Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Developing and Implementing Quality Control Procedures interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Developing and Implementing Quality Control Procedures Interview

Q 1. Describe your experience developing and implementing quality control procedures.

My experience in developing and implementing quality control procedures spans over ten years across diverse industries, including manufacturing and software development. I’ve consistently followed a structured approach, beginning with a thorough understanding of the product or service’s specifications and customer requirements. This involves collaborating with cross-functional teams to identify critical quality characteristics and potential failure points. Then, I design and implement appropriate QC procedures, encompassing everything from raw material inspection to final product testing and verification. This includes creating detailed checklists, work instructions, and forms, ensuring traceability and accountability throughout the process. For instance, in a recent project involving the manufacture of medical devices, I spearheaded the implementation of a new quality management system (QMS) leading to a 20% reduction in defect rates within six months. This involved not only implementing new testing procedures but also retraining staff and improving communication workflows.

Furthermore, I regularly review and update QC procedures based on performance data and emerging best practices. This iterative process guarantees the ongoing effectiveness of our quality control system, adapting to evolving demands and identifying areas for continuous improvement.

Q 2. Explain the different types of quality control charts and when you would use each.

Several types of quality control charts are used, each designed for specific applications. The choice depends on the type of data being analyzed and the nature of the process being monitored.

- Control Charts for Variables: These charts monitor continuous data, like weight, length, or temperature.

- X-bar and R chart: Tracks the average (X-bar) and range (R) of a sample of measurements to detect shifts in the process mean or variability. For example, in a bottling plant, it might track the average fill volume and the variation in fill volume across a sample of bottles.

- X-bar and s chart: Similar to X-bar and R but uses the standard deviation (s) instead of the range, offering better statistical power with larger sample sizes.

- Control Charts for Attributes: These charts monitor discrete data, like the number of defects or the percentage of non-conforming items.

- p-chart: Monitors the proportion of nonconforming units in a sample. A manufacturing plant might use it to track the percentage of defective components in a batch.

- c-chart: Monitors the number of defects per unit. A quality control inspector might use it to track the number of scratches on a surface of a manufactured item.

- u-chart: Monitors the average number of defects per unit when the sample size varies from one sample to another.

The selection of the appropriate chart depends on the type of data (variable or attribute) and the nature of the process being monitored. Understanding this distinction is critical to effective quality control.

Q 3. How do you define and measure key performance indicators (KPIs) for quality control?

Key Performance Indicators (KPIs) for quality control are measurable values that demonstrate the effectiveness of the quality control system. The specific KPIs depend heavily on the context, but some common examples include:

- Defect Rate: The percentage of non-conforming products or services. A lower defect rate indicates better quality.

- Yield: The percentage of good units produced relative to the total number of units started. A higher yield shows improved efficiency and quality.

- Customer Complaints: The number of complaints received from customers regarding quality issues. Fewer complaints indicate greater customer satisfaction and higher quality.

- Return Rate: The percentage of products returned due to quality defects. A lower return rate is a strong indicator of good quality.

- Process Capability Index (Cpk): Measures how well the process is capable of meeting specified tolerances. A Cpk value greater than 1.33 indicates a robust process.

Measuring these KPIs involves collecting data, analyzing it using statistical methods, and regularly reporting on the findings. This data drives continuous improvement efforts. For example, tracking the defect rate over time can reveal trends, enabling proactive adjustments to processes to prevent future defects.

Q 4. What are some common quality control methodologies you’re familiar with (e.g., Six Sigma, Lean)?

I’m proficient in several quality control methodologies, including:

- Six Sigma: A data-driven approach focused on minimizing variation and defects. It uses statistical tools and methodologies to identify and eliminate the root causes of defects, aiming for near-perfection (six standard deviations from the mean). I’ve utilized DMAIC (Define, Measure, Analyze, Improve, Control) for process optimization in several projects.

- Lean Manufacturing: A methodology aimed at eliminating waste and improving efficiency throughout the entire production process. It focuses on streamlining workflows, reducing lead times, and improving overall value for the customer. I’ve successfully implemented Lean principles in manufacturing settings by identifying and eliminating non-value-added activities, improving workflow, and reducing lead times.

- Total Quality Management (TQM): A holistic approach that involves all employees in the pursuit of continuous quality improvement. It emphasizes customer satisfaction, employee empowerment, and continuous improvement cycles. This is a philosophy I’ve integrated across all my quality control implementation projects.

The selection of the most appropriate methodology depends on the specific context, including the nature of the process, the type of defects being addressed, and the organizational culture.

Q 5. How do you handle discrepancies between expected and actual quality levels?

Discrepancies between expected and actual quality levels require a systematic approach to investigation and resolution. The first step is to objectively quantify the discrepancy, identifying the specific quality characteristics that are not meeting expectations. Then, a thorough investigation is needed to pinpoint the root cause(s) of the problem.

This often involves:

- Data Analysis: Examining historical data to identify trends and patterns.

- Process Mapping: Visualizing the process flow to identify potential points of failure.

- Root Cause Analysis (RCA): Employing techniques like the 5 Whys or Fishbone diagrams to identify the underlying causes of the discrepancy.

Once the root cause(s) are identified, corrective and preventative actions (CAPA) are developed and implemented. These actions should address the root cause(s) directly, preventing similar issues from recurring. Finally, the effectiveness of the CAPA is monitored using the relevant KPIs, ensuring the corrective actions have achieved the desired results and the quality levels are back on track. For example, if the defect rate for a particular product increases, a thorough investigation might reveal a faulty batch of raw materials or a poorly calibrated machine. Addressing these issues directly solves the problem and prevents recurrence.

Q 6. Describe your experience with root cause analysis techniques.

I have extensive experience with several root cause analysis (RCA) techniques. These techniques are crucial in identifying the underlying causes of quality issues, enabling the implementation of effective corrective actions.

- 5 Whys: A simple yet effective method where you repeatedly ask ‘why’ to drill down to the root cause of a problem. This technique is excellent for quickly identifying the root causes of simple problems. For instance, if a product is malfunctioning, asking “Why?” repeatedly can uncover issues like poor component quality or incorrect assembly.

- Fishbone Diagram (Ishikawa Diagram): A visual tool that helps identify potential causes contributing to a particular effect. Categories such as materials, methods, manpower, machinery, and environment are used to brainstorm potential causes and trace them back to a root cause. This is helpful for complex problems with multiple contributing factors.

- Pareto Analysis: A technique used to identify the ‘vital few’ causes that contribute to the majority of problems. This focuses efforts on addressing the most impactful issues first. For instance, if 80% of customer complaints stem from a specific product defect, Pareto analysis highlights the need to prioritize fixing that specific issue.

The choice of RCA technique depends on the complexity of the problem and the available data. Often, a combination of techniques is employed for a more comprehensive analysis.

Q 7. How do you ensure effective communication and collaboration within a quality control team?

Effective communication and collaboration are critical for a successful quality control team. I prioritize this through several strategies:

- Regular Team Meetings: Conducting frequent meetings to discuss progress, share updates, and address challenges. These meetings are crucial for information flow and collaborative problem-solving.

- Clear Communication Channels: Establishing clear and efficient communication channels, such as email, instant messaging, and project management software, to ensure information is readily accessible and shared promptly.

- Defined Roles and Responsibilities: Clearly defining roles and responsibilities within the team to prevent overlaps and ensure accountability.

- Training and Development: Providing regular training and development opportunities for team members to enhance their skills and knowledge.

- Open and Transparent Communication: Fostering an open and transparent communication environment where team members feel comfortable sharing ideas, concerns, and feedback. This encourages collaborative problem-solving and enhances team cohesion.

Ultimately, a strong team culture is essential. I believe in building trust and mutual respect to encourage open dialogue and constructive feedback. This collaborative environment increases team effectiveness and helps to achieve higher quality standards.

Q 8. Explain your approach to identifying and mitigating quality control risks.

Identifying and mitigating quality control risks is a proactive process, not a reactive one. My approach begins with a thorough risk assessment, systematically identifying potential problems at each stage of the production or service process. This involves brainstorming sessions with the team, reviewing past performance data (looking for trends and common failure points), and analyzing process flow charts to pinpoint vulnerabilities. For instance, in a software development project, a risk might be insufficient testing leading to bugs in the final product. In a manufacturing setting, it could be faulty raw materials causing defects.

Once risks are identified, I prioritize them based on their likelihood and potential impact. A risk matrix is a useful tool for this. Then, I develop mitigation strategies for each risk. This might involve implementing new control measures, such as adding extra testing phases or investing in more robust equipment. It could also mean revising existing procedures, improving employee training, or strengthening supplier relationships. Crucially, I always ensure these mitigations are cost-effective and proportionate to the risk.

Regular monitoring and review are also essential. I establish key performance indicators (KPIs) to track the effectiveness of the mitigation strategies. If a risk materializes despite mitigation efforts, I conduct a root cause analysis to understand what went wrong and implement corrective actions to prevent recurrence. This iterative approach ensures continuous improvement in quality control.

Q 9. How do you stay current with industry best practices and quality control standards?

Staying current in the dynamic field of quality control requires a multi-faceted approach. I actively participate in professional organizations like the American Society for Quality (ASQ), attending conferences, webinars, and workshops to learn about the latest advancements and best practices. This exposes me to new techniques, technologies, and regulatory updates.

I also subscribe to relevant industry publications and journals, keeping abreast of emerging trends and research. Furthermore, I regularly review industry standards and guidelines, including those related to specific sectors I’m involved in. I leverage online resources, such as reputable websites and open-access research papers, to enhance my knowledge. Finally, I actively seek out opportunities for professional development, including certifications to validate and enhance my expertise. For example, obtaining a Six Sigma certification demonstrates proficiency in data-driven quality improvement methodologies.

Q 10. What experience do you have with ISO 9001 or other quality management systems?

I have extensive experience working with ISO 9001:2015, a globally recognized standard for quality management systems. In my previous role at [Previous Company Name], I was instrumental in leading our team through the ISO 9001 certification process. This involved developing and implementing a comprehensive quality management system encompassing all aspects of our operations, from planning and resource management to internal audits and management review. We successfully achieved certification, which significantly improved our operational efficiency and customer satisfaction.

Beyond ISO 9001, I have also worked with other quality management systems tailored to specific industries, including [mention specific systems if applicable, e.g., automotive’s IATF 16949 or medical device’s ISO 13485]. My experience encompasses all stages of a quality management system, from its initial design and implementation to ongoing maintenance and continuous improvement.

Q 11. Describe a time you had to implement a new quality control procedure. What challenges did you face?

In a previous project involving the implementation of a new software testing procedure, we transitioned from manual testing to automated testing using Selenium. The primary challenge was the initial learning curve for the team. Many team members were accustomed to the manual process and were hesitant to adopt the new technology. To address this, we implemented a comprehensive training program with both theoretical and hands-on components. We also paired experienced testers with those less familiar with the technology to facilitate knowledge transfer and provide support.

Another challenge was integrating the automated testing process into our existing workflow. This required careful planning and coordination to minimize disruption to the overall development cycle. We phased in the implementation, starting with critical functionalities and gradually expanding to other areas. We also faced challenges with maintaining and updating the test scripts as the software evolved. This required a robust version control system and a clear process for managing changes to the test automation framework.

Despite these initial hurdles, the transition to automated testing ultimately proved successful. It significantly improved the efficiency and accuracy of our testing process, leading to higher quality software releases and reduced defect rates. This experience highlighted the importance of thorough planning, effective communication, and ongoing support when implementing new quality control procedures.

Q 12. How do you prioritize quality control tasks and manage competing deadlines?

Prioritizing quality control tasks and managing competing deadlines requires a structured approach. I typically use a combination of techniques, including risk-based prioritization and agile methodologies. I start by identifying all quality control tasks, assessing their urgency and impact on overall project goals. Tasks that pose the highest risk or have the most significant potential impact are prioritized first. For example, addressing a critical bug in software before release would take precedence over a minor cosmetic issue.

I then utilize project management tools, such as Gantt charts or Kanban boards, to visualize the schedule and track progress. This allows me to allocate resources effectively and identify potential conflicts early on. Regular communication with stakeholders is crucial to ensure everyone is aligned on priorities and potential delays are addressed promptly. Agile methodologies, with their iterative approach and emphasis on flexibility, are particularly helpful in managing competing deadlines and adapting to changing requirements.

Finally, I regularly monitor progress, adapt the plan as needed, and communicate openly with team members to ensure that quality is not compromised due to time constraints. A well-defined escalation process is also in place to handle urgent issues efficiently.

Q 13. Describe your experience with statistical process control (SPC).

Statistical Process Control (SPC) is a powerful tool for monitoring and improving processes. My experience with SPC includes using control charts, such as X-bar and R charts, to track process variation over time. I’ve used these charts to identify trends, patterns, and out-of-control signals that indicate a need for corrective action. For example, in a manufacturing process, an increasing trend in the average defect rate could be detected using an X-bar chart, prompting an investigation into the root cause.

Beyond simple control charts, I have experience with more advanced SPC techniques, including capability analysis (Cp and Cpk) to determine if a process is capable of meeting specifications and process behavior charts (e.g., I-MR charts) for individual measurements. My expertise also extends to interpreting control chart results, applying appropriate statistical tests, and communicating findings to relevant stakeholders. I understand the importance of using SPC data to drive continuous improvement efforts and make data-driven decisions to enhance quality.

Q 14. What are the key elements of a successful quality control plan?

A successful quality control plan hinges on several key elements: First, it must be clearly defined, with specific objectives and measurable KPIs. This ensures everyone understands what needs to be achieved and how success will be measured. Second, it needs to be comprehensive, covering all stages of the process, from design and development to production, delivery, and post-sales support.

Third, it requires a robust methodology, outlining the procedures, techniques, and tools to be used for quality control. This might include statistical process control, inspection protocols, testing procedures, and corrective action plans. Fourth, the plan needs appropriate resources, including skilled personnel, adequate equipment, and sufficient budget. Finally, a successful quality control plan incorporates a feedback loop, enabling continuous improvement. This involves regularly monitoring the effectiveness of the plan, analyzing results, and making necessary adjustments to optimize the process and enhance quality over time.

Think of it like baking a cake: you need a clear recipe (defined objectives), the right ingredients (resources), the proper baking techniques (methodology), and regular checking to make sure it’s baking correctly (monitoring and feedback). Without all these elements, you’re unlikely to get a consistently high-quality cake—or product.

Q 15. How do you ensure that your quality control procedures are effective and efficient?

Effective and efficient quality control procedures are the backbone of any successful organization. My approach focuses on a proactive, data-driven strategy, combining preventative measures with reactive adjustments.

- Proactive Measures: This involves implementing robust processes from the design phase. We use techniques like Failure Mode and Effects Analysis (FMEA) to identify potential failure points and implement preventative controls before they impact production. Regular equipment calibration and preventative maintenance are critical components here. For example, in a food manufacturing setting, we’d meticulously check temperatures at each stage of processing to prevent bacterial growth.

- Reactive Adjustments: Continuous monitoring and data analysis are crucial. We utilize control charts (like Shewhart charts or CUSUM) to track key performance indicators (KPIs) and identify trends. If a process drifts outside acceptable limits, we immediately investigate the root cause using tools like Pareto analysis and fishbone diagrams to pinpoint the problem and implement corrective actions. For instance, if our defect rate suddenly increases, we might discover it’s linked to a specific machine malfunctioning, prompting timely maintenance.

- Process Optimization: We don’t just react to problems; we actively seek to improve. Lean methodologies, Six Sigma principles, and Kaizen events help us streamline processes, eliminate waste, and continuously improve our quality control system. This might involve automating repetitive tasks or redesigning a workflow to reduce errors.

By combining these proactive and reactive approaches, we ensure our quality control procedures are both effective in preventing defects and efficient in using resources.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle customer complaints related to product quality?

Handling customer complaints is paramount. My approach prioritizes prompt response, thorough investigation, and customer satisfaction.

- Acknowledgement and Investigation: Every complaint is acknowledged immediately, assuring the customer that their issue is being addressed. We thoroughly investigate the root cause, using the information provided by the customer in conjunction with internal data. This often involves examining production records, testing the affected product, and interviewing relevant personnel.

- Corrective Action: Once the root cause is identified, we implement corrective and preventative actions to prevent similar issues from occurring again. This might involve adjusting a machine setting, revising training materials, or improving a process step.

- Resolution and Communication: We provide the customer with a clear explanation of the issue and the steps taken to resolve it. We aim to offer a fair resolution, which might involve a replacement product, a refund, or other compensation. Throughout this process, we maintain open and transparent communication with the customer, keeping them updated on our progress.

- Data Analysis: Every customer complaint is logged and analyzed to identify patterns and trends. This data helps us improve our quality control procedures and prevent future complaints. For instance, if multiple complaints relate to a specific product feature, it indicates a potential design flaw needing revision.

The goal is not just to resolve individual complaints but to learn from them and continuously improve our products and services.

Q 17. What software or tools do you use for quality control and data analysis?

My experience encompasses a wide range of software and tools for quality control and data analysis. The specific tools employed depend on the project and industry. However, some common tools I utilize include:

- Statistical Software Packages:

RandMinitabare powerful tools for statistical process control (SPC), data analysis, and creating control charts. They allow me to perform complex statistical analyses and visualize data to identify trends and anomalies. - Spreadsheet Software:

Microsoft ExcelorGoogle Sheetsare invaluable for data organization, tracking, and basic statistical analysis. I use these for quick data summaries and initial trend analysis. - Quality Management Systems (QMS) Software: Software like

TrackViaorJirahelps manage quality control documentation, track nonconformances, and manage corrective and preventative actions (CAPA). These systems ensure traceability and facilitate compliance with industry standards. - Data Visualization Tools: Tools like

TableauorPower BIare excellent for creating dashboards that visually represent key performance indicators, providing management with a quick overview of quality metrics.

The key is selecting the right tools for the specific task. Often a combination of tools is used for comprehensive quality control.

Q 18. How do you measure the effectiveness of your quality control procedures?

Measuring the effectiveness of quality control procedures is crucial for continuous improvement. We use a multi-faceted approach to assess effectiveness:

- Key Performance Indicators (KPIs): We track several KPIs, such as defect rates, customer complaints, rework rates, and process capability indices (Cp, Cpk). These metrics provide quantitative data on the performance of our quality control system. A significant drop in the defect rate, for example, indicates an improvement in effectiveness.

- Internal Audits: Regular internal audits assess the effectiveness of our quality control procedures against predefined standards and best practices. These audits identify areas for improvement and ensure compliance with regulations.

- Customer Satisfaction Surveys: Customer feedback provides valuable qualitative data on the perception of product quality. High customer satisfaction scores indicate an effective quality control system.

- Process Capability Analysis: This statistical technique assesses the ability of a process to meet predefined specifications. A high process capability index suggests a robust and effective quality control system.

By combining quantitative and qualitative data, we obtain a holistic view of the effectiveness of our quality control procedures and can make informed decisions regarding areas for improvement.

Q 19. How do you train and mentor team members on quality control procedures?

Training and mentoring are vital for maintaining a high standard of quality control. My approach is a combination of structured training and on-the-job mentoring:

- Structured Training: This involves formal training sessions covering quality control principles, relevant tools and techniques, and our company’s specific quality control procedures. We use a mix of classroom instruction, interactive workshops, and online modules to cater to different learning styles.

- On-the-Job Mentoring: Experienced team members mentor newer employees, providing practical guidance and support during daily tasks. This hands-on approach helps build confidence and ensures that best practices are consistently applied.

- Regular Refresher Training: We conduct periodic refresher training to ensure team members stay updated on changes in procedures, new technologies, and industry best practices.

- Performance Feedback and Continuous Improvement: We provide regular performance feedback to identify areas where individuals can improve their quality control skills. This includes feedback on their application of quality control tools and their adherence to company procedures.

Investing in team member training and development ensures that everyone understands and effectively applies quality control procedures, leading to a culture of continuous improvement.

Q 20. What are the key differences between quality control and quality assurance?

While both quality control (QC) and quality assurance (QA) aim to improve product quality, they differ in their focus and approach:

- Quality Control (QC): QC is a reactive process focused on inspecting finished products or processes to identify defects. It’s about ensuring that products meet predefined specifications. Think of QC as the final check before a product is shipped.

- Quality Assurance (QA): QA is a proactive process focused on preventing defects from occurring in the first place. It involves establishing and maintaining quality systems and procedures throughout the entire product lifecycle, from design and development to production and delivery. QA ensures the right systems are in place to consistently produce quality products.

An analogy: imagine baking a cake. QC is checking the finished cake to ensure it’s baked properly, while QA is ensuring you have the right recipe, ingredients, and oven temperature to bake a perfect cake every time.

Q 21. Describe your experience with auditing quality control processes.

I have extensive experience auditing quality control processes across various industries. My approach is methodical and thorough, focusing on both compliance and effectiveness:

- Planning and Scoping: I begin by clearly defining the scope of the audit, identifying the specific processes and procedures to be reviewed. This involves understanding the organization’s quality management system (QMS) and relevant industry standards.

- Data Collection: I collect data through a combination of document reviews, interviews with personnel, observation of processes, and examination of records. This ensures a comprehensive understanding of the quality control system.

- Analysis and Evaluation: I analyze the collected data to identify any gaps, weaknesses, or nonconformances in the quality control system. This often involves comparing actual performance to established standards and best practices.

- Reporting and Recommendations: I prepare a comprehensive audit report documenting my findings, including any identified nonconformances and associated root causes. I provide specific recommendations for improvement, outlining corrective and preventative actions to address identified issues.

Through rigorous auditing, I help organizations identify opportunities to improve their quality control procedures, ensuring compliance with standards and ultimately enhancing product quality and customer satisfaction. A recent audit I conducted for a pharmaceutical company resulted in the implementation of enhanced cleaning validation procedures, minimizing the risk of product contamination.

Q 22. How do you ensure data integrity in your quality control processes?

Data integrity in quality control is paramount. It ensures the accuracy, consistency, and reliability of data used for decision-making. We achieve this through a multi-pronged approach.

- Data Validation: Implementing checks at each stage of data entry and processing to catch errors early. This could involve automated checks for data type, range, and consistency, as well as manual reviews by trained personnel. For example, a weight measurement that falls outside expected parameters would trigger an alert.

- Version Control: Maintaining a clear audit trail of all data modifications. This allows for easy tracking of changes and ensures that the most up-to-date information is used. Imagine a spreadsheet where every edit is timestamped and attributed to a specific user.

- Data Backup and Recovery: Implementing robust systems to protect data from loss or corruption. This includes regular backups, redundancy measures, and disaster recovery plans. This is crucial in case of accidental deletion or hardware failures.

- Access Control: Restricting access to data based on roles and responsibilities, preventing unauthorized modifications. This ensures only authorized personnel can alter critical data, reducing the risk of accidental or malicious changes.

- Data Governance Policies: Establishing clear guidelines and procedures for data handling, storage, and retention. These policies ensure everyone is working under the same rules, fostering consistency and accountability.

By combining these strategies, we ensure that our data is reliable, trustworthy, and forms a solid foundation for our quality control decisions.

Q 23. What is your experience with preventative quality control measures?

Preventative quality control focuses on proactively preventing defects rather than reacting to them. My experience encompasses a wide range of techniques, from designing robust processes to implementing comprehensive training programs.

- Process Design: I’ve been involved in designing processes that minimize the potential for errors by incorporating features like automated checks, visual aids, and standardized procedures. For example, creating a checklist for a complex assembly process significantly reduces the likelihood of missing steps.

- Supplier Management: Working closely with suppliers to ensure they meet our quality standards is crucial. This includes rigorous quality audits, pre-production inspections, and ongoing performance monitoring. Think of a manufacturer vetting their parts suppliers to guarantee consistent quality of components.

- Preventive Maintenance: Regularly maintaining equipment and tools to prevent breakdowns and ensure consistent performance. Imagine a factory regularly servicing its machinery to prevent unexpected downtime.

- Employee Training: Providing comprehensive training to employees on quality procedures, problem-solving techniques, and the use of quality control tools is critical. This ensures everyone understands their role in maintaining quality.

- Statistical Process Control (SPC): Using statistical methods to monitor and control processes, identifying potential problems before they lead to significant defects. Control charts are frequently used here to visualize process variation and identify out-of-control situations.

By focusing on preventative measures, we’ve significantly reduced defect rates and improved overall product quality, leading to cost savings and increased customer satisfaction.

Q 24. Describe a time you identified a process improvement opportunity related to quality control.

In a previous role, we were experiencing high rejection rates for a particular product due to inconsistencies in the final packaging process. Initially, we blamed the packaging machine, but after investigating, I discovered the root cause lay in the training of the packaging operators.

My Solution: I developed a structured training program that included hands-on practice, visual aids, and detailed process documentation. This addressed the knowledge gaps and improved operator proficiency. The program also incorporated a feedback mechanism, allowing operators to immediately highlight potential issues or improvements.

Results: After implementing the new training, the rejection rate for that product dropped significantly. This improvement demonstrates that focusing on people and process optimization, rather than just focusing on machinery or equipment, can yield substantial results.

Q 25. How do you handle situations where quality control measures are not being followed?

When quality control measures aren’t followed, a systematic approach is vital.

- Identify the root cause: Through interviews, observations, and data analysis, understand *why* the procedures weren’t followed. Was it due to lack of training, unclear instructions, insufficient resources, or something else?

- Address immediate issues: Take corrective action to rectify any immediate problems stemming from the non-compliance. This might involve stopping the process, quarantining defective items, or implementing temporary fixes.

- Implement corrective actions: Develop and implement specific actions to prevent recurrence. This might include revising procedures, providing additional training, improving communication, or enhancing monitoring systems.

- Monitor effectiveness: Track the effectiveness of the corrective actions taken. Are the issues resolved? Does the problem recur? This feedback loop ensures the chosen solutions truly address the problem.

- Documentation: Meticulously document all steps, including the root cause analysis, corrective actions taken, and their effectiveness. This forms a valuable record for future reference and continuous improvement.

The key is a balanced approach: addressing the immediate consequences while tackling the underlying reasons for non-compliance. This prevents future incidents and fosters a culture of compliance.

Q 26. Explain your understanding of different sampling techniques in quality control.

Sampling techniques are crucial in quality control, allowing us to draw inferences about a larger population based on a smaller sample. The choice of technique depends on various factors such as cost, time, and the nature of the population.

- Random Sampling: Every item in the population has an equal chance of being selected. This is ideal for homogeneous populations. Imagine selecting a few cookies from a large batch to assess their quality.

- Stratified Sampling: The population is divided into subgroups (strata) based on relevant characteristics, and a sample is randomly selected from each stratum. This is useful for heterogeneous populations. For example, sampling from different production batches to capture potential variations.

- Systematic Sampling: Items are selected at regular intervals from the population. This is simple to implement but can be problematic if the population has a cyclical pattern. Picking every tenth item from a production line.

- Cluster Sampling: The population is divided into clusters (groups), and some clusters are randomly selected for sampling. This is cost-effective when geographically dispersed. Imagine randomly selecting a few stores from a retail chain to inspect their inventory.

Understanding the strengths and limitations of each technique is crucial for selecting the most appropriate method to ensure the sample accurately reflects the population and the results are statistically sound.

Q 27. How do you balance the cost of quality control with its effectiveness?

Balancing cost and effectiveness in quality control is a constant challenge. It’s not about minimizing cost but about optimizing the cost-benefit ratio.

We achieve this by:

- Risk Assessment: Identifying and prioritizing areas with the highest potential for defects and focusing resources there. This involves a careful analysis of potential failure modes and their impact.

- Cost-Benefit Analysis: Comparing the cost of implementing various quality control measures against the potential benefits of preventing defects. This includes considering the cost of rework, scrap, customer returns, and reputational damage.

- Process Optimization: Continuously improving processes to reduce the need for extensive quality control checks. A more efficient process intrinsically produces fewer defects.

- Technology: Utilizing automation and advanced statistical techniques to increase efficiency and reduce labor costs associated with quality control.

- Continuous Improvement: Regularly reviewing and refining quality control procedures to ensure they remain effective and cost-efficient. The goal is continuous optimization, not a static solution.

The ultimate goal is to achieve the highest level of quality at the lowest possible cost. This involves finding that sweet spot where the investment in quality control yields the greatest return.

Q 28. Describe your experience with corrective and preventive action (CAPA) processes.

Corrective and Preventive Action (CAPA) is a systematic approach to addressing quality issues. My experience involves a structured process encompassing investigation, root cause analysis, corrective actions, and preventive measures.

- Problem Identification and Reporting: Establishing clear channels for reporting quality issues, ensuring they are promptly identified and documented.

- Investigation: Thoroughly investigating the issue to understand its nature, extent, and impact. This often involves gathering data, conducting interviews, and reviewing relevant documents.

- Root Cause Analysis: Using tools like the 5 Whys, Fishbone diagrams, or Pareto charts to identify the underlying causes of the problem, not just the symptoms.

- Corrective Action: Implementing actions to correct the immediate problem, ensuring that the current defect is resolved.

- Preventive Action: Implementing measures to prevent the recurrence of the problem. This could involve process improvements, training, equipment upgrades, or changes to supplier agreements.

- Verification and Validation: Confirming that the corrective and preventive actions have been effective and that the problem has been resolved. This might involve monitoring, data analysis, and audits.

- Documentation: Maintaining detailed records of the entire CAPA process, from initial reporting to verification of effectiveness. This helps track progress and identifies trends.

Effective CAPA processes are crucial for continuous improvement, reducing the likelihood of recurring issues and improving overall product and service quality. I’ve successfully implemented CAPA across various projects, resulting in significant reductions in defect rates and enhanced overall quality systems.

Key Topics to Learn for Developing and Implementing Quality Control Procedures Interview

- Defining Quality: Understanding different quality standards (ISO 9000, Six Sigma, etc.) and their application to various industries. Practical application: Analyzing a specific product or process and identifying appropriate quality metrics.

- Control Charts and Statistical Process Control (SPC): Learning to interpret control charts (e.g., X-bar and R charts) and using SPC techniques to monitor and improve processes. Practical application: Designing a control chart to monitor a key process parameter and identifying out-of-control points.

- Root Cause Analysis (RCA): Mastering techniques like the 5 Whys, Fishbone diagrams, and Pareto analysis to identify the underlying causes of quality defects. Practical application: Conducting a RCA on a recent quality issue and proposing corrective actions.

- Quality Management Systems (QMS): Understanding the principles and implementation of QMS, including documentation, auditing, and continuous improvement. Practical application: Describing the role of a QMS in ensuring consistent product quality.

- Developing and Implementing QC Procedures: Creating practical, measurable, and achievable quality control procedures. Practical application: Developing a step-by-step procedure for a specific quality control task.

- Auditing and Corrective Actions: Performing internal audits to assess compliance with quality standards and implementing effective corrective and preventive actions (CAPA). Practical application: Discussing the process for handling audit findings and implementing improvements.

- Problem-Solving Methodologies: Applying structured problem-solving approaches (e.g., DMAIC) to address quality issues efficiently. Practical application: Walking through the steps of DMAIC to solve a hypothetical quality problem.

Next Steps

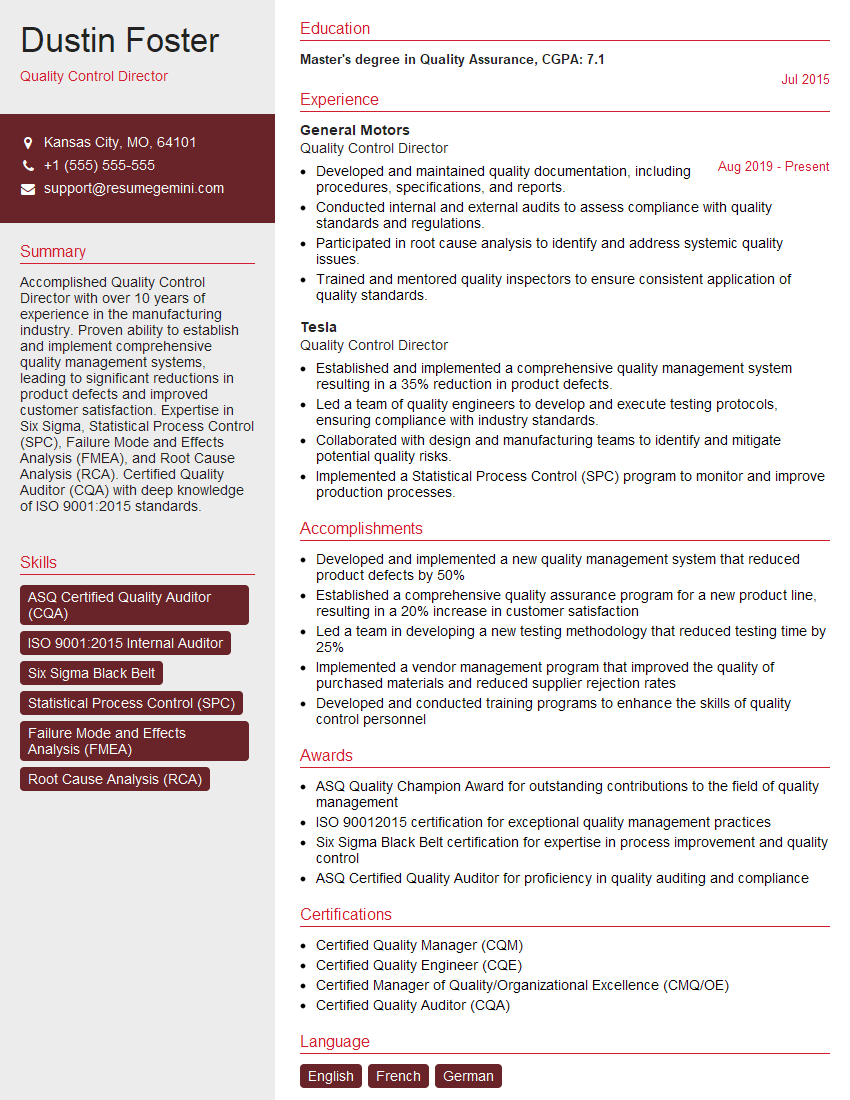

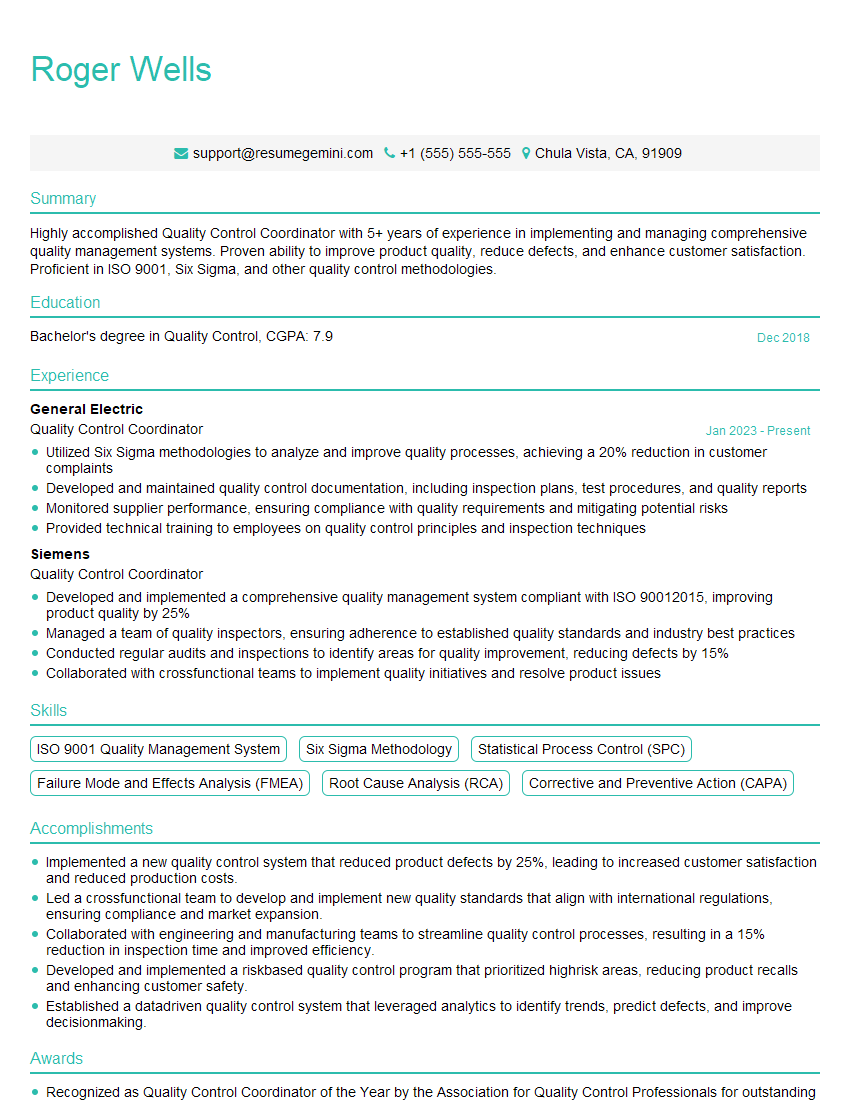

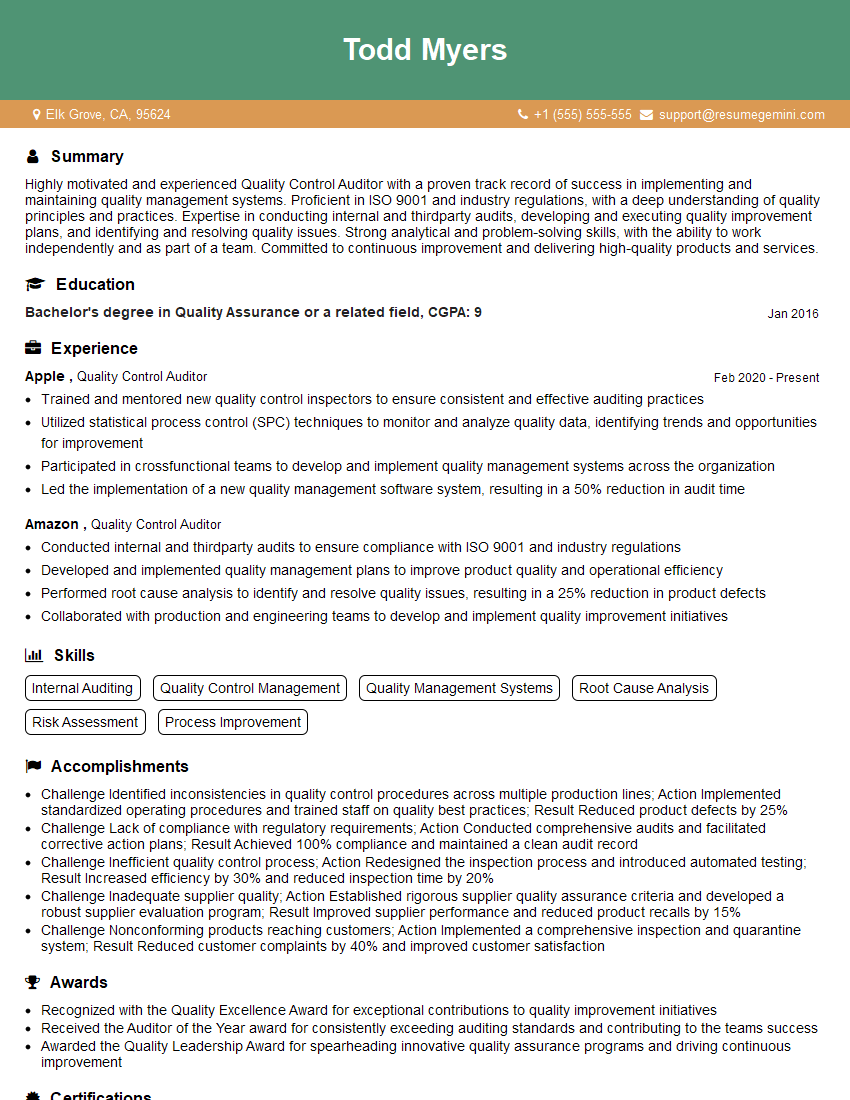

Mastering the development and implementation of quality control procedures is crucial for career advancement in many fields. It demonstrates your ability to ensure product quality, improve efficiency, and reduce costs – highly valued skills in today’s competitive market. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience. Examples of resumes tailored to roles in Developing and Implementing Quality Control Procedures are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good