The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Planning and scheduling of joist setting operations interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Planning and scheduling of joist setting operations Interview

Q 1. Explain the process of creating a joist setting schedule.

Creating a joist setting schedule involves a systematic approach that ensures efficient and safe installation. It begins with a thorough understanding of the project blueprints, specifying the type, size, and quantity of joists needed for each section of the building.

Next, I’d break down the project into smaller, manageable tasks. This might involve separating the work by floor, building section, or even by specific joist types. Each task receives an estimated duration based on past experience and considering factors such as crew size, accessibility, and potential complications.

- Task Definition: Clearly define each task, such as ‘Install main floor joists, Section A,’ including specifics like joist type and quantity.

- Duration Estimation: Estimate time needed per task. This could involve referencing historical data from similar projects or using a time-study approach.

- Resource Allocation: Determine the manpower, equipment, and materials needed for each task. This ensures resources aren’t over-allocated or under-utilized.

- Sequencing: Organize tasks in a logical order, respecting dependencies. For example, installing support beams before setting joists is crucial.

- Scheduling: Use a scheduling tool (more on this in a later answer) to visually represent tasks, durations, and dependencies. This often creates a Gantt chart.

Finally, I review and refine the schedule, factoring in potential delays and adjusting resource allocation as needed. It’s an iterative process, regularly checked against progress on the ground.

Q 2. How do you determine the critical path for joist setting?

Identifying the critical path in joist setting is vital for timely project completion. The critical path represents the longest sequence of dependent tasks in the project schedule. Any delay in a task on this path directly impacts the overall project timeline.

I use a combination of techniques to determine the critical path. First, I use the project schedule created (as described above). This allows visual identification of the longest path from start to finish. Many scheduling software packages automatically highlight this path.

Secondly, I consider potential risks. For example, if there’s a risk of delayed material delivery impacting a particular task, I’d perform a sensitivity analysis. This involves assessing how delays in different tasks affect the overall schedule and thus identify the most vulnerable components of the critical path.

Think of it like a relay race: the critical path is the team with the slowest runner—even a small delay for this runner makes the whole team finish later.

Q 3. What software do you use for joist setting scheduling?

I’ve worked extensively with several software packages for joist setting scheduling, each with its own strengths. Microsoft Project is a widely used industry standard, offering robust features for task management, resource allocation, and critical path analysis. It allows for easy generation of Gantt charts, providing a clear visual representation of the schedule.

I’ve also had positive experiences with Primavera P6, which is particularly powerful for large-scale projects with complex dependencies. It allows for more detailed resource leveling and risk management capabilities. For smaller projects, I’ve found Asta Powerproject to be a good option, offering a simpler interface while still providing necessary scheduling functions.

The choice of software depends on the complexity of the project and the specific needs. In each case, the software aids me in maintaining accurate schedules, tracking progress, and managing resources effectively.

Q 4. Describe your experience with resource allocation in joist setting.

Resource allocation in joist setting is crucial for efficiency and project success. It involves determining the optimal number of workers, equipment, and materials needed for each task within the schedule. My approach starts with a careful assessment of the tasks and their resource requirements based on the schedule we created.

I leverage the capabilities of scheduling software to help with resource allocation. These tools allow me to simulate different resource allocation scenarios, helping determine the optimal distribution that minimizes conflicts and delays. For instance, if we have limited cranes, I use the software to find the best way to allocate that crane across different tasks while ensuring that no task faces unnecessary delays due to lack of equipment.

On a recent high-rise project, we faced a shortage of experienced foremen. By carefully analyzing the tasks and their complexity, we prioritized the most critical tasks, assigning the experienced foremen to those and allocating less experienced personnel to less critical tasks, under their supervision. This prevented any major bottlenecks.

Q 5. How do you handle delays or unforeseen issues during joist setting?

Delays and unforeseen issues are inevitable in construction. My approach focuses on proactive identification and mitigation. First, I establish a robust communication system to allow rapid identification of problems. This includes regular site visits and daily progress meetings with the team.

When a delay occurs, I perform a thorough analysis to understand its root cause. Was it material delivery delays, equipment malfunction, or unforeseen site conditions? Once identified, I use the scheduling software to reassess the impact on the critical path. This helps to determine potential mitigation strategies.

Strategies might include: reallocating resources from less critical tasks, adjusting task durations (realistic estimations), or negotiating with subcontractors to expedite work. Transparent communication with stakeholders is key, keeping them updated on the impact of delays and the steps taken to address them.

For example, on a recent project, a sudden storm caused a delay. We quickly reassessed the schedule and adjusted timelines, prioritizing work that wasn’t weather-dependent while also proactively contacting material suppliers to minimize disruptions.

Q 6. How do you ensure the safety of workers during joist setting?

Worker safety is paramount. My approach to ensuring safety during joist setting involves a multi-faceted strategy starting with comprehensive safety training for all workers. This includes training on proper lifting techniques, fall protection measures, and the use of personal protective equipment (PPE).

I ensure that all workers have the necessary PPE, including hard hats, safety harnesses, and safety footwear. Furthermore, I enforce strict adherence to safety regulations and company policies. This includes regular safety inspections and the implementation of strict safety protocols at the job site.

Before any joist setting operation commences, a thorough risk assessment is undertaken to identify potential hazards and develop mitigation strategies. This might involve erecting scaffolding, implementing fall protection systems, or setting up designated work zones. Regular safety briefings and toolbox talks are held to reinforce safety awareness and address any concerns.

Q 7. What are the key performance indicators (KPIs) you track for joist setting?

Tracking key performance indicators (KPIs) is essential for evaluating the effectiveness of the joist setting process. The KPIs I monitor include:

- Schedule Adherence: The percentage of tasks completed on time, indicating overall project efficiency.

- Cost Efficiency: Tracking actual costs against budgeted costs, helping to identify areas for cost savings.

- Safety Record: Number of safety incidents, providing an indication of the effectiveness of safety protocols.

- Productivity Rate: Tracking the number of joists installed per worker-hour, indicating efficiency of the work crew.

- Material Waste: The amount of material wasted during the process, highlighting potential areas for improvement in material management.

Regular monitoring of these KPIs allows for timely identification of issues, enabling corrective actions and ensuring the overall success of the project.

Q 8. Explain your understanding of different joist types and their impact on scheduling.

Understanding joist types is crucial for effective scheduling. Different joist materials (wood, steel, composite) and designs (I-joists, parallel chord trusses, etc.) have varying installation methods and required support systems. This directly impacts the time needed for installation, the resources required (equipment and manpower), and potential sequencing dependencies with other trades.

- Wood Joists: Generally quicker to install than steel, but may require more on-site cutting and fitting, potentially leading to longer installation times for complex layouts. They are also more susceptible to weather conditions.

- Steel Joists: Heavier and require specialized lifting equipment, leading to potentially slower installation speeds but often more efficient for large spans. They are less susceptible to weather issues.

- Composite Joists: Offer a blend of the benefits of wood and steel, potentially offering a balance in installation speed and efficiency, but may require specialized handling and fastening techniques.

For example, a project using pre-fabricated I-joists might have a faster joist setting schedule than one using on-site fabricated wood joists. The choice of joist type significantly impacts the overall project timeline and resource allocation, therefore it needs to be considered very early in the scheduling process.

Q 9. How do you coordinate joist setting with other trades on a construction site?

Coordinating joist setting with other trades is critical for a smooth workflow. This involves careful sequencing and communication. We use a variety of methods for this coordination:

- Pre-construction Meetings: Detailed planning sessions with all relevant trades (e.g., framers, MEP, drywallers) to identify potential conflicts and establish a collaborative approach.

- Detailed Scheduling Software: Software like Primavera P6 or Microsoft Project allows for visualization of task dependencies and potential overlaps. This allows us to identify conflicts early on.

- BIM (Building Information Modeling): Using BIM software helps to visualize the structural elements in 3D and identify potential clashes between joists and other building systems (HVAC, plumbing, electrical). This significantly reduces conflicts on the site.

- Regular On-Site Meetings: Daily or weekly meetings with the on-site team keep everyone updated on progress and address any emerging issues promptly.

For example, the MEP trades need access to the ceiling space after the joists are set, so their work is scheduled to follow joist installation. Similarly, drywall installation cannot start until the joists are set and inspected. Careful coordination prevents costly delays and rework.

Q 10. Describe a time you had to optimize a joist setting schedule.

On a recent high-rise project, we faced a challenge with the delivery of steel joists being delayed by two weeks. This threatened to disrupt the entire project schedule. To optimize the schedule, we implemented the following steps:

- Prioritization: We prioritized the critical path sections of the building where joists were most needed to support other ongoing work.

- Resource Allocation: We increased the number of joist-setting crews and utilized overtime hours strategically to accelerate the installation.

- Just-in-time Delivery: We worked closely with the steel supplier to ensure timely delivery of remaining joists in smaller batches, precisely aligned with the installation progress.

- Workarounds: Where possible, we used temporary supports to allow other trades to proceed with their work in certain areas, even if joists weren’t fully installed.

Through these efforts, we minimized the overall impact of the delay and only suffered a one-week project delay instead of the projected two. This demonstrated the importance of having contingency plans and a flexible approach.

Q 11. How do you manage material procurement for joist setting?

Material procurement for joist setting requires a meticulous process to ensure timely delivery and minimize delays. This involves:

- Accurate Quantity Takeoff: A precise quantity takeoff from the structural plans is essential to avoid under-ordering or over-ordering.

- Lead Time Consideration: Knowing the lead time for each material is critical. Steel joists, for instance, typically have longer lead times compared to wood.

- Vendor Selection: Choosing reliable vendors with a proven track record is crucial. We assess their delivery capabilities and reputation.

- Material Tracking: Implementing a system to track material orders, deliveries, and storage is crucial for visibility and proactive management of potential issues.

For example, if the lead time for steel joists is 8 weeks, then the order needs to be placed at least 8 weeks before the installation is scheduled. This prevents delays and helps in adhering to the schedule.

Q 12. How do you handle conflicts between the joist setting schedule and other project tasks?

Conflicts between the joist setting schedule and other tasks are inevitable. Effective conflict resolution involves:

- Proactive Communication: Open and frequent communication with all relevant parties is key. This helps to identify potential conflicts early on.

- Negotiation and Compromise: Finding mutually agreeable solutions requires flexibility from all parties involved. This may involve adjusting schedules or resource allocation.

- Prioritization Based on Critical Path: Tasks on the critical path (those that directly impact the project’s overall completion date) should be prioritized. This might require delaying non-critical tasks.

- Change Management Process: If changes are necessary, a formal change management process should be followed to document decisions and their impact on the schedule and budget.

For instance, if the concrete pour for the foundation is delayed, the joist setting schedule also needs to be adjusted accordingly. Good communication and a flexible approach help mitigate the impact.

Q 13. What is your experience with lean construction principles in joist setting?

Lean construction principles significantly improve joist setting efficiency. We apply these principles through:

- Value Stream Mapping: Identifying and eliminating waste in the joist setting process. This includes reducing unnecessary movement, waiting time, and overproduction.

- 5S Methodology: Organizing the jobsite to improve efficiency and reduce search time for materials and tools. A clean and organized workspace directly translates to quicker installation times.

- Pull Planning: Using a visual scheduling tool to help the team understand the sequence of work and identify potential bottlenecks proactively.

- Kaizen Events: Holding regular meetings with the team to identify and implement improvements in the joist setting process. Continuous improvement is critical for efficiency.

By adopting lean practices, we have seen improvements in installation times, reduced material waste, and improved team morale, directly translating to project cost and schedule benefits.

Q 14. How do you communicate the joist setting schedule to the construction team?

Effective communication is critical for a successful joist setting operation. We use a multi-pronged approach:

- Project Schedule Distribution: Sharing the detailed project schedule with all relevant parties, including subcontractors, ensures everyone understands their responsibilities and deadlines.

- Daily Huddles: Short, daily meetings with the on-site team provide updates on progress, identify any issues, and ensure everyone is on the same page.

- Visual Management: Using visual aids like task boards or Gantt charts provides a clear picture of progress and helps track milestones effectively. This promotes better understanding and accountability.

- Progress Reports: Regular progress reports to the project management team keep stakeholders informed of the project status and highlight any potential risks or challenges.

Clear communication ensures everyone is aligned and helps avoid misunderstandings which ultimately prevents delays and rework.

Q 15. How do you use progress tracking tools for joist setting?

Progress tracking in joist setting relies on a combination of visual inspections and digital tools. We start with a clearly defined schedule, broken down into manageable tasks like joist delivery, placement, fastening, and inspection. Visual progress tracking involves regularly walking the site to assess the completion of each task. For instance, I’ll check the number of joists placed against the daily target.

Digital tools significantly enhance this process. I’ve used software like Microsoft Project and Primavera P6 to create dynamic schedules that update as the project progresses. These programs allow us to input actual completion times, identify deviations from the plan, and generate reports that highlight areas needing attention. For example, if we’re behind schedule on a specific task, the software will highlight it, allowing for immediate corrective action. We also utilize mobile apps that allow for real-time updates from the field, ensuring the schedule remains current and accurate.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with different scheduling methodologies (e.g., CPM, PDM).

My experience encompasses both Critical Path Method (CPM) and Precedence Diagramming Method (PDM) scheduling. CPM focuses on identifying the critical path – the sequence of tasks that directly impacts the project’s overall completion time. Any delay on the critical path delays the entire project. I’ve used this extensively in fast-track projects where minimizing overall duration is crucial. For example, on a recent high-rise project, we used CPM to optimize the joist setting schedule, identifying critical dependencies like crane availability and concrete curing times.

PDM, on the other hand, offers more flexibility in representing task relationships. It allows for complex dependencies beyond simple predecessor-successor relationships. I find PDM particularly useful for projects with many concurrent tasks and intricate interdependencies. For example, in a large-scale commercial building project, PDM helped us manage the coordination between joist setting, MEP installations, and drywall finishing – all happening concurrently.

Q 17. How do you ensure the accuracy of the joist setting schedule?

Ensuring schedule accuracy starts with meticulous planning. This involves accurate quantity takeoffs, realistic task durations based on historical data and crew performance, and considering potential delays (weather, material delivery, etc.).

Regular progress meetings are crucial. We compare planned versus actual progress, analyzing any variances. If delays occur, we investigate the root cause – be it equipment malfunction, material shortages, or unforeseen site conditions – and implement corrective actions. Frequent communication with subcontractors is key to keeping everyone informed and aligned with the schedule. Finally, I utilize Earned Value Management (EVM) techniques to track budget and schedule performance, allowing for early identification and resolution of potential issues.

Q 18. What are the potential risks associated with joist setting and how do you mitigate them?

Joist setting presents several risks. These include potential falls from heights, crane accidents, incorrect joist placement leading to structural issues, and material damage. Mitigation involves strict adherence to safety protocols – using appropriate fall protection equipment, ensuring proper crane operation and load capacity, and conducting thorough inspections before and after joist placement.

We also implement risk management plans, identifying potential hazards and establishing procedures to mitigate them. For example, a risk register documenting potential problems like bad weather, material delays, or equipment failures helps us proactively develop contingency plans. This might involve securing backup equipment, having alternate material sources, and building buffer time into the schedule. Regular safety training for the crew is also paramount.

Q 19. How do you incorporate quality control measures into the joist setting schedule?

Quality control is integrated throughout the joist setting schedule. This begins with verifying material quality upon delivery – checking for damage or defects. During installation, we implement regular inspections to ensure correct spacing, alignment, and fastening.

After placement, a final inspection verifies compliance with structural drawings and building codes. This often includes using laser levels for accurate alignment and employing qualified inspectors to review the work. Any non-conformances are documented, corrective actions are implemented, and the completed work is then re-inspected. Documentation of each inspection, along with any corrective actions, is crucial for maintaining a detailed quality control record.

Q 20. How do you handle changes to the joist setting schedule during construction?

Schedule changes are inevitable in construction. When a change occurs, we first assess its impact on the critical path and overall project timeline. This often involves using project management software to simulate different scenarios.

The change request process is crucial. It includes documentation of the change, its justification, impact assessment, cost implications, and the revised schedule. This ensures transparency and buy-in from all stakeholders. We then communicate the revised schedule to the team and adjust resource allocation as needed. Regular monitoring of the revised schedule helps ensure we stay on track after the change has been implemented.

Q 21. Explain your experience with using project management software for joist setting.

I have extensive experience using various project management software for joist setting, including Microsoft Project, Primavera P6, and Asta Powerproject. These tools allow for creating detailed schedules, tracking progress, managing resources, and analyzing potential delays.

For example, in Microsoft Project, I can create a work breakdown structure (WBS) for the joist setting operations, assign tasks to different crews, define dependencies, and generate Gantt charts to visualize the schedule. The software enables ‘what-if’ scenarios – allowing us to see the impact of delays or changes to resource availability. This proactive approach ensures we can effectively manage risks and keep the project on schedule and within budget.

Q 22. How do you ensure the joist setting schedule aligns with the overall project schedule?

Aligning the joist setting schedule with the overall project schedule requires meticulous planning and proactive communication. It’s not just about fitting joist installation into a timeframe; it’s about understanding its dependencies and critical path within the project.

My approach involves several key steps: First, I thoroughly review the master project schedule, identifying all tasks preceding and following joist setting. This includes foundation work, wall framing, and any MEP (Mechanical, Electrical, and Plumbing) installations that might interfere. Second, I develop a detailed joist setting schedule, breaking down the work into smaller, manageable tasks, such as delivery, staging, lifting, and installation. This schedule incorporates realistic durations for each task, factoring in crew size, material availability, and potential weather delays. Third, I use project management software to integrate the joist setting schedule into the master schedule, allowing for real-time tracking of progress and identification of potential conflicts. This software enables easy visualization of dependencies, helping to proactively identify and mitigate delays. Finally, I regularly communicate with other project stakeholders – general contractors, subcontractors, and material suppliers – to ensure everyone is on the same page and any potential issues are addressed promptly. For example, a delay in concrete curing could easily postpone the joist setting, so early detection is critical.

Q 23. What is your experience with different types of joist connections?

My experience encompasses a wide range of joist connections, each with its own strengths and weaknesses. I’m proficient in working with various methods, including:

- Shear Connectors: These include headed studs, channel connectors, and other devices that transfer shear forces between the joist and the supporting structure. I’ve extensively used headed studs in high-rise construction projects, understanding their capacity and ensuring proper installation to prevent premature failure.

- Bolted Connections: This method provides strong and reliable connections, particularly suitable for heavier joists. However, careful consideration must be given to bolt spacing, torque, and corrosion prevention. I’ve managed projects where bolted connections were crucial for ensuring structural integrity, emphasizing the importance of proper inspection and quality control.

- Welded Connections: Welding offers a robust and efficient connection but requires skilled welders and adherence to stringent safety standards. I’ve overseen projects utilizing welded connections, prioritizing compliance with relevant codes and the use of qualified welding personnel.

- Composite Connections: This involves integrating the joist with the concrete slab to form a composite structural member. Designing and implementing composite connections requires a deep understanding of structural analysis and material properties. I’ve used this technique effectively in situations demanding high load-bearing capacity.

Selecting the appropriate connection type depends on factors like the joist material, load requirements, construction methods, and budget. I always prioritize the selection that maximizes safety and efficiency.

Q 24. Describe your understanding of the load-bearing capacity of different joists.

Understanding the load-bearing capacity of different joists is paramount for ensuring structural integrity. Several factors influence this capacity:

- Joist Material: Steel joists are generally stronger and more capable of spanning greater distances than wood joists. The type of steel used (e.g., grade 50 vs. grade 60) also greatly influences strength.

- Joist Section: The shape and dimensions of the joist significantly affect its strength. Deeper sections and wider flanges lead to higher load-bearing capacity. I regularly consult steel and wood joist design manuals to verify specifications and ensure they meet or exceed required loads.

- Span Length: Longer spans necessitate larger and stronger joists to support the same load. Using proper calculation methods is essential to avoid design failures.

- Load Type: The type of load (dead load, live load, snow load, seismic load) directly impacts the capacity needed. It’s crucial to accurately estimate these loads according to building codes and local conditions.

I’m proficient in using engineering software and calculation methods (e.g., moment calculations) to determine the required joist size and spacing for a given load. I always ensure that the selected joists meet or exceed the design loads while adhering to all relevant building codes and standards. I often perform site inspections to verify dimensions and avoid discrepancies with the design specifications.

Q 25. How do you address potential material shortages during joist setting?

Material shortages can severely disrupt a project’s schedule. To mitigate this risk, I employ a multi-pronged approach. First, I carefully review the bill of materials early in the planning phase to accurately estimate the quantities needed. Second, I engage with reliable material suppliers and establish firm order schedules with sufficient lead times. Third, I maintain regular communication with suppliers to track order status and anticipate any potential delays. Fourth, I build contingency plans into the schedule to account for potential shortages. This might involve using alternative materials (if approved by the engineer), adjusting the installation sequence, or prioritizing critical areas. In one instance where a steel joist supplier experienced an unforeseen delay, we immediately substituted a similarly rated joist from a different supplier to minimize downtime. This required coordination with the engineer to ensure compliance, but it saved valuable time and prevented a major schedule disruption.

Q 26. How do you handle weather-related delays during joist setting?

Weather-related delays are an unavoidable reality in construction. To minimize their impact, I incorporate weather monitoring into the project schedule. I work with a specialized weather forecasting service to obtain daily updates, allowing me to anticipate potential delays. I incorporate buffer time into the schedule for expected delays caused by inclement weather, such as rain or high winds, which can make crane operations unsafe. If significant weather events are predicted, I proactively communicate with the project team to implement contingency plans, such as relocating resources to other tasks or suspending work temporarily. For example, if heavy rain is forecast, we may focus on interior work until the weather improves. Moreover, detailed documentation of weather-related delays is maintained to support any potential claims for time extensions.

Q 27. Explain your experience with working with different types of joist lifting equipment.

Experience with various joist lifting equipment is crucial for efficient and safe joist setting. My experience includes using:

- Tower Cranes: These are ideal for large-scale projects, enabling efficient lifting of heavy joists to significant heights. I’m well-versed in crane operation safety protocols and load capacity calculations. I emphasize the importance of having qualified crane operators and ensuring proper load charts are utilized.

- Mobile Cranes: These are highly versatile for accessing areas that tower cranes can’t reach. I’ve used these extensively in projects with limited access. Safety is always a paramount concern, especially when operating near power lines or other obstacles.

- Forklifts: For lighter joists, forklifts can provide efficient and cost-effective lifting solutions. I’ve used forklifts for staging materials and moving them to installation areas in various projects. I ensure that the forklifts are appropriately sized for the joist loads and are operated by certified personnel.

- Gin Poles: These are more traditional methods, particularly useful in smaller or more confined spaces where larger cranes are impractical. I’ve utilized gin poles in several projects, appreciating their efficiency in specific circumstances.

The selection of lifting equipment depends on the project’s scale, joist weight, accessibility, and budget constraints. In every case, safety is my top priority, adhering to all relevant safety regulations and using only certified equipment and personnel.

Q 28. How do you ensure compliance with building codes and regulations during joist setting?

Compliance with building codes and regulations is non-negotiable in joist setting. My approach involves:

- Thorough Code Review: I begin by carefully reviewing all applicable building codes (e.g., IBC, local codes) to understand the requirements for joist design, installation, and safety. I pay close attention to specific sections relating to structural requirements, load calculations, and safety protocols.

- Engineer’s Stamped Drawings: I work closely with structural engineers to ensure that all joist designs are properly engineered and approved. I will only proceed with the designs that carry the appropriate engineer’s stamp of approval.

- Regular Inspections: I perform regular inspections throughout the setting process, checking for compliance with design specifications, load calculations, and safety standards. Any deviations from the approved plans are immediately addressed and documented.

- Proper Documentation: Thorough documentation of all aspects of the joist setting process is crucial. This includes inspection reports, material certifications, and any modifications made to the original plans. I always keep accurate records which greatly aid in potential audits and show regulatory compliance.

- Qualified Personnel: I always ensure that the crew involved in joist setting are appropriately trained, certified, and aware of the safety regulations. This is critical for preventing accidents and ensures compliance.

Non-compliance can lead to serious consequences, including project delays, legal issues, and safety hazards. Therefore, proactive compliance is not merely a procedural step but a critical aspect of responsible construction management.

Key Topics to Learn for Planning and Scheduling of Joist Setting Operations Interview

- Project Planning & Sequencing: Understanding the critical path, dependencies between tasks (e.g., foundation completion, material delivery), and developing a realistic schedule.

- Resource Allocation: Optimizing the use of labor, equipment (cranes, forklifts), and materials to minimize downtime and maximize efficiency. Practical application: Creating a resource histogram to visualize resource needs over time.

- Risk Management: Identifying potential delays (weather, material shortages, equipment malfunctions) and developing mitigation strategies. This includes creating contingency plans.

- Safety Procedures and Regulations: Demonstrating knowledge of OSHA or relevant safety standards for joist setting, including fall protection and load-bearing calculations.

- Budgeting and Cost Control: Understanding the cost implications of different scheduling approaches and the ability to track expenses against the budget.

- Scheduling Software & Tools: Familiarity with project management software (MS Project, Primavera P6, or similar) and their application to joist setting operations.

- Communication & Collaboration: Highlighting the importance of effective communication with subcontractors, engineers, and site management to ensure smooth operations.

- Quality Control & Inspection: Understanding the processes involved in ensuring joists are installed correctly and meet specifications. This includes knowing inspection procedures and checklists.

- Problem-Solving & Decision-Making: Demonstrating the ability to analyze and resolve scheduling conflicts, material delays, or other unforeseen challenges on the jobsite.

Next Steps

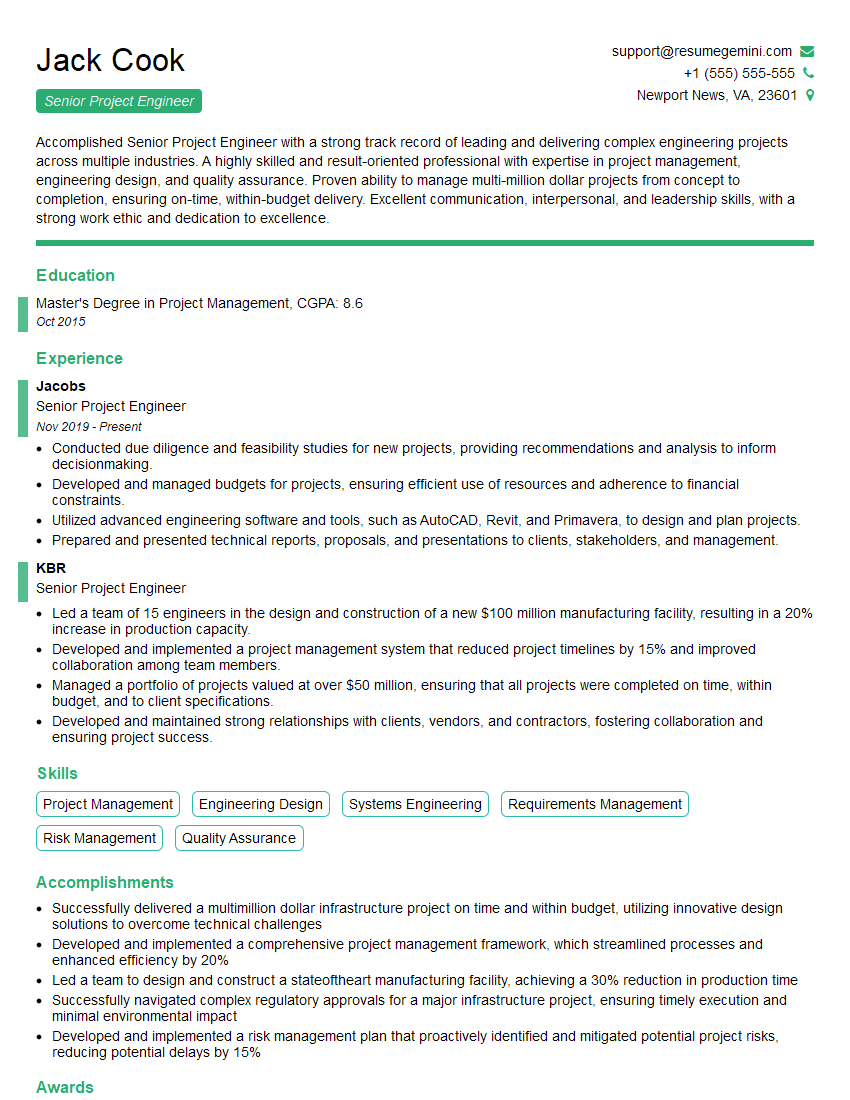

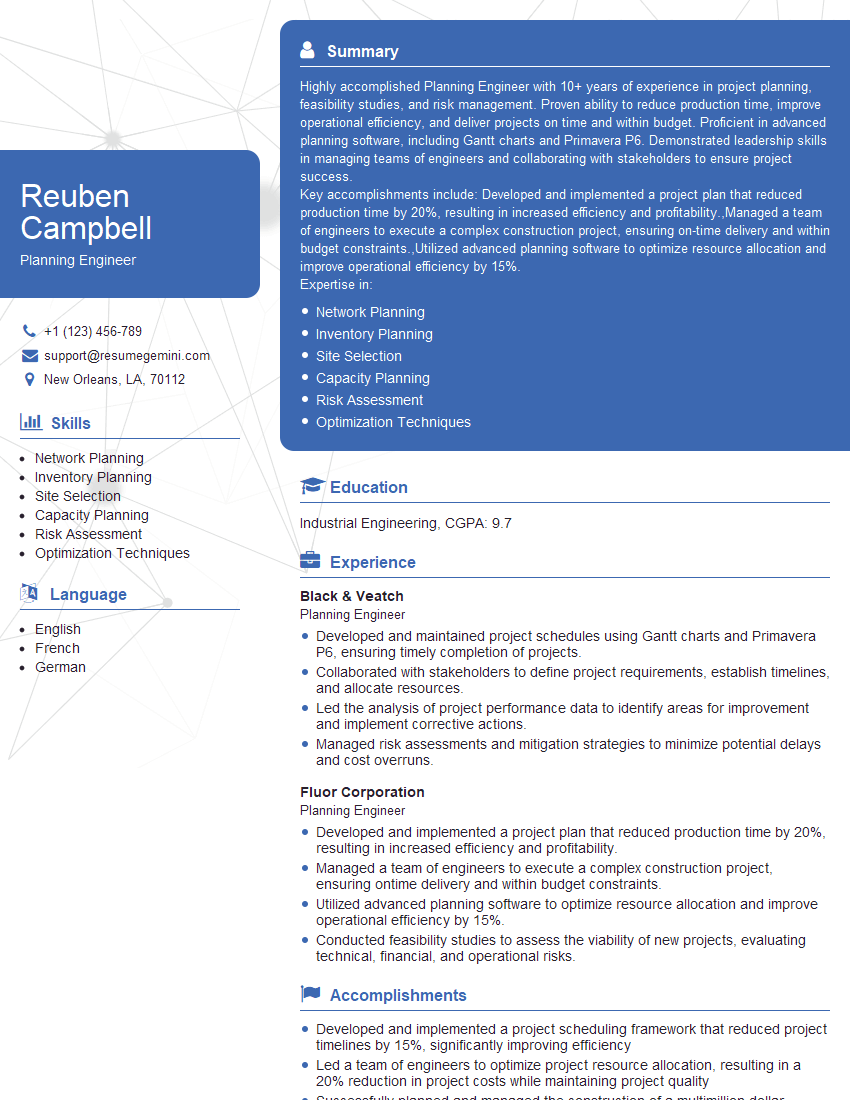

Mastering the planning and scheduling of joist setting operations is crucial for career advancement in construction management. It demonstrates your ability to manage complex projects efficiently and safely, leading to increased responsibility and higher earning potential. To maximize your job prospects, focus on creating an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource for building professional resumes, and we provide examples tailored specifically to Planning and scheduling of joist setting operations to help you present yourself effectively to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good