Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Shoe repair troubleshooting interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Shoe repair troubleshooting Interview

Q 1. Describe your experience diagnosing and repairing common shoe sole issues.

Diagnosing and repairing shoe sole issues is a cornerstone of shoe repair. It often begins with a thorough inspection. I look for wear patterns, separation from the upper, and damage types. Common issues include worn heels, worn-out outsoles, and sole separation.

For worn heels, I assess the extent of the damage. Minor wear might just need a heel tap, while more significant damage requires a complete heel replacement using materials that match the original. Similarly, worn outsoles might be repairable with a resoling, using either a full or partial replacement. The choice depends on the remaining sole’s condition and the customer’s budget. For sole separation, I carefully clean the surfaces, apply a strong adhesive, and often reinforce the area with stitching for a long-lasting repair.

For example, I recently repaired a pair of well-loved hiking boots with significant sole wear. Instead of replacing the entire sole, which would be costly, I performed a partial resoling, focusing on the heavily worn heel and toe areas. This extended the life of the boots significantly at a fraction of the cost of a full replacement.

Q 2. How do you identify and address different types of heel damage?

Heel damage varies greatly, from minor scuffs to complete heel breakages. My initial assessment focuses on identifying the type and extent of the damage. I look for cracks, crumbling, significant wear, and separation from the shoe.

- Minor damage (scuffs, small cracks): Often addressed with a simple heel repair using a matching leather or rubber patch and adhesive.

- Moderate damage (significant wear, larger cracks): May require a partial heel replacement, where I carefully remove the damaged portion and build up the heel with layers of new material, shaping it to the original form.

- Severe damage (complete breakage or significant separation): Demands a full heel replacement. I’ll remove the old heel entirely, prepare the shoe for the new heel, and then attach a new heel using strong adhesives and, in many cases, reinforcement stitching.

The choice of material – leather, rubber, or composite – depends on the original heel material and the intended use of the shoe. I always strive for durability and a seamless blend with the existing shoe components.

Q 3. Explain your process for repairing torn leather or fabric uppers.

Repairing torn leather or fabric uppers requires precision and patience. My approach starts with a careful cleaning of the torn area. Next, I assess the type of tear and the material. For small tears, I might use a specialized leather adhesive and carefully patch the area with a matching piece of leather or fabric. For larger tears, stitching becomes essential, often combined with adhesive.

Stitching requires expertise to match the original stitch pattern and tension. I select a thread that complements the shoe’s color and material. For delicate fabrics, I may use a finer needle and thread. For tougher leathers, a sturdier approach is necessary. Often, I’ll use a combination of techniques – using adhesive to hold the edges together while applying stitching for strength and a seamless finish.

For instance, I recently repaired a tear on a vintage leather handbag. After carefully cleaning the tear, I used a specialized leather adhesive to align the edges. Then, using a saddle stitch (a durable hand stitch), I meticulously closed the tear, matching the existing stitch pattern of the bag. The result was an invisible and strong repair that preserved the bag’s integrity.

Q 4. What are the different stitching methods used in shoe repair, and when would you use each?

Several stitching methods are employed in shoe repair, each suited to specific tasks and materials.

- Blind Stitch: Creates nearly invisible stitches, ideal for delicate repairs on uppers or attaching patches.

- Saddle Stitch: A strong, durable hand stitch often used for leather work. It’s excellent for attaching soles and repairing tears in thicker leathers.

- Machine Stitch: Used for tasks requiring speed and consistency, such as attaching outsoles or closing up seams. Various stitch patterns can be employed depending on the machine and the specific need.

- Whip Stitch: A simple hand stitch suitable for closing edges and finishing seams.

The choice depends on factors such as the material being stitched, the location of the repair, the desired durability, and the aesthetic requirements. For example, I’d use a blind stitch for a small tear on a fine leather shoe but a saddle stitch for attaching a new leather sole.

Q 5. How do you handle repairs requiring specialized tools or materials?

Some shoe repairs require specialized tools and materials. This might include specialized adhesives for various materials (leather, rubber, vinyl), specialized needles and thread for specific stitch types, heel-building materials, and various types of machinery.

When faced with such repairs, I assess the required tools and materials. If I don’t possess them, I have established relationships with suppliers to ensure prompt acquisition. I thoroughly research the repair method and ensure I have the necessary expertise before starting. For particularly complex or delicate repairs, I might consult with other experts in the field to ensure the best possible outcome. Safety is paramount, so I always use the appropriate safety equipment while using specialized tools like stitching machines.

For example, replacing a Goodyear welt requires specialized tools such as a welt knife and stitching machine. I possess these tools, and my experience enables me to perform this repair flawlessly. The goal is always to preserve the shoe’s integrity and functionality using the correct method and materials.

Q 6. What are the common causes of shoe breakdown and how do you prevent them?

Shoe breakdown is often caused by a combination of factors: excessive wear and tear, improper care, and inherent weaknesses in construction.

- Excessive Wear: This is simply the result of regular use. Proper maintenance, such as regular cleaning and conditioning, can mitigate wear and tear.

- Improper Care: Exposure to extreme temperatures, moisture, or harsh chemicals can damage the materials. Regular cleaning and appropriate storage conditions are crucial.

- Poor Construction: Some shoes are simply made with inferior materials or construction techniques, making them prone to breakdown. This is less controllable but understanding the construction helps in preventative measures.

Preventing breakdown involves regular maintenance: cleaning shoes regularly, using shoe trees to maintain shape, conditioning leather to keep it supple, and promptly addressing minor repairs before they worsen. Selecting well-made shoes from reputable brands also minimizes the risk of early failure.

Q 7. Explain your approach to identifying and fixing problems with shoe construction (welt, Goodyear, cemented).

Identifying and fixing problems with shoe construction (welt, Goodyear, cemented) requires a deep understanding of each method.

- Goodyear Welted: Issues might include separation of the welt from the upper or sole. Repair involves restitching or replacing the affected parts. This is a complex repair requiring experience.

- Cemented Construction: Problems frequently involve sole separation. Repair might involve resoling or reinforcing the existing adhesive bond with additional adhesive. The success often depends on the adhesive used and the condition of the remaining materials.

- Welt Construction (Other types): Similar to Goodyear, issues might involve separation of the components. Repair focuses on restitching and reinforcing the affected areas. The complexity of repair is dependent on the exact type of welt construction.

My approach involves a thorough inspection to diagnose the problem’s nature and extent. I then select the appropriate repair technique and materials. I prioritize preserving the shoe’s original construction methods as much as possible. For instance, a separated Goodyear welt repair would not involve simply gluing the parts together; it involves restitching to maintain the structural integrity of the construction.

Q 8. How do you determine the best course of action for repairing a damaged zipper or buckle?

Assessing zipper or buckle damage requires a methodical approach. First, I visually inspect the extent of the damage – is it a broken slider, a separated zipper tape, or a detached buckle? For zippers, I check if the teeth are broken or misaligned. For buckles, I examine the strap connection and the buckle’s integrity. The course of action depends on the severity. A simple slider replacement is straightforward. More extensive zipper damage might involve replacing the entire zipper. This involves carefully removing the old zipper, measuring the required length, and precisely installing the new one, ensuring proper alignment of the teeth. For buckles, simple repairs could involve replacing a snapped strap or tightening loose rivets. Severe buckle damage necessitates replacing the entire buckle, often requiring careful stitching or riveting to secure the new buckle to the shoe.

Example: A customer brings in a boot with a broken zipper slider. I replace the slider with a matching one, testing it thoroughly to ensure smooth operation. If the zipper teeth are broken, I’d recommend zipper replacement, as repairing the teeth is often more time-consuming and less reliable.

Q 9. What are the safety precautions you observe while using power tools for shoe repair?

Safety is paramount when using power tools. I always start with proper eye protection – safety glasses are non-negotiable. Hearing protection, such as earplugs or muffs, is essential to protect against the noise of machinery like rotary grinders or sewing machines. I ensure the workspace is well-lit and clutter-free to minimize tripping hazards. Power tools must be in good working order, with sharp blades and properly functioning guards. Before operating any power tool, I thoroughly inspect it for any damage and ensure it’s securely plugged into a grounded outlet. I never reach across the blade or rotating parts, and I always use a stable work surface to prevent accidental slippage. After use, I switch off the power tools and allow them to cool down before cleaning or storing.

Example: Before using a rotary grinder to smooth the edges of a sole, I always check that the grinding wheel is securely fastened and that the safety guard is properly attached. I also ensure the shoe is securely clamped in a vice to prevent movement.

Q 10. How do you match leather or fabric colors and textures for repairs?

Matching leather or fabric colors and textures is crucial for aesthetically pleasing repairs. I utilize a variety of techniques. First, I carefully examine the undamaged areas of the shoe to determine the exact color and texture. Then I consult my extensive collection of leather and fabric scraps and dyes. For minor repairs, I may find a close enough match from my existing stock. If not, I utilize leather dyes or fabric paints, applying them in thin layers to avoid harsh contrasts. I carefully blend the dye or paint to ensure a seamless transition between the repaired and original areas. For textured materials like suede, I often use specialized suede cleaners and conditioners to revive the original texture before carefully applying a matching dye.

Example: A customer has a scuff on their brown leather handbag. I use a brown leather dye, applying it in thin layers, and blending it carefully to the existing leather, avoiding stark lines.

Q 11. Describe your experience with working with various materials like leather, suede, and synthetic materials.

Years of experience have given me proficiency in handling a wide range of materials. Leather requires different techniques depending on its type – full-grain, top-grain, or bonded. I understand how to work with different thicknesses and textures, employing appropriate tools and adhesives for each. Suede is more delicate and requires specialized cleaning and repair methods to maintain its nap and texture. Synthetic materials, on the other hand, often require different adhesives and techniques; they can sometimes be more challenging to work with than natural materials, as they may react differently to adhesives and dyes. My experience allows me to choose the best approach for each material, ensuring a lasting and aesthetically pleasing repair.

Example: Repairing a tear in full-grain leather requires different techniques and adhesives compared to repairing a crack in a synthetic material. I’d use a stronger, more durable adhesive for full-grain leather.

Q 12. How do you maintain and clean your shoe repair tools?

Maintaining my tools is critical for their longevity and my safety. After each use, I thoroughly clean all tools, removing any debris or adhesive residue. I use appropriate cleaning agents specific to the tool’s material (e.g., solvent for metal parts, specialized cleaners for leather-working tools). Sharp tools, like knives and awls, are kept honed and sharpened regularly to maintain efficiency and prevent accidents. Sewing machine needles are regularly inspected and replaced as needed. All tools are stored in organized containers or racks, preventing rust and damage. Regular lubrication, as per the manufacturer’s recommendations, ensures smooth operation and extends the life of motorized tools.

Example: I clean my stitching awls with a wire brush to remove any embedded thread or leather scraps, then lubricate them with a light oil to prevent rust.

Q 13. Explain the process of resoling a shoe.

Resoling a shoe is a complex process requiring precision and skill. It begins with careful assessment of the shoe’s condition and the type of sole needed. The old sole is removed using specialized tools, taking care to avoid damaging the upper part of the shoe. The remaining remnants of the old sole and heel are cleaned, and any unevenness is addressed. A new sole, cut to the exact dimensions, is applied. The choice of material depends on the shoe and its intended use – leather, rubber, or synthetic materials are commonly used. The new sole is attached using specialized adhesives and, often, stitching. The edges are then trimmed, shaped, and finished to match the original design. The heel is also replaced or repaired, depending on the level of wear and tear, using similar processes. Finally, the shoe is thoroughly inspected before being returned to the customer.

Example: For a dress shoe, I might use a leather sole, applying it with a strong adhesive and then meticulously hand-stitching the sole to the welt to ensure a robust and long-lasting repair.

Q 14. How do you assess the repairability of a damaged shoe?

Assessing the repairability of a damaged shoe involves a thorough evaluation. I begin with a visual inspection, noting the extent of the damage. Are there structural issues, significant tears, or water damage? The type and quality of materials used in the shoe are also factors. A shoe made from high-quality leather is often more repairable than one made from inferior materials. Then, I consider the cost-effectiveness of repair versus replacement. Minor repairs, such as replacing a heel or patching a small scuff, are usually cost-effective. However, extensive damage – especially to the structural components of the shoe – might make repair impractical or even impossible. The customer’s expectations also play a role. Ultimately, I provide an honest and transparent assessment of the shoe’s repairability, offering potential solutions and associated costs.

Example: A shoe with significant water damage leading to significant degradation of the inner structure is likely not worth repairing. The cost and effort involved in replacing the damaged inner components outweighs the value of the shoe itself.

Q 15. What type of adhesive is best for various materials?

Choosing the right adhesive is crucial for successful shoe repair. The best adhesive depends entirely on the materials you’re bonding. Think of it like choosing the right glue for a specific project – you wouldn’t use superglue on delicate fabric!

- Leather to Leather: A high-quality contact cement designed for leather is ideal. These cements provide strong bonds that are flexible enough to withstand the bending and flexing of shoes. Examples include Barge Cement or similar professional-grade leather adhesives.

- Rubber to Rubber or Rubber to Leather: A strong, flexible rubber cement works well. These often need a slightly longer drying time to ensure a secure bond.

- PVC or Synthetic Materials: Specialty adhesives formulated for plastics and synthetics are essential. Incorrect glue can cause the material to break down over time.

- Fabric to Leather or Fabric to Rubber: A flexible fabric adhesive or a strong all-purpose adhesive might be used, ensuring it’s compatible with the other materials involved. Testing on a hidden area first is always recommended.

Always follow the manufacturer’s instructions for application and drying time. Improper application can weaken the bond significantly. Remember to properly clean and prepare the surfaces before applying any adhesive for the best results.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle customer complaints or dissatisfaction?

Handling customer complaints is a key aspect of running a successful shoe repair business. My approach focuses on active listening, understanding their concerns, and finding a mutually agreeable solution.

I always start by letting the customer fully explain their dissatisfaction. I then carefully examine the repaired shoe to understand the issue from a technical standpoint. Transparency is key; I explain what I observed and what might have caused the problem, avoiding technical jargon.

Depending on the situation, solutions might include: re-doing the repair at no extra charge, offering a partial refund, or suggesting alternative solutions. Even if it’s not my fault (for example, if the customer damaged the shoes after the repair), I try to find a way to alleviate their frustration, perhaps offering advice on future shoe care. The goal is to ensure customer satisfaction and maintain a positive reputation.

Q 17. Describe your experience in working with different shoe types (e.g., boots, sneakers, dress shoes).

My experience spans a wide variety of shoe types, each presenting its unique challenges and repair techniques.

- Boots: Boots often require more robust repairs, focusing on durable stitching, heel and sole replacement, and waterproof sealing.

- Sneakers: Sneaker repair can involve everything from replacing worn-out midsoles and outsoles to cleaning and restoring the uppers. Understanding the different materials used in various sneaker models is crucial.

- Dress Shoes: These require meticulous attention to detail. Repairs often focus on maintaining the shoe’s elegant appearance, which may involve delicate stitching, polishing, and heel restoration.

I’ve worked on everything from vintage leather boots requiring specialized leather work to modern athletic shoes with complex construction. This diverse experience allows me to adapt my techniques to suit the specific needs of each shoe type.

Q 18. How do you prioritize multiple repair requests?

Prioritizing repair requests involves balancing urgency, complexity, and material availability. I typically use a combination of factors to create a queue.

- Urgency: Customers with shoes needed for an immediate event (wedding, job interview) naturally get priority.

- Repair Complexity: More involved repairs (complete sole replacement, extensive stitching) will often take longer and might be scheduled accordingly.

- Material Availability: If a specific part (like a heel tap for a particular shoe model) is on backorder, I might adjust the queue to accommodate that delay.

I maintain a clear and organized system (often a digital calendar or task management software) to track repairs, estimated completion times, and customer contact information. Transparent communication with customers about expected completion times is essential for managing expectations.

Q 19. What are some common mistakes made in shoe repair, and how can they be avoided?

Many common mistakes in shoe repair stem from improper preparation, tool use, or material selection.

- Poor Surface Preparation: Not properly cleaning and preparing surfaces before gluing or stitching leads to weak bonds and poor results. Think of it like trying to paint a dirty wall—the paint won’t adhere properly.

- Using Incorrect Adhesives: Using the wrong adhesive for the material being repaired can lead to the bond failing under stress.

- Improper Stitching Technique: Incorrect stitching tension, improper needle selection, or inadequate preparation can cause the stitches to break or come loose.

- Ignoring Minor Issues: Ignoring minor damage early on often leads to more significant and costly repairs later.

Avoiding these mistakes involves meticulous preparation, the correct selection of tools and materials, and a keen eye for detail throughout the entire repair process. Regular maintenance and proper cleaning of the tools are also essential.

Q 20. Describe a time you had to troubleshoot a particularly challenging repair.

I once had a customer bring in a pair of antique riding boots with extensive damage to the leather uppers and a completely detached sole. The leather was extremely fragile, and the original stitching was almost completely deteriorated.

The challenge was to repair the boots while preserving their historical integrity. I painstakingly cleaned and conditioned the leather, using specialized stitching techniques and adhesives designed for delicate materials. I had to source antique leather that closely matched the existing leather and carefully patch the damaged areas. The sole required a complete reconstruction using traditional methods. The repair took significantly longer than a standard repair, but the result was a beautifully restored pair of boots, preserving a piece of history.

Q 21. What are your skills in using specialized shoe repair machinery (e.g., stitching machines, molding machines)?

I’m proficient in using various specialized shoe repair machinery. My skills include:

- Stitching Machines: I’m experienced with both industrial and smaller, more specialized stitching machines, capable of handling various thread types and stitch patterns to meet the requirements of different shoe constructions.

- Molding Machines: I’m comfortable using molding machines to create custom lasts and heel shapes, essential for repairing or restoring heels and soles to their original forms.

- Other Machinery: This includes experience with buffing and polishing machines, edge finishing equipment, and other specialized tools for precise and effective shoe repair.

Regular maintenance of this equipment is crucial to ensure accurate and efficient repairs. I understand the safety protocols associated with operating this machinery and always prioritize safety in my work.

Q 22. How do you handle rush orders or urgent repairs?

Handling rush orders requires a blend of efficient prioritization and clear communication. First, I assess the repair’s urgency and complexity. Simple repairs, like replacing a heel, can often be slotted in between other jobs. More complex work, such as resoling a heavily worn boot, requires a more careful assessment of the time needed. I always communicate realistic timelines to the customer, avoiding over-promising. For truly urgent situations, I might offer expedited service with a slightly increased fee to compensate for the adjusted workflow. For example, if a customer needs their work boots fixed before an important job, I’ll prioritize their order and, if possible, work late to meet their deadline. This transparency builds trust and ensures everyone is on the same page.

Q 23. What are the limitations of certain repair methods?

Different repair methods have their limitations. For instance, while gluing is a common and effective method for attaching soles, it’s not suitable for heavily worn or damaged shoes. The glue won’t adhere properly to degraded materials. Similarly, stitching, while incredibly strong, requires specific skill and appropriate materials. Trying to stitch a damaged leather sole with improper thread could lead to further weakening. Resoling with new materials might not perfectly match the original aesthetic, particularly with vintage or unique shoes. It is crucial to thoroughly assess the damage before choosing the most appropriate repair method. Each method works best under certain conditions, and misapplication can lead to unsatisfactory results.

Q 24. What is your understanding of the importance of proper fit in shoe repair?

Proper fit is paramount in shoe repair. A poorly fitted shoe, even after repair, will cause discomfort and potential foot problems. Before any repair, I meticulously assess the fit of the shoe on the customer’s foot. I examine the shape, size and any pressure points. This informs my repair strategy. For instance, if a heel is worn down on one side, indicating improper gait, I might suggest orthotic inserts alongside the repair to address the underlying cause. If the shoe is too tight, I might advise against major repairs unless the issue can be resolved through adjustments like stretching or minor alterations. Ignoring fit issues would undermine the quality of the repair and potentially harm the customer’s feet.

Q 25. How do you stay updated with new techniques and materials in shoe repair?

Staying current in shoe repair requires continuous learning. I subscribe to relevant trade publications and attend workshops whenever possible. These events showcase new tools, techniques, and materials. I also actively engage in online forums and communities dedicated to shoe repair, learning from the experience of others. Experimenting with new materials responsibly is also vital. For example, I recently incorporated a new type of eco-friendly glue that provides excellent bonding strength while being less harmful to the environment. Staying updated ensures I can offer the best possible service and use the most efficient, sustainable, and advanced methods available.

Q 26. Explain your experience with repairing orthopedic shoes.

Repairing orthopedic shoes requires extra care and precision. The goal is to maintain the structural integrity of the shoe and ensure its continued effectiveness in supporting the wearer’s feet. This involves a thorough understanding of the different components of the shoe and how they work together. I carefully examine the existing modifications, like custom orthotics, to ensure the repair does not interfere with their functionality. Sometimes, I might need to consult with the podiatrist or orthotists who prescribed the shoes before proceeding. This could involve replacing worn-out materials while preserving the existing support mechanisms. Improper repair could compromise the support system, leading to discomfort and injury.

Q 27. How do you manage inventory and supply orders for shoe repair materials?

Inventory management is critical for smooth operation. I use a combination of physical inventory tracking and a simple spreadsheet to monitor stock levels. I categorize my materials (e.g., soles, heels, threads, glues) and set minimum stock levels. When a supply runs low, an automated notification reminds me to reorder. I work with reliable suppliers that can provide a consistent supply of quality materials. I also take into account seasonal demand, ordering larger quantities of specific materials during peak seasons. This organized system helps avoid shortages and ensures I always have the necessary supplies on hand to complete repairs efficiently. Regularly reviewing my inventory helps identify slow-moving items and informs my purchasing decisions.

Q 28. What are the environmental considerations associated with shoe repair?

Environmental considerations are a growing concern in shoe repair. I try to minimize waste by reusing materials wherever possible and choosing eco-friendly alternatives when feasible. This includes using water-based glues and solvents, as they have a lower environmental impact compared to chemical-based options. I responsibly dispose of hazardous materials like old adhesives according to local regulations. I also encourage customers to opt for repairs over buying new shoes whenever possible, reducing the overall environmental impact associated with shoe production. Choosing durable, well-made shoes initially also contributes to reducing long-term waste.

Key Topics to Learn for Shoe Repair Troubleshooting Interview

- Common Shoe Construction: Understanding different types of shoe construction (e.g., cemented, Goodyear welted, stitch-down) is crucial for diagnosing repair needs and selecting appropriate techniques.

- Material Identification & Properties: Knowing the properties of various leathers, soles, and other materials will help you assess damage and choose the correct repair methods and materials. Practical application: Identifying a cracked leather heel and selecting the appropriate patching method.

- Heel & Sole Repair Techniques: Mastering techniques like replacing heels, resoling, and patching will demonstrate your practical skills. Practical application: Diagnosing and repairing a worn-down rubber sole using appropriate tools and materials.

- Upper Repair Techniques: This includes stitching, patching, and repairing tears in the shoe’s upper. Practical application: Repairing a split seam in a leather boot using appropriate stitching techniques.

- Troubleshooting Common Issues: Developing the ability to identify and resolve common problems such as loose stitching, broken heels, worn-out soles, and damaged uppers. Practical application: Correctly identifying the cause of a shoe slipping off the foot and recommending a suitable solution.

- Tools & Equipment: Familiarity with essential shoe repair tools, their uses, and maintenance is essential. Practical application: Selecting the appropriate stitching machine and needles for repairing different leather types.

- Customer Service & Communication: Effectively communicating with customers about repair options, timelines, and costs is critical. Practical application: Clearly explaining the repair process and potential outcomes to a customer.

- Safety Procedures & Workplace Practices: Understanding and adhering to safety protocols in a shoe repair shop. Practical application: Demonstrating the safe and correct use of machinery and tools.

Next Steps

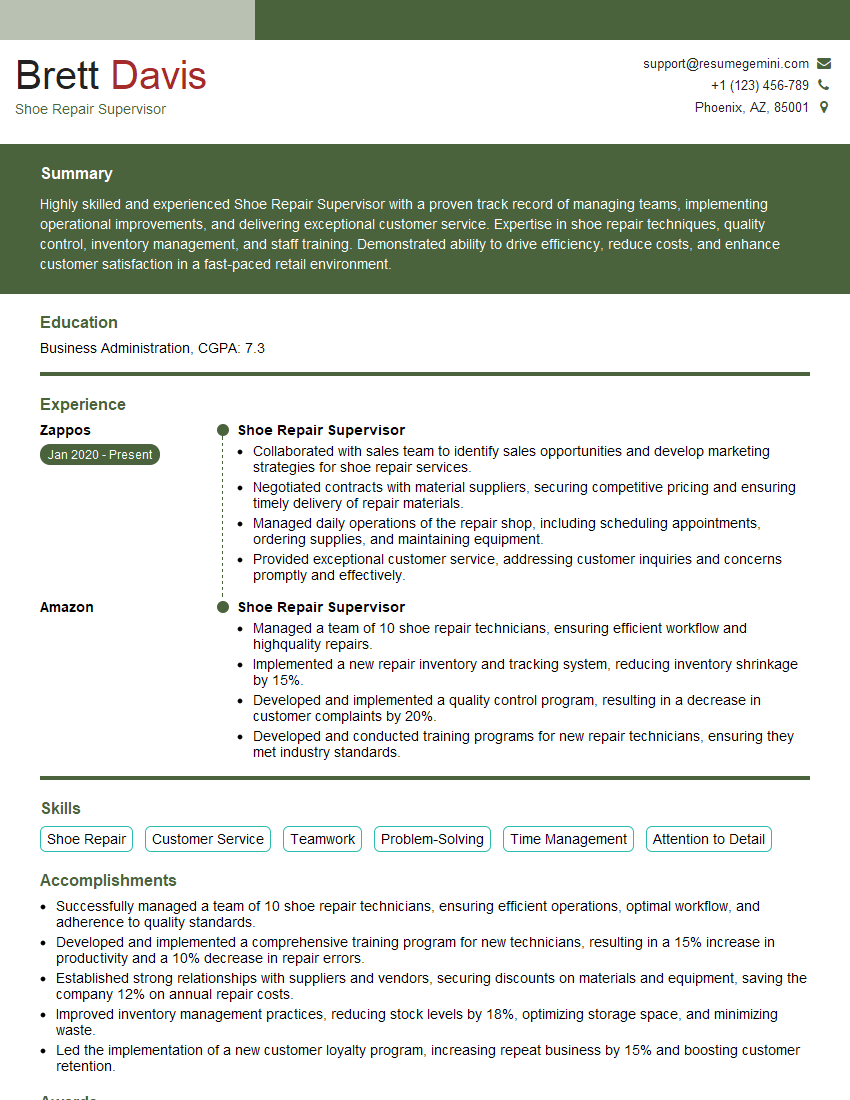

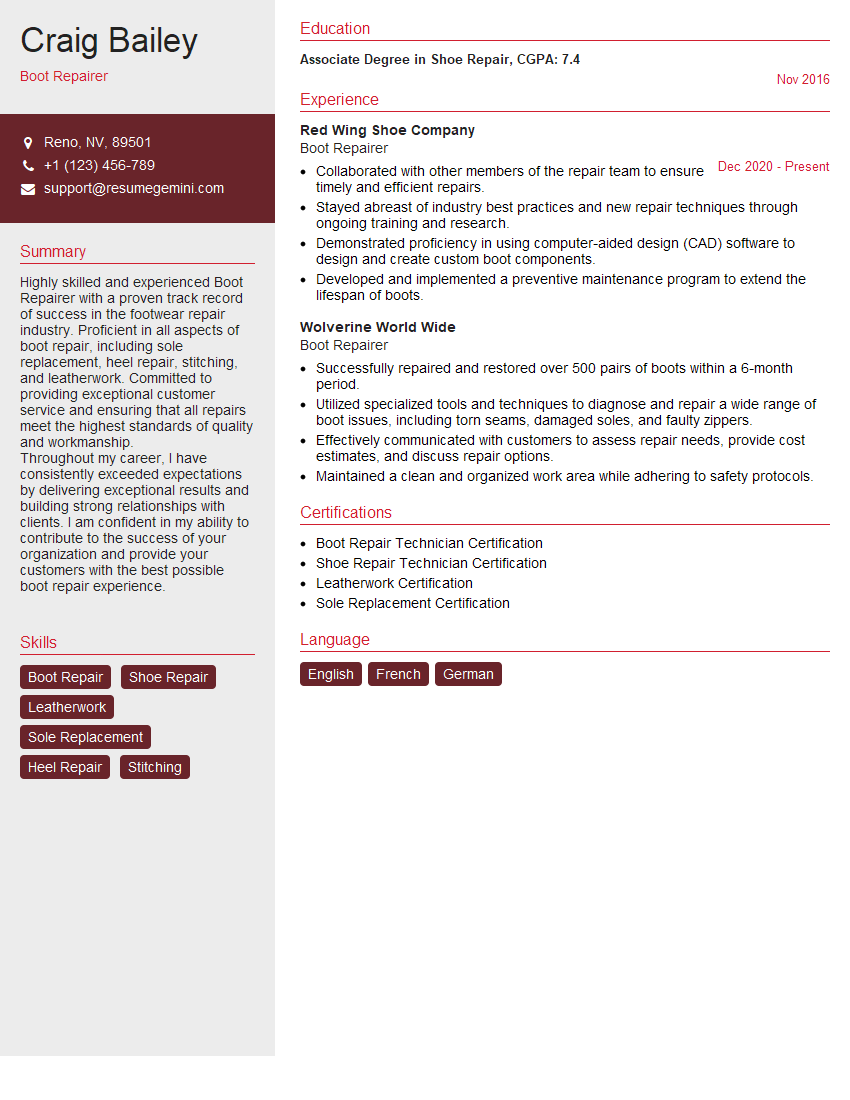

Mastering shoe repair troubleshooting is key to a successful and rewarding career. Proficiency in diagnosis and repair opens doors to diverse opportunities and allows you to offer high-value services. To enhance your job prospects, focus on crafting an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a compelling resume tailored to the shoe repair industry. Examples of resumes specifically tailored to shoe repair troubleshooting are available, showcasing how to present your skills to potential employers. Use ResumeGemini to build your best possible resume and stand out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good