Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential ASTM D3917 interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in ASTM D3917 Interview

Q 1. Explain the purpose and scope of ASTM D3917.

ASTM D3917, “Standard Test Methods for Determining the In-Place Density of Soil and Aggregate by the Nuclear Methods,” outlines procedures for measuring the density of soil and aggregate materials in their natural state, directly in the field. This is crucial for various engineering applications, ensuring that construction projects meet the specified compaction requirements and thus ensuring stability and longevity. The scope encompasses both dry and wet density determination using nuclear gauges, covering a range of soil types and applications from road construction to embankment stability assessments.

Q 2. Describe the different types of soil samples used in ASTM D3917 testing.

ASTM D3917 doesn’t explicitly define ‘types’ of soil samples in a classificatory sense like the Unified Soil Classification System (USCS). Instead, it focuses on the in-situ condition. The method applies to a wide range of soil and aggregate materials, including granular soils (sands and gravels), cohesive soils (clays and silts), and mixtures thereof. The key is that the material must be in its natural, undisturbed state to obtain a representative measurement of its in-place density. Preparation involves ensuring a level surface for accurate gauge placement, not altering the material’s density.

Q 3. What are the limitations of the ASTM D3917 test method?

Several limitations exist within ASTM D3917. Firstly, the method is sensitive to moisture content variations. Accurate readings necessitate careful consideration of moisture content, potentially requiring separate moisture content tests. Secondly, the method is unsuitable for certain materials, such as those containing significant amounts of large boulders or highly variable materials that hinder consistent gauge readings. Calibration is also critical and must be performed and checked regularly to ensure accuracy. Additionally, the method requires specialized equipment (nuclear gauges), which adds cost and requires trained personnel. Finally, there’s the inherent radiation safety aspect which necessitates adhering strictly to safety guidelines.

Q 4. How does sample preparation affect the results of ASTM D3917 testing?

Sample preparation, or rather, the lack of significant sample preparation, is key to the accuracy of ASTM D3917. Any disturbance of the soil can drastically alter its density. The goal is to measure the in-place density, so activities such as excessive digging, compacting, or even vibrations from heavy machinery near the testing area must be avoided. The test area should be carefully cleaned to ensure there is no debris that could interfere with the measurement. Properly clearing a flat, representative area, and taking care to not compact the area during preparation is critical to obtaining accurate and reliable results. Imagine trying to measure the density of a perfectly stacked pile of sand – if you disturb it, you alter the density measurement.

Q 5. Explain the significance of the various parameters measured in ASTM D3917.

ASTM D3917 primarily measures in-place dry density (ρd) and in-place wet density (ρb). The dry density represents the mass of soil solids per unit volume, excluding the water content. This is a crucial parameter for evaluating the compaction effort in construction projects. The wet density includes the mass of both soil solids and water. The difference between these two values is used to calculate the moisture content which affects the soil’s engineering properties. These parameters are vital because they are directly related to the soil’s strength, stability, and bearing capacity. For instance, a low dry density indicates insufficient compaction, leading to potential settlement and structural instability in pavements or embankments.

Q 6. What are the potential sources of error in ASTM D3917 testing, and how can they be minimized?

Potential errors stem from several sources. Inaccurate calibration of the nuclear gauge, improper placement of the gauge, variations in soil moisture content, presence of large rocks or other obstructions affecting the measurement, and operator error during the procedure are all sources of error. These can be minimized through rigorous calibration, careful gauge placement using level surfaces, comprehensive moisture content measurements in conjunction with density tests, pre-testing for the presence of large obstructions, detailed operator training, and adherence to the test method’s specified procedures. Using multiple tests and averaging can help mitigate some errors. Regular maintenance and quality control checks on the equipment are essential.

Q 7. How do you interpret the results of an ASTM D3917 test?

Interpretation of ASTM D3917 results involves comparing the measured in-place dry density to the specified or required dry density for the project. If the measured density falls below the required density, it indicates insufficient compaction. This requires further investigation and potentially remedial compaction efforts. Conversely, a density exceeding the specified range might indicate over-compaction, which can also have negative consequences. The results, along with moisture content data, should be carefully analyzed in the context of the project specifications and the soil’s engineering properties. For example, a low dry density in a road subgrade could lead to rutting and premature failure. Understanding these relationships is essential for making informed engineering decisions.

Q 8. What is the difference between static and dynamic compaction in the context of ASTM D3917?

ASTM D3917, which covers the laboratory compaction characteristics of soil using standard effort, distinguishes between static and dynamic compaction methods primarily in how the compactive force is applied.

Static compaction uses a gradually applied load to the soil sample. Imagine slowly pressing down on a pile of sand – that’s analogous to static compaction. This method is typically performed using a static compaction apparatus where a known weight is incrementally added to the soil contained within a cylindrical mold. The weight is carefully applied to prevent vibration or shock, ensuring a controlled and uniform compaction. This approach provides insights into the soil’s response to gradual loading, relevant to understanding settlement behavior under static loads.

Dynamic compaction, on the other hand, simulates the effects of impact or vibration. Think of repeatedly dropping a hammer onto the same pile of sand. The compactive energy is delivered through repeated impacts or vibrations. In ASTM D3917, this is usually achieved using a mechanical device that drops a specified weight from a predetermined height. This approach is more akin to conditions experienced during construction activities such as those involving heavy equipment and is valuable in predicting compaction behavior under dynamic loads.

The key difference lies in the method of energy application: gradual and controlled in static compaction versus rapid and repetitive in dynamic compaction. The resulting dry density and optimum moisture content will typically differ between these two methods, leading to different interpretations of the soil’s compaction behavior.

Q 9. Describe the equipment and apparatus required for performing ASTM D3917 testing.

Performing ASTM D3917 requires specific equipment and apparatus. Precision and careful calibration are crucial for accurate results.

- Compaction Mold: A cylindrical mold of specified dimensions (typically 4-inch diameter and 4.5-inch height) is used to contain the soil sample during compaction. This mold must be clean and free of any debris.

- Compaction Hammer or Rammer: This device delivers the compactive effort. For static compaction, a weight incrementally added to the soil is utilized. Dynamic compaction methods, as mentioned earlier, use a mechanical device dropping a weight from a certain height.

- Balance or Scale: An accurate scale capable of measuring the weight of the soil sample and other components with a precision of at least 0.1 grams (or suitable unit) is essential for accurate measurements.

- Drying Oven: A controlled-temperature oven is needed to dry the soil sample to determine the moisture content.

- Other tools:** A scoop, spatula, mixing bowl, and graduated cylinders for measuring water. Additionally, tools to remove the compacted soil from the mold would also be required.

The specific equipment and procedures will depend on whether static or dynamic compaction is used; however, the standards define these details for each method.

Q 10. How do you ensure the accuracy and precision of ASTM D3917 test results?

Ensuring the accuracy and precision of ASTM D3917 test results requires meticulous attention to detail throughout the testing process.

- Calibration of Equipment: All equipment, particularly the balance and the compaction hammer (if using the dynamic method), must be calibrated according to the manufacturer’s instructions and verified regularly with traceable standards. Regular calibrations ensure accurate measurements of weight, height, and compaction force. Any discrepancies must be documented.

- Proper Sample Preparation: Thorough mixing of the soil sample before testing is crucial to ensure uniformity. Representative samples must be obtained from the entire lot and the sample must be prepared and handled correctly to minimize errors due to sample variation.

- Controlled Testing Environment: The temperature and humidity of the testing environment should be monitored and controlled, as environmental conditions can affect the moisture content of the soil and thus affect the results.

- Multiple Tests: Performing multiple tests on split samples and calculating the mean and standard deviation helps assess the variability and precision of the results. The more tests performed, the better the estimate of the true mean. Outlier results should be carefully investigated and potentially excluded based on established criteria.

- Quality Control Measures: Regular use of control samples alongside the unknown samples aids in ensuring the quality and repeatability of the test results, allowing for quick identification of any procedural errors or equipment malfunction.

Implementing a well-defined quality control plan is essential to maintain the consistency and reliability of the results over time. Documentation of all steps including equipment calibration, sample preparation, and test execution, are fundamental to the process.

Q 11. Explain the importance of proper sample handling and storage in ASTM D3917.

Proper sample handling and storage are paramount for reliable ASTM D3917 results. Changes in moisture content can significantly affect the compaction characteristics of the soil.

Sample Collection: The collected sample must represent the material being characterized. A suitable sampling plan is needed to achieve this. This involves collecting numerous small samples that are then combined to form a homogenous larger sample.

Sample Preparation: The sample should be carefully prepared to achieve uniformity and consistency. This typically involves crushing the sample (if necessary), removing any large stones or foreign materials, and thoroughly mixing it to obtain a homogenous material.

Moisture Control: Before the testing begins, a significant portion of the sample is weighed and placed in an oven to determine the initial moisture content. The sample should then be carefully prepared for compaction by reaching a specific moisture content as per the test procedure. This may require careful addition of water followed by mixing to allow the water to become uniformly distributed within the soil.

Storage: If testing cannot be immediately completed, the sample must be stored in airtight containers to prevent loss or gain of moisture. Storage conditions should also maintain the sample in a state as close as possible to its original state to avoid any changes that would influence the final results.

Ignoring proper sample handling and storage can lead to inaccurate results and misinterpretation of the soil’s compaction properties.

Q 12. How do you determine the appropriate number of tests required for ASTM D3917?

Determining the appropriate number of tests for ASTM D3917 depends on several factors, including the variability of the soil, the required level of precision, and the project’s overall objectives. There isn’t a fixed number prescribed in the standard. Instead, the standard emphasizes good statistical practices.

Variability of Soil: Highly variable soil requires more tests compared to more uniform soil. More tests reduce the effect of natural variability and provide a more reliable assessment of the average compaction characteristics.

Precision Requirements: Higher precision requirements necessitate a larger number of tests. This allows for a reduction in the margin of error and a more precise determination of the optimal moisture content and maximum dry density.

Project Specifics: The scope and importance of the project will play a role in determining the number of tests. A critical project where safety is paramount, such as an embankment dam, might require significantly more testing compared to a smaller project with lower risks. As a general rule, using three tests per condition (moisture content level) is often sufficient for routine projects. To provide a reasonable mean and standard deviation, a minimum of three tests is often recommended for most situations; however, higher numbers are often used to provide a more accurate representation of the soil’s behavior.

Statistical analysis of the results should always be conducted to determine the level of variability and to determine whether the number of tests used was sufficient for a given level of confidence.

Q 13. What are the reporting requirements for ASTM D3917 test results?

ASTM D3917 test results reporting requires a specific format to ensure clarity and consistency.

The report should include:

- Project Information: Project name, location, date of testing, and the responsible party.

- Soil Description: A complete description of the soil sample, including its origin, classification (e.g., according to Unified Soil Classification System), and any relevant visual characteristics.

- Sample Preparation Details: Information about the sample collection, preparation methods, including details on the methods used to obtain a homogenous sample, and moisture content determination.

- Compaction Details: A clear description of the compaction method used (static or dynamic) along with the specific parameters used, such as the compaction energy, number of compaction layers, and the diameter of the hammer used (if applicable).

- Test Results: The results should include the dry density values for each of the tested moisture contents, presented in tabular or graphical form (often a compaction curve showing the relationship between moisture content and dry density).

- Maximum Dry Density and Optimum Moisture Content: The maximum dry density (MDD) and the optimum moisture content (OMC) should be clearly identified and reported as these represent important compaction characteristics.

- Number of Tests Performed: The number of tests performed at each moisture content should be documented.

- Standard Deviation of results: Standard deviation should be reported for each of the moisture contents tested.

- Any anomalies or observations: Any anomalies or deviations from standard procedures should be mentioned in the report.

The report should be clear, concise, and easy to understand, allowing for the information to be used for proper engineering judgment and decision-making.

Q 14. How does moisture content affect the results of ASTM D3917 testing?

Moisture content significantly impacts the results of ASTM D3917 testing. It directly affects the dry density and compactibility of the soil.

At lower moisture contents, the soil particles tend to be more rigid and less cohesive. As a result, the soil may not compact easily, resulting in a lower dry density. Conversely, at higher moisture contents, the water acts as a lubricant, increasing soil particles’ mobility and allowing them to pack closer together, leading to higher dry density. However, an excessive amount of water can hinder compaction by creating a water-saturated state that prevents the soil particles from making good contact. As a result, the dry density would also decrease.

The optimal moisture content (OMC) is the moisture content at which the maximum dry density (MDD) is achieved. This point represents the most efficient level of compaction for a given soil and compaction effort. The relationship between moisture content, dry density, and compaction effort is usually plotted as a graph (compaction curve) which shows the optimum moisture content at which a maximum dry density can be achieved.

Therefore, precise control and measurement of moisture content are crucial for obtaining accurate and reliable compaction results. Any variations in moisture content will directly affect the results obtained for the maximum dry density and optimum moisture content.

Q 15. Explain the concept of relative density as it relates to ASTM D3917.

ASTM D3917, Standard Test Methods for In-situ Density of Soil Using the Sand Cone Method, utilizes the concept of relative density indirectly. It doesn’t directly calculate relative density, which is a measure of how densely packed soil particles are relative to their loosest and densest possible arrangements. Instead, it measures the in-situ dry density (ρd) of the soil. This dry density is then compared to the maximum and minimum dry densities (ρdmax and ρdmin, respectively) determined through separate laboratory tests (often using ASTM D698). These maximum and minimum densities provide the context to understand how compacted the field soil is. Although not explicitly stated as ‘relative density’ in the test method, the comparison allows for an implicit understanding of the soil’s relative density.

Imagine a jar of marbles: you can arrange them loosely, leaving lots of gaps, or tightly, maximizing the number of marbles. The in-situ dry density from D3917 is like measuring the overall density of marbles in a jar that’s already been filled. The laboratory tests (to determine ρdmax and ρdmin) are analogous to figuring out the densest and loosest packing possible for those same marbles.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle non-conforming test results in ASTM D3917?

Non-conforming test results in ASTM D3917, meaning results outside the acceptable range specified in the project’s quality control plan, must be handled systematically. First, it’s crucial to meticulously review the entire testing procedure. Were there any procedural errors? Were equipment calibrations current and accurate? Were proper sampling techniques followed? Identifying procedural errors could explain the discrepancy.

If procedural errors are identified and corrected, repeat testing is required on new samples. If no errors are found, it’s important to investigate the cause of non-conformity. This might involve additional testing, such as moisture content determination (ASTM D2216) or grain size analysis (ASTM D422). The additional data might pinpoint a localized variation in soil density.

Documentation of the non-conforming results, the investigation undertaken, and the corrective actions implemented is vital. A report detailing the investigation and its findings should be prepared. Ultimately, the decision on how to proceed depends on the significance of the non-conformity within the context of the overall project. It might involve remediation, acceptance based on other evidence, or even redesign depending on the nature of the discrepancy and its potential consequences.

Q 17. Describe the relationship between ASTM D3917 and other relevant geotechnical tests.

ASTM D3917 is intrinsically linked to other geotechnical tests. The in-situ density it provides is crucial for many other analyses. For instance, it’s often used in conjunction with moisture content determination (ASTM D2216) to calculate the in-situ dry unit weight. This value is vital input for calculating the degree of saturation and understanding the soil’s behavior under load.

Furthermore, the results of ASTM D3917 are often compared to laboratory compaction tests (like ASTM D698) to assess the level of field compaction achieved. Grain size distribution (ASTM D422) helps interpret the compaction characteristics and provides context to the density results, for example, understanding if the obtained density is consistent with the material’s inherent properties. Together, these tests provide a comprehensive understanding of the soil’s engineering properties.

Finally, the bearing capacity and settlement analyses during geotechnical design often rely on the soil’s density and its derived properties. The interplay of these tests leads to a more robust geotechnical assessment of a site.

Q 18. What are the key differences between ASTM D3917 and other methods for determining soil density?

Several methods determine soil density, each with strengths and weaknesses. ASTM D3917 (sand cone method) is an in-situ method, meaning it measures density in the ground, making it valuable for large-scale projects. However, it’s somewhat labor-intensive and can be affected by operator skill.

Other methods include the nuclear density gauge (ASTM D6938), which is faster and less labor-intensive but requires specialized equipment and trained personnel for proper use, and also involves potential radiation safety considerations. The rubber balloon method also exists, providing a quick estimation, but it is less accurate for more heterogeneous soil conditions.

The choice of method depends on factors like project scale, budget, required accuracy, soil conditions, and available equipment. For example, a large highway project might favor the nuclear method due to speed, while a smaller site investigation might use the sand cone method for its simplicity and relatively low cost.

Q 19. Discuss the implications of ASTM D3917 test results on geotechnical design.

The results of ASTM D3917 significantly impact geotechnical design. The in-situ dry density directly influences calculations of bearing capacity, settlement, and slope stability. For example, a lower-than-specified density indicates insufficient compaction, leading to a higher risk of settlement under loading.

In foundation design, a low density might necessitate modifications – a deeper foundation, increased foundation size, or improved soil conditions through compaction or other ground improvement techniques to ensure the structure’s stability. In slope stability analysis, low density can increase the risk of landslides. Accurate density measurements are essential for designing safe and stable structures.

Imagine designing a building on soil with unexpectedly low density. The building might settle more than predicted, causing cracks in walls and other structural issues, highlighting the critical role of ASTM D3917 in ensuring safe and economical geotechnical design.

Q 20. How does the gradation of soil affect the results of ASTM D3917 testing?

Soil gradation, the distribution of particle sizes, significantly affects the results of ASTM D3917. Well-graded soils (containing a range of particle sizes) generally achieve higher maximum dry densities compared to poorly graded soils (predominantly composed of one size fraction). This is because well-graded soils have better particle interlocking, allowing for denser packing.

For instance, a sandy soil with a well-defined gradation would generally exhibit a higher maximum dry density than a silty soil with limited size variation. This difference in achievable density, which is reflected in the maximum and minimum dry density values, affects the interpretation of the in-situ density obtained from the ASTM D3917 test. A density that might be acceptable in a well-graded soil could be unacceptable for a poorly-graded soil with a much lower maximum potential density.

Understanding the gradation of soil is therefore essential for interpreting the density results and ensuring accurate and safe geotechnical design and construction.

Q 21. Describe the role of ASTM D3917 in quality control during construction.

ASTM D3917 plays a crucial role in quality control during construction, especially in earthworks. It provides a means to verify that compaction requirements, specified in the project’s specifications, have been met. Regular field density testing ensures that the compacted soil achieves the required density for stability and performance.

During the construction of embankments, roads, and other earthworks, routine testing using the sand cone method verifies that each layer is compacted to the specified density. If the measured density is below the specified requirement, corrective measures, such as additional compaction, are implemented before proceeding. This ensures that the completed structure meets the required strength and stability parameters.

Imagine a large dam. Regular ASTM D3917 testing throughout its construction guarantees the stability of the structure, minimizing the risk of failure and ensuring the safety of the surrounding population. This is a critical role for ASTM D3917 in ensuring quality and safety in civil engineering projects.

Q 22. How do you ensure that the testing procedures comply with ASTM D3917 standards?

Ensuring compliance with ASTM D3917, the standard test method for density of soil in place by the nuclear method, requires meticulous attention to detail throughout the entire testing process. This starts with selecting the appropriate nuclear gauge for the project, ensuring it’s properly calibrated, and following the prescribed procedures explicitly. We begin by verifying that the equipment is in compliance with the manufacturer’s specifications and is calibrated using traceable standards. This calibration should be documented and reviewed regularly.

Next, we meticulously follow all steps outlined in ASTM D3917, including sample selection, preparation, measurement procedures, and data analysis. This involves carefully selecting representative test locations, ensuring proper probe insertion depth and avoiding factors that could influence the reading such as moisture variations or unusual soil conditions. Detailed field logs documenting procedures, equipment settings, and environmental conditions are crucial for traceability and quality control. Finally, we adhere strictly to the calculation methods specified in the standard to ensure the accuracy of our density readings.

Imagine baking a cake: You need the right ingredients (our equipment), the correct recipe (ASTM D3917), and precise measurements (calibration and procedure) to ensure a perfect outcome. Any deviation can affect the final result.

Q 23. Explain the importance of calibration and maintenance of equipment used in ASTM D3917 testing.

Calibration and maintenance are paramount in ASTM D3917 testing. A poorly calibrated or malfunctioning nuclear gauge will lead to inaccurate density readings, potentially compromising project safety and engineering decisions. Regular calibration ensures the gauge provides consistent and reliable measurements, traceable to national or international standards.

Calibration should involve using certified sources of radiation, if applicable, and standardized density blocks or materials of known density. A calibration curve should be generated and compared to manufacturer’s data to verify the accuracy of the gauge. This should be performed regularly, often before and after each field day, or at set intervals defined by the manufacturer. Maintenance involves regular checks of the gauge’s components, such as the detector, source, and electronic components. These checks may include cleaning the probe, inspecting for any damage, and verifying proper functioning of the electronics. A comprehensive maintenance log should meticulously record all calibrations, maintenance activities, and any repairs or replacements.

Consider a scale used for weighing ingredients: An uncalibrated scale will produce inaccurate results, just as a poorly maintained nuclear gauge will generate unreliable density data.

Q 24. How do you address discrepancies between laboratory and in-situ density measurements?

Discrepancies between laboratory and in-situ density measurements using ASTM D3917 can stem from several factors. These include variations in soil sampling techniques, differences in soil moisture content between the in-situ measurement and the lab sample, and errors in either the in-situ or lab measurement process itself.

To address these discrepancies, we first critically examine the methodologies used for both tests. We assess the representativeness of the samples collected for laboratory testing, considering factors such as sample volume, location, and potential disturbance. We then scrutinize the accuracy of both the field measurements (using the nuclear gauge) and the laboratory measurements (e.g., using the water displacement method). We also analyze whether the soil moisture content differs significantly between the in-situ condition and the lab-prepared sample. For example, a significant moisture content loss during sample transportation to the lab would affect results.

If significant discrepancies persist after rigorous review, additional testing may be required to pinpoint the source of error. This might include comparing the results to data obtained with other methods, conducting additional in-situ or lab measurements, or considering alternative explanations like soil heterogeneity.

Q 25. What are some common challenges encountered when performing ASTM D3917 testing?

Common challenges encountered during ASTM D3917 testing include:

- Difficult soil conditions: Highly variable soils, presence of rocks or debris, and hard or compacted layers can hinder probe insertion and produce unreliable readings.

- Environmental factors: Temperature variations, precipitation, and high winds can influence the readings and affect the gauge’s performance.

- Equipment malfunctions: Malfunctioning equipment, including batteries, detectors or electronics, can lead to inaccurate results.

- Operator error: Inadequate training or improper use of the equipment can compromise the quality of the results.

- Safety concerns: Handling radioactive sources (if applicable) requires strict adherence to safety procedures and appropriate personnel training.

Addressing these challenges involves thorough planning, proper training, use of appropriate equipment, and adherence to strict quality control procedures.

Q 26. How would you troubleshoot problems encountered during ASTM D3917 testing?

Troubleshooting ASTM D3917 testing problems involves a systematic approach. First, we review the entire testing process, including equipment calibration, procedures, and data analysis, checking for any deviations from the ASTM D3917 standard. We then examine the field logs for any unusual events or conditions that might have affected the measurements. If equipment is suspected, we check for malfunctions, including low battery, detector issues, or electronic failures. If errors remain, we consider recalibrating the equipment, and if that’s unsuccessful, potentially seek assistance from the equipment manufacturer or a qualified expert.

For example, if repeated measurements at the same location are inconsistent, it’s important to consider soil heterogeneity, errors in probe insertion, or equipment malfunction. Systematic checks are crucial in identifying the root cause. In situations where multiple sources of uncertainty exist, we may utilize statistical analysis to quantify the uncertainty in the final density results.

Q 27. Describe a situation where ASTM D3917 testing was critical to project success.

During a large-scale earthworks project, accurate compaction control was crucial to ensuring the stability of a major highway embankment. ASTM D3917 testing was employed to verify that the compacted fill met the specified density requirements throughout the construction process. Initially, some areas showed lower-than-required densities. By using ASTM D3917, we pinpointed the deficient areas and were able to implement corrective measures, including additional compaction efforts, before any significant stability issues arose. This proactive approach ensured project success, preventing costly repairs and potential safety hazards. Had we not used ASTM D3917, undetected compaction issues might have compromised the embankment’s stability, potentially leading to structural failure and significant project delays and expense.

Q 28. How do you stay up-to-date on the latest developments and revisions in ASTM D3917?

Staying up-to-date with ASTM D3917 and its revisions is essential for maintaining competence and ensuring test accuracy. We regularly consult the ASTM International website for updates, revisions, and new publications. We also participate in industry conferences, workshops, and training courses related to geotechnical testing and nuclear gauges. Professional memberships in relevant organizations, such as the American Society of Civil Engineers (ASCE), provide access to publications, updates, and networking opportunities with experts in the field. Staying engaged with the latest industry news and best practices ensures that our testing procedures remain aligned with the current standards and technological advancements.

Consider it like a doctor continually updating their medical knowledge – to provide the best care, one must stay informed about new discoveries, procedures, and best practices.

Key Topics to Learn for ASTM D3917 Interview

Ace your ASTM D3917 interview by mastering these key areas. Remember, a deep understanding of both theory and practical application is crucial.

- Standard Test Method Overview: Thoroughly understand the purpose and scope of ASTM D3917, including its limitations and applicability to various materials.

- Sample Preparation and Handling: Master the techniques for proper sample selection, preparation, and handling to ensure accurate and reliable test results. Consider the impact of different preparation methods on the final outcome.

- Test Procedure and Equipment: Familiarize yourself with the detailed steps involved in the test procedure, including the operation and maintenance of the necessary equipment. Understand potential sources of error and how to mitigate them.

- Data Analysis and Interpretation: Learn how to accurately analyze the collected data, perform calculations, and interpret the results in the context of material properties. Practice interpreting different data scenarios and drawing meaningful conclusions.

- Quality Control and Assurance: Understand the importance of quality control measures throughout the testing process. Be prepared to discuss methods for ensuring the accuracy and reliability of the test results.

- Troubleshooting and Problem Solving: Develop your ability to troubleshoot common problems encountered during testing and propose effective solutions. Think critically about potential sources of error and how to address them.

- Reporting and Documentation: Understand the requirements for proper reporting and documentation of test results, including the use of standard formats and terminology.

Next Steps

Mastering ASTM D3917 significantly enhances your value in the materials science and engineering fields, opening doors to exciting career opportunities. A strong understanding of this standard demonstrates your technical expertise and attention to detail, making you a highly sought-after candidate.

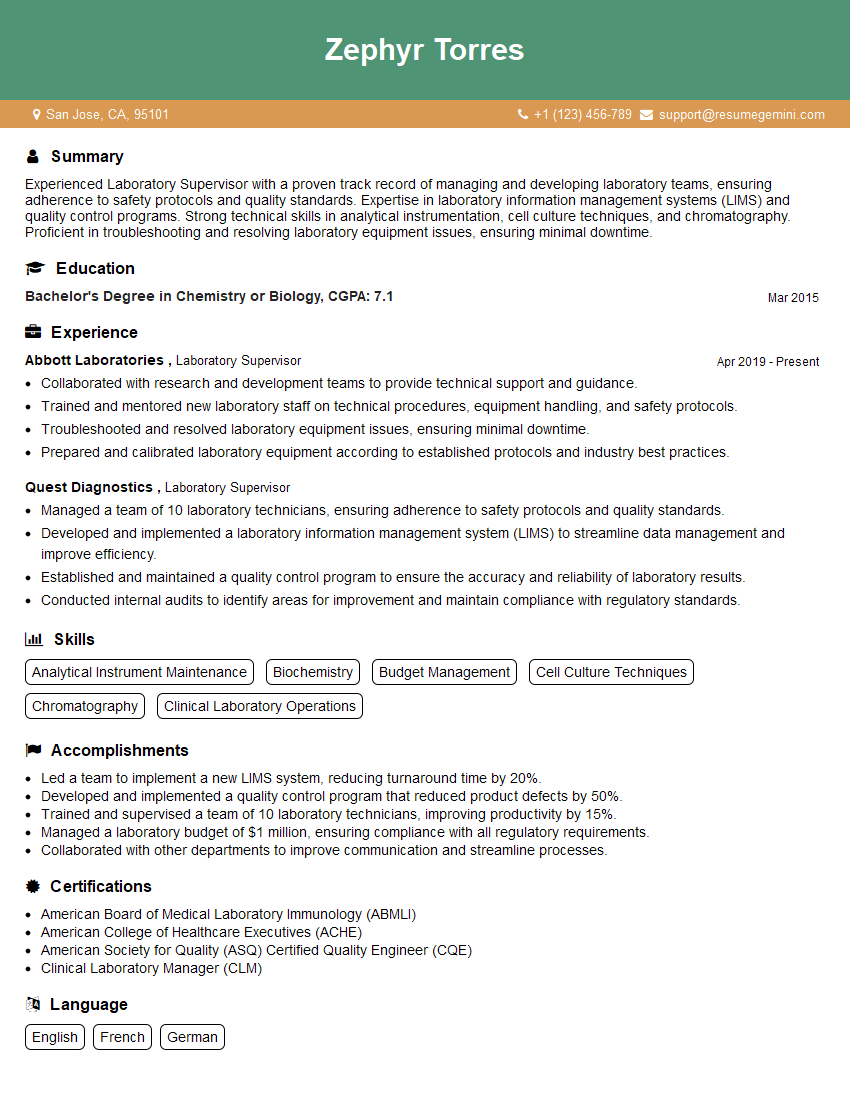

To further boost your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. We offer examples of resumes tailored to ASTM D3917 to give you a head start. Take the next step towards your dream career – build a winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good