Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Knowledge of different leather types and their properties interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Knowledge of different leather types and their properties Interview

Q 1. What are the key differences between full-grain, top-grain, and genuine leather?

The terms “full-grain,” “top-grain,” and “genuine” leather represent different levels of processing and quality. Think of it like peeling an onion; each layer represents a different level of refinement.

Full-grain leather is the highest quality. It retains the entire natural grain layer of the hide, untouched by sanding or buffing. This makes it the most durable and develops a beautiful patina over time. Scratches and marks are part of its character, adding to its unique story. Imagine a well-worn baseball glove – that’s the type of character full-grain develops.

Top-grain leather has the top layer of the hide sanded to remove imperfections, then a finish is applied. This makes it smoother and more consistent in appearance but less durable and resistant to scratches than full-grain. It’s a good balance between quality and affordability.

Genuine leather is often a misleading term. It usually refers to the lower layers of the hide, which are split and may even be combined with other materials. While it’s technically leather, it lacks the strength and longevity of full-grain or even top-grain. Think of it as the ‘lesser’ parts of the onion. The consistency and durability can vary considerably.

Q 2. Explain the process of tanning leather. What are the different tanning methods?

Leather tanning is the process of transforming raw animal hides into durable, usable leather by preventing decomposition. It involves several crucial steps:

Pre-tanning: This stage involves cleaning the hide, removing excess flesh and hair, and soaking it to prepare it for tanning.

Tanning: This is where the magic happens. The hide is treated with tanning agents to cross-link the collagen fibers, making it resistant to decay and giving it strength and flexibility. Different tanning methods exist:

Chrome tanning: The most common method, using chromium salts. It’s faster and more cost-effective, resulting in softer leather.

Vegetable tanning: A traditional method using plant extracts like tree bark or leaves. It produces a firmer, more durable leather that develops a rich patina but is slower and more expensive.

Aldehyde tanning: Uses aldehydes like glutaraldehyde. It creates a leather with good water resistance.

Post-tanning: This involves processes like dyeing, fat liquoring (adding oils to soften the leather), and finishing to create the desired look and feel.

Q 3. Describe the characteristics of different leather finishes (e.g., patent, nubuck, suede).

Leather finishes significantly impact the leather’s appearance and feel. Each finish offers unique properties:

Patent leather: A highly polished finish with a glossy, almost plastic-like shine. It’s water-resistant but less breathable. Think of classic rain boots.

Nubuck: A velvety soft finish created by sanding the grain side of the leather. It is delicate and requires special care, as it’s prone to staining and abrasion. It’s often found in high-end shoes and apparel.

Suede: A soft, napped finish created by sanding the flesh side of the leather. Similar to nubuck, it’s delicate and needs careful cleaning. Suede jackets and boots are classic examples.

Full-grain: As mentioned earlier, this finish is essentially the absence of a finish, and is therefore the most durable.

Q 4. How do different leather types react to water and moisture?

Different leather types react to water and moisture differently, primarily depending on the tanning method and finish.

Full-grain leather, especially vegetable-tanned, is less prone to water damage but will still absorb some moisture. It’s best to protect it with a leather conditioner and avoid prolonged exposure to water.

Top-grain and genuine leathers are generally more susceptible to water damage due to their finishing processes. Water can stain, damage the finish, and cause the leather to become stiff. Use leather protectant sprays to minimize water damage.

Finished leathers like patent are more water-resistant due to their protective coatings, but they can still be damaged by prolonged exposure to water.

Nubuck and suede are highly susceptible to water damage and should be treated with a water-repellent spray. Any moisture should be dealt with promptly using a soft cloth.

Q 5. What are the common defects found in leather and how are they identified?

Leather can have several common defects, many originating from the animal’s life or the tanning process. Here are some examples:

Scars and brands: Natural markings from the animal’s life, often seen in full-grain leather. These are often considered character marks rather than defects.

Insect bites: Small holes caused by insects. These are usually more noticeable in lighter-colored leathers.

Stretch marks: Visible lines on the leather’s surface. These usually occur on the hides of older animals.

Grain cracks: Small cracks in the grain layer, often caused by improper tanning or aging.

Color inconsistencies: Variations in the shade of the leather, potentially from the tanning process or dyeing.

These defects are usually identified by visual inspection. Careful examination, especially under good lighting, is crucial for quality control.

Q 6. How does the grain of leather affect its durability and appearance?

The grain of leather, the natural texture of the hide’s surface, significantly impacts both durability and appearance.

Durability: A tightly woven grain typically indicates stronger, more durable leather. The grain’s structure provides resistance to scratches, tears, and wear. A looser grain is more susceptible to damage.

Appearance: The grain gives leather its unique character. The texture and pattern of the grain contribute to the leather’s overall visual appeal. Fine, even grain gives a smoother, more refined look, while a more textured grain creates a rustic appearance.

For example, a handbag made from leather with a tight grain will likely be more resistant to wear and tear compared to one with a loose grain. Likewise, the choice of grain will influence the overall aesthetic of a product. The grain and the finish often work together to define the quality and character of a leather product.

Q 7. Compare and contrast the properties of calfskin, lambskin, and goatskin.

Calfskin, lambskin, and goatskin are all popular types of leather, each with distinct properties:

Calfskin: Known for its fine grain, softness, and smooth texture. It’s relatively strong and durable, making it suitable for high-quality shoes, handbags, and jackets. It’s often considered a luxury leather.

Lambskin: Extremely soft, supple, and lightweight. It’s less durable than calfskin but prized for its luxurious feel. It’s often used in clothing, gloves, and accessories.

Goatskin: A strong, durable leather with a slightly pebbled grain. It’s more resistant to scratches and wrinkles than calfskin or lambskin. It’s often used in gloves, luggage, and outdoor gear.

In essence: Calfskin offers a good balance of softness and durability, lambskin prioritizes softness and luxury, and goatskin emphasizes strength and resilience.

Q 8. Explain the importance of leather conditioning and its impact on leather longevity.

Leather conditioning is crucial for maintaining the suppleness, durability, and overall longevity of leather goods. Think of it like moisturizing your skin – it prevents cracking, dryness, and premature aging. Leather, being a natural material, loses moisture over time, becoming brittle and prone to damage. Conditioning replenishes these lost oils and moisturizers, keeping the leather hydrated and flexible.

The impact on longevity is significant. Regularly conditioned leather will resist cracking, scuffing, and fading far better than neglected leather. A well-conditioned leather handbag, for instance, will retain its shape and beauty for many years, whereas an unconditioned one might start to crack and peel within a few months. The process strengthens the leather fibers, making them more resistant to wear and tear.

- Improved Appearance: Conditioning restores the leather’s natural luster and suppleness, making it look richer and more vibrant.

- Increased Durability: By hydrating the fibers, conditioning enhances the leather’s resistance to cracking, scratching, and other forms of damage.

- Extended Lifespan: Proper conditioning significantly extends the life of your leather goods, saving you money in the long run.

Q 9. How would you assess the quality of a leather sample?

Assessing leather quality requires a keen eye and a multi-sensory approach. I’d start by examining the grain – the natural surface texture of the hide. A fine, even grain indicates superior quality, while a coarse or uneven grain suggests lower quality or potentially damaged leather. Then I’d check the thickness and consistency; high-quality leather is typically more substantial and uniform throughout.

Next, I’d assess the feel. High-quality leather should be soft, supple, and have a pleasant feel to the touch. It shouldn’t feel stiff, brittle, or overly dry. The smell is also a good indicator; genuine leather often has a subtle, natural scent. Artificial or low-quality leather might have a strong, chemical odor. Finally, I’d perform a simple stretch test – gently stretching a small area of the leather. High-quality leather should return to its original shape without showing signs of cracking or creasing.

Consider the following:

- Grain: Fine, even, and consistent grain is indicative of better quality.

- Thickness: Thicker leather generally indicates better durability and quality.

- Smell: A natural, subtle scent is a good sign, whereas strong chemical odors may indicate low quality.

- Touch: Soft, supple, and pleasant to the touch is a positive indicator.

- Stretch Test: Leather should return to its original shape without cracking or creasing.

Q 10. What are the common methods used for repairing leather damage?

Repairing leather damage depends on the type and severity of the damage. Minor scratches and scuffs can often be addressed with leather cleaners and conditioners. For deeper scratches, a leather filler can be used to even out the surface. This filler is carefully applied and then blended to match the leather’s color and texture.

More significant damage, such as tears or holes, might require more advanced techniques such as patching or stitching. For tears, a matching piece of leather can be carefully glued and stitched in place. Holes can sometimes be filled with specialized leather repair compounds.

Professional leather restoration often employs specialized tools and techniques. These can include:

- Leather Cleaners: Remove dirt and grime.

- Leather Conditioners: Hydrate and restore suppleness.

- Leather Fillers: Repair scratches and minor imperfections.

- Leather Patches: Repair tears and holes.

- Leather Dyes: Color-match repairs to the surrounding leather.

Remember, successful leather repair often requires patience, attention to detail, and the use of appropriate materials.

Q 11. What are some sustainable and ethical considerations in the leather industry?

Sustainability and ethical considerations are increasingly important in the leather industry. Traditional leather production often involves significant environmental impacts, including water pollution from tanning processes and greenhouse gas emissions from livestock farming. Ethical concerns relate to animal welfare and working conditions within the industry.

Several initiatives are promoting more sustainable and ethical practices. This includes the use of vegetable tanning methods, which are less polluting than chrome tanning. Farmers are adopting more sustainable grazing practices to reduce the environmental impact of livestock farming. Certifications like the Leather Working Group (LWG) audit tanneries for environmental and social responsibility.

Consumers can contribute by choosing leather products from brands committed to sustainable and ethical sourcing. Looking for certifications and transparency in supply chains can help make informed choices.

- Sustainable Tanning: Using vegetable tannins or other eco-friendly methods.

- Responsible Sourcing: Ensuring leather comes from farms practicing good animal welfare.

- Reduced Water and Energy Consumption: Implementing efficient manufacturing processes.

- Waste Reduction and Recycling: Minimizing leather waste and finding ways to recycle it.

- Fair Labor Practices: Ensuring fair wages and safe working conditions for all workers in the supply chain.

Q 12. Discuss the impact of different dyes and finishes on the properties of leather.

Dyes and finishes significantly impact the properties of leather. Dyes primarily affect the color and appearance, while finishes influence the leather’s feel, durability, and resistance to water and stains. Aniline dyes, for instance, penetrate the leather deeply, resulting in a natural, soft feel but making the leather more susceptible to staining and fading. Pigmented finishes, on the other hand, sit on the surface, providing excellent protection against scratches and stains but reducing the natural feel.

Different finishes can also change the leather’s breathability. Some finishes are designed to be breathable, allowing air to circulate, while others create a more sealed surface. The choice of dye and finish depends on the intended application and desired properties. For example, a shoe leather might benefit from a durable, water-resistant finish, while a glove might require a softer, more breathable finish.

- Aniline Dyes: Penetrate deeply, provide a natural look and feel but offer less protection.

- Semi-aniline Dyes: A compromise between aniline and pigmented dyes, offering a balance of natural look and protection.

- Pigmented Dyes: Sit on the surface, offer greater protection but can reduce the natural feel.

- Topcoats and Finishes: Provide additional protection against scratches, water, and stains, but can alter the leather’s breathability.

Q 13. How does temperature affect leather’s physical properties?

Temperature significantly affects leather’s physical properties. Exposure to high temperatures can cause the leather to dry out, become brittle, and crack. Conversely, extremely low temperatures can make the leather stiff and less flexible. This is because leather is a natural material composed of protein fibers that are sensitive to temperature changes.

High temperatures can also cause the leather to fade or change color. Direct sunlight, for instance, can significantly damage leather over time. Therefore, it’s crucial to protect leather from extreme temperatures, both hot and cold. Storing leather goods in a cool, dry place away from direct sunlight is recommended.

- High Temperatures: Can cause drying, brittleness, cracking, and color fading.

- Low Temperatures: Can cause stiffness and reduced flexibility.

- Direct Sunlight: Causes significant damage over time due to UV radiation and heat.

Q 14. How would you determine the appropriate leather type for a specific application (e.g., handbag, shoe, upholstery)?

Choosing the appropriate leather type for a specific application involves considering factors like durability, flexibility, aesthetics, and intended use. For a handbag, full-grain leather is a popular choice due to its durability and beautiful natural grain. However, if a softer, more supple feel is desired, top-grain or corrected-grain leather might be more suitable. The choice will also depend on the intended style and price point.

For shoes, the selection depends on the type of shoe. Full-grain or top-grain leathers are suitable for dress shoes, offering durability and a polished appearance. For more rugged shoes, a stronger, more durable leather like calfskin or suede might be preferable. Suede, for example, offers a soft and luxurious feel but requires more careful maintenance.

Upholstery requires leather with exceptional durability and resistance to wear and tear. Full-grain leather is often preferred, but also consider its resistance to stains and fading. Thickness and colorfastness are key factors to consider here.

In short, selecting the right leather requires understanding the demands of the application and balancing desired aesthetics with functional needs.

- Handbags: Full-grain, top-grain, or corrected-grain leather based on desired durability, feel, and price.

- Shoes: Full-grain, top-grain, calfskin, or suede based on shoe type, desired aesthetics, and durability needs.

- Upholstery: Full-grain leather (often treated for added durability and stain resistance).

Q 15. Describe the different methods used to measure leather thickness and tensile strength.

Measuring leather thickness and tensile strength are crucial for quality control and product development. Thickness is determined using a calibrated instrument called a thickness gauge, often a micrometer. It measures the thickness at multiple points across a leather sample to account for variations. The average reading provides the leather’s thickness, usually expressed in millimeters or fractions of an inch. Tensile strength, a measure of how much force the leather can withstand before breaking, is assessed using a universal testing machine. A leather strip is clamped at both ends, and the machine gradually applies force until the sample breaks. The maximum force recorded, divided by the original cross-sectional area of the strip, yields the tensile strength, usually expressed in megapascals (MPa) or pounds per square inch (psi).

For example, a high-quality full-grain leather might have a thickness between 1.0 and 1.4 mm and a tensile strength exceeding 20 MPa, while a thinner, more delicate leather intended for garment applications might measure 0.7-1.0 mm and have a lower tensile strength.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common testing procedures used to ensure leather quality?

Ensuring leather quality involves a battery of tests, depending on the intended application. These tests broadly fall into categories assessing physical properties, chemical properties, and appearance.

- Physical Tests: These include measuring thickness (as discussed above), tensile strength, elongation (how much the leather stretches before breaking), tear strength (resistance to tearing), bursting strength (resistance to pressure), and abrasion resistance (resistance to wear and tear). These help assess the durability and structural integrity of the leather.

- Chemical Tests: These analyze the leather’s chemical composition, looking for the presence of harmful substances, assessing its water resistance, and determining its colorfastness (resistance to fading). These tests ensure the leather is safe for use and meets required standards.

- Appearance Tests: These are subjective but crucial, evaluating factors like grain pattern, surface finish, and overall aesthetic appeal. These tests, often conducted by experienced graders, ensure the leather meets the desired look and feel.

For instance, a leather intended for upholstery would need high tensile strength and abrasion resistance, while a leather for gloves might prioritize flexibility and softness. These tests inform material selection and manufacturing processes to ensure the final product meets its intended use and quality standards.

Q 17. Explain the concept of leather grading and its significance.

Leather grading is a crucial process that categorizes leather based on its quality characteristics. This involves assessing various factors like thickness, grain uniformity, the number of imperfections (scars, wrinkles, insect bites), and its overall appearance. Graders, often with years of experience, visually inspect the hides and assign a grade accordingly. Higher grades represent leather with fewer imperfections and more consistent quality, usually commanding higher prices.

The significance of grading lies in its role in product pricing, application suitability, and customer expectations. A top-grade leather might be used for high-end handbags or car interiors, while a lower grade may be appropriate for less visible applications. This system ensures transparency and allows buyers to select leather that meets their specific needs and budget. Grading standards can vary between tanneries and countries, but generally, the higher the grade, the better the quality and the higher the cost.

Q 18. How do you identify genuine leather from faux leather?

Distinguishing genuine leather from faux leather requires a keen eye and a few simple tests. Genuine leather possesses a unique natural texture and irregularities that are difficult to replicate. Here are some ways to tell the difference:

- Texture and Feel: Genuine leather has a natural grain pattern, often with subtle variations in thickness and texture. It feels warm and supple to the touch. Faux leather tends to feel more uniform and plastic-like.

- Smell: Genuine leather has a characteristic, somewhat earthy odor. Faux leather often has a synthetic or plasticky smell.

- Burn Test (Use Caution!): Carefully burn a small, inconspicuous piece of the material. Genuine leather will smell like burning hair and leave a powdery ash. Faux leather will smell like burning plastic and may melt or drip.

- Water Test: Place a drop of water on the surface. Genuine leather will absorb the water slowly and leave a dark mark. Faux leather will repel the water and stay relatively dry.

- Edge Examination: Examine the cut edges. Genuine leather will have an uneven, natural-looking cross-section, while faux leather will usually have a uniform, consistent cross-section.

It’s crucial to be cautious when performing the burn test and always prioritize safety. If unsure, it is always best to inquire about the material’s authenticity from the seller.

Q 19. What are the challenges associated with sourcing sustainable and ethically produced leather?

Sourcing sustainable and ethically produced leather presents many challenges. The biggest issues revolve around environmental impact and animal welfare.

- Environmental Impact: Leather production requires significant resources, including water and energy. Tanning processes can also release harmful pollutants into the environment. Sustainable sourcing aims to minimize this impact through responsible water management, reduced energy consumption, and the use of eco-friendly tanning methods.

- Animal Welfare: The origins of the leather are critical. Ethical sourcing ensures that animals are raised humanely and slaughtered without undue suffering. This necessitates verifying the leather’s traceability throughout the supply chain, from farm to tannery.

- Transparency and Traceability: Lack of transparency in the supply chain makes it challenging to verify claims of sustainability and ethical production. Blockchain technology and other tracking systems are being developed to improve transparency and traceability.

- Certification and Standards: Various certifications, such as Leather Working Group (LWG) certification, attempt to standardize and verify sustainable and ethical practices in the leather industry. However, these certifications vary in scope and rigor.

Overcoming these challenges requires collaboration throughout the leather supply chain, from farmers and ranchers to brands and consumers, emphasizing a commitment to responsible and transparent practices.

Q 20. Describe your experience with different types of leather finishing techniques.

My experience encompasses a wide range of leather finishing techniques, each impacting the leather’s final appearance, feel, and performance. These techniques are crucial in achieving desired aesthetics and functionality.

- Top-Coating: Applying a protective topcoat enhances durability and water resistance. Different topcoats can produce varying levels of shine and texture.

- Embossing: This involves pressing a pattern onto the leather’s surface, creating texture and design. It can range from subtle grain enhancements to bold, decorative patterns.

- Dyeing: This is fundamental; it imparts color to the leather. Techniques range from aniline dyeing (preserving the leather’s natural grain) to semi-aniline and pigmented dyeing (offering more colorfastness and uniformity).

- Finishing Agents: These are applied to achieve specific effects like softening, adding fullness, or altering the leather’s feel. This can include waxes, oils, and resins.

- Glazing: This produces a smooth, glossy finish, enhancing the leather’s sheen. The process often involves several layers of coating and polishing.

Selecting the appropriate finishing technique depends on the type of leather, the final product, and the desired aesthetic and functional properties. For example, a high-end handbag might utilize an aniline dye and a protective topcoat to showcase the leather’s natural beauty, while a more durable item like a car seat might benefit from pigmented dyes and robust coatings.

Q 21. What software or tools are you familiar with that support leather design and manufacturing?

In my work, I’ve utilized several software and tools to support leather design and manufacturing.

- CAD Software (Computer-Aided Design): Software like AutoCAD, Rhino, and specialized leather design programs allow for creating 2D and 3D models of leather products, optimizing patterns, and visualizing the final product.

- CAM Software (Computer-Aided Manufacturing): Software integrates with cutting machines, ensuring precision and efficiency in cutting leather patterns. This minimizes material waste and increases production speed.

- Color Management Software: These programs help maintain color consistency throughout the production process, ensuring that the final product matches the intended design specifications.

- PDM (Product Data Management) Software: This software helps manage all aspects of the leather product lifecycle, from design to production to delivery, improving collaboration and traceability.

- Digital Imaging Software: Software like Photoshop is valuable for manipulating images of leather samples, enhancing design visualization, and preparing marketing materials.

The use of these tools increases efficiency, reduces errors, and allows for better collaboration among designers, manufacturers, and other stakeholders in the leather industry.

Q 22. How do you stay current with trends and advancements in the leather industry?

Staying current in the dynamic leather industry requires a multifaceted approach. I consistently monitor industry publications like Leather & Leather Goods and JAT, attending international trade shows like APLF and Lineapelle to witness firsthand the latest innovations in tanning techniques, finishing processes, and new leather types. I actively participate in online forums and professional networks, connecting with other experts and researchers to share knowledge and insights. Furthermore, I regularly review market research reports to understand evolving consumer preferences and trends in leather applications, ensuring my knowledge base remains up-to-date and relevant.

For example, recently I learned about advancements in vegetable tanning that significantly reduce environmental impact while maintaining the desirable characteristics of the leather. This constant engagement allows me to adapt my expertise and offer solutions that meet current market demands.

Q 23. Explain your understanding of leather care and maintenance.

Leather care and maintenance are crucial for extending the lifespan and preserving the beauty of leather products. The approach depends heavily on the type of leather. Full-grain leathers, for instance, are more durable and require less frequent cleaning than suede or nubuck. Generally, regular cleaning with a soft, damp cloth is recommended, followed by conditioning to maintain suppleness and prevent cracking. Conditioners replenish the natural oils lost over time, crucial for maintaining the integrity of the leather. Specific products, such as leather cleaners and protectors, should be chosen carefully, based on the leather type to prevent damage.

For example, using harsh chemicals on delicate suede can lead to discoloration or damage to the nap. Regular dusting, especially for items like handbags and shoes, prevents the accumulation of dust and dirt, which can eventually clog pores and cause premature aging.

Storage is also important; keeping leather goods in a cool, dry place away from direct sunlight and extreme temperatures prevents fading and cracking.

Q 24. What is your experience working with different leather suppliers?

My experience with leather suppliers spans a wide range, from small, family-run tanneries specializing in exotic leathers to large international corporations providing mass-produced materials. I’ve worked closely with suppliers in different regions, including Italy, known for its high-quality calfskin, and India, a significant producer of goat and sheep leather. This diverse experience has allowed me to understand the unique strengths and challenges of each supplier, their production methods, and their commitment to sustainability. I evaluate suppliers based on factors such as quality consistency, ethical sourcing practices, adherence to environmental standards, and their ability to meet delivery deadlines. The ability to build strong relationships with suppliers is essential for procuring quality leather consistently.

For example, during a project requiring high-end, vegetable-tanned leather, I collaborated extensively with a small Italian tannery known for its traditional methods and commitment to sustainable practices. This ensured not only the quality of the final product but also aligned with our commitment to ethical sourcing.

Q 25. Describe a situation where you had to troubleshoot a problem with a leather product.

In one instance, we encountered a significant color variation in a batch of leather intended for a high-volume production run. The initial assessment pointed to inconsistencies in the tanning process. Our troubleshooting involved a systematic approach: First, we reviewed the supplier’s tanning records to identify potential deviations from standard procedures. Next, we conducted thorough physical inspections of the affected leather, meticulously documenting the variations in color and texture. We then contacted the supplier to discuss the issue, sharing our findings and collaboratively investigating the root cause. Ultimately, we identified a problem with the dye application process at the supplier’s facility, which led to adjustments in their procedures and ensured consistent coloring for subsequent batches. The solution involved not just replacing the faulty leather but collaborating with the supplier to prevent future occurrences.

Q 26. How do you manage the quality control of leather products throughout the manufacturing process?

Quality control of leather products is a continuous process, starting from raw material selection and extending through every stage of manufacturing. We implement a multi-layered approach, beginning with rigorous inspection of incoming hides for defects such as scars, insect bites, and inconsistencies in thickness. Throughout the tanning, finishing, and cutting processes, regular quality checks are conducted at key stages using standardized procedures and quality control tools. This includes visual inspections, thickness measurements, and assessments of physical properties like tensile strength and tear resistance. We also employ statistical process control (SPC) methods to monitor variations and proactively address potential issues. Finally, a comprehensive inspection of the finished product ensures the product meets the required specifications and standards before shipment. Employing this multi-layered system ensures that defects are identified and addressed early in the process, minimizing waste and maximizing customer satisfaction.

Q 27. What are the potential risks and challenges associated with handling different types of leather?

Handling different types of leather presents unique risks and challenges. For example, exotic leathers like crocodile or snakeskin require specialized handling to avoid damage to their delicate scales or texture. Full-grain leathers, while durable, can be susceptible to scratches and require careful handling during manufacturing. Suede and nubuck leathers are particularly sensitive to moisture and staining, demanding careful cleaning and protection. In addition, certain leathers may contain allergens or pose health risks if not handled properly. Therefore, it’s crucial to have a comprehensive understanding of the properties of each leather type and implement appropriate safety measures, including appropriate personal protective equipment (PPE) like gloves and masks where necessary.

For instance, working with chrome-tanned leathers requires precautions to minimize exposure to chromium compounds, known to be potentially hazardous. Proper ventilation and handling procedures are essential in such cases.

Q 28. Describe your understanding of the environmental impact of leather production and how it can be mitigated.

The environmental impact of leather production is a significant concern. Traditional tanning processes often involve substantial water consumption and generate large amounts of wastewater containing harmful chemicals. The raising and slaughtering of animals for leather also contribute to greenhouse gas emissions. However, significant progress is being made towards sustainable leather production. This includes adopting cleaner tanning methods like vegetable tanning, which relies on natural tannins instead of harsh chemicals; implementing water recycling and treatment systems to minimize water pollution; and promoting responsible sourcing of hides from animals raised under ethical and sustainable conditions. Furthermore, exploring alternative materials like plant-based leathers is gaining traction. By actively engaging with suppliers committed to sustainable practices and continuously seeking innovative solutions, we can minimize the environmental footprint of the leather industry.

Examples of mitigation include using water-efficient tanning processes, implementing waste management systems, and collaborating with suppliers adhering to responsible forestry practices. This holistic approach is essential for creating a sustainable future for the leather industry.

Key Topics to Learn for Knowledge of Different Leather Types and Their Properties Interview

- Leather Classification: Understanding the different types of leather (e.g., full-grain, top-grain, genuine, bonded) and their production processes. This includes distinguishing characteristics and identifying quality indicators.

- Leather Properties and Characteristics: Exploring the physical properties of leather such as thickness, grain pattern, texture, strength, durability, breathability, and water resistance. Knowing how these properties vary across different leather types is crucial.

- Leather Finishing Techniques: Familiarize yourself with various finishing methods (e.g., aniline, semi-aniline, pigmented) and how they affect the final appearance, feel, and durability of the leather. Be prepared to discuss the pros and cons of each method.

- Leather Applications and Suitability: Understand the best applications for different leather types based on their properties. For example, which leather is best for upholstery, footwear, apparel, or accessories? Knowing this demonstrates practical application of your knowledge.

- Leather Defects and Quality Control: Learn to identify common leather defects (e.g., scratches, scars, wrinkles) and understand how these imperfections affect the value and suitability of the leather for various applications. This showcases your understanding of quality control processes.

- Leather Care and Maintenance: Discuss appropriate care and maintenance techniques for different leather types to preserve their quality and extend their lifespan. This demonstrates practical knowledge and problem-solving skills.

- Sustainability and Ethical Sourcing: Be prepared to discuss the environmental impact of leather production and the importance of sustainable and ethical sourcing practices. This demonstrates awareness of current industry trends.

Next Steps

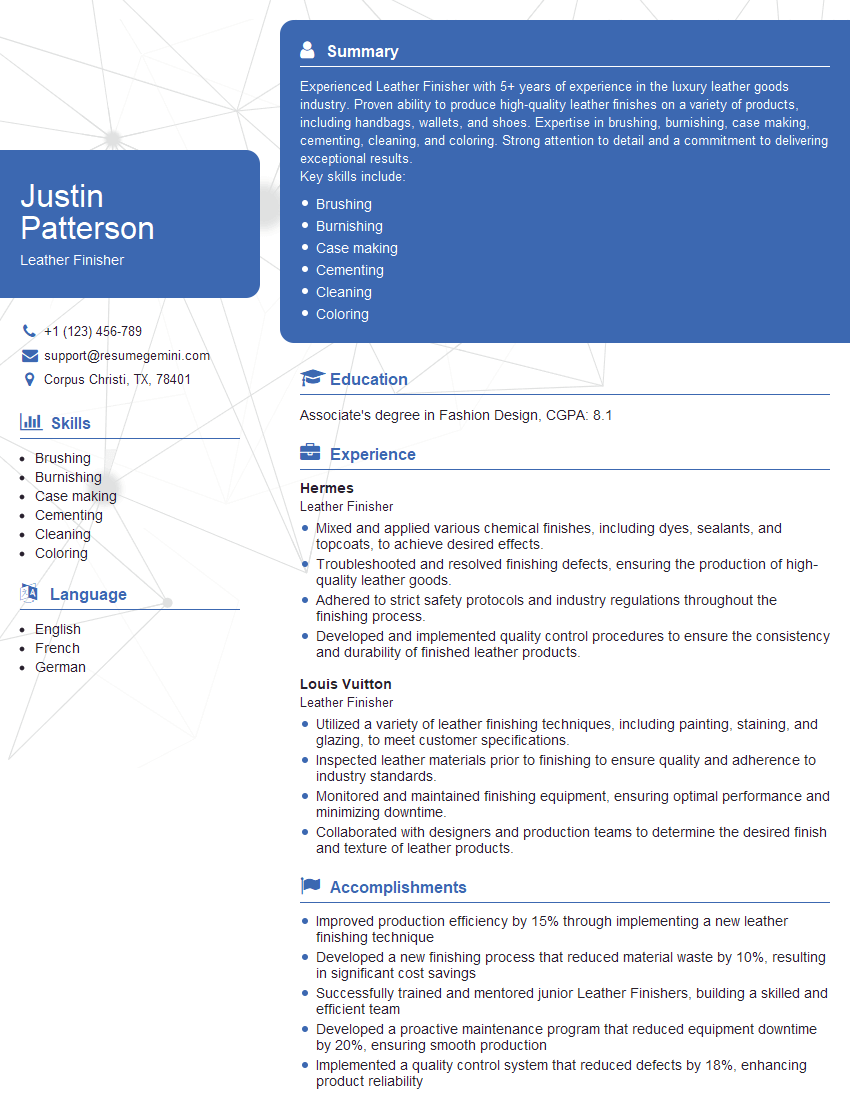

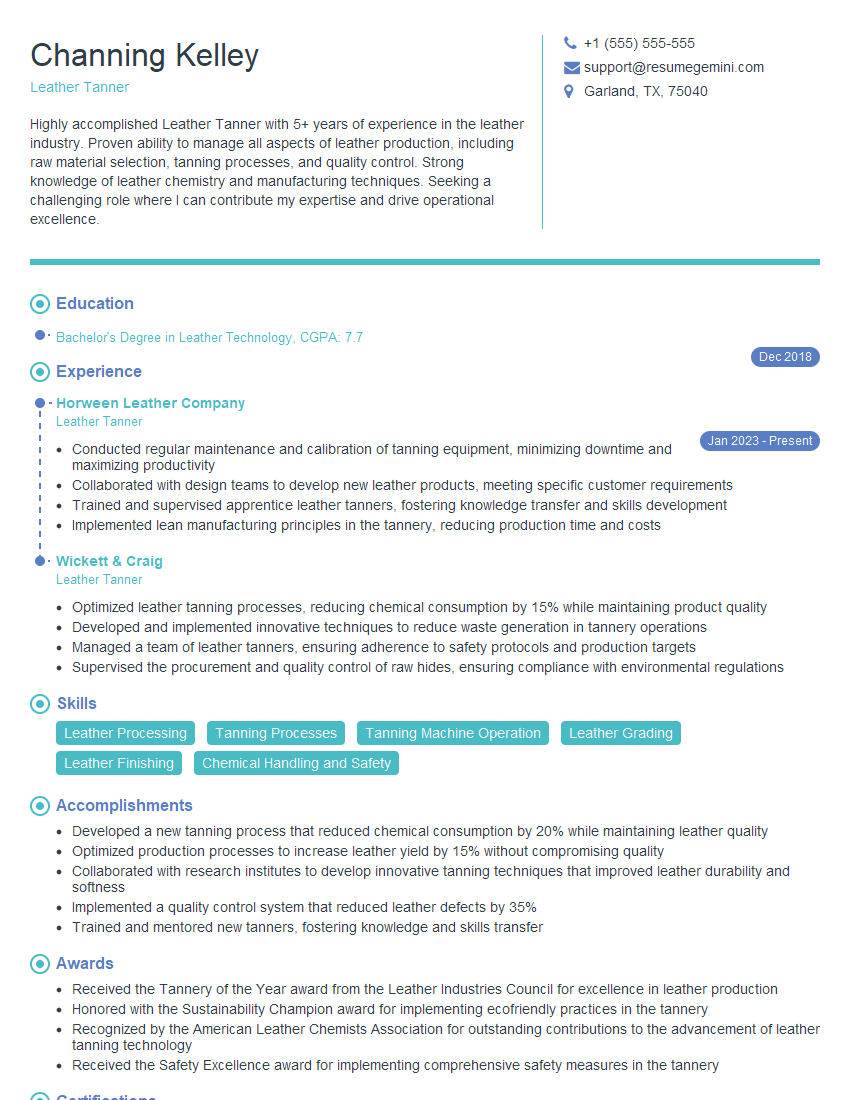

Mastering knowledge of different leather types and their properties is essential for career advancement in the leather industry. A strong understanding of these concepts will significantly enhance your interview performance and open doors to exciting opportunities. To increase your job prospects, focus on building an ATS-friendly resume that effectively showcases your expertise. We highly recommend using ResumeGemini, a trusted resource, to craft a professional and impactful resume. ResumeGemini offers examples of resumes tailored to roles requiring knowledge of different leather types and their properties, helping you present your skills and experience in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good