Unlock your full potential by mastering the most common Renewable Energy Installation and Maintenance interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Renewable Energy Installation and Maintenance Interview

Q 1. Explain the different types of solar panels and their applications.

Solar panels, also known as photovoltaic (PV) panels, come in several types, each with its own strengths and weaknesses. The most common are monocrystalline, polycrystalline, and thin-film panels.

- Monocrystalline Silicon: These panels are made from a single silicon crystal, resulting in high efficiency (typically 18-22%) and a sleek, black appearance. They are ideal for high-performance applications where space is limited, such as rooftop installations in densely populated areas.

- Polycrystalline Silicon: Made from multiple silicon crystals, these panels are slightly less efficient (around 15-17%) than monocrystalline panels but are generally less expensive. Their blueish appearance is distinctive. They’re a good choice for larger-scale projects where cost-effectiveness is prioritized.

- Thin-Film Solar Panels: These panels use thin layers of photovoltaic material, such as amorphous silicon, cadmium telluride (CdTe), or copper indium gallium selenide (CIGS). They are flexible, lightweight, and can be integrated into various surfaces. However, their efficiency is generally lower (around 8-12%) than crystalline silicon panels. They find applications in building-integrated photovoltaics (BIPV) and in situations requiring flexibility.

The choice of panel type depends on factors like budget, available space, aesthetic preferences, and the specific energy needs of the application. For example, a homeowner with limited roof space might opt for high-efficiency monocrystalline panels, while a large-scale solar farm might favor the cost-effectiveness of polycrystalline panels.

Q 2. Describe the process of installing a grid-tied solar PV system.

Installing a grid-tied solar PV system involves several key steps. It’s a complex process requiring specialized knowledge and adherence to safety regulations.

- Site Assessment and Design: This involves analyzing the roof or land area for sun exposure, shading, and structural integrity. A system design is created based on energy needs and available space.

- Permitting and Inspections: Obtaining necessary permits from local authorities is crucial. Inspections ensure the system complies with safety codes.

- Mounting System Installation: This involves attaching the mounting racks to the roof or ground, ensuring structural stability and proper orientation towards the sun.

- Panel Installation: Solar panels are carefully mounted onto the racking system, ensuring proper connections and spacing for optimal performance and ventilation. Wiring is done neatly and securely.

- Wiring and Connections: PV panels are connected in series and parallel to create strings, which are then routed to the inverter. Careful attention to wiring diagrams is crucial to avoid errors.

- Inverter Installation: The inverter converts the DC electricity from the panels into AC electricity suitable for use in homes or businesses. It’s usually mounted indoors, in a protected and ventilated area.

- Electrical Connection to the Grid: The system is connected to the home’s electrical panel, usually through a specialized interconnection device, allowing for energy exchange with the grid.

- Testing and Commissioning: A thorough system check is performed to ensure proper functionality, including voltage, current, and power output measurements. This is often followed by an inspection by the utility company.

Throughout the entire process, meticulous attention to detail and adherence to safety protocols are paramount.

Q 3. What safety precautions are crucial during solar panel installation?

Safety is the top priority during solar panel installation. Neglecting safety precautions can lead to serious injuries or even fatalities. Some crucial precautions include:

- Roof Safety: Using proper fall protection equipment (harnesses, safety lines) is absolutely mandatory when working at heights. Roof anchors should be properly installed and inspected.

- Electrical Safety: Always de-energize circuits before working on them. Use appropriate personal protective equipment (PPE) like insulated gloves and safety glasses. Never work on energized systems.

- Tool Safety: Use tools in good condition and appropriate for the task. Proper storage and handling of tools are essential to avoid accidents.

- Weather Conditions: Avoid working during inclement weather, such as rain, snow, or high winds. Extreme temperatures can also pose risks.

- Fire Safety: Be aware of potential fire hazards associated with electrical work. Have a fire extinguisher readily available.

- Teamwork and Communication: Clear communication among team members is critical, particularly when working at heights or near energized equipment.

Following established safety procedures and adhering to all relevant codes and regulations are essential to ensure a safe working environment.

Q 4. How do you troubleshoot a malfunctioning solar inverter?

Troubleshooting a malfunctioning solar inverter requires a systematic approach. Here’s a step-by-step process:

- Check for obvious problems: Inspect the inverter for any physical damage, loose connections, or tripped circuit breakers. Look for any error codes displayed on the inverter’s screen.

- Verify power input: Measure the voltage and current at the input terminals of the inverter to ensure sufficient power is coming from the solar panels. A low input voltage or current could indicate a problem with the panels, wiring, or other components.

- Inspect the output: Check the voltage and current at the output terminals of the inverter. A lack of output suggests a fault within the inverter itself.

- Check ground connections: Ensure that the ground connections of the inverter and solar array are properly made and grounded to the earth.

- Consult the inverter manual: The manual often provides troubleshooting guides and diagnostic information for specific error codes. Understanding the error codes is crucial for identifying the problem.

- Contact a qualified technician: If the problem cannot be resolved using these steps, it’s best to contact a qualified solar technician to diagnose and repair the fault. Working with high-voltage systems requires expertise.

Remember, always prioritize safety when troubleshooting electrical equipment. Never attempt to repair an inverter unless you are properly trained and have the necessary safety equipment.

Q 5. Explain the working principle of a wind turbine.

Wind turbines convert the kinetic energy of wind into electricity. They work on a simple principle: the wind turns the blades, which are connected to a rotor. The rotor spins a generator, producing electricity.

Imagine a pinwheel. The wind pushes the blades, causing them to spin. In a wind turbine, this rotational energy is harnessed. The rotor is connected to a gearbox that increases the rotational speed, driving a generator that converts mechanical energy into electrical energy. This electricity is then sent to the grid via a transformer.

Different types of wind turbines exist, including horizontal-axis wind turbines (HAWTs) which are the most common type you see, and vertical-axis wind turbines (VAWTs), which have a vertical axis of rotation. The choice of turbine depends on factors like wind speed, site conditions, and cost.

Q 6. What are the common maintenance tasks for wind turbines?

Regular maintenance is essential for the optimal performance and longevity of wind turbines. Common tasks include:

- Blade inspections: Checking for cracks, erosion, damage from lightning strikes, or bird impacts.

- Gearbox lubrication: Regular oil changes and lubrication are crucial to prevent wear and tear.

- Generator maintenance: Regular checks for overheating, vibrations, and any signs of malfunction.

- Yaw system inspection: The yaw system keeps the turbine facing into the wind; regular checks ensure its proper function.

- Tower inspection: Checking for corrosion, structural damage, or loose bolts.

- Electrical system checks: Testing wiring, connections, and ensuring proper grounding to prevent electrical faults.

- Control system monitoring: Regular monitoring of turbine performance data through SCADA (Supervisory Control and Data Acquisition) systems.

A well-maintained wind turbine is more efficient, safer, and has a longer lifespan. Neglecting maintenance can lead to premature failure and costly repairs.

Q 7. How do you diagnose and repair a faulty wind turbine blade?

Diagnosing and repairing a faulty wind turbine blade requires specialized skills and equipment. The process involves several steps:

- Visual inspection: A thorough visual inspection is carried out to identify the location and extent of the damage. This may involve using drones or climbing the tower for a close-up examination.

- Non-destructive testing (NDT): Techniques such as ultrasonic testing or infrared thermography are used to assess the internal condition of the blade and detect hidden flaws.

- Damage assessment: Based on the inspection results, the extent of the damage is assessed. This determines the appropriate repair method.

- Repair options: Repair options range from minor repairs, such as filling small cracks, to more extensive repairs involving section replacement or even complete blade replacement. The choice of repair method depends on the severity of the damage and the blade’s design.

- Repair implementation: The chosen repair is carefully implemented, ensuring the structural integrity of the blade is restored.

- Post-repair inspection: After the repair, thorough inspections are carried out to verify the structural integrity and aerodynamic performance of the blade.

Repairing wind turbine blades is a complex task requiring specialized knowledge, specialized equipment, and adherence to strict safety protocols. It’s crucial to engage qualified technicians with the necessary expertise to ensure the safety and efficiency of the turbine.

Q 8. Describe the different types of batteries used in renewable energy storage systems.

Renewable energy storage systems rely on various battery technologies, each with its strengths and weaknesses. The choice depends on factors like cost, lifespan, power output, energy density, and environmental impact.

- Lead-acid batteries: These are mature, relatively inexpensive, and well-understood. However, they have a shorter lifespan and lower energy density compared to other options. Think of them as the workhorses – reliable but not the most efficient.

- Lithium-ion batteries: Currently the dominant technology for many applications due to their high energy density, long lifespan, and relatively fast charge/discharge rates. They are used in electric vehicles and are increasingly common in large-scale renewable energy storage. Think of these as the sports cars – high performance, but often more expensive.

- Flow batteries: These separate energy storage from power, offering scalability and long lifespans. They’re particularly suitable for large-scale, long-duration energy storage, making them ideal for grid-scale applications. Imagine them as a giant water tank – slowly releasing energy over a long period.

- Sodium-ion batteries: A promising emerging technology with lower cost and potentially more sustainable materials than lithium-ion. They’re still under development but are expected to compete in the market in the coming years. Consider them the up-and-coming technology, offering a potentially cheaper and more sustainable solution.

- Solid-state batteries: These utilize solid electrolytes instead of liquid ones, offering improved safety and potential for higher energy density. They are still in the relatively early stages of commercialization but hold significant promise for future applications.

Selecting the right battery type is crucial for system optimization and requires a detailed analysis of the specific project requirements.

Q 9. What are the key components of a geothermal energy system?

Geothermal energy systems utilize the Earth’s internal heat for energy production. Key components include:

- Resource Assessment and Exploration: Detailed geological surveys to identify suitable geothermal resources.

- Wells: Deep wells are drilled to access the hot water or steam. The drilling process itself is complex and requires specialized equipment and expertise.

- Heat Exchanger: The heat from the geothermal fluid is transferred to a working fluid (often water) in a heat exchanger, preventing direct contact between the geothermal fluid and the power generation equipment. This is crucial for efficiency and safety.

- Turbogenerator: The heated working fluid drives a turbine connected to a generator, producing electricity. This is similar to the process used in conventional power plants, but with a different heat source.

- Reinjection Well: After the heat extraction, the cooled geothermal fluid is usually reinjected back into the ground to maintain reservoir pressure and minimize environmental impact. This is an environmentally responsible practice that ensures the longevity of the resource.

- Power Conditioning Equipment: Transformers and other equipment to prepare the electricity for transmission to the grid.

The efficiency and lifespan of a geothermal system depend heavily on careful site selection, well design, and proper fluid management.

Q 10. Explain the process of commissioning a new renewable energy system.

Commissioning a renewable energy system is a critical process that ensures its proper functionality and compliance with safety standards. It involves several key stages:

- Pre-commissioning: This includes inspections, testing of individual components, and verification of installation according to the design specifications. Think of this as a final check before the system goes live.

- System Integration and Testing: Connecting all components and conducting thorough tests to verify the system’s integrated operation. This may involve simulating various operating conditions.

- Performance Testing: Measuring the system’s output and efficiency against design specifications under various operating conditions. This involves specialized equipment and data logging.

- Safety Inspections: Rigorous safety checks to ensure compliance with all relevant codes and standards. This might involve third-party inspections for regulatory compliance.

- Documentation and Handover: Complete documentation of the commissioning process, including test results and operational manuals. This ensures the smooth operation and maintenance of the system after handover.

A successful commissioning process minimizes operational issues and maximizes the system’s energy production and longevity. Any deficiencies identified during commissioning are rectified before the system is declared operational.

Q 11. How do you ensure the safety of workers during renewable energy system maintenance?

Worker safety is paramount during renewable energy system maintenance. A comprehensive safety plan is essential and includes:

- Lockout/Tagout Procedures: Strict procedures for de-energizing equipment to prevent accidental electric shocks. This is a critical safety measure to protect workers from energized systems.

- Personal Protective Equipment (PPE): Providing and enforcing the use of appropriate PPE, such as hard hats, safety glasses, high-voltage gloves, and fall protection equipment, depending on the task. PPE is the first line of defense for many hazards.

- Training and Competency: Ensuring that all workers are properly trained and certified to perform their tasks safely. This includes training on hazard identification and risk mitigation techniques.

- Safe Work Practices: Implementing and enforcing safe work practices, including proper lifting techniques, working at heights procedures, and confined space entry protocols. A focus on preventative measures is key.

- Emergency Response Plan: Developing and regularly practicing an emergency response plan that outlines procedures for handling accidents or emergencies. Emergency preparedness is crucial to minimizing the impact of any incident.

- Regular Inspections and Audits: Conducting regular safety inspections and audits to identify potential hazards and ensure compliance with safety regulations. A proactive approach is essential to identifying and rectifying potential issues.

Safety is a continuous process requiring vigilance and proactive measures to prevent accidents.

Q 12. What are the environmental considerations in renewable energy installation?

Environmental considerations are central to renewable energy installation. Key aspects include:

- Habitat Disturbance: Minimizing the impact on wildlife and natural habitats during construction and operation. This might involve careful site selection and mitigation measures.

- Land Use: Considering the land use impact and selecting sites that minimize land clearing and habitat fragmentation. A comprehensive environmental impact assessment is often required.

- Water Usage: Efficient water management in projects like solar farms and geothermal power plants. Reducing water consumption and minimizing water pollution are essential.

- Waste Management: Proper disposal or recycling of construction materials and waste generated during operation. This includes the responsible management of spent batteries.

- Visual Impacts: Minimizing the visual impact of installations through careful site selection, design, and integration with the surrounding landscape. Aesthetics can be a concern for some communities.

- Noise Pollution: Mitigation of noise pollution, particularly from wind turbines and other equipment. Noise assessments are often part of the permitting process.

Environmental impact assessments and mitigation plans are crucial to ensure responsible development and operation of renewable energy projects.

Q 13. What are the key performance indicators (KPIs) for a solar farm?

Key Performance Indicators (KPIs) for a solar farm provide insights into its efficiency and overall performance. Important KPIs include:

- Energy Yield: Total energy produced over a specific period, often measured in kWh or MWh. This is a fundamental indicator of overall performance.

- Capacity Factor: The ratio of actual energy generated to the maximum possible energy generation given the installed capacity. A higher capacity factor indicates better performance. Think of it as how well the system performs given its potential.

- Performance Ratio (PR): An overall measure of system performance, considering various factors such as solar irradiance, temperature, and system losses. It reflects the efficiency of the entire solar power system.

- Specific Yield: Energy produced per kilowatt-peak (kWp) of installed capacity. This indicates how efficiently the system converts solar energy into electricity.

- System Availability: The percentage of time the system is operational and generating power. This indicates the reliability and uptime of the system.

- O&M Costs: Operating and maintenance costs per kWh of energy produced. This reveals the financial efficiency of the system.

Monitoring these KPIs allows for proactive maintenance and optimization of the solar farm’s performance.

Q 14. How do you interpret data from a SCADA system for a wind farm?

A Supervisory Control and Data Acquisition (SCADA) system provides real-time data on various aspects of a wind farm’s operation. Interpreting this data is crucial for efficient management and maintenance. Key data points include:

- Turbine Performance: Individual turbine power output, rotational speed, blade pitch angles, and operational status. Identifying underperforming turbines requires a thorough analysis of individual parameters.

- Environmental Data: Wind speed and direction, ambient temperature, and humidity. Understanding these conditions helps explain variations in power output and allows for predictive maintenance.

- Grid Conditions: Voltage, frequency, and power flow. Ensuring the wind farm is operating within grid parameters is vital for grid stability.

- System Alarms and Events: Real-time alerts and historical logs of system events, including faults and maintenance activities. Quick response to alarms is critical for minimizing downtime.

- Predictive Maintenance Indicators: Data analysis to identify potential equipment failures before they occur. This allows for scheduled maintenance, improving reliability and reducing unplanned downtime.

SCADA data analysis is an integral part of wind farm operations. It helps maximize energy production, reduce downtime, and optimize maintenance strategies. Sophisticated data analytics and visualization tools can be used to identify trends and predict potential issues, ensuring efficient and reliable wind farm operation.

Q 15. Describe your experience with troubleshooting electrical issues in renewable energy systems.

Troubleshooting electrical issues in renewable energy systems requires a systematic approach, combining theoretical knowledge with practical skills. I begin by prioritizing safety – always disconnecting the system from the grid and ensuring appropriate lockout/tagout procedures are followed. Then, I use a combination of diagnostic tools like multimeters, clamp meters, and infrared cameras to pinpoint the problem.

For example, I once worked on a solar array experiencing intermittent power output. Using a multimeter, I systematically checked the voltage and current at each panel and its connection points. I discovered a loose connection at one of the combiner boxes, causing intermittent voltage drops. Tightening the connection resolved the issue. Another time, an infrared camera revealed a hotspot on a solar panel, indicating a failing cell, which was then replaced.

My approach always includes documenting findings, taking photos, and creating clear reports for clients. This ensures transparency and aids in preventing future issues. I am also proficient in using specialized software for analyzing system data to identify recurring problems or potential system weaknesses.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your skills in using specialized tools and equipment for renewable energy installation and maintenance?

My skillset with specialized tools and equipment is extensive. I’m proficient in using a variety of tools for solar, wind, and other renewable energy installations and maintenance. This includes:

- Solar PV Installation Tools: Stringing tools, crimpers, wire strippers, torque wrenches, solar panel handling equipment, roof mounting systems and tools.

- Wind Turbine Maintenance Equipment: Specialized lifting and safety equipment, wind speed and direction anemometers, thermal imaging cameras for detecting overheating components, and diagnostic software for analyzing turbine performance data.

- Electrical Testing Equipment: Multimeters, clamp meters, insulation resistance testers, power quality analyzers, and earth ground resistance testers.

- Other Equipment: Aerial lifts, trenchers, and other heavy equipment where appropriate and licensed.

I’m adept at selecting the appropriate tool for the job, understanding its limitations, and ensuring its proper maintenance and calibration to maintain accuracy and safety. Safety is always my top priority when using any equipment.

Q 17. How do you ensure compliance with relevant safety regulations and standards?

Compliance with safety regulations and standards is paramount in renewable energy work. I am thoroughly familiar with and adhere strictly to OSHA, NEC, and any other applicable local, state and national codes. This includes understanding and implementing:

- Lockout/Tagout procedures: Ensuring complete isolation of electrical systems before any work begins.

- Arc flash hazard mitigation: Implementing appropriate PPE and safety measures when working on energized systems.

- Fall protection: Using harnesses, lanyards, and other safety equipment when working at heights.

- Electrical safety regulations: Adhering to proper wiring techniques, grounding, and bonding practices.

- Working at heights and confined space entry: Following all appropriate safety training and procedures.

I proactively seek out and stay updated on any changes to regulations and standards to ensure ongoing compliance. It’s not just about following rules, but understanding why they are in place to ensure the safety of myself and others.

Q 18. Explain your experience with different types of renewable energy technologies.

My experience spans a range of renewable energy technologies, including:

- Photovoltaic (PV) systems: I have extensive experience in designing, installing, and maintaining grid-tied and off-grid solar PV systems, encompassing various panel types (monocrystalline, polycrystalline, thin-film), inverters, and battery storage solutions. I understand different system designs, including ground-mount, roof-mount, and tracking systems.

- Wind energy systems: I’m experienced in small-scale wind turbine installation and maintenance. This includes understanding different turbine types (horizontal axis, vertical axis), generator systems, and safety protocols for tower climbing and maintenance.

- Hydropower systems: I have knowledge of micro-hydro systems, understanding the principles of water flow and energy conversion. This includes experience with system design, turbine selection, and grid integration.

- Biomass energy systems: My understanding extends to smaller scale biomass systems and their maintenance, focusing on safe handling and operation.

This broad experience allows me to approach each project with a holistic understanding of the technologies involved and how they interact with each other and the grid.

Q 19. Describe your experience with project management in renewable energy projects.

I possess significant experience in project management within the renewable energy sector. My approach emphasizes a structured methodology incorporating detailed planning, resource allocation, risk assessment, and effective communication. I routinely use project management tools such as Gantt charts and critical path analysis to manage timelines and resources effectively.

For instance, in a recent solar farm project, I was responsible for managing a team of installers, procuring materials, scheduling inspections, and ensuring adherence to the project budget. We successfully completed the project on time and within budget, resulting in a fully functional solar farm that exceeded client expectations. This involved proactive risk management, identifying and mitigating potential delays, such as material shortages or weather disruptions.

My ability to collaborate effectively with clients, engineers, and subcontractors is crucial for successful project delivery. I am comfortable adapting to changing project needs and resolving unexpected issues efficiently, maintaining clear and transparent communication throughout the process.

Q 20. How familiar are you with different grid connection procedures for renewable energy systems?

I’m very familiar with various grid connection procedures for renewable energy systems. The specifics vary by location and utility company, but generally involve these steps:

- Application Process: Submitting detailed system design plans and specifications to the relevant utility company for review and approval.

- Interconnection Agreement: Negotiating and signing an interconnection agreement that outlines technical requirements, grid connection fees, and responsibility allocation.

- System Design and Testing: Designing the system to meet the utility company’s requirements and undergoing rigorous testing to ensure safety and grid compatibility.

- Metering and Installation: Installing the necessary metering equipment and connecting the system to the grid according to approved plans.

- Commissioning: Thoroughly testing and commissioning the entire system to ensure proper operation and performance.

My experience includes working with different grid operators and navigating their specific requirements, ensuring seamless interconnection and compliance with all applicable regulations.

Q 21. What software and tools are you proficient in using for renewable energy design and analysis?

My software proficiency includes PVsyst, Helioscope, and AutoCAD for design and analysis. I am also comfortable using various data acquisition and monitoring software for collecting and analyzing performance data from installed systems. This includes:

- PVsyst: Used for detailed design and simulation of photovoltaic systems, assessing energy production and system performance under various conditions.

- Helioscope: Used for analyzing solar irradiance, shading, and other site-specific factors impacting solar energy production.

- AutoCAD: Used for creating detailed system designs, including layout drawings, electrical schematics, and other technical documentation.

- Monitoring Software: Proficient in using various monitoring platforms to collect real-time data on system performance, enabling identification of potential issues or areas for improvement.

These tools help to optimize system design, ensure efficient operation, and provide crucial data for system maintenance and troubleshooting.

Q 22. Describe your experience with preparing technical reports and documentation.

Preparing comprehensive technical reports and documentation is crucial for effective communication and project management within the renewable energy sector. My experience spans various aspects, from initial site assessments and design specifications to detailed installation reports and post-installation maintenance logs. I’m proficient in using various software to create these reports, including AutoCAD for system schematics, Microsoft Excel for data analysis and reporting, and specialized software for energy modeling.

For instance, in a recent 5MW solar farm project, I was responsible for compiling a comprehensive technical report encompassing everything from the initial feasibility study and environmental impact assessment to the final as-built drawings and performance data. This included detailed equipment specifications, wiring diagrams, safety protocols, and a thorough analysis of the system’s efficiency and predicted energy output. The report was instrumental in obtaining regulatory approvals and ensuring seamless handover to the client.

My reports consistently follow a structured format, ensuring clarity and ease of understanding for both technical and non-technical audiences. I also ensure all data is accurately presented, meticulously cross-referenced, and appropriately documented for future reference.

Q 23. How do you stay updated with the latest advancements in renewable energy technologies?

Staying current in the rapidly evolving field of renewable energy technologies is paramount. I employ a multi-pronged approach to continuous learning. This includes actively participating in industry conferences and webinars, such as those hosted by the IEEE Power & Energy Society and the Solar Energy Industries Association (SEIA). I also subscribe to relevant industry journals and online publications, like Renewable Energy Focus and Solar Power World, to stay informed about the latest research and technological breakthroughs.

Furthermore, I actively engage with online learning platforms like Coursera and edX, pursuing specialized courses on topics such as advanced inverter technologies, smart grid integration, and battery storage systems. Networking with peers and colleagues through professional organizations like the American Solar Energy Society (ASES) provides valuable insights and opportunities for knowledge exchange. Finally, I regularly review manufacturers’ specifications and technical documentation for new equipment and components, ensuring I remain familiar with the latest offerings and advancements in the field.

Q 24. Describe your problem-solving skills with a specific example from a renewable energy project.

During the commissioning phase of a wind turbine installation project, we experienced intermittent power fluctuations despite all components appearing to function nominally. This presented a significant challenge, as the client was eager to begin full-scale operation. Initially, we focused on troubleshooting individual components, but each test proved inconclusive.

My approach was systematic. We systematically reviewed all the system’s data logs, checking for anomalies in voltage, current, and frequency readings. This revealed a subtle pattern of voltage drops coinciding with specific wind speeds. It turned out that the problem wasn’t with a single component but rather with the interaction between the turbine’s control system and the grid. Specifically, a slight miscalibration in the turbine’s pitch control was causing power oscillations when the wind speed was above a certain threshold.

The solution involved re-calibrating the pitch control system using specialized diagnostic software provided by the manufacturer. After this adjustment, the power fluctuations ceased entirely, and the wind turbine operated smoothly at full capacity. This experience underscored the importance of careful data analysis and systematic troubleshooting in complex renewable energy systems.

Q 25. How would you handle a situation where a renewable energy system malfunctions during peak hours?

A system malfunction during peak hours requires a rapid and effective response to minimize disruption and potential financial losses. My approach would involve a prioritized, multi-stage response:

- Immediate Assessment: First, remotely access the system’s monitoring and diagnostics to identify the nature and severity of the malfunction.

- Emergency Procedures: If the issue poses a safety hazard (e.g., fire, electric shock), initiate established safety protocols and immediately contact emergency services.

- Isolation & Mitigation: If possible, safely isolate the affected section of the system to prevent further damage or wider system failure.

- Troubleshooting: Based on the initial assessment, begin troubleshooting, drawing on my experience with various system components (inverters, panels, batteries, etc.). This might involve checking for loose connections, faulty components, or software glitches.

- Temporary Solutions: If a quick fix isn’t immediately feasible, implement temporary solutions (e.g., switching to backup power if available) to minimize downtime and restore partial functionality.

- Permanent Repair: Coordinate with specialized technicians or the equipment manufacturer to schedule the permanent repair of the faulty components. This includes procuring necessary replacement parts and scheduling the repair work at the most convenient time for minimal disruption.

- Post-Incident Report: Document the entire incident, including the cause of failure, the steps taken to mitigate the problem, and any lessons learned. This ensures improved system reliability and helps prevent similar incidents in the future.

Q 26. What is your experience with different types of inverters used in renewable energy systems?

My experience encompasses a wide range of inverters commonly used in renewable energy systems. I’m familiar with both string inverters and central inverters, as well as microinverters and power optimizers. I understand the advantages and disadvantages of each type and can select the most appropriate inverter for a given project based on factors such as system size, budget, and specific site conditions.

String inverters, while cost-effective, are vulnerable to shading effects on individual panels. Central inverters offer high efficiency but can lead to significant power loss if one panel malfunctions. Microinverters provide excellent performance in shaded conditions and offer superior monitoring capabilities but typically come with a higher initial cost. Power optimizers represent a compromise between string and microinverters, mitigating shading effects without the complexity and cost of individual microinverters.

Furthermore, I’m knowledgeable about different inverter technologies, including grid-tied, off-grid, and hybrid inverters. I also understand the importance of safety compliance standards like UL 1741 SA for grid-tied inverters and the necessity of appropriate grounding and surge protection.

Q 27. How familiar are you with the permitting and regulatory processes related to renewable energy projects?

Navigating the permitting and regulatory landscape is a crucial aspect of successful renewable energy project implementation. My experience involves working with various local, state, and federal agencies to secure the necessary approvals for numerous projects. I understand the importance of complying with building codes, interconnection standards, and environmental regulations.

This includes preparing and submitting detailed permit applications, including engineering plans, site surveys, and environmental impact assessments. I’m familiar with the interconnection procedures required by utility companies and can effectively manage the process to ensure timely approval. I’m also aware of the various renewable energy incentives and tax credits available at different levels of government and can help clients navigate these programs to maximize financial benefits.

For example, in a recent community solar project, I successfully managed the entire permitting process, working closely with local authorities to obtain all necessary approvals within the stipulated timeframe. This involved meticulous documentation, regular communication with the regulatory bodies, and proactive problem-solving to address any concerns or objections raised during the review process.

Q 28. Explain the importance of routine maintenance in maximizing the lifespan of renewable energy systems.

Routine maintenance is crucial for maximizing the lifespan and efficiency of renewable energy systems. Just like regular servicing of a car ensures optimal performance and longevity, consistent maintenance of renewable energy installations prevents premature degradation and maximizes their energy output. A well-maintained system will also reduce the risk of unexpected breakdowns and minimize downtime.

For photovoltaic (PV) systems, this includes regular cleaning of solar panels to remove dirt, debris, and bird droppings that can significantly reduce energy production. Visual inspections of wiring, connectors, and grounding systems are equally important to detect any signs of wear or damage. For wind turbines, maintenance involves inspecting blades, gearboxes, and generators, checking for cracks, vibrations, or lubrication issues. Battery storage systems require regular monitoring of cell voltage, temperature, and state-of-charge to ensure optimal performance and prevent premature degradation.

A comprehensive maintenance plan, tailored to the specific system, its components, and the environmental conditions, ensures prolonged operational life, high system efficiency, and minimizes the risk of expensive repairs or replacements. A proactive approach to maintenance is always more cost-effective than reactive emergency repairs.

Key Topics to Learn for Renewable Energy Installation and Maintenance Interview

- Solar PV Systems: Understanding system components (panels, inverters, racking), installation procedures, safety regulations, troubleshooting common issues, and performance monitoring techniques.

- Wind Turbine Technology: Familiarization with different turbine types, maintenance schedules, blade repair and inspection, gearbox maintenance, and safety protocols specific to wind energy.

- Battery Storage Systems: Knowledge of various battery chemistries, their applications in renewable energy, installation best practices, safety considerations (including fire prevention), and maintenance procedures.

- Grid Integration and Interconnection: Understanding the process of connecting renewable energy systems to the electrical grid, relevant codes and standards, safety procedures, and troubleshooting grid-related issues.

- Remote Monitoring and Diagnostics: Experience with utilizing remote monitoring systems for preventative maintenance, data analysis to identify potential problems, and utilizing diagnostic tools for efficient troubleshooting.

- Health and Safety Regulations: Comprehensive knowledge of OSHA (or equivalent regional) safety regulations, working at heights, electrical safety, and personal protective equipment (PPE) requirements in renewable energy installations.

- Electrical Wiring and Circuitry: Solid understanding of AC/DC circuits, wiring diagrams, troubleshooting electrical faults, and adhering to electrical codes for safe and efficient system operation.

- Problem-Solving and Troubleshooting: Demonstrating ability to diagnose and solve problems effectively, whether through systematic approaches, analytical skills, or creative solutions. This is crucial for both installation and maintenance aspects.

Next Steps

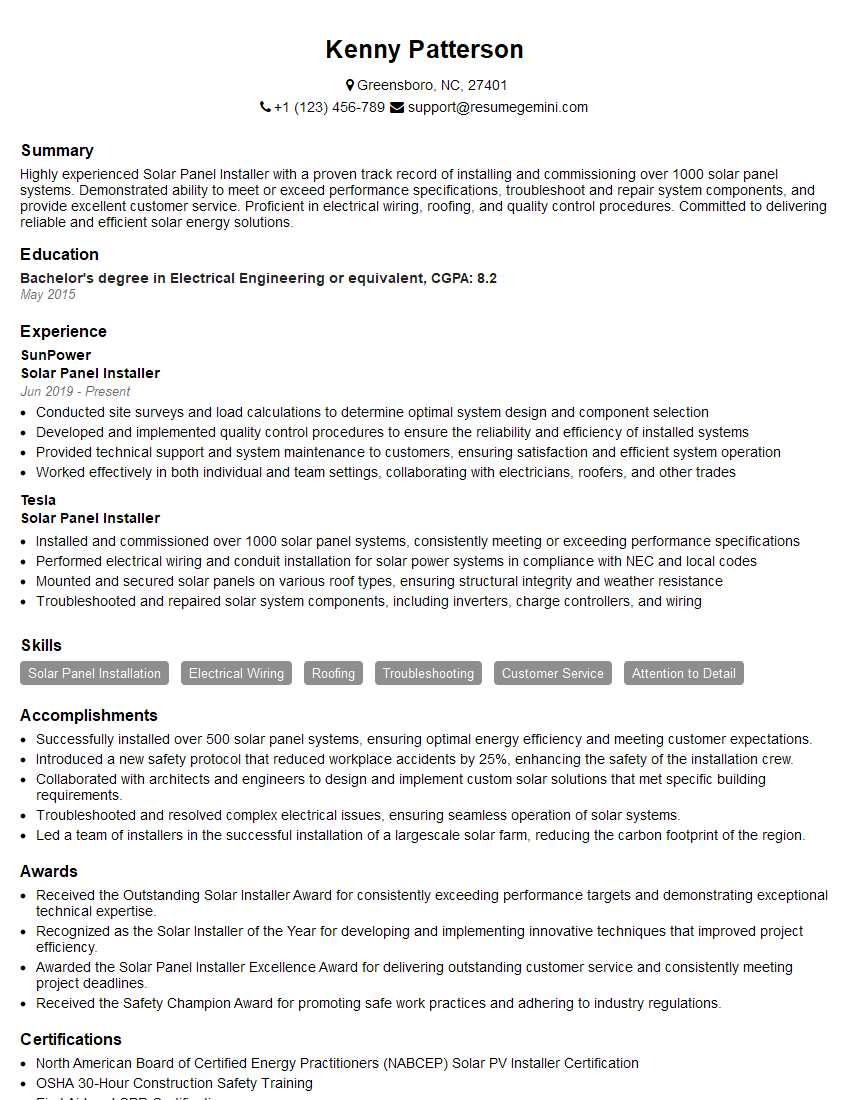

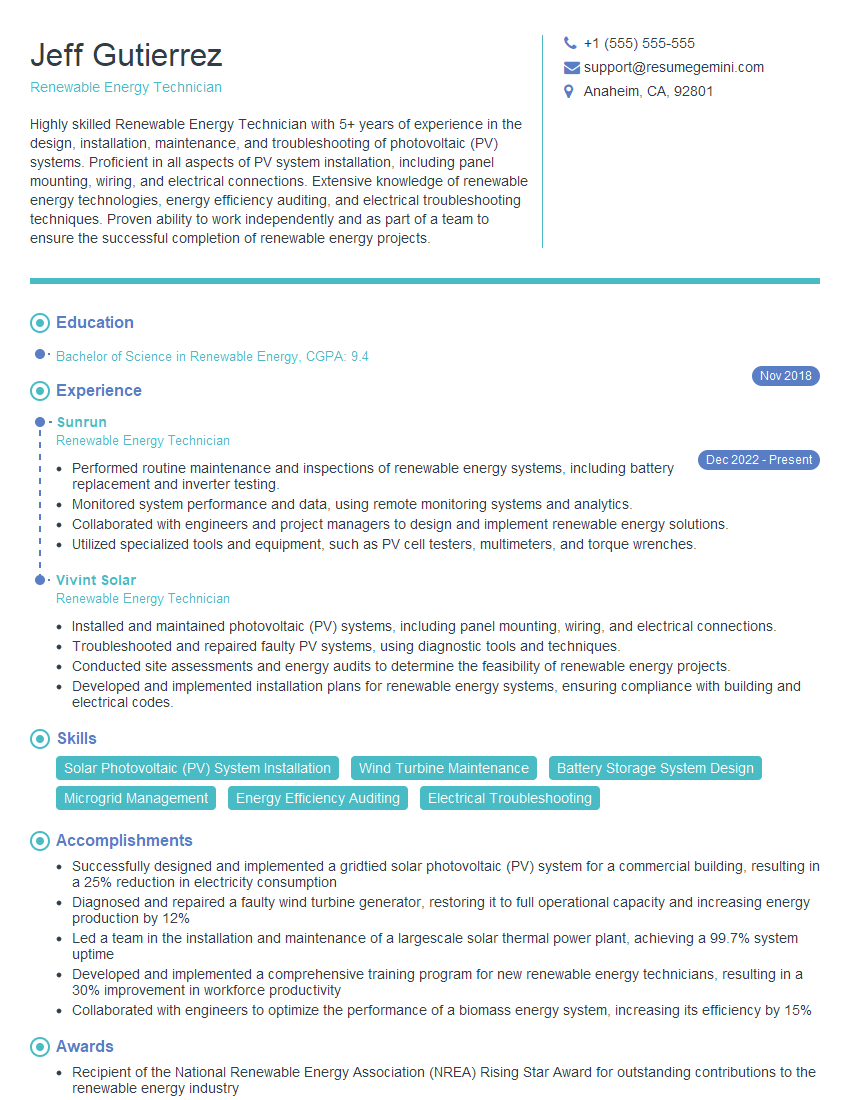

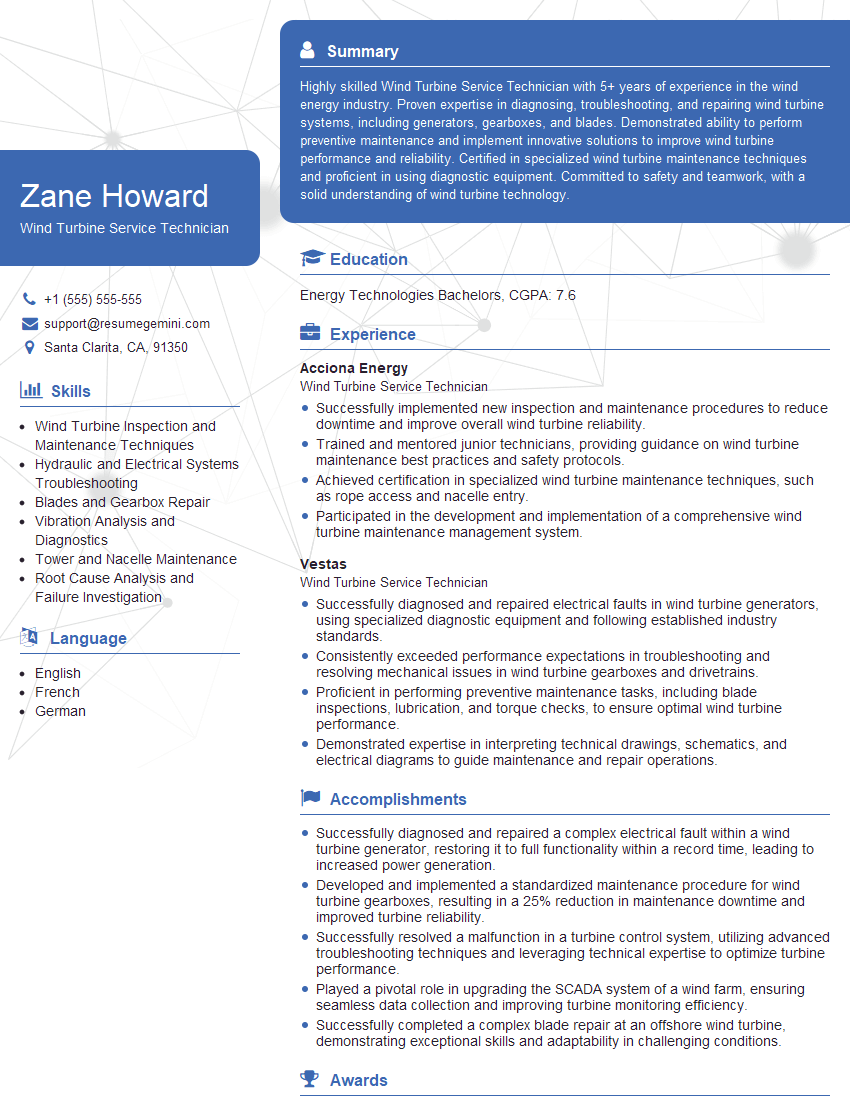

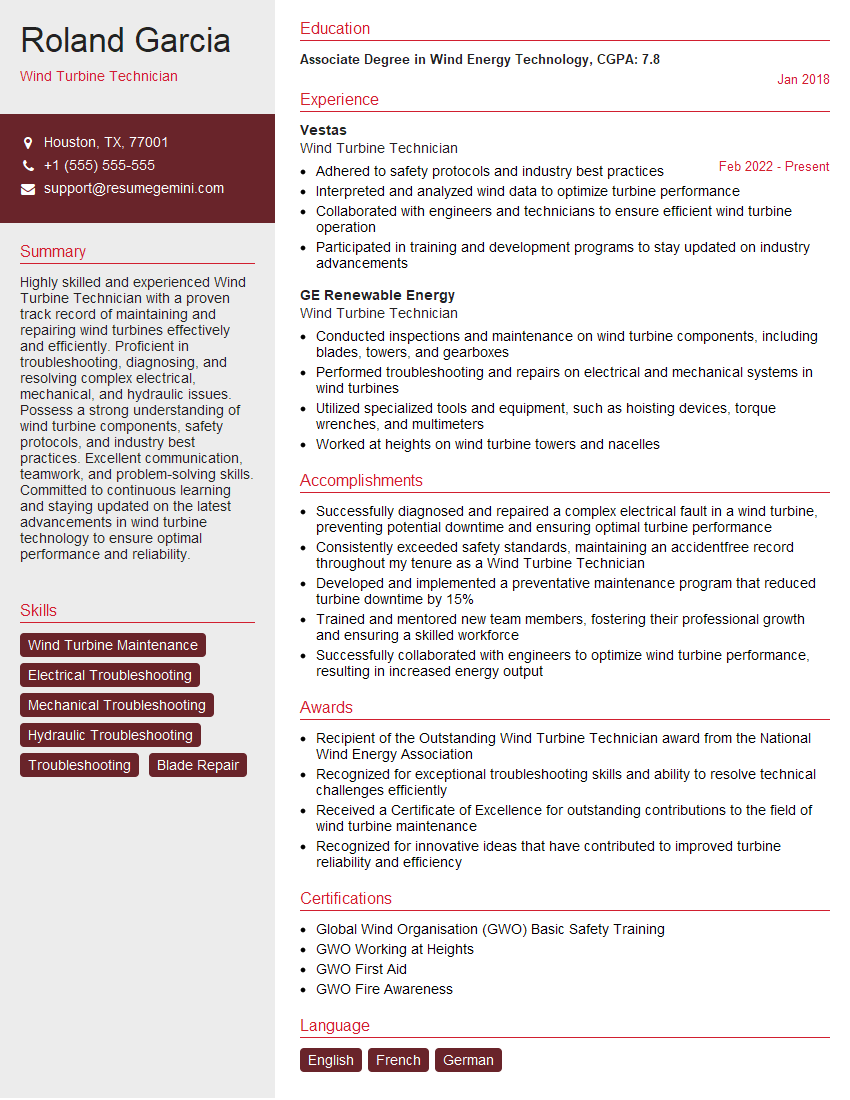

Mastering Renewable Energy Installation and Maintenance positions you for a rewarding and impactful career in a rapidly growing industry. Demand for skilled professionals is high, offering excellent job security and growth potential. To maximize your job prospects, create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Renewable Energy Installation and Maintenance are available, providing you with a strong foundation to build upon. Take the next step and craft a resume that reflects your expertise and helps you land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good