The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Stage Equipment and Instrument Maintenance interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Stage Equipment and Instrument Maintenance Interview

Q 1. Describe your experience maintaining stage lighting equipment.

Maintaining stage lighting equipment involves a multifaceted approach encompassing preventative maintenance, troubleshooting, and repair. My experience includes working with a wide range of fixtures, from basic incandescent and halogen lamps to sophisticated LED and moving head units. Preventative maintenance consists of regular inspections – checking connections, ensuring proper ventilation to prevent overheating, and cleaning lenses and reflectors to maintain optimal light output. I regularly test DMX channels and data lines for signal integrity, and ensure the proper functioning of safety features like ground connections and circuit breakers.

For example, during a recent production, I noticed a gradual dimming of several LED PAR cans. Through systematic checks, I identified a faulty power distribution unit, and promptly replaced it preventing a significant disruption to the show. My experience also includes replacing bulbs, cleaning filters, and performing minor repairs like replacing damaged cables or connectors. I’m proficient in working with both analog and digital lighting control systems, ensuring smooth operation and accurate color mixing.

Q 2. How do you troubleshoot a faulty microphone?

Troubleshooting a faulty microphone begins with a methodical approach. First, I visually inspect the microphone for any obvious damage such as a broken cable, cracked casing, or loose connections. Then, I’ll check the microphone’s power source – ensuring it’s properly connected and receiving power if it’s a condenser mic. Next, I check the audio mixer or interface to confirm the microphone channel is correctly selected and the gain is properly set. A common issue is simply a muted channel or insufficient gain. If the problem persists, I’ll use a known working microphone on the same channel and setup to isolate the issue.

If the problem is still present after checking the cabling and connections, I will use a multimeter to check the continuity of the microphone cable and test the microphone’s output signal. If the microphone is still faulty, I would then swap it out to rule out external interference and to maintain the quality of the performance.

Q 3. Explain the process of rigging a heavy lighting fixture.

Rigging a heavy lighting fixture is a crucial aspect of stage production that requires meticulous attention to safety and proper techniques. It’s never a solo task. It always involves at least two trained riggers. The process starts with a thorough risk assessment, considering the weight of the fixture, the type of rigging hardware, and the load-bearing capacity of the structure. We use pre-calculated rigging plans detailing the load distribution, points of attachment, and safety factors. All equipment undergoes a rigorous safety check before use – looking for signs of wear, damage, or corrosion.

We then use appropriate lifting equipment such as chain motors, counterweights, and safety lines to safely hoist the fixture into position. The fixture is secured using multiple attachment points, ensuring redundancy and stability. Each connection is double-checked and inspected to ensure it is secure. Following hoisting, we conduct a final weight test before the fixture is fully operational. Safety lines are always utilized as a backup measure and the entire process adheres strictly to industry best practices and safety regulations.

Q 4. What safety procedures do you follow when working with stage equipment?

Safety is paramount when working with stage equipment. My approach is grounded in adherence to strict safety regulations and industry best practices. This includes regular equipment inspections for wear and tear, proper grounding of electrical equipment to prevent shocks, using appropriate Personal Protective Equipment (PPE) like gloves and safety glasses, and following lock-out/tag-out procedures when working with electrical systems. I always ensure that sufficient space is maintained around equipment to prevent accidents and utilize proper lifting techniques to prevent injuries during manual handling of equipment.

Before every event, I conduct a thorough safety briefing with the crew, emphasizing the importance of following established protocols. Furthermore, I participate in regular safety training sessions to stay updated on the latest industry practices and to understand the potential hazards associated with the equipment we are working with. In particular, I always maintain a thorough understanding of weight limits and proper load-bearing capabilities of all equipment.

Q 5. How do you maintain the sound system’s clarity and balance?

Maintaining the clarity and balance of a sound system requires a combination of technical skills and artistic judgment. It starts with proper microphone placement and selection, ensuring that each instrument and vocal is captured effectively. EQ (equalization) is crucial for shaping the sound – removing muddiness in the low frequencies or harshness in the highs. This is a balance; too much EQ can cause a loss of the natural sound. I frequently use graphic EQs and parametric EQs to shape each channel’s frequency response.

Gain staging is equally important; setting appropriate input and output levels prevents distortion and clipping. I always use a sound level meter to monitor and adjust levels across different instruments and channels to ensure consistent sound across the performance. Additionally, I use digital audio workstations (DAWs) to fine tune and balance the output based on the specific venue and its acoustics and often perform room tuning to address acoustic imbalances.

Q 6. What are the common causes of audio feedback, and how do you address them?

Audio feedback, that ear-piercing squeal, is caused by a positive feedback loop where sound from a loudspeaker is picked up by a microphone and amplified again, creating a reinforcing cycle. Common causes include: microphones placed too close to speakers, excessive microphone gain, improper speaker placement, and acoustic reflections within the room.

Addressing feedback involves a multi-pronged approach: reducing microphone gain, adjusting EQ to cut frequencies causing feedback, repositioning microphones away from speakers, using directional microphones, and implementing feedback suppression systems. Sometimes, strategically placing sound absorption materials around the room helps to reduce reflections. It’s an iterative process; adjustments may need to be made based on the acoustic characteristics of the specific venue.

Q 7. Describe your experience with different types of stage lighting instruments.

My experience spans a wide range of stage lighting instruments, including incandescent and halogen ellipsoidals for precise beam control, LED PAR cans for wash lighting and color mixing, moving head fixtures for dynamic effects, and profile spotlights for focused illumination. I’m comfortable working with both conventional and intelligent lighting systems. I understand the differences in their color temperatures, light output, and control methods. I’m also familiar with the use of gels and filters to modify the color of light, and the use of gobo patterns to create interesting shapes and designs.

For example, I’ve extensively used LED fixtures to create energy-efficient and vibrant lighting designs for concerts and theatrical productions. For a recent musical, I utilized a combination of moving head fixtures and profile spotlights to create dynamic and focused lighting effects, enhancing the storytelling and atmosphere of the performance. My expertise extends to the use of lighting control consoles and software for programming and managing complex lighting sequences.

Q 8. Explain your knowledge of different types of cables and connectors used in audio and video systems.

Understanding different cable types and connectors is fundamental in audio and video. The wrong cable can lead to signal loss, noise, or even equipment damage. Let’s break down some key examples:

- Audio Cables:

- XLR (Cannon): Primarily used for balanced audio signals, minimizing noise interference. Commonly found in microphones, speakers, and mixing consoles. They have three pins: 1 (ground), 2 (+), and 3 (-).

- TRS (1/4 inch): Can be balanced or unbalanced, often used for instruments, headphones, and line-level audio. Balanced TRS cables use a tip, ring, and sleeve to carry the positive, negative, and ground signals respectively. Unbalanced only use tip and sleeve.

- RCA (Phono): Unbalanced, primarily for consumer audio like home stereos and older video equipment. These are susceptible to noise.

- USB: Digital audio transmission, increasingly common for high-quality audio interfaces and digital mixing consoles.

- Video Cables:

- HDMI: High-Definition Multimedia Interface, digital format carrying both audio and video signals. Widely used for high-resolution displays.

- DVI: Digital Visual Interface, digital video only. Common in professional video applications.

- SDI (Serial Digital Interface): Professional standard for transmitting uncompressed digital video signals over long distances with minimal loss.

- Composite/Component: Analog video formats; composite uses a single cable, while component uses separate cables for R, G, B.

Proper connector matching is crucial. For example, plugging an XLR microphone into a 1/4-inch input may result in a weak or no signal. Careful identification and use of the correct cables for each piece of equipment are paramount for reliable performance.

Q 9. How do you handle a malfunction during a live performance?

Handling malfunctions during a live performance requires quick thinking and a systematic approach. My first response is always to assess the situation: identify the problem (e.g., no sound from a specific microphone, flickering lights), determine its impact on the show, and gauge the urgency.

For example, if a microphone cuts out, I’d quickly check the cable connection, the microphone itself, and the channel on the mixer. If the issue is the microphone, I’d have a backup readily available. If it’s a cable issue, I’d have a replacement ready and quickly swap it. If the issue is the mixer channel, I’d attempt to isolate and troubleshoot while simultaneously communicating with the sound engineer to find an alternate routing method.

Communication with the performers and the sound/lighting engineer is key. A calm, clear explanation of the situation helps to avoid panic and ensures everyone is aware of the problem and the proposed solution. In some situations, a quick workaround, such as switching to a backup system, is the best approach. After the performance, I will take the time to fully diagnose and repair the original issue, preventing it from occurring again.

Q 10. What are your skills in diagnosing and repairing electrical faults in stage equipment?

Diagnosing and repairing electrical faults demands a methodical process coupled with a strong understanding of electrical principles. My approach involves a series of steps:

- Safety First: Always power down equipment before working on it. Use appropriate personal protective equipment (PPE).

- Visual Inspection: Check for obvious issues such as loose connections, damaged cables, or burnt components.

- Testing: Use multimeters to check voltage, continuity, and resistance. This helps pinpoint the source of the problem – a faulty capacitor, a broken wire, etc.

- Component Replacement: If necessary, I can replace faulty components with suitable replacements. This requires a thorough understanding of circuit boards and their components.

- Troubleshooting: If the fault is not immediately apparent, I’ll use a systematic approach to test different sections of the circuit to isolate the problem area.

For example, if a stage light isn’t working, I might first check the power supply, then the bulb, then the wiring connecting to the dimmer pack. My experience with soldering, using specialized tools like oscilloscopes, and interpreting schematics allows me to effectively troubleshoot and repair a wide range of electrical issues.

Q 11. Describe your experience working with different types of audio consoles.

I have extensive experience with various audio consoles, from small analog mixers to large-scale digital consoles. This includes:

- Analog Consoles: I’m proficient in operating and maintaining analog consoles, understanding concepts like gain staging, EQ, and aux sends. I’ve worked with both classic and modern analog designs from brands like Yamaha, Mackie, and Soundcraft.

- Digital Consoles: My experience extends to digital consoles from manufacturers like Digico, Avid, and Yamaha. I understand their advanced features like DAW integration, automation, and scene recall. I’m familiar with the software interfaces and their associated workflows.

My experience spans various applications, from live music and theatre to corporate events. I can adapt my approach to the specific needs of each console and event. I’m also comfortable with both the practical operation and the technical maintenance of these systems.

Q 12. Explain your experience with preventive maintenance of stage equipment.

Preventive maintenance is crucial for ensuring the longevity and reliability of stage equipment. My approach is proactive and encompasses several key practices:

- Regular Inspections: I perform regular visual inspections of all equipment, checking for wear and tear, loose connections, or any signs of damage.

- Cleaning: Regular cleaning removes dust and debris, which can affect performance and lifespan. This includes cleaning pots, faders, and connectors.

- Cable Management: Proper cable management prevents damage and ensures easy access during setup and troubleshooting.

- Calibration and Testing: Periodic calibration ensures accuracy and performance. I use testing equipment to verify the functionality of audio and lighting systems.

- Documentation: Maintaining comprehensive documentation of all maintenance procedures helps to track issues and prevent future problems.

For example, I’d develop a schedule for regularly testing and cleaning microphones, checking the connections on lighting fixtures, and ensuring the proper functioning of all cables and connectors. This approach helps to prevent unexpected failures during critical events and minimizes downtime.

Q 13. How do you prioritize tasks during a busy show setup or teardown?

Prioritizing tasks during a busy show setup or teardown is critical for efficiency. My approach is based on a combination of planning and situational awareness:

- Pre-Show Planning: A detailed run sheet, outlining all tasks in the order of priority, helps me anticipate potential bottlenecks.

- Critical Path Analysis: I identify tasks that are essential for the show to proceed (e.g., setting up the main PA system) and prioritize them accordingly.

- Teamwork and Communication: Effective communication with my team allows for parallel task execution. Clear assignments ensure everyone works efficiently.

- Flexibility: Unexpected issues can arise, requiring adjustments to the original plan. My flexibility allows me to adapt and re-prioritize tasks.

- Time Management: Setting realistic timeframes for each task allows for efficient use of time and resources.

During a quick turnaround, I’d focus on the essential elements, such as getting the main sound and lighting systems operational, and delegate tasks that are less critical to the start of the show. Then I can tackle the remaining items during any breaks.

Q 14. What software are you proficient in for controlling lighting or sound?

My proficiency in software for controlling lighting and sound encompasses a range of industry-standard applications:

- Lighting Consoles: I’m experienced in using lighting control software such as MA Lighting grandMA2, ETC EOS, and ChamSys MagicQ.

- Sound Consoles: I’m familiar with the software interfaces of various digital consoles, enabling me to configure and manage audio routing, processing, and automation. Examples include Digico SD series software, Avid Venue software and Yamaha CL/QL series software.

- Audio Editing Software: I have experience with DAWs (Digital Audio Workstations) like Pro Tools, Logic Pro X, and Ableton Live, though this is more for post-production and less about live control.

This knowledge allows me to program and operate complex lighting and sound designs effectively, adapt to various software environments, and utilize the advanced features offered by these systems. I am always eager to learn and adapt to new software and updates.

Q 15. Describe your experience with automated curtain systems and their maintenance.

Automated curtain systems, ranging from simple electric tracks to complex counterweight systems, are crucial for efficient scene changes. My experience encompasses installation, troubleshooting, and preventative maintenance of various types. This includes regular lubrication of moving parts, inspecting safety mechanisms like limit switches and emergency stops, and testing the motor and control systems for smooth and reliable operation. For example, I once diagnosed a malfunctioning system by identifying a loose wire in the control box after systematically checking the power supply, motor, and track components. Regular preventative maintenance, like cleaning dust and debris from the tracks and checking the tension of the curtain itself, prevents more serious and costly repairs.

- Regular Inspections: Weekly visual checks for wear and tear, including track alignment and cable integrity.

- Lubrication: Monthly lubrication of moving parts to ensure smooth operation and reduce friction.

- Safety Checks: Quarterly testing of limit switches and emergency stop mechanisms to ensure they function correctly.

- System Testing: Complete system testing, including full-range operation, at least twice a year.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the safety of performers and audience members during a show?

Ensuring safety is paramount. My approach is proactive and multi-layered, starting with pre-show inspections of all equipment – from rigging to lighting to sound – to identify and rectify any potential hazards. I meticulously check weight limits on rigging systems and ensure that all safety mechanisms, such as safety chains and locking mechanisms, are correctly engaged. Clear communication with the stage manager and production crew is crucial. For example, we use a color-coded system for indicating the status of equipment (green for operational, yellow for caution, red for unsafe), and I always conduct a thorough briefing with the crew before each performance highlighting any potential risks. For audience safety, I ensure that emergency exits are clear and properly lit and that any potential hazards in the audience area are addressed and secured.

Q 17. Explain your experience with different types of stage effects (e.g., smoke, haze).

My experience spans various stage effects, from low-lying fog to dense smoke and atmospheric haze. I’m proficient in operating and maintaining a range of machines, including fog machines, haze generators, and even specialized effects like snow machines. Understanding the different types of fluids and their compatibility with the equipment is critical. I always prioritize safety, ensuring proper ventilation and adhering to all relevant safety regulations when using these machines. For instance, I’ve had to troubleshoot a fog machine that was producing inconsistent output by cleaning its internal components and replacing its faulty heating element. Additionally, I’m knowledgeable about the environmental impact of these effects and always look for eco-friendly alternatives whenever possible.

Q 18. Describe your experience with maintaining video projectors and screens.

Maintaining video projectors and screens involves a multi-faceted approach. It starts with regular cleaning of the projector lenses and filters to maintain image clarity. I perform regular lamp replacements according to manufacturer recommendations and keep spare lamps on hand to avoid show interruptions. For screens, proper cleaning and inspection for damage are crucial. I also regularly check the projector’s alignment and calibration to ensure accurate image projection. In one instance, I resolved a problem with blurry projections by cleaning a heavily dust-laden filter, highlighting the importance of consistent preventative maintenance.

- Lens Cleaning: Regular cleaning of projector lenses using specialized lens cleaning solutions.

- Lamp Replacement: Proactive lamp replacement according to manufacturer’s specifications.

- Screen Inspection: Regular checks for tears, creases or discoloration.

- Calibration: Periodic calibration of projector settings to optimize image quality.

Q 19. How do you manage inventory and maintenance records for stage equipment?

I use a computerized inventory management system to track all stage equipment. This system allows for easy tracking of equipment location, maintenance history, and condition. Maintenance records are meticulously documented, including dates of service, repairs performed, and any parts replaced. This system enables efficient scheduling of preventative maintenance and quick identification of problematic equipment. The system also generates reports that help optimize inventory levels and identify potential cost savings through planned maintenance. A well-organized inventory management system is essential for efficient operation and reduces the risk of costly downtime due to equipment failure.

Q 20. What are the common problems associated with dimmer systems?

Dimmer systems, while vital, are prone to several issues. Faulty dimmer packs can cause inconsistent dimming curves or even complete failures. Loose connections, especially in older systems, are a common cause of flickering or intermittent dimming. Overheating is another concern, often due to inadequate ventilation or overloaded circuits. Preventative maintenance, including regular inspections of wiring, connections and thermal checks, is crucial. I have personally addressed such issues by replacing faulty components, upgrading outdated systems, and implementing improved ventilation strategies. Proactive maintenance prevents costly show interruptions and ensures the safety of the electrical system.

Q 21. How do you test and calibrate audio equipment?

Testing and calibrating audio equipment involves a systematic approach. I begin by visually inspecting the equipment for any damage. Then, I use specialized test equipment like signal generators and oscilloscopes to measure signal levels, frequency response, and distortion. Calibration involves adjusting settings to meet industry standards and ensure optimal performance. This can involve aligning levels across different channels and adjusting equalization settings. For example, I recently calibrated a sound system using pink noise and a spectrum analyzer to ensure a flat frequency response throughout the venue. Accurate calibration is critical for achieving a clear, balanced and consistent sound throughout the venue.

Q 22. Explain your understanding of signal flow in audio and video systems.

Signal flow, in both audio and video systems, refers to the path a signal takes from its source to its final destination. Think of it like a river flowing from its source to the sea. In audio, the source might be a microphone, and the destination might be speakers. In video, the source could be a camera, and the destination a projector or screen. Understanding signal flow is crucial for troubleshooting and optimizing system performance.

Audio Signal Flow Example: A singer’s voice (source) is picked up by a microphone (input), amplified by a mixer (processing), sent through an equalizer (processing), routed to a digital audio workstation (DAW; processing), processed further, and finally sent to power amplifiers (processing) and then to loudspeakers (output). Any break or malfunction along this path will interrupt the signal.

Video Signal Flow Example: A camera (source) captures video and sends it to a switcher (processing), which selects the appropriate camera feed. This signal then goes to a video processor (processing), which adjusts brightness, contrast, etc. Finally, it’s sent to a projector or display (output).

Proper signal flow is essential for clear audio and video. Issues like hum, feedback, or signal loss often indicate problems within the signal path. A clear understanding helps identify the source of these issues quickly.

Q 23. What are the differences between various types of microphones and their applications?

Microphones are classified in many ways, but the most common distinctions are based on their transduction principle (how they convert sound waves into electrical signals) and polar pattern (their sensitivity to sound from different directions).

- Dynamic Microphones: These are robust, handle high sound pressure levels well, and require no external power. They’re ideal for live sound reinforcement and recording loud instruments like drums or amps. Example: Shure SM58.

- Condenser Microphones: These are more sensitive and offer a wider frequency response, making them suitable for capturing subtle nuances in vocals and acoustic instruments. They typically require phantom power (48V). Example: Neumann U 87.

- Ribbon Microphones: These produce a warm, natural sound with a unique character, often used for recording instruments like guitars and horns. They are generally more fragile and less resistant to high sound pressure levels. Example: Royer R-121.

Polar Patterns: These dictate how sensitive the microphone is to sound coming from various directions.

- Cardioid: Most common; highly sensitive to sound from the front, less sensitive from the sides and rear, reducing feedback.

- Omnidirectional: Equally sensitive to sound from all directions; useful for capturing ambient sound.

- Figure-8: Equally sensitive to sound from front and rear, rejecting sound from the sides; used for specific recording techniques.

The choice of microphone depends heavily on the application. For instance, a dynamic cardioid microphone is perfect for live vocals, while a condenser microphone with a cardioid or figure-8 pattern might be preferred for recording delicate acoustic instruments in a studio.

Q 24. How do you ensure compliance with safety regulations and standards in your work?

Safety is paramount in stage equipment and instrument maintenance. I strictly adhere to all relevant safety regulations and standards, including those set by OSHA (Occupational Safety and Health Administration), local electrical codes, and equipment manufacturer guidelines.

My approach includes:

- Regular Safety Inspections: I perform thorough inspections of all equipment before each event, checking for frayed wires, damaged plugs, exposed wiring, and any other potential hazards. This involves visual inspection and testing equipment with appropriate tools.

- Lockout/Tagout Procedures: When working on electrical equipment, I always follow proper lockout/tagout procedures to prevent accidental energization. This ensures safety for myself and others.

- Proper Grounding and Earthing: I ensure all equipment is properly grounded to prevent electrical shocks and reduce noise interference. This is crucial for both the safety of personnel and the quality of the signal.

- Safe Lifting Techniques: When handling heavy equipment, I use appropriate lifting techniques and, when necessary, employ lifting equipment to prevent injuries.

- Personal Protective Equipment (PPE): I consistently use appropriate PPE, such as safety glasses, hearing protection, and work gloves, as needed.

Documentation of all inspections and maintenance activities is meticulously maintained, ensuring accountability and tracing any potential issues.

Q 25. Describe your experience with troubleshooting and repairing video switching systems.

My experience with troubleshooting and repairing video switching systems encompasses a wide range of scenarios, from simple cable issues to complex software problems. I’m proficient in working with various switching systems, including both analog and digital, using different protocols such as SDI and HDMI.

My troubleshooting process generally follows these steps:

- Identify the problem: This involves pinpointing the exact nature of the malfunction – no signal, incorrect signal routing, distorted images, etc.

- Isolate the source: Systematically check each component, starting from the input devices (cameras) and moving toward the output (monitors or projectors). This often involves signal tracing, testing cables, and using test equipment.

- Test each component: Once a potential source of the problem is identified, thorough testing is performed to verify if it is indeed faulty. This could involve signal generators, oscilloscopes, and multimeters.

- Repair or replace: Based on the results of testing, the faulty components are either repaired or replaced, ensuring that replacements are compatible with the existing system.

- Verify the repair: After making repairs, a complete system check is performed to confirm that the issue has been successfully resolved and that there are no further repercussions.

I have experience working with various brands of switchers and have successfully diagnosed and repaired issues ranging from faulty input cards to software glitches and faulty control systems.

Q 26. What are the key differences between analog and digital audio systems?

The key difference between analog and digital audio systems lies in how they represent and transmit sound. Analog systems represent audio as continuous electrical signals that directly mirror the sound waves, while digital systems convert the audio into numerical data (bits) for processing and transmission.

- Analog Audio: Think of a vinyl record; the groove represents the sound wave continuously. Analog systems are susceptible to noise and degradation over time and distance due to signal loss and interference. They are generally warmer-sounding but can lack the dynamic range and precision of digital systems.

- Digital Audio: Think of an MP3 file; sound is broken down into discrete samples that are represented by numbers. Digital systems are resistant to noise and degradation and can be easily copied without loss of quality. They allow for higher precision, wider dynamic range, and more extensive signal processing capabilities, but might lack the warmth some associate with analog.

In professional settings, digital audio has become dominant due to its advantages, but analog equipment still plays a vital role, especially for achieving specific sonic characteristics. Many studios integrate both analog and digital elements to achieve a desired sound.

Q 27. Describe a time you had to deal with a challenging technical issue on a tight deadline.

During a large-scale outdoor concert, the main PA system experienced a complete audio failure 15 minutes before the headliner was due to take the stage. Panic ensued! The initial diagnostics pointed towards a power supply issue in the main amplifier rack, but the problem was not immediately apparent. The rack housed numerous high-power amplifiers, and replacing them one by one wasn’t feasible with the tight deadline.

Under extreme pressure, I implemented a systematic troubleshooting process: First, I isolated the power supply using multimeters to confirm it was faulty, then I used a spare PA system (designed for smaller venues) as a temporary solution. This involved rerouting signal cables from the main stage mixer to the backup system. We succeeded in having the headliner on stage with functioning audio 7 minutes after the failure. While the backup system offered compromised sound quality (due to capacity limitations), it prevented a complete show cancellation.

This experience highlighted the importance of having redundant systems, backup plans, and a methodical troubleshooting approach when facing unexpected equipment failure under pressure.

Q 28. How do you stay up-to-date with the latest technologies and trends in stage equipment?

Staying current in the rapidly evolving field of stage equipment and instrument maintenance requires a multifaceted approach:

- Industry Publications and Websites: I regularly read trade publications and visit reputable websites focused on professional audio and video technology. These resources provide updates on new products, technologies, and industry trends.

- Trade Shows and Conferences: Attending industry trade shows and conferences allows for direct interaction with manufacturers, seeing new products in action, and learning from experts’ presentations.

- Manufacturer Training and Certifications: I actively seek out training opportunities and certifications offered by leading manufacturers of stage equipment. This ensures my knowledge remains up to date with specific equipment.

- Online Courses and Webinars: Many online platforms offer courses and webinars on advanced topics in audio and video technology, allowing continuous professional development.

- Networking with Peers: Engaging with other professionals in the field, through online forums, professional organizations, or informal discussions, provides invaluable insights and shares best practices.

This continuous learning ensures that I’m prepared to address the challenges posed by new technologies and maintain my expertise in the evolving world of stage equipment.

Key Topics to Learn for Stage Equipment and Instrument Maintenance Interview

- Audio Systems: Understanding sound reinforcement principles, mixer operation, microphone techniques, troubleshooting common audio issues (feedback, distortion), and preventative maintenance procedures for PA systems and microphones.

- Lighting Systems: Familiarity with various lighting fixtures (LED, incandescent, moving lights), control consoles (conventional and digital), lighting design basics, troubleshooting lighting problems (faulty bulbs, dimmer issues), and safe handling of lighting equipment.

- Rigging and Safety: Knowledge of safe rigging practices, load calculations, proper use of lifting equipment (chain hoists, counterweights), understanding of weight limits, and adherence to safety regulations.

- Instrument Maintenance (Musical Instruments): Basic understanding of instrument setup, tuning, troubleshooting common issues (broken strings, loose parts), and preventative maintenance for various instruments (guitars, keyboards, drums).

- Preventive Maintenance Schedules: Developing and implementing preventative maintenance plans for stage equipment, understanding the importance of regular inspections, and documenting maintenance procedures.

- Troubleshooting and Problem Solving: Developing systematic approaches to diagnose and resolve technical issues, using diagnostic tools effectively, and documenting solutions for future reference.

- Health and Safety Regulations: Understanding and complying with relevant health and safety regulations for working with stage equipment and electrical systems.

- Working with Teams: Highlighting collaboration skills and experience working effectively in a team environment during setup, maintenance, and troubleshooting.

Next Steps

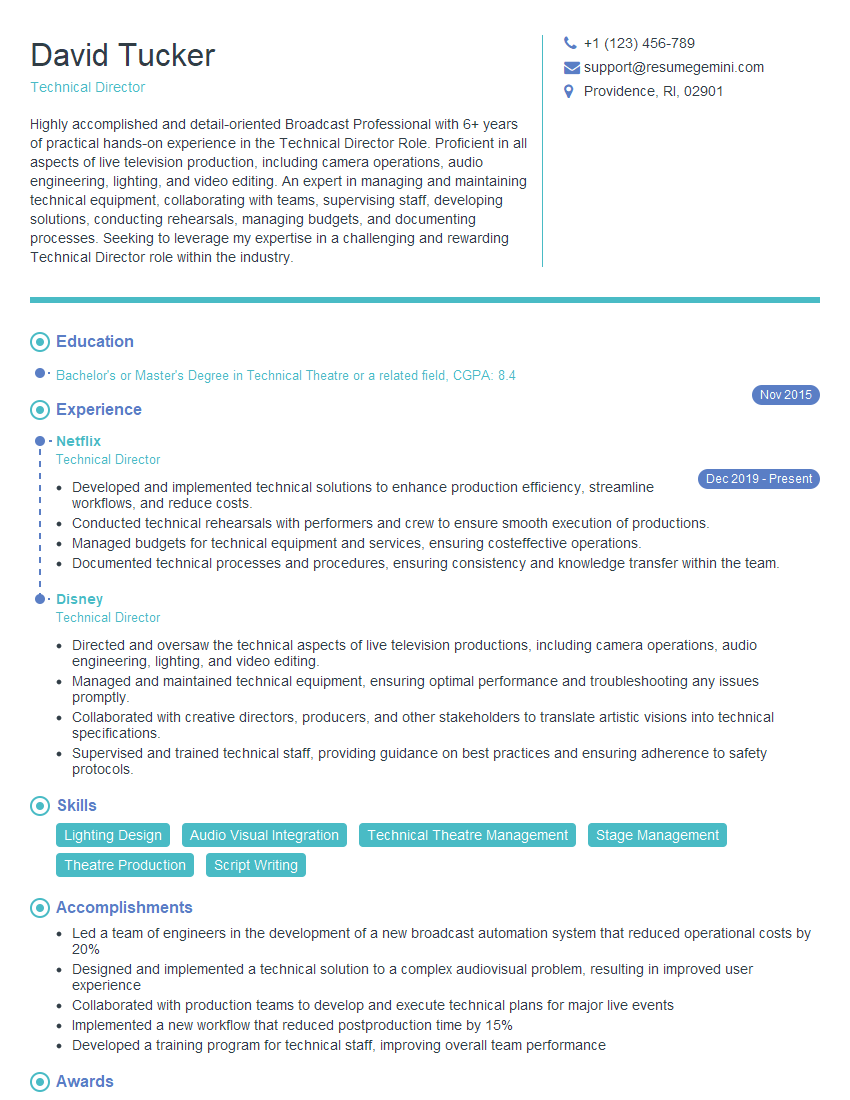

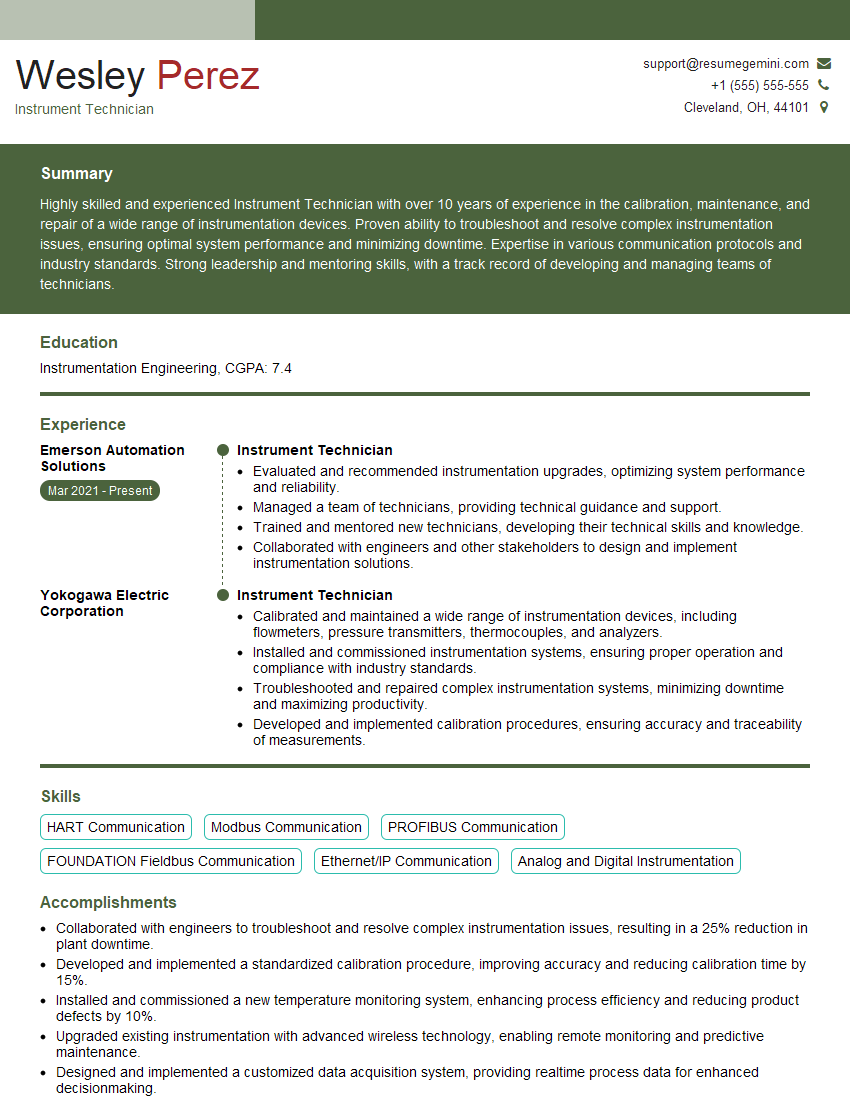

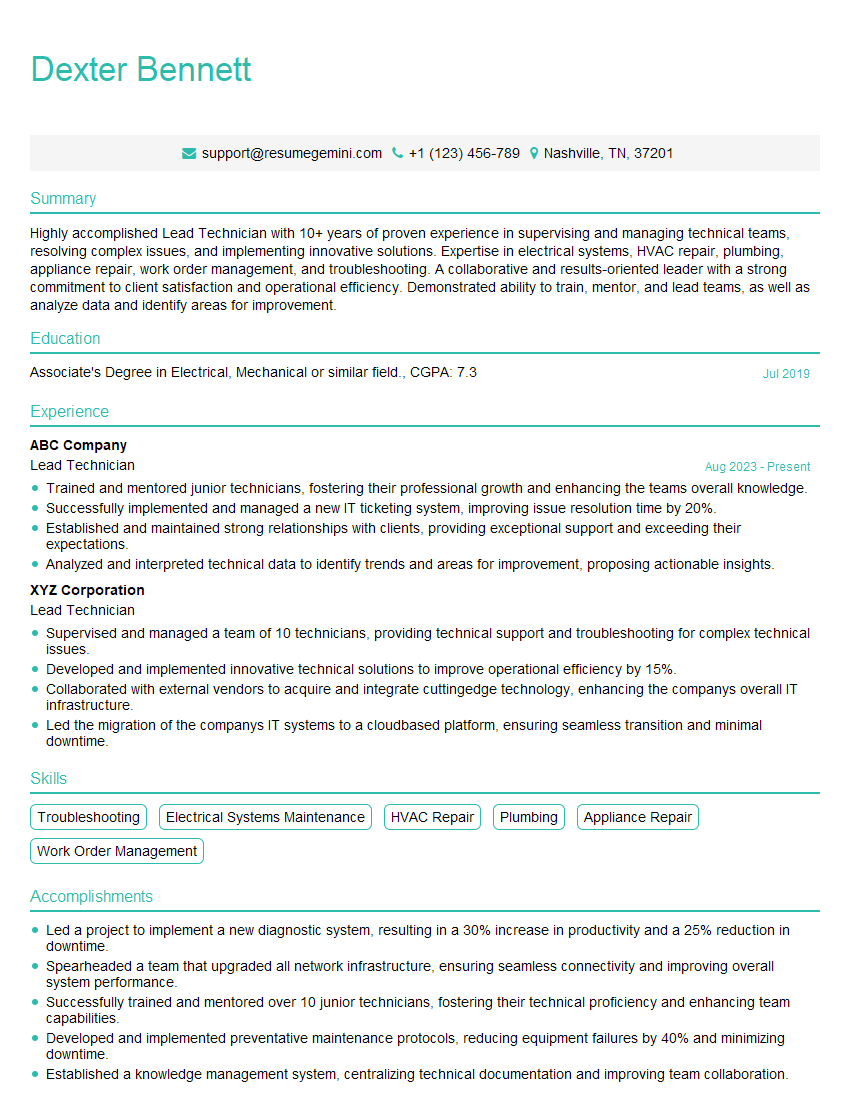

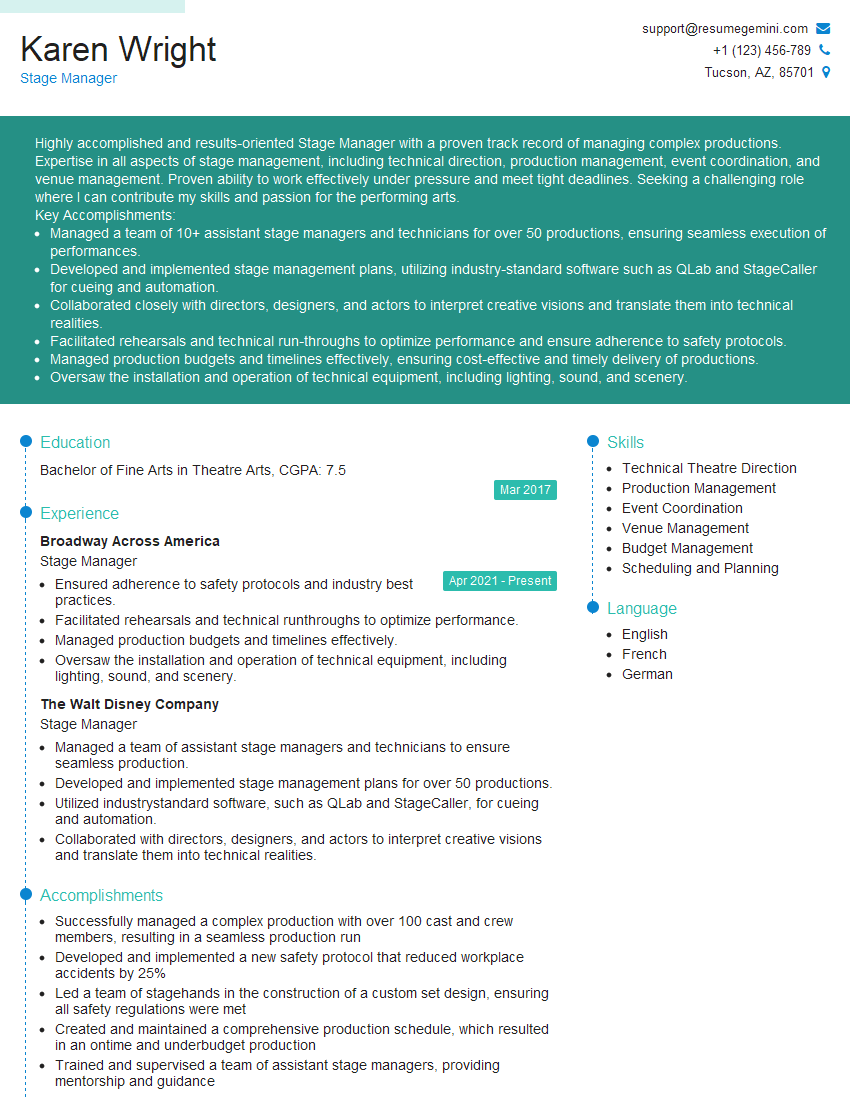

Mastering Stage Equipment and Instrument Maintenance opens doors to exciting careers in live events, theater, and music production. A strong understanding of these crucial skills significantly increases your employability and potential for career advancement. To stand out, create a compelling and ATS-friendly resume that showcases your expertise. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the demands of this competitive field. Examples of resumes specifically designed for Stage Equipment and Instrument Maintenance professionals are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good