Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Understanding boat maintenance regulations interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Understanding boat maintenance regulations Interview

Q 1. What are the key components of a Vessel Safety Check?

A Vessel Safety Check (VSC) is a free, voluntary inspection performed by trained volunteers to help boaters ensure their vessels meet minimum safety standards. It’s like a safety checkup for your boat, aimed at preventing accidents and promoting safe boating practices.

- Navigation lights: Are they functioning correctly and properly visible? This is crucial for preventing collisions at night.

- Personal Flotation Devices (PFDs): Do you have enough US Coast Guard-approved PFDs for everyone on board, and are they in good condition? Think of these as your boat’s seatbelts – essential for safety.

- Fire extinguishers: Are they properly sized, readily accessible, and fully charged? A fire on a boat is a serious threat, so preparedness is key.

- Ventilation: Is your boat properly ventilated to prevent the buildup of dangerous fumes from fuel? This is particularly important for gasoline-powered boats.

- Sound-producing devices: Do you have a functional horn or whistle? This is vital for signaling other vessels.

- Visual distress signals: Do you have flares or other distress signals? These are your SOS – crucial for summoning help in an emergency.

- Boat paperwork: Do you have all the necessary documentation, such as registration and proof of insurance? This is important for legal compliance.

During a VSC, inspectors will visually examine these and other safety components. They won’t perform mechanical repairs but offer advice and highlight areas needing attention. Think of it as a preventative maintenance check-up rather than a rigorous mechanical inspection.

Q 2. Explain the role of the Coast Guard in enforcing boat maintenance regulations.

The Coast Guard plays a vital role in enforcing boat maintenance regulations through inspections, investigations, and enforcement actions. Their authority stems from various federal laws and regulations aimed at ensuring maritime safety and environmental protection.

Inspections: Coast Guard personnel can board vessels to inspect for compliance with safety and environmental regulations. This may occur during routine patrols or in response to reports of violations.

Investigations: If an accident or pollution incident occurs, the Coast Guard will investigate to determine if any regulations were violated. This may involve examining vessel maintenance records and interviewing crew members.

Enforcement actions: If violations are found, the Coast Guard can issue warnings, citations, fines, and even seize vessels. The severity of the penalties depends on the nature and severity of the violation.

Example: A boat operating without proper navigation lights at night could face a citation and fine. A vessel responsible for a significant oil spill could face far more serious consequences, including hefty fines, potential criminal charges, and extensive remediation efforts.

Q 3. Describe the different types of marine pollution and their regulations.

Marine pollution encompasses the introduction of harmful substances into the marine environment, harming aquatic life and human health. Regulations aim to prevent and mitigate such pollution.

- Oil pollution: Oil spills from vessels are a major concern. Regulations dictate how much oil a vessel can carry, how it’s stored and handled, and procedures for responding to spills. The International Convention for the Prevention of Pollution from Ships (MARPOL) is a key international treaty addressing this.

- Sewage and wastewater: Discharge of untreated sewage is strictly regulated. Vessels must have approved sewage treatment systems or adhere to specific discharge rules depending on their location.

- Garbage and plastic waste: Throwing garbage overboard is illegal. Vessels are required to properly manage and dispose of their waste, usually ashore.

- Ballast water: Ballast water, taken on by vessels for stability, can carry invasive species. International regulations aim to minimize the transfer of these species.

- Air pollution: Regulations control vessel emissions to reduce air pollution in port areas and coastal zones.

Enforcement varies by jurisdiction, but typically involves inspections, penalties for violations, and requirements for pollution response plans.

Q 4. What are the requirements for maintaining a vessel’s logbook?

Maintaining a vessel’s logbook is a crucial aspect of responsible boat ownership. It’s a record of the vessel’s operation, maintenance, and any incidents that occur.

Requirements vary depending on the vessel type and jurisdiction, but generally, a logbook should include:

- Dates and times of operation: When and where the vessel was operated.

- Maintenance records: Details of any maintenance performed, including dates, work done, and by whom.

- Fueling records: Amounts of fuel purchased and dates of fueling.

- Crew details: Information on who was onboard during each trip.

- Incident reports: Detailed records of any accidents, near misses, or equipment malfunctions.

- Weather conditions: Notes on sea conditions and weather during operation.

Why is it important? A well-maintained logbook can be invaluable in case of accidents, insurance claims, or regulatory inspections. It helps demonstrate due diligence in vessel maintenance and operation.

Example: A logbook entry might state: “October 26, 2024: Engine oil changed by John Doe. Vessel operated from 10:00 AM to 4:00 PM, calm seas, clear skies. No incidents reported.”

Q 5. How do you ensure compliance with ballast water management regulations?

Ballast water management regulations are crucial for preventing the spread of invasive aquatic species. These regulations require vessels to either treat their ballast water to kill or remove organisms before discharge or to exchange ballast water at sea.

Ensuring compliance involves:

- Installing and maintaining approved ballast water management systems (BWMS): These systems use various technologies like filtration, UV treatment, or electrochlorination to remove organisms from ballast water.

- Following operational procedures: This includes proper record-keeping, regular system maintenance, and adherence to discharge standards.

- Regular inspections and testing: Ensuring the BWMS is functioning correctly and meeting regulatory requirements.

- Crew training: Training crew members on the proper operation and maintenance of the BWMS and the relevant regulations.

- Record-keeping: Maintaining detailed records of ballast water management activities, including system performance data and maintenance logs.

Failure to comply can result in significant penalties, including fines and vessel detention.

Q 6. What are the regulations regarding the use and storage of hazardous materials on a boat?

Regulations regarding hazardous materials on boats are stringent due to the potential risks involved. The storage, handling, and disposal of these materials must adhere to strict guidelines to prevent accidents and environmental harm.

Key aspects of the regulations include:

- Proper labeling and storage: Hazardous materials must be clearly labeled and stored in designated areas to prevent spills and accidental exposure. Storage containers should be leak-proof and securely fastened.

- Material Safety Data Sheets (MSDS): MSDS should be readily available for all hazardous materials on board, providing information on safe handling, storage, and emergency procedures.

- Emergency response plans: Vessels carrying hazardous materials must have contingency plans for dealing with spills or leaks.

- Disposal procedures: Hazardous materials must be disposed of responsibly, typically ashore at designated facilities.

- Quantity limits: There may be restrictions on the amount of certain hazardous materials that can be carried on a vessel.

Example: Gasoline, paints, solvents, and certain cleaning products are examples of hazardous materials frequently found on boats. These need to be handled and stored according to the regulations.

Q 7. Explain the importance of regular hull inspections and what to look for.

Regular hull inspections are crucial for maintaining the structural integrity and seaworthiness of a vessel, preventing costly repairs, and ensuring safety.

Importance: The hull is the boat’s primary structure. Damage or deterioration can lead to leaks, loss of buoyancy, and potential sinking.

What to look for:

- Cracks and gouges: Check for any cracks, gouges, or damage to the hull’s surface. Pay close attention to areas near the keel, propeller, and underwater fittings.

- Corrosion: Examine the hull for signs of corrosion, particularly in areas where metal parts are attached. This is especially important for metal hulls.

- Fouling: Check for marine growth (barnacles, algae, etc.) that can increase drag and reduce speed and fuel efficiency. Regular cleaning is essential.

- Leaks: Check for any signs of leaks, including water stains or moisture buildup inside the hull.

- Through-hull fittings: Inspect all through-hull fittings (seawater intakes, drains, etc.) for leaks or damage. Ensure they are properly sealed.

Frequency: The frequency of hull inspections depends on several factors, including vessel type, usage, and environmental conditions. At a minimum, a thorough inspection should be conducted annually, or more frequently if the boat is used extensively or operates in harsh conditions. A professional inspection by a qualified marine surveyor might be needed every few years for larger or older vessels.

Q 8. Describe the maintenance requirements for different types of boat engines (outboard, inboard, diesel).

Maintaining different boat engines requires a tailored approach. Think of it like car maintenance – a sports car needs different care than a pickup truck.

- Outboard Engines: These are relatively simple to maintain. Regular tasks include checking the oil level and changing it according to the manufacturer’s recommendations, lubricating the lower unit with the correct grease, inspecting the propeller for damage, and cleaning the engine after each use to prevent corrosion. Regularly inspecting fuel lines and filters for leaks or blockages is critical. A yearly service by a qualified mechanic is advised to ensure optimal performance and prevent costly failures.

- Inboard Engines: These require more extensive maintenance due to their complexity. In addition to the basics of oil and filter changes, you’ll need to check the cooling system (both raw water and freshwater), monitor the engine’s temperature gauge constantly, and check the drive shaft alignment. Regular inspections of the fuel system, including the tank, lines, and filters, are vital to avoid fuel starvation or leakage issues. A professional mechanic should service an inboard engine annually, and more frequently if used heavily.

- Diesel Engines: Diesel engines are known for their durability but demand specific attention. Fuel filters should be checked and replaced regularly, as diesel fuel is prone to contamination. The cooling system requires careful attention, including checking the antifreeze levels and ensuring proper functioning of the heat exchanger. Regular lubrication of engine components is essential. Similar to inboard engines, yearly professional service is highly recommended.

Remember, always consult your engine’s owner’s manual for specific maintenance schedules and recommendations. Ignoring maintenance can lead to catastrophic engine failure.

Q 9. What are the legal requirements for carrying safety equipment on a recreational vessel?

Safety regulations vary by location, but most jurisdictions mandate essential safety equipment for recreational vessels. Think of it as your boat’s emergency kit – you hope you never need it, but you’re glad you have it if you do.

- Personal Flotation Devices (PFDs): These are crucial, and the number required usually depends on the vessel’s capacity. All PFDs must be USCG approved and in good condition.

- Visual Distress Signals: These help alert rescuers in an emergency. Common examples include flares, day/night flags, and a hand-held air horn.

- Navigation Lights: These are essential for night navigation to ensure other vessels can see you. They must be properly functioning.

- Fire Extinguisher(s): The type and number of extinguishers required depend on the vessel’s size and engine type. Make sure your extinguishers are regularly inspected and recharged.

- Marine Radio: While not always mandatory for smaller vessels, a VHF radio is extremely valuable for communication with other boats and emergency services.

- First-Aid Kit: An adequately stocked first-aid kit is essential for handling minor injuries.

It’s vital to check your local regulations for precise requirements, as they can change. Don’t compromise on safety; being prepared can save lives.

Q 10. Explain the process of obtaining a Certificate of Compliance for a vessel.

Obtaining a Certificate of Compliance (CoC) involves verifying that your vessel meets all applicable safety standards and regulations. It’s similar to getting a car inspected before it’s roadworthy.

- Prepare your Vessel: Ensure your boat is thoroughly cleaned and that all safety equipment is present, in good working order, and correctly installed.

- Gather Necessary Documents: Collect all relevant paperwork, such as proof of ownership, engine specifications, and any previous survey reports.

- Schedule an Inspection: Contact your local authority responsible for boat registrations and inspections. Schedule an appointment for a survey or inspection of your vessel.

- Undergo Inspection: A surveyor will thoroughly examine your vessel to verify compliance with safety standards, including hull integrity, engine functionality, and the presence and condition of required safety equipment.

- Address Deficiencies: If any issues are found, you’ll need to rectify them before the CoC can be issued.

- Receive Certificate: Once all requirements are met, the issuing authority will provide the CoC. This certificate is proof that your boat adheres to the safety regulations.

The specific procedure might vary slightly by location, so it’s best to contact your local maritime authority for precise instructions.

Q 11. How do you interpret and apply relevant regulations to specific boat maintenance scenarios?

Interpreting and applying regulations requires a systematic approach. Consider it like solving a puzzle – you need to identify the pieces (regulations) and how they fit together (specific scenarios).

- Identify Applicable Regulations: Determine which regulations apply based on the vessel’s size, type, and intended use, as well as your location.

- Analyze the Scenario: Carefully assess the specific boat maintenance scenario – what work needs to be done, what equipment is involved, and what are the potential risks.

- Cross-Reference Regulations: Match the scenario with the relevant regulations. Consider potential overlaps or exceptions.

- Develop a Compliance Plan: Based on the regulations and scenario, create a plan to ensure compliance. This might involve specific equipment, procedures, or certifications.

- Document Everything: Maintain meticulous records of all maintenance activities, inspections, and any repairs, including dates and signatures, to prove compliance.

Example: If a regulation mandates specific intervals for engine oil changes, and you find yourself performing maintenance on an engine that’s overdue, your compliance plan would involve an immediate oil change and documentation of that action.

Q 12. What are the consequences of non-compliance with boat maintenance regulations?

Non-compliance with boat maintenance regulations can have serious consequences, ranging from minor fines to significant legal repercussions. Think of it like driving without insurance – the risks outweigh the benefits.

- Fines and Penalties: Depending on the severity of the infraction, you could face substantial fines.

- Vessel Seizure: In serious cases, your vessel could be seized until the issue is resolved.

- Legal Liability: If your negligence causes an accident or injury due to lack of maintenance, you could face lawsuits with significant financial implications.

- Insurance Issues: Your insurance policy might be invalidated if your boat isn’t properly maintained and registered.

- Criminal Charges: In extreme cases of negligence resulting in serious harm, criminal charges might be filed.

Preventing non-compliance is far simpler and less costly than dealing with the consequences. Regular maintenance and adherence to regulations are vital.

Q 13. How do you stay updated on changes in boat maintenance regulations?

Staying updated on changes to boat maintenance regulations requires consistent effort. It’s like following a constantly evolving instruction manual.

- Official Government Websites: Regularly check the websites of your local maritime authorities and relevant regulatory bodies for updates and notices.

- Industry Publications: Subscribe to boating magazines and newsletters that cover regulatory changes.

- Professional Organizations: Join boating associations or professional organizations in the marine industry. These often provide updates and training on regulations.

- Networking: Connect with other boat owners and professionals in the field. Information sharing can be a valuable tool.

- Attend Seminars and Workshops: Participate in educational opportunities related to boating safety and regulations.

Proactive monitoring ensures you remain informed and compliant. Falling behind on regulations can put you and others at risk.

Q 14. Describe your experience with conducting preventative maintenance on various boat systems.

Throughout my career, I’ve performed preventative maintenance on numerous boat systems, from small outboard-powered dinghies to large diesel-powered yachts. It’s a blend of technical skills and meticulous attention to detail.

- Engine Systems: I’ve conducted routine oil and filter changes, fuel system inspections, cooling system flushes, and other engine-specific maintenance tasks, always adhering to manufacturer specifications.

- Electrical Systems: I’ve checked battery voltage, cleaned battery terminals, inspected wiring for damage, and tested all electrical components to ensure optimal performance and prevent electrical fires.

- Plumbing Systems: I’ve inspected and repaired water systems, ensuring proper water pressure, leak detection, and the functioning of water pumps and tanks.

- Hull and Deck: I’ve inspected the hull for any signs of damage, performed anti-fouling treatments to prevent marine growth, and completed regular cleaning and waxing of the deck to protect it from the elements.

- Safety Equipment: I’ve consistently checked and maintained all safety equipment, ensuring it’s readily accessible, functional, and compliant with regulations.

My approach is always proactive, aiming to identify potential problems before they escalate into costly repairs. Preventative maintenance is significantly more cost-effective and safer in the long run. Each project is treated with the same level of precision and commitment to safety.

Q 15. What is your experience with troubleshooting and repairing common boat maintenance issues?

Troubleshooting and repairing boat maintenance issues is a multifaceted process requiring a blend of practical skills, theoretical knowledge, and diagnostic acumen. My experience encompasses a wide range of issues, from minor engine problems to major hull repairs. I approach troubleshooting systematically, starting with a thorough visual inspection, followed by diagnostic testing using specialized tools. For example, if a boat’s engine won’t start, I’d first check the battery, fuel supply, and ignition system. If the issue is more complex, I might use a diagnostic scanner to pinpoint the problem within the engine’s electronic control unit (ECU). My repair experience covers various systems including engine repair (inboard and outboard), electrical systems, plumbing, and hull maintenance. I’m proficient in fiberglass repair techniques, handling issues like cracks, osmosis, and gelcoat damage. I also routinely service and maintain various boat systems, ensuring their optimal performance and safety.

For example, I once diagnosed a persistent engine misfire on a client’s sailboat. After checking the usual suspects (spark plugs, fuel delivery), I used a compression tester to identify a problem with one of the cylinders. This led me to discover a damaged piston ring, which required an engine rebuild. My methodical approach ensures efficient and effective repairs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you document boat maintenance activities to meet regulatory requirements?

Accurate documentation of boat maintenance activities is crucial for compliance with safety regulations and for efficient vessel management. I use a combination of methods to ensure comprehensive and readily auditable records. This includes detailed logbooks, digital databases, and photographic evidence. The logbook meticulously records every maintenance task, including the date, time, description of the work performed, parts used, and any observations. Digital databases offer a searchable and easily accessible record of maintenance history, streamlining future maintenance planning and regulatory compliance. Photographic evidence provides visual proof of repairs and condition assessments.

For example, after completing a propeller shaft replacement, my documentation would include a detailed description of the procedure, photos of the old and new shaft, the part numbers of the replacement components, and the names of the technicians involved. This ensures complete traceability and fulfills any requirements for audits or insurance claims. Furthermore, I always ensure the documentation adheres to relevant industry standards and regulatory guidelines set by the Coast Guard or other governing bodies.

Q 17. Explain your understanding of environmental regulations related to boat maintenance and disposal of waste.

Environmental regulations concerning boat maintenance and waste disposal are stringent and crucial for protecting our waterways. My understanding encompasses the proper disposal of hazardous materials such as oil, antifreeze, and solvents, adhering strictly to local and national regulations. I’m knowledgeable about the appropriate use of environmentally friendly cleaning agents and the prevention of water pollution from bilge pumping. I understand the regulations surrounding the disposal of waste from sanitation systems and the importance of preventing greywater discharge. This includes working with designated waste disposal facilities to ensure environmentally responsible handling.

For instance, I ensure that all oil changes are handled responsibly, including the proper collection and disposal of used oil in designated containers and facilities. I regularly educate boat owners on best practices for preventing pollution, which includes avoiding the use of harmful chemicals and properly maintaining their bilge systems. This proactive approach safeguards the environment and fosters responsible boat ownership.

Q 18. How do you handle emergencies related to boat malfunctions or accidents?

Handling emergencies related to boat malfunctions or accidents necessitates a calm, decisive, and methodical approach. My emergency response plan includes immediate assessment of the situation, prioritizing safety for all onboard. I’m trained in emergency procedures, including first aid, fire suppression, and the use of emergency communication equipment. Depending on the severity, this might involve contacting emergency services (Coast Guard, etc.), conducting damage control, and ensuring the safety of passengers and the vessel.

For example, in a scenario involving an engine failure far from shore, I would immediately assess the situation, initiate emergency procedures, activate the EPIRB (Emergency Position-Indicating Radio Beacon), and contact emergency services while simultaneously implementing appropriate damage control measures such as deploying a sea anchor or utilizing sails if available. My training in emergency procedures ensures effective and life-saving response in critical situations.

Q 19. How do you communicate effectively with vessel owners regarding maintenance needs and regulations?

Effective communication with vessel owners is pivotal for successful maintenance and regulatory compliance. I use clear, concise language, avoiding technical jargon where possible. I explain complex issues in simple terms, ensuring owners understand the maintenance requirements and the rationale behind them. I actively encourage questions and ensure owners understand the potential consequences of neglecting maintenance, emphasizing safety and legal compliance. My communication involves various methods including written reports, email updates, and face-to-face discussions.

For instance, when explaining the need for hull cleaning to prevent biofouling, I’d not only explain the process but also its impact on fuel efficiency, speed, and the vessel’s overall condition, along with potential legal repercussions for non-compliance with anti-fouling regulations. This helps foster a collaborative relationship built on mutual understanding and shared responsibility.

Q 20. Describe a time you identified a potential safety hazard related to a vessel and how you addressed it.

During a routine inspection of a client’s motor yacht, I noticed significant corrosion on the steering cable. This posed a serious safety hazard, as a complete failure could result in loss of steering control. I immediately reported this to the owner, detailing the severity of the issue and the potential dangers. I recommended immediate replacement of the cable, providing a detailed cost estimate and emphasizing the urgency of the repair. The owner agreed to the repair, and I ensured the vessel was not used until the replacement was complete. This proactive identification and resolution of a potential hazard prevented a potentially catastrophic accident.

Q 21. What are your skills in using diagnostic tools for boat maintenance?

My diagnostic skills encompass a wide array of tools and technologies specific to boat maintenance. This includes proficiency in using engine diagnostic scanners to identify faults in electronic engine control systems, multi-meters for electrical diagnostics, compression testers to assess engine cylinder health, and various other specialized equipment for diagnosing problems in hydraulic systems, fuel systems and steering systems. I’m skilled in interpreting the data obtained from these tools, making accurate diagnoses, and determining the appropriate repair strategies.

For example, I use a diagnostic scanner to check for error codes in the electronic control unit of an outboard motor, which helps pinpoint issues like faulty sensors or malfunctions in the fuel injection system. This precise diagnostic capability avoids unnecessary repairs and ensures effective and timely fixes, maximizing efficiency and minimizing downtime. Continuous professional development ensures I stay updated on the latest technologies and diagnostic methodologies.

Q 22. How familiar are you with different types of marine coatings and their applications?

My familiarity with marine coatings is extensive. I understand that choosing the right coating is crucial for protecting a vessel from the harsh marine environment, extending its lifespan, and ensuring its aesthetic appeal. Different coatings serve different purposes.

- Anti-fouling paints: These prevent marine growth like barnacles and algae from attaching to the hull, reducing drag and improving fuel efficiency. I’ve worked extensively with various types, from ablative (wearing away gradually) to self-polishing (releasing biocides slowly), selecting the appropriate type based on the vessel’s type, usage, and location.

- Primer coatings: These prepare the surface for topcoats, providing adhesion and corrosion protection. I’m proficient in applying epoxy primers, polyurethane primers, and zinc-rich primers, understanding their specific properties and application techniques.

- Topside paints: These protect the above-waterline surfaces from UV degradation, weathering, and impact damage. I’m experienced with various types, including polyurethane, acrylic, and two-part epoxy systems, each offering different levels of durability and gloss.

- Underwater coatings: Beyond anti-fouling, these might include specialized coatings to prevent corrosion on metal components like propellers or rudders. I understand the importance of selecting coatings compatible with the underlying metal and the specific environmental conditions.

For example, I once worked on a project where we had to meticulously select and apply a multi-layered coating system for a classic wooden yacht, combining epoxy primers, specialized wood preservatives, and a high-quality varnish to ensure both protection and the preservation of its historical integrity.

Q 23. What experience do you have with electrical systems on boats?

My experience with boat electrical systems is comprehensive, encompassing both AC and DC systems. I’m adept at troubleshooting, repair, and installation. I understand the unique challenges posed by the marine environment, such as corrosion, vibration, and moisture.

I’ve worked with various components, including:

- Batteries: I can assess battery health, troubleshoot charging systems, and select appropriate batteries for different applications. I’m familiar with both lead-acid and lithium-ion battery technologies and their specific maintenance requirements.

- Wiring systems: I understand the importance of proper wire sizing, routing, and termination to ensure safety and reliability. I’m proficient in using marine-grade wiring and connectors to prevent corrosion and ensure proper insulation.

- Electrical panels: I can design, install, and troubleshoot electrical panels, ensuring proper circuit protection and distribution.

- Navigation equipment: I’m familiar with the electrical systems supporting various navigational instruments, including GPS, radar, and autopilots.

- Lighting systems: I can design and install effective and energy-efficient lighting systems, including LED lighting options.

For instance, I once successfully diagnosed and repaired a complex electrical fault on a large sailing yacht which involved tracing a faulty wire within a complex network to a corroded connector hidden deep within the vessel.

Q 24. Explain your knowledge of plumbing and sanitation systems on boats.

My knowledge of boat plumbing and sanitation systems is detailed. These systems require specialized attention due to the confined space and the need to manage wastewater effectively and prevent contamination.

My expertise includes:

- Freshwater systems: I can install, maintain, and repair freshwater tanks, pumps, and distribution systems. I understand the importance of water quality and prevention of contamination.

- Wastewater systems: I’m familiar with various types of heads (toilets), holding tanks, macerators, and discharge systems, ensuring compliance with environmental regulations. I’m experienced in troubleshooting and repairing leaks and blockages.

- Greywater systems: I can design and implement effective greywater systems to manage shower and sink wastewater, minimizing environmental impact.

- Plumbing materials: I use appropriate marine-grade materials, including corrosion-resistant pipes and fittings, to ensure longevity and prevent leaks.

In one instance, I effectively resolved a recurring issue of a blocked waste line by utilizing a combination of plumbing snakes and high-pressure water jets, followed by a thorough visual inspection using a borescope camera to confirm a successful repair and preventing future problems.

Q 25. What are your skills in welding and metal fabrication related to boat repair?

My welding and metal fabrication skills are essential for boat repair. I’m proficient in various welding techniques, including MIG, TIG, and stick welding, and I’m experienced in working with various metals, including aluminum, stainless steel, and mild steel.

I can fabricate custom components, repair damaged structures, and reinforce weakened areas. I understand the importance of proper welding preparation, including cleaning, fitting, and preheating. I prioritize creating strong, reliable, and aesthetically pleasing repairs that meet marine standards.

For example, I recently fabricated and welded a custom stainless steel bracket to support a damaged radar arch on a motor yacht, ensuring both structural integrity and a seamless visual integration with the existing structure. This required precise measurements, careful fitting, and meticulous welding technique.

Q 26. How do you handle the paperwork associated with marine surveys and inspections?

Handling marine survey and inspection paperwork is a crucial part of my work. I’m meticulous in documenting all aspects of the survey, including any identified defects or necessary repairs.

This includes:

- Preparing detailed reports: My reports accurately reflect the vessel’s condition, including photographic evidence, detailed descriptions of defects, and recommendations for repairs.

- Maintaining accurate records: I maintain organized records of all inspections, ensuring easy access to information for future reference.

- Ensuring compliance: I ensure that all paperwork complies with relevant regulations and industry standards.

- Communicating effectively: I clearly and concisely communicate survey findings to clients and relevant authorities.

Understanding the legal implications of accurate and thorough documentation is paramount. A carefully documented survey protects both the surveyor and the client. I’m experienced in managing all documentation required by insurance companies or regulatory bodies.

Q 27. What is your understanding of the different classes and types of vessels and their unique maintenance needs?

My understanding of different vessel classes and types and their unique maintenance needs is comprehensive. I recognize that maintenance requirements vary greatly depending on factors like vessel size, construction material, propulsion system, and intended usage.

I’m familiar with various vessel types including:

- Sailing yachts: Requiring regular sail maintenance, rigging inspections, and hull cleaning.

- Motor yachts: Needing engine maintenance, electrical system checks, and hull cleaning.

- Fishing vessels: Requiring specialized gear maintenance, deck maintenance, and frequent hull cleaning due to potential damage.

- Commercial vessels: Subject to stringent regulatory inspections and maintenance schedules, requiring detailed record-keeping.

For instance, maintaining a fiberglass sailboat differs significantly from maintaining a steel-hulled commercial fishing vessel. A fiberglass boat might require attention to osmosis prevention while a steel vessel might demand more frequent hull cleaning and anti-corrosion treatments.

Q 28. Describe your experience with working in a team environment to complete boat maintenance projects.

Teamwork is fundamental in boat maintenance. I thrive in collaborative environments, understanding that complex projects often require diverse skill sets. I’m adept at delegating tasks, coordinating efforts, and ensuring everyone is working towards the same goal efficiently and safely.

My approach involves:

- Clear communication: I ensure open and consistent communication among team members, providing clear instructions and updates.

- Efficient task allocation: I assign tasks based on individual expertise, optimizing the workflow.

- Problem-solving collaboratively: I actively involve team members in problem-solving, fostering a shared understanding and fostering creativity in solutions.

- Maintaining a safe working environment: I prioritize safety, ensuring compliance with all safety regulations and procedures.

One recent project involved a full refit of a classic wooden motorboat. The team included carpenters, painters, electricians, and mechanics. Through effective communication and task allocation, we completed the project on time and within budget, resulting in a beautifully restored vessel. Teamwork is vital; a successful outcome necessitates efficient and clear collaboration.

Key Topics to Learn for Understanding Boat Maintenance Regulations Interview

- Hull Maintenance: Understanding materials (fiberglass, aluminum, wood), cleaning procedures, repair techniques, and preventative measures against osmosis and corrosion. Practical application: Troubleshooting common hull problems and explaining preventative maintenance schedules.

- Engine Maintenance: Familiarization with different engine types (inboard, outboard, sterndrive), routine maintenance tasks (oil changes, filter replacements, belt inspections), troubleshooting engine malfunctions, and understanding safe engine operation. Practical application: Describing a systematic approach to diagnosing engine problems and performing basic maintenance.

- Safety Equipment & Regulations: Knowledge of mandatory safety equipment (life jackets, flares, fire extinguishers, etc.), relevant regulations regarding their usage and maintenance, and emergency procedures. Practical application: Demonstrating understanding of legal requirements and explaining how to ensure equipment is compliant and in good working order.

- Electrical Systems: Understanding basic electrical components (batteries, wiring, bilge pumps), troubleshooting electrical issues, and ensuring safe electrical practices onboard. Practical application: Diagnosing problems with battery charging systems or bilge pumps.

- Preventative Maintenance Schedules: Developing and implementing comprehensive maintenance plans, understanding the importance of regular inspections, and utilizing logbooks for record-keeping. Practical application: Designing a preventative maintenance schedule for a specific vessel type.

- Environmental Regulations: Understanding regulations related to waste disposal (bilge pumping, sewage), oil spills, and responsible boating practices. Practical application: Explaining procedures for proper waste disposal and minimizing environmental impact.

Next Steps

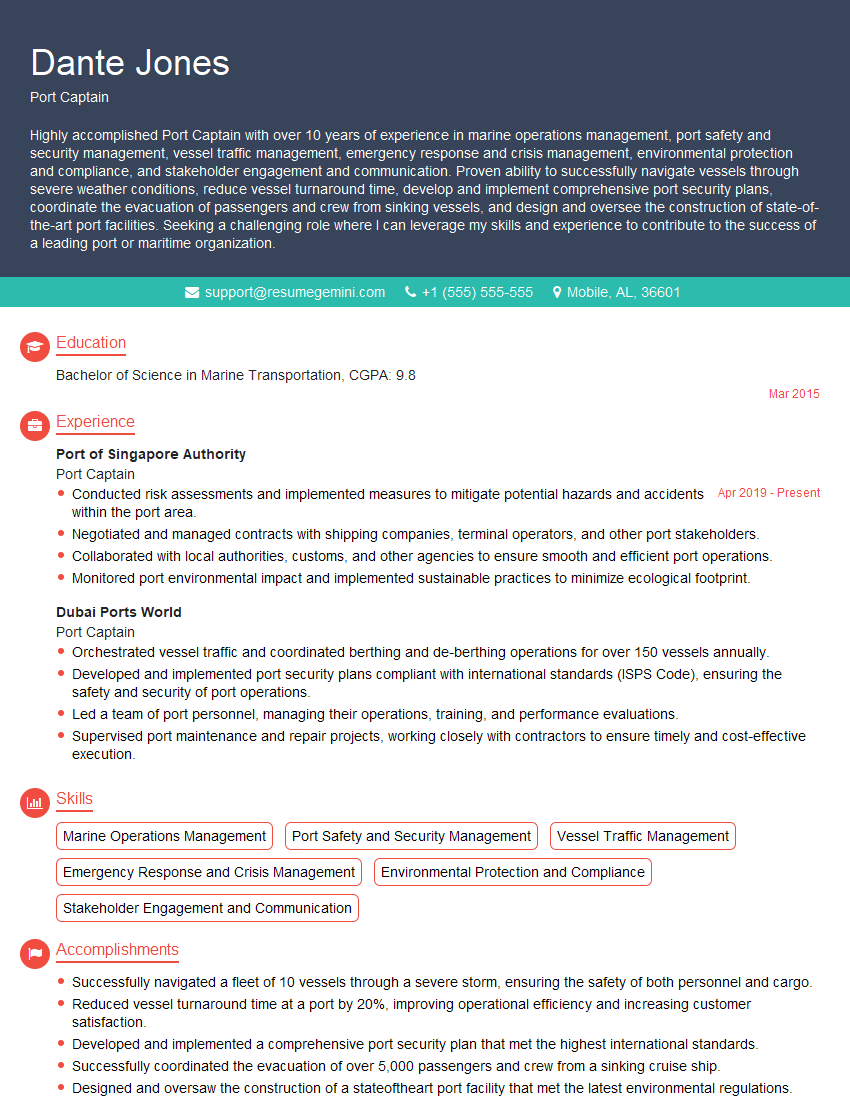

Mastering boat maintenance regulations significantly enhances your marketability within the maritime industry, opening doors to diverse and rewarding career opportunities. A strong, ATS-friendly resume is crucial for showcasing your skills and experience effectively to potential employers. To build a compelling resume that highlights your expertise in boat maintenance and surpasses applicant tracking systems (ATS), we recommend using ResumeGemini. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to boat maintenance regulations, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good