Preparation is the key to success in any interview. In this post, we’ll explore crucial ANSI Y14.41 interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in ANSI Y14.41 Interview

Q 1. Explain the fundamental concepts of Geometric Dimensioning and Tolerancing (GD&T).

Geometric Dimensioning and Tolerancing (GD&T) is a symbolic language used on engineering drawings to precisely define the size, form, orientation, location, and runout of features on a part. Instead of relying solely on traditional plus/minus tolerances which only specify the size of a feature, GD&T uses symbols and zones to define the allowable variation of a part’s geometry. This ensures parts function correctly even with slight variations during manufacturing. It allows for clearer communication between designers and manufacturers, leading to improved quality control and reduced manufacturing costs. Imagine building a car – GD&T ensures that parts fit together precisely, preventing malfunctions.

Fundamentally, GD&T uses a system of frames of reference (datums) to define where measurements are taken from. Tolerances are then defined relative to these datums, providing a more comprehensive and accurate representation of acceptable variation than traditional tolerancing methods.

Q 2. What is the difference between feature control frame and a datum reference frame?

While both feature control frames and datum reference frames are crucial components of GD&T, they serve distinct purposes. A feature control frame specifies a geometric tolerance for a specific feature. This frame defines the type of tolerance (e.g., position, flatness, circularity), the tolerance zone, and any modifiers (e.g., material condition modifiers). Think of it as the rule for a single feature.

A datum reference frame, on the other hand, establishes the coordinate system to which the feature control frames refer. It’s defined by three mutually perpendicular datums (usually planes or axes), providing a stable reference for measuring the features. It’s the foundation upon which the measurements are based. In essence, the datum reference frame is the stage, and the feature control frames are the actors performing on that stage, each with their own specific instructions (tolerances).

Q 3. Describe the three basic types of tolerances.

GD&T encompasses three fundamental tolerance types:

- Size Tolerances: These define the permissible variation in the dimensions of a feature, such as the diameter of a hole or the length of a shaft. They’re represented by traditional plus/minus tolerances (e.g., Ø10 ± 0.1) but are often augmented with geometric tolerances to fully define the feature’s acceptability.

- Form Tolerances: These specify the allowable deviation from the ideal geometric form of a feature. Examples include straightness, flatness, circularity, cylindricity. Imagine a perfectly straight line versus a slightly bent line – form tolerance quantifies this deviation.

- Orientation, Location, and Runout Tolerances: These tolerances control the spatial relationship between features. Orientation tolerancing dictates the allowable angular variation (e.g., parallelism, perpendicularity), location tolerances specify the permissible deviation from a designated position (e.g., position, concentricity), and runout tolerances control the variation in radial and axial movement.

Q 4. What are the different types of datum features and how are they established?

Datums are theoretically perfect geometric surfaces (planes, axes, or points) that serve as reference points for measurements. There are three primary types:

- Datum Plane: A theoretically flat surface used as a reference. This is often a machined surface of a part.

- Datum Axis: A theoretically straight line, often the center axis of a cylindrical feature (e.g., a hole or shaft).

- Datum Point: A theoretically dimensionless point, often the intersection of two or more datums.

Datum features are the actual physical features on the part that represent the datums. They are designated on the drawing by a capital letter (A, B, C, etc.) and are usually the most stable and accurately manufactured features on the part. The selection of datum features is critical for ensuring accurate and repeatable measurements. Careful consideration needs to be given to their selection based on the part’s functional requirements.

Q 5. Explain the meaning of the following symbols: Ø, ⊥, ∥, ●, and M.

These symbols are frequently used in GD&T:

Ø: Diameter⊥: Perpendicularity∥: Parallelism●: Indicates a feature control frame or a datum featureM: Material Condition Modifier (Maximum Material Condition)

Q 6. What are the different types of geometric tolerances?

ANSI Y14.5M covers a wide range of geometric tolerances, including:

- Form Tolerances: Straightness, Flatness, Circularity, Cylindricity

- Orientation Tolerances: Perpendicularity, Angularity, Parallelism

- Location Tolerances: Position, Concentricity, Symmetry

- Runout Tolerances: Circular Runout, Total Runout

Each of these tolerances controls a specific aspect of a feature’s geometry and its relationship to other features or datums. The choice of which tolerance to use depends entirely on the functional requirements of the part.

Q 7. How do you interpret a position tolerance with a MMC modifier?

A position tolerance with an MMC (Maximum Material Condition) modifier means that the tolerance zone is largest when the feature is at its maximum material limit (largest possible size for external features, smallest for internal features). As the feature size decreases (towards its least material condition), the allowable variation (the tolerance zone) shrinks proportionally. This is because the functional requirement might be more stringent when the feature is larger; if the hole is oversized, it might be too loose, causing a functional problem. By using MMC, the designer ensures that even with a slightly smaller feature, the position remains within the acceptable range, guaranteeing functionality across the range of possible sizes.

For example, a position tolerance of 0.1 MMC applied to a hole means that the hole’s centerpoint must lie within a 0.1 diameter zone when the hole is at its smallest permissible size. If the hole is larger, the allowable variation remains the same; the tolerance zone does not change, even though the hole’s size changes. This effectively ‘tightens’ the positional tolerance as the feature’s size decreases. Therefore, MMC provides a functional guarantee for the position while allowing for some variation in the feature size.

Q 8. Explain the concept of Material Condition Modifiers (MMC, LMC, RFS).

Material Condition Modifiers (MCMs) in ANSI Y14.5-2009 (and its successor, ASME Y14.5-2018) are crucial for defining the allowable variation in a feature’s size and location. They specify the condition of the feature at which the tolerance is applied. Let’s break down the three main MCMs:

- Maximum Material Condition (MMC): This represents the feature’s largest possible size (for external features like shafts) or smallest possible size (for internal features like holes). Imagine a hole; at MMC, it’s at its smallest permissible diameter. Tolerances are generally easier to achieve at MMC because the feature has less ‘wiggle room’.

- Least Material Condition (LMC): This is the opposite of MMC. It represents the feature’s smallest possible size (for external features) or largest possible size (for internal features). Using our hole example, at LMC, the hole is at its largest permissible diameter. Tolerances at LMC are more challenging to meet.

- Regardless of Feature Size (RFS): This modifier means the tolerance applies regardless of the feature’s actual size within its specified tolerance range. It’s a simpler approach, but it can lead to tighter tolerances.

Think of it like this: Imagine you’re making a key and a lock. The key’s shaft needs to fit within the lock’s hole. Using MMC/LMC allows for variability in the key’s size, as long as it fits the hole at both its largest and smallest allowable sizes. RFS would be a much more stringent tolerance.

Q 9. What are the implications of using the wrong material condition modifier?

Using the wrong MCM can have significant consequences, potentially leading to part failure or assembly issues. Here’s why:

- Incorrect Functionality: If you use LMC when you should have used MMC, you might end up with a part that doesn’t assemble correctly. For instance, a shaft made at LMC (smallest diameter) may not fit into a hole made at MMC (smallest diameter) even if both parts are within individual tolerance.

- Increased Manufacturing Costs: Applying stricter tolerances than necessary (e.g., using RFS where MMC would suffice) increases manufacturing difficulty and cost due to tighter machining precision required.

- Rejected Parts: Using the wrong MCM can easily cause parts to be rejected during inspection because they’ll seem to be out of tolerance even though the assembly might be acceptable. This could lead to wasted materials and production delays.

- Safety Concerns: In critical applications, incorrect MCMs could lead to safety hazards if a part with inadequate tolerance is produced.

It’s crucial to accurately determine which MCM is most appropriate for each feature based on functional requirements and assembly considerations. The drawing should clearly indicate the chosen MCM.

Q 10. Describe the concept of datums and their importance in GD&T.

Datums are fundamental to GD&T. They’re theoretical points, axes, or planes established on a part or assembly to which other features’ dimensions and tolerances are referenced. They provide a stable, consistent reference frame for dimensional control, effectively anchoring the tolerance zones.

Imagine you’re building a house. The foundation is your datum – it’s your reference point for everything else. You wouldn’t start building the walls before you have a solid foundation, and similarly, in GD&T, you need well-defined datums for accurate control.

Their importance lies in:

- Providing a Common Reference Frame: This ensures consistent measurement and avoids ambiguity about which part of the part is being referenced.

- Simplifying Complex Tolerances: They allow for clearer and more accurate control of complex part geometries.

- Improving Assembly Accuracy: Datum references facilitate precise part mating in an assembly.

Datums are typically identified on drawings with symbols (such as A, B, C) and usually represented by specific features of the part, like a machined surface or a hole.

Q 11. How do you determine the datum reference frame for a part?

Determining the datum reference frame involves identifying the primary, secondary, and tertiary datums based on the part’s function and assembly requirements. The order of precedence is crucial; the primary datum is the most stable and essential reference, followed by the secondary and tertiary datums.

Here’s a step-by-step approach:

- Identify Functional Requirements: Determine which features are most critical for the part’s function and assembly. These features often become primary datums.

- Select Datum Features: Choose features suitable for datums based on their size, surface finish, and stability. Larger, more stable features are generally preferred.

- Determine Datum Reference Frame (DRF) Order: Establish the order of precedence: primary (A), secondary (B), and tertiary (C). Consider factors such as which features are most critical to assembly and stability. For instance, a flat mounting surface might be a primary datum.

- Document the DRF: Clearly indicate the chosen datum features and their order on the engineering drawing using the appropriate symbols and callouts.

For instance, a machined block might have a primary datum (A) defined by its largest and flattest surface, a secondary datum (B) defined by a cylindrical hole, and a tertiary datum (C) defined by another surface. The order ensures consistency and accuracy.

Q 12. Explain how to interpret a profile tolerance.

A profile tolerance controls the form and orientation of a feature’s surface relative to a specified datum or datums. Instead of controlling individual points, it controls the entire profile of the surface. This is described with two types, profile of a surface and profile of a line.

Understanding a profile tolerance requires looking at:

- Tolerance Zone: A zone defined by the tolerance value (e.g., 0.1 mm) which the entire feature’s surface or line must fall within relative to the datum.

- Datum Reference Frame: The datum or datums to which the profile tolerance is referenced (e.g., A, B, or A|B). The feature’s profile is checked to fall within the tolerance zone relative to the datum reference frame.

- Material Condition Modifier (MCM): MMC, LMC, or RFS, which dictates the condition at which the tolerance is applied.

Let’s say we have a profile tolerance of 0.1 mm relative to datum A. A measuring instrument (like a CMM) would check if every point on the feature’s surface stays within 0.1 mm of the perfect surface defined by datum A.

Q 13. What is the difference between a positional tolerance and a profile tolerance?

Both positional and profile tolerances control the location of features, but they do so in different ways:

- Positional Tolerance: Controls the location of a feature’s center point (or axis) relative to a datum reference frame. It focuses on the precise location of a single point or axis. Imagine a hole that needs to be precisely located with respect to other features.

- Profile Tolerance: Controls the form and orientation of a feature’s entire surface or line relative to a datum reference frame. It focuses on the overall shape and orientation of the feature, not just a single point. Imagine a complex curve that needs to stay within certain limits of its overall shape.

Think of it like this: positional tolerance is like aiming for a specific point on a target, while profile tolerance is like keeping the entire arrow within a designated zone on the target.

Q 14. How do you measure a feature of size?

Measuring a Feature of Size (FOS) requires careful consideration of the tolerance and Material Condition Modifier (MCM). FOS refers to features like holes and shafts where both the size and location matter.

The measurement process depends on whether the MMC, LMC, or RFS modifier is specified:

- MMC/LMC: For these modifiers, the measurement involves determining the actual size of the FOS and verifying whether it falls within the specified tolerance at the appropriate MCM. This might involve measuring the diameter of a hole and checking whether it’s within tolerance.

- RFS: With RFS, the feature size and location must both be within tolerance regardless of the actual size. Both size and location are checked individually.

Measuring tools can include calipers, micrometers, optical comparators, or Coordinate Measuring Machines (CMMs). The choice of tool depends on the feature’s size, shape, and precision requirements. A CMM is generally preferred for higher accuracy and complex geometries.

Additionally, for any measurement involving MMC or LMC, you will need to consider the bonus tolerance.

Q 15. What are the different methods for measuring GD&T characteristics?

Measuring GD&T characteristics involves selecting appropriate methods based on the specific geometric control and the required accuracy. Methods range from simple hand tools to sophisticated coordinate measuring machines (CMMs). The choice depends on factors like feature size, tolerance, and the complexity of the part.

- Direct Measurement: This involves directly measuring the feature using tools like calipers, micrometers, dial indicators, and height gauges. For example, measuring the diameter of a cylindrical feature with a micrometer. This is suitable for simple features and lower accuracy requirements.

- Indirect Measurement: This involves measuring related features to determine the characteristic of interest. For example, measuring the distance between two datum surfaces to determine the position of a hole. This method is often necessary for complex features.

- Coordinate Measuring Machines (CMMs): CMMs offer high precision and automation for complex parts and tighter tolerances. They measure points in 3D space, allowing for comprehensive analysis of various GD&T characteristics, such as form, orientation, location, and runout.

- Optical Measurement Systems: These systems use optical methods like laser scanning to capture 3D surface data. This is particularly useful for complex freeform surfaces. An example is a laser scanner used for reverse engineering.

- Scanning Probe Microscopes (SPMs): For extremely high precision and nanoscale measurements, SPMs such as atomic force microscopes (AFMs) can be used to achieve sub-nanometer resolution. These are primarily used for research and very specialized applications.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you select the appropriate measuring instruments for GD&T inspection?

Selecting the right measuring instrument for GD&T inspection is crucial for accurate and reliable results. The choice depends on several factors: the type of GD&T characteristic to be measured, the feature size and tolerance, the material of the part, and the required accuracy.

- Accuracy and Resolution: The instrument’s accuracy should be significantly higher than the tolerance being inspected. For example, a tolerance of 0.01 mm requires an instrument with accuracy of at least 0.005mm or better. The resolution needs to be fine enough to distinguish between acceptable and unacceptable variations.

- Feature Type and Size: Different instruments are designed for different types of features. For example, a micrometer is best suited for measuring diameters, while a height gauge is better for measuring heights.

- Material: The material of the part can influence the measurement method. For instance, soft materials might require specialized probes to avoid damaging the surface.

- Accessibility: The instrument must be able to access the feature being measured without causing obstruction or damage to the part.

- Calibration: Regularly calibrated instruments ensure accuracy. Calibration records should be maintained to prove traceability.

For example, for inspecting the flatness of a surface, a straight edge and dial indicator might suffice. However, for inspecting the position of a hole relative to datum features, a CMM is likely necessary to obtain the needed accuracy and coordinate data.

Q 17. Describe different types of coordinate measuring machines (CMMs) and their applications.

Coordinate Measuring Machines (CMMs) are highly precise instruments used to measure the geometry of parts in three dimensions. Several types exist, each with its strengths and applications:

- Bridge-type CMM: This is a common design where a bridge structure moves along a granite or steel bed. These are suitable for a wide range of parts and sizes, offering a good balance of accuracy and cost.

- Gantry-type CMM: A gantry CMM uses a larger gantry structure and typically has a larger measurement volume. These are ideal for inspecting large parts. Their size and stability enhance accuracy on larger geometries.

- Horizontal-arm CMM: This type uses a horizontal arm structure which can offer improved access to complex parts or parts with difficult orientations. The horizontal design offers better reach and maneuverability.

- Articulated-arm CMM: These portable CMMs use flexible arms allowing measurement in tight spaces and on parts that are difficult to mount on a traditional CMM. Their portability is a key advantage for in-situ inspections.

- Multi-sensor CMMs: Many CMMs offer multiple sensor options, like touch probes, laser scanners, and vision systems, expanding their capabilities to measure different types of features and surfaces.

Applications vary widely. Bridge-type CMMs are often used in automotive manufacturing for inspecting engine parts, while gantry CMMs are used in aerospace for checking large aircraft components. Articulated-arm CMMs might be used on a factory floor for spot-checking during assembly. Selection depends on the part size, geometry, accuracy requirements, and budget.

Q 18. Explain the process of creating a GD&T control plan.

A GD&T control plan is a document that outlines the inspection process for verifying that a part meets the GD&T specifications on its engineering drawing. Creating a comprehensive plan involves these steps:

- Review the Drawing: Carefully examine the engineering drawing to identify all GD&T characteristics and their associated tolerances. Note datums, references, and all the specifications.

- Select Measurement Methods: Choose the appropriate measurement methods and instruments for each GD&T characteristic, considering factors like accuracy, feasibility, and cost. Refer to the methods previously discussed.

- Develop Inspection Procedures: Write clear and concise procedures for each measurement, including detailed setup instructions, measurement steps, and acceptance criteria. Include diagrams and any special tooling requirements.

- Identify Inspection Equipment: List all the measuring equipment needed, specifying model numbers and calibration schedules. This guarantees equipment availability and traceability.

- Determine Sampling Plans: Decide on a sampling plan, defining the number and selection of parts to be inspected for each characteristic. The sampling plan should reflect the risk profile and production volume.

- Define Acceptance Criteria: Establish clear criteria for accepting or rejecting a part based on measurement results. This often involves defining limits and allowance for variation.

- Document the Plan: Compile all the information into a formal control plan, including all procedures, equipment lists, sampling plans, and acceptance criteria. This plan serves as a reference for the inspection process.

- Review and Approve: The control plan must be reviewed and approved by relevant stakeholders such as quality engineers, manufacturing engineers, and design engineers before implementation.

A well-defined GD&T control plan ensures consistency and accuracy throughout the inspection process, improving the overall quality and reducing defects.

Q 19. How do you interpret and apply GD&T symbols on engineering drawings?

Interpreting and applying GD&T symbols on engineering drawings requires a thorough understanding of ANSI Y14.5M-2009. The symbols convey the design intent regarding geometric tolerances and relationships between features. Each symbol represents a specific geometric characteristic and has a defined format.

For example, a positional tolerance is represented by a symbol that looks like a circle with a cross inside it. The symbol is followed by a numerical value representing the tolerance zone, a material condition modifier (MMC, LMC, RFS) that specifies how the tolerance is applied, and potentially a reference to datum features.

<Example: Σ 0.1 (MMC) A|B

In this example:

Σrepresents the positional tolerance.0.1is the tolerance zone.(MMC)denotes that the tolerance is applied at the maximum material condition (MMC) of the feature of size.A|Brefers to the datum features A and B.

Understanding these elements is crucial for correct interpretation and accurate manufacturing. Misinterpretation can lead to rejected parts or parts that fail in service. Proper training and the use of clear and unambiguous drawings are vital to avoid issues.

Q 20. Describe the relationship between GD&T and manufacturing processes.

GD&T and manufacturing processes are intrinsically linked. GD&T defines the acceptable geometric variations, whereas manufacturing processes determine the actual geometric characteristics of a part. A strong understanding of both is crucial for efficient and accurate production.

- Process Capability: Manufacturing processes have inherent variations. GD&T tolerances must be realistic and achievable within the capabilities of the chosen manufacturing processes. An impossible tolerance will simply lead to wasted time and resources.

- Process Selection: The choice of manufacturing process (e.g., casting, machining, 3D printing) significantly influences the achievable geometric tolerances. Processes capable of delivering the required precision should be selected.

- Fixture Design: Fixtures used in manufacturing play a significant role in achieving GD&T requirements. Poorly designed fixtures can introduce errors, making it difficult to meet tolerances. Fixtures need to be aligned with datum references specified in the GD&T.

- Tooling Selection: The accuracy of cutting tools, molds, and dies directly impacts the accuracy of the manufactured part. Tool wear and tool maintenance impact the accuracy of final parts.

- Quality Control: GD&T serves as a foundation for quality control and inspection procedures. Measurements based on GD&T ensure parts meet design specifications and functional requirements.

For example, if a design calls for tight tolerances on the position of a hole, the manufacturing process should be chosen and set up carefully (e.g., precise CNC machining with appropriate jigs and fixtures) to ensure those tolerances are achieved.

Q 21. How do you handle discrepancies between design intent and actual measurements?

Discrepancies between design intent (GD&T specifications) and actual measurements require a systematic investigation to determine the root cause and corrective action. This is crucial for improving process control and preventing future occurrences.

- Verify Measurement Accuracy: First, verify that the measurements themselves are accurate. Check the calibration status of the measuring instruments and repeat the measurements to confirm consistency.

- Review the GD&T Specification: Ensure the GD&T symbols and tolerances on the drawing are clear and correctly interpreted. Consult with the design engineer if needed.

- Analyze the Manufacturing Process: Examine the manufacturing process to identify potential sources of error. This might involve evaluating machine settings, tooling, fixture design, or operator skills.

- Assess Material Variation: Consider whether material variations (e.g., thermal expansion, inconsistent material properties) could be contributing to the discrepancy.

- Determine Corrective Actions: Based on the root cause analysis, implement appropriate corrective actions. This might include adjusting machine parameters, improving fixturing, retraining operators, or modifying the manufacturing process.

- Document Findings: Thoroughly document the entire investigation, including the discrepancies, root cause analysis, corrective actions taken, and verification of effectiveness. This documentation helps prevent recurrence.

For example, if the positional tolerance of a hole is outside the specified limits, the investigation might reveal that the CNC machine’s tool path was incorrect, leading to an offset in the hole’s position. The corrective action would then involve reprogramming the machine and verifying the corrected tool path.

Q 22. Explain the concept of tolerance stack-up and how to manage it.

Tolerance stack-up refers to the cumulative effect of individual tolerances on the overall dimensions of an assembly. Imagine building a tower with blocks; each block has a slightly different size, and these variations accumulate, potentially making the final tower height significantly different from the intended height. This is precisely what tolerance stack-up represents in engineering.

Managing tolerance stack-up is crucial for ensuring the functionality and reliability of a product. We use several techniques:

- Statistical Methods: Instead of simply adding worst-case tolerances (which often leads to overly conservative designs), we use statistical methods like RSS (Root Sum Square) to predict the likely variation in the final assembly. This considers the probability of individual parts being at their extreme tolerance limits. For instance, it’s unlikely all parts will simultaneously be at their maximum or minimum size.

- Tolerance Allocation: This involves strategically distributing the allowable tolerance across different features. Features critical to functionality receive tighter tolerances, while less critical features can have looser tolerances, optimizing cost and manufacturability. This requires a deep understanding of the design and its functional requirements.

- Geometric Dimensioning and Tolerancing (GD&T): GD&T, as defined in ANSI Y14.5M, provides a powerful language to precisely define part dimensions and their permissible variations. It considers not only size but also form, orientation, location, and runout, offering greater control over the assembly process. For example, using Position tolerance ensures that features are located correctly relative to one another, even if individual part dimensions vary within their specified tolerances.

- Design for Manufacturing (DFM): This involves considering manufacturing capabilities during the design process. Selecting appropriate manufacturing processes and materials helps minimize variability and simplifies the assembly process. For example, choosing a more precise manufacturing process might eliminate the need for overly tight tolerances on specific features.

Effective tolerance stack-up management requires careful planning, collaboration between designers and manufacturers, and a thorough understanding of statistical methods and GD&T.

Q 23. What is the impact of GD&T on product quality and cost?

GD&T significantly impacts both product quality and cost. It improves quality by ensuring parts fit together as intended, reducing the likelihood of assembly issues and field failures. Clear GD&T specifications leave less room for interpretation and miscommunication, leading to greater consistency in manufacturing.

However, implementing GD&T can initially increase costs. The upfront investment in training, software, and potentially more precise manufacturing processes can be significant. However, the long-term cost benefits often outweigh the initial investment. Reducing scrap, rework, and warranty claims leads to significant cost savings. Furthermore, GD&T-driven designs often allow for the use of less expensive manufacturing methods because the tolerances are more precisely defined and managed, reducing unnecessary precision.

Consider this analogy: Building a house with precise specifications (GD&T) might cost more initially, but it’s much less likely to have structural problems or require costly repairs later. Similarly, a product with well-defined GD&T is less likely to fail in the field.

Q 24. Discuss the role of GD&T in reducing manufacturing variability.

GD&T plays a vital role in reducing manufacturing variability by providing a standardized and unambiguous way to specify part dimensions and tolerances. Traditional tolerancing methods often lead to ambiguity and misinterpretations, resulting in parts that may be manufactured within their individual tolerances yet fail to assemble correctly.

GD&T addresses this by focusing on the functional requirements of the parts. By specifying tolerances on the relationship between features (e.g., position, concentricity), GD&T ensures that even with variations in individual dimensions, the assembled product maintains its intended functionality. This reduces the need for extremely tight tolerances on individual features, thus lessening the burden on the manufacturing process and reducing variability.

For example, using a Position tolerance for a hole ensures the hole is located correctly relative to other features, regardless of small variations in the hole’s diameter or its location within the tolerance zone. This provides greater flexibility to the manufacturer while ensuring the functional requirement is met.

Q 25. Describe your experience with GD&T software and its applications.

I have extensive experience with various GD&T software packages, including [mention specific software, e.g., Autodesk Inventor, SolidWorks, Creo Parametric]. These tools are essential for creating and verifying GD&T annotations on CAD models. They help automate the process of tolerance stack-up analysis, allowing for efficient identification and resolution of potential assembly issues. I’ve used these tools throughout various project stages, from initial design and tolerance allocation to verifying manufacturing feasibility and conducting tolerance stack-up analysis. This involves utilizing the software’s simulation capabilities to predict the potential variations in the final assembly based on different tolerance combinations. The software also helps in generating clear and accurate GD&T drawings that effectively communicate design intent to manufacturers.

For example, in a recent project involving a complex aerospace component, I used [mention software] to simulate different manufacturing scenarios and to optimize the tolerance distribution, thereby reducing the manufacturing cost without compromising the functionality of the component.

Q 26. What are the common mistakes made when applying GD&T?

Common mistakes in applying GD&T include:

- Overlooking Datum Features: Incorrectly defining or neglecting datum features can lead to misinterpretations of tolerances and potentially incorrect part manufacturing. Datums are fundamental to GD&T and must be carefully selected.

- Incorrect Tolerance Selection: Choosing inappropriate tolerance types or values for specific features. Using a wrong tolerance type can lead to misinterpretation and assembly issues.

- Poor Communication: Lack of clear communication between designers and manufacturers regarding GD&T specifications. This can lead to misunderstandings and incorrect part production.

- Ignoring Stack-Up Analysis: Failing to conduct thorough tolerance stack-up analysis can lead to unforeseen assembly issues and product failures.

- Over-Constraining the Design: Imposing too many constraints on a design can make it difficult and costly to manufacture, without necessarily adding to functionality. A balanced approach that prioritizes functional requirements is crucial.

Addressing these mistakes requires meticulous planning, a deep understanding of GD&T principles, and effective communication with manufacturing personnel.

Q 27. How do you stay updated on the latest developments and revisions in ANSI Y14.5M standards?

I stay updated on ANSI Y14.5M standards through several methods:

- Active Membership in Professional Organizations: I maintain membership in relevant professional organizations like ASME (American Society of Mechanical Engineers) which provides access to standards updates, training, and networking opportunities.

- Regular Review of Standards Documents: I regularly review the latest versions of ANSI Y14.5M and other relevant GD&T standards to ensure my knowledge is current and aligns with the latest best practices.

- Participation in Training and Workshops: I actively participate in training courses and workshops on GD&T to keep abreast of recent developments and advanced techniques.

- Industry Publications and Journals: I regularly follow relevant industry publications and journals that discuss advancements and best practices related to GD&T.

- Online Resources and Forums: I use online resources, such as technical websites and forums, to stay informed about updates, discussions, and interpretations of GD&T principles.

Keeping up-to-date with the latest standards ensures that I can effectively apply the most current best practices to my work and contribute to the development of high-quality and reliable products.

Key Topics to Learn for ANSI Y14.41 Interview

- Datum Reference Frames: Understand the establishment and application of datum reference frames in geometric dimensioning and tolerancing (GD&T). Be prepared to discuss their practical implications for manufacturing and inspection.

- Feature Control Frames (FCFs): Master the interpretation and application of FCFs, including the understanding of symbols, modifiers, and their impact on part tolerances and acceptance criteria. Practice applying them to real-world scenarios.

- Geometric Tolerances: Develop a strong understanding of different geometric tolerances (e.g., form, orientation, location, runout) and how they control the shape and position of features. Be able to explain their practical applications in various manufacturing processes.

- Material Condition Modifiers: Know how material condition modifiers affect the interpretation and measurement of geometric tolerances. Understand the implications of “MMC,” “LMC,” and “RFS.”

- Basic Dimensioning and Tolerancing: Review fundamental principles of dimensioning and tolerancing to establish a solid foundation for understanding more complex GD&T concepts. This includes understanding unilateral and bilateral tolerances.

- Bonus: Advanced GD&T concepts: Explore advanced topics like position tolerancing with multiple datums, profile tolerances, and circularity/cylindricity tolerances, to showcase a deeper understanding and prepare for more challenging interview questions.

- Problem-Solving using GD&T: Practice interpreting engineering drawings with GD&T specifications and solving practical problems related to part inspection, manufacturing processes, and tolerance stack-up analysis.

Next Steps

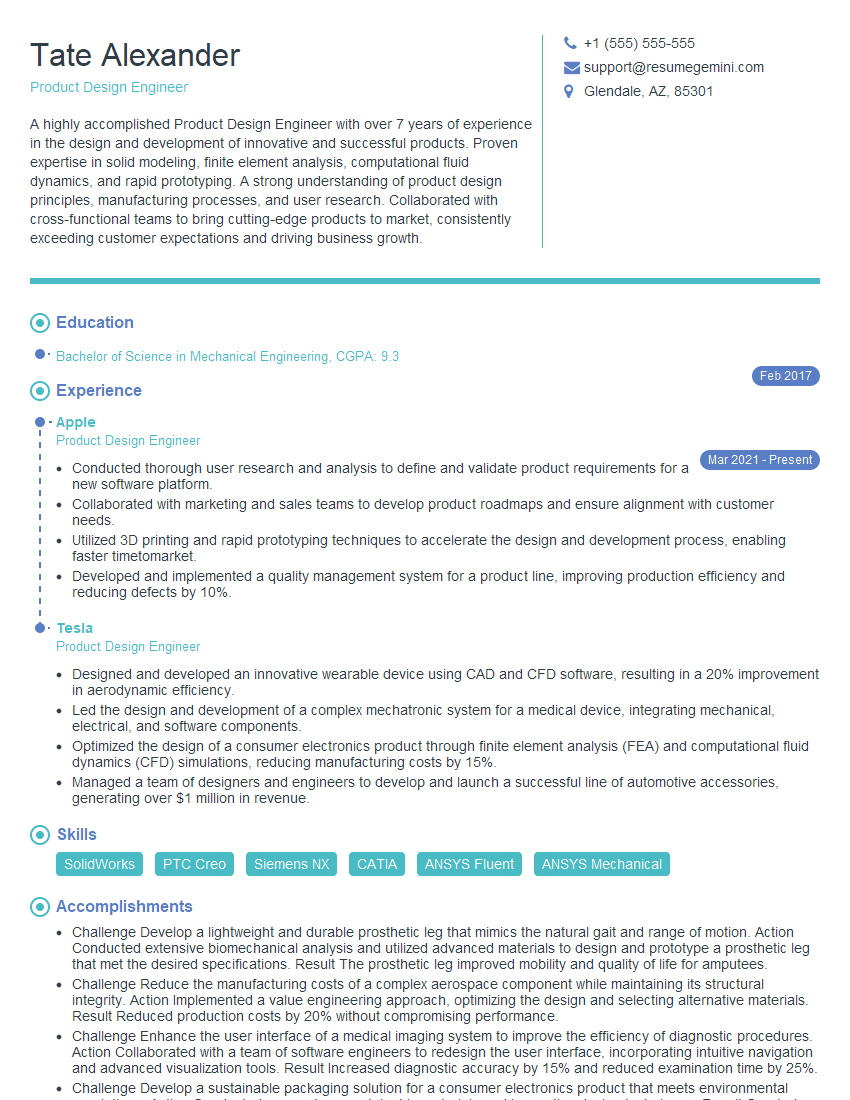

Mastering ANSI Y14.41 is crucial for career advancement in engineering, manufacturing, and quality control. A strong understanding of GD&T demonstrates technical proficiency and problem-solving abilities highly valued by employers. To maximize your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to ANSI Y14.41 expertise are available through ResumeGemini to guide your efforts. Invest the time to showcase your skills – it’s an investment in your future!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good