Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Rigging and handling ropes interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Rigging and handling ropes Interview

Q 1. What are the different types of rope used in rigging?

Selecting the right rope for a rigging job is crucial for safety and efficiency. Different ropes are designed for different loads, environments, and applications. Here are some common types:

- Manila Rope: A natural fiber rope made from abaca, known for its strength and flexibility, but susceptible to moisture and UV degradation. Often used in less demanding applications.

- Nylon Rope: A synthetic fiber rope offering high strength-to-weight ratio, excellent elasticity (meaning it stretches and absorbs shock), and resistance to abrasion. A popular choice in many rigging scenarios.

- Polyester Rope: Another synthetic option, offering similar strength to nylon but with higher resistance to abrasion and less stretch. Ideal where a more stable, less elastic rope is needed.

- Polypropylene Rope: A lightweight, buoyant rope with good resistance to chemicals and rot. Frequently used in marine environments or where low weight is a priority, but it has lower tensile strength compared to nylon or polyester.

- Wire Rope: Composed of many steel wires braided together, offering exceptional strength and durability. Used for heavy-duty lifting and applications requiring high tensile strength but is susceptible to corrosion if not properly maintained.

The choice depends entirely on the specific application, considering factors like load capacity, environmental conditions (sun, water, chemicals), and required flexibility.

Q 2. Explain the importance of proper knot tying in rigging.

Proper knot tying is paramount in rigging; a poorly tied knot can lead to catastrophic equipment failure and severe injury or death. The knot must securely hold the load under stress, and equally important, it must be easy to untie after the load is released. Think of it like this: the knot is the keystone of your rigging system.

A few critical aspects of knot tying in rigging include:

- Knot Selection: Choosing the right knot for the job is vital. Different knots are suited for different tasks and rope types. For example, a bowline is excellent for making a loop that won’t slip, while a clove hitch is useful for attaching a rope to a post or ring.

- Tightness: A knot must be tied tightly to prevent slippage. This often involves tensioning the rope and ensuring all parts of the knot are snug against each other.

- Inspection: Always carefully inspect your knots before putting them under load. Check for any loose strands or areas of weakness.

Imagine a scenario where a poorly tied bowline slips while lifting a heavy beam – the consequences could be devastating. Therefore, rigorous attention to detail is a life-saving necessity.

Q 3. Describe the different types of slings used in lifting operations.

Slings are the crucial link between the lifting equipment and the load. Their selection is critical to ensure a safe lift. Several types are commonly used:

- Round Slings: Made from synthetic fibers (nylon, polyester) and formed into a loop. They are versatile and conform well to oddly shaped loads, offering excellent shock absorption. However, they can be prone to twisting and damage if not handled correctly.

- Endless Webbing Slings: Woven synthetic fibers create a flat sling, ideal for distributing loads evenly across a surface. They’re durable, easy to inspect, and offer clear markings for SWL.

- Chain Slings: Made from high-strength alloy steel chains, these are robust and suited for heavy-duty lifts of rigid loads. However, they are more rigid and can damage the load’s surface.

- Wire Rope Slings: Similar to wire rope, these slings offer high strength but require careful handling to prevent damage and kinking.

Each sling type has its strengths and weaknesses. The choice will always depend on the weight, shape, and nature of the load, as well as the lifting environment.

Q 4. How do you calculate the safe working load (SWL) of a sling?

Calculating the Safe Working Load (SWL) of a sling is not a calculation you perform; it’s provided by the manufacturer. The SWL is the maximum load a sling can safely support under ideal conditions. It’s stamped or tagged on the sling itself. This information is crucial for ensuring the safe operation of any lift.

However, understanding factors influencing the SWL is essential:

- Type of Sling: Different sling types have varying SWLs based on material, construction, and configuration.

- Angle of Lift: Lifting at angles greater than 90 degrees reduces the effective SWL. Formulas or charts are available to account for the angle (e.g., a 30-degree angle drastically reduces the effective load).

- Number of Legs: Using multiple slings to lift a load distributes the weight. If using multiple legs, the SWL of a single leg may be used for calculations, bearing in mind the load sharing.

- Condition of Sling: Any damage or wear reduces the SWL, potentially significantly. Regular inspection and maintenance are vital.

Always consult the manufacturer’s documentation and relevant safety standards to correctly determine the safe working load for a specific sling and application. Never exceed the SWL!

Q 5. What are the safety regulations and procedures for rigging?

Rigging safety is governed by stringent regulations and procedures designed to minimize risk. These regulations vary by location and industry but typically include:

- Pre-Lift Planning: A detailed plan outlining all aspects of the lift, including load weight, sling type, lifting equipment, and safety procedures.

- Competent Personnel: Only trained and authorized personnel should perform rigging operations. Riggers need specific knowledge, training, and experience.

- Equipment Inspection: Thorough inspection of all rigging equipment (ropes, slings, shackles, hooks, etc.) before every use is mandatory.

- Safe Work Practices: Following established safety procedures, such as proper signaling, load securing, and hazard awareness, is crucial.

- Personal Protective Equipment (PPE): Riggers must use appropriate PPE, including hard hats, safety glasses, gloves, and high-visibility clothing.

- Emergency Procedures: Procedures for handling emergencies and equipment failures should be well-defined and practiced.

Ignoring these regulations can have serious consequences. Always prioritize safety; it’s not just a guideline; it’s a life-saving necessity.

Q 6. How do you inspect rigging equipment before use?

Rigging equipment inspection is a non-negotiable step before every use. A thorough inspection can prevent accidents. Here’s a systematic approach:

- Visual Inspection: Carefully examine all components for visible damage, such as cuts, abrasions, fraying, corrosion, or deformations. Pay particular attention to the areas subjected to maximum stress – such as end fittings, splices, and attachments.

- Check for Wear and Tear: Look for signs of excessive wear, including broken or flattened strands in wire ropes or significant wear on webbing slings. If these are present, the equipment needs immediate replacement.

- Check for Kinks, Bends, and Knots: Kinks and bends weaken ropes and slings drastically, as do knots in any equipment. Kinks should be identified, and the equipment should be replaced immediately.

- Check for Proper Functioning: Test any moving parts or mechanisms to ensure they operate smoothly and securely.

- Documentation: Record the inspection findings, noting any damage or issues identified. This ensures traceability and accountability.

Remember, even small imperfections can lead to failure under load. If in doubt, discard the equipment and replace it.

Q 7. What are the signs of wear and tear on ropes and slings?

Recognizing signs of wear and tear on ropes and slings is vital for preventing accidents. Here are some key indicators:

- Fraying or Broken Strands (Ropes and Slings): This indicates weakening of the material and a significant reduction in strength.

- Cuts, Abrasions, or Punctures: These can severely compromise the structural integrity of the rope or sling.

- Excessive Wear: General wear, particularly at points of contact or bending, signals that the rope or sling is nearing the end of its useful life.

- Discoloration or Stiffness (Synthetic Ropes): This could signify chemical damage or degradation.

- Corrosion (Wire Ropes and Chain Slings): Rust and corrosion weaken the material significantly and can compromise the SWL.

- Kinks or Bends (Wire Ropes): These drastically reduce the strength of wire ropes.

- Melting, Burning, or Chemical Damage (Synthetic Ropes and Slings): Damage to the fiber structure drastically reduces its strength.

If any of these signs are observed, the rope or sling should be immediately removed from service and replaced. Remember, damaged rigging equipment is a significant safety hazard.

Q 8. Explain the different types of hitches and their applications.

Hitches are fundamental knots used in rigging to secure a rope to an object or another rope. They vary greatly in their strength, ease of tying, and specific applications. Here are a few common types:

- Bowline: Forms a fixed loop that won’t slip. Excellent for attaching a rope to a ring or other fixed point, making it ideal for securing a load to a lifting point. Think of it as a reliable ‘eye’ at the end of your rope.

- Clove Hitch: A quick and easy hitch, ideal for temporary attachments. It’s frequently used to secure a rope to a post or ring but isn’t as strong as a bowline for heavy loads. It’s useful for quickly securing a guide rope or a temporary attachment point.

- Half Hitch: A simple loop around an object; it’s rarely used alone but serves as a building block for more complex hitches. Often used in conjunction with other hitches to increase security.

- Figure Eight Knot: Primarily used to create a stopper knot at the end of a rope to prevent it from running through a pulley or other device. It is not suitable as a primary securing hitch.

- Timber Hitch: Specifically designed for securing a rope around a cylindrical object like a log or beam. Its strength and ability to tighten under load make it essential for hauling and securing timber.

The choice of hitch depends entirely on the specific job. For critical lifts, using the appropriate hitch and properly securing it is paramount. Always double-check your knots before commencing any lift!

Q 9. Describe the process of planning a rigging operation.

Planning a rigging operation is crucial for safety and efficiency. It’s not just about knowing the knots; it’s about a systematic approach. Here’s a breakdown:

- Assessment of the Load: Determine the weight, dimensions, center of gravity, and any potential hazards associated with the load. This includes assessing the load’s condition; a damaged load could become unstable during lifting.

- Site Survey: Inspect the working area, identifying potential obstacles, ground conditions, and environmental factors (wind, rain). Ensure sufficient clearance for the lift and safe access for personnel.

- Equipment Selection: Choose appropriate lifting equipment (cranes, slings, shackles, etc.) based on the load’s weight and characteristics. Ensure all equipment is in good working order and certified.

- Rigging Plan Development: Create a detailed plan outlining each step of the lift, including hitch selection, sling angles, and lifting points. Consider the lift path and potential points of contact during the process.

- Risk Assessment: Identify potential hazards and develop mitigation strategies. This should involve a thorough review of the plan and a discussion of any unforeseen circumstances that could arise.

- Communication Plan: Establish clear communication protocols between the rigging crew, crane operator, and other personnel involved. Pre-determined hand signals and communication channels prevent miscommunication.

- Pre-lift Checklist: Develop a checklist to ensure all procedures are followed before beginning the lift. This provides a structured approach to safety.

A well-planned rigging operation minimizes risks and ensures a smooth and safe lift. Skipping any of these steps could have serious consequences.

Q 10. How do you ensure the stability of a load during lifting?

Load stability during lifting hinges on several key factors:

- Proper Slinging: Use the correct type and size of slings appropriate for the load’s weight and shape. Ensure the slings are evenly distributed to maintain a balanced lift. Avoid sharp bending angles, which can significantly reduce the sling’s capacity.

- Center of Gravity: Accurately determine and account for the load’s center of gravity. An unbalanced load will sway and create instability. Using a spreader bar can help to equalize the weight distribution and control the swing.

- Appropriate Lifting Points: Select strong and structurally sound lifting points on the load. These points must be capable of handling the load’s weight without damage or deformation. Avoid weak points, such as corners or edges, especially when lifting items of odd shape.

- Controlled Movement: The crane operator should make smooth and controlled movements to avoid sudden jerks or swings. Communication between the rigger and operator is essential to ensure a steady lift.

- Environmental Factors: Wind conditions significantly impact load stability. Strong winds can make it difficult to control the lift, potentially leading to an accident. Lifting operations should be suspended in high-wind conditions.

Think of it like balancing a plate on a stick – any unevenness or unexpected movement will cause it to fall. The same principle applies to load stability in rigging.

Q 11. What are the emergency procedures in case of a rigging failure?

Rigging failures can have catastrophic consequences. Emergency procedures are critical:

- Immediate Stop: The first response is to immediately stop the lift if a rigging failure is suspected or observed. This prevents further damage or injuries. Give the crane operator clear signals to stop.

- Secure the Load (if possible): If the load is still suspended, attempt to secure it using backup equipment or methods. This may require additional slings or alternative attachment points; prioritize safety over speed.

- Clear the Area: Evacuate personnel from the immediate vicinity of the failed lift. Establish a safe perimeter to prevent injury from falling debris or the unstable load.

- Assess the Damage: Once the area is secure, assess the extent of the failure. Identify the cause of the failure for reporting and future prevention.

- Notify Authorities: Report the incident to the appropriate authorities, depending on the severity and location. This may include emergency services, regulatory bodies, and the company’s safety department.

- Investigate and Report: Conduct a thorough investigation to determine the root cause of the failure and implement corrective actions to prevent similar incidents in the future.

Emergency procedures should be clearly defined and regularly practiced to ensure a swift and effective response in the event of a rigging failure.

Q 12. How do you communicate effectively with crane operators during lifting operations?

Effective communication with crane operators is paramount. A breakdown in communication can be disastrous. Here are key strategies:

- Pre-Lift Briefing: Hold a pre-lift briefing to discuss the rigging plan, potential hazards, and communication protocols. Everyone needs to understand the plan before starting.

- Standardized Hand Signals: Use standardized hand signals that are clearly understood by both the rigger and the operator. These should be agreed upon beforehand and practiced regularly. This is particularly important in noisy environments.

- Two-Way Radio Communication: If appropriate for the environment, use two-way radios for clear verbal communication, especially during complex lifts. Ensure everyone is familiar with the radio channels and procedures.

- Clear and Concise Instructions: Give clear, concise, and unambiguous instructions to the operator. Avoid jargon or technical terms that they might not understand.

- Confirmation of Instructions: Always get confirmation from the crane operator that they understand and will follow the instructions. The operator should repeat back the commands to confirm understanding.

- Constant Visual Monitoring: Maintain constant visual contact with the crane operator and the load during the lift. This allows for immediate response to any issues.

Clear communication builds trust and minimizes the risk of misunderstandings that can lead to accidents.

Q 13. What are the different types of lifting equipment used in rigging?

Rigging utilizes a wide range of equipment, each with specific applications:

- Cranes: The primary lifting device, available in various types (tower cranes, mobile cranes, overhead cranes) each suited to different tasks and environments.

- Slings: Used to connect the load to the crane hook. Come in various materials (wire rope, synthetic webbing, chain) each with different strength and flexibility characteristics.

- Shackles: Connecting links used to join slings and other components. They are critical for load distribution and load connection.

- Hooks: Used to attach slings to the crane hook. Different types of hooks are used for different applications, loads, and safety requirements.

- Spreader Beams: Used to distribute the load over multiple slings, improving stability and reducing stress on individual sling legs.

- Chain Blocks: Hand-operated lifting devices for smaller loads, frequently used for assisting with positioning of components.

- Come-Alongs: Hand-operated pulling devices used for tensioning or pulling tasks. These are valuable for assisting with the lifting of heavier loads.

The selection of appropriate lifting equipment is crucial to the safety and success of any rigging operation. Improperly selected equipment can easily lead to an accident.

Q 14. Explain the importance of using appropriate PPE when rigging.

Personal Protective Equipment (PPE) is non-negotiable in rigging. It’s the first line of defense against potential hazards. Key PPE includes:

- Hard Hats: Protect against falling objects.

- Safety Glasses/Goggles: Protect eyes from flying debris or dust.

- Gloves: Protect hands from cuts, abrasions, and rope burns.

- High-Visibility Clothing: Increases visibility in the work area, crucial for safety, particularly around moving machinery.

- Safety Harness and Lanyard: Essential for working at heights or near unstable loads, providing fall protection.

- Steel-Toe Boots: Protect feet from dropped objects or heavy equipment.

Rigging often involves heavy loads, sharp edges, and moving machinery. Proper PPE significantly reduces the risk of injury. Never compromise on safety; using the appropriate PPE is crucial for every rigging operation.

Q 15. How do you handle different types of loads during rigging?

Handling different types of loads in rigging requires a thorough understanding of the load’s characteristics – weight, shape, center of gravity, and fragility. We use different rigging techniques and equipment based on these factors. For example, a delicate piece of machinery might require soft slings and a gentler lift than a heavy steel beam which can tolerate more robust methods. We always calculate the working load limit (WLL) of all components involved, ensuring a significant safety factor is applied. This means the total load is significantly less than what any single component is rated to handle. For unusually shaped or heavy loads, we may need specialized equipment like spreader beams to distribute weight evenly and prevent damage or tipping. We also consider the environment; lifting in windy conditions requires different approaches than lifting indoors.

Imagine lifting a grand piano versus a concrete slab. The piano requires soft slings and careful handling to avoid damage, while the concrete slab might be lifted using stronger chains or steel wire rope.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of rigging accidents?

Rigging accidents stem from a variety of causes, often interconnected. Human error is a major factor; this includes insufficient training, inadequate planning, failure to follow safety procedures, and misjudgment of loads. Equipment failure is another critical aspect: using damaged or overloaded equipment, improper maintenance, and neglecting regular inspections all contribute to accidents. Environmental factors like extreme weather conditions (high winds, rain, ice) can significantly increase risk. Finally, poor communication amongst the rigging crew can lead to mishaps. In many cases, it’s a combination of these factors that results in an accident.

- Human Error: Incorrect load calculations, neglecting safety protocols, fatigue

- Equipment Failure: Using outdated or damaged equipment, exceeding WLL

- Environmental Factors: High winds, poor visibility, extreme temperatures

- Communication Breakdown: Misunderstandings between crew members during lifts

Q 17. How do you prevent rigging accidents?

Preventing rigging accidents is paramount. It begins with a comprehensive risk assessment that identifies potential hazards and develops mitigation strategies. Rigorous training and certification programs are crucial for all personnel involved, emphasizing safe operating procedures. Regular equipment inspections and maintenance are non-negotiable; damaged equipment should be immediately taken out of service. Clear communication channels must be established amongst the team, ensuring everyone understands the plan and their role. Furthermore, using appropriate personal protective equipment (PPE) such as hard hats, safety glasses, and high-visibility clothing is mandatory. Weather conditions should always be carefully considered, and lifting should be postponed if conditions are unsafe. Implementing a robust permit-to-work system ensures that all necessary safety checks are completed before any lift commences. Finally, having a detailed post-incident analysis after any near misses, helps to identify weaknesses and improve safety procedures.

Q 18. What is your experience with different rigging techniques?

My experience encompasses a wide range of rigging techniques, including:

- Basic Rigging: Using various types of slings (chain, wire rope, synthetic), shackles, hooks, and other hardware for simple lifts.

- Complex Rigging: Employing specialized equipment like spreader beams, gin poles, and crane systems for heavy or oddly shaped loads. This includes understanding the physics of load distribution and stability.

- Critical Lift Rigging: This demands meticulous planning, precise calculations, and multiple redundant safety systems to ensure zero risk to personnel and equipment. This often involves detailed simulations and engineering calculations.

- Specialized Rigging: Experience with underwater rigging, high-altitude rigging, confined space rigging, etc. Each setting presents unique challenges that necessitate specialized training and equipment.

I am proficient in both manual and powered rigging methods, and adept at selecting the most appropriate technique for any given situation, considering factors like load weight, environmental conditions, and accessibility.

Q 19. Describe a challenging rigging project you have worked on and how you overcame the challenges.

One particularly challenging project involved the installation of a massive transformer in a power substation. The transformer was exceptionally heavy and needed to be positioned with extreme precision. Access was limited due to existing infrastructure. The challenge was not just the weight, but the tight tolerances required for its placement. We overcame this by using a sophisticated combination of crane systems, counterweights, and laser-guided positioning systems. A detailed rigging plan was developed, considering wind speed, ground stability, and any potential interference with surrounding equipment. We conducted thorough risk assessments and implemented multiple safety measures, including a comprehensive emergency response plan. Through careful coordination, meticulous execution of the plan, and close communication amongst the team, we successfully completed the installation without incident. This project highlighted the importance of thorough planning, risk management, and a highly skilled team.

Q 20. Explain your understanding of different rigging systems.

Rigging systems can be categorized in several ways. One approach is based on the type of lifting equipment used:

- Crane Systems: These involve various types of cranes (tower, mobile, etc.), which offer high lifting capacity and reach.

- Gin Pole Systems: These utilize a long vertical pole to lift loads, often employed when crane access is limited.

- Derrick Systems: Similar to gin poles but typically larger and more robust, often used for extremely heavy lifts.

- Simple Lifting Systems: These rely on basic rigging hardware like chain hoists, come-alongs, and hand winches for smaller or lighter loads.

Another way to classify rigging systems is by the configuration of the lifting points: single-point lifts, two-point lifts, or multi-point lifts using spreader beams to distribute the load evenly. Understanding the strengths and limitations of each system and selecting the appropriate one for the task at hand is essential.

Q 21. How do you ensure the safety of personnel working around rigging operations?

Ensuring personnel safety is my top priority. This involves multiple layers of protection. Firstly, we establish a designated exclusion zone around the rigging operation, restricting access to authorized personnel only. Clear signage and barriers demarcate the safe working area. Riggers and spotters must wear appropriate PPE, including hard hats, safety glasses, high-visibility clothing, and steel-toe boots. Before any lift, a thorough toolbox talk is conducted, reviewing the rigging plan, safety procedures, and communication protocols. We regularly monitor weather conditions and halt operations if necessary. Moreover, a dedicated safety officer oversees all aspects of the operation, ensuring compliance with safety regulations and identifying potential hazards. Regular safety training and refresher courses are provided to maintain a high standard of competence among the team. Finally, post-operation debriefs are essential to identify areas for improvement and ensure continuous safety enhancement.

Q 22. What are the legal requirements for rigging in your area?

Legal requirements for rigging vary significantly by location, often governed by national or regional occupational safety and health administrations (like OSHA in the US or similar bodies elsewhere). These regulations typically cover aspects such as worker training and certification, equipment inspection and maintenance, load capacity calculations, safe work practices, and emergency procedures. For instance, many jurisdictions mandate regular inspections of rigging hardware, documentation of those inspections, and the use of certified riggers for high-risk operations. Specific regulations might also dictate the type of equipment allowed for certain applications, like the prohibition of damaged or outdated slings. In my area, we adhere strictly to [Insert your area’s relevant legislation/regulation name, e.g., OSHA 1926 Subpart CC], requiring all riggers to hold appropriate certifications, and all equipment to have current proof tests. Failure to comply can result in significant fines, project shutdowns, and even legal action.

Q 23. What is your experience with different types of knots and their applications?

My experience encompasses a wide range of knots, each suited for specific purposes. For example, the Bowline is my go-to knot for creating a reliable, adjustable loop that won’t slip under load – ideal for attaching a load to a sling. I frequently use the Clove Hitch for quickly attaching a rope to a ring or post, though it’s crucial to back it up with another knot for security under heavy loads. The Figure Eight is a reliable stopper knot, preventing rope from running through a system, which is often integrated into other more complex rigging arrangements. For joining two ropes of similar diameter, I rely on the Sheet Bend. In more complex scenarios involving multiple ropes and varying tensions, I employ more advanced knots, like the Flemish Bend, which is strong and reliable for joining two ropes of different sizes or materials. Selecting the correct knot isn’t merely a matter of preference but a critical decision that directly impacts safety and the success of the operation. Improper knot selection can lead to catastrophic equipment failure.

Q 24. How do you calculate the required rigging capacity for a specific load?

Calculating rigging capacity is crucial for safe operations. It’s not just about the load’s weight; it’s a complex calculation considering several factors. The first is the weight of the load itself. Then, we must account for additional forces: angle of the lift (loads suspended at an angle experience greater stress on the rigging), acceleration and deceleration forces (starting and stopping a lift), and any dynamic forces due to movement or environmental conditions (wind, for example). The formula is not a simple equation but a multifaceted risk assessment. We use established engineering principles and safety factors to account for these variables. We also consider the individual capacity ratings of each component in the rigging system – ropes, slings, shackles, hooks – and select equipment with capacities well exceeding the calculated total load. To illustrate, if a calculation suggests a 10,000 lb load, we would use equipment with a significantly higher safety factor (e.g., 5:1), meaning we’d utilize equipment rated for at least 50,000 lbs to provide an adequate margin of safety.

Q 25. Explain your knowledge of different types of anchors and their uses.

My experience includes working with various anchors, each chosen based on the specific ground conditions and the anticipated load. For example, deadmen anchors (typically buried logs or timbers) are effective in stable soil for temporary applications, offering a strong, dependable point of attachment when proper installation techniques are followed. Screw anchors provide excellent holding power in various soils and are easy to install and remove, but they are less suitable for very hard ground. For rocky or hard surfaces, expansion anchors are a preferred choice, expanding to create a secure hold within the material. Choosing the right anchor is paramount because an inadequate anchor can lead to catastrophic failure, endangering lives and property. The choice always involves a detailed assessment of the ground conditions and anticipated loads to select the best and safest solution.

Q 26. What are the factors you consider when selecting appropriate rigging equipment?

Selecting rigging equipment involves meticulous consideration of multiple factors. First, the working load limit (WLL) of each component must exceed the calculated load, allowing for an adequate safety factor. Then, I consider material compatibility; for instance, we must ensure that the sling material is appropriate for the load’s surface and any environmental factors. The condition of the equipment is paramount; any signs of wear, damage, or corrosion necessitate immediate replacement. Inspections are critical, adhering to strict visual and documentation standards and including regular proof testing in accordance with regulations. Additionally, the environmental conditions—temperature extremes, exposure to chemicals, or potential for abrasion—influence equipment selection. Finally, ease of handling and operability are also considered, balancing safety with efficiency.

Q 27. How do you handle unexpected situations during rigging operations?

Handling unexpected situations requires a calm, methodical approach. My training emphasizes risk assessment and mitigation strategies. If a component fails, the immediate response is to secure the situation, ensuring that the load doesn’t fall. This might involve using secondary rigging points or emergency equipment. Then, I conduct a thorough investigation to determine the root cause of the failure, documenting the incident meticulously. This includes taking pictures, recording observations, and identifying any contributing factors. We then review the incident, sharing the lessons learned to prevent future occurrences. Effective communication with the team is critical, ensuring everyone understands the risks and the appropriate responses to potential hazards. Emergency response plans, practiced regularly, are essential in minimizing the impact of unexpected events.

Q 28. Describe your experience with risk assessment in rigging projects.

Risk assessment is integral to every rigging project. My approach follows a structured methodology, starting with identifying potential hazards. This includes considering factors like load characteristics, environmental conditions, equipment limitations, and human factors (fatigue, training level). Next, we assess the likelihood and severity of each hazard, determining the level of risk. This allows us to prioritize mitigation strategies. These strategies can range from selecting appropriate equipment and implementing safe work practices to implementing additional safety measures, such as utilizing taglines or additional personnel. The final step is monitoring and reviewing the effectiveness of our mitigation measures, allowing for adaptive changes throughout the project. Documentation is crucial, providing a record of our risk assessment, the implemented controls, and any modifications made during the operation. This ensures accountability and continuous improvement.

Key Topics to Learn for Rigging and Handling Ropes Interview

- Rope Types and Properties: Understanding different rope materials (e.g., nylon, polyester, steel), their strengths, weaknesses, and appropriate applications in rigging.

- Knots and Hitches: Mastering essential knots and hitches used in rigging, including their proper tying techniques, applications, and limitations. This includes understanding their strength and suitability for different loads.

- Rigging Hardware: Familiarity with various rigging hardware components (e.g., shackles, hooks, slings, clamps) and their safe and effective use. Understanding load ratings and safety factors is crucial.

- Load Calculations and Safety Factors: Applying principles of physics and engineering to calculate safe working loads and incorporate appropriate safety factors to mitigate risk.

- Inspection and Maintenance: Understanding the importance of regular rope and hardware inspection for wear and tear, damage identification, and proper maintenance procedures.

- Safety Regulations and Best Practices: Familiarity with relevant safety regulations, standards, and best practices for rigging operations to ensure a safe working environment.

- Problem-Solving and Troubleshooting: Developing the ability to identify and solve problems related to rigging setups, including troubleshooting issues and making informed decisions under pressure.

- Communication and Teamwork: Effective communication and teamwork are essential in rigging, highlighting your ability to collaborate effectively with colleagues.

Next Steps

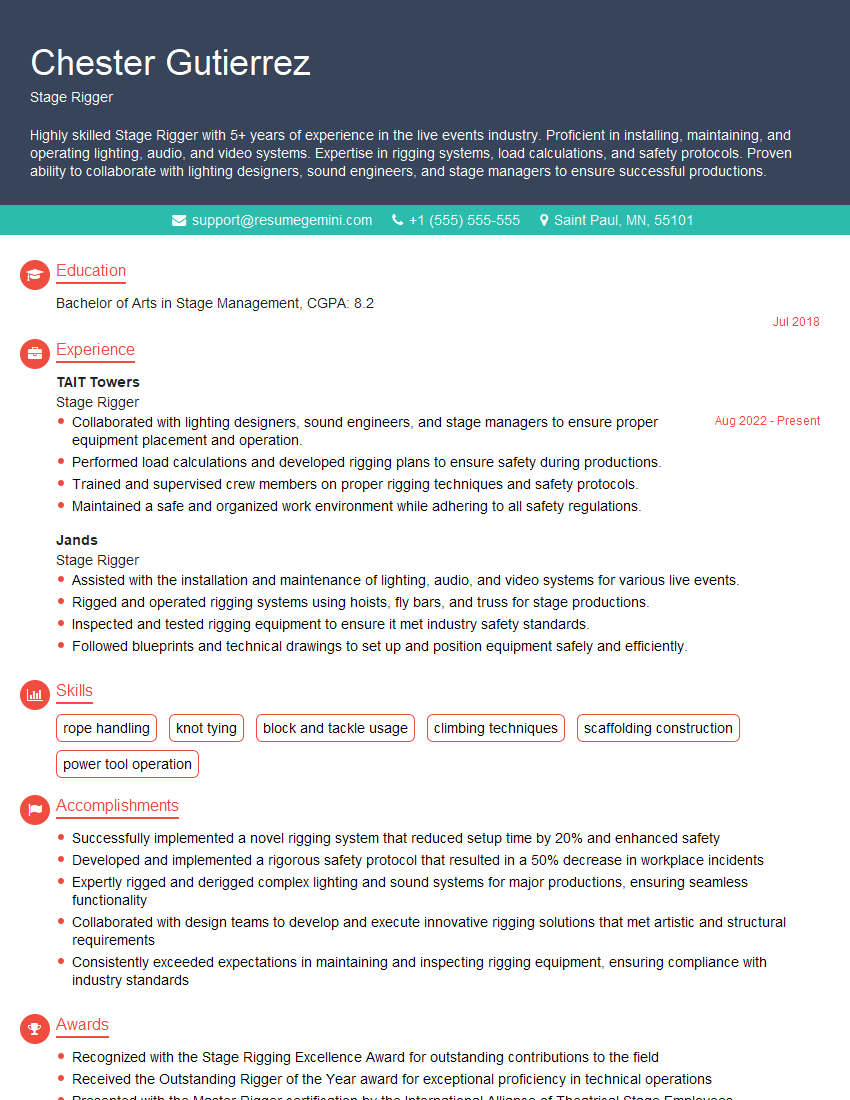

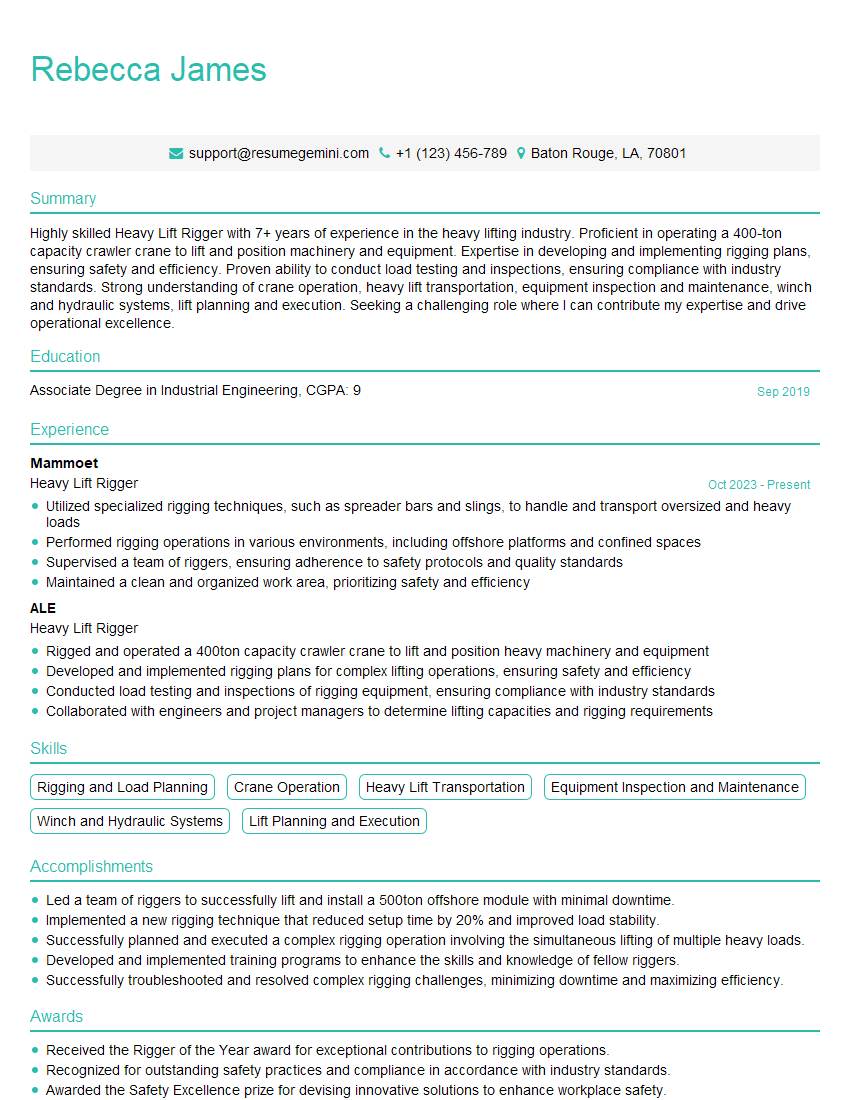

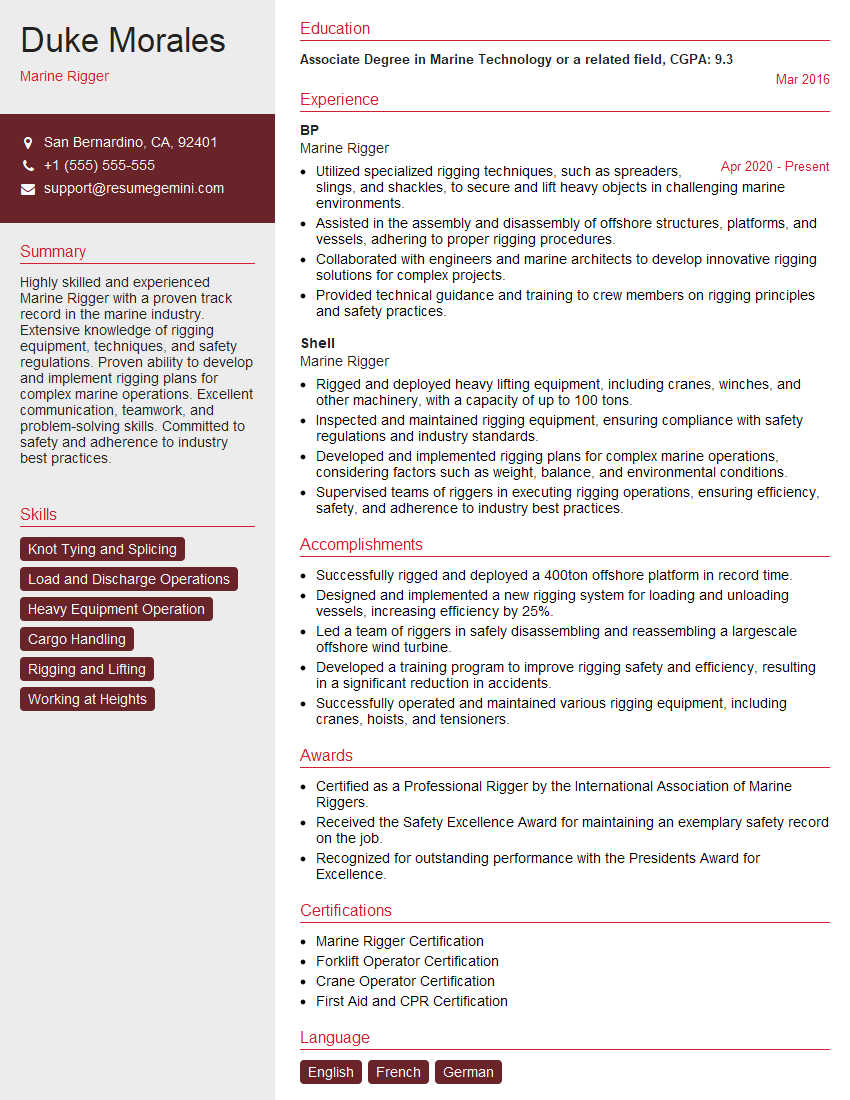

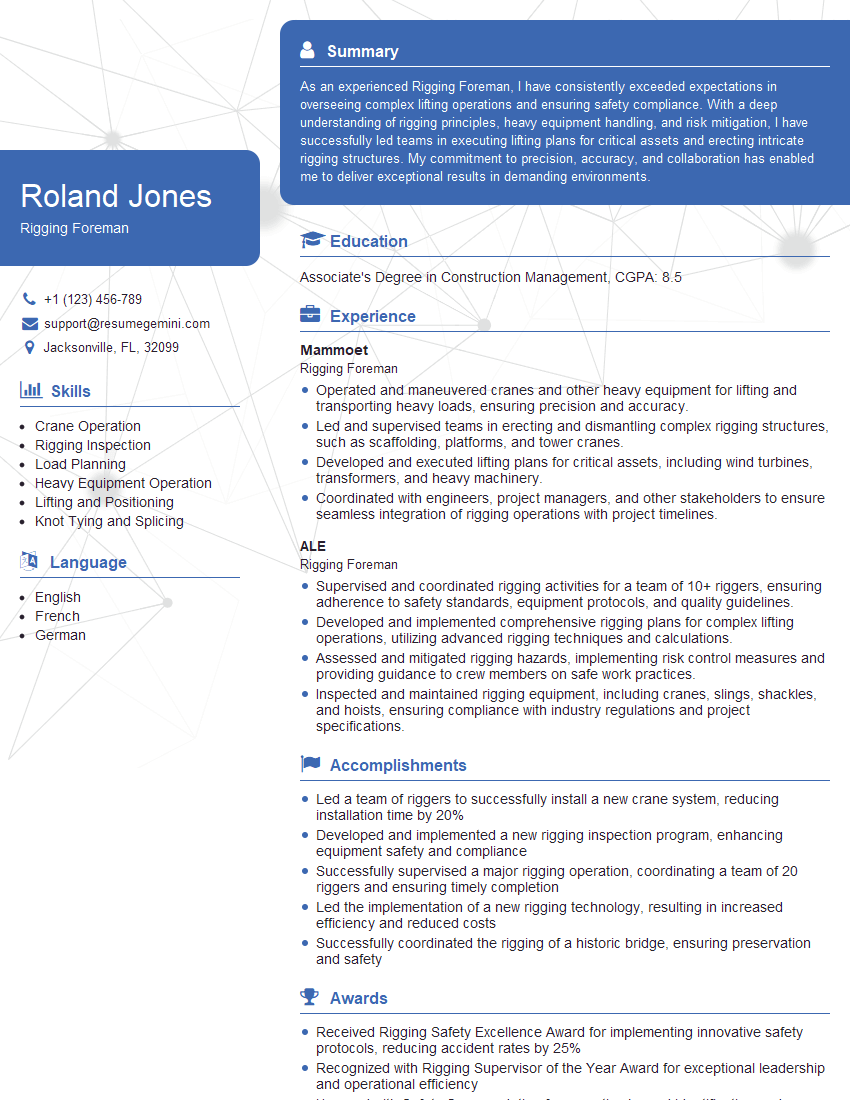

Mastering rigging and rope handling techniques opens doors to exciting career opportunities in various industries, offering growth potential and specialization. A strong resume is your key to unlocking these opportunities. To make your application stand out, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to the Rigging and Handling Ropes industry. Examples of resumes tailored to this field are available to help you create a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good