Cracking a skill-specific interview, like one for Apparel Sourcing and Production, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Apparel Sourcing and Production Interview

Q 1. Explain your experience in negotiating prices with apparel manufacturers.

Negotiating prices with apparel manufacturers requires a strategic approach combining market knowledge, cost analysis, and strong communication. It’s not just about getting the lowest price, but securing a fair price that ensures quality and timely delivery. My process starts with thorough research to understand the prevailing market rates for similar products and production methods. I then analyze the manufacturer’s cost breakdown, which includes raw materials, labor, overhead, and profit margins. This helps me identify areas for potential negotiation. For example, if the raw material costs seem inflated, I’ll leverage my relationships with fabric suppliers to present competitive pricing. I also explore potential trade-offs; perhaps accepting a slightly higher price in exchange for a shorter lead time or higher quality materials. The negotiation itself is a collaborative process. I aim for a mutually beneficial outcome, building a long-term relationship with the manufacturer rather than focusing solely on immediate cost savings. Effective communication is key—clearly outlining my expectations and building rapport are crucial for successful negotiations.

For instance, in a recent project producing 5,000 organic cotton t-shirts, I initially received a quote that seemed high. By analyzing their cost sheet and leveraging my established relationships with organic cotton suppliers, I demonstrated that their raw material cost was 15% higher than the market average. Through open dialogue, we adjusted the price, achieving a 10% reduction without compromising on quality or delivery timelines. This demonstrates the importance of meticulous research and clear communication in achieving favorable price points.

Q 2. Describe your process for selecting and vetting apparel factories.

Selecting and vetting apparel factories is a critical step that directly impacts product quality, delivery timelines, and overall project success. My process involves a multi-stage approach, beginning with identifying potential factories through industry directories, trade shows, and referrals. I then conduct thorough due diligence, focusing on several key areas.

- Capacity and Capabilities: I assess the factory’s production capacity, machinery, and expertise in handling the specific garment construction techniques required for my products. A factory specializing in knitwear would be unsuitable for a complex woven garment.

- Quality Control Systems: A robust quality control system is paramount. I look for evidence of rigorous quality checks at each stage of production, from raw material inspection to final product inspection. This includes examining their AQL (Acceptable Quality Limit) standards and their inspection procedures.

- Social and Environmental Compliance: Ethical sourcing is a priority. I verify that the factory adheres to ethical labor practices, including fair wages, safe working conditions, and compliance with relevant environmental regulations. I often require audits, such as those conducted by independent organizations like WRAP (Worldwide Responsible Accredited Production).

- Financial Stability: Assessing a factory’s financial health ensures they can handle the project’s volume and meet their obligations. This may involve reviewing their financial statements or seeking references from other clients.

- Communication and Collaboration: Effective communication is crucial. I evaluate the factory’s responsiveness, clarity of communication, and ability to collaborate effectively throughout the production process.

Finally, I often conduct a physical factory visit to assess their facilities, observe their operations, and meet the key personnel. This allows for a more thorough evaluation and facilitates a stronger working relationship.

Q 3. How do you manage lead times and ensure on-time delivery?

Managing lead times and ensuring on-time delivery requires meticulous planning and proactive communication. My approach begins with a realistic lead time estimation, factoring in all stages of production, from fabric sourcing and pattern making to sampling, bulk production, and shipping. This estimation involves close collaboration with the factory to understand their production capacity and any potential bottlenecks.

I utilize project management tools to track progress closely, setting clear milestones and deadlines for each stage. Regular communication with the factory, often through daily or weekly updates, helps identify potential delays early on. This proactive approach allows us to address any challenges promptly and implement corrective measures. For example, if a fabric shipment is delayed, we explore alternative sourcing options or adjust production schedules to mitigate the impact on the overall timeline. Transparent communication with clients is crucial. I keep them informed about the production progress and address any concerns proactively. A detailed production schedule shared with the client at the start of the project, along with regular updates, ensures alignment and minimizes surprises.

In a recent project involving a large order of winter jackets, a supplier issue arose causing a delay in button delivery. By identifying this issue early through consistent communication, we proactively secured an alternate button supplier and managed to maintain the agreed-upon delivery date, avoiding any negative impact on the client.

Q 4. What quality control measures do you implement throughout the production process?

Quality control is paramount and I implement a multi-layered approach throughout the production process. It starts with the initial fabric inspection—checking for defects, color consistency, and compliance with specifications. Then, we have in-line inspections during the various stages of garment construction. This may include checking for stitching quality, accurate sizing, and adherence to the technical specifications at critical points like collar attachment, pocket placement, etc. Finally, a thorough final inspection is conducted on a pre-determined percentage of the finished garments using AQL standards (Acceptable Quality Limit) to ensure the overall quality meets our requirements.

We work closely with the factory to ensure they have implemented effective quality control processes and provide ongoing training on quality standards. I often specify the use of quality control checklists and reporting mechanisms. Defective garments are immediately identified and rectified. If the defect rate is consistently high, we delve into the root cause and implement corrective actions with the factory. We also use digital tools and technologies to aid in the process, such as digital pattern making and automated fabric inspection systems for improved efficiency and accuracy.

Q 5. How do you handle unexpected delays or production issues?

Handling unexpected delays or production issues requires a proactive and adaptable approach. The first step involves swift identification of the root cause of the problem. Is it a raw material shortage? A machinery malfunction? A labor issue? Understanding the root cause is key to finding an effective solution.

Once identified, I work closely with the factory to develop and implement a contingency plan. This might involve finding alternative suppliers, adjusting the production schedule, or even renegotiating deadlines with the client. Open communication is crucial here – informing the client promptly about the issue and the steps being taken to resolve it is paramount. Transparency and clear communication can mitigate potential conflicts. Depending on the nature and severity of the issue, I may need to explore alternative production options. This might involve sourcing production from a different factory, which necessitates careful evaluation to ensure the new facility meets our quality and ethical standards. In some cases, negotiating a partial shipment or prioritizing certain critical components might be a practical approach.

In one instance, a natural disaster disrupted the supply chain for a key component. By quickly identifying the problem, we sourced the component from a backup supplier and successfully adjusted the production schedule, resulting in a minimal delay, and ensuring transparency with the client.

Q 6. What are your strategies for mitigating supply chain risks?

Mitigating supply chain risks is a crucial aspect of apparel sourcing. My strategies focus on diversification, building strong relationships, and implementing robust risk management processes. Diversifying sourcing locations and suppliers is a key strategy. This reduces reliance on any single supplier or region, safeguarding against disruptions caused by political instability, natural disasters, or economic downturns.

Building strong, long-term relationships with key suppliers, including factories and raw material providers, fosters trust and collaboration. This enables early warning of potential issues and facilitates prompt resolution. Regular communication and transparent information sharing are essential in these relationships. In terms of risk management, I develop contingency plans for various scenarios. This includes having backup suppliers identified for key components and negotiating flexible payment terms with suppliers to provide some buffer against potential financial issues. Regular audits of our suppliers are conducted to assess compliance with ethical and environmental standards. Finally, tracking and monitoring geopolitical events, economic trends, and industry-specific risks enable us to anticipate and adapt to potential disruptions.

Q 7. Describe your experience with different fabric types and their sourcing.

My experience encompasses a wide range of fabric types, including cotton, linen, silk, wool, polyester, nylon, and blends. Sourcing these fabrics requires a deep understanding of their properties, quality standards, and market availability. Each fabric type has unique characteristics that influence its suitability for specific garments. For instance, cotton is known for its breathability and comfort, making it ideal for summer apparel, while wool offers warmth and durability, suitable for winter wear. Polyester provides durability and wrinkle resistance, often used in performance wear.

Sourcing fabrics involves identifying reliable suppliers with the necessary certifications and quality standards. I often work with fabric mills directly to ensure quality and control costs, but also utilize fabric agents and wholesalers when necessary. The sourcing process involves specifying fabric composition, weight, color, and finish, along with testing samples to meet the required quality standards. Sustainability is a growing concern; therefore, I frequently source eco-friendly fabrics like organic cotton, recycled polyester, or Tencel, aligning with our commitment to responsible sourcing. Factors like lead times, minimum order quantities, and pricing are also carefully evaluated when selecting a fabric supplier.

For example, in a recent project designing a luxury women’s wear collection, sourcing high-quality silk required extensive research to identify a reputable silk mill that met our standards for sustainability and ethical labor practices. This involved thorough analysis of their certifications, visiting the mill, and reviewing samples to ensure the silk met our exacting quality expectations.

Q 8. How familiar are you with global trade regulations and compliance requirements?

Global trade regulations and compliance are paramount in apparel sourcing. My familiarity extends to understanding and adhering to rules governing tariffs, quotas, country-of-origin labeling (COO), and various trade agreements like the USMCA or the EU’s GSP schemes. I’m well-versed in import/export procedures, documentation requirements (e.g., commercial invoices, packing lists, certificates of origin), and customs processes. I also have a strong grasp of ethical sourcing standards like the Fair Labor Association’s Workplace Code of Conduct and environmental regulations regarding restricted substances (like REACH in the EU or California’s Proposition 65). My experience includes proactively identifying potential compliance risks and developing mitigation strategies to ensure seamless trade operations and avoid penalties. For example, I recently successfully navigated a change in US tariffs on imported textiles by shifting sourcing to a different country with preferential trade access, resulting in significant cost savings for the company.

Q 9. Explain your experience with managing production costs and budgets.

Managing production costs and budgets requires a multifaceted approach. It begins with a thorough understanding of all cost components – raw materials, labor, manufacturing overhead, transportation, and duties. I employ various strategies to optimize costs, including negotiating favorable pricing with suppliers, exploring alternative materials, streamlining production processes, and leveraging economies of scale. For example, I once negotiated a 15% reduction in fabric costs by consolidating orders across multiple product lines and working with the supplier to secure a bulk discount. I also utilize sophisticated costing models and regularly track key performance indicators (KPIs) such as unit cost, production efficiency, and waste rate to identify areas for improvement. Budget management involves meticulous forecasting, regular monitoring, and proactive adjustments based on market trends and production challenges. I’ve successfully managed multi-million dollar budgets, consistently delivering projects within budget and timeline.

Q 10. How do you utilize technology to streamline the sourcing and production processes?

Technology plays a crucial role in streamlining sourcing and production. I utilize Product Lifecycle Management (PLM) software to manage designs, specifications, and sample approvals, fostering seamless communication among designers, manufacturers, and quality control teams. I’m proficient in using sourcing platforms to discover and connect with potential suppliers, compare quotes efficiently, and track production progress. Furthermore, I leverage data analytics to identify trends, optimize inventory management, and predict future demand. For example, I implemented a new PLM system that reduced lead times by 15% by improving communication and collaboration throughout the supply chain. We also use digital tools for virtual inspections, reducing travel costs and improving quality control.

Q 11. How do you build and maintain relationships with suppliers?

Building and maintaining strong supplier relationships is crucial for long-term success. It goes beyond simply securing the lowest price. I focus on building trust and transparency through open communication, regular visits to supplier factories, and collaborative problem-solving. I emphasize mutual respect and fair business practices, and I treat suppliers as partners rather than mere vendors. For example, I’ve established long-term relationships with several key suppliers that have resulted in preferential pricing, faster lead times, and access to innovative materials. Regular performance evaluations and feedback mechanisms are used to continuously improve efficiency and collaboration. Addressing issues promptly and fairly helps foster loyalty and ensures a sustainable supply chain.

Q 12. Describe your experience with different manufacturing processes (e.g., cut-and-sew, knitting).

My experience encompasses a wide range of manufacturing processes, including cut-and-sew, knitting (both weft and warp), weaving, and embroidery. I understand the nuances of each process, including the machinery involved, the skill sets required, and the associated costs and lead times. For example, in cut-and-sew, I’m familiar with different types of stitching, fabric handling, and pattern making. With knitting, I understand the variations in stitch structures, yarn types, and the capabilities of different knitting machines. This broad knowledge enables me to make informed decisions regarding production methods, select suitable factories, and optimize production schedules. I can identify and mitigate potential risks associated with each process, ensuring timely and high-quality production.

Q 13. How do you ensure the ethical and sustainable sourcing of materials?

Ethical and sustainable sourcing is a core value. I work with suppliers who adhere to strict ethical labor practices and environmental standards. This includes ensuring fair wages, safe working conditions, and compliance with relevant regulations such as those related to child labor and environmental protection. I use third-party audits to verify compliance and promote transparency throughout the supply chain. I actively seek out suppliers who use sustainable materials, such as organic cotton or recycled fabrics, and who employ environmentally friendly production methods. We also explore innovative materials and processes to minimize our environmental footprint, like using water-efficient dyeing techniques. This commitment to sustainability not only aligns with ethical values but also contributes to a more resilient and responsible business model. It also enhances our brand reputation and attracts environmentally conscious consumers.

Q 14. How do you manage inventory and minimize waste?

Effective inventory management and waste minimization are critical for profitability and sustainability. I employ a combination of strategies, including forecasting techniques to predict demand accurately, just-in-time (JIT) inventory management to minimize storage costs and reduce waste, and robust quality control processes to minimize defects. I use data analysis to track inventory levels, identify slow-moving items, and optimize stock levels. Waste minimization includes optimizing fabric cutting layouts to minimize fabric scraps, utilizing scraps for secondary products, and implementing recycling programs for production waste. I also work closely with suppliers to improve production efficiency and reduce waste at the source. By implementing these strategies, we have significantly reduced our inventory carrying costs and minimized waste, leading to cost savings and a positive impact on the environment.

Q 15. Explain your experience in capacity planning and forecasting.

Capacity planning and forecasting in apparel sourcing involves predicting the production capacity needed to meet future demand. It’s like planning a large party – you need to estimate how many guests are coming (demand) and make sure you have enough chairs, food, and space (capacity). This process involves analyzing historical sales data, understanding seasonal trends, and considering new product introductions.

My approach begins with data collection. I use tools like Salesforce and Excel to analyze past sales figures, identifying peak seasons and slow periods. Then, I use forecasting techniques like moving averages or exponential smoothing to predict future demand. I also factor in potential risks, such as material shortages or unexpected delays. For example, if a new trendy design is launched, I would adjust the forecast upwards accordingly, and secure additional production capacity from factories in advance to avoid bottlenecks.

Once the demand forecast is complete, I assess the factory’s current capacity and identify any gaps. This might involve optimizing existing production lines, investing in new machinery, or exploring partnerships with additional factories. It’s a continuous process of monitoring, adjusting, and refining predictions to ensure we can consistently meet demand without overspending on idle capacity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you track and analyze key performance indicators (KPIs) in apparel production?

Tracking and analyzing KPIs in apparel production is crucial for identifying areas for improvement and ensuring efficiency. Key KPIs include lead times, production output, defect rates, on-time delivery, and unit cost. I utilize a combination of methods to monitor these.

Firstly, I implement a robust data collection system. This involves using Production Management Systems (PMS) like SAP or Oracle. These systems allow for real-time tracking of production progress, capturing data at each stage from cutting to packaging. Secondly, I create dashboards and reports using business intelligence tools like Tableau or Power BI to visualize the KPIs and identify trends. For instance, a consistently high defect rate in a particular factory might indicate a need for improved training or equipment upgrades. Similarly, consistently exceeding lead times could point to the need to negotiate better delivery schedules with factories or review production processes.

Finally, regular meetings with production managers and factory representatives are held to review the KPIs and implement corrective actions. Using data-driven insights, we can identify bottlenecks, optimize processes, and continuously improve efficiency and product quality.

Q 17. How do you handle customer complaints or quality issues?

Handling customer complaints and quality issues requires a systematic and empathetic approach. It’s about damage control and customer retention. My first step is acknowledging the issue and showing empathy for the customer’s frustration.

I then initiate a thorough investigation to determine the root cause of the problem. This may involve examining the product itself, reviewing production records, and contacting the relevant factory. For instance, if there are recurring complaints about stitching quality, we’d examine the sewing machine maintenance records at the factory, the training of the sewing operators, and the quality of the threads used. We often implement a robust 8D problem-solving approach to identify the root cause and prevent future recurrence.

Once the root cause is identified, corrective actions are put in place. These could involve factory retraining, process improvements, material sourcing changes, or even replacement of defective products. Transparent and timely communication with the customer throughout this process is crucial. It’s about building trust and restoring confidence in our brand. Finally, I document everything – from the initial complaint to the resolution – to prevent similar problems from occurring in the future.

Q 18. Describe your experience in developing and implementing sourcing strategies.

Developing and implementing sourcing strategies involves a multifaceted approach, prioritizing cost-effectiveness, quality, ethical compliance, and timely delivery. It’s like building a strong supply chain, securing reliable partners who can deliver the goods.

My experience starts with thorough market research. This includes identifying potential suppliers, assessing their capabilities (capacity, technology, certifications), and comparing their pricing. I leverage online platforms like Alibaba and Global Sources to source new factories, but I also heavily rely on my existing network and industry contacts for referrals. I also weigh factors such as geographical location (considering shipping costs and lead times), political stability, and infrastructure development when choosing factories.

Once potential suppliers are identified, I conduct thorough factory audits to assess their compliance with social and environmental standards. Then, I negotiate contracts, clarifying pricing, payment terms, quality standards, and delivery schedules. The strategy isn’t static; it continuously evolves based on market dynamics, factory performance, and evolving customer demands. It’s a constant balancing act of optimizing cost, quality, and ethical considerations.

Q 19. What software or tools do you utilize for apparel sourcing and production management?

Effective apparel sourcing and production management relies on a suite of software and tools. My workflow integrates several key systems.

For product lifecycle management (PLM), I use Centric PLM or similar systems to manage product design, development, and sourcing. This allows for streamlined collaboration among design teams, sourcing agents, and factories. For supply chain management, I use SAP SCM or comparable tools to track inventory, manage shipments, and monitor production progress. Microsoft Excel remains a mainstay for data analysis and report generation. Google Sheets is used for simpler collaborative tasks, whilst specialised programs for design support like Adobe Illustrator and Photoshop are essential.

Furthermore, communication tools like Slack and Microsoft Teams facilitate seamless communication with factories, agents, and internal teams. Data visualization tools, such as Tableau and Power BI are key for reporting and identifying trends in KPIs.

Q 20. Explain your experience in conducting factory audits.

Conducting factory audits is essential for ensuring compliance with ethical and quality standards. It’s like a thorough health check for a factory – ensuring they operate safely and ethically.

My audit process adheres to globally recognized standards like SA8000 (social accountability) and BSCI (Business Social Compliance Initiative). The audit covers various aspects, including working conditions, wages, hours of work, child labor, health and safety, and environmental practices. I use a checklist to ensure consistency and completeness of the inspection, and I typically conduct both pre-audit document reviews and on-site inspections. During the on-site inspection, I interview workers, review factory records, and physically inspect the facilities. I also check for relevant certifications and licenses.

After the audit, I produce a comprehensive report that details findings, highlights areas of compliance and non-compliance, and recommends corrective actions. This report is shared with the factory and relevant stakeholders, and it’s used to inform our sourcing decisions and ongoing factory monitoring.

Q 21. How do you ensure compliance with social and environmental standards?

Ensuring compliance with social and environmental standards is paramount. It’s about ethical sourcing and minimizing the environmental footprint of the apparel industry – doing what’s right for people and the planet.

My approach involves several key strategies. First, I only work with factories that demonstrate a strong commitment to ethical and environmental responsibility. I verify their compliance through third-party audits and certifications, such as WRAP (Worldwide Responsible Accredited Production), GOTS (Global Organic Textile Standard), and OEKO-TEX. Second, I integrate social and environmental criteria into our sourcing contracts, making compliance a contractual obligation. Third, I conduct regular factory monitoring and follow-up audits to ensure ongoing compliance and address any emerging issues.

Furthermore, I actively promote sustainable practices throughout the supply chain, encouraging the use of eco-friendly materials, reducing waste, and improving energy efficiency. Collaboration with NGOs and industry initiatives is also key to staying updated on best practices and promoting transparency. It’s about continuous improvement and a long-term commitment to ethical and sustainable sourcing.

Q 22. How do you resolve conflicts between suppliers and internal teams?

Resolving conflicts between suppliers and internal teams requires a proactive, diplomatic approach focused on collaborative problem-solving. I begin by fostering open communication – actively listening to both sides to understand their perspectives and concerns. This often involves clarifying expectations from the outset, ensuring clear communication of specifications and deadlines.

For example, if a supplier is facing delays due to unforeseen circumstances like raw material shortages, I’ll work with the internal team to explore alternatives, such as adjusting timelines or finding alternative suppliers for specific components, while maintaining quality standards.

If the conflict involves quality issues, I’d initiate a thorough investigation, involving on-site inspection if necessary. Documentation is crucial; I meticulously track all communication and agreements. Finally, I facilitate a joint meeting to discuss the findings and collectively agree on a resolution plan, which is documented and agreed upon by all parties.

Sometimes, unfortunately, compromise isn’t possible and more drastic measures like contract renegotiation or even supplier replacement may be necessary. However, these are always last resorts, as building strong, reliable relationships with suppliers is crucial for long-term success.

Q 23. Describe your experience with different types of apparel orders (e.g., bulk, small batch).

My experience encompasses a wide range of apparel orders, from large-scale bulk productions to smaller, more specialized batch orders. Bulk orders require efficient management of large quantities of materials and intricate logistical planning, often involving negotiating favorable pricing with suppliers based on volume discounts. I’ve managed projects involving tens of thousands of units, requiring meticulous inventory control and careful monitoring of production timelines to meet deadlines and prevent stockouts.

Conversely, small batch orders offer agility and customization. These are often ideal for testing new designs or responding quickly to market trends. The process requires close collaboration with the supplier to ensure efficient production even with smaller volumes, often prioritizing speed and flexibility over sheer economies of scale. For example, I’ve managed orders for limited-edition collections requiring intricate embroidery or unique fabric treatments that need specialized machinery, hence demanding tighter quality control.

In either case, the core principles remain the same: precise communication, clear specifications, rigorous quality control and adherence to ethical sourcing practices.

Q 24. How do you manage the documentation and communication throughout the production process?

Effective documentation and communication are the cornerstones of successful apparel production. I utilize a robust system that combines digital tools with physical records. This often includes a centralized project management software to track orders, deadlines, and communication logs.

Each order starts with a detailed purchase order (PO) outlining specifications, quantities, deadlines, and payment terms. This is followed by regular communication with suppliers via email, video conferencing, or instant messaging. Key updates are logged in the project management system, ensuring transparency and accountability. Regular reports on production progress, including quality control checks and inspection reports, are generated and shared with all stakeholders.

Physical samples and approved designs are meticulously documented, and I ensure all relevant compliance documents, such as certificates of origin and test reports, are stored securely and easily accessible. This detailed documentation not only helps maintain transparency and accountability but also assists in dispute resolution and audits.

Q 25. What are your strategies for identifying and mitigating potential production risks?

Risk mitigation is an integral part of my approach. I identify potential risks throughout the entire production cycle using a combination of proactive strategies and reactive measures. This starts with a thorough risk assessment at the beginning of the project. Key areas considered include supplier reliability, geopolitical instability, raw material availability, and potential quality issues.

Proactive measures include diversifying suppliers to reduce dependency on a single source, establishing strong communication channels with suppliers, and conducting regular quality control checks during production. I also incorporate contingency plans, such as having backup suppliers or alternative materials readily available in case of unforeseen disruptions.

Reactively, I continuously monitor production progress and immediately address any emerging issues. I’m adept at identifying and quickly implementing solutions to problems, including negotiating with suppliers for adjustments or finding creative solutions to minimize disruptions. Regular performance reviews of suppliers and thorough analysis of production data help further identify and minimize future risks.

Q 26. How do you prioritize tasks and manage competing deadlines in a fast-paced environment?

Prioritizing tasks in a fast-paced environment demands efficient time management and organizational skills. I rely on a combination of project management methodologies, prioritizing tasks based on urgency and importance using tools like Eisenhower Matrix (Urgent/Important). This allows me to focus on critical tasks while delegating or postponing less important ones.

For example, if a critical delivery is approaching, I’ll prioritize tasks directly impacting that deadline, while less urgent ones, such as market research, may be temporarily postponed. I use project management software to visually track progress on all tasks, deadlines, and resource allocation. Regularly updating this system and holding progress meetings with the team allows for quick identification and resolution of potential bottlenecks.

I also value effective communication, keeping the team informed of priorities and changes. Clear delegation of responsibilities and trust in team members’ abilities are crucial for efficient task management and meeting competing deadlines.

Q 27. Describe your experience in cost estimation and price negotiation.

Cost estimation and price negotiation are crucial for profitability. My approach starts with a thorough understanding of the product specifications, including materials, labor costs, and manufacturing processes. I use a combination of cost accounting principles, historical data, and market research to develop accurate cost estimations.

For example, I’ll break down the cost of production into its various components (raw materials, labor, overhead, etc.). I use industry benchmarks and supplier quotes to get a realistic understanding of the price range. Negotiations with suppliers leverage my deep understanding of the market and my ability to leverage volume discounts or other favorable terms.

The process is iterative, refining estimates as more information becomes available. This involves analyzing supplier quotes, considering potential risks and contingency costs, and building in a reasonable profit margin. I view price negotiation as a collaborative process, aiming to find a price point that is fair to both parties and ensures the project remains profitable.

Q 28. How do you leverage data and analytics to improve efficiency in apparel sourcing and production?

Data and analytics play a pivotal role in improving efficiency. I use data from various sources including production records, quality control reports, supplier performance metrics and market trends to identify areas for improvement. For example, analyzing production data may reveal bottlenecks in specific processes, allowing for targeted interventions like process optimization or improved resource allocation.

Supplier performance data, including lead times and defect rates, allows for better supplier selection and performance management. Market trend analysis helps predict demand and optimize inventory levels. Using business intelligence tools to visualize this data and create insightful dashboards makes identifying patterns and anomalies easier, allowing for data-driven decision-making.

By systematically tracking key metrics and analyzing them regularly, I can identify inefficiencies, predict potential problems, and optimize various aspects of the apparel sourcing and production process, ultimately leading to cost savings, improved quality and faster lead times.

Key Topics to Learn for Apparel Sourcing and Production Interview

- Sourcing Strategies: Understanding different sourcing models (e.g., domestic vs. offshore, direct vs. indirect), evaluating supplier capabilities, and negotiating favorable terms.

- Supplier Selection & Management: Developing criteria for selecting reliable and ethical suppliers, building strong relationships, and managing supplier performance through regular communication and audits.

- Production Planning & Control: Mastering production planning techniques, managing lead times, optimizing inventory levels, and implementing quality control measures throughout the production process.

- Fabric & Material Selection: Understanding different fabric types, their properties, and suitability for various garments. Knowing how to source high-quality materials at competitive prices.

- Costing & Budgeting: Accurately estimating production costs, including raw materials, labor, and overhead. Developing and managing budgets effectively.

- Quality Assurance & Control: Implementing robust quality control procedures at each stage of production, from raw material inspection to finished goods inspection. Understanding quality standards and certifications (e.g., ISO 9001).

- Ethical & Sustainable Sourcing: Understanding and applying ethical sourcing principles, including fair labor practices, environmental sustainability, and responsible waste management.

- Supply Chain Management: Optimizing the entire supply chain, from raw material sourcing to finished goods delivery, to ensure efficiency and minimize disruptions.

- Technology in Apparel Production: Familiarity with relevant technologies such as CAD/CAM, PLM software, and automated production systems.

- Problem-Solving & Decision-Making: Demonstrating the ability to identify and resolve problems related to sourcing, production, and quality control effectively and efficiently.

Next Steps

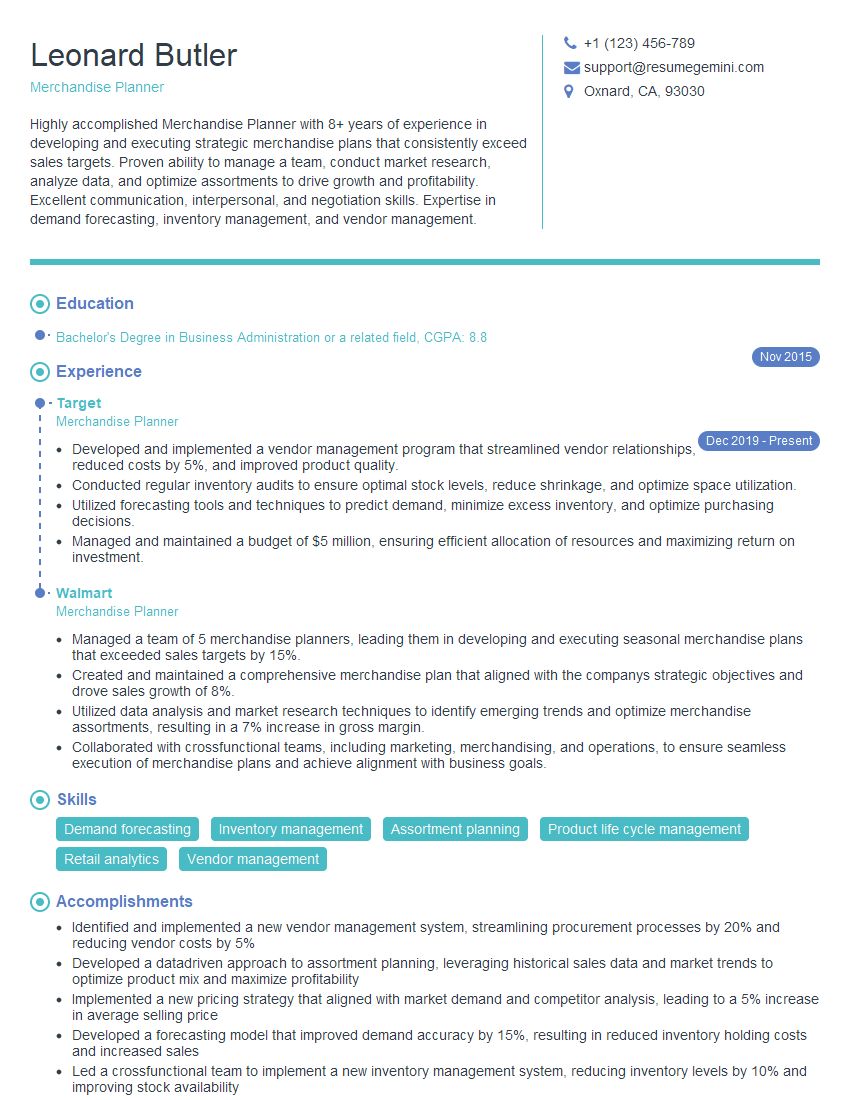

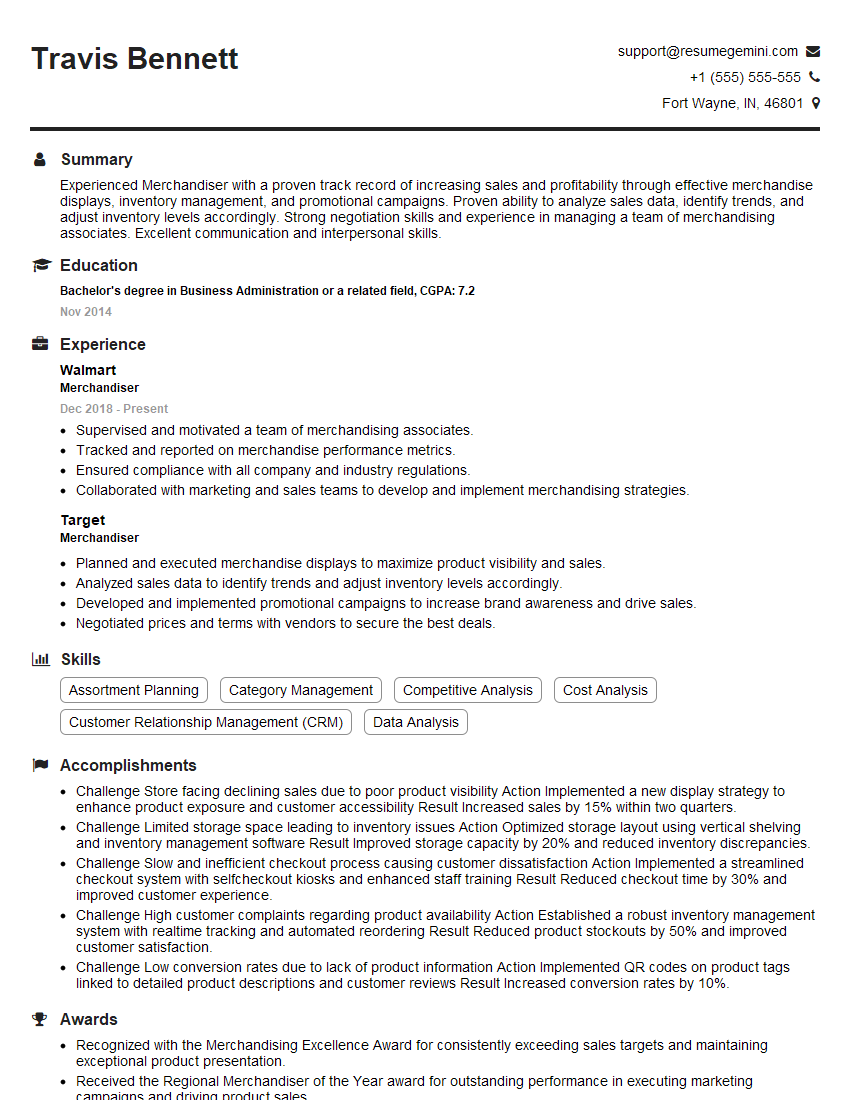

Mastering Apparel Sourcing and Production is crucial for a successful and rewarding career in the fashion industry. It opens doors to leadership roles, higher salaries, and greater influence within your organization. To maximize your job prospects, creating an ATS-friendly resume is essential. This ensures your qualifications are easily identified by applicant tracking systems used by most companies. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and resources to craft a compelling narrative, highlighting your skills and experience effectively. Examples of resumes tailored to Apparel Sourcing and Production are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good