Preparation is the key to success in any interview. In this post, we’ll explore crucial Gauge R&R interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Gauge R&R Interview

Q 1. Explain the difference between repeatability and reproducibility in Gauge R&R.

Gauge R&R (Repeatability and Reproducibility) studies assess the variation in measurements obtained using a specific measuring device. Repeatability refers to the variation observed when the same appraiser measures the same part multiple times. It reflects the inherent variability of the gauge itself. Reproducibility, on the other hand, represents the variation observed when different appraisers measure the same part. This captures the variation due to differences in appraiser techniques or interpretations.

Think of it like this: Imagine you’re measuring the length of a bolt. Repeatability is how consistently you can measure that bolt if you measure it five times in a row. Reproducibility is how consistently different people in your team can measure that same bolt. If there’s a large difference in measurements between appraisers, the reproducibility is poor, even if each appraiser is consistent with themselves (good repeatability).

Q 2. What are the key assumptions of a Gauge R&R study?

Several key assumptions underpin a valid Gauge R&R study:

- Normality of data: The measurement data should be approximately normally distributed. While minor deviations are often acceptable, severe departures can compromise the study’s validity.

- Independence of measurements: Measurements should be independent of each other. For instance, the measurement of one part shouldn’t influence the measurement of another.

- Constant variance: The variability in measurements should remain consistent across different parts and appraisers. This means that the spread of the data shouldn’t change significantly depending on the part or the appraiser.

- Random sampling: The parts selected for the study should represent the population of parts being measured. A biased selection of parts will lead to biased results.

Violation of these assumptions can lead to inaccurate conclusions. Techniques like data transformations or non-parametric methods might be used to address some assumption violations.

Q 3. Describe the different methods for conducting a Gauge R&R study (e.g., ANOVA, Xbar-R).

Several methods exist for conducting a Gauge R&R study. The most common are:

- ANOVA (Analysis of Variance): This is a statistical method that partitions the total variation in the measurements into different sources: part-to-part variation, appraiser-to-appraiser variation, repeatability variation, and error variation. It’s a powerful technique but requires the assumptions mentioned earlier to hold.

- Xbar-R (or Xbar-s) Method: This method uses control charts to analyze the variation. It’s less statistically rigorous than ANOVA but is easier to understand and implement. Xbar represents the average measurement, and R (or s) represents the range (or standard deviation) of measurements. This method is particularly useful for quick assessments and smaller datasets.

The choice of method depends on the dataset size, the desired level of statistical rigor, and the analyst’s familiarity with the techniques. Software packages like Minitab and JMP readily perform these analyses.

Q 4. How do you interpret the components of variation in a Gauge R&R study (e.g., %Contribution)?

The output of a Gauge R&R study typically presents the different sources of variation as percentages of the total variation. These percentages represent the contribution of each source to the overall measurement uncertainty. For example:

- %Contribution of Gage R&R: This represents the combined contribution of repeatability and reproducibility to the total variation. A higher percentage indicates greater measurement error from the gauge itself.

- %Contribution of Part-to-Part Variation: This represents the natural variation among the parts being measured. This variation is independent of the measurement system.

- %Contribution of Repeatability: This shows the percentage of variation due to the gauge’s repeatability (the same appraiser measuring the same part multiple times).

- %Contribution of Reproducibility: This shows the percentage of variation due to the reproducibility (different appraisers measuring the same part).

By examining these percentages, one can identify the dominant sources of variation and prioritize improvement efforts. For example, a high %Contribution of Reproducibility suggests a need for better training for appraisers or a clearer measurement procedure.

Q 5. What are the acceptable limits for %Contribution of Gage R&R?

There’s no universally accepted threshold for the acceptable %Contribution of Gage R&R. The acceptable limit depends heavily on the application and the context. However, general guidelines are often used as a rule of thumb:

- <10%: Generally considered acceptable. The measurement system is contributing very little to the overall variation.

- 10-30%: Marginally acceptable. The measurement system might be adequate but could benefit from improvement.

- >30%: Generally considered unacceptable. The measurement system is significantly contributing to the overall variation and needs improvement.

The decision of whether to accept or reject a measurement system should not solely rely on these percentage contributions. It’s crucial to consider the overall process variation (part-to-part variation) and the specifications of the measured characteristic. A high Gage R&R percentage might be acceptable if the part-to-part variation is even higher.

Q 6. How do you determine the appropriate number of appraisers and parts for a Gauge R&R study?

Determining the appropriate number of appraisers and parts is crucial for a statistically sound Gauge R&R study. The selection depends on several factors:

- Number of Appraisers: Typically, at least two appraisers are needed to assess reproducibility. More appraisers provide better estimates, but increasing the number beyond 3-5 typically offers diminishing returns. The number of appraisers should reflect the typical number of operators using the gauge in a production environment.

- Number of Parts: The number of parts should represent the variation in the parts themselves. A rule of thumb is to use at least 5-10 parts, but more parts are usually better, especially if part-to-part variation is expected to be high. A minimum of 5 parts helps to understand the part-to-part variation more accurately. The number should cover the expected range of part measurements.

- Number of Measurements per Part per Appraiser: Each appraiser should measure each part at least 2-3 times to assess repeatability. Three measurements per part per appraiser are typically recommended to get a more robust assessment.

Software packages can assist in determining the optimal sample size based on the desired power and confidence levels. Pilot studies can also be beneficial to better estimate the variability and inform the final sample size.

Q 7. Explain the concept of Gage R&R using a practical example.

Let’s consider a car manufacturing plant that measures the diameter of piston rings using a caliper. A Gauge R&R study is conducted to evaluate the measurement system’s accuracy and precision. Three appraisers each measure ten piston rings three times each. The results are analyzed using ANOVA, revealing significant variation due to reproducibility; different appraisers obtain considerably different measurements for the same piston ring. This indicates a lack of clarity in the measurement procedure or inconsistencies in appraiser techniques. The analysis might also show significant repeatability error, suggesting that the caliper itself has some inconsistency.

The high reproducibility and potentially high repeatability variation indicate that the measurement system (the caliper and the appraisers) requires improvement. Actions might involve retraining the appraisers on consistent measurement techniques, calibrating the caliper, or even replacing the caliper with a more precise instrument. The study would then help determine the source of measurement error and guide decisions to improve the measurement process.

Q 8. How do you handle outliers in a Gauge R&R data set?

Handling outliers in Gauge R&R is crucial because they can significantly skew the results and lead to inaccurate conclusions about the measurement system’s performance. Outliers represent measurements that are unusually far from other measurements in the dataset. Before removing an outlier, we must understand why it exists. Was there a genuine error in measurement (e.g., a misread scale, operator mistake), or does it represent a true variation within the system under test? We usually perform a thorough investigation to identify the root cause.

Methods for Handling Outliers:

- Investigation: The first step is always investigation. Examine the data collection process for errors. Were there any unusual circumstances during data collection? Did the operator report any problems?

- Visual Inspection: Box plots and scatter plots are useful for visually identifying potential outliers. These plots highlight data points that fall significantly outside the typical range.

- Statistical Tests: Formal statistical tests such as the Grubbs’ test can be used to identify outliers statistically. However, remember that statistical tests alone aren’t sufficient justification for removal. Always correlate them with the investigation step.

- Transformation: In some cases, a data transformation (e.g., logarithmic transformation) can help reduce the influence of outliers without removing them entirely.

- Removal (with Caution): Only remove outliers if a thorough investigation reveals a clear error in the data collection process. Always document the reason for removal and the potential impact on the results. In cases where removal is necessary, consider alternative analysis methods like robust statistics that are less sensitive to outliers.

Example: Imagine a Gauge R&R study where one measurement is far outside the range of others, and you discover that the operator recorded the wrong measurement value in the datasheet. In this case, it’s reasonable to correct the outlier value if the actual reading is known.

Q 9. What are the limitations of a Gauge R&R study?

While Gauge R&R studies are invaluable for assessing measurement system capability, they have limitations:

- Assumption of Normality: Many Gauge R&R analyses assume that the data are normally distributed. If this assumption is violated (which can happen with skewed distributions or with small sample sizes), the results might not be accurate or reliable. Transformations can mitigate this, but the interpretation of results must be adjusted accordingly.

- Limited Scope: A Gauge R&R study assesses the variation in a measurement system only under specific conditions. It doesn’t necessarily reflect performance under different operating conditions, different operators, or over time (unless these factors are explicitly included in the study design).

- Operator Effects: It can be challenging to fully disentangle the effects of different operators, especially if there’s interaction between operators and parts. Well-designed studies with appropriate randomization and sufficient replication are crucial to minimize this limitation.

- Part-to-Part Variation: A significant amount of variation in the parts themselves can mask or diminish the measurement system’s variation. This can lead to an underestimation of the measurement system’s actual error. A larger number of parts helps to reduce the impact of this limitation.

- Focus on Repeatability and Reproducibility: Gauge R&R primarily focuses on repeatability (variation within an operator) and reproducibility (variation between operators). It doesn’t directly assess other critical aspects of measurement systems, such as accuracy, bias, or linearity. A comprehensive assessment needs to include these extra components.

Therefore, the results of a Gauge R&R study should be interpreted with caution, keeping these limitations in mind. Combining the Gauge R&R analysis with other quality control tools gives a more complete picture.

Q 10. How do you determine if a measurement system is adequate for its intended use?

Determining if a measurement system is adequate depends on its intended use and the acceptable level of variation. We generally use the %Contribution (percentage contribution of variation from each source) from the Gauge R&R study. Acceptable %Contribution thresholds vary by industry and application but generally aim for low values for Gage Variation. Typical benchmarks are a total Gauge R&R variation of less than 10%, with variation due to repeatability (measurement error) and reproducibility (operator variation) both less than 5%. A common rule of thumb is that total Gauge R&R should be less than 30% of the total variation. However, these are guidelines, not hard rules. The acceptable level of variation is ultimately determined by considering the overall process specifications and the associated costs of poor measurements (e.g. time, money, safety).

Example: In a manufacturing setting producing precision parts with tight tolerances, the acceptable %Contribution for Gauge R&R might be significantly lower than in a situation with less stringent tolerances. A low %Contribution would reflect a highly capable measurement system suitable for the given task. Conversely, a high %Contribution would indicate that the measurement system is inadequate and needs improvement.

Beyond %Contribution, consider:

- Bias: The measurement system should not consistently overestimate or underestimate the true value.

- Linearity: The measurement system should provide accurate measurements across the full range of the measurement scale.

Q 11. What are the different types of Gage R&R studies?

There are several types of Gauge R&R studies, each designed to address specific aspects of measurement system variation:

- Cross (or Expanded) Gage R&R: This is the most comprehensive type. It involves multiple operators measuring multiple parts multiple times. This design provides the most complete assessment of repeatability, reproducibility, and part-to-part variation.

- Nested Gage R&R: This is used when the number of operators is limited or when certain operators only measure a subset of the parts. Statistical analysis accounts for the nesting structure of the data.

- Attribute Gage R&R: This is used when the measurement data is categorical or qualitative (e.g., good/bad, pass/fail). Methods such as the Kappa statistic or other agreement measures are used to assess the agreement among different operators.

- ANOVA (Analysis of Variance) based Gage R&R: This uses ANOVA techniques to partition the total variation into components attributable to the parts, operators, and measurement error. This is often the approach used in software packages.

The choice of study type depends on the specific resources available, the complexity of the measurement system, and the research questions being asked.

Q 12. Explain the concept of Bias in a Gauge R&R study.

Bias in a Gauge R&R study refers to a systematic error in the measurement system. It means that the measurement system consistently overestimates or underestimates the true value. For example, if a scale consistently reads 1 kg higher than the actual weight, it shows a positive bias of 1 kg. Bias isn’t about random variation; it’s about a consistent, systematic deviation. A high bias indicates that the measurement system is inaccurate, even if the precision (repeatability and reproducibility) is high. A biased measurement system leads to incorrect decisions and poor quality control.

Identifying Bias: Bias is typically assessed by comparing the average measurement to a known reference value. For example, if we know the true value of a part and compare it to the average measurement taken by multiple operators, we can determine if bias exists and its magnitude. This usually needs a standard (or master) part of known value.

Impact of Bias: A biased measurement system can lead to faulty conclusions about the product or process being measured. This can lead to significant implications such as rejecting good parts or accepting bad parts, ultimately impacting quality, safety, and even financial performance.

Q 13. How do you assess the linearity of a measurement system?

Linearity in a Gauge R&R study assesses whether the measurement system provides consistent accuracy across its entire measurement range. A measurement system is linear if the measured values are proportional to the actual values throughout the range. Non-linearity indicates that the measurement system is accurate in some parts of the range but inaccurate in others, often manifesting as increasing or decreasing errors at the extremes of the range.

Assessing Linearity: Linearity is often assessed by measuring a set of parts that span the entire measurement range of the gauge. A graph (often called a linearity plot) is then created showing the average measurement for each part against its known or reference value. A straight line is fitted to this data. The deviation of the data points from this line indicates non-linearity.

Methods for Assessing Linearity:

- Linear Regression: A linear regression model can be used to quantify the relationship between the measured values and the reference values. The residuals (differences between the observed and predicted values) are an indication of the linearity.

- Graphical Methods: Scatter plots of measured values versus reference values visually demonstrate linearity or non-linearity. Significant deviations from a straight line indicate non-linearity.

Implications of Non-Linearity: Non-linearity can have serious consequences, as the measurement errors will vary depending on the value being measured. This can lead to incorrect assessments of process capability and increase the risk of making poor decisions based on inaccurate measurements.

Q 14. What software packages are commonly used for Gauge R&R analysis?

Several software packages are widely used for Gauge R&R analysis. The choice depends on factors like the specific analysis needs, user preference, and available resources.

- Minitab: Minitab is a very popular and user-friendly statistical software package commonly used in quality control. It offers a straightforward interface for performing Gauge R&R analysis.

- JMP: JMP is another powerful statistical software package with strong capabilities for Gage R&R and other quality control tools. It offers a visually interactive environment.

- R: R is a free and open-source programming language and environment for statistical computing. It provides a wide range of packages for statistical analysis, including Gauge R&R. While requiring more programming expertise, R is versatile and highly customizable.

- Excel: Excel, with the right add-ins or macros, can perform basic Gage R&R analysis. However, it is generally less powerful and less flexible than dedicated statistical software packages, particularly for more complex study designs or situations with outliers.

Many specialized quality management software solutions also incorporate Gauge R&R analysis capabilities.

Q 15. Explain the difference between Gage R&R and Measurement System Analysis (MSA).

While often used interchangeably, Gage R&R (Gauge Repeatability and Reproducibility) and Measurement System Analysis (MSA) are distinct but related concepts. Gage R&R is a specific type of MSA focusing solely on the variation within a measurement system. MSA, on the other hand, is a broader term encompassing various methods to evaluate the accuracy and precision of a measurement system. Think of it this way: Gage R&R is a tool within the MSA toolbox.

Gage R&R specifically assesses two key sources of variation: repeatability (variation due to the gauge itself when used by the same operator) and reproducibility (variation due to different operators using the same gauge). MSA, however, might also include assessments of bias (systematic error), linearity (consistency of measurement across the range), and stability (consistency over time). A complete MSA might include a Gage R&R study as a crucial component, but it will also investigate other aspects of measurement system performance.

Career Expert Tips:

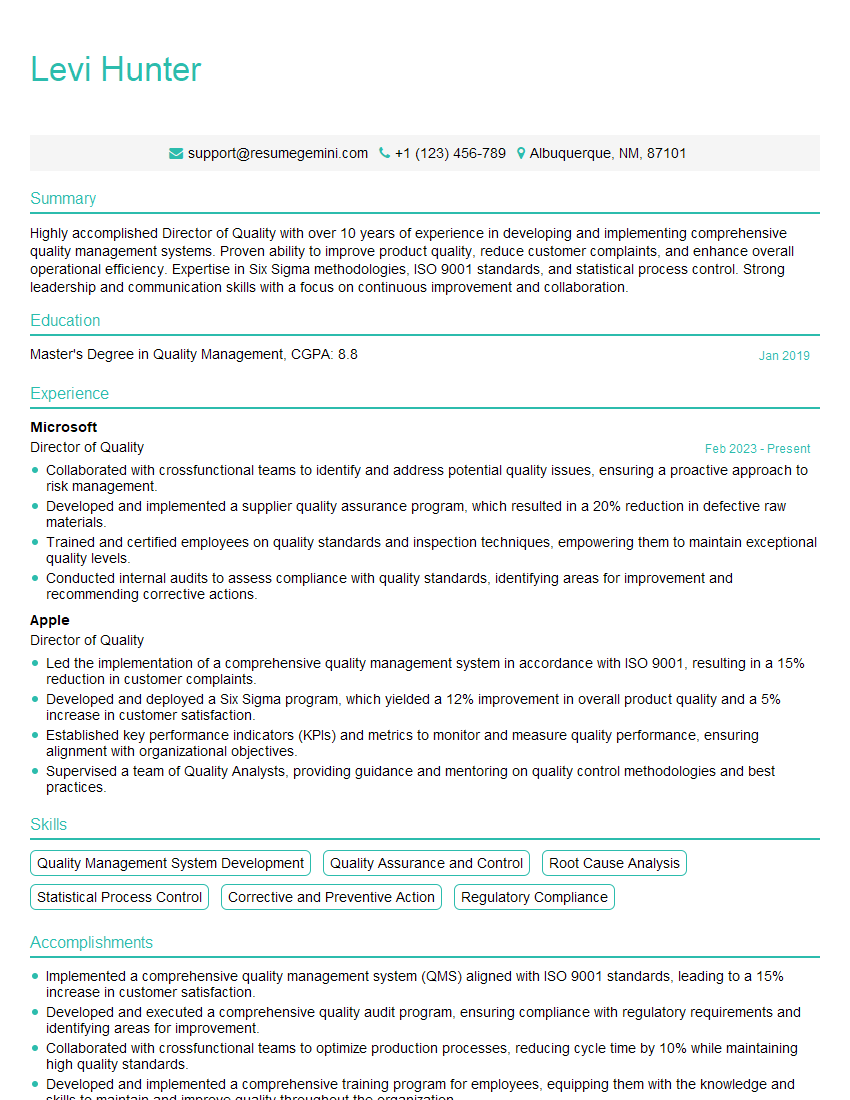

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How would you present the results of a Gauge R&R study to non-technical stakeholders?

Presenting Gage R&R results to non-technical stakeholders requires simplifying complex statistical data. I’d avoid jargon and focus on a clear, visual presentation. A simple bar chart showing the percentage of variation attributed to each source (appraiser, part-to-part, gauge) is very effective. Think of a pie chart illustrating the breakdown of variance. If the gauge variation is a large portion, that needs clear highlighting.

I’d then translate the statistical results into business terms. For instance, instead of stating ‘%GRR’, I’d say something like, “Our measurement system accounts for X% of the total variation in our product. This means that Y% of the observed differences might be due to inconsistencies in how we’re measuring, not actual differences in the product itself.” This emphasizes the impact on decision-making. A simple summary table with key metrics like %GRR, and whether the measurement system is acceptable based on pre-defined criteria is essential.

Q 17. Describe a situation where a Gauge R&R study was critical to improving a process.

I once worked with a manufacturer of precision ball bearings. They were experiencing high rejection rates on their final inspection, impacting profitability significantly. Initially, they blamed inconsistencies in the manufacturing process. However, a thorough Gauge R&R study revealed that a significant portion of the observed variation stemmed from the micrometers used for diameter measurement. The micrometers were old, poorly maintained, and showed significant operator-dependent variation.

The study clearly identified the problem: the measurement system itself was contributing substantially to the rejection rates. After replacing the micrometers with calibrated, modern instruments and providing comprehensive operator training, the rejection rates dropped dramatically. This directly improved product quality, increased customer satisfaction, and boosted profits. This highlighted that sometimes the problem isn’t the process, but how we measure it.

Q 18. What are the potential consequences of using an inadequate measurement system?

Using an inadequate measurement system has far-reaching consequences. It can lead to:

- Incorrect process conclusions: If the measurement system is inaccurate or imprecise, you might misinterpret process performance, leading to unnecessary adjustments or overlooking real problems.

- Wasted resources: Corrective actions taken based on faulty measurements can be costly and ineffective.

- Poor product quality: Inconsistencies in measurement can lead to releasing non-conforming products, harming customer satisfaction and brand reputation.

- Increased scrap and rework: Incorrect measurements can result in products being unnecessarily scrapped or requiring rework, leading to increased costs.

- Regulatory non-compliance: In regulated industries, inaccurate measurements can lead to failing audits and significant penalties.

Q 19. How do you validate a measurement system?

Validating a measurement system involves several steps. First, you define the necessary measurement system accuracy based on the process requirements. Then, a Gage R&R study (or a broader MSA) needs to be conducted to quantify the system’s variation. The results are then compared to pre-defined acceptance criteria, often expressed as a percentage of total variation (%GRR) or a signal-to-noise ratio.

Beyond Gage R&R, validation might involve checking for bias (comparing measurements to a reference standard), linearity (evaluating measurement accuracy across the measurement range), and stability (assessing the consistency of measurements over time). Traceability to national or international standards is crucial for regulatory compliance. Documentation of all aspects of the validation process, including the methods, results, and conclusions, is essential.

Q 20. How do you choose the appropriate sampling method for a Gauge R&R study?

The optimal sampling method for a Gage R&R study depends on the specific application and resources available. However, some general guidelines apply. We need to consider the number of parts, operators, and measurements per part-operator combination. The goal is to achieve statistically sound results while keeping the study manageable.

A common approach involves selecting a representative sample of parts spanning the expected range of the process. The number of parts should be sufficient to capture the process variation. The number of operators selected depends on the context, but typically we involve at least two or three operators to account for inter-operator variation. Each operator measures each part multiple times to assess repeatability. The number of measurements per part-operator combination is often 2-3, balancing precision against time constraints. A balanced design, where each operator measures each part an equal number of times, is often preferred for simpler data analysis.

Q 21. What is the difference between a fixed effects and a random effects model in Gage R&R?

The choice between a fixed effects and a random effects model in Gage R&R influences how we interpret and generalize the results. In a fixed effects model, the selected operators represent the only operators of interest. The results apply only to those specific individuals. This is appropriate if these operators are the only ones who will be using the gauge. Think of highly specialized equipment where only a small, specific team is qualified.

In a random effects model, the selected operators are considered a random sample from a larger population of potential operators. The results can be generalized to the larger population of operators who might use the gauge in the future. This is more common in scenarios where many operators might use the gauge. For example, in a manufacturing line with many operators rotating through various stations. The random effects model gives a more robust estimation of the overall variability.

Q 22. How do you address the issue of operator bias in a Gage R&R study?

Operator bias in a Gage R&R study refers to inconsistencies in measurements caused by the individual performing the measurements. It’s like having multiple chefs prepare the same dish – even with the same recipe, slight variations in technique and interpretation can lead to different outcomes. To minimize operator bias, we employ several strategies:

- Proper Training: Thorough training on the measurement instrument and procedure ensures all operators understand and apply the same techniques. This includes clear instructions, demonstrations, and practice sessions with feedback.

- Standardized Procedures: Creating detailed, step-by-step instructions for measurement minimizes room for individual interpretation. This might involve specifying the exact positioning of the part, the force applied, or the reading method.

- Randomization: Operators should measure parts in a randomized order, preventing any systematic bias based on fatigue, learning curve, or part order. For instance, don’t let an operator measure all the easy parts first, then the challenging ones.

- Blinding: In some cases, blinding the operator to the part identity can reduce preconceived notions or expectations. For example, the parts could be labeled with random codes instead of their actual values.

- Multiple Operators: Using multiple operators allows us to statistically assess the contribution of operator variation. If the operator variation is significant, it suggests further training or improved procedures are necessary.

By addressing these factors, we ensure that the variation observed in the Gage R&R study is a true reflection of the measurement system’s capabilities and not simply a consequence of individual operator differences.

Q 23. Explain the concept of ‘within-part variation’ in a Gauge R&R study.

Within-part variation refers to the variability observed when measuring the same part multiple times using the same gauge and operator. Imagine trying to measure the length of a small metal rod multiple times with a caliper. Even with the most careful measurements, slight variations will occur due to inconsistencies in how the rod is positioned or how the caliper’s jaws make contact. This is within-part variation.

This variation is inherent to the part itself, the measurement instrument, and even the operator’s skill in handling the part. It’s not related to differences between parts or operators, but rather to the reproducibility of a single measurement on a single part. A high within-part variation indicates the measuring instrument isn’t capable of capturing precise measurements, which can lead to inaccurate conclusions about the process. We need to understand this variation to determine if the measuring device is fit for purpose.

Q 24. How do you improve the accuracy and precision of a measurement system?

Improving the accuracy and precision of a measurement system requires a multi-faceted approach:

- Calibration: Regularly calibrate the measurement instrument against a known standard. This ensures the instrument is reading correctly and hasn’t drifted over time.

- Operator Training: As mentioned earlier, well-trained operators are crucial. Proper training on the instrument, procedures, and best practices will significantly reduce operator-related variation.

- Improved Measurement Techniques: Analyze the measurement process to identify and eliminate sources of variation. This might involve using jigs or fixtures to standardize part positioning or using a more precise measuring instrument.

- Environmental Control: Ensure consistent environmental conditions (temperature, humidity) during measurements, as these factors can affect measurements, especially in sensitive applications.

- Gauge Selection: Choose the appropriate gauge for the application. A gauge with too low resolution might not be able to detect small variations, while a gauge that is too precise might introduce unnecessary complexity and variation.

- Statistical Process Control (SPC): Implement SPC charts to monitor the measurement system’s performance over time. This allows early detection of any drifts or changes in accuracy or precision.

By systematically addressing these aspects, you can refine the measurement process, leading to more reliable and trustworthy data for decision-making.

Q 25. Describe the different sources of variation in a measurement system.

Sources of variation in a measurement system can be categorized into:

- Part-to-Part Variation: This is the inherent variation between different parts being measured. Think of manufacturing tolerances: even parts produced under identical conditions will never be exactly the same.

- Operator Variation: This encompasses the differences in measurements obtained by different operators using the same gauge and part. This can arise from differences in technique, interpretation, or even visual acuity.

- Within-Part Variation (as discussed above): This is the variation observed when measuring the same part multiple times by the same operator using the same gauge.

- Measurement System Variation (Gauge Variation): This includes the variations due to the gauge itself, including repeatability and reproducibility issues within the gauge. It may involve issues like wear and tear or design flaws.

- Environmental Variation: Temperature, humidity, and other environmental factors can influence measurements, especially for sensitive instruments.

Understanding these sources of variation is vital for identifying areas for improvement within the measurement system and for interpreting the results of a Gage R&R study accurately.

Q 26. What are some common errors to avoid when conducting a Gauge R&R study?

Common errors to avoid during a Gage R&R study include:

- Insufficient Sample Size: Using too few parts or operators can lead to inaccurate conclusions, as the study might not capture the full range of variation.

- Poorly Defined Measurement Procedure: Ambiguous or incomplete instructions can lead to inconsistent measurements and inflated variation.

- Inappropriate Gauge Selection: Choosing a gauge with insufficient resolution or precision can lead to inaccurate readings and mask real variations.

- Ignoring Environmental Factors: Failing to control environmental factors can introduce unwanted variation into the study.

- Non-Randomization: Measuring parts in a non-random order can create systematic bias and affect the results.

- Improper Data Analysis: Using incorrect statistical methods or misinterpreting the results can lead to wrong conclusions.

- Insufficient Training: Inadequate operator training can introduce significant operator bias and increase variation.

Careful planning and execution are crucial to ensuring a successful and meaningful Gage R&R study, allowing for effective conclusions on improving the measurement process.

Q 27. How do you determine the sample size for a Gauge R&R study?

Determining the appropriate sample size for a Gage R&R study involves considering several factors, and there’s no single formula. Generally, we aim for a sample size that provides sufficient power to detect important sources of variation while being feasible within the constraints of time and resources. However, guidelines and software tools can help.

Factors influencing sample size include:

- Number of Operators: Usually, at least 2-3 operators are used to evaluate operator variation. More operators improve the study but require more resources.

- Number of Parts: The number of parts should be sufficient to capture the part-to-part variation. Typically, at least 10 parts are recommended, but more might be necessary if the process is highly variable.

- Number of Measurements per Part per Operator: Usually, 2-3 measurements per part per operator are considered. This increases the precision of the within-part variation estimate.

- Desired Power: The statistical power of the study is the probability of detecting a significant effect if it truly exists. A higher power requires a larger sample size.

Software packages designed for Gage R&R analysis, such as Minitab or JMP, often have built-in sample size calculators that consider these factors and provide recommended sample sizes. Consulting these tools is essential for determining the optimal sample size based on the specific context of your study.

Key Topics to Learn for Gauge R&R Interview

- Understanding Gauge R&R: Grasp the fundamental principles and purpose of Gauge Repeatability and Reproducibility studies. Know why it’s crucial for process capability and measurement system analysis.

- Sources of Variation: Be prepared to discuss the different sources of variation in measurement systems (repeatability, reproducibility, part-to-part variation). Understand how these affect the overall measurement uncertainty.

- ANOVA and Statistical Analysis: Familiarize yourself with the statistical methods used in Gauge R&R analysis, particularly ANOVA (Analysis of Variance). Know how to interpret the results and understand the key metrics like %Contribution.

- Practical Applications: Be ready to discuss real-world examples of how Gauge R&R studies are used to improve measurement processes. Consider examples in manufacturing, quality control, or other relevant industries.

- Study Design and Planning: Understand the different study designs (e.g., crossed, nested) and how to choose the appropriate design based on the specific application. Know how to determine the necessary sample sizes.

- Interpreting Results and Improvement Actions: Know how to interpret the results of a Gauge R&R study and recommend appropriate actions to improve the measurement system if necessary. This includes identifying and addressing sources of excessive variation.

- Software and Tools: Familiarity with statistical software packages commonly used for Gauge R&R analysis (e.g., Minitab, JMP) is a plus. Be prepared to discuss your experience with such tools, if applicable.

Next Steps

Mastering Gauge R&R significantly enhances your value in quality-focused roles, opening doors to advanced positions and higher earning potential. To maximize your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your Gauge R&R expertise. Examples of resumes specifically designed for Gauge R&R roles are available through ResumeGemini to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good