less demanding furniture pieces.

- Oriented Strand Board (OSB): Similar to particleboard but uses larger wood strands oriented in specific directions for enhanced strength. OSB is commonly used in construction for sheathing and subflooring.

Choosing the right panel depends on the application. Plywood is best for structural applications, MDF for smooth surfaces, and particleboard for less demanding applications. OSB offers a cost-effective alternative for sheathing and structural uses.

Q 17. What are the advantages and disadvantages of using different wood adhesives?

Wood adhesives are essential for bonding wood components in various applications. Different adhesives offer distinct advantages and disadvantages:

- Polyurethane Adhesives: Offer excellent strength, water resistance, and gap-filling capabilities. However, they can be more expensive and require careful handling.

- Polyvinyl Acetate (PVAc) Adhesives (White Glue): Commonly used for woodworking, PVAc adhesives are relatively inexpensive, easy to use, and readily available. They are suitable for interior applications but offer limited water resistance.

- Resorcinol Adhesives: Provide superior water resistance and are suitable for exterior applications. However, they have a strong odor and require specific safety precautions during application.

- Epoxy Adhesives: Known for their high strength and versatility. They are suitable for bonding a wide range of materials and offer excellent gap-filling capabilities. But they can be more expensive than other options.

The choice of adhesive depends on the application. For outdoor projects, water-resistant options like resorcinol are necessary. For interior projects, the less expensive PVAc glues are often sufficient. For high-strength applications, epoxies or polyurethanes are the better choice. Always consider the specific requirements of the project, including the level of water resistance, strength, and cost effectiveness.

Q 18. How do you ensure the quality and safety of wood products?

Ensuring the quality and safety of wood products involves a multifaceted approach that begins at the source and continues through the manufacturing and distribution processes:

- Sustainable Forestry Practices: Sourcing wood from responsibly managed forests ensures the long-term availability of timber and minimizes environmental impact. Certifications like FSC (Forest Stewardship Council) provide assurance of sustainable practices.

- Quality Control during Manufacturing: Implementing rigorous quality control measures during the manufacturing process helps identify and address defects early. This includes inspecting raw materials, monitoring production processes, and conducting regular testing of finished products.

- Adherence to Safety Standards: Wood products should meet relevant safety standards to ensure they are safe for consumers. This involves using safe adhesives, ensuring proper treatment to prevent rot and insect infestation, and using appropriate finishes to reduce the risk of splinters or other hazards.

- Proper Packaging and Handling: Protecting wood products during transportation and storage is crucial to prevent damage and maintain quality. Appropriate packaging and handling procedures help ensure that products arrive in good condition.

- Product Labeling and Information: Clear and accurate labeling provides consumers with information about the wood species, origin, treatment methods, and any relevant safety precautions.

By implementing these measures, manufacturers and distributors can ensure that wood products are both high-quality and safe for consumers. It’s a matter of ethical sourcing and responsible production throughout the entire supply chain.

Q 19. Explain the concept of wood seasoning and its importance in wood utilization.

Wood seasoning is the process of reducing the moisture content of freshly cut wood to a level suitable for use. Imagine a wet sponge – it’s difficult to work with and prone to warping. Wood is similar. Excess moisture can lead to significant problems.

Importance:

- Preventing Shrinkage and Warping: As wood dries, it shrinks. Uneven drying can lead to warping, cracking, and other defects. Seasoning minimizes these problems by allowing the wood to dry slowly and evenly.

- Improving Dimensional Stability: Seasoned wood is more dimensionally stable, meaning it’s less likely to change shape or size over time. This is crucial for applications where precise dimensions are needed.

- Increasing Strength and Durability: Seasoned wood is generally stronger and more durable than green (wet) wood. It’s less susceptible to decay and insect attack.

- Improving Workability: Seasoned wood is easier to work with, as it’s less likely to split or tear during machining.

Methods: Seasoning can be done through air drying (natural drying) or kiln drying (accelerated drying). Air drying is slower but generally results in better quality wood. Kiln drying is faster but requires careful control to avoid defects.

Q 20. What are the different methods used for evaluating the durability of wood products?

Evaluating the durability of wood products involves assessing their resistance to various factors that can cause degradation. Several methods are used:

- Visual Inspection: A basic assessment to identify visible defects like cracks, knots, or decay.

- Moisture Content Measurement: Determining the moisture content helps assess the likelihood of shrinkage, warping, and decay.

- Mechanical Testing: Testing the strength and stiffness of the wood using standardized methods, such as bending strength or compression strength tests. This quantifies the wood’s resistance to physical forces.

- Durability Testing: Exposing wood samples to various environmental conditions, such as humidity, temperature changes, and fungal attack, to assess their resistance to degradation. This can involve accelerated weathering tests or field tests.

- Chemical Analysis: Analyzing the chemical composition of the wood to determine its resistance to decay or insect attack.

The specific methods used depend on the type of wood product and the intended application. For example, structural timber will require more rigorous mechanical testing than decorative wood veneers. Comprehensive testing provides a reliable measure of the product’s longevity and suitability for the intended purpose.

Q 21. Discuss the economic factors influencing the choice of forest products.

Economic factors significantly influence the choice of forest products. It’s not just about the initial cost of the material, but the overall lifecycle costs.

- Price of Raw Materials: Fluctuations in timber prices due to supply and demand, location, and species directly impact the cost of wood products. A cheaper wood species might be chosen if the project has a tight budget.

- Manufacturing Costs: The cost of processing and manufacturing the wood product, including labor, energy, and equipment, can substantially influence the final price. Different wood species may have varying processing costs.

- Transportation Costs: The distance between the source of the wood and the manufacturing facility or end-user affects the cost. Locally sourced wood is often preferred to reduce transportation expenses and environmental impact.

- Demand and Supply: The market demand for specific wood species influences their price. Scarce or highly sought-after species will command higher prices.

- Durability and Maintenance Costs: The long-term durability of a wood product influences the overall cost. A more durable, expensive material may require less maintenance over time, potentially reducing the overall lifecycle cost.

The decision often involves finding a balance between initial cost, durability, and aesthetic preferences. A life-cycle cost analysis can help compare different options and make informed decisions based on long-term economic considerations.

Q 22. Explain the importance of proper storage and handling of wood products.

Proper storage and handling of wood products are crucial for maintaining their quality, extending their lifespan, and preventing economic losses. Think of it like storing fine wine – improper conditions can ruin the product.

Protection from Moisture: Wood is hygroscopic, meaning it absorbs and releases moisture from the surrounding environment. Excessive moisture can lead to warping, cracking, fungal growth (like mold and mildew), and decay. Proper storage involves keeping wood in a dry, well-ventilated area, often with humidity control.

Protection from Pests: Insects like termites and wood-boring beetles can significantly damage wood products. Proper storage includes using pest-repellent treatments, maintaining cleanliness, and regularly inspecting for infestations. In extreme cases, fumigation might be necessary.

Protection from UV Radiation: Sunlight’s ultraviolet (UV) rays can cause wood to fade and degrade. Storing wood products out of direct sunlight, or using UV-resistant coatings, helps prevent this.

Proper Stacking and Handling: Avoid stacking wood too tightly, which can trap moisture. Use proper lifting techniques to avoid damage during handling. Adequate support prevents warping and bending, particularly in longer boards.

For example, a lumberyard failing to properly cover and shelter its inventory during a rainy season could experience significant losses due to warped or rotted lumber, impacting profitability.

Q 23. Describe the different types of wood finishing techniques and their effects on the wood.

Wood finishing techniques enhance the aesthetic appeal, durability, and protection of wood products. There’s a wide array, each impacting the wood differently.

Staining: Penetrates the wood’s surface, altering its color without significantly changing the texture. It enhances the wood’s grain and offers limited protection.

Sealing: Creates a barrier between the wood and the environment, protecting it from moisture and pests. Examples include penetrating oils, varnishes, and lacquers. Each provides different levels of protection and sheen.

Painting: Provides the most substantial protection against moisture and damage, but completely hides the wood grain. The choice of paint type – oil-based or water-based – influences durability and application method.

Finishing Techniques: Methods for applying finishes vary, from brushing and rolling to spraying. Each technique impacts the final appearance and evenness of the finish.

For instance, a hand-rubbed oil finish on a fine wooden table enhances the grain and provides a soft, natural feel, while a sprayed lacquer finish on kitchen cabinets offers a durable, high-gloss protection.

Q 24. How do you identify and assess the risk of pests and diseases affecting wood products?

Identifying and assessing pest and disease risks in wood products requires a multi-faceted approach. Early detection is key to effective mitigation.

Visual Inspection: Carefully examine the wood for signs of insect infestation (e.g., holes, tunnels, frass – insect droppings), fungal growth (e.g., discoloration, fruiting bodies), or decay (e.g., softening, crumbling). Magnification tools can help identify smaller pests.

Laboratory Analysis: For more detailed diagnosis, samples can be sent to a laboratory for microscopic examination to identify the specific pest or pathogen. This helps in selecting the most effective treatment strategy.

Moisture Meter Readings: High moisture content is a significant factor in wood decay and pest infestations. A moisture meter helps assess risk by determining the moisture levels in wood.

Risk Assessment Factors: Consider the wood species (some are more susceptible to certain pests), the origin of the wood (imported wood can carry invasive species), storage conditions, and past history of pest or disease problems in the area.

For example, detecting the presence of Lyctus beetles in a shipment of hardwood furniture would require immediate action – quarantine, fumigation, and potentially destruction of infested items – to prevent wider spread.

Q 25. Explain the role of certification schemes (e.g., FSC) in sustainable forest management.

Certification schemes like the Forest Stewardship Council (FSC) play a vital role in promoting sustainable forest management. They provide a third-party verification of responsible forestry practices.

Chain of Custody: FSC certification tracks wood products from the forest to the consumer, ensuring that the wood originates from responsibly managed forests and has been processed ethically.

Environmental Protection: FSC standards promote biodiversity conservation, protection of water resources, and reduced greenhouse gas emissions from forest management practices.

Social Responsibility: FSC standards address the social impacts of forestry, including fair labor practices, community engagement, and respect for indigenous rights.

Market Demand: FSC certification creates a market incentive for sustainable forestry, encouraging landowners and businesses to adopt responsible practices.

Consumers increasingly seek out FSC-certified products, driving demand for sustainably sourced wood and supporting responsible forest management practices. This helps protect forests for future generations.

Q 26. What are the emerging trends and innovations in forest product utilization?

The forest product utilization sector is experiencing exciting innovations and trends.

Bio-based Materials: Research focuses on developing new materials from wood components, such as cellulose nanocrystals, for applications in construction, packaging, and composites, reducing reliance on fossil fuels.

Advanced Wood Processing Technologies: Innovations like cross-laminated timber (CLT) are transforming construction, offering stronger, lighter, and more sustainable building materials.

3D Wood Printing: This technology allows for creating complex shapes and designs from wood fibers, enabling customization and efficient material use.

Circular Economy Approaches: Focus is shifting towards maximizing the use of wood resources through recycling, reuse, and the development of biodegradable wood products, reducing waste.

Improved Wood Protection: Development of new, environmentally friendly wood preservatives is ongoing to enhance durability and reduce the need for chemical treatments.

For example, the rise of CLT construction is a testament to the innovative use of wood in high-rise buildings, offering sustainable and efficient alternatives to traditional materials.

Q 27. Describe a situation where you had to troubleshoot a problem related to wood quality or processing.

During a project involving the construction of a timber-framed house, we encountered significant warping in several structural beams. This threatened the structural integrity of the building.

Troubleshooting Steps:

Inspection: We carefully inspected the warped beams, noting the severity and direction of the warp. This revealed uneven moisture content within the beams.

Moisture Meter Testing: We used a moisture meter to measure the moisture content at various points across the beams. This confirmed higher moisture levels in certain sections.

Root Cause Analysis: We determined that inadequate drying of the lumber before construction was the primary cause. The lumber had been stored improperly, leading to uneven moisture absorption.

Corrective Actions: We replaced the severely warped beams with properly dried lumber. For less severely affected beams, we employed techniques like steam bending to partially correct the warping. The remaining beams were treated with a moisture-equalizing sealant.

Preventive Measures: We implemented stricter quality control measures for lumber selection and storage, including improved drying protocols and humidity control during storage.

The situation highlighted the importance of proper lumber drying and storage for preventing quality issues and ensuring structural integrity in construction projects.

Q 28. How do you stay current with the latest advancements in forest product technology?

Staying current in forest product technology requires a multi-pronged approach.

Professional Organizations: Active membership in organizations like the Society of Wood Science and Technology (SWST) provides access to journals, conferences, and networking opportunities.

Trade Publications and Journals: Regularly reading industry publications and scientific journals keeps me updated on the latest research and technological advancements.

Conferences and Workshops: Attending industry conferences and workshops allows me to learn from experts and network with colleagues.

Online Resources: Utilizing online databases and resources, such as scientific journals, industry websites, and online courses, provides access to a wealth of information.

Collaboration and Networking: Staying connected with colleagues and experts in the field through collaborations and networking events helps me learn about new developments.

Continuous learning is essential in this dynamic field to remain competitive and provide the best possible solutions.

Key Topics to Learn for Forest Product Identification and Utilization Interview

- Wood Anatomy and Identification: Understanding wood structure (e.g., growth rings, pores, rays), identifying different species through macroscopic and microscopic examination, and applying this knowledge to assess wood quality and suitability for various applications.

- Wood Properties and Characteristics: Exploring the mechanical, physical, and chemical properties of wood (strength, density, durability, etc.) and their influence on processing and end-use performance. This includes understanding the impact of factors like moisture content and defects.

- Forest Product Manufacturing Processes: Gaining familiarity with the processes involved in converting raw timber into various products (lumber, plywood, pulp and paper, engineered wood products). This includes understanding the machinery, techniques, and quality control measures employed at each stage.

- Sustainable Forest Management Practices: Knowing the principles of sustainable forestry, including responsible harvesting, reforestation, and minimizing environmental impact. This is crucial for understanding the lifecycle of forest products and their environmental footprint.

- Wood Preservation and Treatment: Understanding techniques used to protect wood from decay, insect infestation, and fire. This includes knowledge of different preservatives and their application methods.

- Wood Defects and their Impact: Identifying common wood defects (e.g., knots, checks, shakes) and understanding their effect on strength, durability, and the suitability of the wood for different applications. Learn to assess the severity of these defects.

- Wood Utilization and Applications: Exploring the diverse applications of wood and wood-based products in construction, furniture manufacturing, packaging, and other industries. Understanding market trends and the selection of appropriate wood species for specific applications.

- Quality Control and Testing: Familiarizing yourself with standard testing methods used to evaluate the quality of wood and wood products. Understanding quality assurance procedures throughout the manufacturing process.

Next Steps

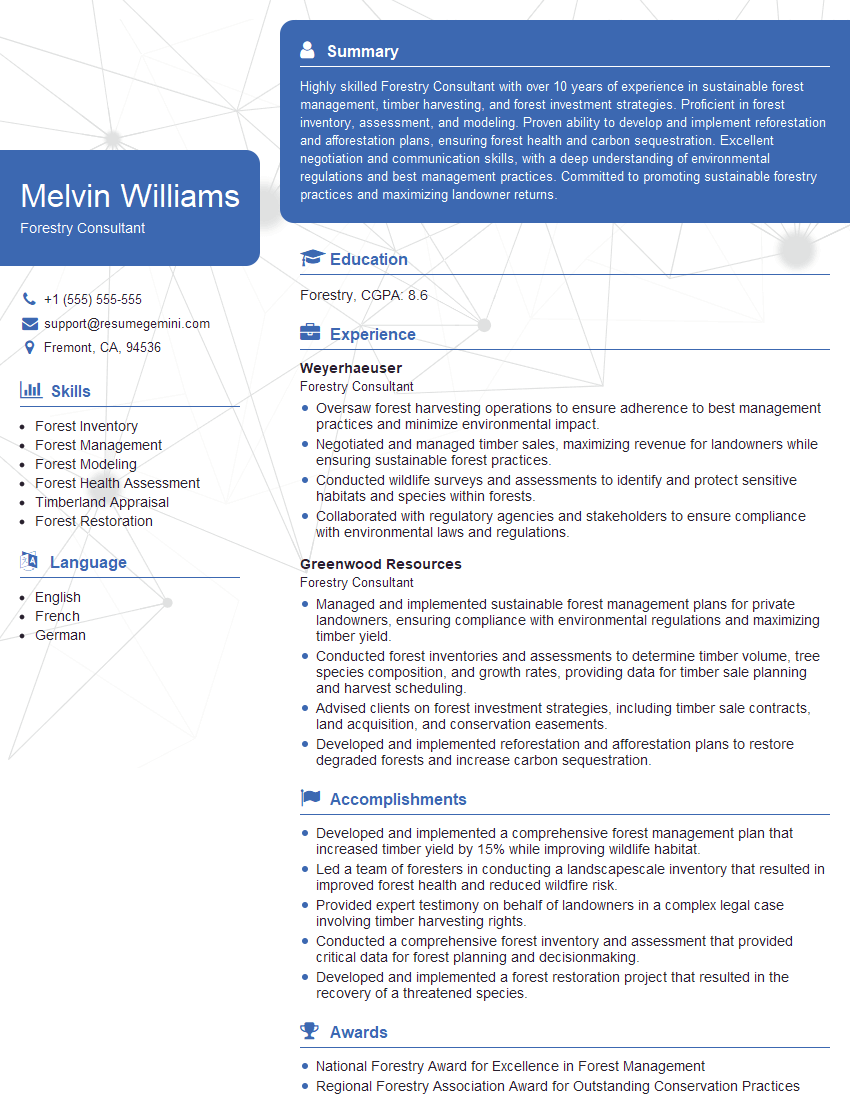

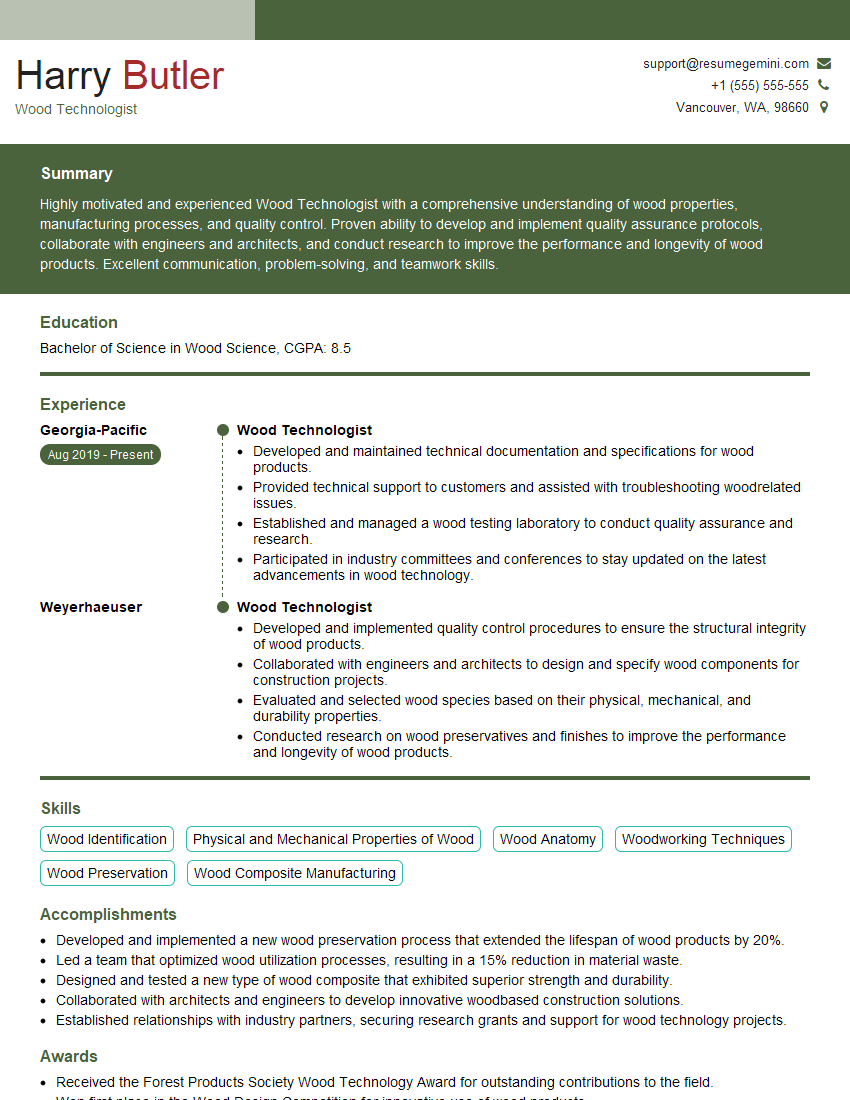

Mastering Forest Product Identification and Utilization opens doors to exciting career opportunities in forestry, manufacturing, construction, and research. A strong understanding of these concepts significantly enhances your marketability and expertise. To stand out, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They even provide examples of resumes tailored to Forest Product Identification and Utilization to help guide your efforts.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good