Cracking a skill-specific interview, like one for Developing and implementing safety plans, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Developing and implementing safety plans Interview

Q 1. Describe your experience in developing and implementing safety plans.

Developing and implementing safety plans is a multifaceted process requiring a deep understanding of potential hazards, risk assessment methodologies, and regulatory compliance. My experience spans diverse industries, including construction, manufacturing, and healthcare. In each role, I’ve been involved in the entire lifecycle – from initial hazard identification and risk assessment, through the development of comprehensive safety plans, to ongoing monitoring, evaluation, and improvement. For instance, in my previous role at a construction firm, I led the development of a comprehensive safety plan that reduced workplace accidents by 35% within a year. This involved a detailed analysis of all construction phases, identification of potential hazards (e.g., falls from heights, equipment malfunctions, material handling), and the implementation of specific control measures (e.g., fall protection systems, regular equipment inspections, safe lifting techniques). The plan also included robust training programs for all employees and regular safety inspections.

Q 2. Explain your understanding of hazard identification and risk assessment methodologies.

Hazard identification and risk assessment are crucial first steps in any safety plan. Hazard identification involves systematically identifying potential sources of harm within a workplace. This can be achieved through various methods, including checklists, site inspections, job hazard analyses (JHAs), and incident investigations. Risk assessment, on the other hand, involves evaluating the likelihood and severity of each identified hazard. Common methodologies include qualitative methods (e.g., using risk matrices to categorize hazards based on likelihood and severity) and quantitative methods (e.g., using fault tree analysis or event tree analysis to quantify the probability of specific events). I have extensive experience using both qualitative and quantitative methods. For example, in a manufacturing setting, I utilized a Failure Mode and Effects Analysis (FMEA) to systematically assess potential equipment failures and their impact on worker safety. This allowed us to prioritize mitigation efforts and allocate resources effectively.

Q 3. How do you prioritize safety risks and allocate resources effectively?

Prioritizing safety risks and allocating resources requires a structured approach. I typically use a risk matrix, assigning a score based on the likelihood and severity of each hazard. Hazards with higher scores receive priority. This allows for the efficient allocation of resources, focusing on the most critical risks first. For instance, a high likelihood and high severity hazard, like working at heights without proper fall protection, would receive immediate attention and resource allocation. This process is iterative and constantly reviewed and updated as conditions change. Furthermore, resources are not only allocated to mitigation strategies but also to training, safety equipment, and ongoing monitoring and evaluation. Regular reviews and audits ensure resources are utilized effectively and the plan adapts to changing circumstances.

Q 4. What are the key elements of a comprehensive safety management system?

A comprehensive safety management system (SMS) is a structured approach to managing workplace safety and health. Key elements include:

- Leadership commitment: Demonstrating a commitment to safety from top management is crucial.

- Hazard identification and risk assessment: A systematic process for identifying and evaluating hazards.

- Risk control: Implementing controls to eliminate or mitigate hazards.

- Emergency preparedness and response: Developing and practicing emergency procedures.

- Training and competency assurance: Ensuring employees have the necessary skills and knowledge.

- Monitoring and evaluation: Regularly tracking safety performance and making improvements.

- Communication and consultation: Open communication between management and employees.

- Documentation and record-keeping: Maintaining detailed records of all safety activities.

Q 5. Describe your experience with conducting safety audits and inspections.

Safety audits and inspections are critical for ensuring the effectiveness of safety plans. My experience includes conducting both planned and unplanned audits and inspections across various settings. Planned audits often involve a systematic review of safety procedures, documentation, and training records. Unplanned inspections are more focused on real-time observation of workplace practices. During audits, I use checklists and observation techniques to identify areas of compliance and non-compliance with safety regulations and internal procedures. For example, in a recent audit of a manufacturing facility, I observed workers not using the appropriate personal protective equipment (PPE). This led to immediate corrective actions, including retraining and stricter enforcement of PPE usage. Findings from audits and inspections are documented, shared with management, and used to improve the SMS.

Q 6. How do you ensure compliance with relevant safety regulations and standards?

Compliance with relevant safety regulations and standards is paramount. I stay updated on all applicable legislation, codes, and industry best practices. This includes regularly reviewing changes to regulations and integrating them into safety plans and procedures. I ensure that all safety activities align with these requirements. Methods for ensuring compliance include using standardized checklists, conducting regular inspections and audits, and employing qualified safety professionals to advise on regulatory compliance. Furthermore, I maintain detailed records of all safety activities to demonstrate compliance to regulatory bodies. Non-compliance can lead to significant penalties, and proactive steps to ensure compliance are critical for the organization’s success and the safety of its employees.

Q 7. Explain your experience in developing and delivering safety training programs.

Developing and delivering effective safety training programs is crucial for creating a culture of safety. My experience encompasses designing, developing, and delivering various training programs tailored to specific job roles and hazards. These programs often combine classroom instruction with hands-on training, simulations, and practical exercises. For instance, I developed a comprehensive training program on lockout/tagout procedures for maintenance personnel in a manufacturing plant. This program included both theoretical instruction and practical demonstrations to ensure that employees could correctly and safely perform lockout/tagout procedures. The effectiveness of the program is monitored through regular assessments and feedback from participants. Training is not a one-time event, but rather an ongoing process to reinforce safety knowledge and skills.

Q 8. How do you investigate and analyze workplace accidents and incidents?

Investigating workplace accidents and incidents requires a systematic approach. Think of it like solving a detective mystery – we need to gather evidence, analyze it, and determine the root cause to prevent future occurrences. My process typically follows these steps:

- Immediate Response: Secure the scene, provide first aid if needed, and notify relevant authorities.

- Data Collection: This involves interviewing witnesses, reviewing documentation (e.g., safety records, maintenance logs), taking photographs and videos, and examining physical evidence.

- Analysis: We use various tools and techniques, such as fault tree analysis (FTA) or root cause analysis (RCA) – like the “5 Whys” method – to identify the underlying causes. For example, if a worker fell from a ladder, we wouldn’t just stop at ‘the worker fell’. We’d ask why: the ladder was unstable (why?), it wasn’t properly secured (why?), there wasn’t adequate training on ladder safety (why?).

- Reporting and Corrective Actions: A detailed report is compiled, outlining findings and recommended corrective actions. This might include new safety procedures, training programs, or equipment upgrades.

- Follow-up: We monitor the effectiveness of the implemented actions to ensure the issue is truly resolved and prevent recurrence.

For example, in a previous role, we investigated a near-miss incident where a worker almost dropped a heavy object. Our investigation revealed a lack of proper lifting techniques training. We implemented a comprehensive training program and saw a significant decrease in near-miss incidents afterward.

Q 9. What methods do you use to communicate safety information effectively to workers?

Effective communication is crucial for safety. I use a multi-pronged approach, tailoring my methods to the audience and the information’s urgency. Think of it as delivering a message in various formats to ensure everyone understands and remembers.

- Toolbox Talks: Short, informal meetings at the start of shifts to discuss specific safety issues.

- Safety Newsletters and Emails: Regular updates on safety policies, upcoming training, and accident statistics.

- Posters and Signage: Visual reminders placed strategically throughout the workplace highlighting key safety messages.

- Interactive Training: Hands-on sessions, simulations, and e-learning modules to enhance engagement and knowledge retention.

- One-on-One Discussions: Addressing specific safety concerns with individual workers.

- Safety Committees: Regular meetings involving workers and management to foster collaboration and address safety concerns.

I also ensure that all communications are clear, concise, and accessible to workers with diverse literacy levels. Using visual aids and simple language is often more effective than lengthy technical documents.

Q 10. How do you promote a strong safety culture within an organization?

Building a strong safety culture isn’t just about rules and regulations; it’s about creating an environment where safety is a shared value and everyone takes ownership. It’s like building a team – everyone needs to understand their role and feel empowered to contribute. I focus on:

- Leadership Commitment: Safety must be championed from the top down. Management’s active involvement sets the tone and demonstrates that safety is a priority.

- Employee Empowerment: Encourage workers to identify and report hazards without fear of reprisal. This often involves providing training on hazard identification and reporting procedures.

- Recognition and Rewards: Acknowledging and rewarding safe behaviors promotes positive reinforcement.

- Open Communication: Creating channels for feedback and actively listening to worker concerns builds trust and fosters a sense of shared responsibility.

- Regular Safety Training: Continuous training keeps safety top of mind and ensures that everyone is up-to-date on best practices.

- Incident Investigation and Learning: Thoroughly investigating incidents, not to blame individuals, but to learn from mistakes and improve safety procedures.

For example, in one organization, I introduced a peer-to-peer safety observation program, where workers could recognize and reward each other for safe work practices. This significantly boosted morale and promoted a more proactive safety culture.

Q 11. Describe your experience in developing emergency response plans.

Developing effective emergency response plans requires a detailed understanding of potential hazards and a clear plan of action. It’s like creating a detailed map for escaping a building on fire – you need to know the exits, the assembly points, and what to do in different scenarios. My approach involves:

- Hazard Identification: Identifying all potential emergencies, considering both internal and external factors (e.g., fires, floods, chemical spills, active shooter situations).

- Risk Assessment: Evaluating the likelihood and severity of each hazard to prioritize responses.

- Emergency Procedures: Developing detailed procedures for each type of emergency, including evacuation plans, emergency contact lists, and roles and responsibilities.

- Communication Plan: Establishing clear communication channels for notifying workers, emergency services, and other stakeholders.

- Training and Drills: Regular training and drills to ensure that workers are familiar with emergency procedures and can respond effectively.

- Testing and Review: Regularly testing and reviewing the plan to ensure its effectiveness and make necessary adjustments.

In a previous role, I developed an emergency response plan for a chemical processing plant that included detailed procedures for handling chemical spills, fires, and medical emergencies. The plan included clear communication protocols, designated assembly points, and emergency equipment locations, which proved invaluable during a minor chemical spill incident.

Q 12. How do you measure the effectiveness of your safety programs?

Measuring the effectiveness of safety programs is crucial to demonstrate their impact and identify areas for improvement. It’s like checking the effectiveness of a medicine – you need to measure the results to know if it’s working. I use a variety of key performance indicators (KPIs) including:

- Accident Rates: Tracking the number and severity of accidents over time.

- Near-Miss Reports: Monitoring the number of near-miss incidents, indicating potential hazards that haven’t yet resulted in an accident.

- Safety Training Completion Rates: Measuring the percentage of employees who have completed required safety training.

- Employee Safety Surveys: Gathering feedback from workers on safety perceptions and concerns.

- Observation Audits: Conducting regular safety observations to identify unsafe behaviors and conditions.

- Compliance Rates: Tracking adherence to safety regulations and procedures.

By analyzing these KPIs, I can identify trends, assess program effectiveness, and make data-driven decisions to improve safety performance. For instance, if accident rates increase, it could indicate a need for additional training or a review of safety procedures.

Q 13. How do you manage safety risks related to specific hazards (e.g., fire, chemical handling)?

Managing safety risks related to specific hazards requires a tiered approach, using the hierarchy of controls to mitigate risk. Think of it as building layers of protection to prevent accidents. My approach involves:

- Elimination: If possible, completely eliminating the hazard. For example, replacing a hazardous chemical with a safer alternative.

- Substitution: Replacing the hazard with a less hazardous alternative. For instance, using a less flammable solvent.

- Engineering Controls: Implementing physical changes to the workplace to reduce the hazard. Examples include installing ventilation systems to reduce chemical exposure, using guards on machinery, and providing proper lighting.

- Administrative Controls: Implementing procedures and policies to manage the hazard. Examples include developing safe work procedures, providing safety training, implementing permit-to-work systems, and establishing lockout/tagout procedures.

- Personal Protective Equipment (PPE): Providing workers with appropriate PPE as a last resort. This includes gloves, eye protection, respirators, and safety footwear.

For fire safety, this might involve sprinkler systems (engineering), fire drills (administrative), and fire-resistant clothing (PPE). For chemical handling, it could include engineering controls like ventilation, administrative controls like safe handling procedures, and PPE like gloves and respirators.

Q 14. Describe your experience with implementing safety controls and preventive measures.

Implementing safety controls and preventive measures involves a systematic approach that considers the hierarchy of controls (elimination, substitution, engineering, administrative, PPE). It’s like building a house – you start with the foundation (elimination) and then add layers of protection (substitution, engineering, etc.). My experience includes:

- Developing and Implementing Safe Work Procedures (SWPs): Creating step-by-step instructions for performing high-risk tasks, ensuring consistency and reducing the potential for error.

- Lockout/Tagout (LOTO) Program Implementation: Implementing a comprehensive LOTO program to prevent accidental energy releases during maintenance or repair activities.

- Machine Guarding: Ensuring that all machinery is properly guarded to prevent contact injuries.

- Ergonomic Assessments and Improvements: Evaluating workstations to identify and mitigate ergonomic risks, such as repetitive strain injuries.

- Developing and Delivering Safety Training Programs: Creating and delivering comprehensive training programs on various safety topics, ensuring that workers are properly trained and understand safe work practices.

- Regular Safety Inspections: Conducting regular inspections of the workplace to identify and address hazards before they lead to accidents.

In a previous role, I implemented a new machine guarding system that significantly reduced the risk of hand injuries, leading to a substantial decrease in workplace accidents. The success of this implementation involved collaboration with engineers, operators, and maintenance personnel to ensure that the new system was both effective and practical.

Q 15. How do you handle conflicts or resistance to safety initiatives?

Addressing resistance to safety initiatives requires a multifaceted approach. It’s not just about enforcing rules, but about building a safety culture where everyone feels responsible and valued. My strategy starts with open communication. I hold regular meetings to explain the why behind safety protocols, using clear, non-technical language and addressing concerns directly. If someone feels a safety measure is impractical, I’ll actively listen and explore alternatives together. For example, if a team resists wearing specific PPE due to discomfort, I’d research alternative PPE options that meet safety standards but offer better comfort. Building trust is key. I demonstrate my commitment to safety by actively participating in safety practices and acknowledging any lapses in the system, not just the individuals’ actions. Positive reinforcement also plays a critical role. I publicly acknowledge and reward employees who consistently prioritize safety, creating a positive feedback loop.

Ultimately, successful safety implementation involves engaging hearts and minds, not just bodies. It’s about fostering a shared sense of responsibility where everyone sees safety not as a burden, but as a collective endeavor to protect each other and create a safer workplace.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your strategies for monitoring and evaluating worker performance in relation to safety?

Monitoring and evaluating worker safety performance goes beyond simply checking for compliance. It requires a balanced approach combining observation, data analysis, and feedback. I utilize a variety of methods, including regular safety audits and observations of work practices to identify potential hazards and ensure adherence to safety protocols. Data analysis of incident reports, near-miss reports, and safety training records helps identify trends and areas needing improvement. For example, a spike in near-miss incidents involving a specific piece of equipment might signal a need for additional training or a review of the equipment’s safety features.

Feedback is crucial. I provide regular constructive feedback to workers, both individually and as a team, highlighting both successes and areas for improvement. This feedback should be specific, actionable, and focused on improvement. I also incorporate employee feedback into the continuous improvement cycle of our safety program. By combining observation, data-driven insights, and constructive feedback, we can build a system that fosters continuous improvement in worker safety performance.

Q 17. Explain your understanding of lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are critical for preventing accidental energization or startup of machinery during maintenance or repair. These procedures ensure that energy sources are isolated and equipment is rendered inoperable before any work begins. My understanding encompasses the entire LOTO process, from identifying energy sources (electrical, mechanical, hydraulic, pneumatic, etc.) to the proper application of locks and tags, verification procedures, and the safe release of the equipment after work is complete. Each step is crucial. The process usually involves:

- Energy Isolation: Shutting off and physically disconnecting all energy sources to the equipment.

- Lockout: Applying a personal lock to the energy isolating device, preventing accidental re-energization.

- Tagout: Attaching a tag clearly identifying the worker performing the lockout and the reason for the lockout.

- Verification: Confirming that the energy source is isolated and equipment is de-energized through appropriate testing methods.

- Release: Following a systematic process for removing locks and tags, ensuring all personnel are clear from the equipment before re-energization.

Thorough training and regular practice drills are vital to ensuring that all workers understand and correctly apply LOTO procedures. Failure to follow LOTO procedures can lead to serious injury or even death.

Q 18. Describe your experience with personal protective equipment (PPE) selection and usage.

Selecting and using appropriate Personal Protective Equipment (PPE) is fundamental to workplace safety. My experience covers the entire process: hazard identification, PPE selection, training on proper use and maintenance, and ensuring compliance. I begin by conducting a thorough hazard assessment to identify the specific risks faced by workers, such as chemical exposure, impact hazards, or hearing damage. Then, I select appropriate PPE that meets relevant safety standards and is comfortable and practical for workers to use. For example, if workers are exposed to high-noise levels, I’d recommend and ensure they use appropriate hearing protection, and if handling chemicals, appropriate gloves and eye protection.

It’s equally important to train workers on the correct selection, donning, doffing, inspection, maintenance, and disposal of PPE. Regular inspections are also conducted to ensure PPE is in good working order and is being used consistently. I emphasize the importance of reporting any damage or malfunction of PPE immediately so it can be replaced.

Q 19. How do you stay up-to-date with changes in safety regulations and best practices?

Staying current with safety regulations and best practices is a continuous process. I actively participate in professional organizations such as OSHA (Occupational Safety and Health Administration) and subscribe to industry-specific publications and newsletters. Attending safety conferences and workshops provides valuable opportunities to network with other safety professionals and learn about new technologies and methodologies. I also regularly review relevant legislation and guidelines issued by regulatory bodies to ensure our safety program remains compliant and up-to-date. Online resources, professional development courses, and industry-specific journals are also crucial tools. For example, OSHA’s website is a primary source for updated regulations and guidance.

This proactive approach ensures that our safety program isn’t just meeting minimum standards but is constantly evolving to meet the latest safety challenges and improve overall safety performance.

Q 20. How do you ensure the proper documentation and record-keeping for safety activities?

Proper documentation and record-keeping are essential for demonstrating compliance and providing valuable insights into safety performance. We utilize a comprehensive system for tracking all safety-related activities, including incident reports, near-miss reports, safety training records, inspections, and audits. This involves detailed documentation of each incident, including a description of the event, contributing factors, corrective actions taken, and any resulting injuries. Near-miss reports are equally important as they reveal potential hazards that could lead to future incidents. The goal is to learn from past events and prevent recurrence.

Our system is designed to be easily accessible and searchable, allowing for efficient retrieval of information for audits, investigations, and continuous improvement efforts. We maintain physical and digital copies of all records to ensure data security and accessibility. All records are securely stored and managed in accordance with applicable data privacy regulations.

Q 21. How do you manage the integration of safety considerations into project planning and execution?

Integrating safety considerations into project planning and execution is not an afterthought; it’s a fundamental element from the initial concept phase. I advocate for a proactive approach where safety is a priority throughout the entire project lifecycle. This starts with a detailed hazard assessment, identifying potential risks associated with each phase of the project. Based on this assessment, we develop a comprehensive safety plan that addresses potential hazards and outlines preventative measures. This plan includes specific safety protocols, training requirements, emergency procedures, and PPE requirements.

During project execution, regular safety meetings and inspections are conducted to monitor progress and ensure compliance with the safety plan. Workers are empowered to raise safety concerns without fear of reprisal, and any identified hazards are addressed promptly and effectively. Regular reviews of the safety plan ensure that it remains relevant and effective throughout the duration of the project. By integrating safety throughout the project lifecycle, we ensure a safer working environment and minimize the risk of accidents and incidents.

Q 22. Describe your experience with safety software and data analysis tools.

My experience with safety software and data analysis tools is extensive. I’m proficient in using several platforms for incident tracking, risk assessment, and safety training management. For example, I’ve utilized software like

SafetySync for incident reporting and analysis, allowing me to track trends, identify root causes, and measure the effectiveness of implemented safety measures. I’m also experienced with using data visualization tools like Tableau and Power BI to create dashboards that provide a clear overview of safety performance indicators, such as injury rates, near misses, and audit findings. This allows for quick identification of areas needing attention. Furthermore, my experience extends to using software for conducting job hazard analyses (JHAs) and developing safety training programs. I understand the importance of data integrity and ensuring accurate data collection for meaningful insights, and I am adept at designing and implementing data-driven safety strategies.

Q 23. How would you address a scenario with a high-risk situation that needs immediate action?

Addressing high-risk situations demanding immediate action requires a structured approach. My first step is always to ensure the safety of everyone involved. This might involve evacuating personnel, shutting down equipment, or establishing a secure perimeter. Simultaneously, I’d initiate a rapid risk assessment, identifying immediate hazards and prioritizing actions to mitigate them. Imagine a scenario where a chemical spill occurs. First, I would immediately cordon off the area, alert emergency services, and evacuate personnel. Then, I’d implement the emergency response plan specifically designed for chemical spills – this includes using appropriate Personal Protective Equipment (PPE) and employing containment and cleanup procedures outlined in the plan. Next, I’d initiate a thorough investigation to determine the root cause of the spill, focusing on prevention for future incidents. Post-incident, a debrief would be held to review the response, identify any shortcomings and make improvements to the emergency response plan and procedures. Open communication is crucial throughout the process; workers need to feel safe and involved in the recovery.

Q 24. Describe your experience in creating and implementing safety policies.

My experience in creating and implementing safety policies spans various industries and organizational structures. I follow a phased approach, starting with a thorough hazard identification and risk assessment process. This involves consulting with subject matter experts, reviewing industry best practices, and analyzing historical incident data. Once hazards are identified and risks assessed, I develop policies and procedures addressing each hazard, including controls and mitigation strategies. These policies are clearly documented, ensuring they are easily understood and accessible to all employees. For example, in developing a policy regarding working at heights, I would incorporate specific requirements for fall protection equipment, training programs, and inspection schedules. After implementation, regular audits and reviews are conducted to assess the effectiveness of the policies and make necessary adjustments. This iterative process ensures policies remain relevant and effective, and workers are trained on their use.

Q 25. How do you involve workers in safety planning and decision-making processes?

Involving workers in safety planning and decision-making is paramount. I firmly believe that a safe work environment is built collaboratively. I employ several techniques to ensure worker participation. Firstly, I conduct regular safety meetings and toolbox talks, providing platforms for workers to voice concerns, suggest improvements, and share near-miss experiences. Secondly, I actively seek feedback through surveys and suggestion boxes to identify areas needing attention and address latent safety issues. Thirdly, I involve workers in the development and review of safety procedures, allowing their practical experience to inform the creation of effective and realistic guidelines. For instance, when developing a new safety procedure for machinery operation, I would involve the operators themselves in the discussion to capture their insights and ensure the procedure is both safe and practical to follow. This participatory approach fosters ownership, improves compliance, and leads to a safer and more productive work environment.

Q 26. What are the key performance indicators (KPIs) you track to monitor safety performance?

The key performance indicators (KPIs) I track to monitor safety performance are multifaceted, reflecting both lagging and leading indicators. Lagging indicators measure past performance and include:

- Total Recordable Incident Rate (TRIR)

- Lost Time Incident Rate (LTIR)

- Days Away, Restricted, or Transferred (DART) rate

- Number of safety observations conducted

- Number of near misses reported

- Employee safety training completion rates

- Number of safety audits conducted and findings

Q 27. How do you manage safety during remote work or field operations?

Managing safety during remote work or field operations requires a proactive and adaptable approach. For remote workers, this means providing clear safety guidelines, including ergonomic recommendations for home workstations and cybersecurity best practices. Regular check-ins and virtual safety training sessions are crucial. For field operations, the focus is on providing proper equipment, personal protective equipment (PPE), and comprehensive risk assessments for each job site. Real-time communication technologies and GPS tracking can enhance safety monitoring and emergency response. For example, if a field worker is working in a remote location, I’d ensure they have satellite communication devices, proper protective gear, and a detailed emergency action plan. Regular communication and well-defined procedures are critical to maintaining safety standards when employees are working outside of a traditional office environment.

Q 28. Explain your understanding of incident reporting and investigation procedures.

Incident reporting and investigation procedures are fundamental to a robust safety management system. I ensure that a clear and accessible reporting system is in place, encouraging employees to report all incidents, no matter how minor. Investigations should be thorough and impartial, aiming to identify the root cause of the incident, not just the immediate cause. I utilize a structured investigative approach, often incorporating techniques such as the “5 Whys” to delve deeper into the reasons behind the incident. The investigation findings are documented meticulously, including photos, witness statements, and analysis of contributing factors. Corrective actions are then developed and implemented to prevent similar incidents from occurring in the future. Finally, a post-incident review is conducted to evaluate the effectiveness of the investigation, the implemented corrective actions, and the overall safety management system. The goal is continuous improvement – learning from each incident to strengthen the organization’s safety culture.

Key Topics to Learn for Developing and Implementing Safety Plans Interview

- Hazard Identification and Risk Assessment: Understanding methods like HAZOP, FMEA, and JSA to proactively identify potential hazards and assess their risks. Practical application: Developing a risk assessment matrix for a specific workplace scenario.

- Safety Plan Development: Creating comprehensive safety plans encompassing preventative measures, emergency procedures, and communication strategies. Practical application: Designing a safety plan for a construction site or manufacturing facility, considering legal compliance and best practices.

- Emergency Response Planning: Designing and implementing effective emergency response procedures, including evacuation plans, first aid protocols, and communication systems. Practical application: Developing a detailed response plan for a chemical spill or fire.

- Safety Training and Communication: Developing and delivering effective safety training programs to employees, ensuring understanding and compliance. Practical application: Creating training materials and conducting training sessions on specific safety regulations or procedures.

- Regulatory Compliance: Understanding and adhering to relevant safety regulations, standards, and legislation. Practical application: Ensuring a workplace complies with OSHA regulations or industry-specific safety standards.

- Incident Investigation and Reporting: Conducting thorough investigations into workplace incidents, identifying root causes, and implementing corrective actions. Practical application: Analyzing a near-miss incident to prevent future occurrences.

- Safety Auditing and Inspections: Conducting regular safety audits and inspections to identify potential hazards and ensure compliance with safety regulations. Practical application: Developing a checklist for regular safety inspections and reporting findings.

- Personal Protective Equipment (PPE): Selecting, using, and maintaining appropriate PPE to mitigate risks. Practical application: Specifying the required PPE for different tasks and ensuring proper training on its use.

Next Steps

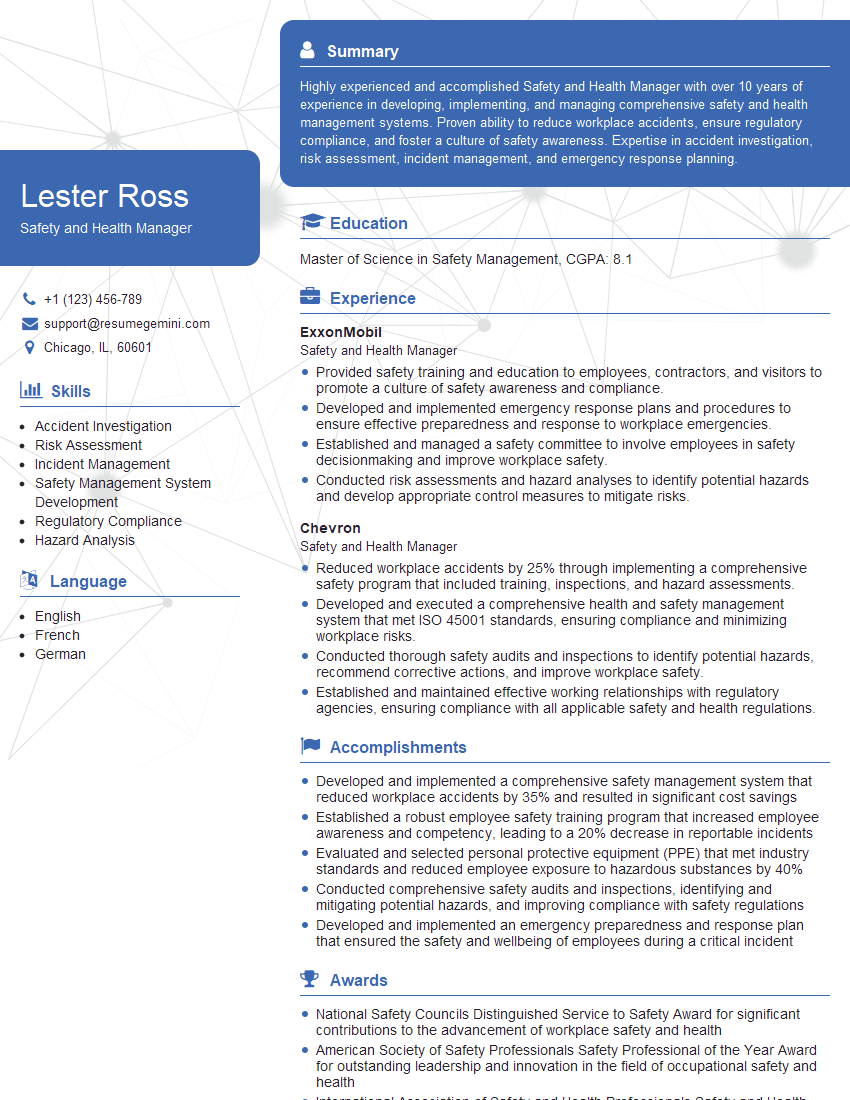

Mastering the development and implementation of safety plans is crucial for career advancement in many industries, demonstrating your commitment to workplace safety and proactive risk management. A strong resume is essential to showcase these skills effectively. Crafting an ATS-friendly resume significantly increases your chances of getting your application noticed. We recommend using ResumeGemini to build a professional and impactful resume tailored to highlight your expertise in developing and implementing safety plans. Examples of resumes tailored to this field are available to help guide you. Invest time in crafting a compelling resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good